FEED YOUR PRINTER

IF YOU’RE HAVING A BAD DAY, THIS PRODUCT IS ROLLING WITH GOOD VIBES

www.winkle.shop TABLE OF CONTENTS 3 ABOUT US 7 TYPES OF MATERIALS 17 PLA SILK 18 PLA TOUGH PLA HD - HIGH DEFINITION 8 PLA 870 - INDUSTRIAL ENGINEER 10 PLA 850 11 TPE FLEXIBLE 12 ASA - UV RESISTANT 13 ABS 14 15 PETG 16 PLA WOOD 19 PLA HIGH SPEED 20 PLA MATTE 21 PP (POLYPROPYLENE) 22 PRINTING PARAMETERS 23 PACKAGING

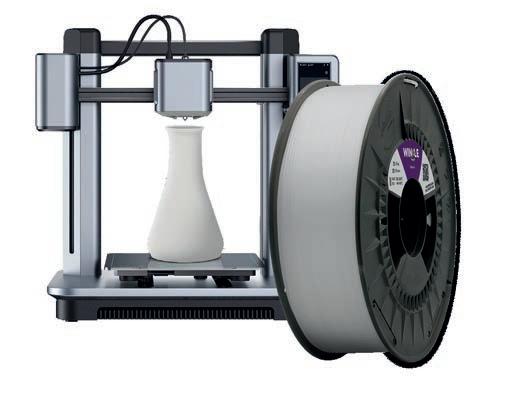

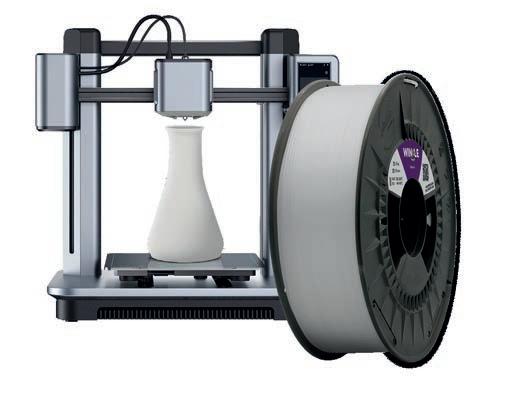

Winkle is a company specialized in the manufacture of 3D filaments.

We were born out of the Customers’ need to find a partner they could trust. Thanks to this, we have managed to create a high quality filament at a very competitive price.

We have a wide variety of materials and we can boast of having one of the widest chromatic ranges in the market.

Wide range of materials and colours

Sustainable Engagement: biodegradable material, recycled - reused packaging and use of green renewable energy

Transportation service

Global agreements with the main transport companies

3

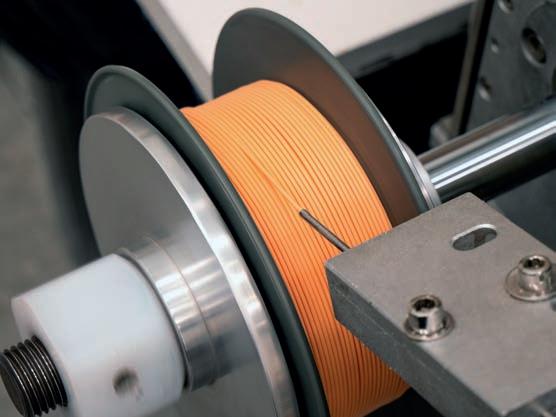

Our factory is located in Salamanca. Here we have the most complete machines on the market to ensure that the filament is always of the highest possible quality.

In just a few years, we have managed to position ourselves as one of the major references in the national market. We are present in more than 25 countries and have a manufacturing capacity of over 800 tons per year.

In short, we have succeeded in creating a premium filament that has enabled us to achieve our current status as an international market leader, while maintaining a constant focus on quality, innovation and customer satisfaction.

4

MADE IN SALAMANCA

QUALITY

The raw material and the machinery we work with allow us to manufacture one of the most complete filaments in the market.

TRANSPARENCY

Our team of professionals always serves customers and distributors with sincerity as a flag.

SUSTAINABILITY

We manufacture 99% biodegradable product, recycled and reused packaging. In addition, we use more than 190 photovoltaic panels that supply energy to our factory.

PROACTIVITY

We anticipate changes in the environment and we are pioneers in implementing them.

PASSION

We like what we do and we enjoy making a product that ends up becoming excellent creations

JOY

Our company’s philosophy is to be “in the loop”. We present ourselves as a close brand focused in providing and guaranteeing you the best treatment possible.

5

TYPES OF MATERIALS www.winkle.shop PLA HD - HIGH DEFINITION 8 PLA 870 - INDUSTRIAL ENGINEER 10 PLA 850 11 TPE FLEXIBLE 12 ASA - UV RESISTANT 13 ABS 14 PETG 15 PLA WOOD 16 PLA SILK 17 PLA TOUGH 18 PLA HIGH SPEED 19 PLA MATTE 20 POLYPROPYLENE (PP) 21

PLA HD - HIGH DEFINITION

PLA is a biodegradable plastic obtained from natural resources such as starch, extracted from corn, sugar cane, sugar beet and wheat. It is the most widely used in 3D printing thanks to its excellent properties and ease of printing.

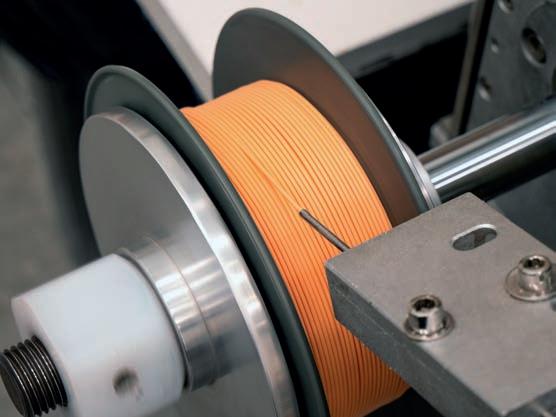

Thanks to our extensive quality control, we guarantee a consistent diameter throughout the entire winding, which will ensure the highest possible quality prints. It is specifically designed to prevent printer jams, providing a trouble-free printing experience. In addition, we are committed to providing a product free of impurities that can alter its physical, chemical and aesthetic properties.

Available diameters

1.75 mm and 2.85 mm

Spool size

300 g (only 1,75 mm) and 1 Kg

PRINTING PARAMETERS

Nozzle temperature

Between 190ºC and 230ºC

Bed temperature

Between 50ºC and 70ºC

Print speed 50-90 mm/s

Volumetric speed Up to 14 mm³/s

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market EXCELLENT ADHESION TO

8

PRINT

BIODEGRADABLE EASY TO PRINT COLOUR 100% FINISH 90% BRIGHTNESS 90% RESISTANCE TO IMPACT 40% FLEXIBILITY 20% WARPING 10% CONTRACTION 10% DIFFICULTY 10% HARDNESS 50%

BEDDING BETWEEN COATS

IN A VENTILATED PLACE

AVAILABLE COLOURS

9

BLUE DARK BRONZE EMERALD GREEN AGATE VIOLET PLA HD PASTEL

PLA HD STANDARD

CLOUD BLUE

COTTON CANDY PINK

TURQUOISE BLUE

BANANA YELLOW TURMERIC YELLOW

EBONY BROWN

BUBBLE GUM PINK MAHOGANY BROWNDEVIL RED NEMO ORANGE BEIGECANARY YELLOW

AVOCADO GREENECOTISA GREEN SKY BLUEPACIFIC BLUE WINKLE PURPLE MAUVE

ACACIA BROWN ASH GREY

NACREGLACIER WHITE JET BLACK ARMY PURPLE

ORANGE GREEN

ELECTRIC YELLOW

PLA HD TEXTURE

MARBLE SAND ALIEN GREEN

PLA 870 - INDUSTRIAL ENGINEER

PLA 870 is manufactured with a unique NatureWorks Ingeo 3D870 formulation. This achieves 50% higher impact strength than ABS, with 120% following post-process annealing.

It also stands out for its ability to withstand higher temperatures and its better flow rate, making it easier to process and providing greater precision in printing. All this, while maintaining the ease of printing of a polymer such as PLA.

Available diameters

1.75 mm and 2.85 mm

Spool size

300 g (only 1,75 mm) and 1 Kg

PRINTING PARAMETERS

Nozzle temperature

Between 200ºC and 230ºC

Bed temperature

Between 50ºC and 60ºC

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

* Change to green colour in the chart is due to the baking process of the material

AVAILABLE COLOURS

10

JET BLACK GLACIER WHITEASH GREY CANARY YELLOW AVOCADO GREEN PACIFIC BLUE DEVIL RED USE OF AN ADHERENT TO THE WARM BED PRINT IN A VENTILATED PLACE BIODEGRADABLE EASY TO PRINT FINISH 100% COLOUR 100% BRIGHTNESS 90% HARDNESS 70% *85% RESISTANCE TO IMPACT 60% *75% FLEXIBILITY 20% WARPING 10% CONTRACTION 10% DIFFICULTY 10% Print speed 50-80 mm/s

PLA 850

INGEO 850 PLA is an advanced material used in 3D printing that offers increased strength and durability compared to standard PLA. Its improved formulation gives it superior mechanical properties, resulting in printed objects with higher strength and toughness, such as prototype parts, educational material, display parts, and more.

Available diameters

1.75 mm and 2.85 mm

Spool size

300 g (only 1,75 mm) and 1 Kg

PRINTING PARAMETERS

Nozzle temperature

Between 190ºC and 230ºC

Bed temperature

Between 50ºC and 70ºC

Print speed 50-80 mm/s

PRINTING SPEED SUPPORTED: UP TO 200 MM/S RECOMMENDED 60 MM/S

AVAILABLE COLOURS

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

11

JET BLACK TRANSPARENT GLACIER WHITEASH GREY FINISH 100% COLOUR 100% BRIGHTNESS 90% FLEXIBILITY 20%

PRINT

VENTILATED PLACE BIODEGRADABLE EASY TO PRINT HARDNESS 50% RESISTANCE TO IMPACT 40% WARPING 10% CONTRACTION 10% DIFFICULTY 10%

IN A

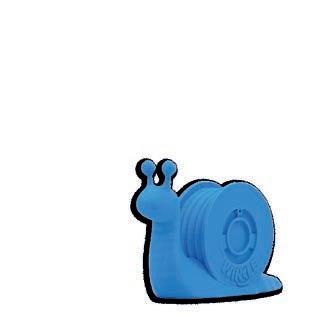

TPE FLEXIBLE

TPE stands out for its flexible and elastic properties, especially its ability to withstand repeated deformations without losing mechanical properties.

It exhibits exceptional interlayer adhesion, outperforming conventional elastic materials, achieving a unique combination of strength and flexibility, making it ideal for the manufacture of parts requiring elasticity, such as casings, gaskets or toys.

PRINTING PARAMETERS

Nozzle temperature

Between 230ºC and 240ºC

Bed temperature

Between 60ºC and 80ºC

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

12

JET BLACK PACIFIC BLUE

GLACIER WHITENATURAL

AVOCADO GREEN BEIGE

FINISH 100% RESISTANCE TO IMPACT 100% RESISTANCE TO TEMPERATURE 90% RESISTANCE TO TEARING 90% COLOUR 90% FLEXIBILITY 80% RESISTANCE TO TENSILE STRENGTH 90% RESISTANCE TO COMPRESSIVE STRENGTH 80% CONTRACTION 20% WARPING 20% BRIGHTNESS 50% HARDNESS 40% Print speed 20-40 mm/s FILAMENT PULL SHOULD BE AS CLOSE AS POSSIBLE TO THE EXTRUDER PRINT IN A VENTILATED PLACE PRINT IN A CLOSED BOX

DEVIL RED CANARY YELLOW

ASA - UV RESISTANCE

ASA, an improved alternative to ABS that exceeds in high resistance to environmental stress cracking. It has approximately ten times more resistance to weathering and ultraviolet radiation compared to ABS, while retaining gloss, colour and mechanical properties.

This makes it an ideal choice for applications demanding durability and stability in harsh environmental conditions, such as outdoor parts, automotive components or signage.

Available diameters

1.75 mm and 2.85 mm

Spool size

200 g (only 1,75 mm) and 1 Kg

PRINTING PARAMETERS

Nozzle temperature

Between 240ºC and 260ºC

Bed temperature

Between 70ºC and 100ºC

AVAILABLE COLOURS

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

13

HARDNESS 100% CONTRACTION 20% BRIGHTNESS 50% COLOUR 50% Print speed 40-60 mm/s FINISH 90% DIFFICULTY 70% RESISTANCE TO IMPACT 90% FLEXIBILITY 30% WARPING 10% JET BLACK NATURAL ASH GREY

ABS

Consisting of acrylonitrile, butadiene and styrene, ABS offers rigidity, chemical resistance, toughness and high temperature stability due to acrylonitrile. The presence of butadiene improves toughness, especially at low temperatures, giving ABS high impact resistance. Styrene adds mechanical strength, rigidity, gloss and hardness to the material.

These properties make ABS highly versatile and easy to post-process, allowing operations such as machining, sanding, polishing, painting and glued with ease.

Available diameters 1.75 mm

Spool size 250 g y 1 Kg

PRINTING PARAMETERS

Nozzle temperature

Between 230ºC and 260ºC

Bed temperature

Between 70ºC and 100ºC

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

AVAILABLE COLOURS

14

Print speed 50-70 mm/s EASY TO PRINT AND GOOD ADHESION BETWEEN COATS PRINT IN A VENTILATED PLACE PRINT IN A CLOSED BOX FINISH 90% DIFFICULTY 70% HARDNESS 100% RESISTANCE TO IMPACT 80% FLEXIBILITY 40% WARPING 40% CONTRACTION 20% COLOUR 50% BRIGHTNESS 50% JET BLACK NATURALGLACIER WHITE

PETG

PETG stands out for its improved chemical structure, which makes it more transparent, less brittle and easier to print compared to conventional PET. It is distinguished by its higher temperature resistance and properties such as higher elasticity, impact resistance and good interlayer adhesion.

Although it requires a higher melting temperature, it offers better strength and printability compared to ABS and is more complex compared to PLA.

Suitable for printing lighting elements, exhibition pieces, etc.

PRINTING PARAMETERS

Nozzle temperature

Between 220ºC and 240ºC

Bed temperature

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

Between 60ºC and 80ºC 1.75 mm and 2.85 mm

size

g (only 1.75 mm) and 1 Kg

AVAILABLE COLOURS

15

Spool

300

RESISTANCE TO IMPACT 90% COLOUR 100% FINISH 100% BRIGHTNESS 100% HARDNESS 80% WARPING 10% DIFFICULTY 10% CONTRACTION 10% FLEXIBILITY 80% EASY TO PRINT PRINT IN A VENTILATED PLACE EASY TO PRINT AND GOOD ADHESION BETWEEN COATS Print speed 50-70 mm/s AQUAMARIN BLUE AMBER ORANGE DEEP MAUVE LIME GREEN

PLA WOOD

PLA WOOD is a natural fibre-based 3D printing filament that enhances the properties of PLA with a load of wood fibres. This combination offers practical benefits such as increased strength and durability compared to conventional PLA.

This textured filament provides a unique aesthetic finish, with a look, feel and appearance similar to wood. It is therefore particularly suitable for the creation of decorative pieces, making it an ideal choice for creative and functional projects.

Available diameters

1.75 mm

Spool size

300 g and 750 g

PRINTING PARAMETERS

Nozzle temperature

Between 190ºC and 220ºC

Bed temperature

Between 50ºC and 60ºC

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

EXCELENT ADHESION TO BEDDING BETWEEN COATS

PRINT IN A VENTILATED PLACE

A 0.6 NOZZLE (MINIMUM) IS RECOMMENDED FOR PRINTING THIS FILAMENT

16

COLOUR 100% FINISH 100% WARPING 10% BRIGHTNESS 10% CONTRACTION 10% FLEXIBILITY 20% RESISTANCE TO IMPACT 40% DIFFICULTY 30% HARDNESS 50% Print speed 40-70

mm/s

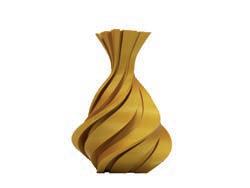

PLA SILK

PLA SILK has been enhanced with additional polymers that provide high light scattering and light reflection, creating the distinctive silky smooth finish, bringing spectacular gloss and excellent detail to prints.

Based on PLA as the core material, it retains the properties of standard PLA, such as easy shaping, no warping and low shrinkage, and goes further by offering higher mechanical and thermal strength.

The intensity of this silky surface varies according to the printing parameters, allowing the visual appearance to be adjusted by reducing or increasing the printing speed and temperature.

Available diameters

1.75 mm

Spool size

300 g and 1 Kg

PRINTING PARAMETERS

Nozzle temperature

Between 200ºC and 230ºC

Bed temperature

Between 50ºC and 70ºC

40-80 mm/s

AVAILABLE COLOURS

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

COLOUR 100% FINISH 100% BRIGHTNESS 100% WARPING 10% DIFFICULTY 10% CONTRACTION 10% FLEXIBILITY 20% RESISTANCE TO IMPACT 40% HARDNESS 50%

speed

MERCURY SILVER KINGS GOLD OLD COPPER SNOW WHITE RUBY PINK STEEL BLUE RUBY RED IRISH GREEN

Print

PLA TOUGH

PLA TOUGH has an impact resistance and strength twice that of ABS, combined with the ease of printing and rigidity characteristic of PLA. It is noted for its excellent inter-layer adhesion, allowing printed objects to achieve remarkable mechanical strength properties. In addition, its exceptional machinability eases a variety of post-processing techniques, such as drilling, sanding, CNC and threading.

This perfect combination makes the Tough the optimal choice for the manufacture of tools or industrial parts requiring high impact, tensile and flexural strength, even for large parts.

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

Stiff, strong and durable. Industrial opaque finish.

PRINTING PARAMETERS

AVAILABLE COLOURS

18

Available diameters 1.75 mm and 2.85 mm Spool size 300 g and 1 Kg

Nozzle temperature Between 200ºC and 220ºC Bed temperature Between 50ºC and 70ºC PLA HD Impact ISO 179 3,4kJ/m2 30kJ/m2 23kJ/m2 22kJ/m2 PLA TOUGHPLA 870ABS RESISTANCE TO IMPACT 100% HARDNESS 100% FINISH 100% COLOUR 70% BRIGHTNESS 10% WARPING 10% FLEXIBILITY 10% DIFFICULTY 10% CONTRACTION 10% Print speed 40-80 mm/s EXCELENT ADHESION TO BEDDING BETWEEN COATS PRINT IN A VENTILATED PLACE EASY TO PRINT

PLA HIGH SPEED

Our supersonic high speed 3D printing filament has been created to maximise efficiency and performance without compromising part quality.

HIGH SPEED PLA's improved mechanical properties surpass those of standard PLA, especially in high-speed printing. These include significantly improved interlayer bond quality and higher impact resistance. Its higher fluidity and higher thermal capacity allow for faster melting and cooling, resulting in smooth surfaces and sharp details on printed parts.

Ideal for fast, detailed printing, it easily prints large models with exceptional dimensional accuracy, even at high speeds.

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

Available diameters 1,75 mm

PRINTING PARAMETERS

Nozzle temperature

Between 220ºC and 250ºC

Bed temperature

Between 40ºC and 60ºC

Spool size 1 Kg

EXCELENT ADHESION TO BEDDING BETWEEN COATS PRINT IN A VENTILATED PLACE EASY TO PRINT

19

Volumetric speed Print speed ACABADO 100% COLOR 95% BRILLO 95% DUREZA 55% RESISTENCIA AL IMPACTO 90% FLEXIBILIDAD 25% WARPING 5% CONTRACCIÓN 10% DIFICULTAD 15% GLACIER WHITE AVOCADO GREEN JET BLACK CANARY YELLOW DEVIL RED SKY BLUE ASH GREY

PLA MATTE

PLA Matte has the same characteristics as PLA-HD with the particularity of having a matte finish. This will give your parts a superior printing result. Optimal for high speed printing, it retains the properties of standard PLA, such as easy modelling, no warping and low shrinkage.

This filament has a soft and smooth texture with no sheen, reducing the plastic feel and improving the final appearance. The matte finish of the printed surface scatters light, decreasing the visibility of print lines.

It is perfect for a variety of applications, from creating functional models such as prototypes, repair parts and tools, to decorative pieces such as figurines, flower pots and photo frames. In addition, it is ideal for art projects such as sculptures and jewellery, and is also useful in catering and packaging.

PRINTING PARAMETERS

Nozzle temperature

Between 190ºC and 210ºC

Bed temperature

Between 40ºC and 60ºC

Print speed 60 mm/s

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

* Compatible with most FDM 3D printers on the market

AVAILABLE COLOURS

20

Available diameters 1.75 mm Spool size 1 Kg

SMOKE GREY CREAM WHITE GRAPHITE BLACKRASPBERRY RED COBALT BLUE EXCELENT ADHESION TO BEDDING BETWEEN COATS PRINT IN A VENTILATED PLACE BIODEGRADABLE EASY TO PRINT COLOUR 100% FINISH 100% BRIGHTNESS 15% WARPING 5% DIFFICULTY 15% CONTRACTION 10% FLEXIBILITY 25% RESISTANCE TO IMPACT 90% HARDNESS 55%

PP (POLYPROPYLENE)

Polypropylene (PP) is a versatile and reliable material that stands out for its unique combination of light weight, low density and exceptional mechanical properties such as flexibility and impact resistance.

Polypropylene's hydrophobic properties not only make it ideal for industrial and automotive components that demand durability and resistance, even to chemicals, but also make it a versatile and cost-effective solution. From the manufacture of robust parts to the printing of dishwasher and microwave safe objects, this material finds application in a wide range of environments, meeting both industrial and domestic needs.

PRINTING PARAMETERS

Nozzle temperature

Between 220ºC and 25 0ºC

Bed temperature

Between 85ºC and 100ºC

Print speed

30 mm/s

(first layer at 25 mm/s)

* The indicated parameters are valid for correctly calibrated printers (P&D, mechanical and fuser)

* Supervised and tested manufacturing process (diameter, colour and winding) to guarantee the quality of our product

Available diameters 1,75 mm

Spool size

700 g and 1500 g

AVAILABLE COLOURS

21

FINISH 100% COLOUR 95% BRIGHTNESS 95% HARDNESS 55% RESISTANCE TO IMPACT 90% FLEXIBILITY 25% WARPING 5% CONTRACTION 10% DIFFICULTY 15% BLACK WHITE NATURAL PRINT IN A VENTILATED PLACE USE OF AN ADHERENT TO THE WARM BED IS RECOMMENDED PRINT IN A CLOSED BOX LOW SPEED PRINTING RECOMMENDED

PRINTING PARAMETERS

PLA HD Between 190ºC y 230ºCBetween 50ºC y 70ºC

mm/s

to 14 mm³/s (volumetric speed)

870 Between 200ºC y 230ºCBetween 50ºC y 60ºC

mm/s PLA 850 Between 190ºC y 230ºCBetween 50ºC y 70ºC

y 240ºCBetween

y

to 600 mm/s

to 24 mm³/s (volumetric speed)

mm/s (first layer at 25 mm/s) PLA HIGH SPEED Between 220ºC y 250ºCBetween 40ºC y 60ºC

Between 220ºC y 250ºCBetween 85ºC y 100ºC

22

50-90

50-80

50-80

20-40

ASA Between 240ºC

70ºC

100ºC 40-60 mm/s ABS

70ºC

50-70

PETG

50-70

40-70

50ºC

40-80 mm/s PLA

Between 200ºC

220ºCBetween 50ºC

70ºC 40-80 mm/s PLA

40ºC

60 mm/s

NOZZLE BED TEMPERATURE PRINT SPEED

PLA

mm/s TPE FLEXIBLE Between 230ºC

60ºC y 80ºC

mm/s

y 260ºCBetween

y

Between 230ºC y 260ºCBetween

y 100ºC

mm/s

Between 220ºC

240ºCBetween 60ºC y 80ºC

mm/s PLA WOOD Between 190ºC y 220ºCBetween 50ºC y 60ºC

mm/s PLA SILK Between 200ºC y 230ºCBetween

y 70ºC

TOUGH

y

y

MATTE Between 190ºC y 210ºCBetween

y 60ºC

PP

30

Up

Up

Up

PACKAGING

Winkle spools are shipped in a hermetic system zip bag. This is a sustainable packaging able to provide a new useful life that is much more respectful with the environment, while promoting the use of non-polluting materials and the great importance of this green way of packaging. This innovative bag not only reduces the impact on the environment but also helps to archive our comprimise with Sustainable Development Resources.

Packaging includes a small bag of silica inside. This process protects the filament from damages due to humidity or other weather ussues. Thanks to this and also to the zip system bag we optimize our filament for a perfect use.

An identity labeled sticker with a transparent basement for chromatic purposes allows our packaging to be easily distinguished from ourside. Packaging measures are properly settled to preserve the filament and its delivery as long as its storage.

Reusable bag, spool and silica bag Winding improvement

Constant

Ø 1.75 mm / 2.85

± 0.05 mm

diameter

mm

23

@winkle3d.global @winkle3d.global @winkle_3d @winkle3d @winkle3d @winkle3d