RECRUIT AND RETAIN LIKE A PRO

Mower manufacturers discuss the trends and technologies landscape professionals should keep in mind this upcoming season.

The choice of LANDSCAPE PROS.

12.

Mower manufacturers discuss the trends and technologies landscape professionals should keep in mind this upcoming season.

04. EDITOR’S NOTE

06. DIGITAL HITS

08. FRESH CLIPPINGS

37. PROJECT PROFILE

38. NEW PRODUCTS

42. CONTRACTOR PROFILE

18. BUSINESS MANAGEMENT | RECRUIT AND RETAIN LIKE A BOSS

The labor market is challenging, and every sector is feeling the pinch. These insights will help you win more often at recruiting and retention.

20. LAWN CARE | CHOOSE THE RIGHT SPREADER-SPRAYER

A rundown of spreader-sprayer options lawn care operators can use to put down lawn care products this spring and summer.

24. MOWING & MAINTENANCE | SPRING CLEANUP MAINTENANCE MUSTS

Equipment experts explain how to properly maintain equipment ahead of spring cleanups and offer up mulching tips.

28. EQUIPMENT & TECHNOLOGY | COMPACT EQUIPMENT MAINTENANCE

Manufacturers lay out what types of maintenance landscape pros should be performing on their compact equipment.

30. HARDSCAPES & DESIGN | WHEELS VERSUS TRACKS

Tips to help landscape pros decide whether to use wheels or tracks on excavators and why.

34. LIGHTING & IRRIGATION | TAKE CONTROL OF YOUR IRRIGATION SYSTEM

A look at the benefits of irrigation controllers and how irrigation pros can take advantage of them.

20

Green Industry Pros [USPS 003-763 and ISSN 2168-121X (print), ISSN 21681228 (online)] is published six times a year: January/February, March, April, May/June, July/August, September/October by AC Business Media, 201 N. Main Street, Ste 350., Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI 53538 and additional mailing offices. POSTMASTER: Send address changes to Green Industry Pros, P.O. Box 3605, Northbrook, IL 60065-3605.

SUBSCRIPTIONS: Individual subscriptions are available without charge in the U.S. to qualified subscribers. Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S., $35 per year; Canada/Mexico, $60 per year; and all other countries, $85 per year. All subscriptions payable in U.S. funds, drawn on U.S. bank. Back issues, if available, cost $10 prepaid. Printed in the USA. Copyright 2023 AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recordings or any information storage or retrieval system, without permission from the publisher.

Well, everybody, believe it or not, it’s that time of year to shake off the snowy remnants of winter, dust off the maintenance equipment that’s been hibernating in the shed and get your crews ready to warm themselves up as we head into the sprint that is the busy spring season.

Of course, it’s important to remember that some regions may get hit with a stray snow storm here or there in the early spring months, but for the most part, it’s time for landscape professionals around the country to “rise and grind.”

To get that momentum going—and keep it going—we have quite a spread of fresh content and ideas for you to think about as we kick off the season.

Our cover story gives a rundown of what landscape pros can expect from the latest mower technology and how they can use it to their advantage (p. 12); our business management department provides insight on what companies can do to make sure their bench is stacked throughout the season (p. 16); our mowing and maintenance department lists the different types of maintenance landscape pros

should be performing on equipment so it’s ready to go with minimal downtime this season and offers up a few mulching tips (p. 24); and our irrigation section explains how irrigation professionals can properly install smart controllers and what they can do to recycle outdated irrigation components (p. 34).

Outside of this issue, we’re also gearing up to present our annual Women in the Green Industry Award, the winner of which will be profiled in our May/June issue. And, on social media, we’re rearing to go on our Mower Madness campaign, which will pit the industry’s top mowers against one another and ask you, our audience, to vote on your favorites.

Stay tuned to our social media channels for more on those initiatives. In the meantime, I wish you all a healthy and productive spring season!

What are you most looking forward to this spring season? I’d love to hear your thoughts—and I’m sure your fellow readers would to. Email your ideas to swebb@acbusinessmedia.com or connect with me on LinkedIn by following the QR code below.

EDITORIAL

Editor Sarah Webb swebb@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Associate Editor Emry Lloyd elloyd@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Willard Kill

ADVERTISING/SALES

Brand Director Jason DeSarle jdesarle@acbusinessmedia.com

Sales Representative Megan Perleberg mperleberg@acbusinessmedia.com

Sales Representative Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director............................................... Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605 Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847) 291-4816 circ.greenindustrypros@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518)339-4511 | bart.piccirillo@infogroup.com

REPRINTS & LICENSING

Megan Perleberg mperleberg@acbusinessmedia.com

Would you like to stay up to date on the latest news across the green industry but can’t wait for the next print issue of Green Industry Pros magazine to come out? Be sure to subscribe to our e-newsletters—including The Pro Report, The Tech Report and The Lawn Care Report, just to name a few—using the QR code, so you can stay informed on what’s going on around the industry. https://gpros.co/y668un

Tune in to the latest episode of Green Industry Pros’ Grass Roots podcast to hear what Jay Worth, marketing manager of SingleOps, has to say about the latest recruiting and retention practices. Do you have an interesting story that you’d like to talk about on our podcast? Email your ideas to Green Industry Pros Editor Sarah Webb at swebb@acbusinessmedia.com, and you may be featured in an upcoming episode of our Grass Roots podcast. And, while you’re at it, be sure to check out our vibrant archive of past conversations with industry experts using the QR Code. https://gpros.co/ks7w40

To stay up to date on the latest happenings around the green industry, be sure to follow Green Industry Pros’ social media channels: youtube.com/GreenIndustryPros

@greenindpros @greenindustrypros @greenindustrypros

champion the success of its owners is inspiring to me and aligns perfectly with the way I think about growth,” said Sutton. “Last year, the company saw record-breaking success across its roster, and the unification of Empower Brands creates opportunities for unparalleled growth in 2023. I am thrilled to be joining the team at this pivotal moment in the brand’s history, and I’m looking forward to the developments to come.”

Check out the latest news and updates from people and companies around the green industry, including Yanmar, Empower Brands and more.

Yanmar Compact Equipment plans to expand its Minnesota facility by 32,000 square feet. It will also be hiring hundreds of new workers in the future.

“We received a lot of support through the investment of Yanmar Co. Ltd, and several city, county and state grants and loans to help make this expansion happen,” said Tate Johnson, president of Yanmar CE NA. “The expansion will improve efficiency, allowing us to better serve our customers as we continue to grow as a leader in compact equipment.”

The Grand Rapids, Minn., expansion and a subsequent paint system will increase paint capacity by up to three times with maximum automation and allow a parts manufacturing capacity increase of up to two times of the previously occupied space. This project sets an example for future capacity increases with company officials projecting the addition of hundreds of full-time positions over the next five years.

Empower Brands has appointed franchise development expert R. Scott Sutton as its new chief development officer.

“Empower’s ‘Franchisee First’ culture and mission to

Sutton has more than two decades of franchising experience and will play a critical role in capitalizing on each brand’s growth potential through the expansion and execution of franchise development strategies across Empower Brands’ portfolio. Sutton holds a bachelor’s degree from the University of Oklahoma and is both a certified franchise executive and a certified merger and acquisition adviser. He also serves as an elected member of the Board of Trustees of the International Franchise Association’s (IFA) Foundation and is a member of the IFA’s Legislative Action Group. He is a former chairman of the Emerging Franchisor Conference and served on the Board of the International Institute of Franchise Education at the Huizenga School of Business and Entrepreneurship at Nova Southeastern University. In 2019, Sutton was named by the M&A Adviser organization as the Corporate Development Professional of the Year.

In his new role as an executive sales consultant for the Boss team, Simon Prine will work with companies in the landscape and snow removal industries.

“I’m thrilled to join the Boss team,” said Prine. “My experience selling and using business management software in the field has given me a great understanding of its capabilities. I can’t wait to help Boss clients improve their operations and increase their profitability while giving them more time in their day.”

Prine has more than 30 years of experience in the landscape and snow industry. He started his own one-man lawn operation called Simon Says Lawn Maintenance with just a pickup truck and a mower. Prine worked his way up through the ranks at Clintar, eventually managing six branches. In addition to his extensive operations experience, he also has 15 years of sales experience in the landscape industry.

@Bussarin.stock.adobe.com

Landscape Management Network (LMN) unveiled the results of its State of the Landscaping Industry survey, which is part of an ongoing educational series to help landscapers benchmark against the competition, grow profits and run successful businesses. Below are key findings:

• Ninety-six percent of landscapers grew their revenue in 2022, with nearly a quarter of respondents reporting they grew revenue by 20 percent to 50 percent.

• The most pressing issue facing business owners remains a shortage of skilled labor, with more than half (51 percent) unable to hire enough staff to fill vacant roles in 2022. However, this response is drastically lower than responses to LMN’s 2022 State of the Industry Report, when 92 percent of respondents expressed concern about workforce shortages. To make seasonal roles more appealing and boost retention, respondents report using bonus systems and prioritizing career development.

• While landscapers say training is a top priority, 58 percent of survey respondents allow new hires to work without any formal training. Of the respondents who maintain a training program, only 8 percent spend more than a full day training new employees.

• Eighty-five percent of respondents report using landscape business management software to create annual budgets, know how much they can spend on staff pay increases, bonuses and training and maintain a healthy profit.

https://gpros.co/q0ybcj

Project EverGreen and Boss Snowplow celebrated SnowCare for Troops week Jan. 22-28.

Project EverGreen’s SnowCare for Troops program provides complementary snow and ice removal services for the families of deployed military personnel.

More from Project EverGreen about the SnowCare for Troops program includes:

• SnowCare for Troops has been running for more than 13 years.

• SnowCare for Troops has evolved into more than just a service to clear driveways and sidewalks of snow and ice. It’s a lifeline for military families in need to help maintain their independence and go about their daily routines taking care of family, work and school. Professional contractors, groups and individuals volunteer their time and provide their own equipment and materials to clear the snow for military families in need.

• GreenCare for Troops is SnowCare for Troops’ sister program. It has delivered an estimated $15 million in donated lawn, landscape and snow removal services and peace of mind to thousands of military families in need across the country.

https://gpros.co/5htuz7

This upcoming issue of SnowPRO will focus on efficiency tips and tricks to make snow operations run smoothly, and we want to hear from you. No matter where you’re located in the country, you’ve probably found the right systems and processes that work for your company each snow season.

@PiLensPhoto.stock.adobe.com

Why not share them with your fellow SnowPRO readers? We’re sure they would love to hear them.

Has your company used software to streamline operations? Have your crews come up with any efficiency hacks while on the job? Do you have any sort of checklist crews work through before they roll out? What about in the offseason—is there any maintenance your team performs during the summer months to make sure your trucks and equipment are ready to go by the first snow?

Whatever the case, we want to know it all!

If you have efficiency hacks you would like to share with the readers of SnowPRO and your professional peers, reach out to Editor Sarah Webb at swebb@acbusinessmedia.com, and you may be featured in an upcoming issue of SnowPRO.

The latest news and updates from the people and companies around the green industry, including Takeuchi-U.S. and Bobcat Co.

Takeuchi-U.S. has named Jeffrey Baldwin as its new Central Midwest regional product manager and Austin Wells as its new Southwest regional business manager.

Baldwin is now responsible for supporting all the company’s dealers and national rental accounts in the Central Midwest region, which includes Iowa, Kansas, Missouri, Nebraska and Oklahoma. He will also train the region’s salesforce on product features, benefits, applications and how to perform effective machine demonstrations. Based in the Tulsa, Okla., area, Baldwin comes to Takeuchi from Vacuworx Global where he served as director of sales in the construction, utility and demolition markets. He managed and optimized the company’s dealer network, including onboarding, training and account development.

“Jeff’s experience in all facets of inside sales, outside sales, customer service and training position him for great success in his new role at Takeuchi,” said Shay Klusmeyer, Western Division sales manager for Takeuchi-U.S. “He’s very customer focused, driven and accountable, which are qualities that will help him build strong, positive relationships with our dealers in the Central Midwest region.”

Wells will manage all sales activity in the Southwest region, which includes Texas, New Mexico and Colorado. His duties will include dealer development and recruitment, inventory control, forecasting, promotions, sales planning and goal setting within that region. Located in Katy, Texas, Wells comes to Takeuchi from Bank of the West where he was a vice president and senior national account manager. While there, he managed Takeuchi Financial Services, working directly with the company’s dealer network to secure retail financing and credit approvals. Wells holds a bachelor’s degree in business administration from the University of Mississippi.

“Austin has a unique background, having worked on the financial services side of the equipment business prior to joining Takeuchi as a regional business manager,” said Klusmeyer. “His experience working with dealers as well as his excellent relationship-building and communication skills make him a great fit as a regional business manager. We’re pleased to have him as a part of our team in the growing Southwest region.”

Bobcat Co. has expanded its nationwide aftermarket parts distribution center (PDC) network with the opening of a new, 396,000-square-foot facility in Atlanta.

This is the second Bobcat PDC opened in the past months to meet growing demand for Bobcat equipment in the marketplace. Bobcat also opened a new PDC in Reno, Nev., in September 2022. These two new facilities join the company’s existing Bobcat PDC near Chicago in Woodridge, Ill.

“The opening of this new facility in Atlanta is reflective of Bobcat’s growth and our ongoing commitment to providing a level of service befitting of a longtime, industry leader,” said Mike Ballweber, president of Bobcat Co. North America. “This facility is intentionally located in Georgia so we can support the businesses of our customers and dealer partners throughout the Southeast region and beyond, all while providing them with greater parts availability and faster deliveries.”

Bobcat’s PDC facilities support same-day order processing and extended order hours, expanded dealer support programs and customer service hours, improved speed of delivery times and additional shipping carrier options.

With the opening of these two facilities in Reno and Atlanta, Bobcat has nearly doubled its warehouse footprint. Between the three locations, Bobcat’s combined warehouse footprint in North American is now 896,000 square feet. The Bobcat PDC facilities are managed and staffed by APL Logistics, with the Atlanta location employing 85 people.

BY SARAH WEBB

BY SARAH WEBB

Alot has changed in the mower segment the past couple years—battery technology has improved to provide landscape pros with longer run times, autonomous and semiautonomous mowers have become a serious topic of conversation and upgraded features on many mowers have upped the efficiency of landscape operations.

And yet, one aspect remains the same: Landscape pros continue to rely on their mowers to beautify their customers’ spaces and support their livelihoods. Because let’s face it—machine downtime during the busy season means landscapers aren’t making money.

“Labor constraints continue to be a headlining issue in the industry,” says Aaron Griffith, director, professional dealer sales at Stanley Black & Decker. “With staffing now requiring more time and resources, businesses should prioritize equipment to help increase efficiency and productivity.”

Mower manufacturers lay out the features landscapers should keep in mind so they can remain a cut above the rest—and mow on this season.

Until recently, gas-powered mowers have been the industry standard, widely accepted as the only solution to offer sufficient power, run time and speed for the professional user, says Anthony Buxton, group manager, product marketing, at Milwaukee Tool.

“However, over the past few years, investment in outdoor power equipment battery technology has become a major focus for manufacturers, resulting in the development of mowers with increasingly powerful and efficient capabilities,” Buxton says. “With the various benefits, such as efficiency, versatility, cost and safety, landscaping companies across the U.S. have been more frequently adding battery-

operated equipment to their trucks.”

Quiet operation and no emissions are among the benefits of batterypowered equipment for customers, according to Gerry Barnaby, senior director of excitement at Ego.

“Quiet landscape maintenance is something on the mind of lots of consumers,” Barnaby says. “With COVID, a lot of people were working from home just to realize how loud landscape machinery can be if it’s gas powered. When commercial landscapers can quiet down their operation, they can work longer hours, and they can work in different environments more effectively, like around hospitals, schools and offices.”

Barnaby adds that for certain

accounts, landscape companies may have an advantage over others in their area if they use battery-powered equipment.

“If a landscaper is in competition for an account, they can come in and say ‘we’re being quiet and eco-friendly,’” Barnaby says. “Then, if you’ve got a number of properties in close proximity, you can shorten your travel time without killing your profit. That makes battery power even more efficient and sellable.”

Lower vibration, noise and emissions levels are also beneficial for crew members, Buxton says.

“Benefits include the elimination of gas headaches, and with the mowers creating substantially lower noise output than gas engines, operators are able to start work earlier and

decrease their exposure to continuous high noise levels, simultaneously improving safety and efficiency,” Buxton says.

“With a simple push-button start, battery-powered equipment eliminates the time it takes to pull start a gas engine, a common frustration and time consumer on the job. Removing the need for engine maintenance, battery-operated equipment frees users from the responsibilities of replacing spark plugs, recoil starters, air filters and carburetors.”

Increased regulations focused on reduced noise and emissions are another reason the industry started to look more toward batteryoperated mowers, Buxton says.

example, California recently passed legislation banning the sale of new gas-powered equipment starting in 2024. It will require new small offroad engines, typically found in lawn, garden and other outdoor power equipment, to be zero emissions and ban the sale of all gas-powered equipment with the model year 2024 and later.

“While this legislation is specific to

California, these laws are expected to gain momentum in other regions and states in the near future, encouraging businesses to begin the transition to battery-operated mowers to follow local restrictions,” Buxton says.

With that in mind, Barnaby says states on the East and Wests Coasts have been early adopters of battery power.

“Depending on where you live, places like California will subsidize you to buy battery-powered equipment,” Barnaby says. “You can always check with your local environmental agencies to see if you have anything in your state. Just buy one set of gear and see if it works for you.”

As the market shifts toward electrification, David Cluka, vice president of sales and marketing at Briggs & Stratton, says the industry needs to reimagine service and support for the machines.

“There

are no more engines with crankshafts or carburetors that may need to be repaired or replaced, no more deck belts to replace. Instead, there are motor controllers and software that may need to be updated,” Cluka says. “As a manufacturer of these products, we need to make sure we properly educate our service teams so they can support our dealers. We also need to equip our dealers with the training and tools to diagnose and repair these products when they come in for service quickly and correctly.”

Further adding to the efficiency push, many mowers now include higher horsepower and larger cutting decks.

“With the lack of workers and trying to get work done quicker, landscapers can now get the same work done in a shorter period of time,” says Sean Dwyer, global product manager, commercial wheeled product at Husqvarna Group. “I noticed the increase in productivity features as the number of workers started to decrease in the last couple of years. Products used to have 30 horsepower (hp) and 60-inch cutting decks, and now you’re seeing up to 40 hp. It might seem like overkill, but if you can cut the grass a mile an hour faster, that can also be quick enough to be 15 percent faster.”

Dwyer adds that landscape professionals in areas like the Midwest and parts of Texas have been keen to adopt the larger, more powerful mowers because in some cases, they cover big swaths of land.

As another way to keep crews happier and more productive, mower manufacturers have also included ergonomic features such as padded seats and intuitive, easyto-reach controls.

“A lot of that stems from ‘how do I keep the workers that I have? Or how do I entice workers?’ If you’re going to put them on something uncomfortable versus put them on something comfortable, that does, in fact, have some bearing,” Dwyer says.

Autonomous and semiautonomous mowers have gained traction as a trending topic in the landscaping industry, Griffith says.

“This technology empowers landscapers to do more with less through maximizing efficiency and minimizing operator training,” Griffith says. “However, few businesses will have the

opportunity to add fully autonomous and robotic mowers to their fleet in 2023. Fortunately, semiautonomous mowers are available to landscapers who are looking to benefit from autonomous technology today. Utilizing highprecision GPS technology, these types of mowers are designed to help minimize overlap and cut straight stripes.”

Charles Quinn, co-founder and CEO at Greenzie, agrees that robotic technology can help landscape

doesn’t control the engines, but it does control the autonomous operation.”

For landscapers thinking of making the leap to new technologies, Dwyer notes that companies should start small to see if it’s right for their company and stick with one brand.

“A lot of this stuff seems to start with a lot of buzz, but then as reality comes in, it’s ‘how can I manage this? How can we do this?’ That’s when you start seeing the real cream rise to the top. New technology will accelerate because of how impactful it is today, and it’s not totally outside the paradigm they’re used to.”

For battery-powered equipment, run time concerns come up frequently among landscapers hesitant to adopt the technology.

“In the mind of the landscape professional, run time is everything,” Barnaby says.

companies in various ways, such as by alleviating the labor crisis.

Greenzie is a software that powers autonomous mowers.

“We use robotic equipment to take job openings, not jobs, and we reduce their crew so that they can do more with less equipment,” Quinn says.

“We focus primarily on software that makes landscapers more efficient. The software is the brains of some of the autonomous operation. It

“Obviously, with gas, you can just bring the truck over replenish the supply, whereas with battery power, you either have to recharge the battery or invest enough to have another charged battery to get through your day, but think of the money you pay for gas and the time spent when you’re having to go to the gas station and wasting time on the clock. You can have the batteries ready to go before you leave the shop.”

Dan Stibral, product training specialist at Bobcat Mowers, adds that battery life can depend on a variety of factors.

“What we’re seeing is that battery life varies depending on the grass conditions, but overall, we’re seeing upward of eight to 10 hours in the field,” Stibral says.

He adds that slower mowing during shoulder seasons can also

From the shock-absorbent platform to the adjustable tower, every single inch of this mower was intentionally designed for perfection. The new Grasshopper Stand-On Mower. EVERY. DETAIL. MATTERED.

©2023 The Grasshopper Company

©2023 The Grasshopper Company

help landscape professionals save on battery life.

“That’s really where you see a lot of battery life savings,” Stibral says. “The jack rabbit mode is really the biggest eater and consumer of that battery, so when you indicate that you want slow back, you’re cutting less grass, maybe taking just an inch off the top, but you can do that later in the season where it’s pretty cool and dry.”

In any case, many manufacturers say the dynamic over the next several years will be interesting as more and more landscapers begin to make the switch.

“A lot of landscapers don’t want to change; they like things the way they are,” Dwyer says. “They can they go down the street, fill up with gas, go cut the grass and do what they do. There are, however, a lot of them out there that look at the environmental aspect and the quiet. And now, there’s a lot more that can be forced into having to have the newer solutions if they want to do business with some of these municipalities. Some may want to save the planet, and for some, it’s a marketing thing.”

He adds that it will begin with trust, especially with autonomous equipment.

“There are a lot of people that are a little bit wary right now, but I think you’ll see a lot more movement

that way because it helps solve your manpower issue,” Dwyer says. “If a landscaper has a piece of equipment that they can send on its own to go cut an acre while they’re trimming and whatnot, they’ve just eliminated a person and made their operation that much more efficient.”

Are these trends on par with what you’ve seen in the industry? Have any of these trends helped your company become more profitable and efficient? What other mower trends have you noticed lately? Let us know by emailing Green Industry Pros Editor Sarah Webb at swebb@acbusinessmedia.com

For more on robotic mowing trends, follow the QR code for the article where mower manufacturers provide a look at how the robotic mowing industry can help grow the green industry.

https://gpros.co/7tcl59

Finally, stay tuned for our April issue, where we will dig into the latest when it comes to stand-on mowers.

The pursuit of the perfect cut. Reliable performance. A smooth ride. Whatever it is you’re after, all-new zero-turn mowers from STIHL are here to help you in your pursuit. From their innovative engineering to the durable construction that comes with being Made in America*, our full line of zero-turn mowers gives homeowners and pros the performance and precision they expect from STIHL with the power and reliability they demand. If you’re ready to cut a new path forward, then we invite you to come along for the ride.

This labor market in the landscape industry poses a challenge as every sector is feeling the pinch. These insights will help landscape professionals win more often at recruiting and retention.

Companies want ambitious people, and they rarely want someone who is only there for a paycheck. Keep ambitious people and recruit new ones by showing them how to advance. Having a defined career path and sharing it early and often inspires those go-getters to grow. This attracts them to your company and keeps them motivated.

Today’s workforce has the luxury of working for a company they believe in. They want and choose to work for companies whose values align with theirs. Make sure you’ve got a “Why?” behind your company’s purpose. The “Why?” cannot be making money. They want their workplace to contribute time and money to help low-income residents. They want to work for a company committed to participating in youth sports, for example. Fighting climate change is important to many, so talk about the CO2 offset from the trees you’re planting. Giving purpose is a great way to win in today’s labor market.

If your employees can’t fulfill their obligations outside work and do their job well, then they will find another workplace.

They have a choice of where to work at the end of the day. Be generous with paid time off, and don’t bother people while they’re out. Make it easy for them to take time off. Let them do the things that fulfill them outside of work, and they’ll give you their best while they’re at work.

You’ll hear this from several places, which is that healthy culture is a must for today’s workers. Younger millenials and Gen Z workers are used to living lean because of the economic challenges people are experiencing postpandemic. They live at home or rent rather than having a mortgage mostly because of financial reasons or not wanting to work at a job with a poor work environment. They’ll leave if they feel things are toxic. Create a supportive work environment. Allow people to give input and actually adopt some suggestions. There are some excellent ideas from young people, and you can use them. Ask about their well-being and be concerned about their answers. Create a way for them to give you feedback and make changes based on it. Allow them to work collaboratively to solve problems. Do these things, and you’ll keep more employees. Better retention means less energy and money invested in recruiting.

If you don’t have a thoughtful, easy, engaging onboarding process, you’ll spend more time recruiting. One study found that quality onboarding led to an 82 percent increase in

employee retention. Make it easy to apply on your website and don’t require all the info you’ll need if you hire them. Allow them to complete this as electronically as possible. That means all of the new hire paperwork. Most importantly, give them a head start. Show them where to park on day one, for example, or introduce them to their manager or supervisor. If that person is unavailable during the day, then have them send a short video introducing themselves. Email new hires videos that are three minutes or less explaining how to wear personal protective equipment properly, operate the equipment they’ll be using daily and load and unload the equipment at a jobsite. Nail onboarding, and you won’t have to do it as often.

Jobber released a report in 2022 that the average U.S. landscaper’s salary was $14.62 per hour. Research also found that the average hourly rate in January 2023 was only $14.91 per hour. For comparison, the average national salary for fast food workers is $17.20/ hour, $2.29 per hour higher than landscapers. Warehouse workers and general laborers also make more hourly. Quit saying people don’t want to work because they’ll work where they get paid. So, let’s start paying them. You’ve got to offer pay and benefits such as health insurance, profit sharing and retirement that are competitive with other industries sharing similar physicality and potential for injury. Look at general laborers, warehouse workers or unskilled construction workers in your market for comparison. If you’re still unsure, use the living wage calculator to determine what a family in your area needs to survive.

There’s a massive crossover between good marketing and good recruiting. Good marketers seek to understand their customers. They craft messaging and experiences that attract those ideal customers. If you have rock stars on your team now, conduct stay interviews

with them and find out what makes them tick. Collate all that data from all your highest-performing team members to discover what they have in common. Then, write job descriptions and create application processes that they’d enjoy. Ask them to help you create these experiences. Get their feedback on the job listings and language on the

website. When you deeply understand who is attracted to your company, you’ll attract more like-minded people.

Jay Worth Marketing Manager SingleOps

A rundown of stand-on spreader-sprayer options lawn care operators can use to put down lawn care products this spring and summer.

Push spreaders and backpack sprayers or truckmounted tanks with hoses used to be the standard tools for applicators. However, today stand-on spreader-sprayers have entered the scene.

Stand-on spreader-sprayers are fast, productive and profitable machines to use. It’s important to choose the right machine for your needs.

Productivity. Stand-on spreader-sprayers can apply both granular and liquid materials simultaneously in each pass. By performing (and billing for) two jobs at once, lawn care operators dramatically increase the productivity and profit potential of each applicator. Stand-on spreadersprayers enable each worker to do more with less. Profitability. Because stand-on spreader-sprayers are a productive way to apply materials to lawns and other turf areas, crews can finish more jobs each day. There’s less

wear and tear on you and your crew as well, so it’s more sustainable day after day. It all adds up to increased profit at the end of the day, and especially at the end of the season. Versatility. With the ability to apply a wide range of both liquid and granular materials, modern stand-on spreadersprayers are versatile. Plus, many machines have a wide range of accessories that allow lawn care operators to customize the machine’s capabilities for their specific needs. Safety. Since the operator stands on a platform above the lawn, stand-on spreader-sprayers reduce the potential for operator contact with the materials being applied. This makes for an overall safer work environment for applicators when compared to traditional walk-behind or handheld equipment.

Most modern stand-on spreader-sprayers can be broken into two types, and the difference boils down to how the machine is steered. The two types are spreader-sprayers with steerable front wheels or a pivot in the middle of the frame and zeroturn spreader-sprayers. Ultimately, the choice of which is right for you boils down to needs and budget. There’s not one clear-cut best type of stand-on spreader-sprayer, so let’s take a deeper look at what each type does well.

Zero-turn spreader-sprayers. Most zero-turn spreader-sprayers use a drivetrain setup that’s similar to a zeroturn mower, consisting of hydraulic pumps and wheel motors powering the rear wheels, with pivoting caster wheels at the front. As a result, the value proposition of zero-turn spreader-sprayers is similar to mowers, with enhanced maneuverability and speed, enabling users to make quick work of big application jobs.

Zero-turn spreader-sprayers

often have larger hoppers and tank capacities, enabling them to do more work between fillups. Most zero-turn spreader-sprayers use a boom-type spray mechanism to precisely apply materials. Steerable spreader-sprayers. Steerable spreader-sprayers don’t have zeroturn capabilities, but they can still be good machines for residences.

Typically smaller, many steerable spreader-sprayers can fit through a 36-inch gate. Because steering is a function of turning the wheels, the wheels are always in unison, providing additional hillside stability.

Plan for tomorrow. It makes sense

to purchase equipment that will keep up as more and more clients come on board. The spreader-sprayer should meet your immediate needs, but don’t forget to think about where you want to be in two to three years. Buy quality equipment from a dealer you trust. Purchase highquality equipment from a dealer you have a good relationship with. The dealer is your gateway to parts and accessories, and they can also help ensure you operate it safely. Take a test drive. Controls and control layouts vary from brand to brand, so by test driving or demoing the machines, you can quickly feel if it’s right for you. You want spreader and spray controls to be simple, logical and easy to reach without compromising your speed or direction control.

Much like any piece of equipment, the decision of which spreadersprayer is right for you comes down to your needs, your goals and your preferred user experience.

• Calibration is everything when it comes to using spreadersprayers. If you don’t properly calibrate your machine, you risk overapplying or underapplying product without even knowing it. For precise application rates, it’s crucial to calibrate both the liquid and granular systems on your spreader-sprayer. —

Matt Smith, co-founder and sales manager, Steel Green• Spreader-sprayers are inherently efficient machines, but there are several ways to make them work even harder for you. One is tank mixing, which allows you to apply multiple liquid products at one time. Just be sure to read and follow the labels of the products you’re mixing. You can customize the liquid and granular capacity of your machine to reflect how much of your business is liquid versus granular. Also, look into adding an independent tank if you need the ability to make separate chemical applications with your machine. —

Smith• Another way to use your spreadersprayer more efficiently is to customize it with attachments and accessories specific to the services you offer. In terms of accessories to

customize your spreader-sprayer, look for options that align with the services you offer. — Smith

• Maintenance should include blowing your spreadersprayer off daily and applying an anticorrosion product regularly. It’s also important to winterize the spray system to prevent corrosion and clogs. There’s some additional maintenance if you’re using the machine with a plow in the winter, including snow tires for improved traction. — Smith

experts explain how to properly maintain equipment ahead of spring cleanups and offer up mulching tips.

Maintaining spring cleanup equipment helps ensure the busy season starts off on the right foot.

“Maintenance enhances the life of your product, and without it, you’ll face expensive repair bills that can lead to inefficiencies on the job,” says Noah Hunter, director of customer care, technical support and warranty at Husqvarna. “It’s simple. Landscape companies can’t work with broken equipment. Routine maintenance means small issues can be resolved before they become large and take equipment out of commission.

Failure to perform routine preventive maintenance can lead to equipment operating with less power, more fuel consumption and less desirable results overall.”

While part 1 of this article in the January/February issue described the best ways to prep your crews for spring cleanup season, in this article, manufacturers and landscape professionals detail how to make sure equipment is in tiptop shape and offer up a few mulching tips.

Before crews head out to do the cleanup work, it’s important to take an equipment inventory.

“When you’re pulling the equipment out of storage, go through things,” says Jason Wilk, senior product manager at Echo. “It’s a really good time to make sure air filters are clean and in nice shape. Make sure you don’t have cobwebs or anything. I’ve seen mufflers get

packed with insects over the storage time range, and that will prevent the unit from starting or accelerating.”

Hunter agrees that maintenance of all products should start with a visual inspection by checking for things like clogged cylinder fins, broken components, cracks or leaks.

“Any products with cutting equipment require regular inspection of blades, bars, spur sprockets or chain,” Hunter says. “Pros will want to sharpen or replace any parts that are dull if needed. Additionally, routine maintenance should include checking the safety function of chain brakes.”

Hunter adds that landscape pros should inspect the muffler screen arrestor and make sure it’s not clogged, ensure that sparks don’t fly from the muffler and test their products for performance, making sure all the product switches and functions are working along with achieving proper idle RPM and max RPM.

Once equipment has been inspected, landscape professionals should clean it.

“An engine fails due to overheating, lack of lubrication or dirt ingestion,” says Jeff Taylor, manager, product services, Stihl. “Dirt ingestion is due to an improperly maintained air filter, and overheating is due to not cleaning the unit regularly. As you cut grass or are using a chainsaw, you’ve got sawdust or debris that gets packed around the cylinder of the engine, and that debris doesn’t allow the engine to cool properly.”

Taylor adds that providing crews who clean equipment with safety gear is just as, if not more, important.

“Anytime we’re doing this type of work, we need to make sure we’re dressed properly and using protective gloves and some eye protection because we will use compressed air from time to time to help us clean the product,” Taylor says.

Regular service maintenance items include adding fresh fuel, changing air filters, fuel filters and spark plugs and adding grease to the bevel gear head or hedge trimmer gear cases, if applicable, Hunter says.

“There are some small maintenance items that can be done on a weekly basis,” says Glenn Lovell, senior technical services technician at Oregon Tool. “Or, like when you’re done in the evening, and maybe you’ve got a half-hour to give a glance over the air filters and check to make sure your chain is still sharp and not completely dull.”

He adds that landscape pros can use systems to keep track of that maintenance, whether that’s through pen and paper, a whiteboard or software.

“It can be really hard to set aside time to check all of those things, especially when you’re running as fast as you can to get the different jobs done,” Lovell adds.

For trimmers, Taylor adds landscape pros can also inspect and clean trimmer lines to save on downtime throughout the season.

Wilk suggests making sure there’s grease in the gear case, that drive cables are lubricated and that equipment is generally tuned up.

Make sure screens aren’t plugged up and that fuel lines are clean as well—landscape pros should make sure they aren’t brittle or gummy, as this can cause fuel line failure, Lovell says.

“When it comes to lack of lubrication, make sure the fuel mix is quality and that gasoline is mixed regularly and not stored for more than 60 days,” Taylor says. “On a two-cycle engine, lubrication is in the fuel mix, so it’s important to get proper fuel flow.”

It’s also key to not forget to inspect and lubricate the gear box located at the cutting attachment.

“That’s an item that’s often overlooked,” Taylor says. “Remove the grease plug, inspect it and add grease if necessary in the gear box.”

While battery-powered equipment requires less maintenance in general, it’s important to make sure it’s stored in a warm, dry place.

“If you’re looking to maximize the life of the battery, care and storage is most important,” Taylor says. “Keep them stored in an area that’s dry and away from extreme temperatures. The 50- to 70-degree F range works well, but the main thing is don’t store it below freezing or above 100 degrees F.”

Landscape pros can clean the batteries and battery compartment with a dry cloth as moisture can add to corrosion issues.

Additionally, some battery products have an air filter, so it’s important to clean those, first ensuring the battery is removed to avoid accidental startups. Then, landscapers should wash it, air dry it and reinstall it.

Wilk notes that a lot of spring cleanup success revolves around crews having the proper equipment on hand.

“You don’t want to be using a huge backpack blower in flowerbeds and blow all the mulch out of the beds into the lawn, and on the same token, when you’re trying to do cleanups, the last thing you want to be doing is trying to tackle a whole leaf cleanup job with only handheld blower,” Wilk says. “So, it’s all about having the right amount of equipment to get in there and get the job done and get to the next as fast as possible.”

“Understand customers’ expectations and document their conversations to minimize the likelihood of having to return to correct any mistakes. Conversely, if the customer only needs a rough cut rather than a fine mulch, knowing this ahead of time by referring to one’s notes will allow the contractor to work quickly while still making the customer happy.” —

“Make sure you’re giving your crews the proper tools so they can do the work efficiently.”

Nick Carlson, founder of Mulch Mate

“Stay on top of preventive maintenance. Rainy days and the mulching offseason provide great opportunities to keep equipment in top shape, so landscape professionals can avoid inefficiencies by taking advantage of the downtime they have to ensure everything is in working order.” — Nelson

“Crew members should be aware of thrown debris. While our instincts tell us not to touch a mulcher when it is in use, thrown vegetation or rocks can catch people by surprise. Flag off areas that need to be mulched, as well as the manufacturer’s published clearance radius, to keep people safe from harm.” — Nelson

“Listen to your crews for inefficiencies. We used to put down 80 yards of mulch in a day but were dead. How could we fix that? That’s when Mulch Mate came along, and our guys were doing 200 yards a day, and they were happier because they were using less physical labor.” — Carlson

“Replace polycarbonate windshields and doors any time they are damaged. Inspect for cracks or deep scratches whenever the structural integrity of the machine is compromised and replace the component immediately.” — Nelson

Anew construction season is approaching, and nowadays, projects are more likely than ever to last through the fall and winter, so regular, ongoing maintenance of compact construction equipment is vital.

“Compact construction equipment has advanced over the past 15 years,” says Jason Boerger, senior product line manager at Kioti Tractor. “The hydraulics have improved, and there are more specialty attachments that allow digging into frozen ground. Things we couldn’t do 15 years ago are starting to happen year-round.”

Luke Gribble, solutions marketing manager with John Deere’s Construction & Forestry Division, says there often is no offseason for compact construction equipment.

“While some parts of the country may not have as much construction activity in winter months, a growing number of customers are turning to applications like snow removal to keep machines working throughout the year,” Gribble says. “Additionally, agriculture applications and warmer climates require machines to be working year-round.”

That means maintenance of skid-steers, compact track loaders and excavators, wheel loaders, smaller backhoes and other types of compact construction equipment should continue through the fall and winter months and into the spring.

“Maintenance should be prioritized each day,” Gribble says. “To keep any machine up and running on the job, it’s best to incorporate a maintenance route and follow best practices to keep it operating for longer.”

Some of that care is generic. For example, Boerger says all machines need thorough inspections of all parts. Look for wear and damage. Keep the components greased and top off the oil, engine coolant and other fluids. The idea is to reduce the risk of downtime.

Boerger advises preparing dormant compact construction equipment for the upcoming season not in the spring but at the end of the previous season.

“One thing often overlooked is looking to the operator’s manual for common service intervals,” Boerger says. “Check the recommended service hours for your machine. If you’re close to a service interval and need to do maintenance on a component or take it to the dealer, it’s a lot easier to do that at the end of your working season than at the beginning of the next season.”

Cleanliness is another key factor, says Mike Fitzgerald, marketing manager with Bobcat Co., when it comes to skid-steers and compact track loaders. He says neglect in cleaning can cause filters, vents and electrical components to clog or become damaged.

“Regular washing can prevent the buildup of grease and mud,” Fitzgerald says. “Cleaning protects much more valuable aspects of your equipment than its paint job.”

Here are more steps green industry professionals can take to maintain their compact construction equipment: Keep the fuel tank filled. As temperatures rise and fall, condensation can fill empty space in the fuel tank and mix with the fuel once fuel is added. Filling the tank as the construction season ends keeps condensation out of the tank, Boerger says. Use the right engine oil. Fitzgerald says the oil viscosity should match the temperature outside. A 10W-30 oil is good for temperatures down to –20 degrees F, but for better cold-weather lubrication and protection in temperatures as low as –40 degrees F, try a 5W-40 synthetic oil. Charge the battery. Freezing temperatures can force a loader’s battery to crank twice as hard to turn over and deliver fuel to the engine.

“Before the next project or snowfall, run a load test and check wires and connections for wear or corrosion,” Fitzgerald says. “Even a small defect can result in a loss of cranking amps, leaving you with a dead battery and freezing your project.”

Check the track sag. Gribble says tracks excessively tight can wear down too quickly. If tracks are too loose, they can cause instability in the machine, and the tracks can break loose from the sprocket. Determine the proper track sag by removing all debris between the track and the sprocket, finding the third roller from the rear of the machine and measuring the distance between the bottom of the roller and the top of the track. That distance is the track sag. Consult the operator’s manual for track sag specifications. Clean the undercarriage. Gribble says the undercarriage is integral to the machine’s mobility and productivity. At the end of each day, check the undercarriage for buildup of material and debris, which can damage components or cause them to freeze. Fill cold loader tires. Tire pressure drops with the temperature, and cold weather makes the rubber stiffer, so always check that pressure.

“Repair any leaks suffered in the busy season during your regular maintenance schedule,” Fitzgerald says. “A small leak or nail in the tire is easy to put off in warmer weather because you may only have to fill your tire once a week. In winter, once a week can turn into once a day.”

“Stretch” the equipment. Boerger says an athlete wouldn’t compete before stretching. For compact construction equipment, stretching means allowing the machine and its fluids to warm up before use, especially if it hasn’t run for some time.

“It doesn’t mean you have to work slowly the first week; you’ll be able to work the first day,” Boerger says. “It just means with that at the initial startup, you let everything get up to temperature.”

Gribble recommends a warmup period each day and a cooldown period at the end of each shift to protect engine and hydraulic parts. Ensure the cab is comfortable. Inspect door and window seals to make sure that heat doesn’t escape the cab. Test the heating and defrosting systems.

“Freezing temperatures are no time to test your toughness,” Fitzgerald says. Prepare attachments. Attachments need as much attention as the loader. Inspect the hoses, cylinders and guards, cutting blades and edges for signs of wear or damage.

“If the attachment requires maintenance or lubrication, check the fluid levels before you head out into the cold,” Fitzgerald says. “This is especially important for snow removal attachments that have been collecting dust in your garage since last winter.”

Boerger says routine maintenance of compact construction equipment is one of the best ways to avoid downtime.

“There are no guarantees with equipment downtime, even if you are a careful and thoughtful operator, but routine maintenance reduces your chances of downtime significantly,” Boerger says.

Bob Sandrick Freelance Writer

Bob Sandrick Freelance Writer

Wheeled excavators are beginning to be used more often in North America, especially by county road departments and municipalities.

They can be utilized for common applications like ditch work, landscaping, utilities and virtually any other type of job that excavators are suited for, according to John Waldron, product manager, wheeled excavators, Volvo Construction Equipment.

As their popularity continues to increase in North America, manufacturers have been focused on changing the conventional wisdom that compact wheeled excavators are often viewed as unstable.

“The excavators can still work on uneven ground, without any damage occurring to their undercarriages,” says Geoffrey Andrews, manager of business development, Mecalac North America. “They’re very stable during operation, too, including when they travel uphill with loads.”

Compact wheeled excavators also feature increased safety features aside from a tight swing diameter and strength. The operator directly enters the cab from the side, and there’s no need to climb over the attachment and turn around before the operator sits in the cab seat. Some compact wheeled excavators have a load sensing hydraulic system, which enables operators to fully utilize all available engine power. In turn, they’re not only able to increase their responsiveness but their controllability as well, leading to high stability.

“Just because the excavators have wheels doesn’t mean they have to be solely operated with a steering wheel,” Waldron says. “After all, they feature Comfort Drive Control, which allows operators to control each of their excavators while using only the joystick, resulting in speeds as high as 12 mph.”

Regarding most tracks in construction equipment undercarriages, Andrews believes that North American operators tend to utilize extra wide integrators. Yet, in Holland, manufacturers create factory units on tracks, and the tracks can be bolted over a set of tires. Since the integrators

that are developed overseas aren’t extra wide as they are in North America, they offer higher speeds, often traveling up to 1.5 mph faster than standard North American offerings.

As more and more North American operators seek out tracks that can be used in tight areas, Andrews notices they want more versatility. They implement creative ways to utilize tracks in construction equipment undercarriages, leading manufacturers to determine various methods in which they

can use one piece of track equipment in multiple ways. Some manufacturers provide track sets for wheeled units or enable operators to bolt a chain over their tires, resulting in the creation of a compact track loader (CTL).

Andrews stresses that at one point, North American jobsites had a lot of room to utilize their large equipment. That is no longer the case now as contractors need to maintain smaller footprints. Some tracked models have optional rubber track shoes. Operators can use crawlers on surfaces like asphalt that they don’t want to damage. The rubber track shoes are detachable and can be used whenever operators need traction as well. Using a pad comprised of a durable rubber blend and placed on a steel plate, the track shoes reduce noise and vibration.

“The replacement of single rubber pads is also an easy, cost-effective way to maintain an excavator’s track system, which can be complicated and expensive to repair otherwise,” says Sejong Ko, product manager, large excavators, Volvo Construction Equipment. Which excavators are best to use—and when?

As operators consider the best times to utilize wheeled or tracked excavators, they will need to determine exactly which applications should be performed on the job and the intended usage of the equipment they will be using. Whenever operators use wheeled excavators, they’ll likely save money and time on maintenance and upkeep. Wheeled excavators are lighter than tracked excavators, enabling them to be used more easily, especially when they’re utilized in the proper conditions. At the same time, wheeled excavators are better equipped for long-distance travel, and operators arrive at their desired locations more effectively.

A common misconception currently associated with wheeled excavators, according to Waldron, is that by using them, operators will lose the stability they have while operating crawlers. That is not the case, as wheeled excavators are

not only as stable as crawlers, but they also ensure operators won’t sacrifice breakout, tearout forces, digging depth, power or reach whenever they use them.

“By driving excavators to various segments on their road jobs, operators can save considerable time and money. In particular, by using wheeled excavators, operators will reduce their reliance on a lowboy and eliminate the extra equipment, labor and time they previously needed to load and unload machines,” he says. “Wheeled excavators can also drive faster on roads than tracked models, cause less damage to driving surfaces and tow trailers with attachments or pipes, which decreases transport costs even further.”

The cost savings of purchasing a wheeled excavator goes beyond the initial purchase of the machine and continues throughout the excavator’s lifespan. This is because wheeled excavators can equal both increased labor productivity and cost savings. No commercial driver’s license (CDL) is required for the wheeled excavator, meaning the same person who operates the machine can drive it. Compare that with a truck mounted excavator, which may need to be supported with both an operator and a driver with a CDL.

Wheeled excavators are especially critical for usage in tight spaces as short swing wheeled excavators can work in one lane of traffic, when compared to conventional swing excavators that often require two lanes. If operators work on multiple jobsites that are spread apart, they can utilize wheeled excavators for such distances as well. Operators are advised to use wheeled excavators that have two-piece articulating booms, enabling them to stretch farther, dig deeper and reach higher and closer to the excavators themselves.

“This can be especially beneficial in offering operators more flexibility to go up, around and under obstacles like bridges, guardrails and mailboxes,” Waldron adds. “Additionally, a twopiece boom can provide operators extra lift capacity in tight quarters.”

Although operators tend to utilize wheeled excavators in urban areas that have hard grounds and considerable distances for traveling while tracked excavators are favored for shorter travel distances and ground conditions like mud and uneven terrain, Andrews believes this consensus is changing, especially as more multifunctional wheeled and tracked excavators enter the market. The versatility of wheeled excavators and suggested future innovations that could reduce overinvestment in excess machines on jobsites save contractors time and money.

“A wheeled excavator can be the Swiss Army knife of a fleet and prevent contractors from investing in multiple machines because it can utilize the same attachments as crawler excavators,” Waldron says. “Some original equipment manufacturers also have material handling options on wheeled excavators, which are in high demand and really maximize what the machine can do.”

As Andrews looks ahead to the future, he believes that operators will continue to desire more from their equipment, and wheeled and tracked excavator manufacturers will notice their new requirements and respond accordingly.

“Since wheeled excavators are designed for ease of use and versatility, the excavators are reducing the amount of equipment that operators need to use on their jobsites,” Andrews says. “Whether operators are urban landscapes or ranchers that need to cover a lot of ground, these excavators are—and will continue to be— game-changing technology.”

1. Understand the key differences in tracks versus tires.

• “The first thing customers should know before deciding is to understand the role of tracks and tires in their application.” — Jerry Corder, product manager, construction equipment, Kubota Tractor Corp.

• “Compact wheel loaders (CWLs) are dedicated lifting and loading machines, excelling in landscaping, nursery, residential, commercial and rental applications. They work best on solid, dry ground and move at higher speeds to reach more jobs in a day, making them a great choice for townships and snow removal, to name a few examples.” — Corder

• “A sister machine to CWLs, compact track loaders (CTLs) are nimble, completing many different tasks on any jobsite. CTLs are excellent at dirt work, lifting heavy loads with pallet forks and running attachments. Contrary to CWLs, CTLs excel on uneven, hilly terrain and are great in wet and muddy conditions.” — Corder

2. Determine your biggest jobsite needs.

• “Do your homework to understand the job application and what is needed to complete the job. If the customer understands their needs, there’s a better chance they will make the right purchase. If traveling at higher speeds and getting to other jobsites without needing a truck is a priority, wheels on CWLs would be a good choice. If you are operating on turf that can’t take the abuse tracks would impose, then a wheeled CWL would be preferable. If you anticipate working on more off-road terrain, the tracks on the likes of a CTL will better suit your needs.” — Corder

3. Make room for both tracks and tires in your lineup.

Chris Lewis Freelance Writer“Between the CWL’s loading, dumping and lifting capabilities and the CTL’s nimble maneuverability, there is room for the two models to work collectively. With comparable specifications and performance, if a customer purchases both, the business can be more profitable and have the ability to work in many different job applications.” — Corder

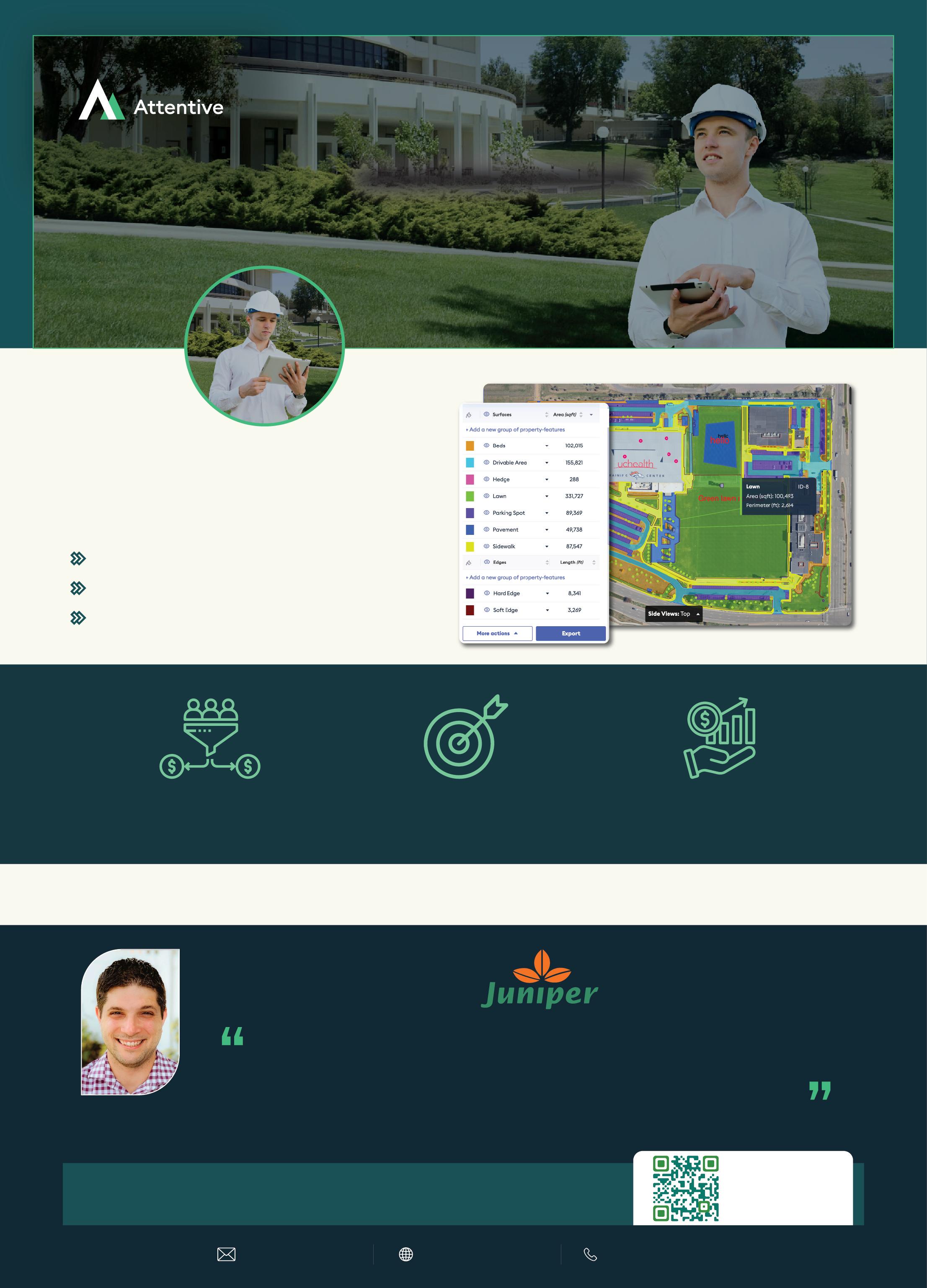

While some irrigation contractors may be hesitant to adopt smart controllers, it may just give them the advantage they need to gain more customers and become more profitable.

“Sometimes, end customers don’t have a lot of respect for the landscape industry, so if a contractor can come in as a water management professional, someone who not just understands but who can use the technology for the purpose of saving their customers water while making their landscape look better, that elevates them to a much higher standard,” says Richard Restuccia, vice president, water management solutions, at Jain Irrigation. “They will automatically start getting more work because they’ll be separating themselves from the competition through the quality of their work.”

Restuccia and Matthew Mikucki,

director of product marketing at SiteOne Landscape Supply lay out the ins and outs of smart controllers and how irrigation pros can take advantage of them.

By using smart controllers, irrigation professionals are providing a better service to their customers, Mikucki says.

“You don’t want to have your homeowner running their irrigation system when it is raining out, and you want to be applying the correct amount of water needed for the plant material when you are looking at the overall amount of water being applied, whether it is from rain or from the irrigation system,” Mikucki says. “Overwatering is as much of an issue as underwatering. Overwatering can cause diseases in your turfgrass and potentially allow pests such as mosquitoes to grow.”

Restuccia notes that the water and cost

savings for customers are also a plus.

“You have to distinguish yourself from the competition by saying ‘we are a water management company, and we may have a higher fee, but because we use smart controllers and manage your water appropriately, we’re going to save you money on your water bills that will more than make up what we’re charging on our higher fee.’”

Additionally, using a smart controller means irrigation pros don’t have to waste labor driving to a site to adjust the system.

“From its most basic level, having a smart controller means you don't have to physically touch the controller to make an adjustment on it,” Restuccia says. “If someone has a traditional controller, and there’s rain coming or winter is coming, they need to drive to a site to shut the controllers off, and the waste of time, labor and fuel is incredible. Think of one account manager handling 15 jobs. This ability for the times to change automatically for you daily is a huge time saver, and it doesn’t cause all that waste that we’re trying to eliminate right now in our environment.”

It’s important to remember that a smart system is not just the irrigation controller, Mikucki says.

Irrigation pros should look at the distribution of water and understand that pressure-regulating sprays ensure the nozzle is performing at the best pressure to maintain optimum performance of the spray head or rotor.

Other components of a smart system include precision spray nozzles, rotary nozzles and drip irrigation systems.

“All these products tie back into the smart controller, which is the brains of the system. This controller uses an internet connection to determine weather, evapotranspiration and calculate the proper amount of water to apply to the turf,” Mikucki says. “The systems are only as smart as the information entered into the controller. Setting up a drip zone or a spray zone is important to make sure the controller can calculate the proper run time for the zone.”

Mikucki and Restuccia agree that performing an irrigation evaluation, or site survey, is key before upgrading or installing an old system.

“They’re going to have to spend some time learning about the basic soil and plant makeup of the jobsite because all of that impacts the amount of water used,” Restuccia says. “They’ll have

to look at the amount of shade on a property, what kind spray heads and rotors are already on-site and more.”

For professionals worried about the time it takes to onboard new technology, Restuccia says that shouldn’t be a prohibitive factor.

Irrigation pros wanting to learn more about implementing smart controllers can look to their manufacturers, distributors and associations for continuing education.

Restuccia adds that irrigation professionals should start thinking about adding the technology now.

“The industry has been slow to adopt because they feel they don’t have the time or labor, but if somebody wants to invest in the technology, it’s time to get on the ball today,” Restuccia says. “There’s plenty of business to go around, and nobody is too late to the game.”

So, what happens to the older irrigation equipment once it’s replaced with newer technology?

One option is to enroll in a recycling program, like the one SiteOne Landscape Supply offers.

“The idea of the program is the contractor looks for customers with older and inefficient systems where they can upgrade them to a new system,” Mikucki says. “All the contractor needs to do is pull the old controller off the wall of the homeowner, take it to a SiteOne branch and turn it in at one of the designated drop boxes. A SiteOne associate will help them pick out a new smart controller from one of our partner companies, and the contractor will save 15 percent on the cost of the controller.”

The program began after SiteOne found that there are upward of 30 million inefficient

@NaMong

irrigation controllers operating in the U.S. and Canada. The company then partnered with Blue Star Recyclers to recycle the old controllers.

The program runs for two months—March and April.

“There is no limit to the number of controllers a contractor can recycle, but it is a 1:1 returned controller and discount,” Mikucki says. “Right now, we are focused on recycling controllers only. There may be opportunities in the future to recycle other components of the irrigation system, but right now the recycling channel is focused on the electronic waste, so we are taking advantage of that and keeping those old controllers out of the landfill.”

There are other options for irrigation professionals who miss that window.

For example, some irrigation manufacturers like Jain Irrigation Systems, offer smart controller options that attach to a conventional controller, thus making it a smart system.

“It makes it so you don’t have to throw away your old controller, and it uses that old controller and makes it a smart controller,” Restuccia says. “We can take over the current controller and download our schedules to it. That way, you don’t lose your old investment, and it’s sustainable.”

ManageMowed in Colorado Springs, Colo., donated its time and services to the Pikes Peak chapter of Habitat for Humanity to help the organization clear properties awaiting development.

It all started with a phone call from the ManageMowed corporate office to the Pikes Peak, Colo., Habitat for Humanity chapter. ManageMowed wanted to offer its services to the organization, free of charge.

Habitat for Humanity is a nonprofit organization that helps families build and improve places to call home—a cause ManageMowed could help with in terms of the landscaping for those properties.

From there, Kirk Kucin, owner of ManageMowed in Colorado Springs, Colo., met with the Habitat for Humanity team representative to walk through two undeveloped properties in southern Colorado Springs that Habitat for Humanity had slated for future home builds.

“Walking through the properties, Eric Wells, the superintendent, told me what they wanted to have done in a perfect world,” Kucin says. “They had a large growth of weeds and native grasses that the city was complaining about. We told him it was definitely something we could take care of so that it wouldn’t be an eyesore until the time that they could build on the property. Any costs associated would be a donation from our company.”

Kucin says

challenges included not knowing the full scope of the properties upfront due to the tall overgrowth and debris.

“In some places, the grasses were 2 feet tall, so it was difficult to see what was below the grass at the dirt level,” Kucin says. “There was some trash and miscellaneous debris that we had to be aware of, and we collected and

disposed of it upon completion of clearing the property.”

To complete the job, three crew members cleared the properties over one day, using string trimmers and blowers, and mowed the properties so they’d be looking pristine when it came time to build on them.

“When our guys spend that time doing the work, they also feel appreciated for taking time to do something for the community,” Kucin says.

Looking ahead, Kucin says ManageMowed is eager to take part in similar cleanup or land-clearing opportunities presented by Habitat for Humanity.

“An emerging brand, we strive to get our name out in the community as much as possible, especially through giving back to other local organizations. Habitat for Humanity has always been both a reputable and recognizable organization, and its mission to help build or improve a place our residents can call home was a great fit with our business model,” Kucin says. “It allowed us to give back to our community, and for the family that we’ll never know, it will mean a lot, so it’s a good thing to do.”

For other companies looking to take part in volunteer opportunities, Kucin says it’s as simple as reaching out to their local organization.

“Through a quick conversation, you will be able to determine if the opportunity is a mutual fit,” Kucin says. “There is more need for volunteers than many people realize, and giving back can be as simple as a three-hour cleanup.”

The Lithium-Ion 1.5kWh Swappable Battery Pack is engineered to provide users with an efficient, versatile and reliable battery power option. The battery’s exchangeable design allows customers to swiftly swap freshly charged packs from application to application, reducing downtime and increasing productivity. The batteries feature a diecast casing design that adds rigidity and reduces vibration and shock response from the pack. The batteries feature a modular design. The batteries use lithium-ion chemistry and technology to ensure reliable performance and feature a 2,000-cycle lifespan with virtually no maintenance. All three battery packs are available for order and offer a total solution with the battery, charger and battery management system that monitors voltage and temperature to assure safe and efficient operations. With the addition of the new batteries, Vanguard now offers a competitive range of battery power solutions including 1.5-kWh, 3.5-kWh, 3.8-kWh, 5-kWh, 7-kWh and 10-kWh options.

https://gpros.co/2h7jok

Case Construction

Equipment’s Minotaur

DL550 compact dozer loader includes:

• The chassis-integrated C-frame with a six-way dozer blade that hydraulically couples into both the chassis of the machine, as well as the attachment coupler.

• Three different track options: 14-inch single-grouser steel tracks; 18-inch triple-grouser steel tracks; and 17.7-inch rubber tracks.

• A 90- or 96-inch six-way blade connected to the integrated C-frame.

• The machine’s electrohydraulic controls with the ability to adjust the blade, steering and shuttle sensitivity to smooth, moderate or aggressive.

• Universal harnesses and brackets to integrate machine control solutions from any of these three providers of precision construction solutions—Leica Geosystems, Topcon and Trimble.

• A 5,500-pound rated operating capacity (50 percent of tipping load) with 12,907 pounds of breakout force in its loader profile.

• A vertical lift pattern and high-flow hydraulics that can deliver up to 41.6 gpm at 4,100 psi.

• Case SiteConnect Module.

https://gpros.co/588lzw

SiteOne Landscape Supply’s LESCO 300 Truck-Mounted Tank Sprayer offers increased profitability for green industry professionals. The new unit features a 300-gallon tank, allelectric start and a 6.5-hp Vanguard engine.

Additional features include:

• The truck-mounted design offers alternative efficiencies compared to a stand-on unit, such as easy towability and space savings.

• A Hydra-Cell pump engineered to be trouble-free and low maintenance, providing users with a lifetime cost savings of up to $6,500.

• The tank sprayer is resistant to corrosive chemicals and features molded, peel-resistant measurement labels for easy reading. It also includes a waterproof, lockable storage compartment.

• The unit attaches to most truck models and covers a large application area.

https://gpros.co/y79owi

Greenworks Commercial’s OptimusZ Range consists of:

• 48-inch, 52-inch and 60-inch ride-on platforms with 18-kWh and 24-kWh battery modules.