Portfolio

720-980-3113 gbfraikor@gmail.com https://www.linkedin.com/in/grant-fraikor-252111201/ issuu.com/grantfraikor

2

EXPERIENCE

GE Johnson, Virtual Design Construction Intern May 2022-August 2022

Responsibilities included modeling in Revit, concrete formwork panel drawings, preforming clash detection, creating Synchro 4d animations, and participated in a design build project for an Early Connections Center in Colorado Springs. Used BIM 360, Bluebeam, SYNCHRO, Navisworks, Revit, Sketchup, and Lumion.

Westridge Recreation Center— Guest Services

May 2019 - January 2022

Responsibilities include managing the access desk, fitness area and outdoor pool access area. Manage daily pass issuance and purchases. Provide management and enforcement of facility rules and regulations. Manage batting cages when assigned and access to tennis courts.

Southridge Recreation Center — Guest Services

April 2018 - May 2019

Responsible for various tasks including fitness center management, access desk, and outdoor pool. Trained and authorized to handle guest entry and storefront merchandise payments, equipment management and guest interaction.

EDUCATION

University of Kansas, 1450 Jayhawk Blvd, Lawrence, KS 66045

Master of Architecture Master of Construction Management

August 2020-Present 3.91 GPA 2022 Spring Deans List

EXTRACURRICULAR

KU Disc Golf Club

Varsity Tennis ThunderRidge 2018-20 Colorado Boys State 2019 ThunderRidge Baseball JV 2016-18 ThunderRidge Soccer JV 2016-18 2017-18 SKSK Camp Counselor (over 50 hours of service in one week) Volunteer for the Special Olympics Tennis Counselor for TRHS youth program

AWARDS

2x Academic Letter - 3.75 or higher in 3 semesters

2019 Underclassmen Awards- FBLA (placed 5th in Risk Management test), Student of the Month 2019 Artist of Merit 2015 President’s Education Awards Program- Outstanding Academic

SKILLS

Revit Rhino Enscape Sketchup Lumion SNCHRO 4d Navisworks

REFERENCES

Kapila Silva 414-334-1290 Kapilads@ku.edu

David Wilt 720-822-1865 wiltd@gejohnson.com

VRay Bluebeam 3ds Max BIM 360 Dynamo Adobe Suite

3

Museum of Human Impact

4 Selected

Early Connections Sunshade

1 0 2 0

5 Selected Works 4 0 3 0 Metcalf Avenue G-Market Nelson Atkins Popup Shop

6 1 0

Rammed Earth Layers of Impact Hertiage Pre-Human Gallary

Service

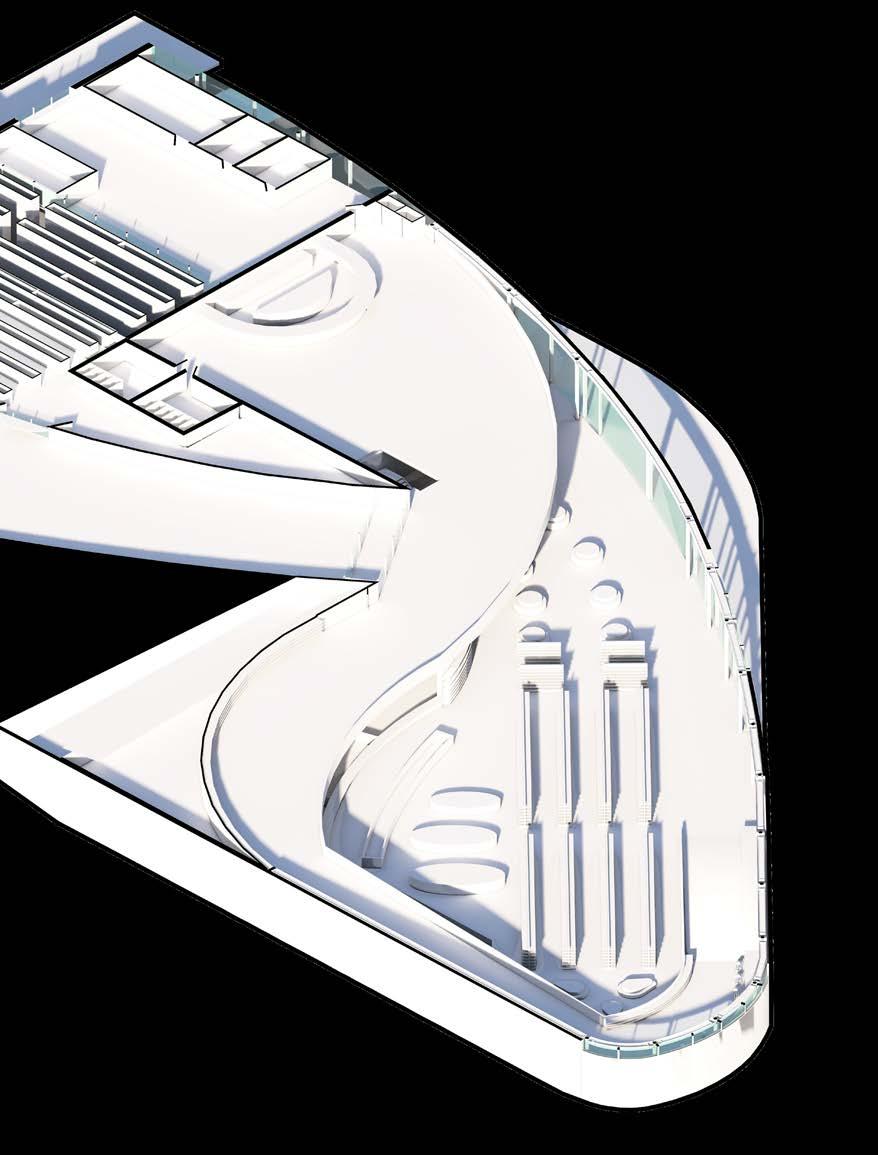

Museum of the Human Impact

-Fort Worth, Texas Fall 2022

Professor: Kapila Silva Fall 2022

Professor: Kapila Silva Fall 2022

From immense ocean pollution to rapid deforestation, our actions as a collective species have resulted in an environmental state now in dire stress. In order to save our planet and ourselves we all need to make a change. From more green and environmentally aware design to the individual impacts, we as humans need to become aware and change what has already been done. The Museum of the Human Impact on the Environment showcases the history and importance that now lays ahead. Through a look into the Pre-human, Industrial Human, and Solutions, users should understand and take action in this so urgent global scenario.

7

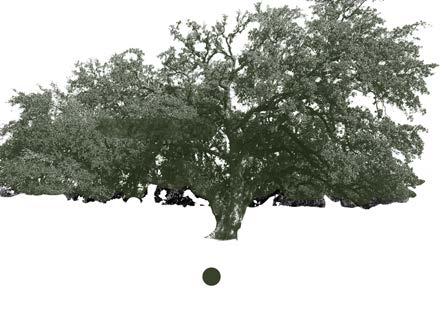

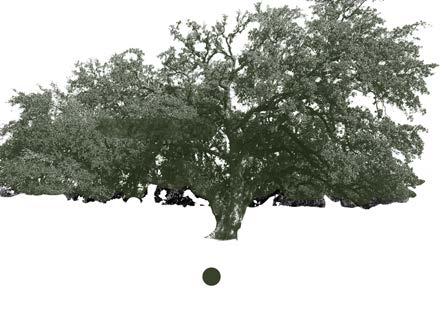

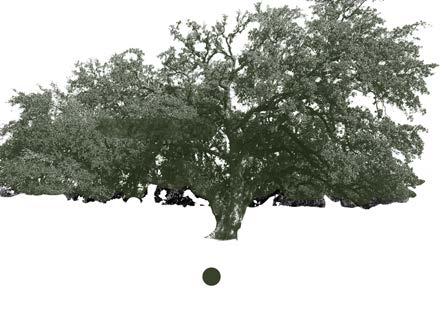

Final Galleries Hertiage Tree HT Ramp

Greenhouses and Solar Technology

Celebrating the Tree

Centered in the once existing parking lot lies the protected Heritage Tree. Instead of avioding the tree, the museum celebrates nature and centers itself around it to acknowledge, protect, and embrace the nature within a site.

Establishing Functions

Programs were subdived into 5 main functions that then were organized based on relation to the Heritage Tree, Orientation to Site, and the Entrance.

Gallary Sequence

Embracing the connection created and Kimble Art Mueseums, the sequence then follows the inspired then end at the tree.

Providing Structure + Envelope

From Structure to Cladding, wood is the primary material to provide a sustainable footprint and pay homage to the beautiful versatility of wood as a building material.

8

ENTRANCE Pre-Human Industrial

SERINITY

EDUCATION

ENTRANCE ADMINISTRATION SERVICE

+ 1 2 4 5

created through the MOMA the entrace and gallary inspired fibbonichi sequence to

Extending Wings

Functions now can expland from each wing creating a museum that fully utilizes the site and connects users outside of the museum to each various function.

Develop Order Through Nature

Utilizing nature’s spiraling and expanding displayed through fractals, trapezoidal modules were developed based on needed function. Flowing towards the Hertiage Tree each module encourages users to appreciate and congregate around the tree.

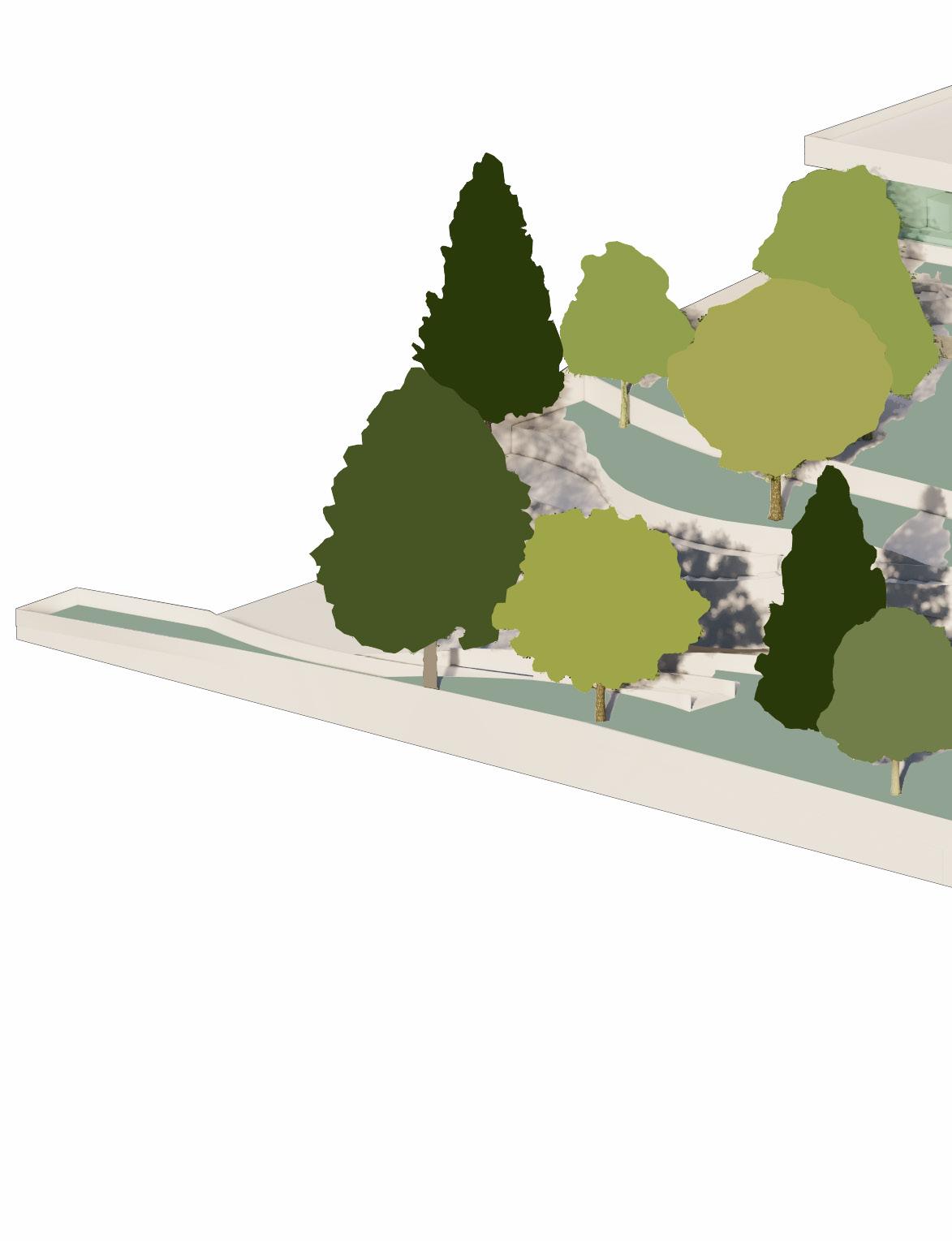

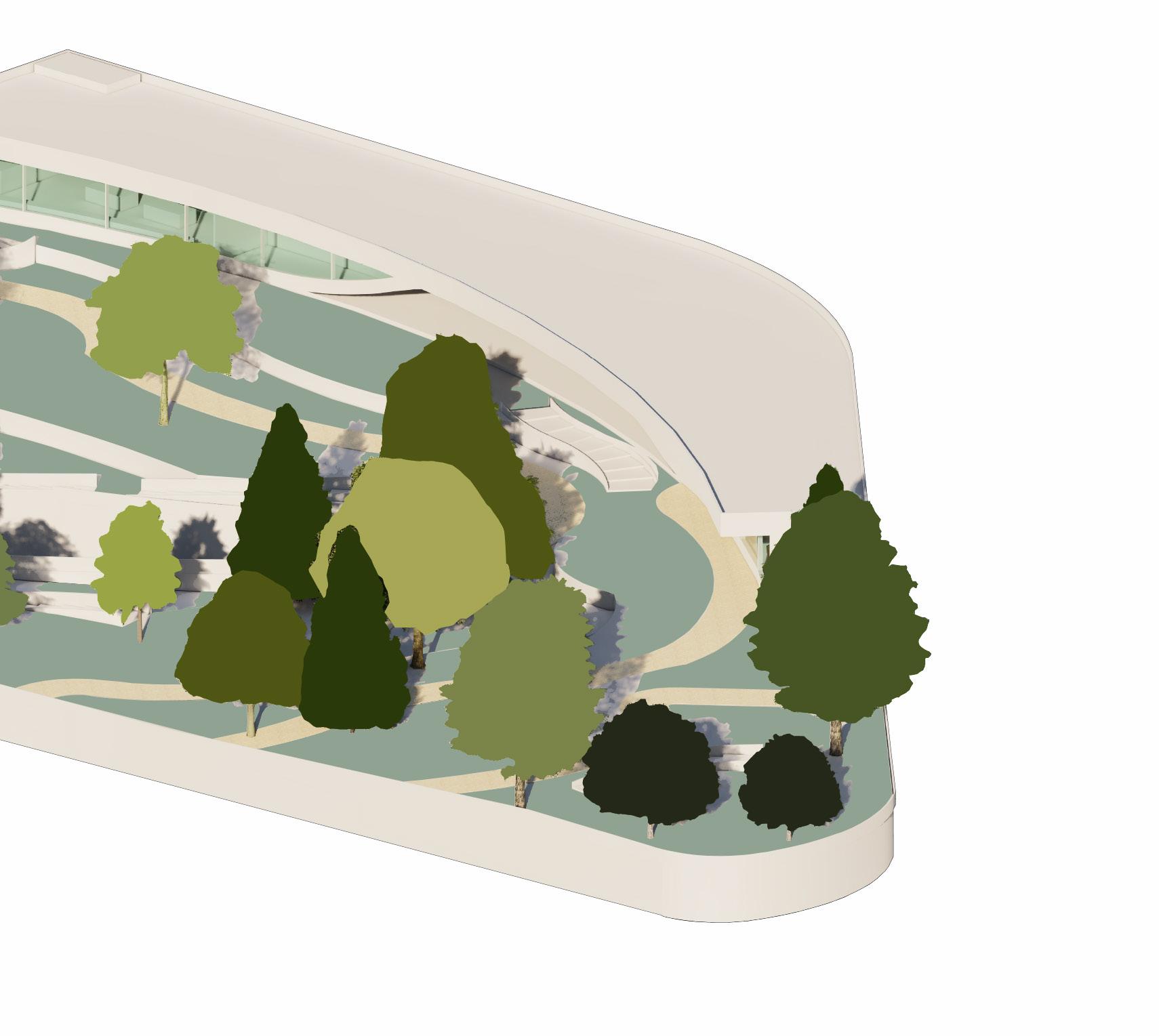

Nature Takes Over

Extensive landscaping then takes over the site to allow for nature to work and collaborate with the meseum. Thus embracing and celebrating what first inspired the design - nature.

9

ENTRANCE Industrial Revoluation Solutions

+

AND SERVICE

PATH

PARKING

ENTRANCE

REFLECTION POOL GREENHOUSES

3 6 7

10 W Lancaster Ave Darnell Street Van Cilburn Way 1 2 8 8 5 9 10 10 10 11 Ground Level 1 Lobby 2 Gift Shop 3 Restaurant 4 Water Gorage Gallery 5 Hertiage Tree Ramp 6 Admin Offices 7 Admin Confrence Rooms 8 Bathrooms 9 Kitchen 10 Storage 11 Service N

11 Ave

8 3 4 7 6

University Drive

12 1 2 2 2 2 2 2 3 4 4 5 6 4 7 7 7 7 4 8 1 Prehuman Gallery 2 Industrial Man Galleries 3 Water Gorge Gallery 4 Museum Storage 5 Service 6 Security 7 Mechichal 8 Bathrooms 9 Kitchen Basement Level

13 4 4 5 3 2 1 6 VOID TO BELOW VOID TO BELOW VOID TO BELOW 1 Solutions Gallery 2 Education Rooms 3 Research 4 Overlook Balcony 5 Hertiage Tree Ramp 6 Bathroom Second Level

14

Northwest Aerial view of Museum

Medium: Ink Pen and Photoshop

Aerial View encompassing how the museum fully utilizing the site and idea behind the fractal

Street View of Entrance Medium: Ink Pen and Photoshop

Water guides users to the entrance of the Museum , paved paths are utilized to signify movement and shape. Extensive Planting can be viewed.

16

Lobby Area Medium: Ink Pen and Photoshop

Water continues with the heavy incorporation of wood and more interior planting.

18 A D E C B Ground Level 0’0” Basement -15’ 0” Second Level 20’0” Roof 1/4”= 1’ 0” 50’ 0” A B C D

19 1 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 25 26 27 28 29 30 31 32 1.87” ACCOYA Shou Sugi Ban Vertical Cladding 2 Stainless Steel Ring Shank 33/4” Horizontal Wood Battens Ventilated Cavity 4 3/4” Vertical Wood Battens 5 Moisture Barrier 6 2 1/2” Rigid Insulation Vapor Barrier 7 8 1 1/4” Exterior Shealthing 9 2” Wood Studs 10 Loose-Fill Insulation 11 1/2” Interior Shealthing 12 Stainless Steel Wood Nails Stainless Steel Wood Nails 13 LUNA TGV BRUSHED Wood Flooring Boards 14 Steel Base Plate Connection 15 1 1/2” Steel Bolts 1 1/2” Steel Bolts 16 Glue Laminated Timber Column 17 External Flashing 18 Galvanized Steel Flashing 19 Moisture Barrier 20 2 1/2” Rigid Insulation 21 Vapor Barrier 1/2” Expansion Joint 22 Steel Hanger Plate Connection 23 Glue Laminated Timber Beam 24 25 Concrete Retaining Wall 26 1/2”= 1’ 0” Smooth Concrete Finish LUNA TGV BRUSHED Wood Flooring Boards 1/2” Interior Shealthing 7-Ply Cross Laminated Timber 27 28 29 30 31 32 1 5 6 7 8 9 10 11 12 13 16 17 18 19 20 21 22 23 24 25 26 27 30 31 32 1.87” ACCOYA Shou Sugi Ban Vertical Cladding 2 Stainless Steel Ring Shank 33/4” Horizontal Wood Battens Ventilated Cavity 4 3/4” Vertical Wood Battens 5 Moisture Barrier 6 2 1/2” Rigid Insulation Vapor Barrier 8 1 1/4” Exterior Shealthing 9 2” Wood Studs 10 Loose-Fill Insulation 11 1/2” Interior Shealthing 12 Stainless Steel Wood Nails Stainless Steel Wood Nails 13 LUNA TGV BRUSHED Wood Flooring Boards 14 Steel Base Plate Connection 1 1/2” Steel Bolts 1 1/2” Steel Bolts 16 Glue Laminated Timber Column 17 External Flashing 18 Galvanized Steel Flashing 19 Moisture Barrier 20 2 1/2” Rigid Insulation 21 Vapor Barrier 1/2” Expansion Joint 22 Steel Hanger Plate Connection 23 Glue Laminated Timber Beam 24 25 Concrete Retaining Wall 26 1/2”= 1’ 0” Smooth Concrete Finish LUNA TGV BRUSHED Wood Flooring Boards 1/2” Interior Shealthing 7-Ply Cross Laminated Timber 27 28 30 31 32 1 2 3 4 5 7 8 9 10 11 12 13 14 15 1Gravel Fill Gravel Fill 2Water Proof Membrane 32 1/2” Rigid Insulation Vapor Barrier 4 2’ Concrete Retaining Wall 5 6 LUNA TGV BRUSHED Wood Flooring Boards 1/2” Interior Shealthing 7 8 5” Concrete Floor Slab 9 10 Moisture Barrier 11 Vapor Barrier 12 2 1/2” Rigid Insulation 13 14 Membrane Flashing 15 4” Perforated Drain Pipe 1/2”= 1’ 0” Stainless Steel Wood Nails 1 2 3 4 5 7 6 8 9 10 11 12 13 14 15 1Gravel Fill Gravel Fill 2Water Proof Membrane 32 1/2” Rigid Insulation Vapor Barrier 4 2’ Concrete Retaining Wall 5 6 LUNA TGV BRUSHED Wood Flooring Boards 1/2” Interior Shealthing 7 8 5” Concrete Floor Slab 9 10 Moisture Barrier 11 Vapor Barrier 12 2 1/2” Rigid Insulation 13 14 Membrane Flashing 15 4” Perforated Drain Pipe 1/2”= 1’ 0” Stainless Steel Wood Nails 1 2 3 4 5 7 8 9 10 11 12 13 14 15 1Gravel Fill Gravel Fill 2Water Proof Membrane 32 1/2” Rigid Insulation Vapor Barrier 4 2’ Concrete Retaining Wall 5 6 LUNA TGV BRUSHED Wood Flooring Boards 1/2” Interior Shealthing 7 8 5” Concrete Floor Slab 9 10 Moisture Barrier 11 Vapor Barrier 12 2 1/2” Rigid Insulation 13 14 Membrane Flashing 15 4” Perforated Drain Pipe 1/2”= 1’ 0” Stainless Steel Wood Nails 2.5’ Rammed Earth 2 1 2’ Concrete Retaining Wall 36” Rammed Earth Steel Hanger Plate Connection Glue Laminated Timber Column DOWNSPOUT FDS34-14.4 Q-Railing Top Mount F 6962 EASY GLASS PRIME Railing 8 10 LUNA TGV BRUSHED Wood Flooring Boards 11 Stainless Steel Wood Nails 12 1/2” Exterior Shealthing 13 5-Ply Cross Laminated Timber 14 Steel Hanger Plate Connection 15 16 Glue Laminated Timber Beam ELBOW FDE341 18 17 1 1/2” Steel Bolts 19 20 1’ Concrete Ramp Footing Gravel Fill 25 4” Perforated Drain Pipe 26 1/2”= 1’ 0” Vapor Barrier 1/2” Rigid Insulation Water Proofing Membrane 2 4 5 6 7 12 13 14 17 19 21 20 26 27 2.5’ Rammed Earth 2 1 2’ Concrete Retaining Wall 36” Rammed Earth 1/2” Steel Bolts 4 Steel Hanger Plate Connection 5 Glue Laminated Timber Beam Glue Laminated Timber Column DOWNSPOUT FDS34-14.4 Q-Railing Top Mount F 6962 EASY GLASS PRIME Railing 8 10 LUNA TGV BRUSHED Wood Flooring Boards 11 Stainless Steel Wood Nails 12 1/2” Exterior Shealthing 13 5-Ply Cross Laminated Timber 14 Steel Hanger Plate Connection Steel Base Plate Connection 15 16 Glue Laminated Timber Beam Glue Laminated Timber Beam ELBOW FDE341 18 17 1 1/2” Steel Bolts 19 20 21 22 1’ Concrete Ramp Footing 23 24 Gravel Fill 25 4” Perforated Drain Pipe 26 6” Concrete Enclosure 27 1/2”= 1’ 0” Vapor Barrier 2 1/2” Rigid Insulation Water Proofing Membrane 1 2 3 4 7 8 9 10 11 13 14 15 16 17 18 19 21 20 22 23 24 25 26 27 2.5’ Rammed Earth 2 1 2’ Concrete Retaining Wall 36” Rammed Earth 1 1/2” Steel Bolts 4 Steel Hanger Plate Connection 5 Glue Laminated Timber Beam Glue Laminated Timber Column DOWNSPOUT FDS34-14.4 6 Q-Railing Top Mount F 6962 EASY GLASS PRIME Railing 7 8 10 LUNA TGV BRUSHED Wood Flooring Boards 11 Stainless Steel Wood Nails 12 1/2” Exterior Shealthing 13 5-Ply Cross Laminated Timber 14 Steel Hanger Plate Connection Steel Base Plate Connection 15 16 Glue Laminated Timber Beam Glue Laminated Timber Beam ELBOW FDE341 18 17 1 1/2” Steel Bolts 19 20 21 22 1’ Concrete Ramp Footing 23 24 Gravel Fill 25 4” Perforated Drain Pipe 26 6” Concrete Enclosure 27 1/2”= 1’ 0” Vapor Barrier 2 1/2” Rigid Insulation Water Proofing Membrane 1 2 3 4 5 6 7 8 9 10 11 13 14 15 16 17 18 19 21 20 22 23 24 25 26 27 3” Steel Tube 2 LUNA TGV BRUSHED Wood Flooring Boards 5 1/2” Interior Shealthing 7-Ply Cross Laminated Timber 1/2” Thermal Gap 1/2” Steel Plate 1/2” Steel Plate 3” Horizontal Tube Laminated Glass 13 WOODS GLASS Way Glass Fin Spider Assembly 2” Wood Beam Frame 15 17 19 22 24 1/2” Steel Clip 1/2”= 1’ 0” 2 9 12 16 17 18 22 Steel Hanger Plate Connection 1 3” Steel Tube 3” Steel Tube 2 3 WOODS GLASS Fin Spider Bracket 4 LUNA TGV BRUSHED Wood Flooring Boards 5 Stainless Steel Wood Nails 6 1/2” Interior Shealthing 7-Ply Cross Laminated Timber 7 8 1/2” Thermal Gap 9 1/2” Steel Plate 1/2” Steel Plate 1/2” Steel Plate 10 3” Horizontal Tube 11 12 Laminated Glass Laminated Glass 13 WOODS GLASS 4 Way Glass Fin Spider Assembly 2” Wood Beam Frame 14 3/4” Steel Tube Connector 3/4” Steel Tube Connector 15 16 17 18 19 20 21 Glue Laminated Timber Beam 22 23 Glue Laminated Timber Column 24 2.5’ Rammed Earth 1/2” Steel Clip 1/2”= 1’ 0” 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Steel Hanger Plate Connection 1/2” Steel Bolts 1Glue Laminated Timber Beam 21/2” Exterior Shealthing 3 4 3” Wood Batting 1/2” Exterior Shealthing 5 3/4” Horizontal Wood Battens 3/4” Horizontal Wood Battens .87” ACCOYA Shou Sugi Ban Cladding Stainless Steel Ring Shank Glue Laminated Timber Beam Glue Laminated Timber Column 10 76¢, 112½0 OFFSETS PIPE 5OxNo.16 PIPE FIXING 13 14 1/2” Exterior Shealthing 15 House Wrap 16 2 1/2” Rigid Insulation 17 Vapor Barrier 1/2” Exterior Shealthing Loose-Fill Insulation 20 2” Wood U Channels Stainless Steel Ring Shank 23 Rubber Matt With Steel Ring Shanks 76¢ ALIGATOR OUTLET with Steel Fascia Bracket 24 .87” ACCOYA Shou Sugi Ban Cladding 25 1/2 Steel Plate Connection System 26 29 LUNA TGV BRUSHED Wood Flooring Boards 30 Stainless Steel Wood Nails 31 1/2” Exterior Shealthing Glue Laminated Timber Beam 1/2”= 1’ 0” 3 6 11 12 13 15 16 17 26 27 28 29 30 31 21 20 1Glue Laminated Timber Beam 21/2” Exterior Shealthing 3 4 3” Wood Batting 1/2” Exterior Shealthing 5 3/4” Horizontal Wood Battens 3/4” Horizontal Wood Battens 6 .87” ACCOYA Shou Sugi Ban Cladding Stainless Steel Ring Shank 7 8 Glue Laminated Timber Beam 9 Glue Laminated Timber Column 10 2” Steel Tube 76¢, 112½0 OFFSETS PIPE 11 SC6O3 Connector and SCREWS 12 5OxNo.16 PIPE FIXING 13 14 1/2” Exterior Shealthing 15 House Wrap 16 2 1/2” Rigid Insulation 17 Vapor Barrier 18 1/2” Exterior Shealthing 19 Loose-Fill Insulation 20 2” Wood U Channels 21 Stainless Steel Ring Shank 22 23 Rubber Matt With Steel Ring Shanks 76¢ ALIGATOR OUTLET with Steel Fascia Bracket 24 .87” ACCOYA Shou Sugi Ban Cladding 25 1/2 Steel Plate Connection System 26 5OxNo.16 PIPE FIXING 27 28 29 LUNA TGV BRUSHED Wood Flooring Boards 30 Stainless Steel Wood Nails 31 1/2” Exterior Shealthing Glue Laminated Timber Beam 1/2”= 1’ 0” 1 2 3 4 5 6 7 8 9 10 11 12 13 24 25 26 27 28 29 30 31 1Glue Laminated Timber Beam 21/2” Exterior Shealthing 3 4 3” Wood Batting 1/2” Exterior Shealthing 5 3/4” Horizontal Wood Battens 3/4” Horizontal Wood Battens 6 .87” ACCOYA Shou Sugi Ban Cladding Stainless Steel Ring Shank 7 8 Glue Laminated Timber Beam 9 Glue Laminated Timber Column 10 2” Steel Tube 76¢, 112½0 OFFSETS PIPE 11 SC6O3 Connector and SCREWS 12 5OxNo.16 PIPE FIXING 13 14 1/2” Exterior Shealthing 15 House Wrap 16 2 1/2” Rigid Insulation 17 Vapor Barrier 18 1/2” Exterior Shealthing 19 Loose-Fill Insulation 20 2” Wood U Channels 21 Stainless Steel Ring Shank 22 23 Rubber Matt With Steel Ring Shanks 76¢ ALIGATOR OUTLET with Steel Fascia Bracket 24 .87” ACCOYA Shou Sugi Ban Cladding 25 1/2 Steel Plate Connection System 26 5OxNo.16 PIPE FIXING 27 28 29 LUNA TGV BRUSHED Wood Flooring Boards 30 Stainless Steel Wood Nails 31 1/2” Exterior Shealthing Glue Laminated Timber Beam 1/2”= 1’ 0” 1 2 3 4 5 6 7 8 9 10 11 12 13 Detail

Detail D Detail E

A Detail B Detail C

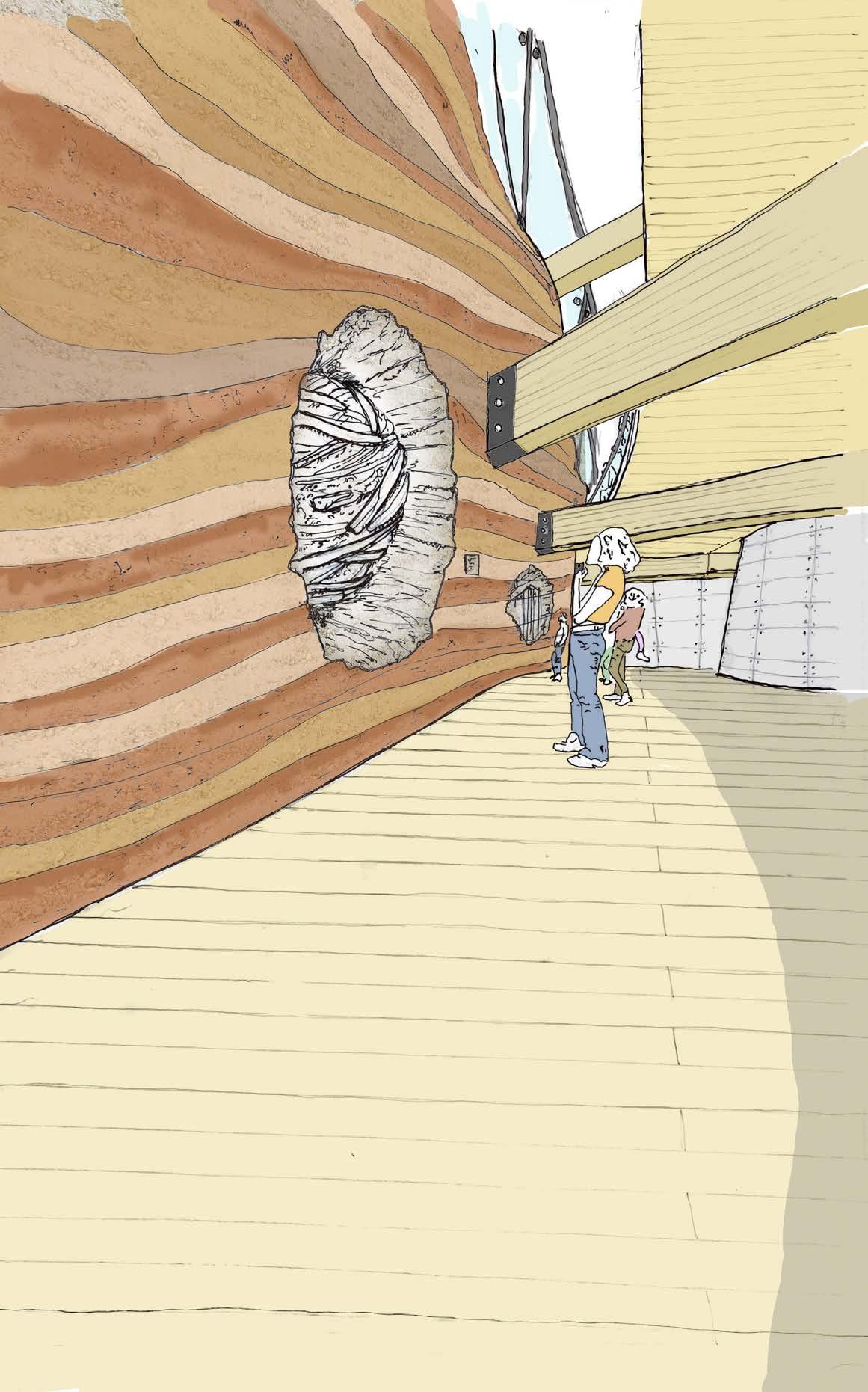

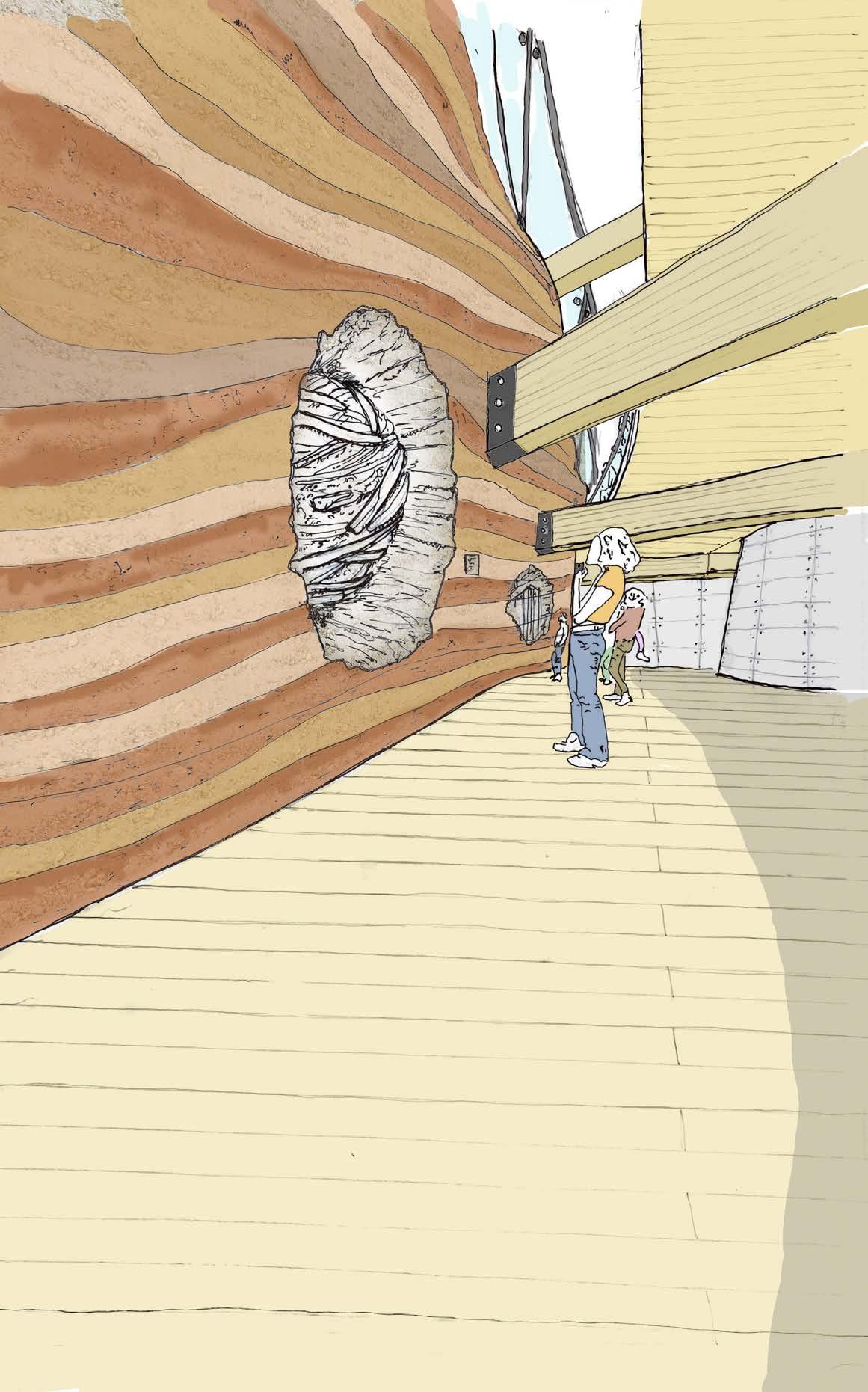

Layers of Impact Rammed Earth Medium: Ink Pen and Photoshop

Rammed Earth and Concrete used in the basement level to pay utilize and teach users of the sustainable materials and how they can be used.

20

Outdoor Courtyard Medium: Ink Pen and Photoshop

Courtyard path guides users to tree . Ramp lies above along with the rammed earth wall that defines the barrier.

21

22 2 0

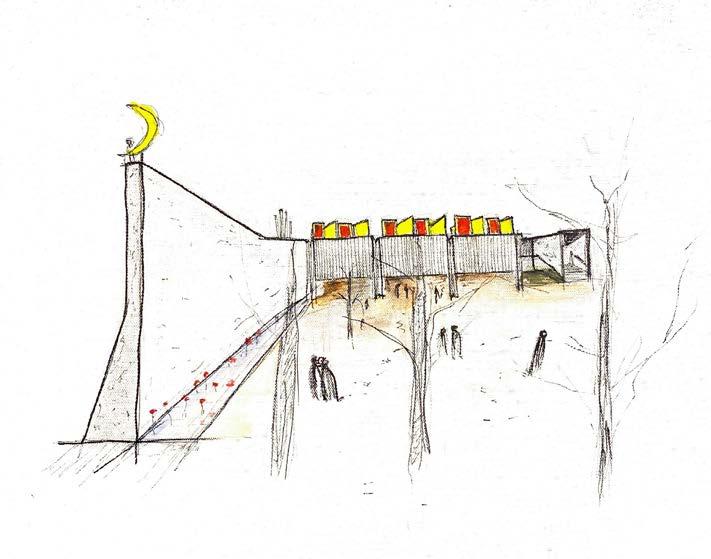

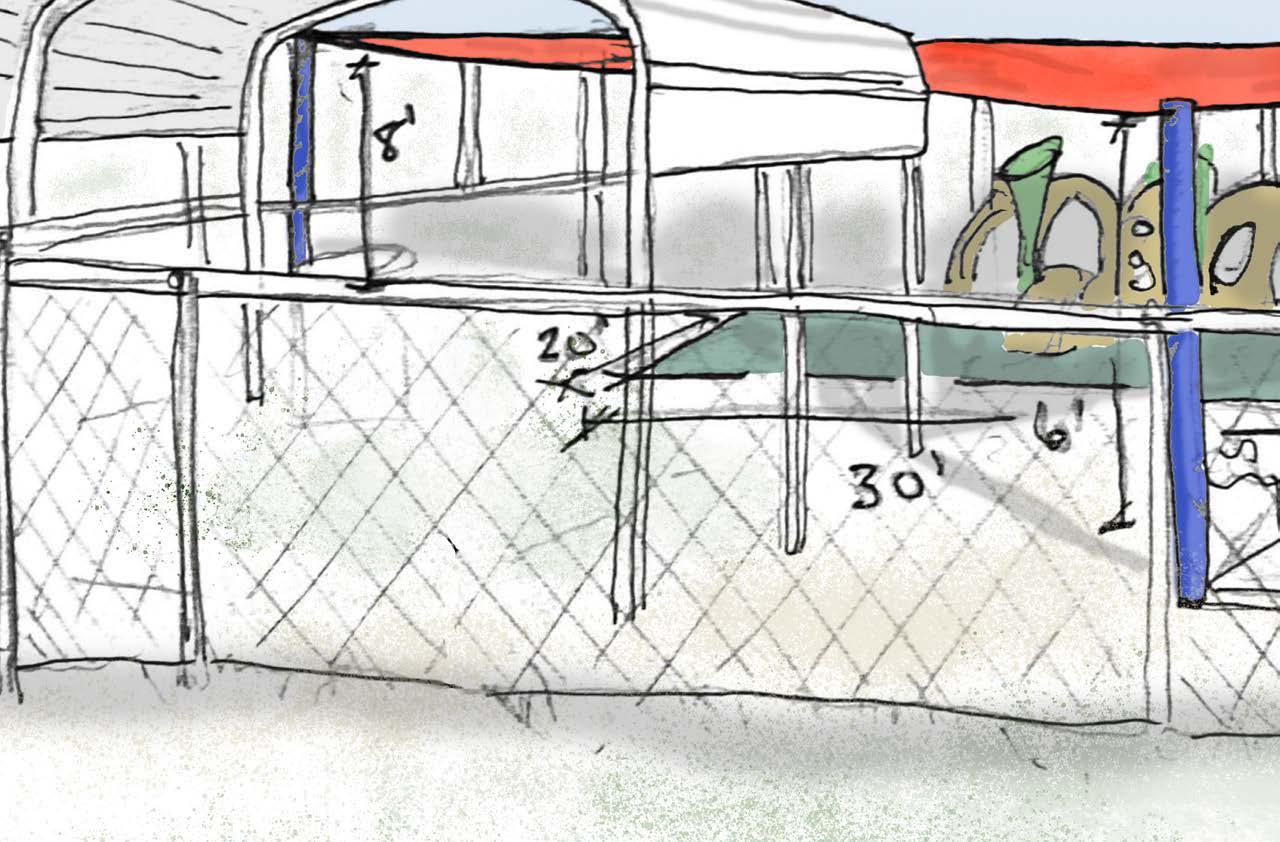

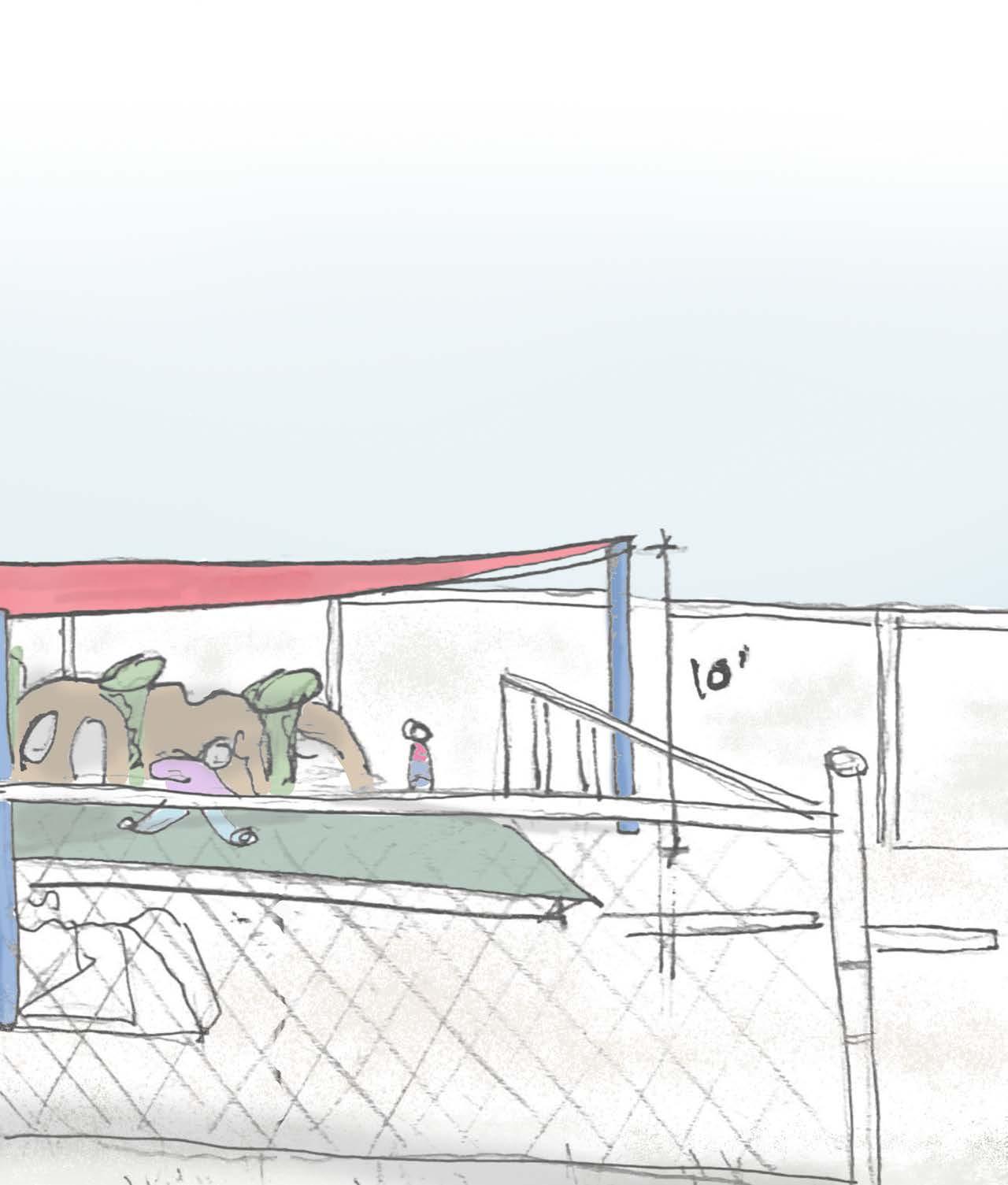

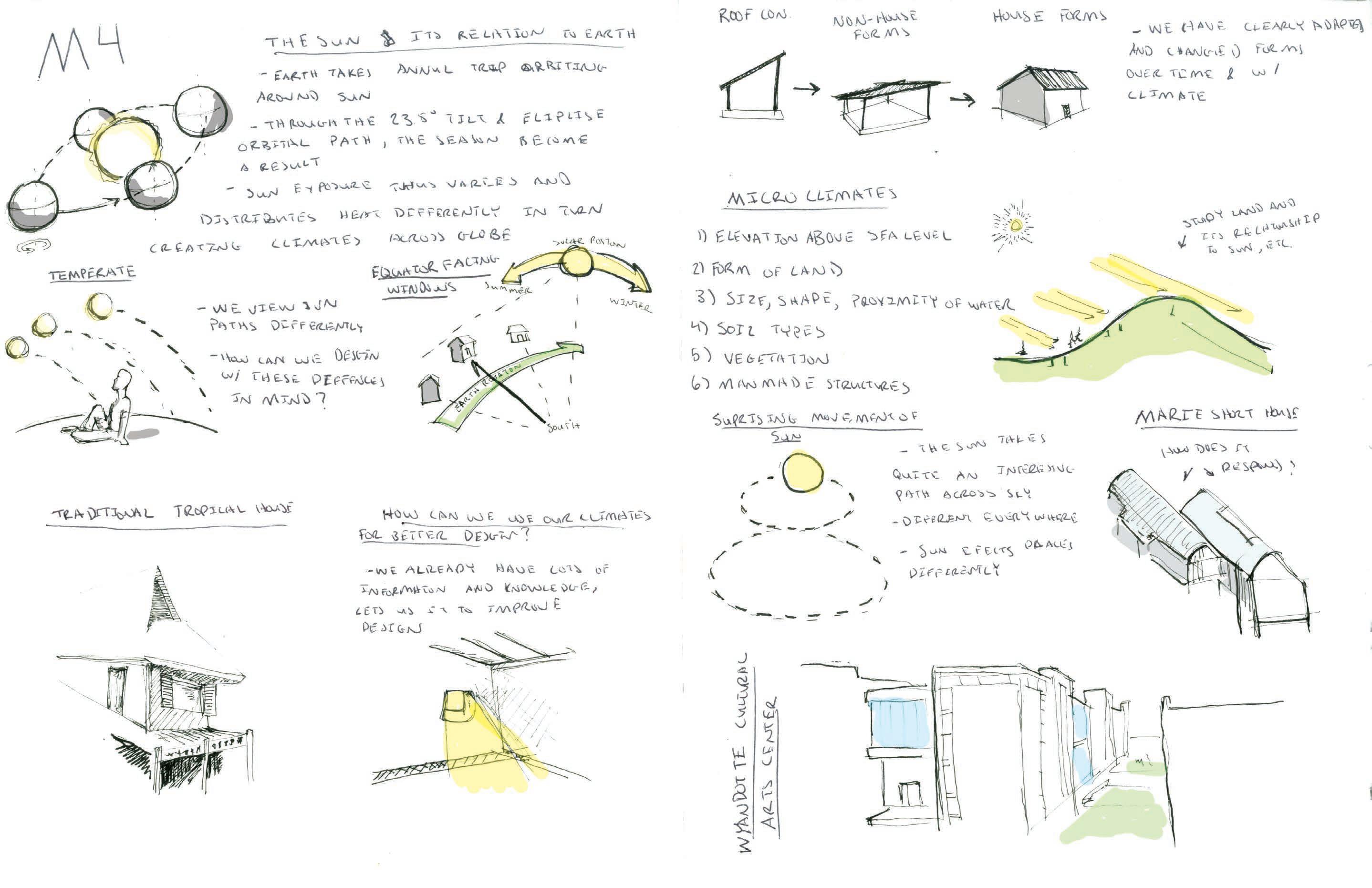

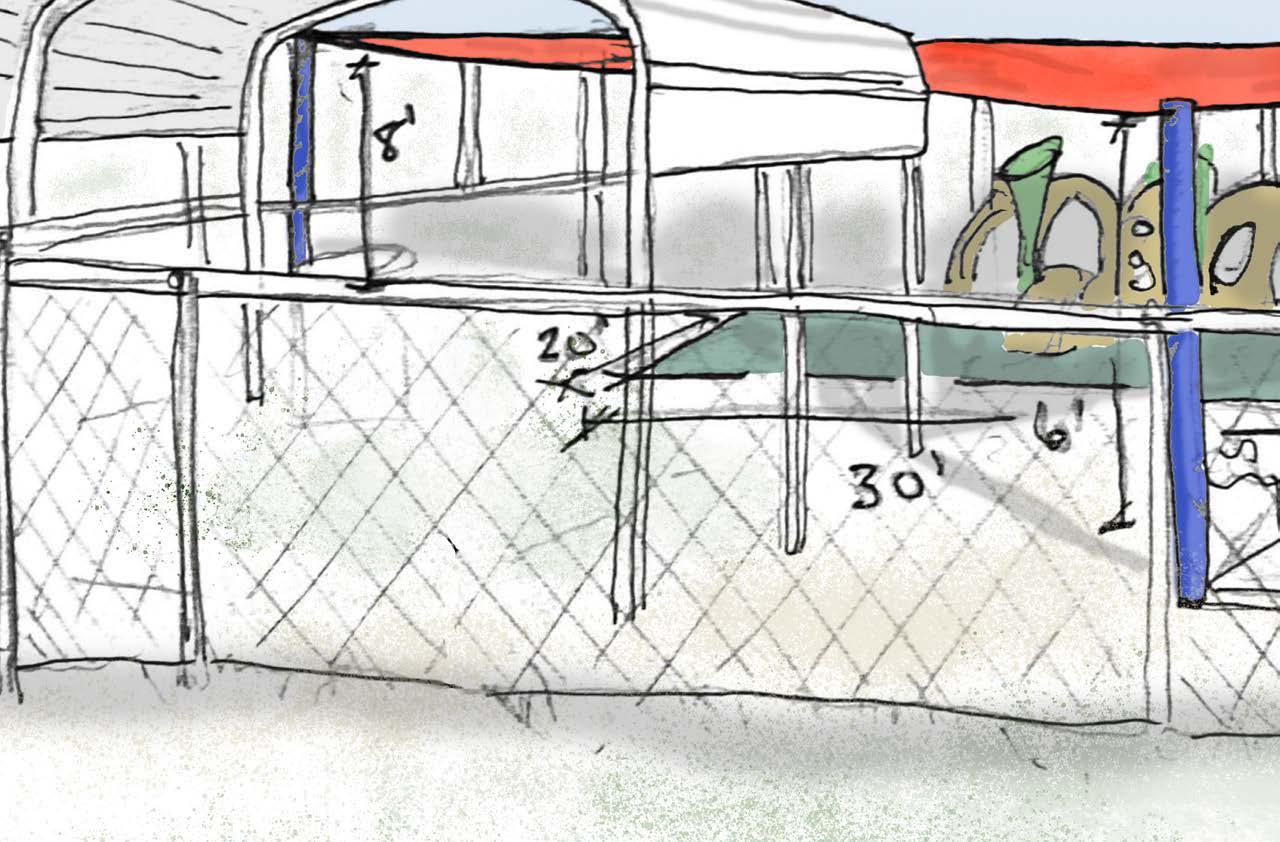

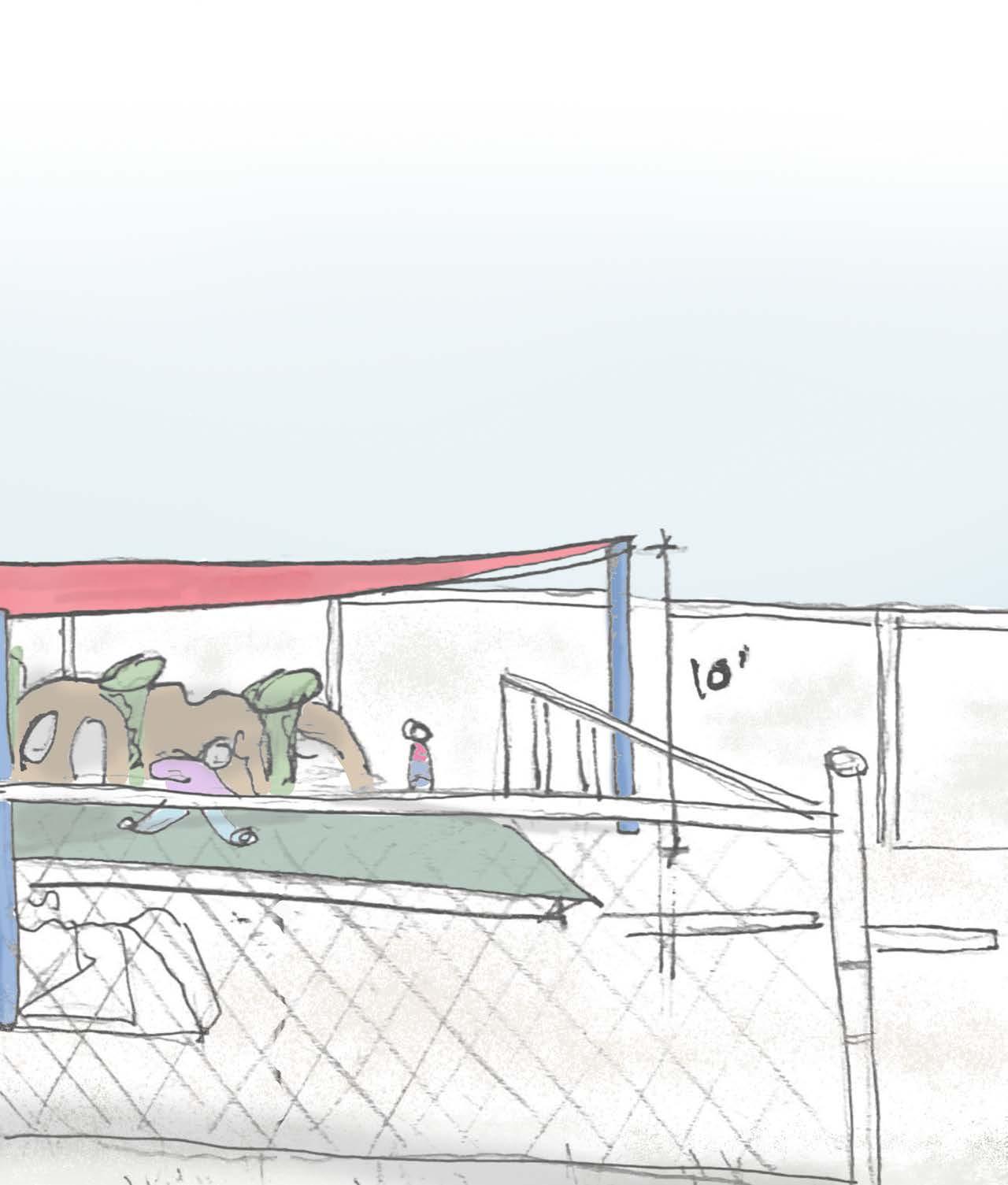

Sketch Drawn at Schematic Meeting

Existing Sunshade Existing Play Equipment Strucutre Proposed Sunshade

Scattered Entrance (Operable Gate)

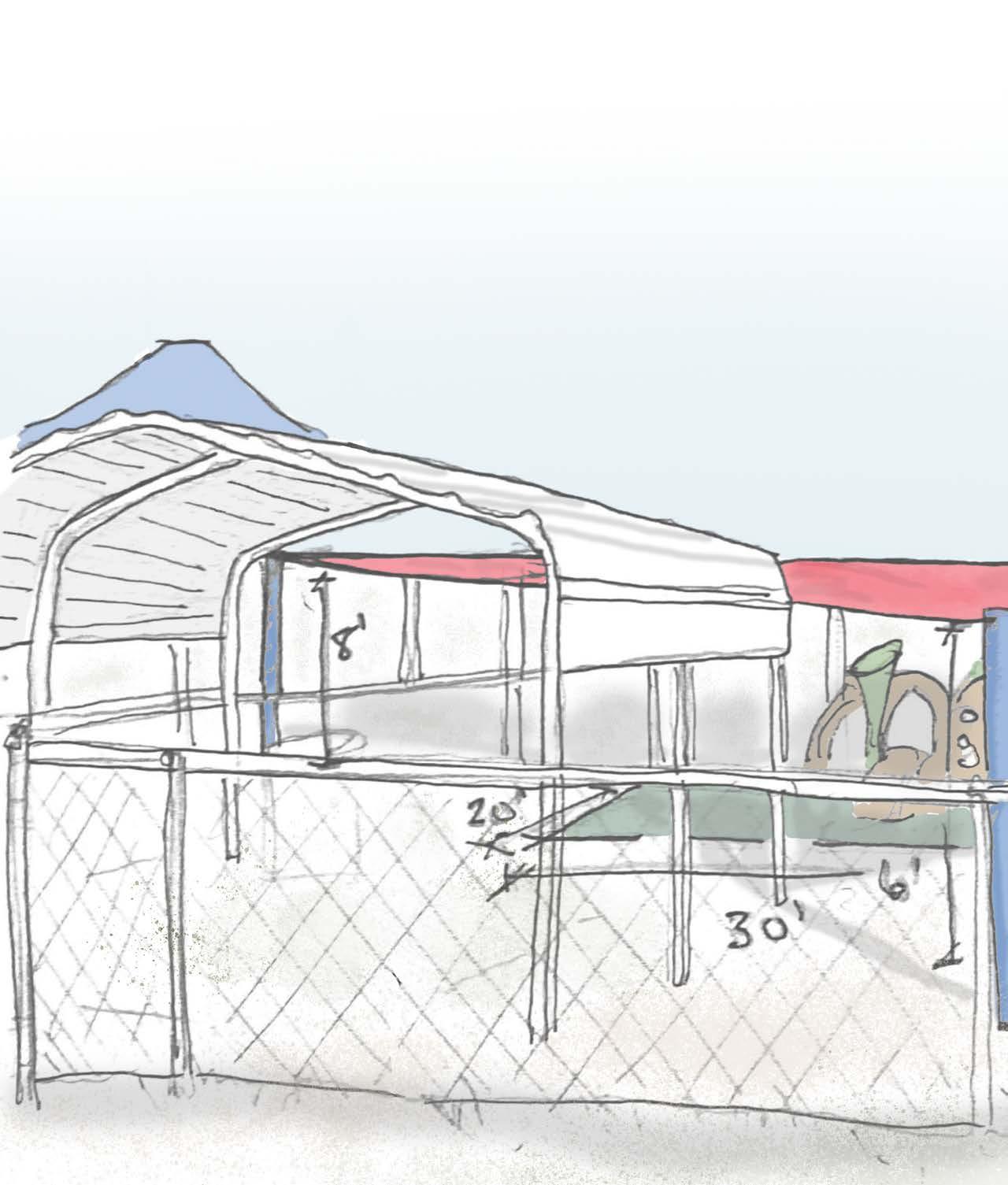

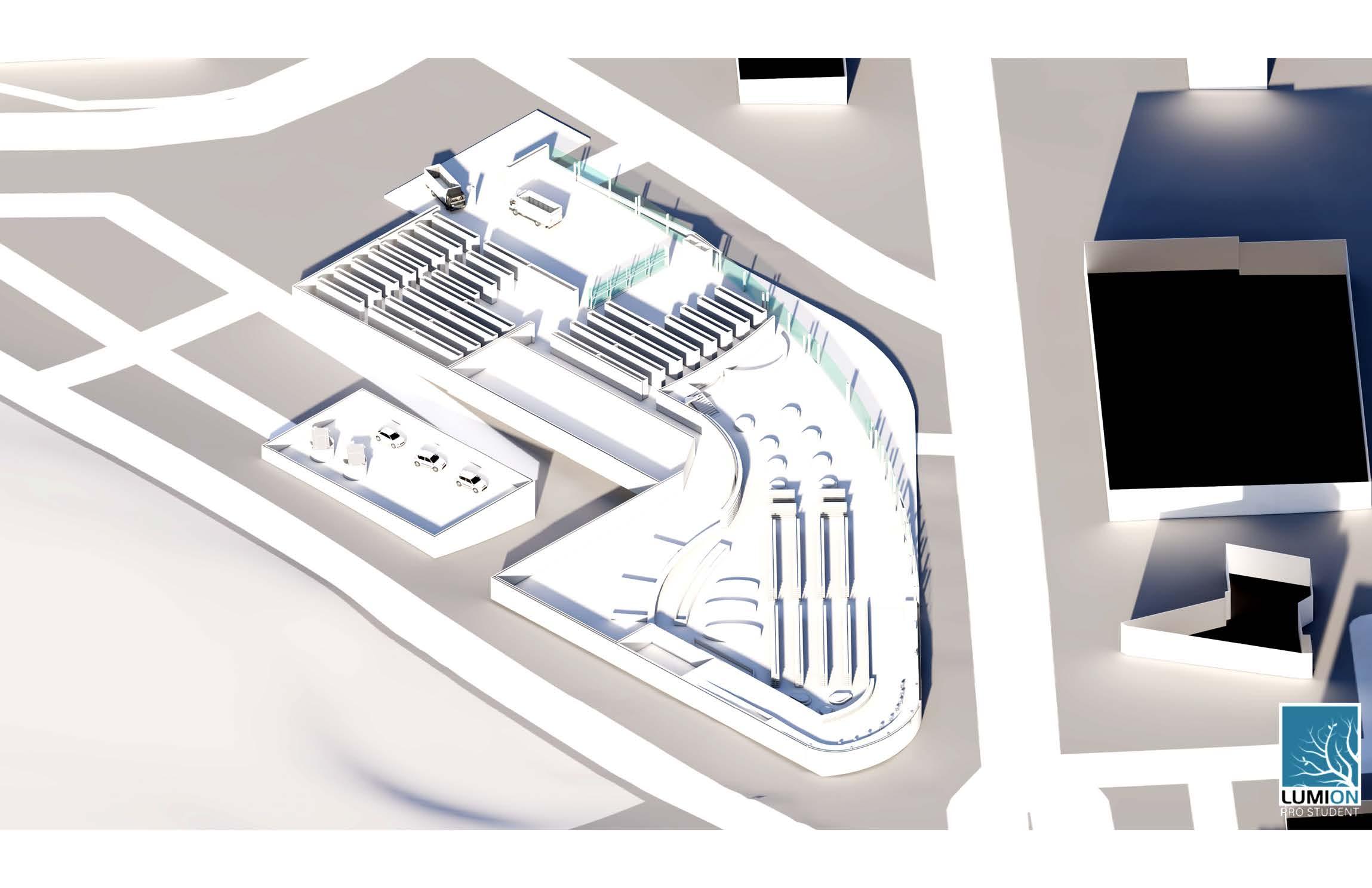

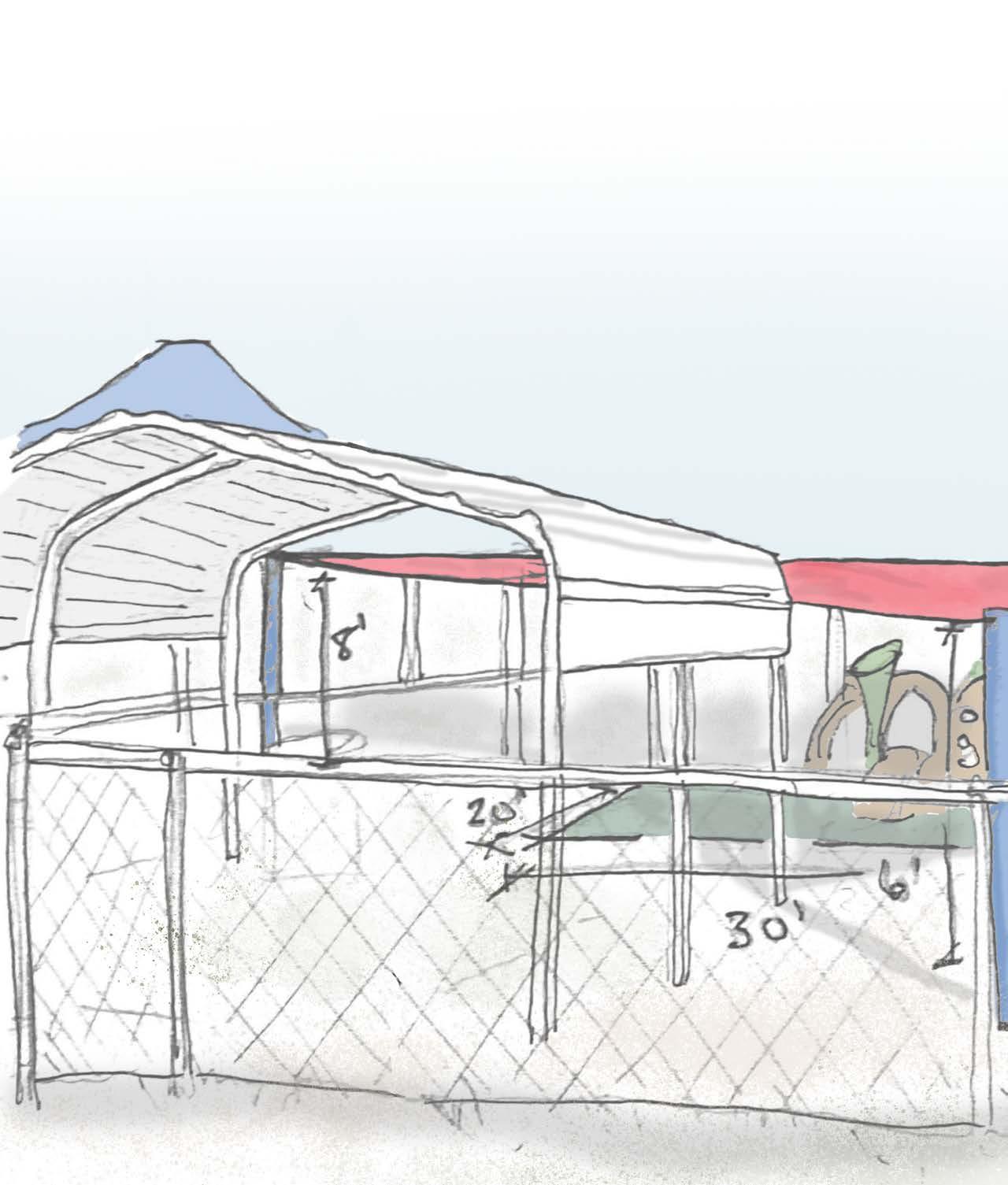

GE Johnson Intern Project

-Denver Tech Center and Colorado Springs Early Connections Learning Center CO Springs

Apart of the GE Johnson Summer Internship program myself and 4 other interns were tasked with designing, procuring, estimating, and constructing a sail sunshade for the Early Connections Center in Colorado Springs, Colorado. Throughout our individual programs and responsibilities, we all were able to successfully provide a shade structure for the learning community of Colorado Springs as well as participate and complete all stages of construction. After completing the internship not only was I able to obtain a depth of knowledge in the construction field as well as the VDC side of construction, but I was also able to be directly apart of a design build project that provides for a community in need.

23

Removable Fence Scattered Equipment Medium: Ink Pen , Markers

Protected Play Equipment

CONCEPT DIAGRAMS

Materials

Simple Design required few materials. Blue Powder Coated Steel Poles with varying heights, Red Canvas, and pole attachments

Placing Poles

Each pole placed then filled with concrete for each hole. Poles leveled and placed by hand.

Site

Playpad with play equipment of pad with chain link fences

Canvas

Canvas was hung by all canvas and placing canvas attachment.

24 DIAGRAMS GRANT FRAIKOR 9/13/2022

1 2 4 5

equipment located in center fences surrounding site.

Canvas

members stretching canvas on each pole attachment.

Pole Holes

4ft deep holes dug using a one-man auger and post hole diggers.

Finshed Form

Sun Shade ready to provide adequate shading for the play equipment throughout the day.

25 University of

School of Architecture

Kansas

3 6

Leveling and Adjusting Shade

Augering Pole Holes

Test hang with clips. Making sure poles and chains with support shade cover.

Using man powered auger to drill 4’ deep holes in order to support wind loads on poles.

26

Using shade to lay out holes for each pole and measuring elements to ensure design.

27

Laying out Plan

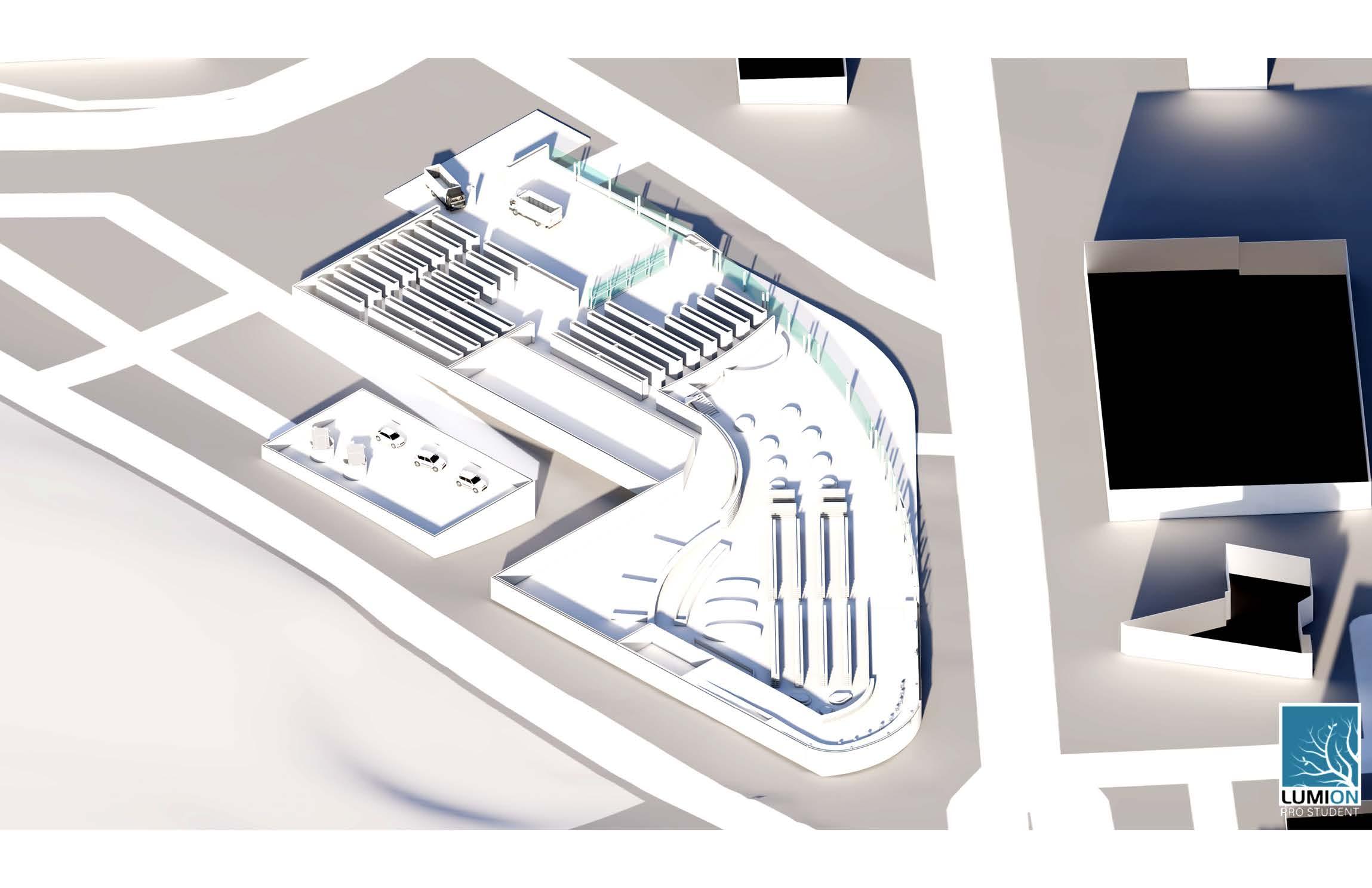

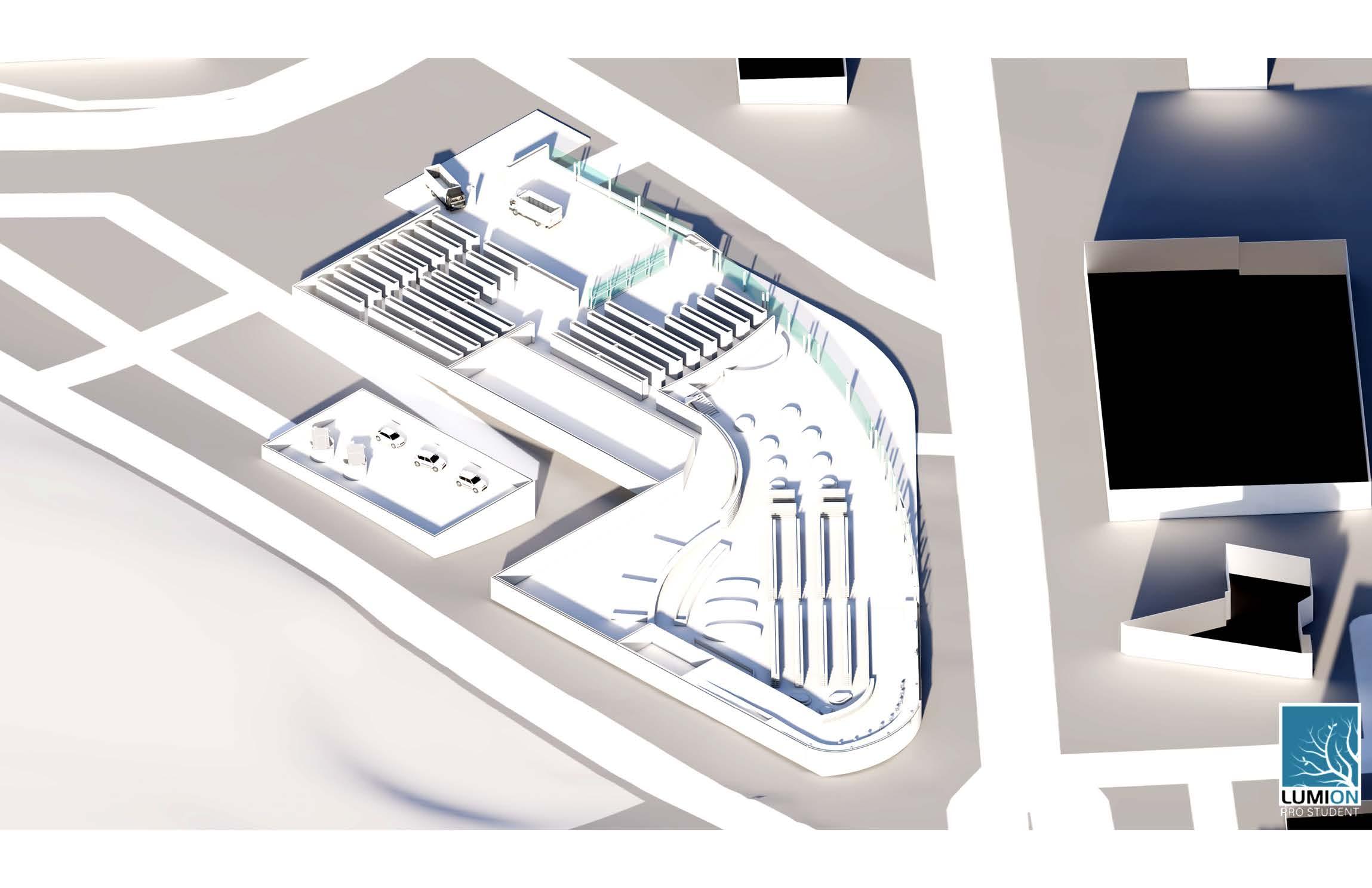

Initial Design Sketch Render Shown

Accounting for various measurements, surrounding context, color scheme, and relation to sun and shading, the intail sketch was done as a first round of design and refrence for the remaider of the project. As shown through the progression the initial design worked quite well throughout the whole process.

A render was done through the mid-point Connections a realistic look at the later. Render was shown to clients of the shade. Client was satisfied with the rest of the playground.

28

1 2

mid-point of the project to provide Early shade that would be built only a month and community effected by construction with look, materiality, and relationship to

Completed Project

Completed in 2 days, the Sunshade for Early Connections now provides sufficient shade through the day for the childern of Colorado Springs. Created for the community of Colorado Springs, GE Johnson helped aid those in need.

29

Shown To Client

3

30 Completed Shade

Finished shade is ready to protect users from CO Springs heat.

31

3 0

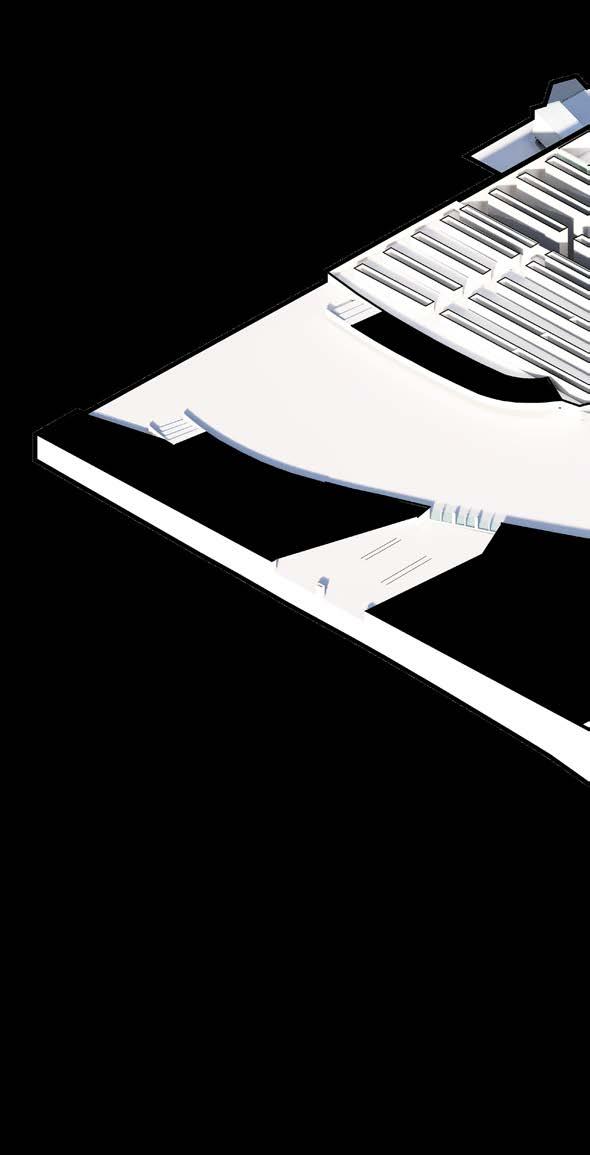

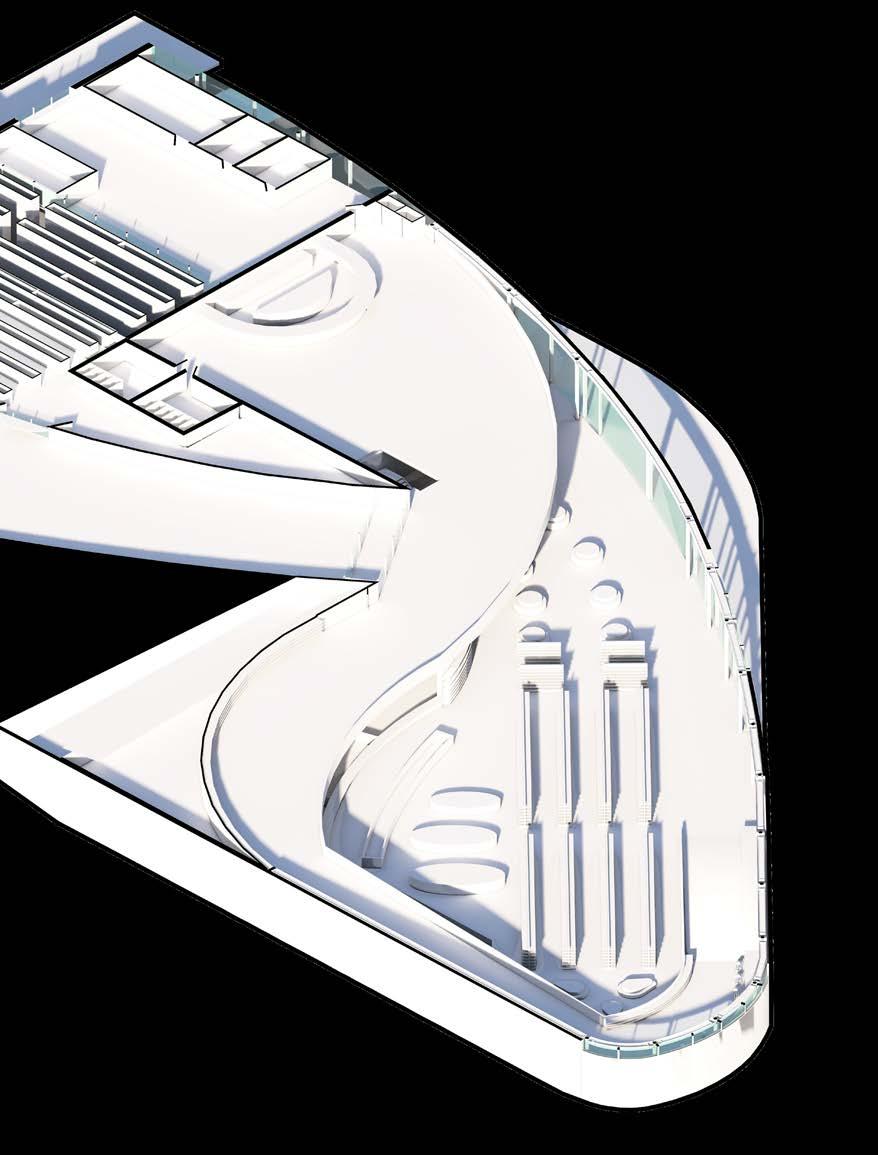

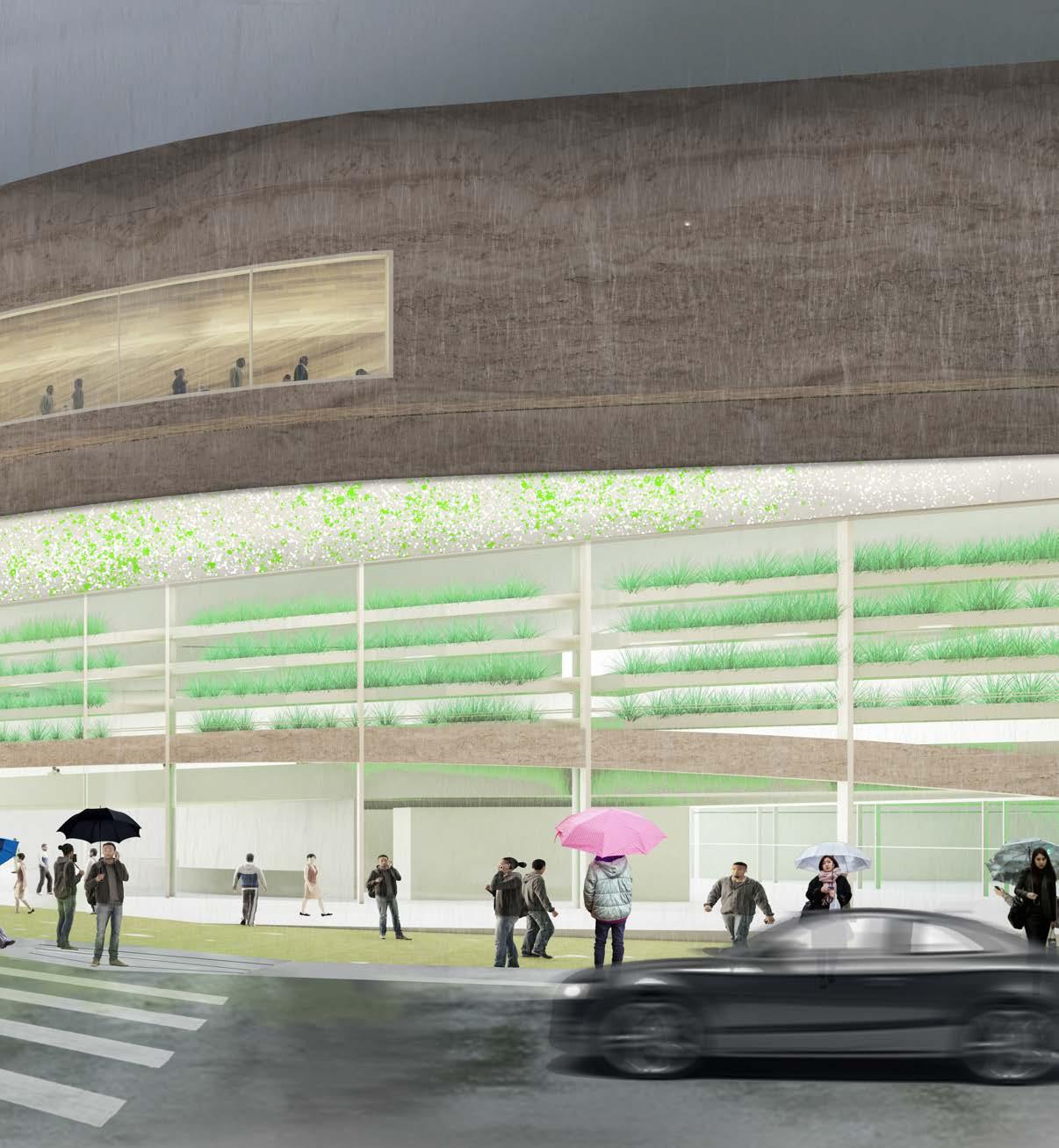

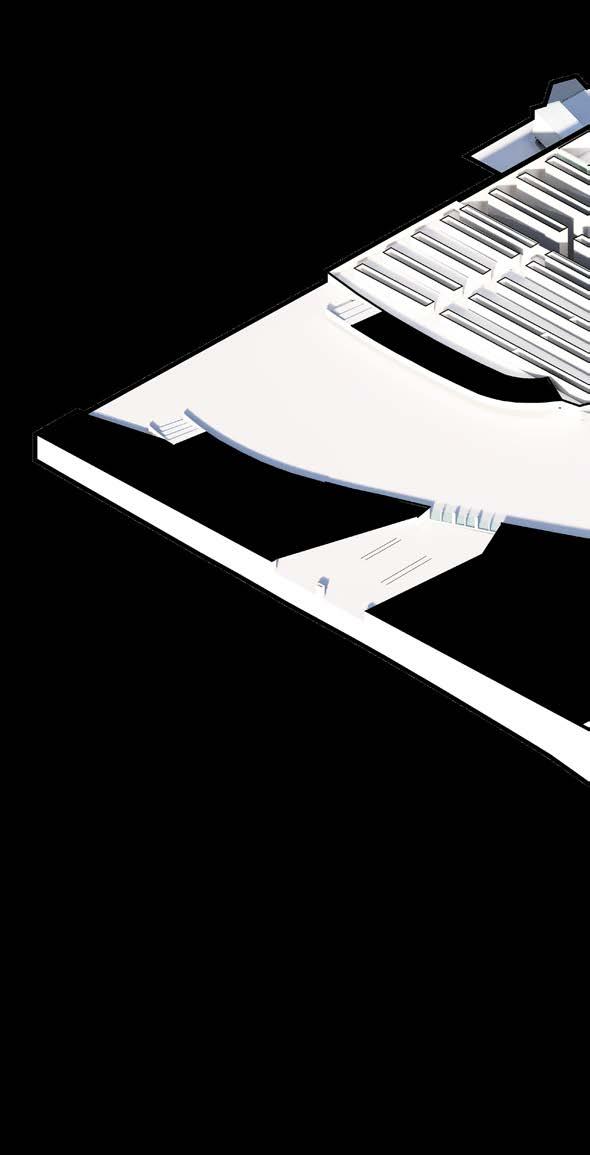

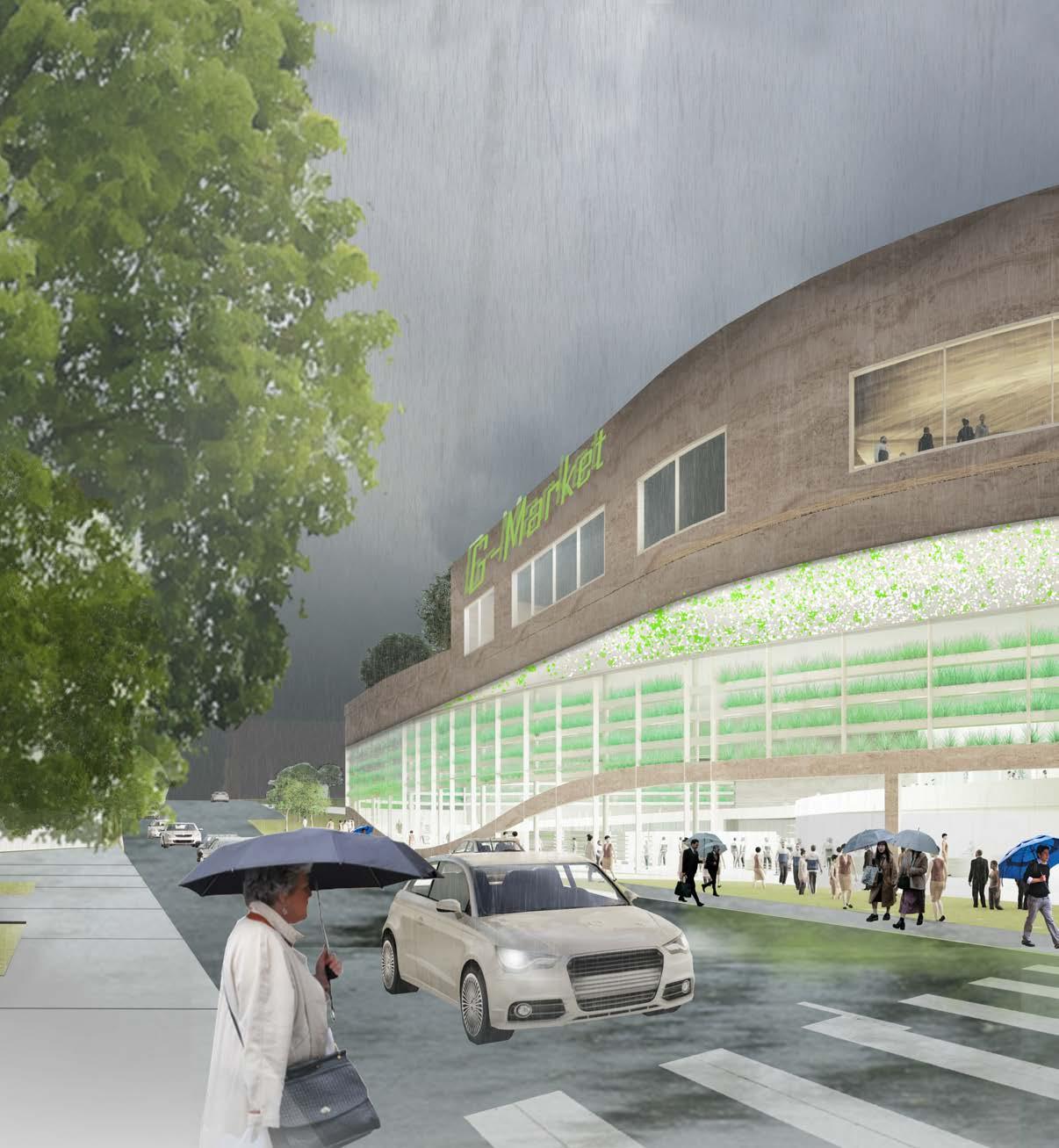

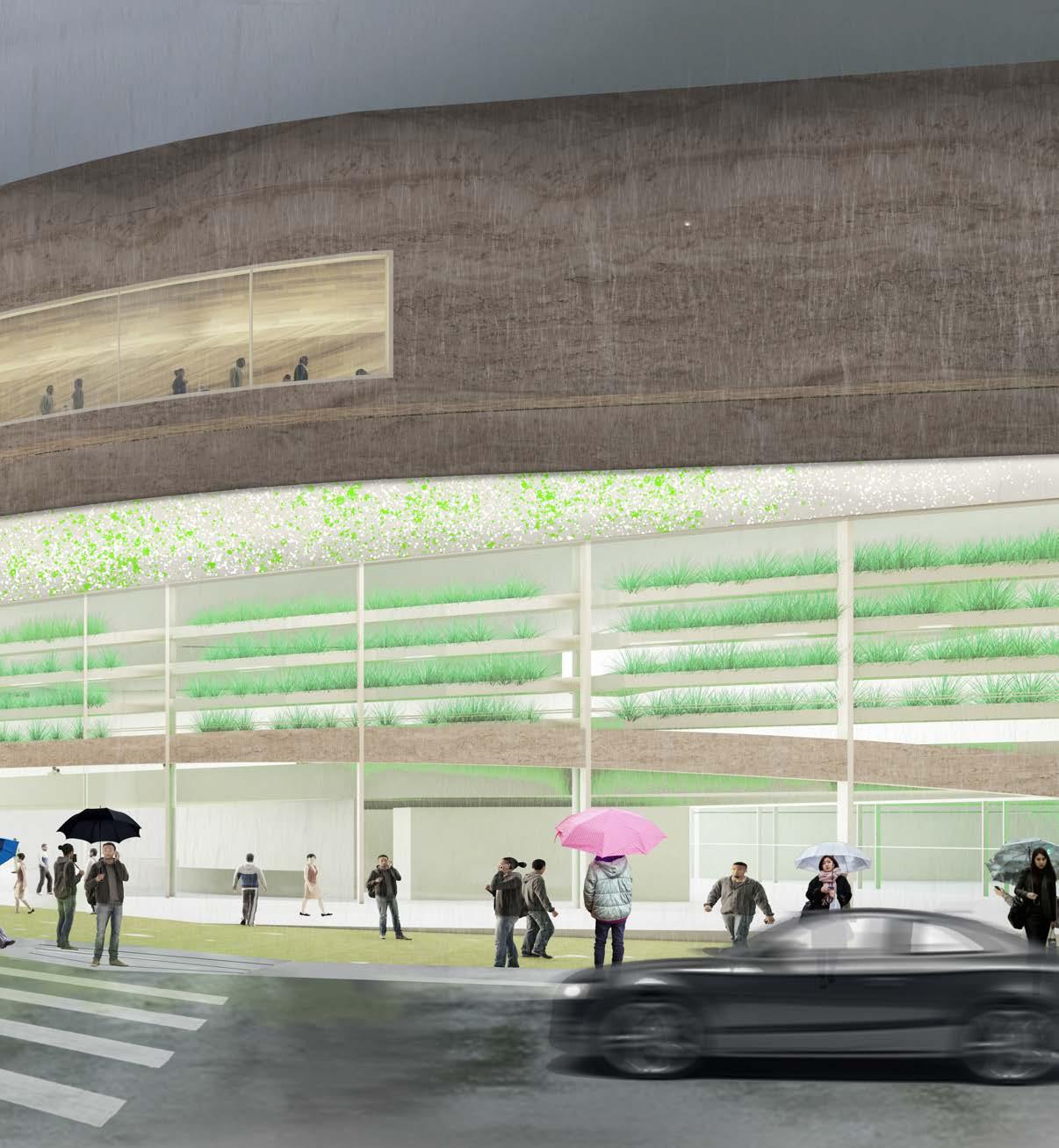

Metcalf Avenue G-Market

-Metcalf Avenue Kansas City, Missouri

Professor: Jae Chang Spring 2021

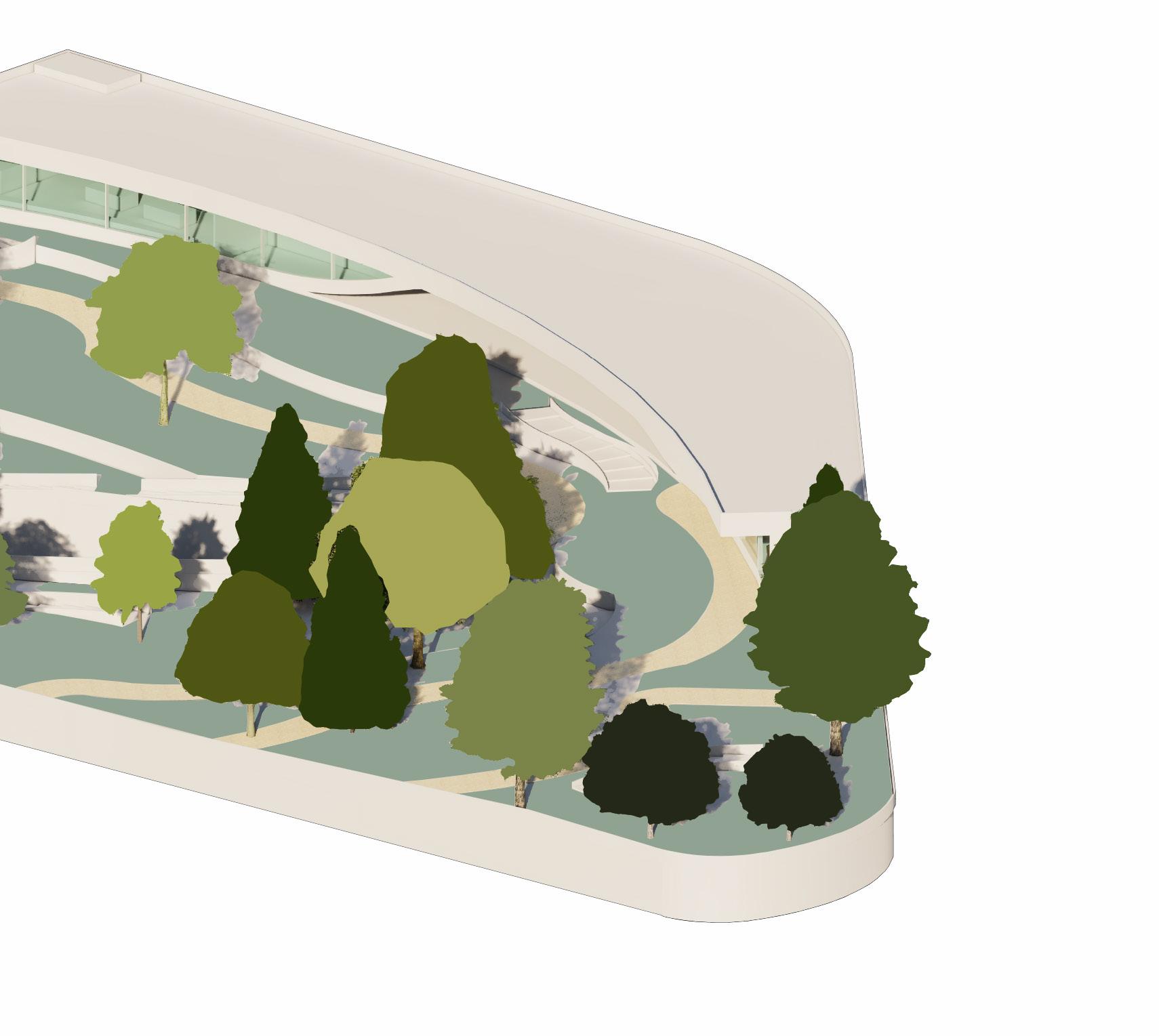

Situated along the unique corner created by Metcalf Ave and Marty Street, the site acts as a key connection between the commercial and residential sides of Metcalf Ave. By utilizing green technology and environmental strategies, the Green Makert creates a grocery store where the community along Metcalf Avenue can shop for groceries, be out with nature, and celebrate in one green grocery store experience.

Green Space Public Parking

Green Space

2 Miles

2 Miles

Public Parking

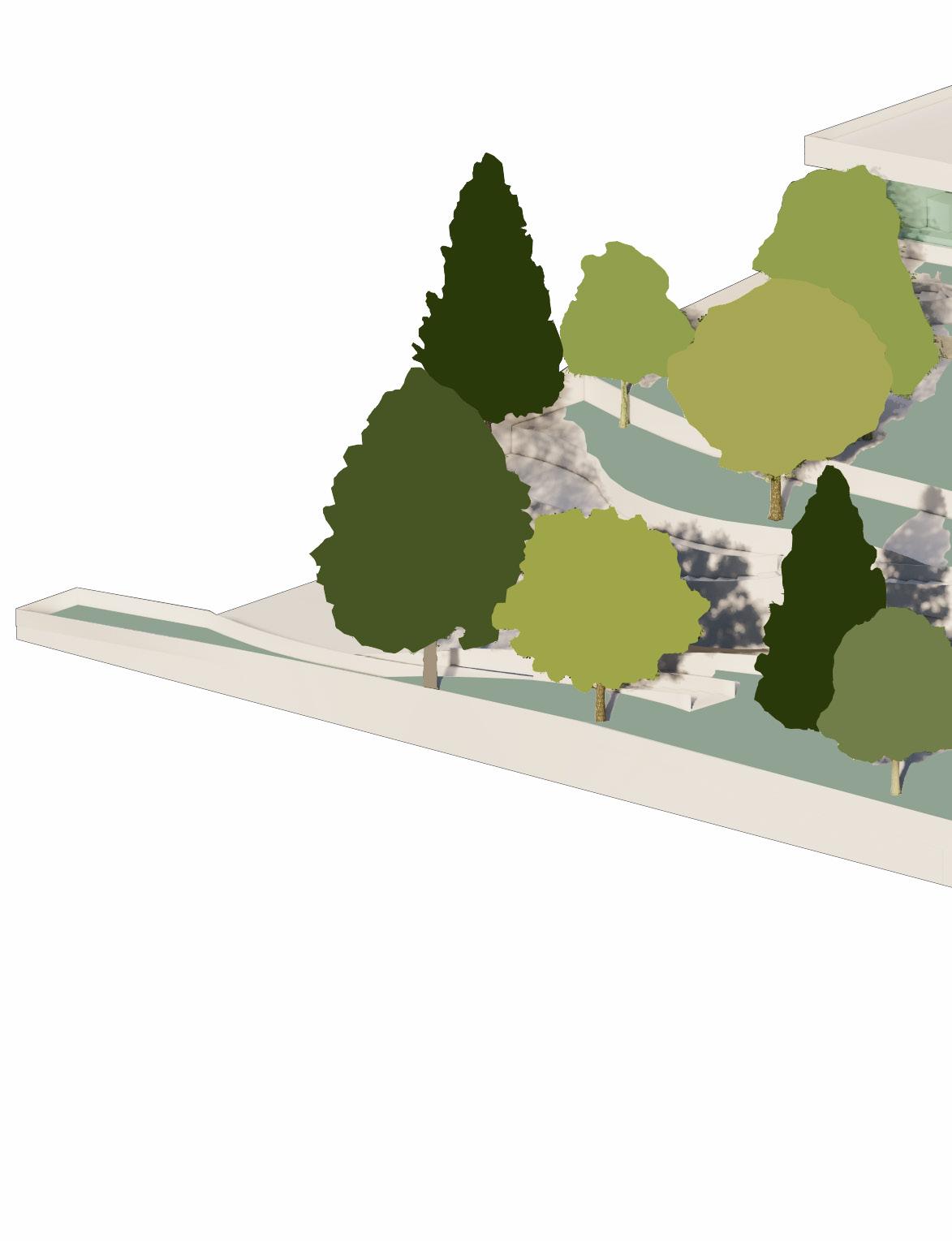

The topography of the site is used in order to building and roof as if it is being lifted from terracing the roof to better emulate the slop

Public Parking Moved underground. More Green space is added

Little green space exists within the Overland Park Area- 2 mile radius

Little green space exists within the Overland Park Area- 2 mile radius

Green Space

Public Parking Moved underground. More Green space is added

Public Parking Moved underground. space is added

Public Parking

Vertical Farming

Entrances

Little green space exists within the Overland Park Area- 2 mile radius.

Roof Design Entrances

Roof Design Entrances

Public parking replaced with parking system. Green spacesupplements utilize site

The topography of the site is used in order to create the from of the building and roof as if it is being lifted from the ground. Then terracing the roof to better emulate the slop of the site.

Cut through the grocery in order to create axis between Community Center and Metcalf Ave

The topography of the site is used in order to create the from of the building and roof as if it is being lifted from the ground. Then terracing the roof to better emulate the slop of the site.

Cut through the grocery in order Community Center and Metcalf

Vertical Farming Vegetation

Cut through the grocery in order to create axis between Community Center and Metcalf Ave

Vertical Farming Vegetation

Entrances

Access points are located near recreation center and metcalf ave to connect both areas and embrace the axis that is then created.

Vertical

Facade is lined by automated vertical store farming as well as a more green

Facade is lined by automated more efficient farming as sustainable

34

Vegetation

1 2 4 5

Little green space exists within the Overland Park Area- 2 mile radius

Roof Design

create the from of the ground. Then of the site.

to create the from of the the ground. Then slop of the site.

underground. More Green

Cut through the grocery in order to create axis between Community Center and Metcalf Ave

Cut through the grocery in order to create axis between Community Center and Metcalf Ave

Parking Roof Design

Vegetation

with underground automated spacesupplements lot to better footprint.

The topography of the site is used in order to create the from of the building and roof as if it is being lifted from the ground. Then terracing the roof to better emulate the slop of the site.

Vegetation

The site is used to create the form by lifting topography.

Vertical Farming

order to create axis between Metcalf Ave

Trees and other Vegetaion is added to the Green Roof in order to increase the usability and feel of the roof environment

Vertical Farming Vegetation

vertical farms for more efficient in green and sustainable glass facade.

automated vertical farms for well as a more green and glass facade.

farms for more efficient in and sustainable glass facade.

Trees and other Vegetaion is added to the Green Roof in order to increase the usability and feel of the roof environment

Facade is lined by automated vertical farms for more efficient in store farming as well as a more green and sustainable glass facade.

Trees and other vegetation is added to the Green Roof in order to increase the usability and feel of the roof environment

35

3 6

36 11 Micro Fulfillment Center 12 Automated Parking Garage 01 Entrance(s) 02 Meat/Seafood 03 Produce 04 Fridge 05 Freezer 06 Dry Goods 07 Cheese and Wine 08 Floral Display 09 Help/Front Desk 10 Pickup N First Floor 12

FloydSt.

37

Metcalf Ave

1 2 3 7 8 10 11 9 4 5 6

38 Second Floor 01 Entrance(s) 02 Cafe/Food 03 Offices 04 Confrence 05 Break Room 06 MFC 07 Elevator 08 Pickup

39 1 2 3 7 8 10 11 4 5

40 Terraced Roof 01 Entrance(s) 02 Restaurant 03 Paths

41 1 2 3

Design Precedents and Section

Taking inspiration from (1) vertical farming in the World Food Building (2) African Terraced Farming, and (3) major multi-purpose structures in Asia, the Green Makert creates a grocery store where numerous functions as well as innovative form and design create a unique yet functional store for the community of Overland Park.

2

1

3

44

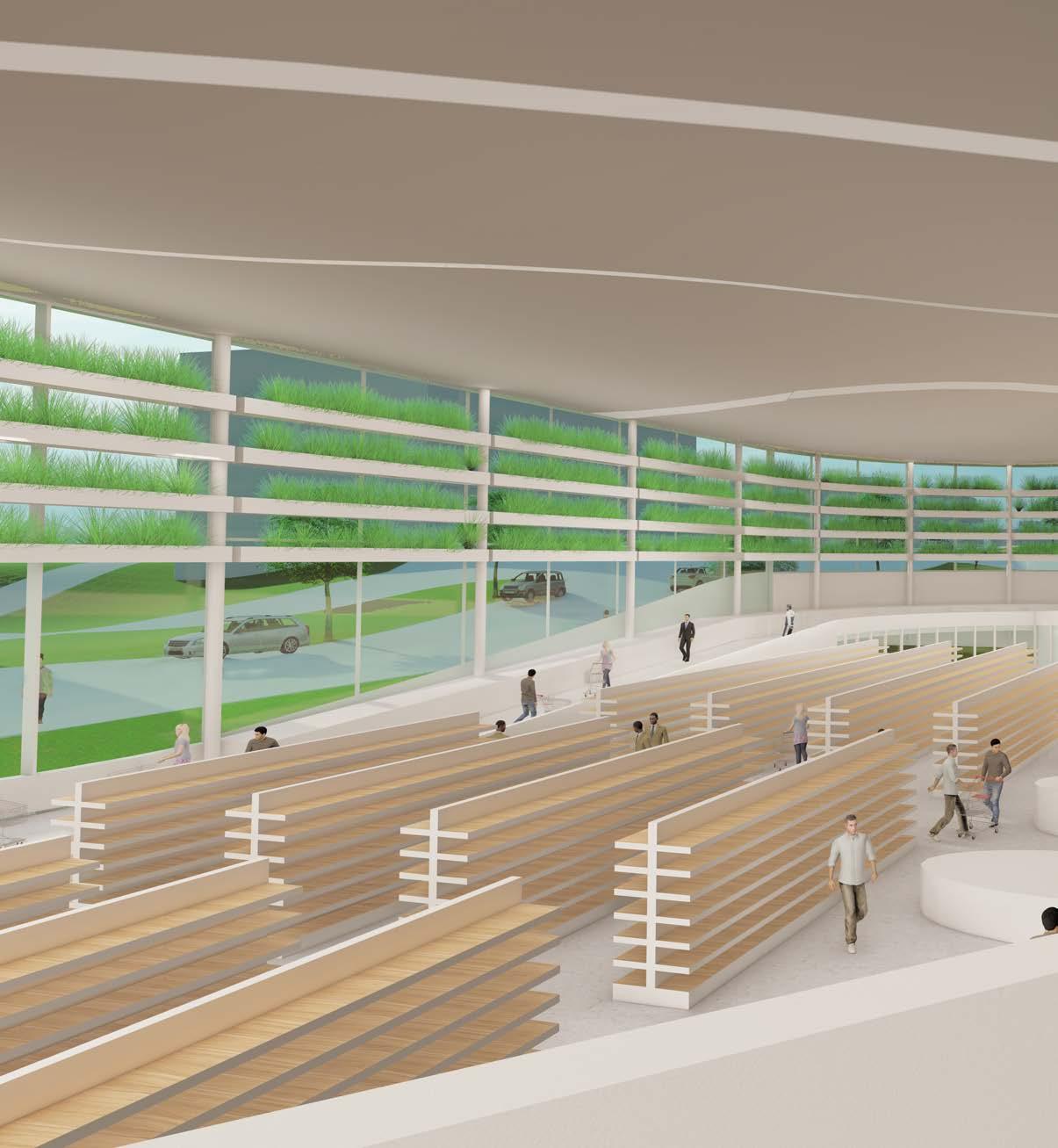

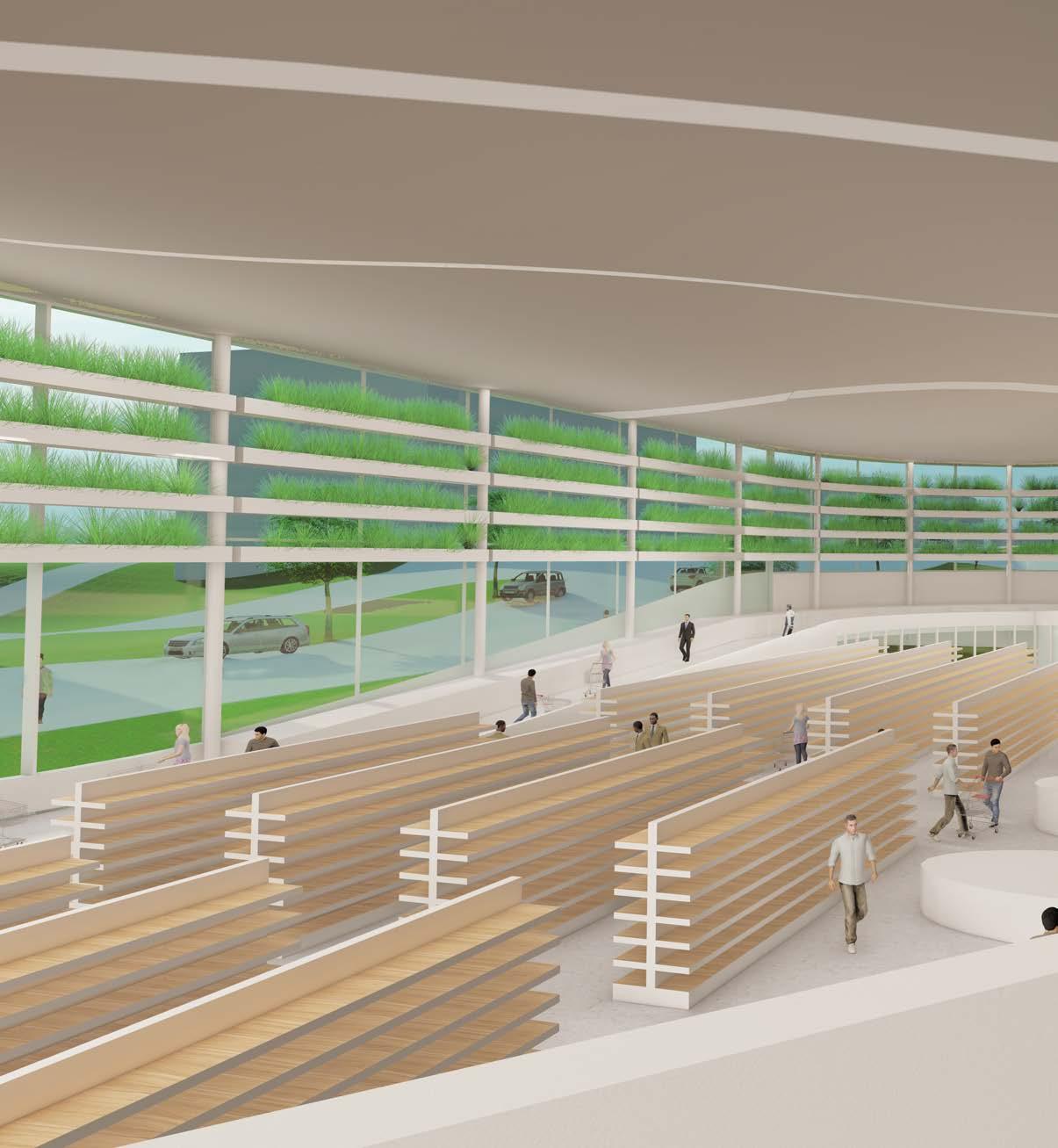

Upper Level View of Store

Medium: Photoshop and Lumion

Large winding ramp is used to define space and provide separate between the various functions of the store.

45

46

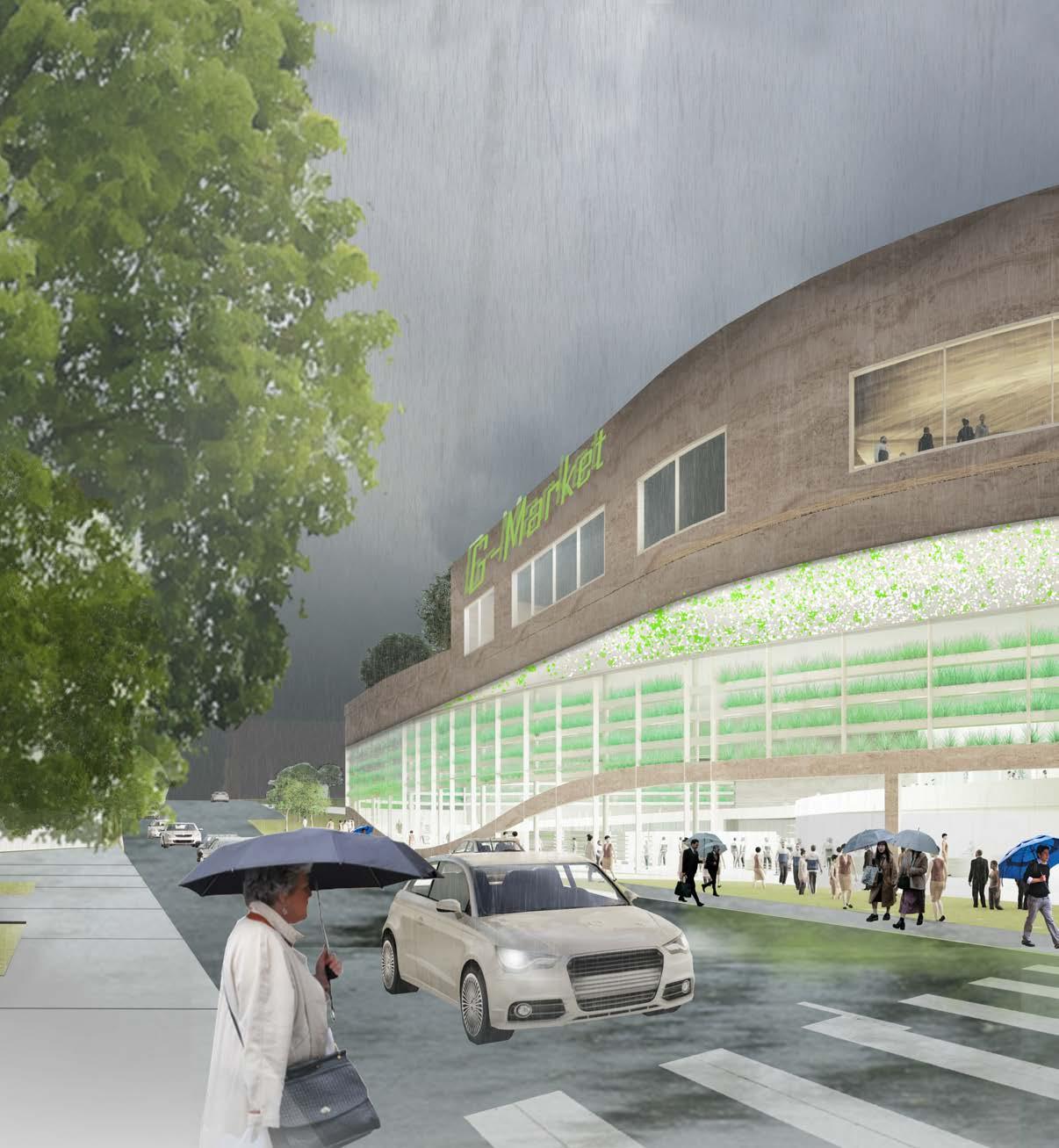

Street View From Metcalf Ave.

47

Medium: Photoshop and Lumion

The vertical farming system lines the street giving a sense of movement and showcasing good green design.

48

4 0

Nelson Atkins Bloch

Street Art

Nelson Atkins Popup Shop

-Overland Park, KS

Professor: Jae Chang Spring 2021

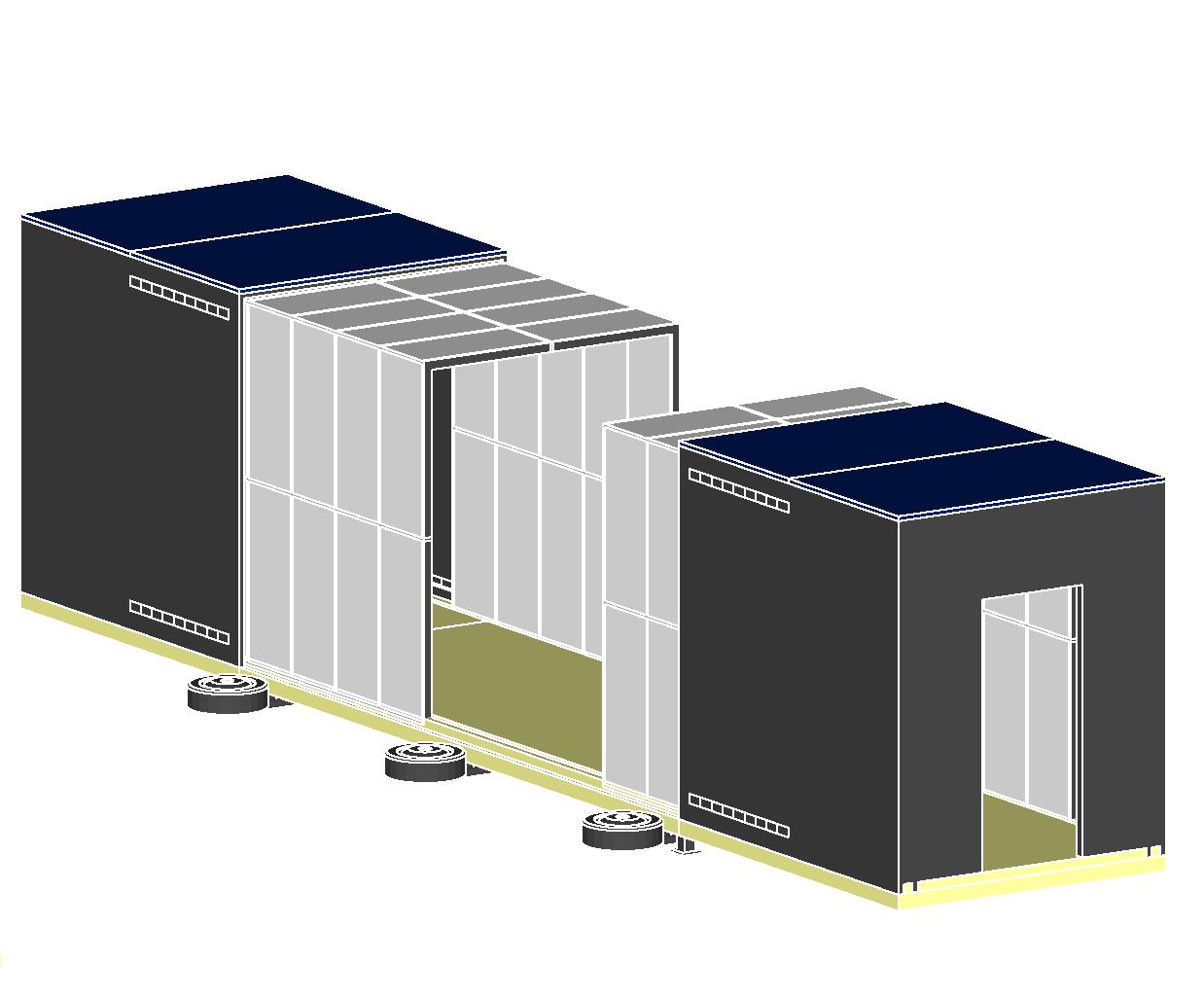

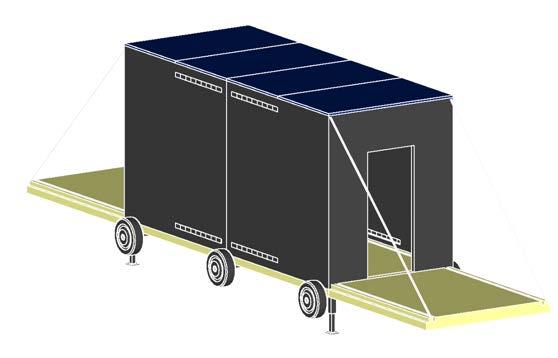

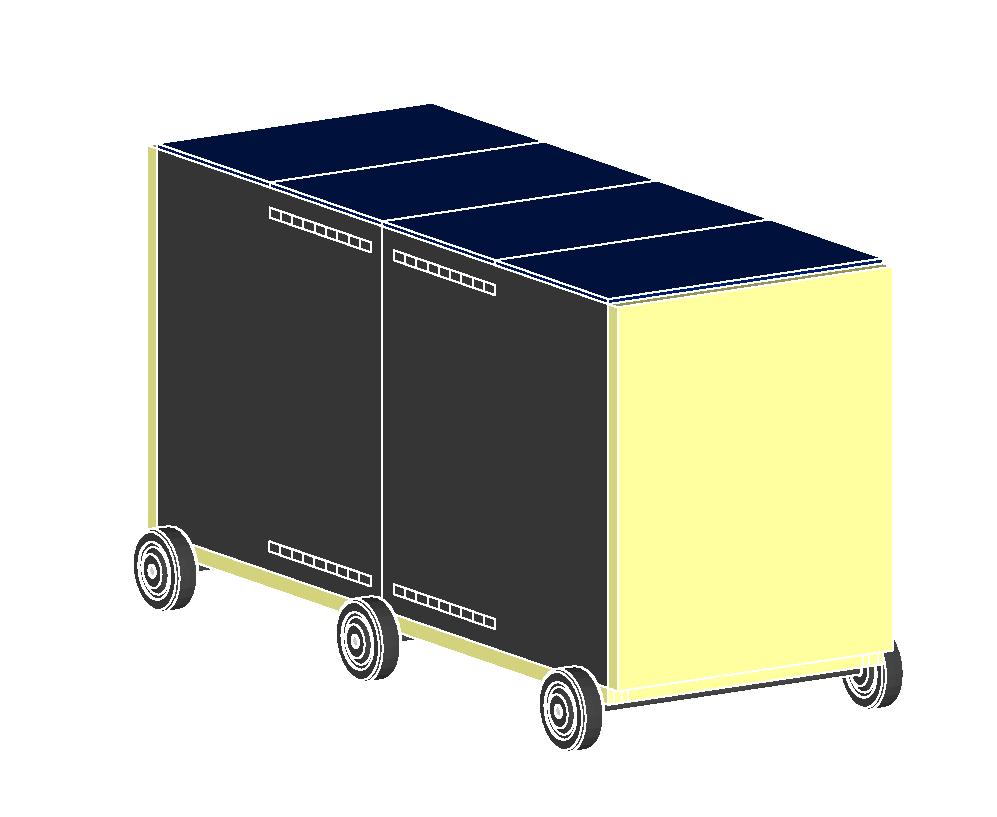

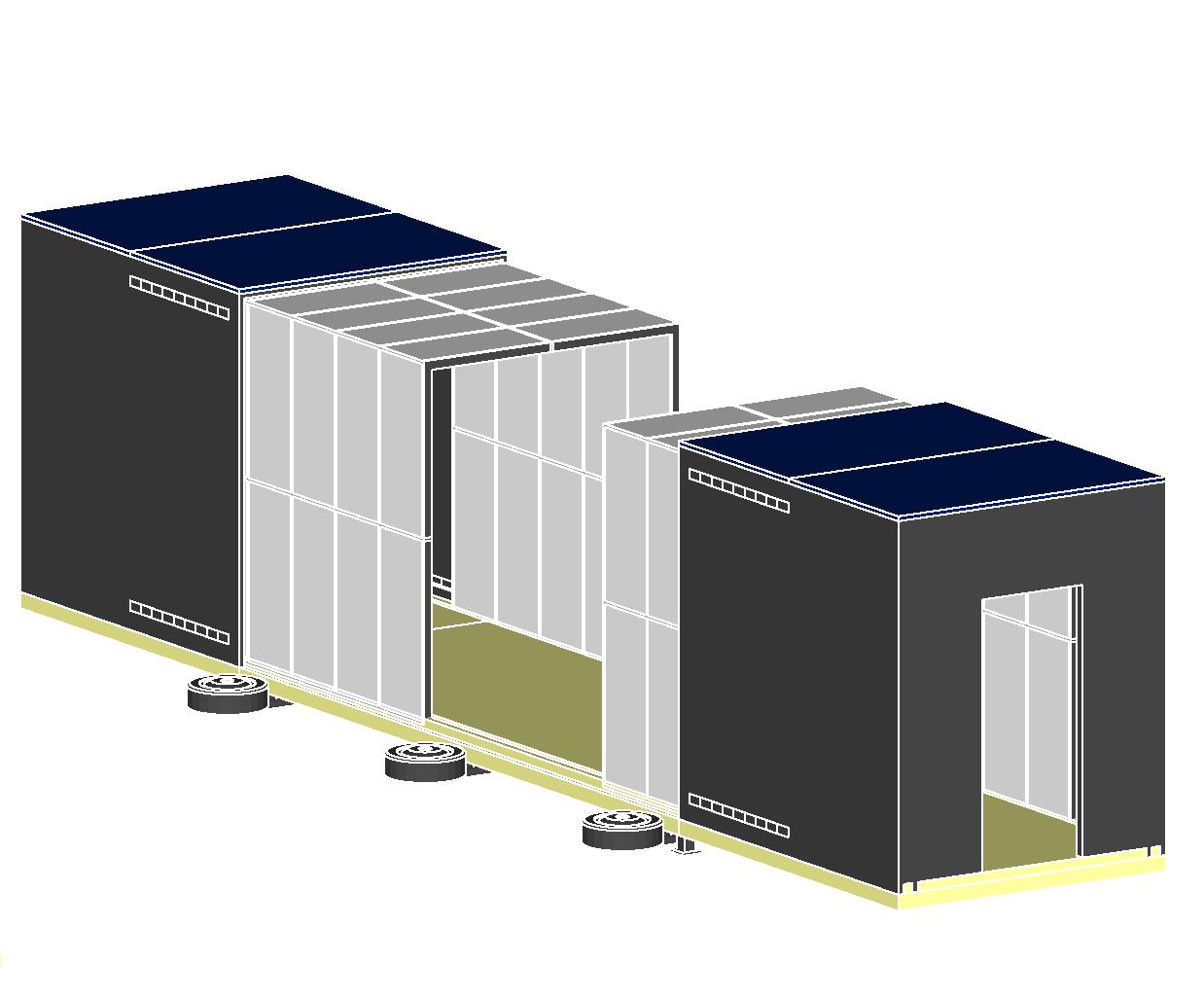

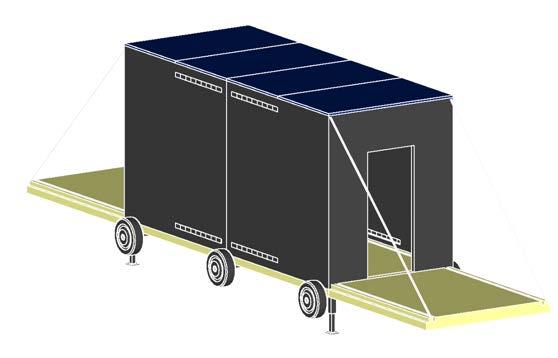

Metcalf Avenue has become a place for urban growth and expansion ever since the Vison Metcalf Project was adopted by the community in 2007. The Nelson Atkins Pop-Up Shop is a new and innovative place were people of the Overland Park (and other locations) can experience, learn, and practice art. Through a collaboration with the Nelson Atkins Art Museum, the pop up shop creates a digital led experience where people can immerse themselves in art. When the shop is not being used for high art, local artists can display and promote the local community as well.

Utilizing technology such as Electrochromic Glass, Smart Interactive Displays, And Bimetallic strips, The Nelson Atkins Pop not only displays unique technology but takes advantage of smart design to create an efficient, interactive, and healthy overall pop-up experience. Along with technology used, the pop-up shop itself takes inspiration from various current art museums, interactive art experiences, and street art to engage and showcase not only street art but teach about the importance of fine and historical art displayed at the Nelson Atkins.

49

Experience

The Van Gogh

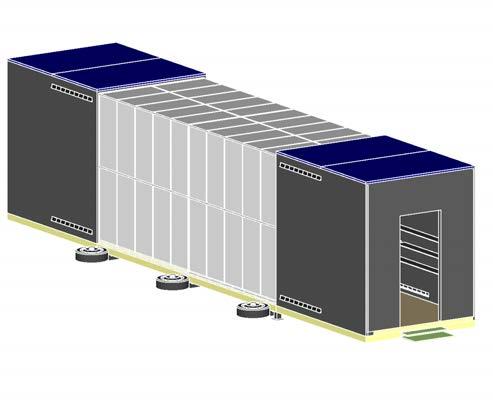

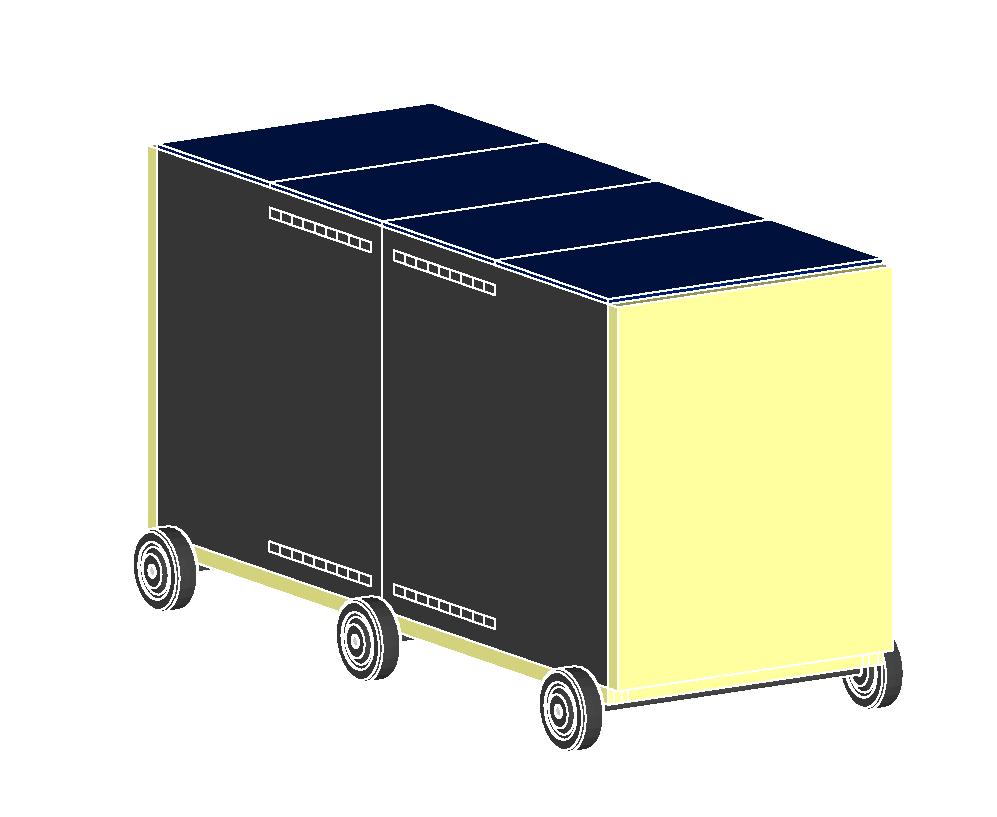

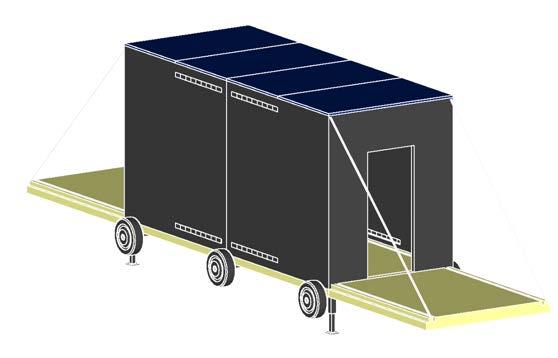

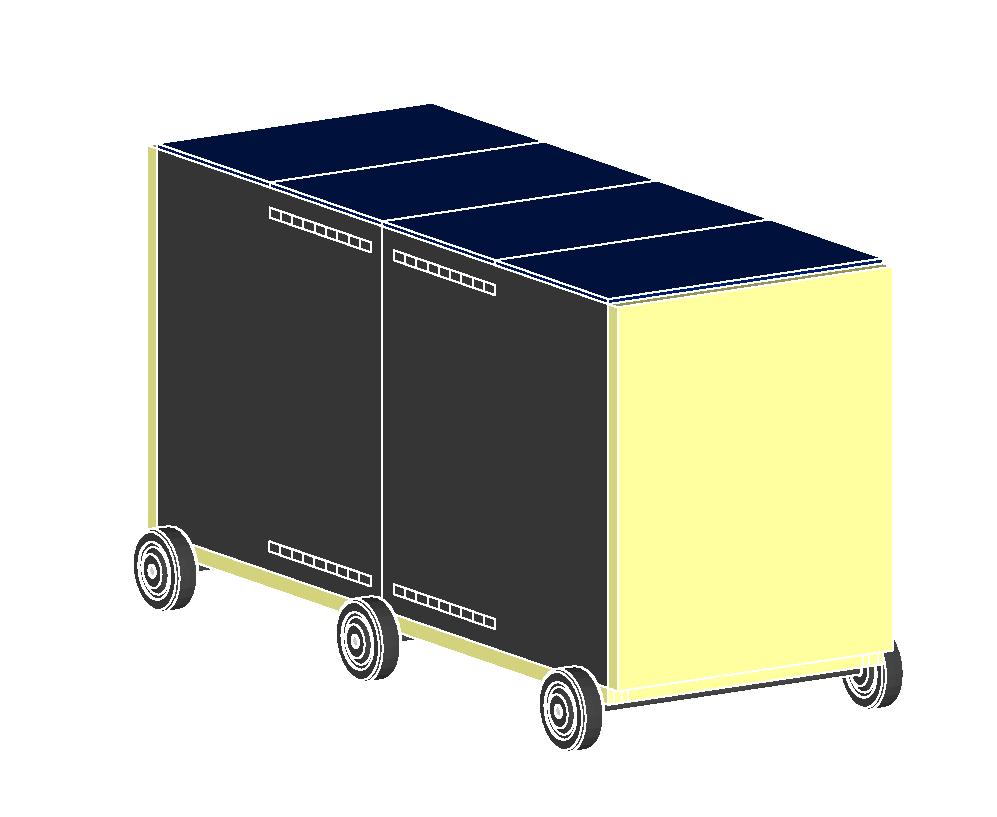

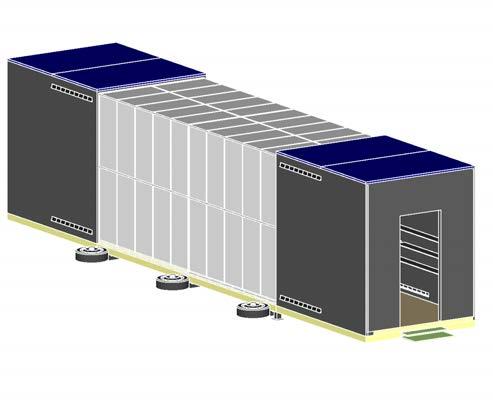

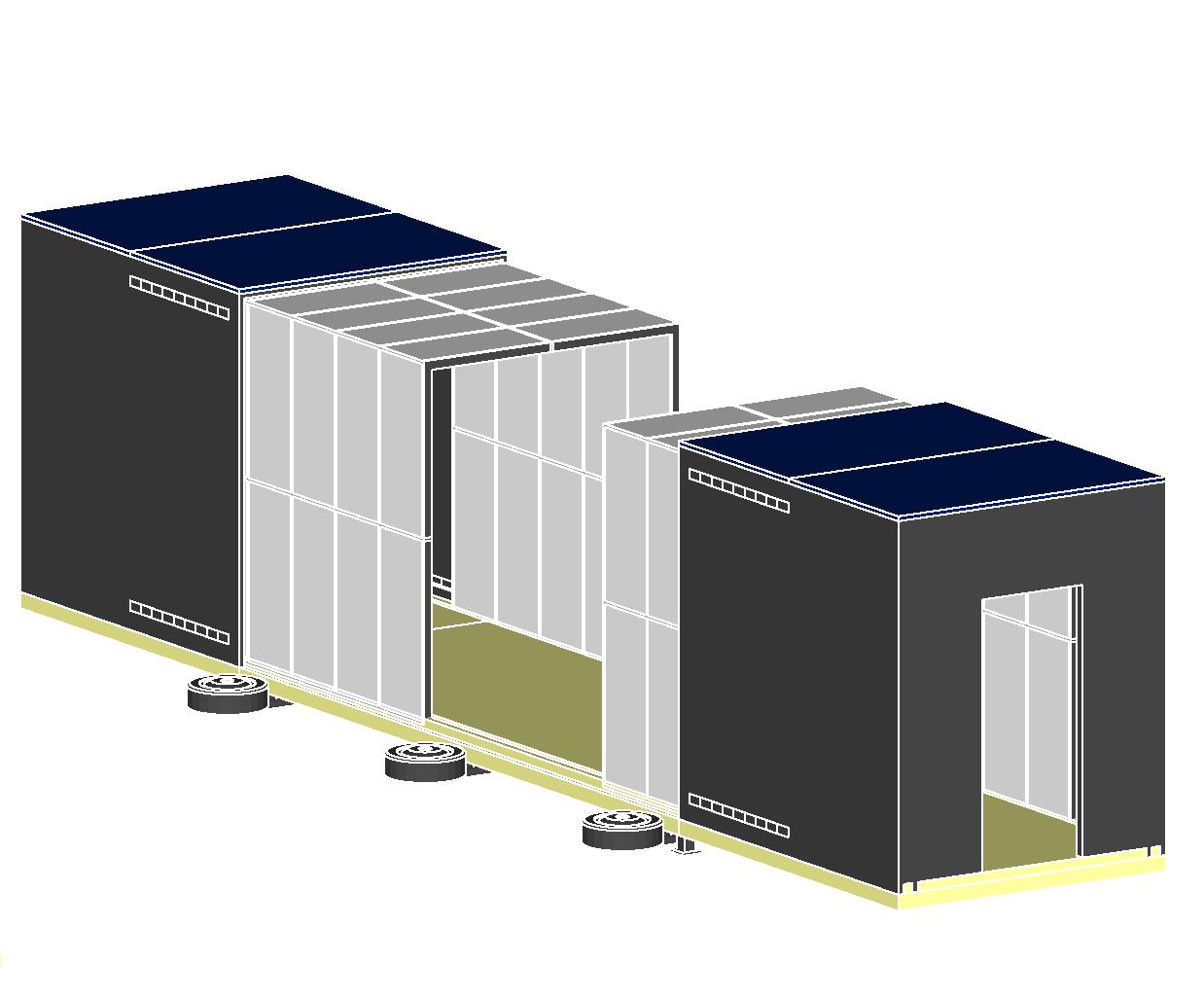

Simple Container transported through semi-hookup system

Main platform lifts up and each end is lifted down in

50

1 2 3

Exterior container slides to each end of platform, system is lowered, tires rotate up and smart glass is revealed

Ready for use and interaction -Ventilation System through Bimetalic Strip System -Solar Panels Used for Energy Collection

51

4

Solar Panels Electrochromic (Transparent

Aerial View

learning

Electrochromic Glass (Transparent LED) Interactive Display Medium: Photoshop, Lumion, Illustrator Interactive Display allows for a fun , exciting, and engaging

experience.

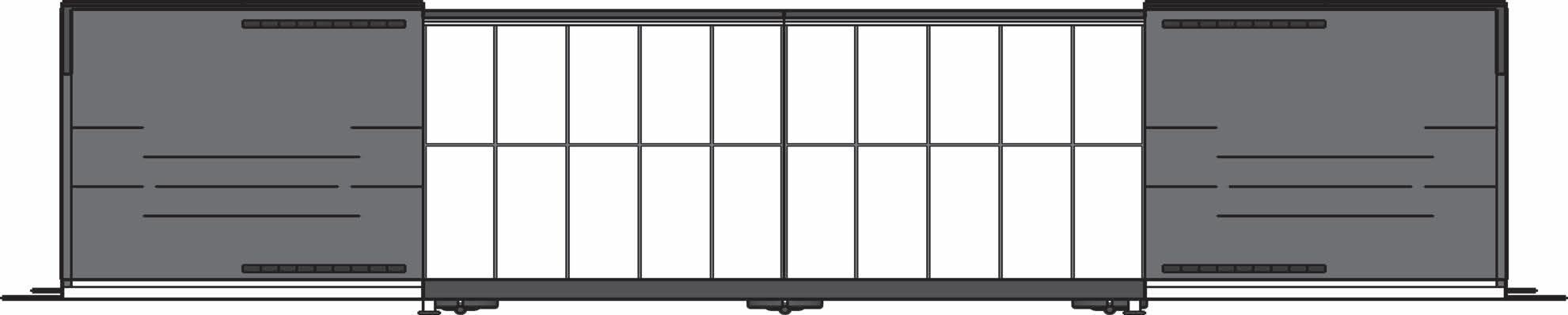

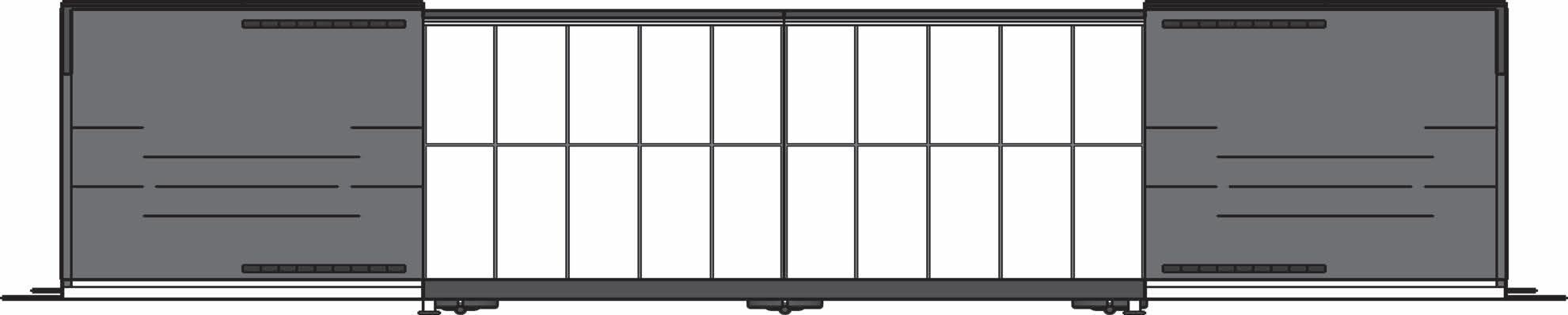

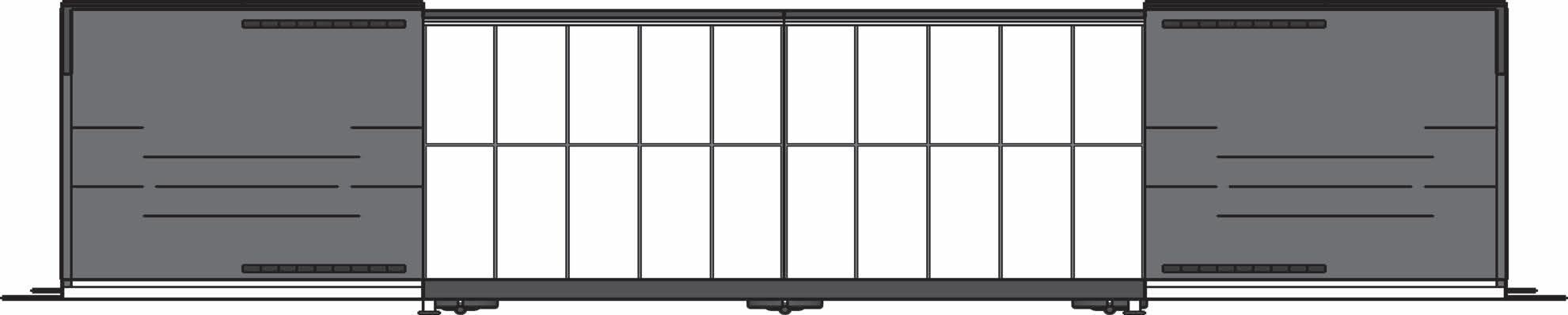

54 1 2 3 3 4 4 5 5 6 6 7 0 5 01 02 03 04 1 2 3 3 05 06 07 4 4 5 5 6 6 6 6 7 1 2 01 Outer Box 02 Middle Section 03 Smart Glass 04 Ventilation System 05 Shelves 06 Tires 07 Stairs 01 Outer Box 02 Middle Section 03 Smart Glass 04 Ventilation System 1 05 Shelves 06 Tires 07 Stairs 4 4 5 5 7 Plan and Sections

55 0 5 01 Outer 02 Middle 03 Smart 04 Ventilation 1 3 3 05 Shelves 06 Tires 07 Stairs 4 4 5 5 6 6 6 6 7 1 2

Day

and Night

Pop-up shop can display both digitally and traditionally, creating a shop or all types of art selling and education.

Medium: Photoshop and Lumion

Medium: Photoshop and Lumion

58 Personal

Hand

59

Hand Drawings

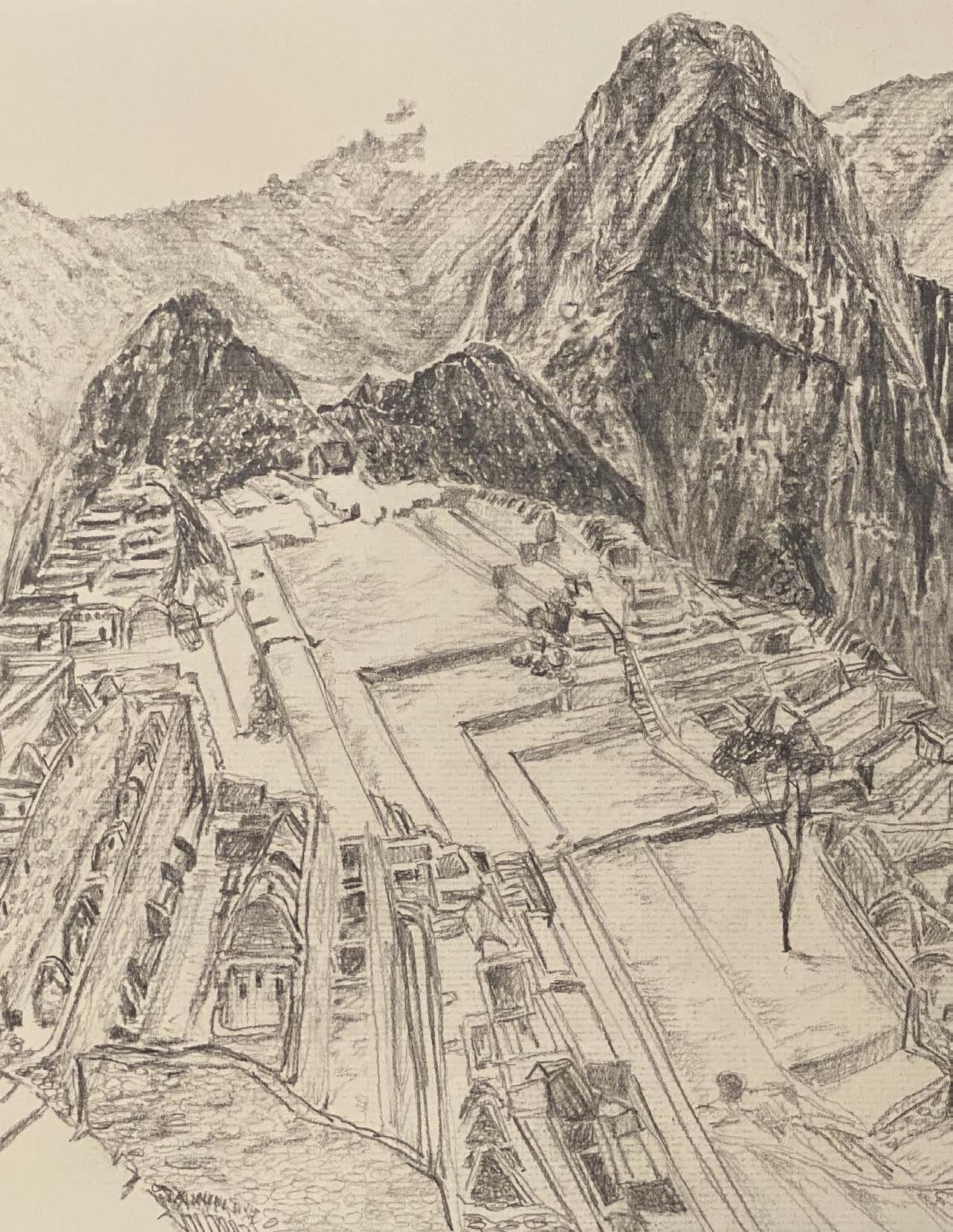

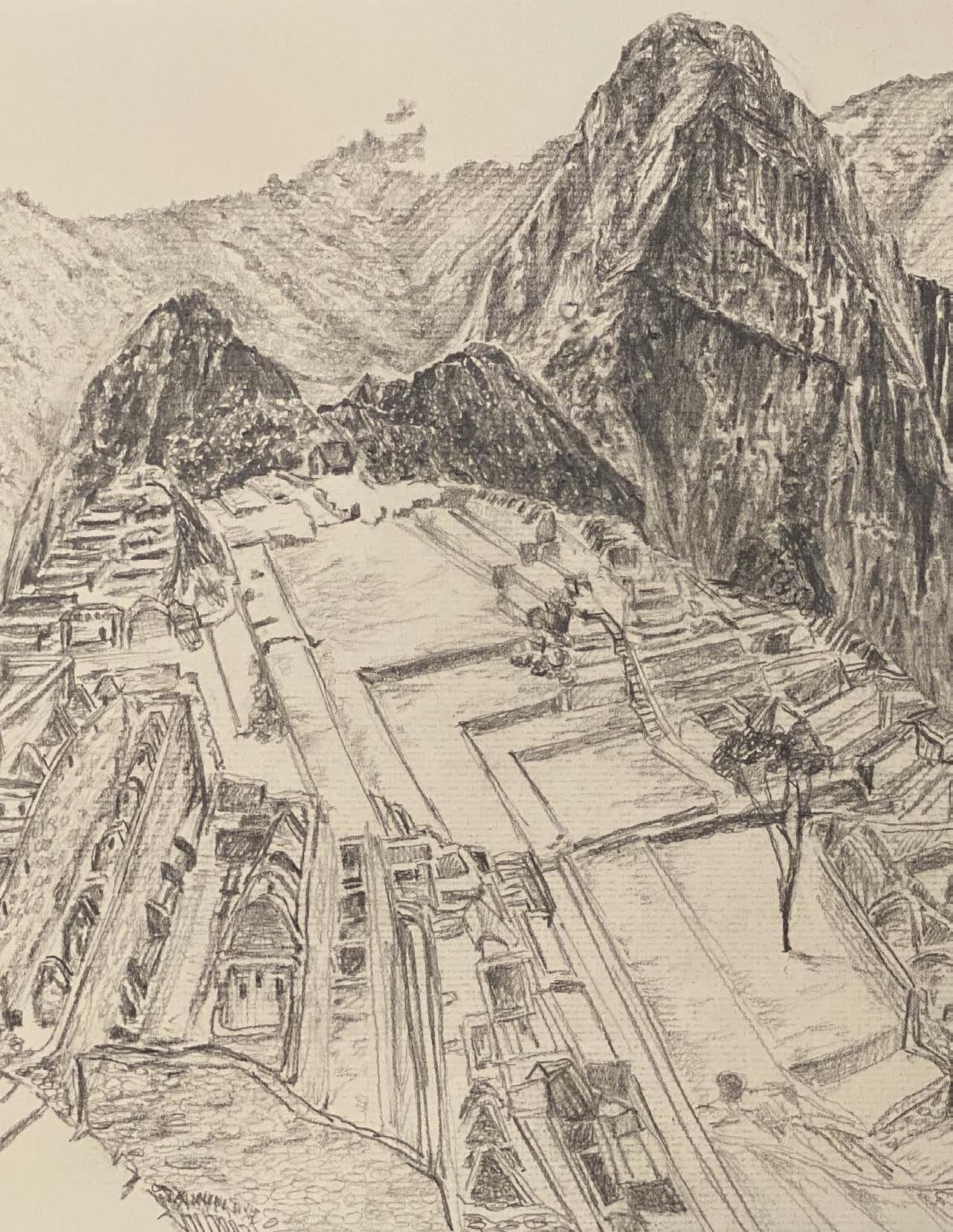

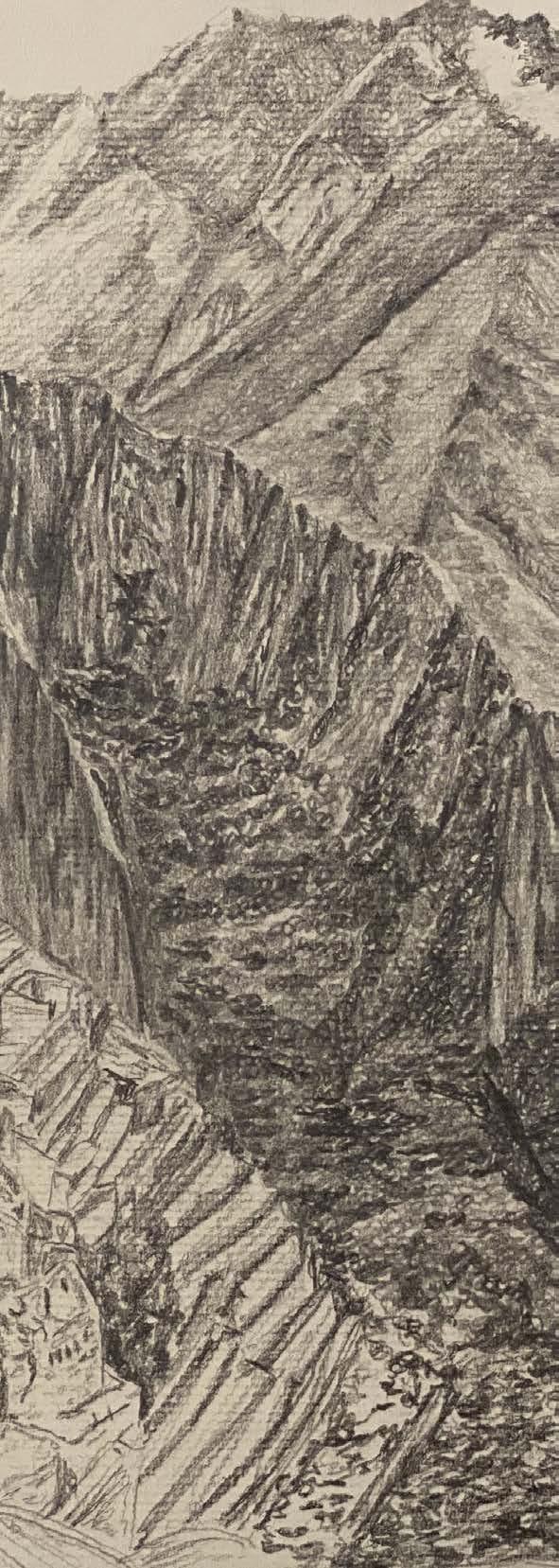

Machu Picchu

-Pencil Personal Work Summer 2020

Machu Picchu is one of our worlds most fantastic and beautiful examples of vernacular architecture. Produced during a personal study of vernacular architecture. The drawing was created to better understand and produce a personal sketch of inspiring and iconic design. Using only a mechanical pencil, the drawing is comprised of only careful shading and linework.

61

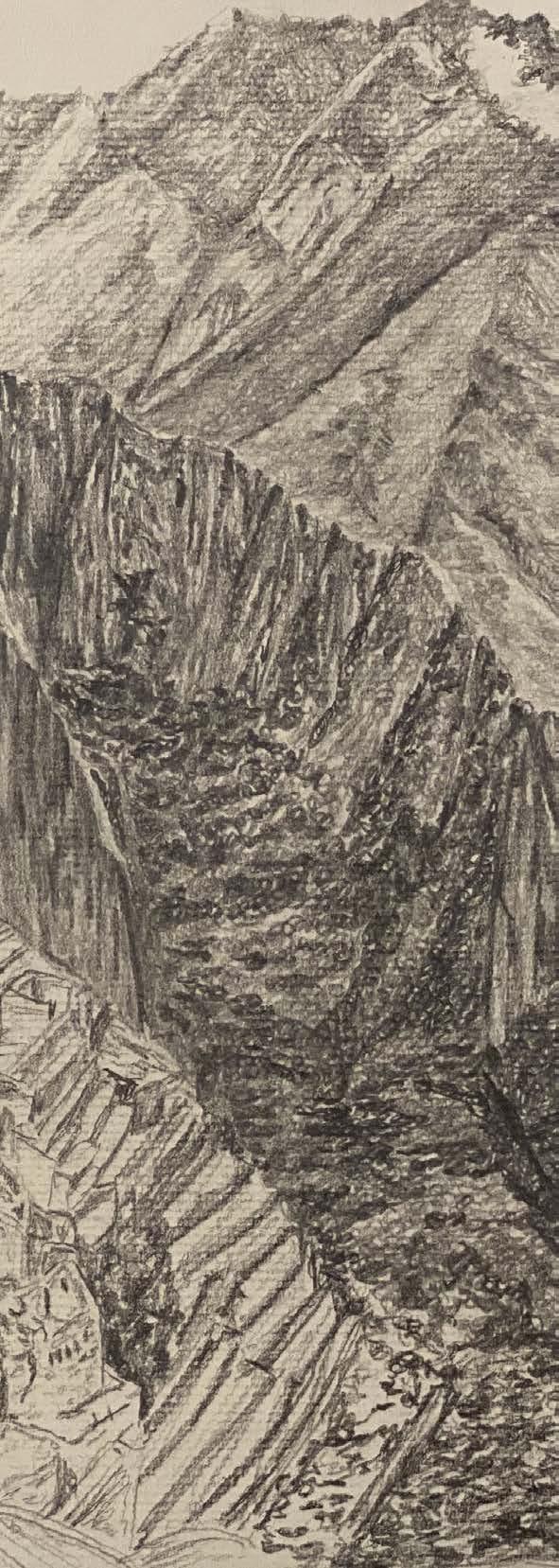

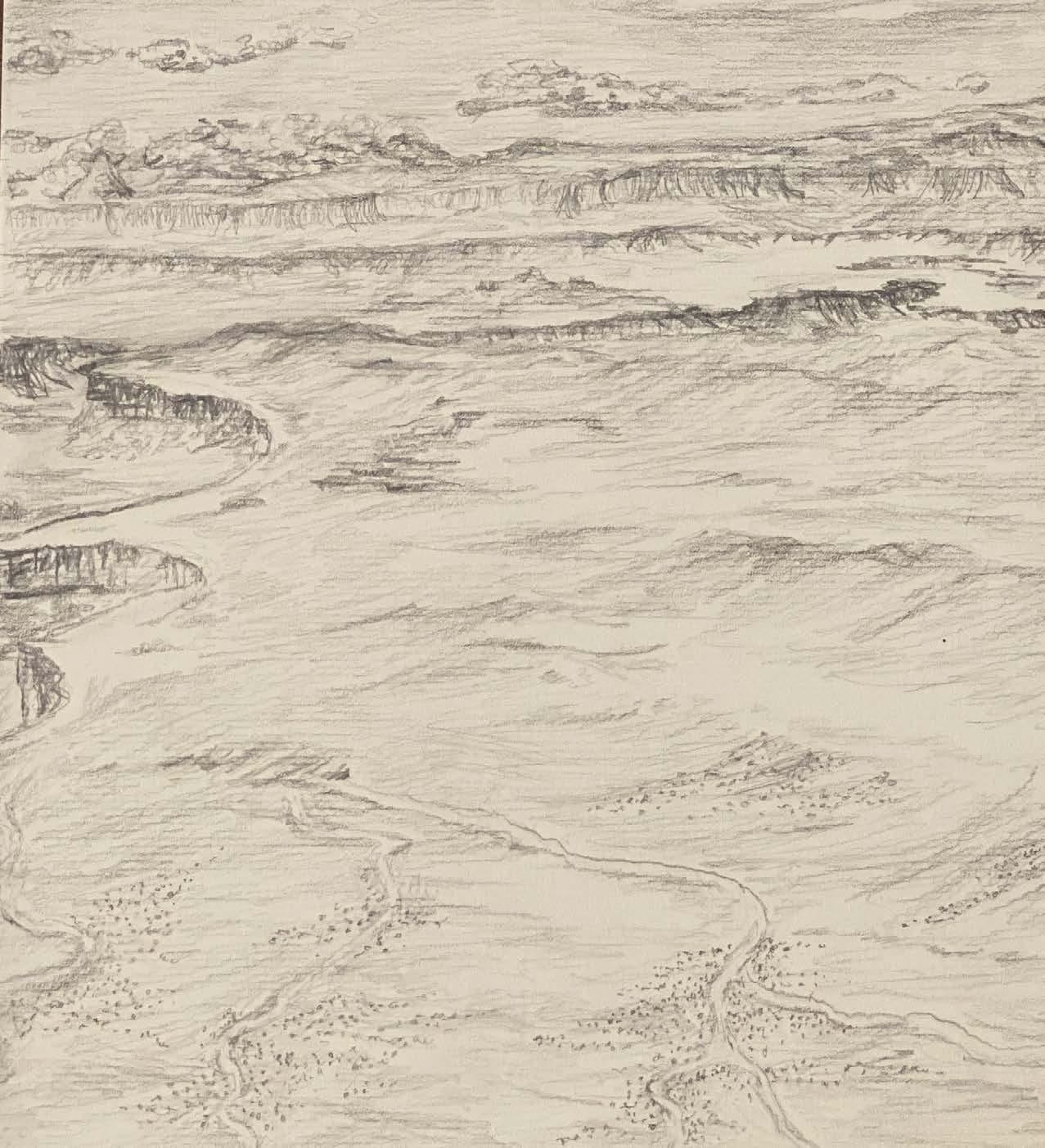

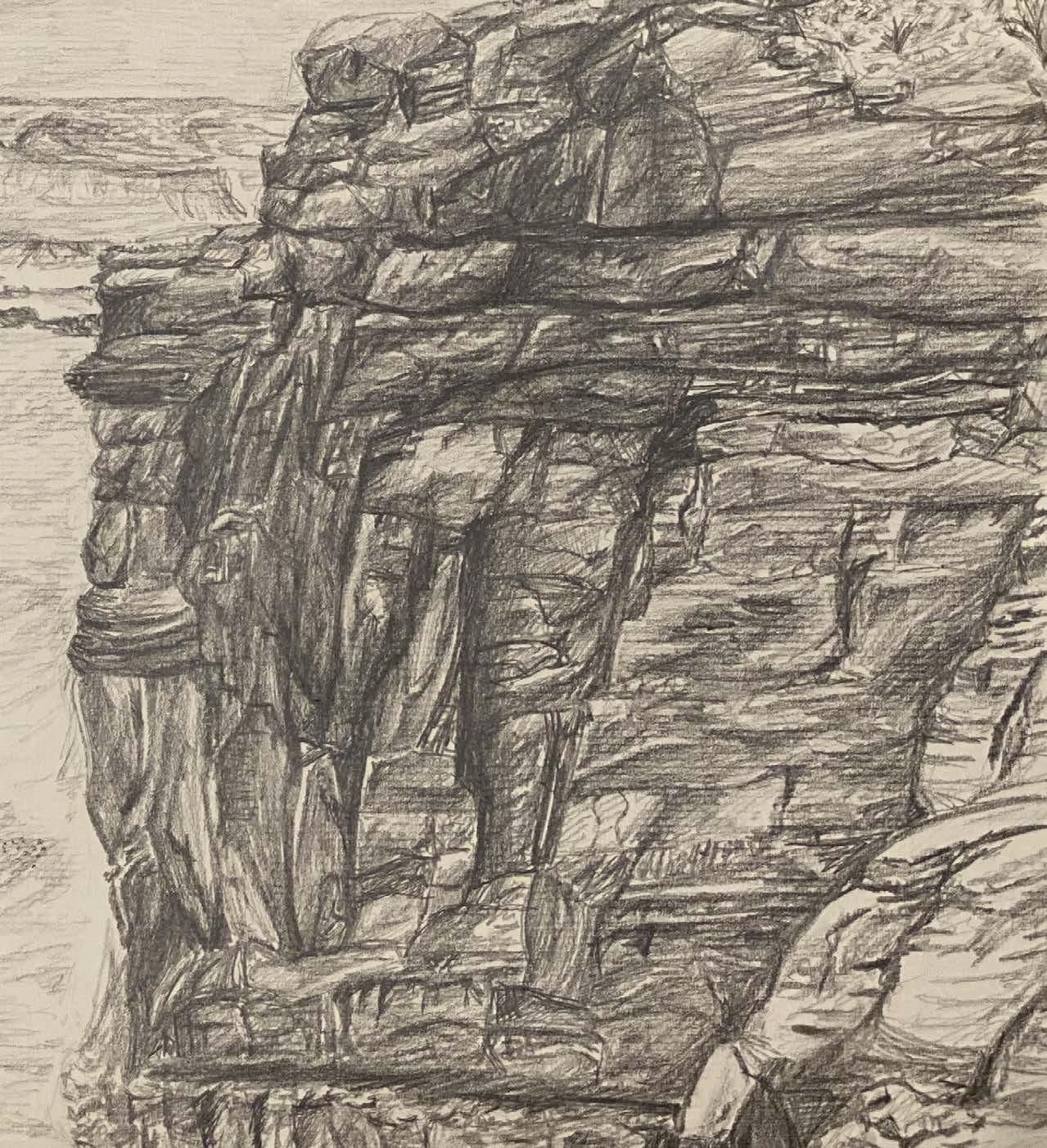

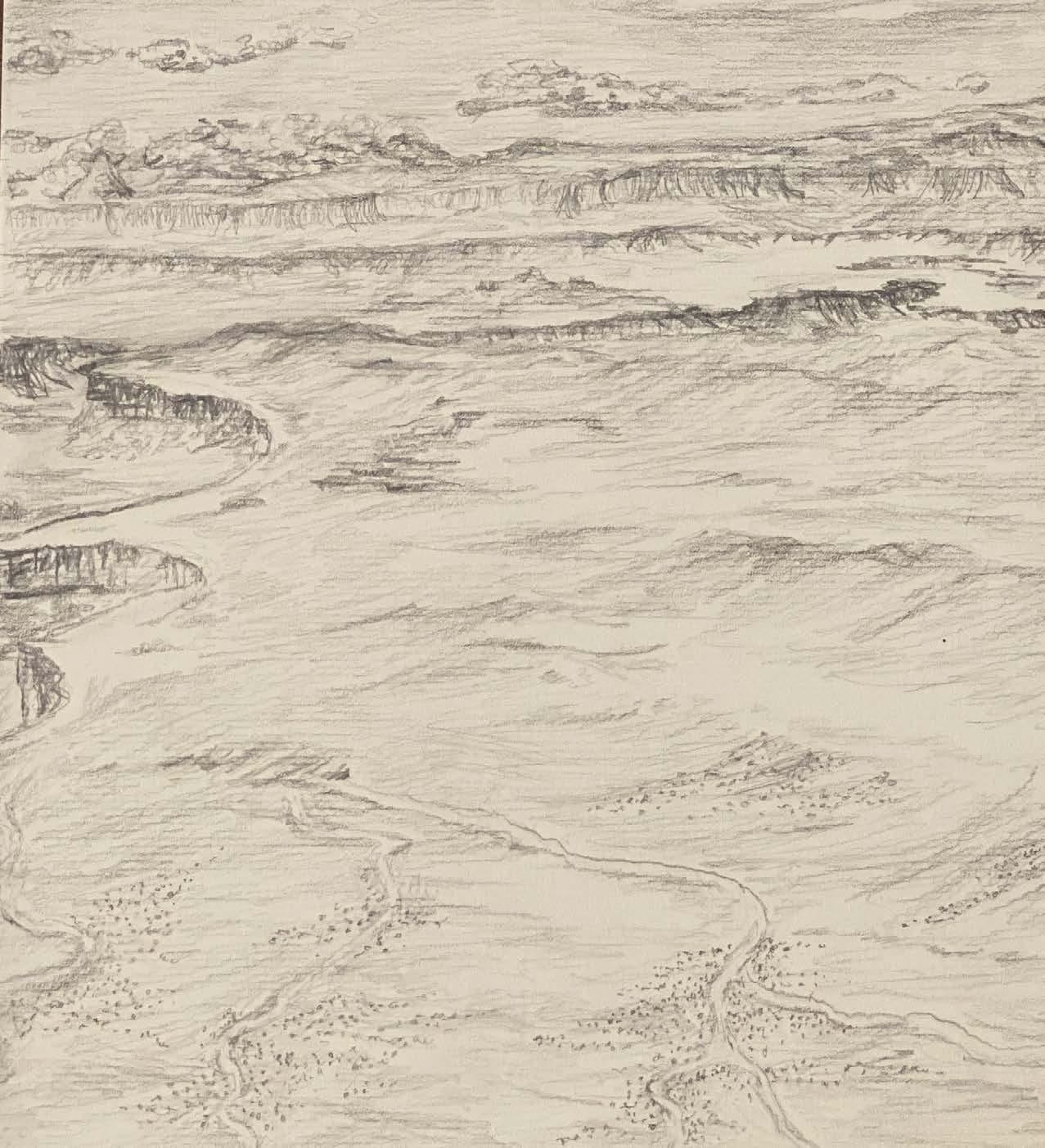

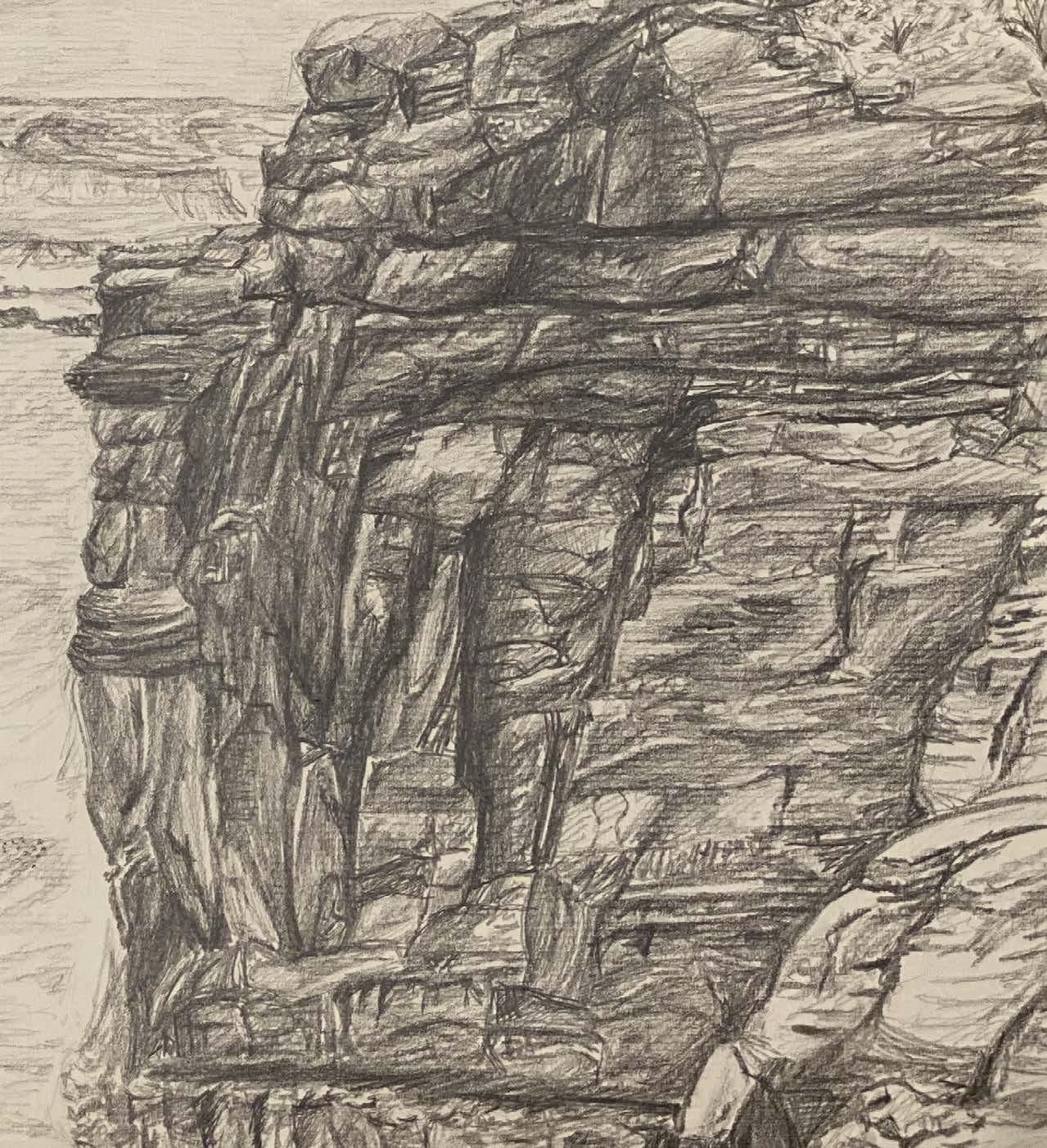

Dead Horse Canyon (Utah)

62

-

Summer 2020

Pencil Personal Work

Created shortly after the Machu Picchu drawing, after traveling to Moab, Utah, I found the landscape to be beautiful. Viewing the rock canyons behind the vast canyon behind, the drawing again is used only mechanical pencil.

63

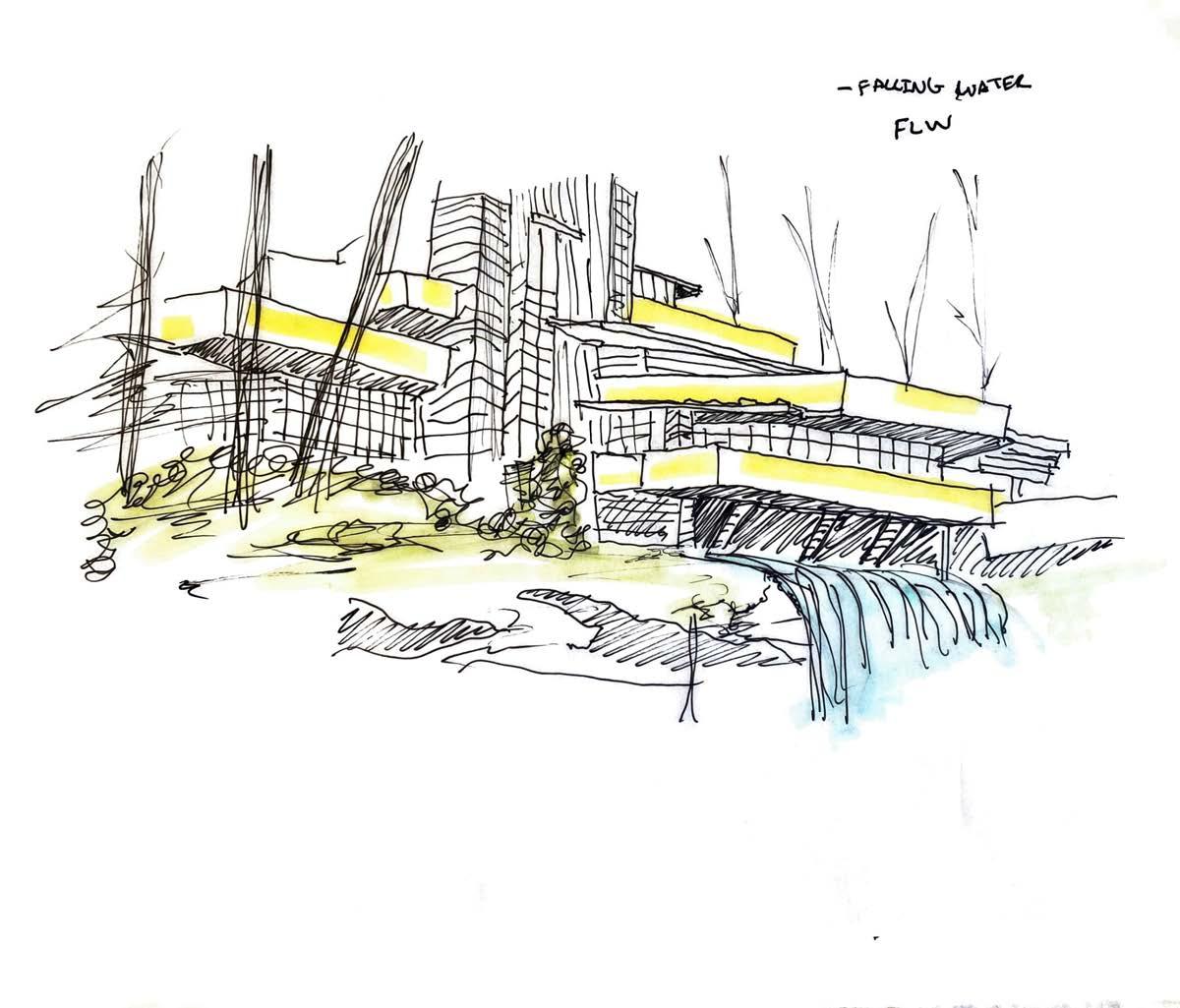

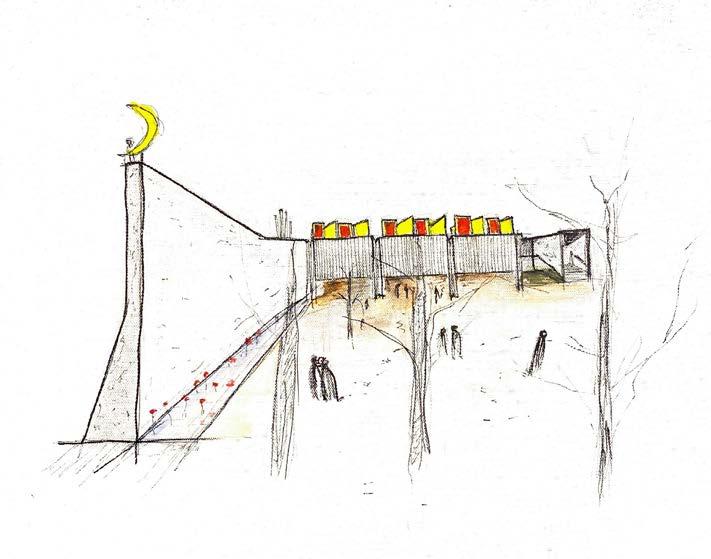

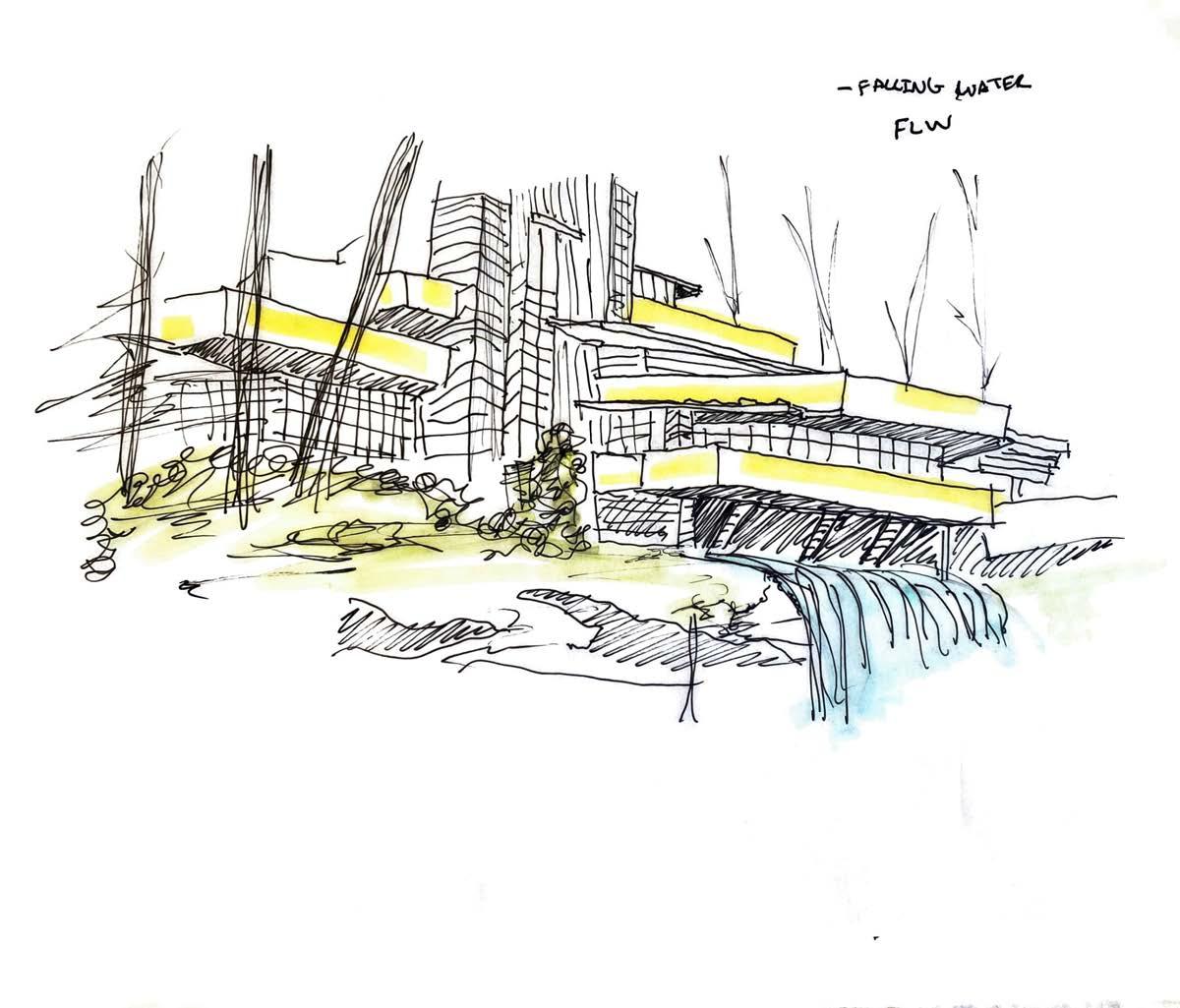

The Pantheon and Falling Water Sketches -Pen and Markers

Personal Work Spring 2022

64

Sketches drawn while learing about the progress and evolution of architecture throughout history. Meant to be sketches drawn under 10min each drawing acts as a practive for quick informative sketchking.

65

Medium: Ink Pen

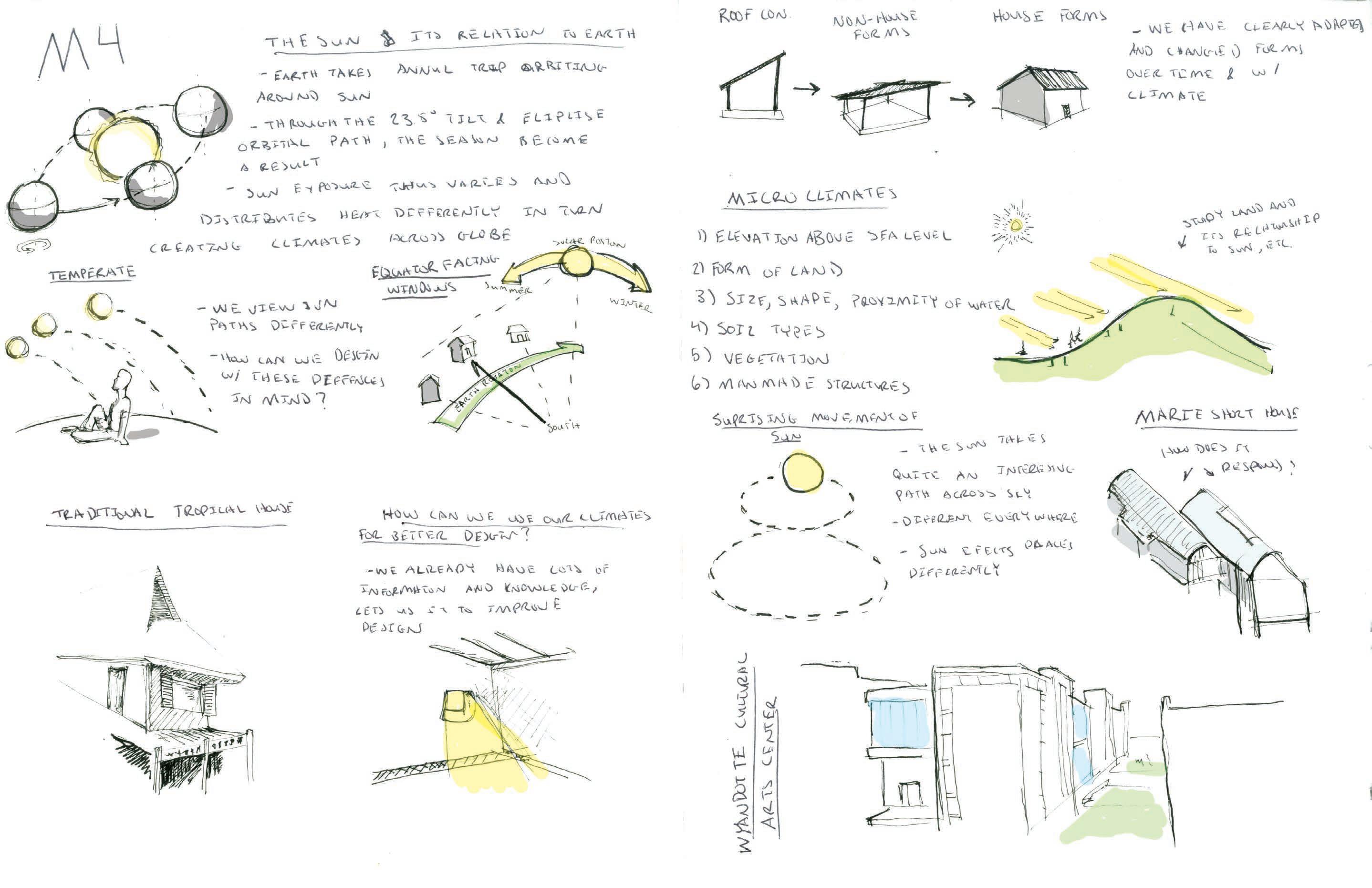

Glenn Murcutt Mosque