4 minute read

Metro Tunnel Project’s Tunnel Boring Machines

The $11 billion Metro Tunnel Project involves the construction of two 9 kilometre-long rail tunnels up to 30 metres below the streets of Melbourne, connecting the Sunbury Line to the Cranbourne and Pakenham lines, with high capacity trains and five new underground stations, including Parkville Station, close to Graduate House. Some of Melbourne’s busiest metropolitan train lines – Sunbury, Cranbourne and Pakenham – will run exclusively through the new tunnels. By taking these lines out of the City Loop, other lines will be able to run more services. Capacity will thus be created on the network to enable half a million more passengers to use the rail system during each peak period. The Metro Tunnel is the first step towards a ‘metro style’ rail network for Melbourne with the ‘turn up and go’ train services that are the hallmark of the world’s great cities such as London, New York, Hong Kong and Singapore. Four tunnel boring machines (TBMs) are being used to build the twin tunnels. TBMs can bore through a variety of ground conditions, from hard rock to sand. The geology of the area is variable. The TBMs are required to excavate through soft soils such as Coode Island Silt, and hard basalts under the Yarra River and in some sections of the western alignment. Many sections of the tunnel alignment feature a ‘mixed-face’ geology, which is both parts hard and soft. To construct the tunnels, the TBMs are progressively lining each tunnel with curved concrete segments as they dig. The twin tunnels will comprise 56,000 individual concrete segments. On average, TBMs move around 10 metres every 24 hours. During tunnelling, noise, vibration and ground movement are monitored and managed in line with strict Environmental Performance Requirements (EPRs). Each TBM is 7.28 metres in diameter, weighs more than 1,100 tonnes and is 120 metres long – as long as 3 E-Class trams end-to-end. The heaviest component is the cutterhead, which weighs 100 tonnes and acts as a drill that can tunnel through rock six times harder than concrete. Each TBM is equipped with a state-of-the-art navigation system to ensure they dig accurately along the tunnel alignments. They are staffed and monitored 24 hours a day, 7 days a week, and fully equipped with staff facilities, including an office, kitchen and toilets. A crew of up to 10 people, including a TBM operator, work on the TBM at any one time. The Metro Tunnel Project is using mix shield TBMs – commonly known as slurry TBMs – that are purpose-built to suit the local ground conditions. Once the TBM’s cutterhead bores through the ground, the excavated material is mixed with slurry and transported back to the above-ground slurry treatment plant. The excavated material is then separated from the slurry and transported to a disposal site. Since May 2020, two TBMs – Joan and Meg – were launched separately from the Arden Station site towards the Parkville Station site. Tunnelling was completed first to the new tunnel entrance at Kensington and just recently through the west end of the Parkville Station. After having been transported to the east end of this station box, TBM 1 (Joan) has broken through to pass just to the north of the Graduate House terraces under Grattan Street. TBM 2 (Meg) will break through this eastern wall in early November to join Joan heading south to the new State Library Station. The two TBMs constructing the tunnels in the east – Alice and Millie – will complete the section of the tunnel between the Anzac Station site and the South Yarra site, and will then tunnel between the Anzac Station site and the Town Hall Station site. The four TBMs are named after ground-breaking women: Victoria’s first female Premier Joan Kirner, Australian women’s cricket captain Meg Lanning, wartime medical hero Alice Appleford

Tunnel Boring Machines are named after ground-breaking Victorian women.

Advertisement

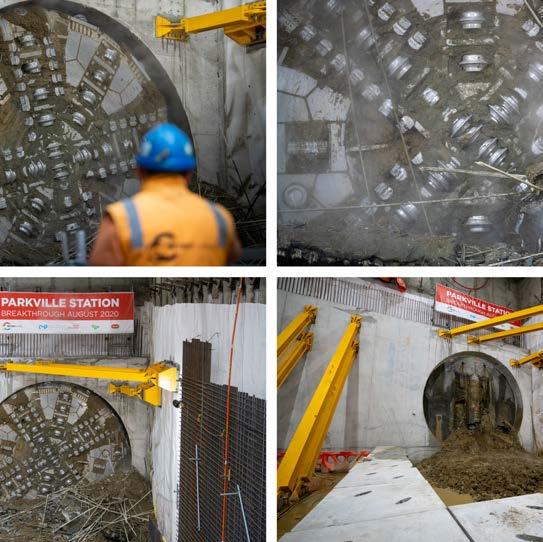

Tunnel Boring Machine Joan breaks through at Parkville Station in August 2020.

and Victoria’s first female Member of Parliament Lady Millie Peacock. As informed by the Premier of Victoria Daniel Andrews early in 2019, tradition dictates that a TBM is given a female name before it can start tunnelling, granting good luck for the project ahead. The tradition dates from the 1500s when miners and military engineers using explosives for excavation prayed to Saint Barbara – the patron saint of tunnellers and miners. By September 2020, the Metro Tunnel Project’s twin rail tunnels were halfway to completion, with the state’s biggest ever public transport project forging ahead. The TBMs have so far excavated more than 364,000 cubic metres of rock and soil and installed more than 30,000 individual concrete segments, each weighing 4.5 tonnes, to line the tunnel walls as crews worked around the clock. Construction on the Metro Tunnel Project has continued during the COVID-19 pandemic, with workers adhering to strict COVID-19 safety measures in line with the Victorian Government’s restrictions. The Metro Tunnel is on track and is expected to be completed by 2025. * * * Tunnel Boring Machine video: https://bit. ly/3jL2q3e.