Optimising Propulsion for Naval Vessels and the Role of Advanced Gas Turbine Technology

Reliable Gas Turbines: Optimal Propulsion

Choice for Sophisticated Naval Combatants

What Marine Forces Need

The Rise of Electrical Warships

Choosing the Next Generation of Propulsion Technologies

Finding the Next Generation of Technologies

TECHNICAL

Published by Global Business Media

STUDY

Email: info@globalbusinessmedia.org

Website: www.globalbusinessmedia.org

Publisher

Global Business Media

Senior Analyst

Martin Richards

Editor

Tom Cropper

Project Manager

Paul Davies

For further information visit: www.globalbusinessmedia.org

The opinions and views expressed in the editorial content in this publication are those of the authors alone and do not necessarily represent the views of any organisation with which they may be associated.

The views and opinions expressed in this publication do not necessarily express the views of the Publishers or the Editor.

While every care has been taken in the preparation of this publication, neither the Publishers nor the Editor are responsible for such opinions and views or for any inaccuracies in the articles.

© 2023. The entire contents of this publication are protected by copyright. Full details are available from the Publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, mechanical photocopying, recording or otherwise, without the prior permission of the copyright owner.

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY Published by Global Business Media Global Business Media Limited 62 The Street Ashtead Surrey KT21 1AT United Kingdom

+44 (0)1737 850 939

+44 (0)1737 851 952

Switchboard:

Fax:

Contents Introduction 2 Tom Cropper, Editor Reliable Gas Turbines: Optimal Propulsion 3 Choice for Sophisticated Naval Combatants Brien Bolsinger, GE’s Marine Solutions, Evendale, Ohio, USA Trends Select Size Needed Benefits and Experience Through Life Cost Customized In-Service Support Advances/New Technologies Conclusion What Marine Forces Need 8 Tom Cropper, Editor A Difficult Period The Environment New World, New Challenges The Rise of Electrical Warships 10 James Butler, Staff Writer Going Electric A Hybrid Solution Market Growth Choosing the Next Generation 12 of Propulsion Technologies Jo Roth, Staff Writer Teething Problems Big Investment, Big Risk Experience Counts Finding the Next Generation of Technologies 14 Tom Cropper, Editor The Future Warship What Does the Future Hold? Aversion to Risk References 16 WWW.GLOBALBUSINESSMEDIA.ORG | 1 Optimising Propulsion for Naval Vessels and the Role of Advanced Gas Turbine Technology TECHNICAL STUDY Published by Global Business Media Reliable Gas Turbines: Optimal Propulsion Choice for Sophisticated Naval Combatants What Marine Forces Need The Rise of Electrical Warships Choosing the Next Generation of Propulsion Technologies Finding the Next Generation of Technologies

THROUGHOUT THE last hundred years the development of marine propulsion has been a story of continual, gradual evolution punctuated by major leaps forward. Today, it’s in need of another, as it looks for a sustainable high performance option for modern operations.

Major advances often come about through necessity. A need for greater durability and superior fuel efficiency sparked the transition from steam to diesel and gas turbines in the seventies. Today, the drive is for cost efficiency, higher performance and lower emissions.

In our opening article, Brien Bolsinger of GE’s Marine Solutions, talks about the next stage of development. Increasingly, he says, navies are moving towards hybrid propulsion systems from a combination of gas turbines and electrical power.

We will then look at why this change is necessary. Money is tight for Western military powers, while they are also looking for solutions which are more environmentally friendly. The next generation of propulsion systems need to be more efficient, affordable and offer higher performance.

As Jo Roth then learns, such solutions can come at a higher price. Many new build projects still rely on diesel

– it may be dirty, it may be inefficient, but it comes with a lower upfront price and is also familiar to engineers. He outlines the key benefits next generation systems can offer, and the most important things buyers should take into consideration when choosing how to propel new vessels.

James Butler then looks at the rise of electric/ diesel hybrids and shows how they are being used to power some of the most technologically advanced warships in existence.

Finally, we will look at what the future holds. From nuclear power to high tech fuel cells, the long term future is full of exciting prospects. Making them all work will be an altogether different challenge.

In determining the propulsion method of their next generation warships, navies are adopting a diverse range of propulsion systems. The challenge for buyers is to get the ideal system for their needs while developers need to prove that theirs offer the very best solution fozr the future.

Tom Cropper Editor

Tom Cropper has produced articles and reports on various aspects of global business over the past 15 years. He has also worked as a copywriter for some of the largest corporations in the world, including ING, KPMG and the World Wildlife Fund.

NEXT GENERATION HELMET MOUNTED LIGHTING SOLUTIONS FOR MODERN MILITARY OPERATIONS

Introduction

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY 2 | WWW.GLOBALBUSINESSMEDIA.ORG

Reliable Gas Turbines: Optimal Propulsion Choice for Sophisticated Naval Combatants

Brien Bolsinger, GE’s Marine Solutions, Evendale, Ohio, USA

TODAY’S NAVIES seek the most costeffective ship hull and machinery to accommodate sophisticated radar, communications, electronic weapon systems and other mission critical equipment. With a typical warship life span of 30+ years, navies must consider acquisition costs, propulsion system reliability and redundancy, as well as long-term operational support and maintenance expenses. Thus it’s crucial to look at the ship’s mission profile and select the most cost effective propulsion system architecture with the appropriate number, size and type of prime movers and/or generator sets. After all, the propulsion system is the heartbeat of the ship; without it online, the ship is dead in the water.

Trends

In peaceful times at sea coupled with the drive to reduce costs, it is still important to heed lessons learned from the past. The need remains for propulsion system redundancy, reliability and high top end speeds. This cost reduction trend can clearly be seen in the move to single gas turbines in recent combined diesel and gas turbine or gas turbine hybrid ship designs. This results in 60% to 70% of the ship’s propulsion power being

derived from a single unit. Although this solution may be more cost effective, it does not serve sailors well in time of war because it impacts propulsion system reliability and ship availability.

The other key factor in reliability of the propulsion system is the selection of proven technology. Using state of the art equipment can come with a heavy price if proven unreliable. Remembering that the ship and the propulsion system enables the mission, demonstrated reliability in all environmental conditions needs to be first and foremost.

Navies are continuing the move from combined diesel and gas turbine propulsion to adopting hybrid configurations using electric propulsion motors with gas turbines for top end speed, to improve overall efficiency and increase operational flexibility. These power-dense solutions using gas turbines and efficient motors, reduce noise, vibration, offer additional ship service power and provide for a quieter warship power and propulsion system.

To illustrate, GE’s LM2500+G4 marine gas turbines were recently selected to power the Italian Navy’s new Pattugliatori Polivalenti d’Altura (PPA) multipurpose offshore patrol ships. GE’s contract is for seven LM2500+G4 gas turbines. GE’s marine gas turbines are modified jet engines

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY WWW.GLOBALBUSINESSMEDIA.ORG | 3

As Environmental Control Areas increase globally in number and size, the commercial shipping industry is adopting various emissions control technologies to meet worldwide requirements

offering the same compact size, power, superior reliability and ease of maintenance of their aircraft engine predecessors.

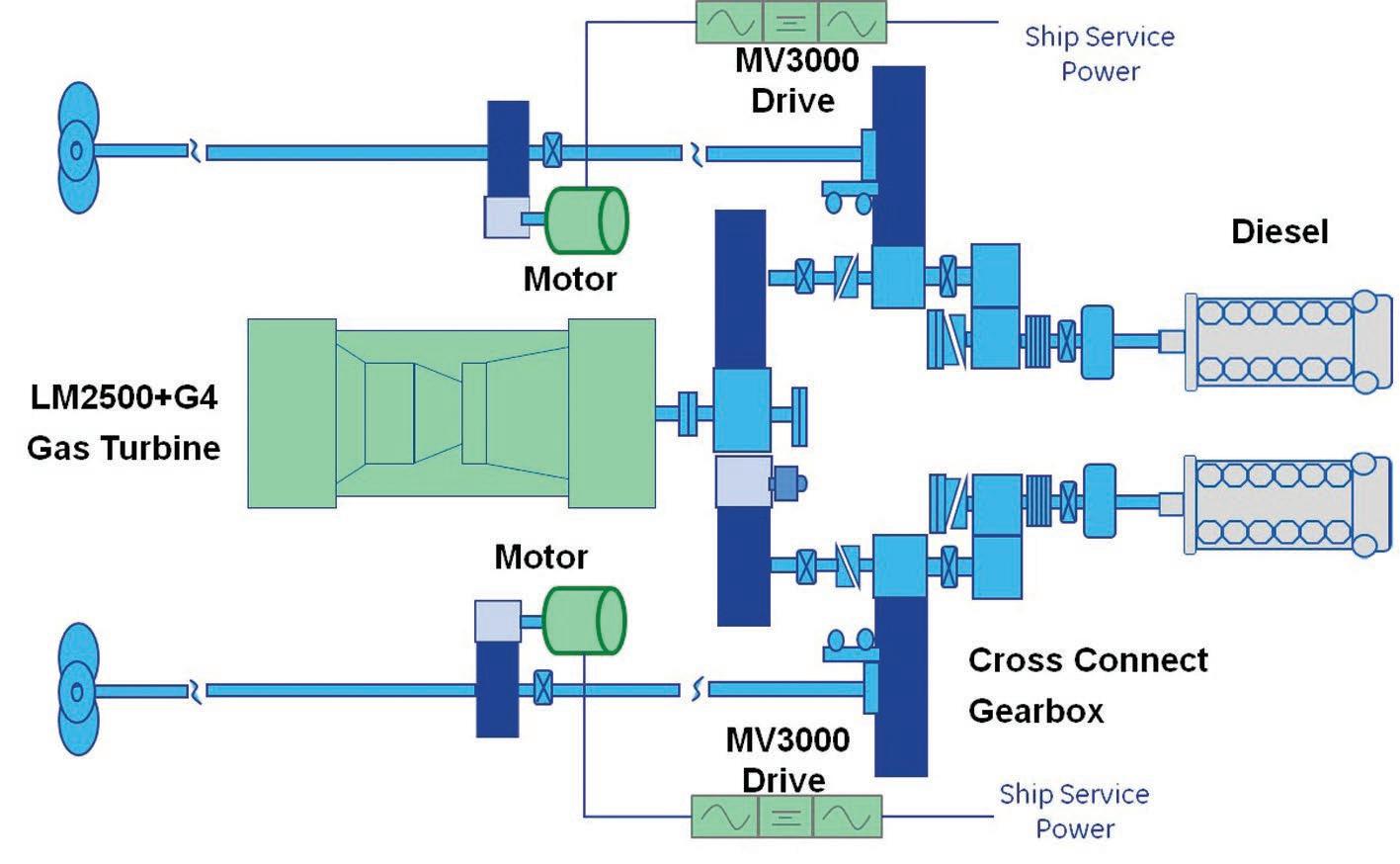

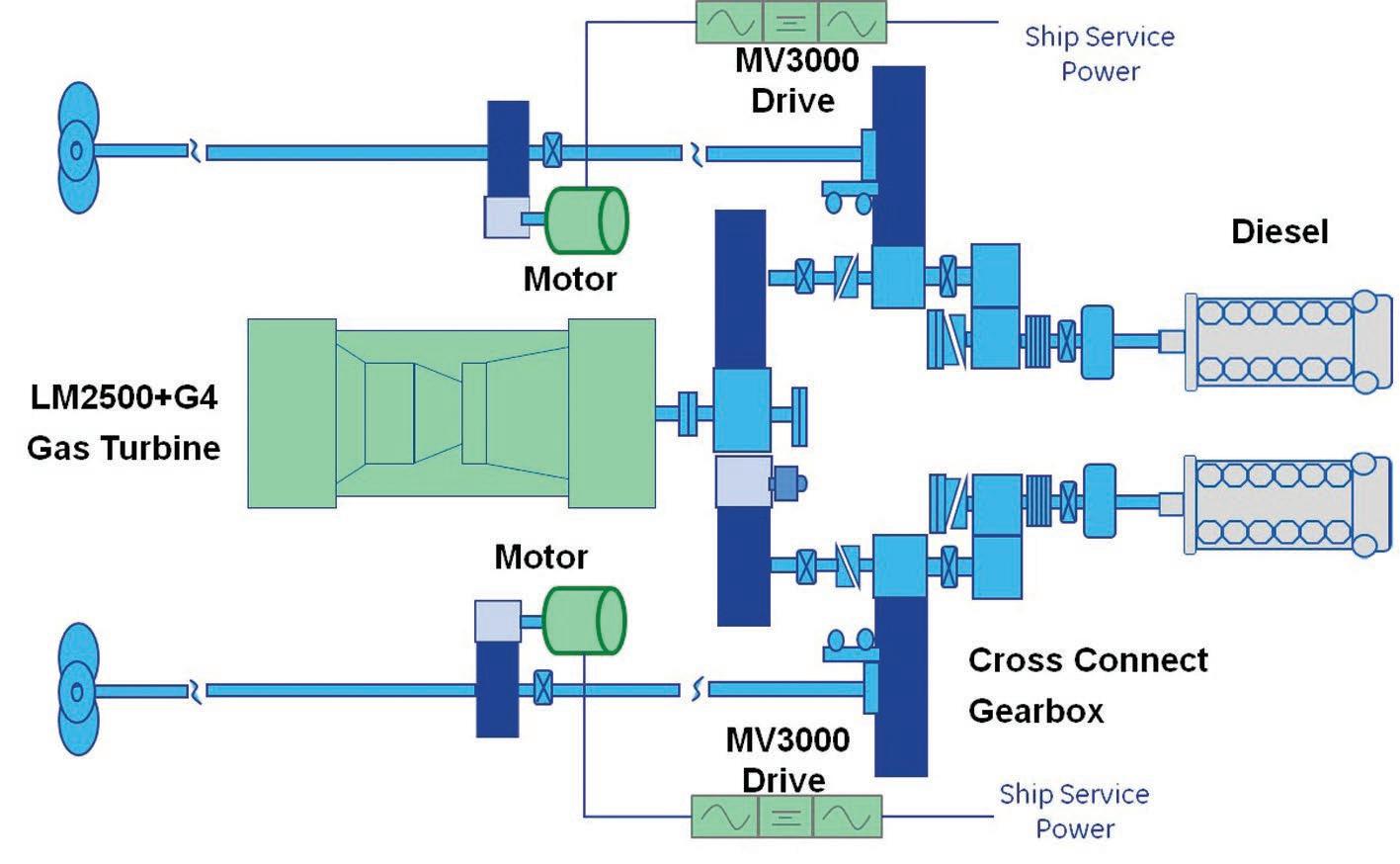

The PPA’s flexible and unique hybrid propulsion plant (shown above) will feature small gearbox mounted motors and GE motor drive for low speed operations, two propulsion diesels for mid-speed service and the LM2500+G4 gas turbine to reach 31+ knots. GE also will be responsible for the electrical system integration of the hybrid system.

The same LM2500+G4 gas turbine powers 20 new European Multi-Mission FREMM frigates for the Italian, French, Egyptian and Moroccan Navies. FREMM’s hybrid propulsion system includes one LM2500+G4 gas turbine, two 2.1 megawatt (MW) electrical motors providing propulsion power and four diesel generating units.

The German Navy’s new F125 frigates feature a hybrid propulsion system with one LM2500

The United States Navy’s amphibious assault ships LHA6 USS AMERICA and LHA7 TRIPOLI (under construction) -- along with LHD8 USS MAKIN ISLAND -- feature the best of GE’s power and propulsion technologies: two LM2500+ directdrive marine gas turbines and an auxiliary electric propulsion. This hybrid configuration enables the ship’s crew to choose the most appropriate, effective and efficient form of propulsion for each operating scenario. Thanks to the ship’s overall efficiency, the U.S. Navy anticipates fuel savings to exceed $250 million over the life of the ship.

In fact, GE’s gas turbine and/or motor and drive technologies are installed on most of the military hybrid propulsions ships in service today. GE can provide an array of propulsion system design and integration services to support next generation ship programs.

As Environmental Control Areas increase globally in number and size, the commercial shipping industry is adopting various emissions control technologies to meet worldwide

SPECIAL REPORT: MARINE PROPULSION: EXPLORING NEW TECHNOLOGIES 4 | WWW.DEFENCEINDUSTRYREPORTS.COM

These power-dense solutions using gas turbines and efficient motors, reduce noise, vibration, offer additional ship service power and provide for a quieter warship power and propulsion system

UNITED STATES NAVY’S USS MAKIN ISLAND COURTESY OF US NAVY - PETTY OFFICER 1ST CLASS MATHEW J. DIENDORF

ITALIAN NAVY’S PPA PROPULSION SYSTEM SCHEMATIC (GE COMPONENTS IN GREEN)

requirements. In a similar manner, navies are considering options for compliance. On land, selective catalytic reduction equipment is widely used for emissions controls. However, this system comes with a high monetary cost in both acquisition and life cycle, requires a lot of space in the exhaust superstructure, is quite large and needs space to carry and store urea. Adapting these land based systems to marine applications is emerging now.

GE’s proven gas turbine Dry Low Emissions (DLEs) combustion system achieves both low NOx and CO simultaneously and can meet IMO Tier 3 emissions levels today by controlling gas turbine firing temperature over its power range. GE’s DLE technology has been successfully deployed on GE’s industrial aeroderviative gas turbine fleet for more than 20 years.

Select Size Needed

GE’s family of proven gas turbines can provide the optimal propulsion system solution, offering a wide range of power outputs from 6,000 to 70,275 shaft horsepower (shp)/4.5 to 52MW (see Table 1). These gas turbines allow naval architects to deliver the required performance while most cost effectively meeting all of the ships’ operational requirements. All reliably operate in some of the most arduous conditions in temperatures ranging from -40o to 120oF/-40o to 48oC.

Currently there are more than 1,300 GE gas turbines logging over 14 million hours, serving 34 navies the world over. GE engines power some of the world’s most sophisticated surface combatants and can be found on 500 naval ships for 100 military ship programs including patrol boats, corvettes, frigates, destroyers, cruisers, supply and amphibious ships and aircraft carriers.

Benefits and Experience

Gas turbines offer navies numerous benefits. For a warship, power density is key. Less propulsion system volume and weight means more availability for combat systems – the primary function of warships. One GE LM2500 aeroderivative marine gas turbine is 78% lighter on a weight basis compared to an equivalent amount of high speed diesel power. This power density offers

great flexibility as to where the propulsion system is placed onboard when driving a generator, requires reduced structural steel to support the system within the ship, and frees up more space.

Other benefits of using gas turbines in any propulsion system configuration include:

l Reduced life cycle costs:

o Fuel economy

o Improved reliability

o Reduced maintenance

o Improved propulsion system availability

l Increased operational flexibility

l Configuration flexibility for maximum system availability/redundancy

Through Life Cost

Beyond efficiency, through life cost is driven by reliability and time between overhaul and maintenance of equipment. The LM2500 requires approximately 300 man hours per year for preventive maintenance. For proper operation, tasks include filter changes and checking fluid levels. Similarly, the majority of infrequent corrective maintenance tasks can be accomplished by ship technical and maintenance staff after completion of only moderate training.

For example, GE’s largest marine customer -- the U.S. Navy – has more than 460 LM2500 engines in service. On average each U.S. Navy LM2500 gas turbine will exceed 25,000 operating hours until overhaul (the average LM2500 customer will overhaul an engine typically once in the life of the ship). An added benefit is engine commonality across platforms within a navy to reduce training, logistics and spares inventory.

GE’s “on condition” maintenance philosophy means that engine overhaul is not time-limited, but arranged when necessary as revealed during a regularly scheduled inspection. When an engine overhaul is required, the gas turbine is removed and replaced by a spare unit, usually within 24 hours, quickly returning the ship to service. Overhaul of the removed asset is not performed in-place onboard the ship, but under shop conditions at a land-based depot facility. This maintenance philosophy, combined with very high reliability and a compact, easy to remove design, yields increased ship availability. Since no rotors are separated, installed gas turbine performance

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY WWW.GLOBALBUSINESSMEDIA.ORG | 5

Another through life cost consideration is the availability of parts, services and support over a warship’s threedecade-long life span

and vibration are as demonstrated in the depot test cell.

With a global installed base and service network, operators can be confident of exceptional OEM support wherever they sail. In addition to deployable technical representatives, GE is a leader in local cooperation for naval and commercial ship support, including Level IV depots in USA, Germany, Italy, Korea, Japan, Spain, Australia/New Zealand and India.

Another through life cost consideration is the availability of parts, services and support over a warship’s three-decade-long life span. Since GE’s aeroderivative gas turbines are used in a plethora of other applications, a robust inventory of parts and support services is available throughout the world. The LM2500, for example, has an annual production volume of nearly 200 engines for applications such as military and commercial marine, power generation, cogeneration, pipelines and offshore platforms.

Customized In-Service Support

Naval customers also can benefit from GE’s customized in-service support agreements to provide predictable gas turbine maintenance costs and lower total cost of ownership -- all with the aim of ensuring optimum fleet readiness.

Consider the Royal Canadian Navy (RCN) where GE developed a customized maintenance support agreement that covers the 24 LM2500 gas turbines that power 12 of the RCN’s HALIFAX-class frigates. GE is now in its 15th year on contract for the RCN. The RCN reaps many benefits, most notably the impressive availability of the LM2500 which averages 99.85% over the contract.

This contract includes immediate onsite technical support 24-hours-a-day, 7-days-aweek, as well as:

l Repair, overhaul and engineering support

l Parts warehousing and inventory management (including spare engines, supply of spare parts and replenishment of inventory)

l Field service representative support (home port and deployed)

l Support of RCN naval engineering school training curriculum for on-engine and equipment maintenance

l Operational level maintenance

l Configuration management

l Supply and distribution of technical manuals

Because of the contract with GE, the RCN can dedicate resources to other equipment and maintenance tasks. The RCN has witnessed a decrease in administrative functions including procurement, inspection, technical support, and material and inventory management associated with the LM2500. The RCN also sees considerable benefits from the contract’s spare LM2500 inventory control features.

Using the successful RCN agreement as a model, GE also developed an agreement with the Royal Australian Navy (RAN) to provide inservice support for the LM2500 gas turbines that power the RAN’s ADELAIDE- and ANZACclass frigates. This multi-year contract covers repair and overhaul of the RAN’s 16 LM2500s and associated accessories, as well as depot level maintenance to be performed by Air New Zealand Gas Turbines (an authorized LM2500 service center and longtime RAN service provider).

GE will provide program management and on-site field service support, and will handle warehouse

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY 6 | WWW.GLOBALBUSINESSMEDIA.ORG

GE engines power some of the world’s most sophisticated surface combatants and can be found on 500 naval ships for 100 military ship programs including patrol boats, corvettes, frigates, destroyers, cruisers, supply and amphibious ships and aircraft carriers

NAVIES CAN BE CONFIDENT OF EXCEPTIONAL SUPPORT FROM GE ONBOARD OR AT A DEPOT WHEREVER THEY SAIL

and inventory management including spare parts and inventory replenishment throughout the life of the contract.

Advances/New Technologies

GE ensures that its gas turbines meet the everchanging needs of its customers, either by making advances to existing equipment or by introducing new technologies to improve overall performance. Some examples follow below:

l GE’s LM6000PG marine module is now certified by Lloyd’s Register and RINA Services following thorough testing which resulted in the module achieving 42 MW. The tests confirmed the quality, compact size, small footprint, low noise and vibration characteristics and the overall performance of the LM6000PG module package. The new PG package is based on highly successful GE Oil & Gas designs that have been used in offshore applications for more than 22 years. The engine inside the package is not new; it is identical to the industrial variant that has logged more than 30 million operating hours. The LM6000PG package is ideal for marine applications including military combatants and offshore projects where space is at a premium.

l LM2500 Module Modernization Program (MMP) now underway with General Dynamics Bath Iron Works and the U.S. Navy will inject updated technology into the gas turbine module enclosure system and reduce enclosure weight by approximately 50% (excludes base structure). This infusion of new technologies will improve the manufacturing and maintainability of the LM2500 marine module, while reducing module weight, noise, radiated heat – and most importantly – life cycle costs. The new marine module will meet global naval requirements, including Mil 901D shock. Once available in 2018, this lightweight design can easily be applied to LM2500 family gas turbines used by other international navies.

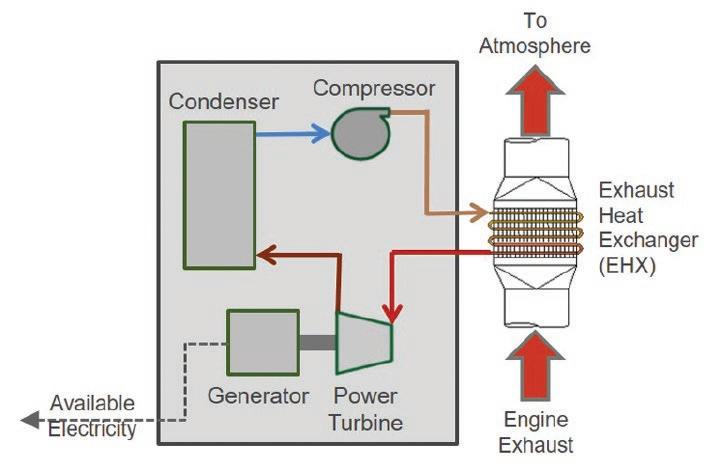

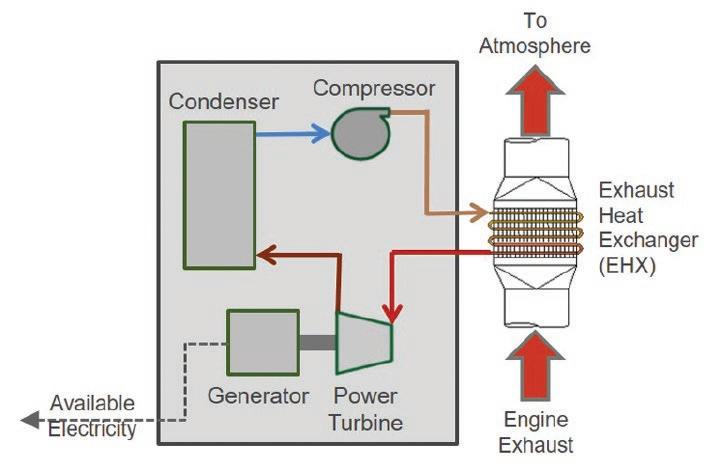

l Exhaust energy-recovery-to-power products developed by Echogen Power Systems are offered exclusively to the marine market

by GE. These products capture the heat inherent in the gas turbine or diesel engine exhaust stream and turn it into electricity. Echogen’s system uses CO2 in a closed loop arrangement, and allows for a more compact, lighter and economical configuration than traditional steam systems. Converting energy that traditionally gets exhausted out of a stack into useful power allows the overall system thermal efficiency to increase to near 50%.

Currently, two different models are under development. The 8 MW unit completed prototype testing (see picture below), where all objectives were met. This size unit is ideal for putting behind an LM2500 gas turbine. In addition, the 1.5-MW, ship-specific solution under development has been granted approval in principal from ABS. This unit fits well with diesel engines in the 12 MW to 15 MW power range or behind a smaller gas turbine like the 4.5 MW GE LM500.

Conclusion

GE’s power dense marine gas turbines reliably log millions of operating hours worldwide in arduous conditions and fluctuating temperatures. These engines also offer ship designers the flexibility as to where the propulsion system is placed onboard. Thus reduced structural steel is required to support the system within the ship, freeing up more space.

GE marine gas turbines are easily maintained and are backed by GE’s global network of authorized service providers. Navies can rely on GE’s family of gas turbines as the optimal propulsion system solution to best match mission operating requirements. ###

Brien Bolsinger is Vice President, Marine Operations, GE’s Marine Solutions; he is based in Evendale, Ohio; brien.bolsinger@ge.com

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY WWW.GLOBALBUSINESSMEDIA.ORG | 7

ECHOGEN EXHAUST-TO-POWER SYSTEM ECHOGEN UNIT ON TEST

Navies can rely on GE’s family of gas turbines as the optimal propulsion system solution to best match mission operating requirements

What Marine Forces Need

Tom Cropper, Editor

A new military age requires a new revolution in military marine propulsion

WESTERN MILITARY forces seem to come under pressure continually from all quarters. The demands of future warfare call for higher performance and greater reliability while the reality of market forces call for lower spending and increased efficiency. Although conventional propulsion systems have undergone periods of modest evolution, all indicators suggest this will not be enough for the future. The good news is that new technologies are coming to the fore, which can help navies cope with these challenges.

A Difficult Period

Western militaries are at a point of transition. After ten years of continuous action encompassing both the Afghan and Iraq wars and the ongoing war on terror, they are moving towards a period of what, they hope, will be comparative peace. That, coupled with the post 2008 trend toward austerity in government spending, has led to a period of retrenchment in budgets. For Treasuries tasked with finding billions of pounds’ worth of savings, fat military budgets were ripe for cutting. Those cuts have been savage.

Between 2010 and 2015 the government cut UK military spending by 15%. So great had been the cut in personnel that, according to a report by the Chatham House Think Tank, the army might not have enough soldiers to use the state of the art military equipment which had already been ordered1. Cuts reduced the Royal Navy to just 19 warships2

A majority of NATO countries seem set to miss their agreed target to spend 2% of their GDP on the military, while even the world’s largest spender on the military, the US, has cut its budgets. In November 2015, Congress agreed to cut $5bn from the defense budget.

All these cuts lead to a greater emphasis on propulsion systems which can reduce the total cost of operation. These costs stem from the initial purchase, to ongoing fuel usage and reliability. Navies will look at through-life costs calculated by how often a system needs maintenance, the time between overhaul and the overall life expectancy of a system. The next

generation of propulsion systems will have to be affordable, fuel efficient and reliable.

The Environment

Fuel efficiency also cuts into another major priority – the environment. The armed forces, including the Navy, are coming under scrutiny across the board. In 2015, environmental protection groups brought law suits over the impact of sonar testing on whales3. The Department of the Navy publishes a regular environmental impact statement to monitor its effects on ecosystems and to demonstrate attempts to minimize any negative impacts.

The last ten years have seen an increase in climate change regulations such as MARPOL Annex VI, designed to prevent air pollution from ships. The Energy Efficiency Design Index on new ships places increased emphasis on energy efficiency in the design of new ships, while the number of environmental control areas in oceans around the world is increasing. However, military ships are “public vessel” and exempt from MARPOL Annex VI and not governed by Energy Efficiency Design Index. Governments might comply but are not required to so. All shipping – whether commercial or military – must conform to stricter emissions guidelines. Many existing propulsion systems will become increasingly unsustainable both from an economic and financial perspective. With more regulations likely to come into force over the next ten years, the onus will be on designers to produce cleaner, more efficient propulsion mechanisms.

Stricter regulations and standards are contributing to growth in the marine propulsions market as demand grows for low emission options. Research and Markets predicts the global marine propulsion engine market to grow by 4.2% CAGR up to 20204. A key factor in this growth has been the rise in the use of Liquefied Natural Gas (LNG) systems which offer a low emission advantage over diesel. Equally, the report predicts rapid growth for hybrid marine propulsion systems. As the report notes, many ports and authorities are

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY 8 | WWW.GLOBALBUSINESSMEDIA.ORG

Western militaries are at a point of transition. After ten years of continuous action encompassing both the Afghan and Iraq wars and the ongoing war on terror, they are moving towards a period of what, they hope, will be comparative peace

“

establishing standards for vessels which operate in certain areas, which means all ship operators – whether commercial, industrial or military – will have to make changes to comply.

New World, New Challenges

Along with the need for higher fuel efficiency, the old imperatives of performance and speed still apply. Military vessels need to be able to provide highly reliable operation, in all environments, from the frozen Arctic to the heat of the Gulf. They must be fast, quiet and agile, which places an enormous burden on performance specifications.

The global geopolitical environment is also becoming more complex and demanding. Deployments in Afghanistan and Iraq may have come to an end, but they are being replaced by the crisis in Syria, where war ships are being deployed to back up ongoing air strikes.

An increasingly aggressive Russia and China also create new threats. While NATO powers have been cutting military spending, both Russia and China have been rapidly expanding theirs5. NATO has boosted its own maritime defenses in the

East to counter increased Russian aggression, and key countries such as the UK have started to reverse their recent trend of spending cuts. Navy deployments continue off the coast of Africa where warships protect commercial shipping from pirates.

When looking to this future, marine forces are investigating a range of short and long term options. In the short term, it looks towards advanced propulsion systems such as hybrid gas turbine, which can provide significant improvements to the existing fleet. In the long term, it focuses on concepts such as nuclear power, biofuels and fuel cells. The choice of propulsion will be an extremely important decision. An inefficient engine can lead to millions of dollars in overspend compared with some of the latest systems. However, there is a wide gap between the understanding and outlook of buyers. Calculating the true cost of an engine system over the course of its lifecycle can be difficult. New and unproven technologies may be attractive, but they also represent a risk. Even so it’s one the Navy will have to take if it is to equip its ships for the modern world.

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY WWW.GLOBALBUSINESSMEDIA.ORG | 9

THE ITALIAN NAVY’S FREMM MULTIPURPOSE FRIGATE IS POWERED BY A GE LM2500+G4 GAS TURBINE-BASED SYSTEM (BY COURTESY OF FINCANTIERI S.P.A. – ALL RIGHTS RESERVED)

Along with the need for higher fuel efficiency, the old imperatives of performance and speed still apply. Military vessels need to be able to provide highly reliable operation, in all environments, from the frozen Arctic to the heat of the Gulf

The Rise of Electrical Warships

James Butler, Staff Writer

Navies are looking for viable alternatives to provide propulsion. Can combined gas turbines offer an effective solution?

BOTH GAS turbine and diesel based engines have played a vital role for the Navy for decades. Diesel power is familiar with a host of engineers already highly trained and skilled. Gas turbines are small, compact and powerful – just the solution for military vessels of all kinds. Over the years, the designs have been updated and honed to perfection. Undoubtedly, there will be more to come with future updates, but the Navy is in need of a revolution, not just evolution. The military needs engines which can operate in a wider range of locations and environments, offer superior power and performance while reducing energy consumption and environmental impact. It is looking to boost power, endurance and speed while simultaneously achieving a huge improvement in fuel efficiency.

Going Electric

The solution, many feel, could come from combined gas turbine and electrical propulsion systems. Electrical motors can provide power for ship board operations, weapons and low speed cruising, while gas turbines provide power for higher speeds. Although they may come with a higher upfront cost than diesel engines, gas turbines offer a lower through life cost as a result of reduced maintenance requirements, increased reliability and greater fuel efficiency. They also offer greater system flexibility and can be used in a range of configurations for maximum efficiency. Gas and electric combos represent an ideal option for warships by offering a high power density ratio. They take up a relatively small space on board a ship compared to the power they deliver, reducing the weight and providing more room for weapons systems.

When combined with an experienced and established provider, they can be configured to match the specific needs of any individual warship. The US Navy amphibious assault

ship, the USS Makin for example, uses a hybrid propulsion system supplied by GE. It comprises two GE LM2500+ Gas turbine direct drive power units and GE’s own auxiliary electric propulsion system.

The LM2500 series has been a staple offering from GE since the 70s. Since then it has been continually updating and improving its technology and the plus model represents the next step. GE estimates a 20% improvement on power output at a simple cycle thermal efficiency of 39%.

The vessel can pick and choose the most appropriate propulsion method depending on its requirements. For example, when idling, propulsion and ship board systems can tick over quietly through the electrical motor. However, if they need more speed, the gas turbines kick in. It’s a flexible system which provides as much or as little power as needed in any given scenario.

When compared to conventional gas turbines or diesel engines, a combined system will cost more up front. However, it produces real savings in terms of ongoing costs. Fuel consumption is lower, installation simpler and maintenance requirements less frequent. After the ship’s maiden deployment, its fuel savings were calculated at $15million over a seven-month period. The US Navy anticipates life time fuel savings in the region of $250million6

A Hybrid Solution

Earlier this year, the Italian Navy selected a similar system from GE for its new Pattugliatori Polivalenti d’Altura (PPA) multipurpose offshore patrol ships. These innovative hybrid ships are designed to combine the functions of a multipurpose frigate with those of an offshore patrol vessel, all within a single vessel. They will use GE’s LM2500+G4 turbines together with a shockproof MV 300 electric power converter. Again the electrical motor powers propellers for low speed propulsion while gas turbines provide

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY 10 | WWW.GLOBALBUSINESSMEDIA.ORG

When compared to conventional gas turbines or diesel engines, a combined system will cost more up front. However, it produces real savings in terms of ongoing costs

additional propulsion power when needed. The PPA also has the ability to provide 2MW of power directly to the shore.

GE has also recently provided equipment for vessels in Japan, the UK, US, Europe and elsewhere in the world. With the number of installations increasing and proving successful, confidence is growing in the concept of hybrid turbine/electric power. These systems are proving themselves in all conditions over a prolonged period of time. Project by project they are demonstrating their worth and the more they do so, the more quickly this space will accelerate.

The market is in a highly receptive state. Budget cuts, combined with recent volatility in fuel markets, and the drive towards environmental sustainability increase the need for fuel efficiency

Market Growth

Cost pressures, the need to maximize space, fuel efficiency and power usage all cause navies to play close attention to hybrid systems. Electrical power is already making great progress. A report from Research and Markets predicts that

the electrical marine vessel market will grow to $6.3bn by 2024, up from $2.6bn in 20147 Hybrid systems enable larger vessels to optimize their power output taking advantage of electrical energy savings, and this market is also growing. A recent report predicts it to reach $4.4bn 2022, growing at a CAGR of 8.02%. The report puts the growth down to soaring demand for flexible power systems, fluctuating energy prices and cost pressures8. As the technology matures and familiarity increases, there is every chance uptake will increase rapidly.

There is no uniform approach to future propulsion technology. Many are looking back and commissioning new build ships based on older but well proven diesel or gas turbine designs. They’re familiar, trusted and have a lower up-front cost. Others are looking to the future and planning for high tech fuel cells or nuclear powered marine vessels. Hybrid gas and electric technology, though, is something which is available today and can provide a step forward in reliability, efficiency and affordability. This is what makes it one of the most attractive technologies on the market.

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY WWW.GLOBALBUSINESSMEDIA.ORG | 11

THE LM2500 IS GE’S MOST POPULAR MARINE GAS TURBINE, USED BY 34 NAVIES WORLDWIDE.

Cost pressures, the need to maximize space, fuel efficiency and power usage all cause navies to play close attention to hybrid systems

Choosing the Next Generation of Propulsion Technologies

James Butler, Staff Writer

The drive is on to find the next generation of military marine propulsion systems, but making it work in the real world can be difficult.

NAVIES ARE looking to develop a new generation of propulsion systems capable of longer endurance, higher speeds and greater efficiency. However, innovation always comes with a risk. Just ask the UK Ministry of Defence.

Teething Problems

Earlier in 2016 they were forced into an embarrassing admission. Their £1bn Type 45 warships featuring a cutting edge propulsion system had a tendency to break down, especially if they were sent into warmer waters such as those found in the Gulf or off the coast of Africa, where they are frequently deployed to combat piracy.

The T45s feature a next generation Integrated Electric Propulsion (IEP) system which uses a combination of diesel generated AC power and gas turbines to power all shipboard operations including lighting, heating and propulsion. The system is designed to be more fuel efficient and operate with a reduced heat signature, making the warship harder to detect.

However, the inter-cooler has a critical design flaw which can cause the gas turbines to fail. When that happens, the electrical load on the generators becomes too great, causing them to trip out. The problems first arose when a Type 45 warship broke down in the Atlantic in 2010 and was forced to be repaired. The systems use a combination of gas turbines and diesel generated AC current to power the ship. They were designed to be more fuel efficient and operate with a lower heat signature, in every area of the world, from the Arctic to tropical climates. For the most part they do, but they are vulnerable to total electronic failures which can shut down everything on board the ship including propulsion. Such problems present clear and obvious safety issues, especially if operating in a hazardous combat environment.

The MOD has described the issues as ‘teething problems’ but such failures not only cause embarrassment, they also make it harder for new technologies to gain acceptance. One of the most startling new boat designs is the so-called Stealth attack boat called ‘Ghost’. Invented by Gregory Sancoff and described as the ‘attack helicopter of the sea’, this remarkable design emulates the angular shape of the Stealth Bomber and is also designed to be hard to spot on radar. Although attracting interest from around the world including the US, Europe and Asia, procurement officers have still expressed serious reservations. In 2014, Sancoff admitted that the US military were wary of working with small enterprises such as his9, and buyers would always be wary of highly innovative approaches which strayed too far from convention.

Big Investment, Big Risk

These reservations are understandable. Investment in the next generation of propulsion systems is a billion-dollar proposition. The military has a track record of spending huge amounts of money on new age designs which proved to be flawed. With financial constraints placing tighter restrictions on where and how military organisations can spend their money, propulsion systems based on recognised and accepted technologies have a distinct advantage. Traditional diesel based systems may be expensive and environmentally unfriendly, but they do have familiarity on their side. Demonstrating their value and overcoming that initial suspicion could be one of the key factors in success for future generation vehicles.

So how do companies do that, and how will buyers decide which system to use?

Trust and reliability will play a major role. Those companies which have a proven track record of providing high quality systems will find themselves at a considerable advantage.

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY 12 | WWW.GLOBALBUSINESSMEDIA.ORG

When choosing a propulsion system, a buyer will benefit from looking at what customer support services are on offer

Buyers will instinctively be more comfortable working with them. That’s not to say innovative start-ups do not have a place. They do. Innovation is critical to the future development of marine propulsion systems and small start-ups are a fertile breeding ground for new age ideas. A route forward for such organizations could be to partner with a larger, more established, company to deliver the scale required to take an idea from concept to implementation.

Experience Counts

Experienced companies can also provide a superior array of support services. They can work closely with each client to tailor a system to the unique requirements of the project. Ongoing support will be readily available as will spare parts for maintenance and repair. In other words, the supplier can often be as important as the technology itself. When choosing a propulsion system, a buyer will benefit from looking at what customer support services are on offer.

Buyers will need to be clear on what they need the new systems to do. For example, with the growth of longer range weapon systems, will vessels still have the same emphasis on speed as they do now? How much will a system cost overall? In factoring this in, buyers will look at total operational life expectancy, as well as the performance specifications they need any new system to deliver.

In delivering the power and performance levels required, a great deal of attention has focused on IEP propulsion systems such as those used by the much maligned T45s. This has been in

development for many years, but is only now gaining attention. As well as the Royal Navy’s T45s, the US Navy’s DDG 1,000 Zumwaltclass destroyers are also making use of an innovative electric propulsion system. The hope is to use a single power source to drive both weapons, shipboard operations and propulsion. The ship will therefore use a single source operating at maximum output where it is most efficient rather than several power outputs which are less efficient.

However, the difficulties faced by the T45 and the fact that this is still a new and emerging technology mean navies around the world are often adopting different strategies. A number of new builds are still relying on diesel. They are rugged, familiar and feel like a safe option. Moreover, they have a slightly lower upfront cost than more advanced hybrid designs.

The future, though, could equally lie in an alternative hybrid model. A hybrid electrical system can be used with a combination of diesel electric and gas turbines. This uses diesel electric generators to provide power to the ship and weapons systems as well as an electrical motor to power the ship during slow running speeds. Gas turbines, meanwhile, are used to deliver increased power output for higher speeds. The advantages come through superior fuel efficiency as well as an extremely low acoustic signature when operating at low speeds.

There is, therefore, no single unified approach to the challenge of marine propulsion in the 21st century. Instead various navies are adopting a diverse range of options in the hope of delivering the gigantic step forward the Navy is looking for.

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY WWW.GLOBALBUSINESSMEDIA.ORG | 13

TYPE 45 DESTROYER RECOVERS LYNX HELICOPTOR

Those companies which have a proven track record of providing high quality systems will find themselves at a considerable advantage

Finding the Next Generation of Technologies

Tom Cropper, Editor

The search is on for the cutting edge technologies which will propel military marine vessels in the future.

IN1906 a new warship took to the seas which was so advanced it rendered all other military vessels obsolete. They called it the Dreadnought and it marked the first giant leap forward in military marine technology of the 20th Century. Now the name is back as developers seek to envision what the warship of the future could look like. In working towards that vision, propulsion will be front and center.

The Future Warship

Powered by steam, the original Dreadnought sparked a gigantic leap forward in terms of what was possible on the seas. The Dreadnought 2050 project seeks to emulate that jump. In many ways it is much like many other future military concepts: ambitious, eye catching and, in all probability, unrealistic. Like all concepts, it’s intended to focus minds on what could be achieved – not necessarily on what will be achieved. Nevertheless, its plans are striking.

Commander Steve Prest, the Royal Navy’s Fleet robotics officer explains the project:

“In 2013 the Royal Navy challenged the defense industry to innovate, and to generate new opportunities to give it an operational edge. We therefore welcome a project that allows some of Britain’s best and brightest young engineers to come up with ideas about what a warship might look like or be equipped with in 2050.”

The concept pictures certainly do make an impact: a sleek, powerful vessel capable of being run by just 50 personnel – down from current levels of 200. At the very top a futuristic looking control tower enables commanders to see what’s happening thousands of miles away10

Such concepts are undoubtedly fascinating, but on a more practical level, how will warships of the future such as the Dreadnought 2050 be propelled? The answer to that question will be critical to the future of military marine vessels.

What Does the Future Hold?

Before we begin to answer, we have to assess what exactly the Navy will need. Technology will have to be affordable and fuel efficient. The age of endless budgets is coming to an end. In a new era of financial austerity, new systems will be increasingly purchased on the basis of cost. That means something which is ideally affordable to buy, but most importantly offers low running costs. Systems will also have to be greener than ever before as more stringent regulations come in to reduce the carbon footprint of shipping.

In 2013 the Royal Academy of Engineering produced a report about alternative options of ship propulsion. It noted that a combination of international climate change agreements and an overall trend towards higher fuel costs could make current propulsion options unsustainable. It examined a number of short term options including:

• Diesel: It’s already widespread and well understood, with engine manufacturers possessing plenty of spare parts and expertise for maintenance. The technology is familiar with a good supply of skilled engineers and training facilities. However, it is dirty and expensive. The long term trend of diesel prices, despite recent volatility, is upwards, and it will always produce harmful emissions such as CO2

• Gas turbines: This high power density propulsion technology has proved popular in many areas of shipping especially the military. However, the fuel for aero-derivative gas turbines is costly compared to conventional fuels.

• Renewable energies: In a bid to spark incremental reductions in fuel usage and cost the marine industry has investigated options for renewable energies such as wind, solar and hydro. However, these are only auxiliary power supplies aimed at augmenting rather than replacing existing power systems.

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY 14 | WWW.GLOBALBUSINESSMEDIA.ORG

Work on nuclear powered marine propulsion has been underway since the 1940s. It offers a clean burning alternative to diesel – there is already a large body of experience in the building of nuclear marine propulsion

These can provide short term gains, but alternative propulsion methods will be critical to provide the gigantic leap forward needed. The report therefore looked into alternatives such as nuclear, biofuels and fuel cells.

Fuel cells have clear attractions. They are a long lasting, lightweight source of fuel which has no emissions other than water, offer good reliability and also the added benefit of near silent running – an important strategic consideration. They have already been used in lower power applications and for powering operations on board submarines, but there is potential in fuel cell propulsion systems. The best current example comes from the German U-212 attack class of submarine which uses an advanced air independent propulsion system for which fuel cell technology is integral.

Work on nuclear powered marine propulsion has been underway since the 1940s. It offers a clean burning alternative to diesel – there is already a large body of experience in the building of nuclear marine propulsion. However, as the report acknowledges, there would be obstacles. The process would require a complete overhaul, while it would also face considerable problems in the form of safety and public perception.

Other possibilities include biofuels – synthetic fuels based on higher alcohols and new types of E-coli and algae. However, more research is required into storage and the impact on health. Battery technology might offer some potential for smaller ships, while there has also been some movement in super-conductor electric motors. However, all these are medium to long term solutions and are some way from being ready for real life use.

Aversion to Risk

The future asks plenty of exciting questions, but the answers are, more often than not, somewhat mundane. Practicalities and realism tend to win the day, which is why exciting future concept designs are so often supplanted by more modest achievable systems. To meet its more immediate requirements, the Navy is looking for propulsion options which are available now and offer a viable solution for the next 50 years. Even these will need to make a gigantic leap forward. The Navy is under pressure to improve performance on all sides and this pressure is achieving results. The next generation of propulsion systems is already showing that they can be lighter, more powerful and more efficient – all of which will be critical in helping the Navy fulfil its obligations now and into the future.

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY WWW.GLOBALBUSINESSMEDIA.ORG | 15

GE’S LM6000PG GAS TURBINE MARINE MODULE, NOW CERTIFIED BY LLOYD’S REGISTER AND RINA SERVICES, IS IDEAL FOR MARINE APPLICATIONS INCLUDING MILITARY COMBATANTS AND OFFSHORE PROJECTS WHERE SPACE IS AT A PREMIUM

The future asks plenty of exciting questions, but the answers are, more often than not, somewhat mundane.

Practicalities and realism tend to win the day, which is why exciting future concept designs are so often supplanted by more modest achievable systems

References:

1 Defence Cuts Mean Military May Not Have Personnel to Operate New equipment: http://www.telegraph.co.uk/finance/newsbysector/industry/defence/11939458/Defence-cuts-mean-military-may-not-have-the-personel-to-operate-new-equipment.html

2 Royal Navy has 260 Captains for just 19 Warships: http://www.dailymail.co.uk/news/article-2465608/Royal-Navys-260-captains-just-19-warships-Defence-cuts-15-times-commanding-officers-vessels.html

3 US Navy to Limit Sonar Testing: http://www.sciencemag.org/news/2015/09/us-navy-limit-sonar-testing-protect-whales

4 Global Marine Propulsion Market:

http://www.prnewswire.com/news-releases/global-marine-propulsion-engine-market-growth-at-42-by-2020---growing-marine-hybrid-propulsion-market---research-and-markets-300272318.html

5 Russia and China Increase Military Spending: http://dailysignal.com/2016/04/11/russia-and-china-increase-defense-spending-while-us-continues-cutting/

6 Electrical Power and propulsion systems: http://www.gepowerconversion.com/industries/marine/power-and-propulsion

7 Electrical Marine Vessel Market: http://evworld.com/news.cfm?newsid=32099

8 Hybrid marine propulsion: http://www.transparencymarketresearch.com/pressrelease/global-marine-hybrid-propulsion-market.htm

9 Steal Boat may be too Innovative: http://www.bloomberg.com/news/articles/2014-08-21/juliet-marines-ghost-boat-will-be-hard-sell-to-u-dot-s-dot-navy

10 Dreadnought 2050: http://news.sky.com/story/dreadnought-2050-the-warship-of-the-future-10347816

OPTIMISING PROPULSION FOR NAVAL VESSELS AND THE ROLE OF ADVANCED GAS TURBINE TECHNOLOGY 16 | WWW.GLOBALBUSINESSMEDIA.ORG