FEBRUARY 2018

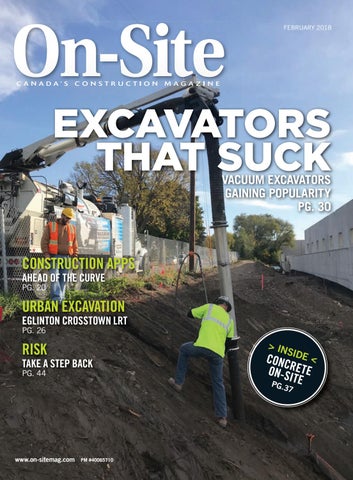

EXCAVATORS THAT SUCK VACUUM EXCAVATORS GAINING POPULARITY PG. 30

CONSTRUCTION APPS AHEAD OF THE CURVE PG. 20

URBAN EXCAVATION

EGLINTON CROSSTOWN LRT PG. 26

RISK

TAKE A STEP BACK PG. 44

> IN S CON IDE <

C ON-SRETE IT E PG. 37

www.on-sitemag.com

ONSITE_Feb18_LAZ.indd 1

PM #40065710

2018-02-08 3:12 PM