BEYOND AUTOMATION

Part 1. Recording Available Edge AI

Part 2. Recording Available AI-Powered CAD

Dive into AI at the edge and discover how today’s models are making AI faster, more scalable and creating greater accessibility for engineers across all industries—from robotics to automotive and beyond.

SPEAKER: Danilo Pau, Technical DirectorSTMicroelectronics

Jack Ferrari, Product Manager - Edge AI MathWorks

Discover how AI-driven design and simulation tools are accelerating innovation across industries.

SPEAKER: Nico Haag, Director, Simulation EngineeringPhysicsX

Théophile Allard, CTO & Co-Founder – Neural Concept

WHY REGISTER?

Part 3. LIVE SESSION

June 25, 2025 AI-Powered Inspection

Learn the advantages of using AI versus traditional techniques in industrial inspection and, the challenges OEMs face when adopting AI-based software.

SPEAKER: Bruno Ménard, Software Director, DALSA | Vision Solutions

Learn about practical strategies related to the integration of AI into your design and production processes.

Find out how trends in Edge AI, AI-powered inspection and AI-powered CAD/simulation are shaping manufacturing and product design. Hear directly from industry leaders about the real-world applications of AI in engineering—including live Q&As and the opportunity to engage in meaningful discussions following each session.

unlock exclusive access to all three webinars and their recordings. Gain valuable insights and content you won’t find anywhere else.

Sponsored by Presented by

DON’T MISS OUTREGISTER TODAY!

In the light of evolution

“Nothing in biology makes sense except in the light of evolution.” It’s a sentiment captured in the title of an essay written by geneticist and evolutionary biologist Theodosius Dobzhansky more than 50 years ago. In short, what Dobzhansky’s referring to is the fact that in order to understand something as it is today, we must first begin to understand its evolution and the forcing functions that have influenced its path through the years. Only then can we fully grasp the true nature of anything. Not so coincidentally, it’s also the only way by which we can look ahead and move forward – by gaining a full appreciation of where we are and how we got here.

It’s a sentiment that can be applied to this very publication, as this issue represents the first of many on which I’ll begin to leave my mark as Editor. As part of my learning curve, I’ve had to settle into a new, and absolutely fascinating, area of technical knowledge and expertise. To do so, I’ve opened myself up to as much information as I’ve been able to about the history of design engineering and machine building and the trends and advances that have helped shape their roles as we know them today.

On that note, within this issue we continue to celebrate 70 years of Design Engineering magazine, looking back at some of the breakthroughs and innovations that we explored within editions of the publication throughout the 70s and 80s. Having taken a step into the past, we leap back into the present and beyond, exploring the ways in which robotics and the advent of Physical AI have resulted in a groundbreaking technological fusion. We analyze the ways in which AI is being integrated into today’s CAD software, and the subsequent impacts it’s having on the work of design engineers and machine builders. And we sit down with auto electrification subject matter experts to discuss the current electric vehicle landscape, and what might be on the horizon as innovation within the sector continues to drive forward.

It’s my hope, as I take the helm of Design Engineering magazine and guide it into the future, that you find the content within this issue informative and enlightening. And I’ll look forward to working on many more issues to come in an effort to capture at least a snippet of the incredible evolution currently transforming the roles of design engineers and machine builders. |DE

SEAN TARRY Editor starry@annexbusinessmedia.com

Editorial Board

DR. MARY WELLS, P.ENG Dean, Faculty of Engineering, University of Waterloo

KEVIN BAILEY CEO, Design 1st

MASSIMILIANO MORUZZI CEO, Xaba

JAYSON

MYERS CEO, NGen Canada

MAY/JUNE 2025

Volume 70, No.3

design-engineering.com

READER SERVICE

Print and digital subsciption inquiries or changes, please contact Angelita Potal Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

EDITOR Sean Tarry (416) 510-5244 • starry@annexbusinessmedia.com

BRAND SALES MANAGER Trish Sutton (437) 995-4651 • tsutton@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER Ilana Fawcett (416) 829-1221 • ifawcett@annexbusinessmedia.com

ACCOUNT COORDINATOR Cheryl Fisher (416) 510-5194 • cfisher@annexbusinessmedia.com

GROUP PUBLISHER Anne Beswick (416) 510-5248 • abeswick@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Beata Olechnowicz (416) 510-5182 • bolechnowicz@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Design Engineering, established in 1955, is published by Annex Business Media, 5 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

Printed in Canada

Publications Mail Agreement #40065710 ISSN: 0011-9342 (Print), 1929-6452 (Online)

Subscriber Services: Canada: $58.65 for 1 year; $94.35 for 2 years; Outside Canada: USA - $143.31; Overseas - $154.02; $10.00 for single copy.

All prices in CAD funds.

Add applicable taxes to Canadian rates.

From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Officer: privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

©2025 Annex Business Media. All rights reserved. DE receives unsolicited features and materials (including letters to the editor) from time to time. DE, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such submissions in whole or in part in any form or medium whatsoever, without compensation of any sort. DE accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. DE is indexed in the Canadian Business Index by Micromedia Ltd., Toronto, and is available on-line in the Canadian Business & Current Affairs Database.

GENERAL

CELEBRATING 100 YEARS OF THE IRON RING

The Calling of an Engineer – a uniquely Canadian tradition –was held for the one hundredth time on Friday, April 25 at the Montreal Science Centre. It’s a tradition that’s celebrated every year in Canada, simultaneously recognized in different regions across the country in honour of graduating engineering students.

Established in 1925, the Calling of an Engineer serves as a reminder of the August 29, 1907, Quebec Bridge Disaster - a tragedy that saw the structure collapse into the St. Lawrence River, killing 75 workers. To remember the tragic event, and to serve as a symbol of the prioritization of public safety and the obligation that engineers carry to serve the public with integrity and ethics, each year graduating engineers receive the Iron Ring.

For more information about the Calling of an Engineer and the prestigious Iron Ring, visit https://ironring.ca.

AUTOMOTIVE

CARBON FIBRE SUPERCARS

UK-based McLaren Automotive recently unveiled its ART supercar – the world’s first vehicle produced by leveraging an aerospace industry composites manufacturing method which uses carbon fibre structures.

The company says that the composites are being optimized to be even lighter, stiffer and stronger

going forward, and are produced creating less waste than traditional methods.

On the heels of this success, Mclaren says it plans to integrate carbon fibre structures into future models of its vehicles.

ENERGY

CLEAN, AFFORDABLE NUCLEAR ENERGY MADE IN CANADA

As part of the Government of Canada’s strategic commitment to continue investing in nuclear energy, it recently announced a preliminary agreement to support the development and modernization of a new natural uranium–fuelled Canadian deuterium uranium (CANDU) nuclear reactor.

The announcement, which was made in March by the Honourable Jonathan Wilkinson, Minister of Energy and Natural Resources, underscores Canada’s intent to ensure a stable and reliable energy supply while securing its place as one of the global energy industry leaders.

“Nuclear is an integral part of Canada’s resilient and independent energy future, and CANDU technology is helping us get there — while creating good domestic jobs and supporting international Canadian energy exports,” he says.

The agreement, made with

AtkinsRéalis - holder of the exclusive license of the CANDU intellectual property – involves the lending of somewhere in the region of $304 million over a fouryear period. The loan will serve to fund half of the company’s MONARK nuclear reactor design project and, ultimately, strengthen Canada’s standing within today’s global energy markets.

“By advancing innovative projects like MONARK reactors, this government is reinforcing our commitment to domestically sourced and processed uranium, which is creating good-paying jobs in Ontario and throughout the country,” says Wilkinson.

“And through investments in the Darlington New Nuclear project and SMRs in Alberta, we are providing a powerful example of how public and private sectors can work together to enhance energy security; advance cutting-edge, made-in-Canada nuclear technologies; and deliver a clean and reliable energy future.”

Together with Atomic Energy of Canada Limited (AECL) – owners of the CANDU intellectual property – AtkinsRéalis are moving forward with the development of the project. The energy partners have announced plans to have the reactor online by 2034-2035 at a location that will be determined at a later date. |DE

Canada’s nuclear energy sources will soon be powered by CANDU technology.

RETRO INNOVATION

Advancing technology and engineering in the 1970s and 1980s. BY

SEAN TARRY

It goes without saying that the roles of engineers and machine builders have changed significantly throughout the years. From the optimization of tools used to develop product concepts to the advent of computers, advances in technology and processes have enhanced the journey from conceptualization to market in ways we never could have imagined.

The 1970s and 1980s bore witness to one of the most fundamentally transformative shifts that engineers and their manufacturing partners have seen to date with the transition from manually drafted designs to those aided by computer. The leap from drafting table to desktop laid a groundwork for engineers going forward and set the stage for the development of more complex and involved machines, equipment and tools.

Fast-forward to 2025, and some of the innovations that were featured within the pages of Design Engineering magazine may

These digitally formative engineering decades also saw the early stages and evolution of automation, electrified motors, the exploration of alternative materials and the expansion of the engineer’s role within the health and energy sectors.

not seem as impressive as they did when the stories were first published. However, it’s safe to assume that without these groundbreaking advancements, the world around us would not be as wondrous as we know it or as full of opportunities to create as it currently is.|DE

January 1975

March 1975

September 1978

October 1983

November 1983

December 1983

THE RISE OF PHYSICAL AI IN ROBOTICS

Technological fusion transforming engineering and manufacturing.

BY SEAN TARRY AND ANDRE VOSHART

As the industrial automation landscape continues to shift and evolve, the integration of artificial intelligence (AI) into robotics is signalling what could turn out to be a new age of efficiency, adaptability and collaboration. Dubbed ‘Physical AI’, this powerful fusion of advanced technologies is enabling robots to perceive, learn and interact with the physical world in ways previously thought impossible. For design engineers and machine builders, understanding the current and future implications of Physical AI is critical in order to remain on the cutting-edge of innovation.

Understanding Physical AI

The term Physical AI refers to the application of AI and machine learning technologies that empower robots with the human-like abilities to perceive and respond to their physical environments. Unlike traditional robots that are preprogrammed and operate following a set of predetermined instructions, robots enabled with AI are equipped to make real-time informed decisions, adapting, adjusting and learning from their interactions.

It’s an incredible technological breakthrough that poses the potential to completely transform a number of different industries and sectors. And, according to Anders Beck, Vice President of Innovation and Strategy at Universal Robots, it’s impact could be most significant within manufacturing and logistics, resulting in tangible enhancements for a number of sectors.

“Physical AI allows robots to go beyond merely executing pre-programmed instructions and gain the ability to learn, adapt, and make informed decisions based on their sensory input,” he asserts. “This advancement is pivotal in enabling robots to handle complex tasks in unstructured settings, thereby reducing the need for manual intervention and enhancing operational efficiency.”

Reshaping advancements

Beck points to a host of recent advancements related to Physical AI that are currently reshaping industrial robotics altogether:

Enhanced perception capabilities – AI-powered vision systems enable robots to recognize and interact with objects under a number of different conditions. Traditional vision systems often require high contrast and repeatable shapes in order to function properly. Deep learning-based vision systems are equipped to adapt to changes in lighting, surface finish and object orientation. Beck notes that, “Deep learning vision systems allow us to train this kind of variability into a single model, so it can handle a range of environmental variations.”

Advanced path planning – The integration of AI accelerators, such as NVIDIA’s Isaac Manipulator’s cuMotion planner, has proven to significantly improve path planning, allowing robots to effectively plan trajectories in complex environments, enhancing speed and precision in tasks like CNC machine tending and assembly.

Learning from human demonstrations – Reinforcement learning techniques enable robots to learn complex tasks by observing human actions. It’s an ability that’s proving to be incredibly beneficial in applications like assembly, where robots can mimic human movements to perform intricate tasks without the need for preprogramming.

Impact on design and machine builders

Given the transformative capabilities of Physical AI, there’s no doubt that its introduction will in turn alter the roles of design engineers and machine builders. Because AI-driven robots can handle many of the complex tasks often undertaken by engineers, their time is freed up, allowing them to focus on honing robot behaviour and system design.

“AI is changing the way design engineers and mechanical engineers approach robotics development by handling the line-by-line programming of motions and I/Os,” says Beck. “This

Photo by Christina Gregorious.

approach allows engineers to focus on commanding higher-level robot behaviours to complete tasks successfully.”

With respect to machine builders, Beck continues, AI-enhanced robotics provide the opportunity to create more flexible and adaptable automation solutions. However, he warns that integrating these technologies presents challenges, including the need for new expertise in AI and machine learning.

“Machine builders will need to learn to leverage AI capabilities when building machines at the user level,” he says. “This may require them to acquire AI technology skills in order to adapt, and to train and work with AI on a technology level.”

Practical industry applications

Beck stresses that although industries are still just approaching

Reinforcement learning in assembly – Using a Universal Robot UR5e cobot, AICA was able to demonstrate reinforcement learning assembly which resulted in the cobot being able to locate and assemble a gear by leveraging AI-driven skills. This approach enables robots to learn complex assembly tasks through trial and error, resulting in improved efficiency and adaptability.

Bimanual assembly – By leveraging two Universal Robot UR5e cobots, Acumino has perfected bimanual assembly in which the cobots learn complex manipulations such as cable handling by simply observing, resulting in significant enhancements to the dexterity and coordination of robotic systems.

AI quality assurance –AI-powered technologies can also be used to improve quality assurance through the detection of anomalies on products and in manufacturing processes, thereby reducing waste and dramatically improving product consistency.

the tipping point when it comes to the potential uses and applications of Physical AI, there are already a number of ways in which the technological advancement is demonstrating its transformative potential:

AI-powered metrology – At the NVIDIA GTC conference, 3D Infotech showcased dynamic metrology using Universal Robots’ UR3e cobot to scan and compare workpieces to CAD models, while projecting inaccuracies, thereby enhancing precision in quality control processes.

Generative AI for CNC tending – T-Robotics recently demonstrated impressive GenAI-driven CNC tending, in which a Universal Robot UR5e cobot was able to interpret natural language for CNC tasks using its ActGPT, simplifying programming and enhancing the versatility of robotic systems in machining environments.

Enhancing production flexibility

A number of significant advantages result from the use of AI-enhanced robots, particularly within high-mix, low-volume manufacturing, Beck explains. He adds that their ability to perceive and respond to the real world allows them to adapt, yielding tremendous benefits.

“AI allows robots to adapt to different part shapes and sizes without requiring extensive reprogramming or fixturing, enabling flexible, high-mix manufacturing.”

This adaptability results in the reduction of downtime and enhancements to labour utilization, making automation accessible to small- and medium-sized businesses and manufacturers, many of whom up until now faced barriers due to the complexity and cost of traditional automation solutions.

The Universal Robot UR10 in use at Elos Medtech in Sweden.

Predictive maintenance and operational efficiency

Beck goes on to explain that AI’s role extends far beyond task execution to include predictive maintenance and operational efficiency. By collecting and processing operational data, AI-powered systems can consistently improve robot performance over time, estimating required service intervals.

Further, automated anomaly and quality detection adds to improved operational efficiency by identifying potential issues before they lead to downtime. Aligning with the goals of predictive maintenance, this proactive approach serves to anticipate and prevent failures, thereby improving uptime and operational efficiency.

The future of physical AI in robotics

Looking ahead, Beck cites several advancements in Physical AI that are poised to significantly impact the development and use of industrial robotics:

Vision-language action models –The development of vision-language action models is providing robots with the ability to understand and execute tasks described in natural language, resulting in simplified programming and enhanced human-robot collaboration by enabling intuitive communication.

Robotics foundation models –Robotics foundation models provide a framework for the development and deployment of robotic systems, facilitating the creation of adaptable and scalable solutions, accelerating the adoption of robotics across industries.

Navigating barriers to AI-driven automation

Given the plethora of enhancements and improvements that Physical AI can help manufacturers achieve, including greater flexibility, precision and efficiency, Beck cautions that there are a number of practical hurdles that remain in the way of the mass adoption of these technologies.

“One of the primary challenges for manufacturers is selecting the right technologies and navigating their integration,” he says. “Traditionally, incorporating AI into cobot-based applications using standard teach pendants or graphical tools has been both

challenging and time-consuming—even for experienced engineers. The process often involves considerable trial and error, especially when integrating vision systems and machine learning capabilities into legacy workflows.”

Compounding the difficulty, adds Beck, is the scarcity of in-house expertise able to maintain the technologies. AI vision systems, for instance, particularly those not designed for ease of use, typically require advanced configuration and maintenance. This complexity leads some manufacturers to resort to leveraging traditional fixturing methods, which, while less flexible, are more familiar to them and easier to manage with existing resources.

Then there’s the cost. The significant initial investment in automation equipment that’s required remains a major deterrent for those looking to implement the advanced technology. However, without the implementation of AI, traditional robots often demand added infrastructure—such as jigs, indexing systems and safety cages—driving up expenses all the same.

For small- and medium-sized businesses and manufacturers, these barriers can seem even more pronounced. The combination of limited resources and a distinct lack of technical expertise

often restricts their ability to invest in or experiment with advanced AI solutions. In addition, the dependence of traditional automation on static environments poses issues related to reliability in dynamic production settings where frequent changeovers or irregularities are the norm.

Human-robot collaboration: getting it right

As robots become smarter and more autonomous, explains Beck, ensuring safe and seamless collaboration with humans is becoming increasingly essential. Fortunately, he adds, AI does more than just power robot actions—it also serves to improve situational awareness and adaptability.

Equipped with advanced perception capabilities, AI-powered robots have the ability to detect and respond to the presence of humans, resulting in safer

(Above) The UR10e Cobot has revolutionized the powder coating process by mimicking human operators.

(Right) A rendering of the Universal Robot UR20.

Photos: Sandra Jelisavcic Villadsen; Universal Robots.

interactions on the factory floor. In addition, says Beck, if leveraged properly, intelligent automation can also complement human labour through the handling of monotonous but cognitively demanding tasks, allowing workers to focus on other tasks, improving productivity and efficiency.

Future-proofing the workforce

For design engineers and machine builders, keeping pace with these advancements means investing in new skill sets, asserts Beck. In fact, he suggests that continuous learning and the ongoing development of skills is likely the biggest advantage anyone working within these disciplines can provide for themselves going forward.

“The rise of AI in industrial automation presents significant opportunities,” he asserts. “But to future-proof your career, you need to build a deep understanding of AI, machine learning and supporting software platforms.”

Among the key areas of required growth are:

• AI and machine learning fundamentals, including deep learning and computer vision;

• Robotic programming environments like Universal Robots’ PolyScope X and NVIDIA’s Isaac SDK;

• Sensor technologies, particularly the use of 3D cameras and real-time data integration;

• Simulation and digital twins, which allow AI models to be trained and tested in virtual environments;

• Human-robot interaction and safety design, which represent an increasingly critical focus as cobots become more prevalent in shared workspaces. Beck stresses that engineers who embrace the notion of continuous learning and maintain a pulse on emerging technologies—from generative AI to robotics foundation models—will position themselves well to lead the next wave of automation innovation.

A future built on collaboration

It’s clear that the capabilities that can be afforded engineers and machine

builders as a result of the implementation of Physical AI are immense. And equally visible is the fact that by overcoming implementation barriers, they will be able to unlock the full potential of intelligent robotics and automation. And, by enabling the right technologies, developing strategic partnerships with AI leaders, and an increasing emphasis on ease of use, industries are steadily moving toward more accessible and adaptable automation. As Beck points out, those that figure out the collaboration piece that serves as the foundation of intelligent automation will thrive, receiving the full spectrum of its benefits.

“Ultimately, the future of industrial robotics is going to be shaped by how effectively humans and AI-powered machines can learn to work together. For manufacturers, engineers, and machine builders, the journey ahead promises not only technical innovation but also a reimagining of work itself toward something much more intelligent, far more collaborative and significantly more human.” |DE

25_003432_Design_Engineering_MAY_JUN_CN Mod: March 14, 2025 2:12 PM Print: 03/20/25 page 1 v2.5

30 YEARS OF SOLIDWORKS

Assessing the software’s new Generative Experience.

BY RALPH GRABOWSKI

Dassault Systemes, under its new CEO, seems finally ready again to embrace Solidworks. For many years, Dassault applied pressure on Solidworks users to switch to its more expensive and less compatible 3dExperience software, which runs on the cloud. On offer is a genuinely confusing array of new program names, such as Solidworks Connected, Solidworks Cloud, Solidworks xDesign and 3dExperience Solidworks. Solidworks users are, however, a stubborn lot who like their MCAD software grounded firmly on the desktop, and many don’t take kindly to what they consider a distraction.

And so, at 3dExperience World 2025, new Dassault CEO Pascal Daloz, who trained as an engineer, announced that he is “A Solidworks lover. Really, I am!”. He and all other executives bore “30” pins, celebrating the 30th anniversary of Solidworks, famous for being the first MCAD program to

Seven generations of Dassault Systemes software, since 1981

launch only on Windows, back in 1995. By comparison, Autodesk came out with Inventor four years later.

But once the anniversary congrats ended, Daloz moved on to acclaim Dassault’s big-iron software. The theme of his keynote speech was The Generative World, where designers take inspiration from nature to create digital twins of everything, and maximize the business at their manufacturing shops. “It results from the convergence of the Experience Economy and the Circular Economy,” he explained, which, to me, wasn’t clear at all. In any case, the slide accompanying his talk showed the generative economy not emerging until 2040. Never mind. Daloz was keen to

Dassault Systemes CEO Pascal Daloz presenting the steps towards a generative economy

Images courtesy of Solidworks.

introduce Dassault’s seventh generation of software, cleverly marked as “3D Univ+rses”. He said it will combine modeling, simulation, and data science, with assistance from generative AI.

Dassault loves coming up with new eponyms and acronyms, and so I was not that surprised to learn that 3D Univ+rses is a XaaS (experience as a service) made up of GenXp (generative experiences), POWER’byAI, VTaaS (virtual twin experience as a service), and Virtual Companions. The long-standing PLM (product lifecycle management) abbreviation is renamed IPLM, short for “intellectual property lifecycle management.” In short, 3D Univ+rses is Dassault’s new trademark for its form of digital twins.

...every software vendor big and small wants to demonstrate a link to AI...

New Generative Experiences

The term ‘generative’ is now ambigu ous in CAD. It refers to 2D drawings generated semi-automatically from 3D models; but it also pertains to a form of AI. So, when Dassault talks about “generative” software, it could be generative-automation or generative-AI -- or generative-economy, as cited by Daloz -- or even generative AI that is constructing generative drawings for the Generative Economy, with software named “Generative.”

Generative Stacked Dimensions lets us sketch on a design, after which it generates dimensional constraints, while Generative NC Machining charts tool paths. When these ship, however, was not revealed.

There’s gotta be AI

Nearly every software vendor big and small wants to demonstrate a link to AI,

in other CAD systems, Aura is starting as a chatbot that’s been fed help files and training guides to assist us in finding answers. Competitors, such as BricsCAD Mechanical, have had this for a couple of years now.

As Dassault develops Aura further, it will alert us to regulations, suggest 3D solutions, and generate change requests. Aura is due to ship as an update to Das-

The new Generative-branded programs from Dassault include Generative Mechanical Assembly for Solidworks xDesign. It’s a virtual reality environment that gathers parts automatically into an assembly, using AI, after we answer a few questions. Once assembled, we can interact with the virtual assembly using real-world-like behaviour. When we need 3D models of existing parts, we can take pictures with our phones using the new Generative 3D Part app. It analyzes the pictures and then generates 3D parts that we can add to our assemblies.

Reaching a sustainable future is like kayaking. With a skilled partner, you can make the right decisions.

Reaching a sustainable future is demanding in many ways. Obstacles and change must be well anticipated to make the right decisions. We are ready to tackle these challenges with you! We will help you to improve your processes to meet your ESG goals, operational optimization and sustainable manufacturing efforts. Let’s team up to improve!

Do

you want to learn more? www.ca.endress.com

30 YEARS OF INNOVATION:

key features that have defined Solidworks

As Solidworks celebrates its 30th anniversary, it’s interesting to look at the standout features and innovations that the CAD software giant has produced over the years:

• Parametric Modeling (1995)

From its introduction, Solidworks set itself apart from competitors by making parametric modeling accessible on Windows-based PCs, and opening up a whole new world of 3D design for engineers and small businesses alike.

• Feature-Based Design Tree (Mid-1990s)

The intuitive, user-friendly feature manager revolutionized CAD navigation, simplifying the identification, modification and management of part features.

• Assembly Mates and Constraints (Late 1990s)

Solidworks streamlined the building of assemblies, allowing users to simulate mechanical functions with simple, drag-and-drop constraints.

• Sheet Metal Tools (2001)

Introducing tools specifically for unfolding, flattening and bending metal parts, sheet metal design became significantly faster and more precise.

• Simulation and FEA Integration (2006)

For the very first time, engineers could validate design within the Solidworks platform by way of built-in simulation tools, saving them time and eliminating the need for third-party software.

• Solidworks PDM (2007)

The inclusion of Product Data Management features gave teams the ability to manage versions, revisions and collaboration with others more effectively.

• 3D Interconnect (2017)

Another game-changing feature, users were provided with the ability to import and work with native CAD files from other platforms without any loss of data.

• Solidworks xDesign and the 3DEXPERIENCE Platform (2019–Present)

A new era was marked by the transition to cloud-based design tools and collaborative product development through the 3DEXPERIENCE platform.

• AI-Powered Design Assistance (2020s)

The most recent releases incorporate AI for design suggestions, feature automation, and error detection, paving the way forward for intelligent CAD.

mid-summer 2025, and so Aura requires an Internet connection. Dassault plans to add more AI functions, as shown to us by Solidworks CEO Manish Kumar by canned demos:

• Adjusting factory floor layouts to meet the latest safety protocols

• Choosing correctly-sized bolts, then applying SmartMates

• Converting raster images into constrained sketches

• Performing real world tests on components through AI-based virtual testing

• Turning meshes into parametric 3D models

On this last item, Kumar exclaimed, “Whether you are working with 3D scan data, imported mesh files, or legacy CAD models, making modifications is easier than ever!”. But then he advised, “...once fully developed.” It seems it’s a tough problem to solve, for he noted that “Multiple teams are exploring different ways of delivering” this capability. Odd, given that solutions already exist, such as from Shining3D. Another demo showed AI in a future version of Solidworks Connected reading a human’s prompt -- “Create renderings of this camper van with beige and silver exterior. For every scene, let’s do a gravel campsite next to a foggy lake by trees at sunrise” -- and generating images automatically, no manual selection of materials or backgrounds. Cool!, although other CAD vendors, such as Nemetschek and its AI

The new Generative Mechanical Assembly environment identifying and assembling parts

xDesign converting a raster image to a constrained sketch

Images courtesy of Solidworks.

Visualizer, already offer AI-generative renderings.

Not all AI functions are immediately available. AI-driven generative design, for instance, will be rolled out in stages over at least two years, so what we saw at 3dExperience World were teasers. Perhaps this is why Develop3D editor-in-chief Stephen Holmes said, “While some or all of these capabilities will eventually reach users, one thing was clear: The desire to keep users tied to the 3DExperience platform and well away from the clutches of emerging [AI] start-ups.”

Business consultant and author Tom Goodwin cautions about the use of AI, warning that its potentially negative implications are very real.

“The security risks are absolutely vast. The legal issues are massive. Even a leap like cloud is still a very slow process, despite the gains being obvious and the threats slight.”

But Dassault says it processes our AI prompts on its 3dExperience servers, and it won’t scan customer design data for itself or for resale to others.

What’s New in Solidworks 2025

The highlight of 3dExperience World is seeing the new functions that’ll be arriving in future releases of Solidworks. Here are some of them:

• Customizing simpler user interfaces for new designers

• Constraining sketches to squares with the Shift key

• Snapping drawing elements to magnetic lines

• Stretching sheet metal flanges to sketch geometry

• Converting boss extrudes to sheet metal

• Inserting tables of families of parts, and rolling up BOMs (bills of materials) of sub-assemblies

• Supporting parts in large assembly settings, with more selection criteria

• Pressing Esc to cancel more running operations

Solidworks is updated several times throughout the year through feature drops. Solidworks 2026 ships later this year, possibly in November.

Going forward

AI has yet to prove itself useful for Solidworks, beyond serving to fill a

marketing checkbox. Some of the AI functions within Solidworks that were shown at 3dexperience World might not ship until 2026, or later. In fact, there’s no mention of a ship date anywhere on the company’s website.

Dassault’s grand plan for its exciting AI/ design future requires that customers hook up online to 3dExperience, which plenty of the 7.5 million Solidworks users have spent the last decade resisting.

“Guys, you are not yet embracing everything we do for you,” complained Daloz during a Solidworks Partner session.

I think this is because Dassault still doesn’t “get” Solidworks, despite professing love for it. Ultimately, something like Aura may not matter, as Solidworks users have thirty years’ experience over the newbie chatbot. Nonetheless, it will be interesting to see what AI can eventually contribute.|DE

AI IN THE CAD/ DESIGN SPACE

A look inside the shift that’s already well underway. BY TREENA HEIN

AI is rapidly changing every sector, including design engineering.

The historic CAD framework (manual drafting, siloed systems, trial-and-error to ensure manufacturability) is poised to melt away into memory.

Integrated AI assistants are now automating routine tasks, providing huge numbers of design options, flagging potential errors, and more. AI-powered tools are also about to enable engineers to skip CAD file creation and help non-engineers become proficient.

All of this drastically shortens product development cycles, explains Head of Growth at PhysicsX Amir Vaziri.

“Over the next couple of years, we anticipate a major shift toward

AI-first digital engineering solutions, with AI models embedded directly into CAD and simulation software,” Vaziri says.

“AI-accelerated simulations will become increasingly common, allowing engineers to validate and refine designs rapidly. Generative AI such as Large Geometry Models (LGMs) will play a central role, enabling engineers to co-design with AI, explore vast design spaces, and significantly reduce manual iteration.”

The combination of LGMs and Large Physics Models (LPMs), Vaziri continues, will provide designers with fast, multi-physics performance feedback across various criteria, streamlining the design process.

Backflip AI CEO and Founder

“Over the next couple of years, we anticipate a major shift toward AI-first digital engineering solutions, with AI models embedded directly into CAD and simulation software,” says PhysicsX’s Amir Vaziri. Image shows Ai. rplane interface: PhysicsX’s public technology demonstrator built on its latest Large Geometry Model, LGM-Aero.

AI is enabling unprecedented levels of innovation and efficiency in design, says Neural Concept’s Thomas Von Tschammer, especially in industries like aerospace.

Greg Mark says “you’re seeing the development of AI tools that fundamentally accelerate the design process. The main goal for us is to get the designer’s vision into the world as fast as possible.”

Let’s dive into this acceleration, starting with AI design generation.

Expansion of options

As Thomas Von Tschammer, General Manager (USA) for Neural Concept, explains, companies are currently under a lot of pressure to develop products more rapidly and to be much more agile, which is exactly what today’s AI systems are addressing.

“For many years, we’ve had engineers spending several hours on a single design, which is computationally very expensive, and now we have AI systems that can generate 1,000 configurations in two seconds,” he says.

“In seconds, AI can also analyze different designs, for example, on safety parameters. All of this means that engineers are freed up from the data-driven

part of the design process. Instead, they can use their knowledge and experience to look at the trade-offs with final design options and make the call.”

Vaziri explains that a crucial role in reducing time to market is played by geometry generation. “We utilize a range of technologies to create new geometries, including our LGM, agents, implicit geometry and more. These technologies have been implemented across various stages of the product life cycle—innovation, design and sales—to deliver tangible value at each phase.”

LPMs are also dramatically reducing simulation times, says Vaziri, “making real-time and near-real-time physics predictions possible, with a click of a button in your CAD tool. This allows engineers to iterate more efficiently and optimize designs without the traditional time constraints of numerical simulation.”

Scan to file

The power of AI is also about to radically speed up the CAD workflow by creating the file itself. In March 2025, Backflip introduced its alpha version of a CAD plug-in for Solidworks that rapidly converts raw 3D scans into fully functional CAD files while preserving feature history. This will allow users to create parametric CAD models that can be easily modified.

“Manufacturers may not have the CAD file for a given part for many reasons,” explains Mark. “Maybe the part was originally made without using CAD or it was made by a third party, and you therefore don’t have the file. If you need to modify that part, one way to get a CAD file of it until now was to 3D scan the part, and then you take that mesh file and re-draw it in a CAD file. But that’s very difficult and time-consuming.”

“There are programs that make this easier but there is nothing that can create that file for you,” Mark continues. “So, we are training our AI, as you would train a highly skilled human, to do this. Right now, it makes a complete file for simple parts, covering about 20 per cent of the scans we give it. About 40 per cent of its file outputs need some human work and the other 40 per cent... it can do parts of the file.”

“But with AI, as we know, the rate of

progress is exponential. It’s updating every few weeks. We are very excited to see designers scan a part and get a finished CAD file to work with.”

Changing skill set

As AI empowers engineers to focus more on the value-added part of their jobs and less on “grunt work,” Von Tschammer says, it means their skill set is starting to shift.

“Today, engineers are spending a lot of time setting up simulations for a design, tweaking the design based on the results, doing another simulation, and so on,” he says. “But AI supercharges them because that’s done for them.They can then make decisions much faster based on what the company needs. So, we are going to see an evolution of engineering skills.

“The programming knowledge is being transferred to AI, so engineering will move to more of a global expertise. It is going from hard skills to more of a focus on deeper understanding of the physics and managing that in a complex global ecosystem to make the right

decision about a design that meets the company’s targets.”

Going beyond

AI is not only changing the relationship of design engineers with their jobs by shifting their skill sets.

Vaziri says AI is now being used “to explore vast design spaces and optimize components and systems beyond human intuition.” This means AI is enabling unprecedented levels of innovation and efficiency in design, he says, especially in advanced industries that involve complex engineering challenges like automotive and aerospace.

Von Tschammer echoes this observation. Neural Concept works a lot in the battery design space, which he describes as a complex engineering problem with an infinite number of designs. In this space, he says “AI can come up with much better designs that you can come up with manually, and it can also very quickly find the design that’s optimal. Then the engineer can spend time on it to learn why it’s optimal... why in terms

of the physics and the tradeoffs.”

“This learning from AI is a big trend. So not only is AI freeing up engineers to focus on more of a global expertise, but it’s also giving us better engineers,” Von Tschammer says.

At the same time, he believes business structure and governance must keep up. “The management of data in AI is very important,” Von Tschammer explains. “You have to make sure you are capturing the data so it can be used in the next development cycle. This is not just about the engineers themselves, but about the entire company environment.”

More designers

Mark also points to the fact that we are about to enter an era of massive expansion in the number of part designers because of AI. “If you look at the evolution of design over the last few decades, we went from paper to AutoCAD to 3D CAD and each time, we brought more people in,” he explains. “AI will bring in the biggest number ever seen.We are working on ways to get ideas from a person’s head into CAD as seamlessly as possible, and that’s going to be hugely beneficial for all industries.”

He adds: “If you look at the automotive sector, there are thousands of brilliant technicians, and we are developing tools that will enable them to easily learn CAD. Tradesmen will also rapidly become proficient in using CAD. To get all of these people off the ground with this suite of tools is a revolutionary change. With the power of AI, we expect that there will be millions of new CAD users in the coming years.”

“If you look at the automotive sector, there are thousands of brilliant technicians, and we are developing tools that will enable them to easily learn CAD,” says Backflip AI’s Greg Mark.

What else is coming?

Vaziri predicts that, in a few years, AI will be poised to fully integrate into the entire engineering life cycle.

“From concept to manufacturing and even in-field performance monitoring, AI models will continuously learn and adapt, optimizing designs not just in development, but throughout their operational life span.”

“AI-powered engineering assistants could become standard, providing real-time insights and suggestions to engineers, much like how AI has transformed coding and

that. Because of the increase in design speed, there will be no throttling of the design. It will be true to the vision.”

CAD innovation: transforming the role of design engineers and machine builders

From the earliest iterations of CAD, the software-based design aid has influenced the role of design engineers and the way they approach their work in more ways than just about anything else. What began as a digital drafting tool has become a powerful innovation engine, influencing everything from product design and simulation to optimization and manufacturing. For design engineers and machine builders alike, CAD advancements through the years have reshaped workflows, accelerated development cycles and introduced a range of possibilities when it comes to automation and product customization.

content creation.”

In Vaziri’s view, however, “AI will not ultimately replace engineers but will enhance their capabilities, freeing them from time-intensive computational tasks and enabling them to focus on innovation and problem-solving at an unprecedented scale.”

“AI will enable more and more productivity,” Mark adds. “Every time something ships, there are features that an engineer would love to have included but they run out of time. It’s exciting that with AI, we’re going to stop

Shift from 2D to 3D modeling – One of the most significant CAD milestones is represented by the transition from 2D to 3D modeling. Occurring in the late 1980s and into the 1990s, systems like AutoCAD allowed engineers to digitize hand-drawn blueprints, resulting in improved precision and documentation.

Parametric and feature-based design – With the introduction of parametric modeling in the mid1990s, the way engineers thought about product design was significantly altered. Rather than defining fixed geometries, engineers were now defining rules and relationships with shapes and pieces that automatically updated as their design evolved. For machine builders, this meant the development of product families and

Photo:

configurable systems with minimal rework required. Features that included design tables and configurations helped users efficiently manage product customization.

Integrated simulation and analysis – The integration of simulation tools into CAD platforms marked a significant sea change as engineers were suddenly able to test structural, thermal and fluid performance without leaving the CAD environment to do so. Finite element analysis (FEA) and computational fluid dynamics (CFD) capabilities within CAD packages allowed users to identify issues or challenges, reduced the need for physical prototypes and improved product reliability.

CAM and digital manufacturing integration – Today, CAD systems are integrated with manufacturing.With the introduction of Computer-aided manufacturing (CAM) software, engineers can generate toolpaths directly from CAD models, bridging the gap between design and production. For machine builders, CAD-CAM integration has helped optimize part manufacturability during the design phase, making it easier to account for tooling constraints, material usage and production costs, while speeding up time to market.

Generative design and AI-powered tools – Most recently, some have started to experiment with the idea of generative design—where engineers input performance requirements, and the software automatically generates multiple geometries to achieve the desired results. Though these designs are often organic-looking and cannot be manufactured by means of traditional methods, they can be 3D printed or CNC machined leveraging modern techniques.

With this advancement, AI is also becoming increasingly embedded into CAD, with machine learning algorithms now helping engineers automate repetitive tasks and predict design errors, while making recommendations concerning possible improvements. This results in the role of the engineer shifting from drafter to decision-maker, allowing more time for creative problem-solving and strategic thinking.

Cloud-based and collaborative platforms – Many modern CAD systems have embraced cloud architecture,

enabling real-time collaboration among multiple individuals, meaning that engineers can now access models anywhere, co-edit designs and integrate with version control systems, all in the cloud. This has transformed how machine builders and design engineers work across teams, locations and suppliers, facilitating quicker iteration cycles and approvals, and improved coordination between design, procurement and manufacturing.

Designing the future

Innovations related to CAD have continuously reshaped mechanical design and machine building, allowing for a more flexible and creative approach to product design and manufacturing. And, as CAD software maintains its course alongside the progression of AI and digital manufacturing, the roles of design engineers and machine builders are likely to continue to evolve for years to come. |DE

Rolling Ring LINEAR DRIVES

Zero

FROM BELTS TO BATTERIES

Automotive electrification is unlocking new space, efficiency and design possibilities

BY DE STAFF

The automotive industry’s evolution through electrification—replacing traditional mechanically driven systems with electric components and systems—is profoundly changing the design of today’s vehicles, which range widely from internal combustion engines and mild hybrids to fully electric architectures.

As systems have evolved from carburetors and simple exhaust systems to precision fuel injectors, emission systems, and traction and braking control systems, similar advancements have been made in electrification with new architectures, components for electric motors, battery packs, and advanced power electronics. Combined, these advancements are pushing engineers to reimagine how vehicles are designed and driven for maximum efficiency, reliability and safety.

Subject-matter experts Matt McWhinney and Kirk Ulery (Molex), and Shawn Luke (DigiKey) shed light on the current state of the electrification movement and key considerations for the future of the automotive industry.

Vehicle model landscape

While demand for EVs and hybrids continues to rise, sales of new EVs have actually slowed in recent months due to market forces, public policy, and still-limited charging infrastructure.

“We’ve had fits and starts on electrification in North America,” says Ulery. “If you’re going more than 100 miles at a time, you know, charging infrastructure needs to be addressed.”

Hybrid vehicles, on the other hand, are outpacing EV sales. According to Edmunds data, hybrid purchases in the

U.S. saw their biggest surge in 2023, increasing from more than 750,000 sales in 2022 to over 1 million in 2023.

Another emerging category is the mild hybrid, which uses a battery-powered electric motor to supplement the internal combustion engine (ICE). Most mild hybrids run on a 48V electrical system, which is a higher voltage than the electrical systems of a traditional ICE vehicle. The 48V system powers components that are not reliant on the engine, enabling better operational efficiency.

Even with the fast pace of innovation in automotive design, ICE vehicles still rule the roadways. According to research by Edmunds, 82 per cent of new vehicles sold today in the U.S. rely on fuel. However, the electrification movement is well underway among traditional vehicles as well as the most advanced high-tech electric models.

Electrifying under the hood

“One constant we’re seeing is a lot more electrification; mechanical systems are becoming electrified in all vehicles for many reasons, especially to drive efficiency,” Ulery notes.

One example is stop-start technology, which turns the engine off when a vehicle stops and automatically restarts when the driver releases the brake or pushes the gas pedal. While this feature can put extra demand on some components, it aims to improve fuel efficiency and reduce GHG emissions.

Other examples of electrification under the hood can be found in radiator fans, power steering, HVAC systems, and cooling pumps—all of which used to be powered by belts attached to the ICE. Electric water pumps are replacing

mechanical radiator pumps for more efficient performance, and the precise control that comes with electrical cooling can extend the lifespan of these parts.

Extended battery management involves coolant that circulates throughout a vehicle to regulate the temperature of the battery pack, electric motors and power electronics.

Switching to electric-powered modules such as power steering pumps makes the system no longer reliant on the engine, reducing parasitic loads and allowing for more available horsepower. Therefore, automakers can install smaller engines in some vehicles and retain the same driving performance while gaining efficiency benefits and outputting lower emissions.

“Electrification has opened the door to innovative new vehicle designs,” Luke notes. “Without the need to accommodate the belt-driven architecture of a traditional internal combustion engine, auto manufacturers have more flexibility in where to distribute batteries and charging ports, the ability to increase

Photos courtesy of Molex.

the amount of space for passengers or cargo, and more.”

Overall, the electrification movement within the automotive industry is serving to replace traditional mechanical systems with precise, electrically controlled alternatives that can be more efficient. Combined with advancements in software control, modern vehicles are cleaner, more energy-efficient, and offer

involves more than just increasing the system voltage. It also requires a change in the electrical foundation. Feature-rich, higher-performance vehicles rely on lighter and smaller components that deliver the same electrical efficiency as a higher-density model.

“The common thing is that both 12V and 48V systems are moving traditional mechanical functions off a serpentine belt to a series of electric motors,” Ulery says. He points to a heavy-duty pickup truck using mechanical energy for its power steering. In many vehicles, this function is becoming electrified. “The amount of energy needed for the power steering takes away from the engine’s horsepower, so by moving it to a separate electrical system, drivers can maintain more power through the drivetrain.”

performance and sustainability for both passenger and commercial drivers.

Vehicle battery advancement

Over the last decade, vehicle manufacturers have switched from 12V to higher voltages, such as 24V (especially for commercial vehicles) and now to 48V batteries to increase power capability, reduce vehicle weight, improve acceleration, and realize fuel savings.

Legislation in the U.S. and Europe has been laying the groundwork for emissions reductions in newly built vehicles. A combination of regulatory and market forces are behind the increasing shift to mild hybrid architectures, which include integrated starter generators.

48V is not only growing in mild hybrids but also seems poised to emerge in more ICE platforms. The shift to 48V architecture

The automotive industry’s move to higher-voltage systems is gradual, given the significant impact on the design and manufacturing process. Each OEM’s transition is on a different timeline based on their products, technical maturity, and the requirements of the customers they serve. Plus, all are held to standards and design practices related to the technologies they will be using, including:

• ISO 21780 covers requirements and tests for the electric and electronic components in road vehicles equipped with an electrical system operating at a nominal voltage of 48V.

• VDA Recommendation 320 is published and maintained by the ZVEI-German Electrical and Electronic Manufacturers’ Association. It covers a range of specifications and test requirements for electric and electronic components in motor vehicles to develop the 48V power supply.

Achieving smart battery management is integral to the success of 48V architecture. With the right design process, automakers can avoid inefficient power storage, increased costs and potential safety risks to drivers.

A Molex connector on a Cybertruck.

CHARTING THE EVOLUTION OF ELECTRIC VEHICLES

The history of the electrification of vehicles is flecked by milestones and technological advancements that have helped drive the revolution forward, fundamentally reshaping the automotive landscape. Here are a handful of the trailblazing innovations that have impacted both passenger and commercial vehicles alike.

Early innovations – Electric vehicles (EVs), for what it’s worth, predate internal combustion engine vehicles by some time. By the late 1800s, the earliest versions of the EV had already gained popularity among drivers for their quiet, clean operation. At the turn of the twentieth century, EVs accounted for nearly one-third of all vehicles on North American roads. However, a combination of limited range, lack of infrastructure and the rise of gasoline-powered cars marginalized interest in EVs among the public.

Modern resurgence – Nearly 100 years later, however, interest in EVs returned. Influenced by a raised awareness concerning environmental issues, General Motors introduced its EV1 in 1996, becoming the first mass produced EV of the modern era. In 2008, the Tesla Roadster raised the EV bar with its high performance and long range.

Mass market electrification – The 2010s bore witness to improved battery technology, reduced cost and continuously increasing range. As a result, many automakers began experimenting with their own EV models, including the Nissan Leaf, Chevrolet Volt (a plug-in hybrid) and Tesla’s Model S, Model X and Model 3.

Charging infrastructure and global policy support – It wasn’t until governments around the world began introducing incentives, subsidies and emissions targets that EV production and adoption accelerated globally. In response, companies across North America and the world started to scale up fast-charging networks in order to address concerns regarding range while improving convenience.

Commercial vehicle electrification – The electrification of buses, delivery vans and long-haul trucks is not anything new.Today, a range of different EV technologies are being leveraged to help power municipal vehicles as well as portions of the logistics sector.

Today and beyond – Currently, just about every automaker has adopted and implemented a clear EV roadmap, investing in innovation around the development of the technology. And supporting their projects are coinciding advances in solid-state batteries, silicon carbide inverters and vehicle-to-grid technology.

As the electrification revolution continues unabated, with innovation happening across every vehicle class, it seems only a matter of time before their use among the public accelerates, driving the future of electrification.

Interconnection fundamentals for safety

With vehicles requiring more power than ever to support increasingly sophisticated electrical features, a reliable connector design for 48V systems relies on several fundamental factors to meet vehicle performance and safety standards.

“Having electronics and the infrastructure—the interconnects to support your vehicle—is essential for safety,” McWhinney says.

Since 48V systems operate at a higher voltage than the standard 12V, connectors and electrical systems must be built with robust materials and proper insulation for safe, reliable performance.

Connector failures can cause vehicle system malfunctions or safety hazards. To prevent disconnections, connectors should include locking mechanisms and strain relief, as well as regular inspections and maintenance checks.

“Safety and monitoring control of the electrical system is more important now than ever,” McWhinney adds.

Maintaining signal quality is crucial for higher-voltage applications. Poor signal integrity can precipitate malfunctions, so connectors must minimize signal loss and interference with shielded cables, as well as proper grounding and strategic placement. Addressing these considerations requires innovation and expertise, which is where advanced connector solutions come into play.

“It feels so much like table stakes, but it’s underrated how important the interconnect is in automotive design—especially for safety,” Luke adds.

Keeping up with change and certification

Meeting safety requirements is a top priority, but McWhinney notes that an additional challenge is the constant change in vehicle electrical system requirements, which pushes manufacturers to keep up and constantly revise connectors and other components.

OEMs can always refer to the US Council for Automotive Research (USCAR) to track performance requirements and carefully review and certify approved components for safe use in the automotive industry.

Components that adhere to USCAR/LV214 or similar qualifications are typically high-quality, rugged, and reliable parts that can take a beating on the road without sacrificing performance.

“With more innovation opportunities in vehicle design, more vehicle manufacturers are embracing electrification practices. Because of the hyper-fast innovation cycle, there are few standard platforms in the space. However, the increased variety offers consumers more options, and we expect the cost of vehicles will likely decrease as technology advances and production ramps up,” Luke notes.

Nod to commercial vehicles

Meanwhile, the electrification transition has been happening within the commercial vehicle space for a much longer period of time than in the passenger car segment. Commercial vehicles quickly transitioned from 12V to 24V systems to power diesel and some electrical systems, which allowed them to have smaller starters. There is also a long history of electric HVAC in commercial vehicles, especially in buses,

construction, agricultural vehicles and heavy-duty trucking.

Commercial vehicles are typically designed to help their owner/operator make money and, therefore, need to work reliably. The pressure for these vehicles to perform reliably is typically higher than that of passenger cars, so extra sealing and robustness are needed.

Electrification unlocks design freedom

Whether designing for passenger or commercial vehicles, engineers must consider numerous complex power-hungry systems and features that not only meet consumer and commercial demand, but are also highly efficient, durable and safe.

As more vehicle systems become electrically driven, engineers gain greater freedom to reimagine component placement, system integration, and vehicle architectures. This flexibility opens the door to novel layouts, optimized space usage, and enhanced performance tailored to suit both passenger and commercial customers.|DE

Kirk Ulery, Molex

Matt McWhinney, Molex

Shawn Luke, DigiKey

CONNECTING WITH CAPACITIVE SENSORS

Carlo Gavazzi recently introduced its new CA18CB and CA30CB capacitive sensors. Combining unmatched IO-Link connectivity with an integrated LED bar graph allows for real-time feedback and simplified setup. And, designed to handle challenging environments, these sensors are capable of withstanding temperatures up to 120°C. Ideal for use with plastic molding, feeding systems, and pellet burners, these sensors provide advanced diagnostics, automatic reconfiguration, and Tripleshield protection, allowing for streamlined machine setup, maintenance, and long-term performance in industrial automation applications.

RUGGED CABLE ASSEMBLIES

Amphenol RF’s IP67-rated RP-SMA jack to AMC4 plug cable assemblies offer compact and reliable RF connectivity that’s perfect for use in constrained spaces and environments.

Engineered with an ultra-thin 1.13 mm coax cable and a right-angle AMC4 plug, these assemblies support high-frequency performance up to 6 GHz. In

addition, the weatherproof design ensures consistent operation in outdoor and industrial settings and are suitable for IoT, automation, and wireless system integration in demanding applications.

POWERFUL SERVO CONTROLLER

Electromate recently launched the latest in its ESCON2 servo controller series from Maxon. Delivering impressive power density and precision control for industrial and robotic systems, these servo controllers are great for both standalone and networked applications. Its compact design and advanced torque/speed control, combined with Motion Studio software, allows for efficient integration and performance tuning. And, tailored for high power, compact setups and space-constrained jobs, ESCON2 offers engineers and machine builders a versatile and reliable motion control solution like no other.

RELIABLE ELECTRIC FILTER FOR TOUGH ENVIRONMENTS

Danfoss Power Solutions’ new Editron EC-LCL1200B electric filter gives users a compact and dependable solution for

high-power, grid-connected mobile machinery. This LCL filter pairs with the EC-C1200 converter to reduce EMI, improve power quality and enable bidirectional AC/DC conversion. Its shock resistance, and 560V AC compatibility makes it a perfect choice for use with tethered electric equipment including drills, excavators, and material handlers. With a compact design, system integration is simplified, allowing OEMs to meet power, space and reliability demands in challenging environments.

NEXT-GENERATION WATER BONDING SYSTEM

EV Group’s GEMINI wafer bonding system significantly improves and enhances high-volume 300-mm MEMS manufacturing. With a redesigned high-force bond chamber, the platform ensures unsurpassed bond quality and yield across larger wafer surfaces, making them ideal for use with vacuum-sealed MEMS devices such as sensors, microspeakers and micromirrors. A great choice for MEMS makers transitioning from 200-mm to 300-mm wafers, the GEMINI water bonding system supports CMOS-MEMS integration and large devices.

EFFICIENT VACUUM CONVEYOR SOLUTION

Offering efficient, flexible solutions for bulk material

transport, Hapman’s Vacuum Conveyors is powered by regenerative blower technology that helps significantly reduce operational costs. Designed for a range of differ ent applications, the system features a reverse-pulse filter cleaning system that results in minimal downtime. Including the MiniVac for obstacle-friendly routing, the space-saving LP Series and the E-Line for enhanced safety, Hapman’s new lineup has users covered, delivering cost-effective conveying systems that boost productivity in manufacturing, processing and industrial automation.

VACUUM FLOW UNIT

SMC recently introduced its new ZHV Vacuum Flow unit - a versatile, maintenance-free solution built for bulk material transfer and work area cleaning. Void of moving parts, the unit functions as both a vacuum and blow-off tool. The vacuum flow rate is three times the supply air, while the blow-off rate is four times the supply air. And, with its large passage diameter, it handles machining chips and fine particles with ease.

VOLUMETRIC 3D PRINTING

Advanced Printed Electronic Solutions (APES) and Manifest

Technologies have teamed up to integrate volumetric 3D printing into the Matrix6D adaptive manufacturing platform. Revolutionizing high-speed, support-free additive production, Manifest’s cone-beam volumetric module rapidly solidifies entire material parts without layers, providing faster fabrication of complex geometries. And, combined with Matrix6D’s magnetically levitated, modular tool stations, the platform delivers scalable, reconfigurable workflows that are ideal for printed electronics, optics, and medical devices.

DEPENDABLE HYBRID CONNECTORS

Hirose’s MT50WA Series hybrid connectors deliver compact solutions that combine power, signal and brake lines all in one interface. Ideal for use with motors, automation systems and office equipment, its one-touch lever lock guarantees a fast and secure connection every time. Designed with high vibration resistance, assembly is simple, providing a high degree of reliability in difficult conditions. Engineered for servo and stepper motor applications, these hybrid connectors offer a streamlined, durable connector option for use in extreme industrial settings.

DIRECT DRIVE LINEAR SERVO ACTUATOR

The new direct drive linear servo actuator by Moticont delivers unmatched levels of speed and precision while reducing noise. Designed in a compact 38.1 mm package with a 25.4 mm stroke, the Monticont servo actuator features 1.25-micron resolution with an internal encoder and built-in HOME and temperature sensors, ensuring accurate

closed-loop performance and thermal protection. Ideal for use within medical, semiconductor, laser and automation applications, its versatile design accommodates side loads, allowing for zero-backlash mounting and universal integration.

VIDEO MEASURING SYSTEM FOR ACCURATE INSPECTION

The new Nikon NEXIV VMF-K Series is a high-performance video measuring system that’s been designed for semiconductor and electronic component inspection. Providing nearly 1.5 times faster measurement throughput than the previous series, the NEXIV VMF-K Series offers superior precision and pinpoint accuracy. Featuring advanced confocal optics for simultaneous 2D and height measurement, the use of the system results in greater productivity and reduced measurement time.

PULL TYPE D-FRAME SOLENOIDS

Magnetic Sensor Systems’ S-20-150 Series of Pull Type D-Frame Solenoids are strong, providing up to 24 pounds of peak force with a 1-inch stroke. Designed for use within a range of different applications, including medical dispensing, valve control and vending machines, these

lightweight solenoids guarantee up to 12 pounds of continuous force. Equipped with a low friction brass guide and a PTFE-coated plunger for longevity, Magnetic Sensor Systems’ solenoids are ideal for use with high-performance, cost-effective solutions.

FANUC’S NEW COBOT AND GO

FANUC’s Cobot and Go is a brand-new state-of-art web tool that helps design engineers and machine builders simplify

automation by connecting them with reliable, pre-engineered collaborative robot solutions. Featuring FANUC’s trusted CRX cobot line, this intuitive and easy-to-integrate platform allows users to search by application, robot model or integrator to find the ideal fit that meets their design and manufacturing needs. With up to 30 kg payloads, 1889 mm reach and eight years of maintenance-free operation, CRX cobots are flexible, safe, and efficient, and are ideal for tasks including welding, inspection, palletizing and more.

Pre-Assembled Disc Spring Stacks

Save Time, Money, & Assure Quality

• Eliminate stack construction time

• Fully customizable stack design & packaging

• Consistent lubrication

• Error-proof stack construction

Application Example:

SPIROL’s Disc Spring Stacks are reliably used in Fuel Cells and Electrolyzers within the hydrogen supply industry.

The sky’s the limit

Waterloo professor takes research chair position to help guide the future of Canadian aerospace innovation.

BY SEAN TARRY

The innovations behind today’s advanced technology, in all its many shapes and forms, move at a pretty impressive rate. Their use and application across industries and sectors, and throughout the daily lives of so many people around the world, impacts just about everything we know. But none of today’s advancements, it seems, pose a greater impact than that of artificial intelligence. Combining this fact with a global aerospace industry that’s on the cusp of embracing AI-powered technologies and solutions to drive efficiencies and reduce costs, Pratt & Whitney Canada recently named Waterloo Assistant Professor, David Del Rey Fernández, as its new Industry-Sponsored Research Chair in Industrial Artificial Intelligence.

AI in aviation

Within his newly appointed position, Del Rey Fernández, who teaches Applied Mathematics, will guide the direction of groundbreaking research involving AI, computational mathematics and sustainable aeronautics. It’s relatively heady work that the university professor says has the potential to inspire new ways of doing things and drive new enhanced levels of safety, efficiency and sustainability for the aerospace industry. And, he adds, it’s a role that presents an opportunity to be a part of the true integration of

Industrial Artificial Intelligence.

“Del Rey Fernández’s research is at the forefront of Industrial AI...”

advanced technologies into the work and processes of those operating within the aerospace industry.

“It is an incredible honour to be named the P&WC Chair in Industrial AI,” he says. “The work that will be accomplished during this chair has the potential to revolutionize the design and safety of next generation gas turbine engines and will provide a template on how to enhance simulation techniques with machine learning as well as use machine learning to accelerate simulation workflows.”

Research focus

Specifically, the focus of Del Rey Fernández and his team will involve the development

of machine learning-based aviation simulation algorithms with the objective of advancing testing design, development and workflow processes. It’s a move by Pratt & Whitney that’s being seen by many as a pointed one, underscoring its commitment to continue driving the latest in advanced research in efforts to drive aircraft propulsion beyond contemporary limits. And, according to Charles Litalien, Executive Director of Engineering Design and Research at Pratt & Whitney Canada, academic connections like the one it’s just formalized with the University of Waterloo is more than an added bonus.

“Over the past decade, Pratt & Whitney Canada

has invested significantly in research and academic collaborations, recognizing that they are essential to the future of aerospace,” he says. “By partnering with leading academic institutions like the University of Waterloo, we are shaping the next era of intelligent aviation—one where sustainability, efficiency and safety take centre stage.”

Revolutionary impacts

In addition to Del Rey Fernández’s role at the University of Waterloo as Assistant Professor within the Applied Mathematics Program, he’s also an integral part of the school’s Data & Artificial Intelligence Institute (Waterloo.AI) – an institution with a mandate of advancing AI-driven solutions across industries through interdisciplinary collaboration. His work with Waterloo.AI has been instrumental in helping it broaden its reach and understanding. In fact, according to Dr. Jimmy Lin, Professor of Computer Science and Co-Director of Waterloo.AI, Del Rey Fernández is often at the cutting-edge of today’s research when it comes to AI and its potential applications.

“Del Rey Fernández’s research is at the forefront of Industrial AI, demonstrating how artificial intelligence can revolutionize manufacturing, predictive maintenance, and intelligent automation. This appointment underscores the importance of bridging academic research with real-world industry challenges.” |DE

David Del Rey Fernández will lead the future of aerospace innovation as Pratt & Whitney Canada’s new Industry-Sponsored Research Chair in

Photo courtesy of University of Waterloo.

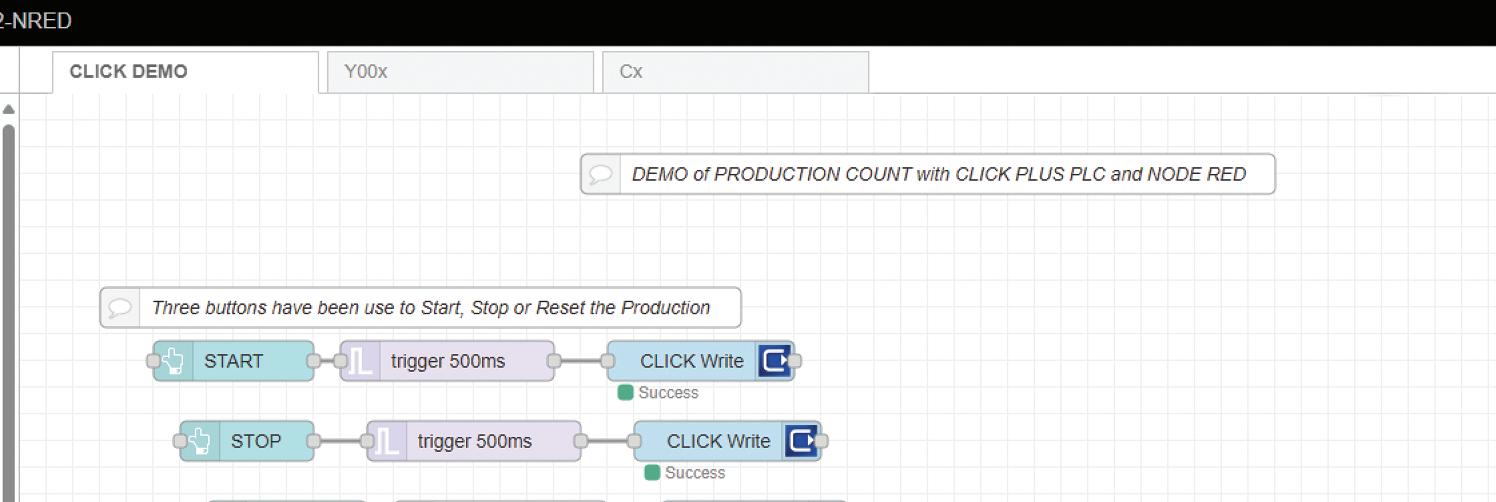

CLICK PLUS CPUs offer the utmost versatility with up to two option slots for custom control configurations.

With the new Node-RED® option slot module, you can combine the most affordable and user-friendly PLC in the industry with one of the most popular open-source software tools in the industrial sector for developing IIoT applications.

• Create interactive and customer-specific HMI dashboards that can be accessed with any browser

• Easily integrate plant-floor data into existing business systems/databases, e.g., MES or ERP systems