SHUTTLE VALVE CATALOG

Gilmore is the technology leader in Hydraulic Shuttle Valves. Our patented shuttle valves combine into three major product families.

Gilmore manufactures a variety of different shuttle types to meet the most rigorous requirements. We offer different features, connections, working pressures, flow capacities and sealing geometry to fit your project requirements. Below are the three major product families of shuttles and their variations, Please reach out to us if you do not see an option fitting your application.

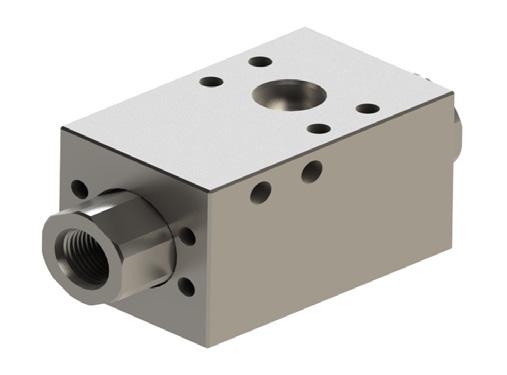

GEN2 Disc Shuttle I Stackable I Biased

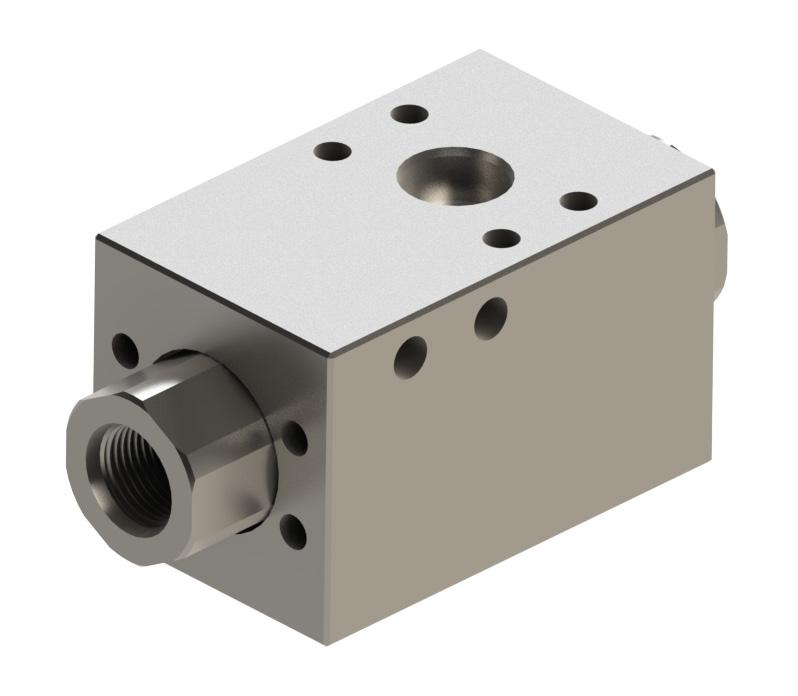

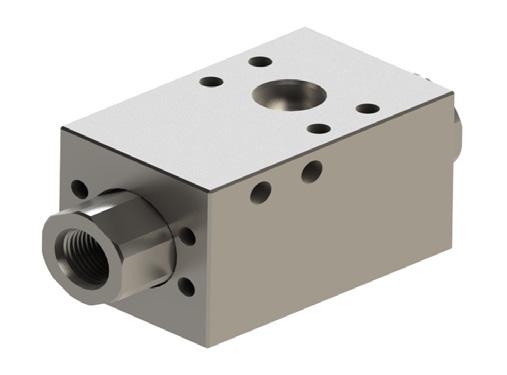

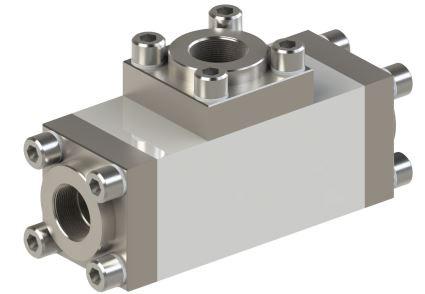

The GEN2 disc shuttle is our reliable low flow shuttle valve. This style is compact, resilient soft seal valves that are perfectly suited for providing redundancy in pilot circuits and actuation of larger components. The patented disc seal geometry has been extensively cycle tested at full MAWP (5000 psi) with 8 GPM flow.

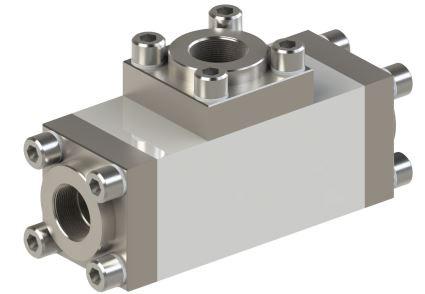

Mark IV Shuttle I Inline I Stackable I Biased

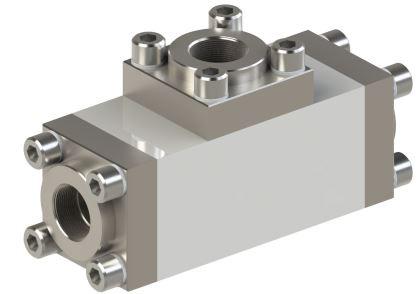

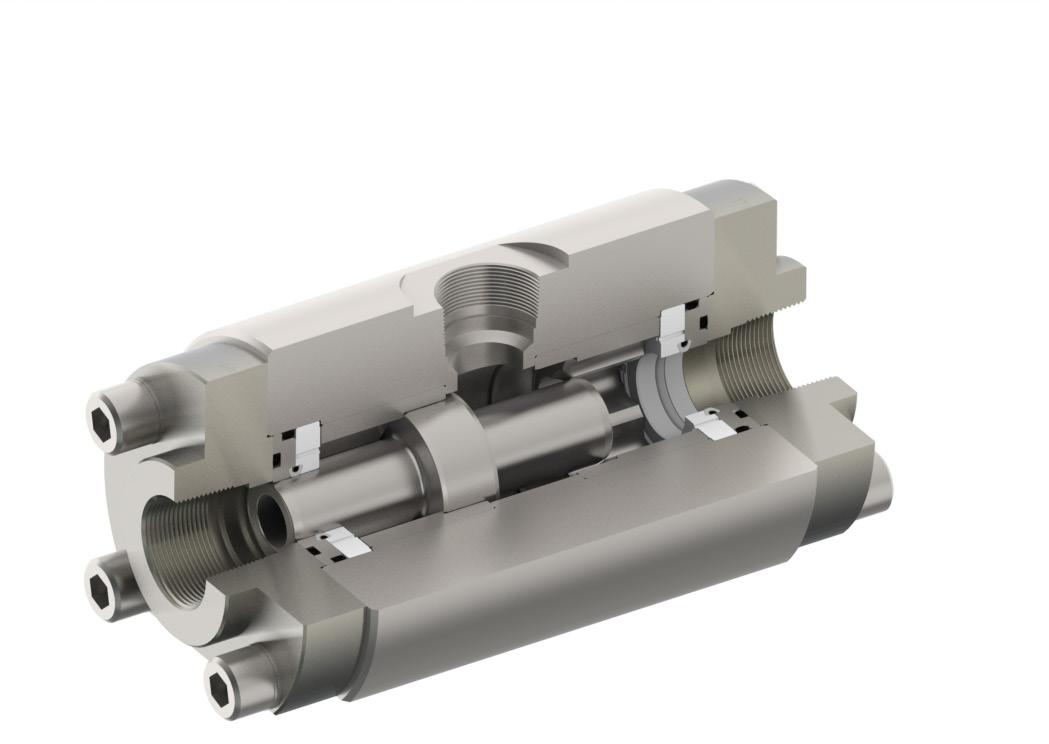

The new standard of reliability. The Mark IV Shuttle Valve improves upon the Mark III, adding better performance and modularity. The increase in cycle life of the valve was proven through extreme testing to meet the demand of 5 year service life under normal operating conditions. Use this valve for new build equipment where you want to have the best performing, most easily serviceable shuttle valve in the market.

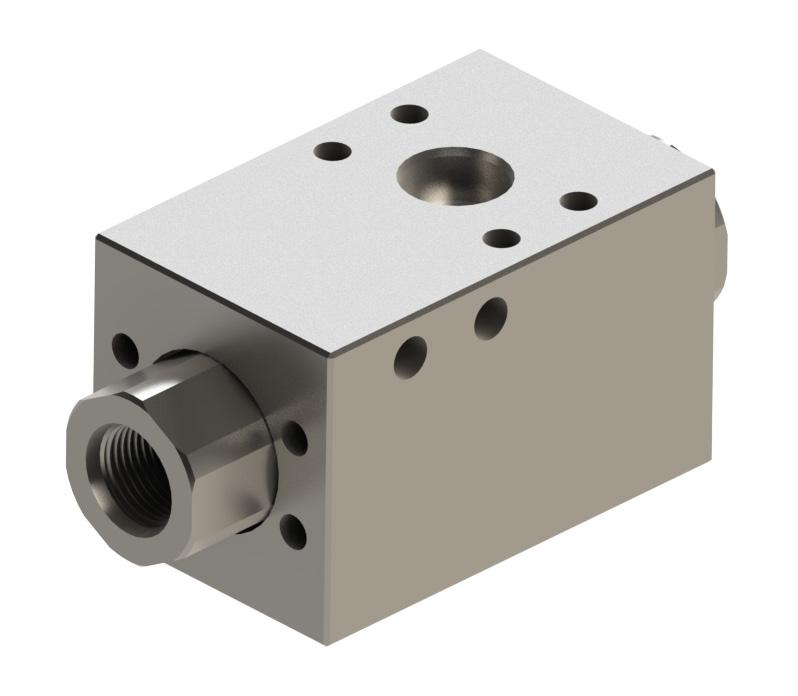

GEN2 V-Seal Shuttle I Inline

The Traditional GEN2 Shuttle Valve design exceeds new offshore industry requirements while keeping the traditional Gilmore shuttle valve footprint. The increase in cycle life of the valve was proven through extreme testing to meet the demand of 5 year service life under normal operating conditions. Use this valve to upgrade the legacy traditional shuttle valves in your existing equipment as they have the same footprint and do not require re-piping .

Table of ContentsShuttle Valve

DRILLING | PRODUCTION | INDUSTRIAL INFO@Gilmore.com www.gilmore.com SHUTTLE -042120-001-02

Shuttles are used as a means to provide redundancy actuation for a critical function. They allow multiple pressure sources to actuate a function when the primary function loses pressure.

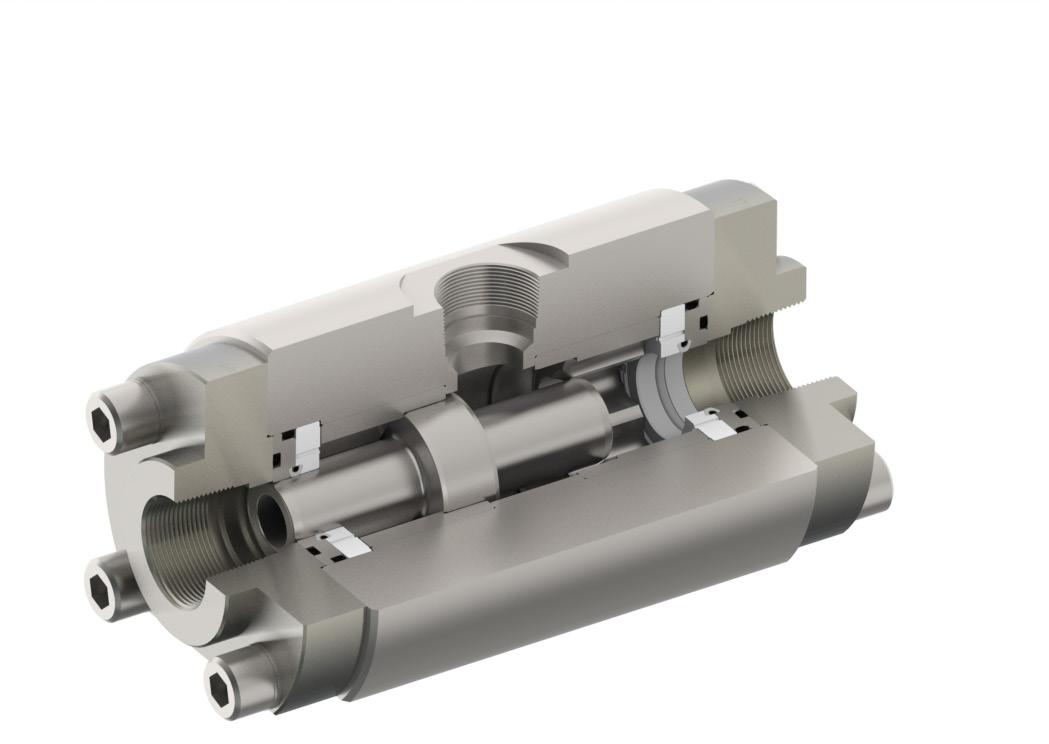

1. Cushioned - also known as hydraulic damping, occurs when the shuttle shifts into a tight clearance cavity between the adapter and the shuttle collar. This serves to slow down the shuttle and reduce shock and wear.

2. Interflow - low or high interflow options deal with how much fluid communi cates between the two inlets as the shuttle shifts from one position to another.

3. HD (Hi Drag) - This feature is an o-ring placed in the shuttle with a higher than standard squeeze. It is used to reduce rapid oscillation that can lead to prema ture failure and helps maintain last position logic.

4. Shuttle - As the only moving component, the shuttle shifts back and forth to allow fluid to pass from a given inlet to the outlet, while blocking the opposite inlet.

5. Metal to Metal Seat - a resilient seat that is far more debris tolerant than elastomeric or soft seat shuttles.

6. Pressure Biased Adapter - used for ROV intervention.

7. Stackable Shuttles - available for Mark IV valves. These designs eliminate excess piping, reduce footprint, simplify connections and decrease leak paths. (See figure 2)

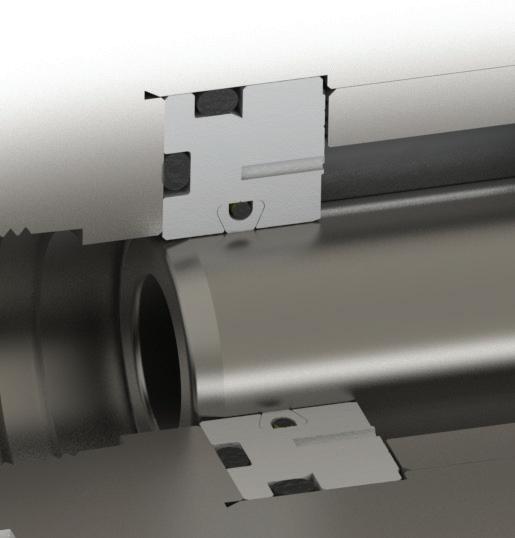

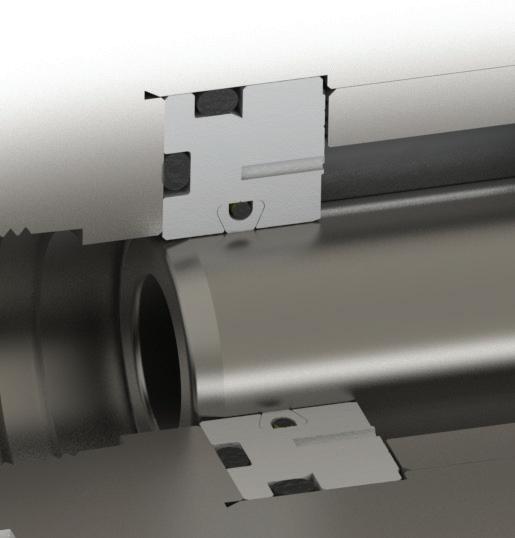

8. V-Seal - A patented technology that utilizes an elastomer and polymer (PTFE) combination that fully engages the o-ring groove, eliminating feathering and extrusion. (See figure 3)

1. 3. 5. 4. 2. 6. 7. Reference SheetShuttle Valve

Figure

1

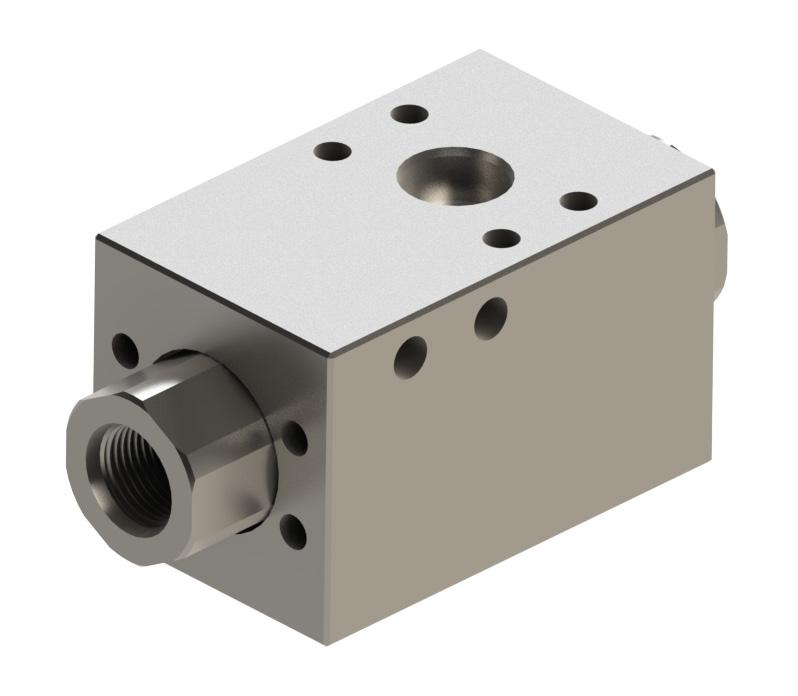

Mark IV

Shuttle

Figure

2

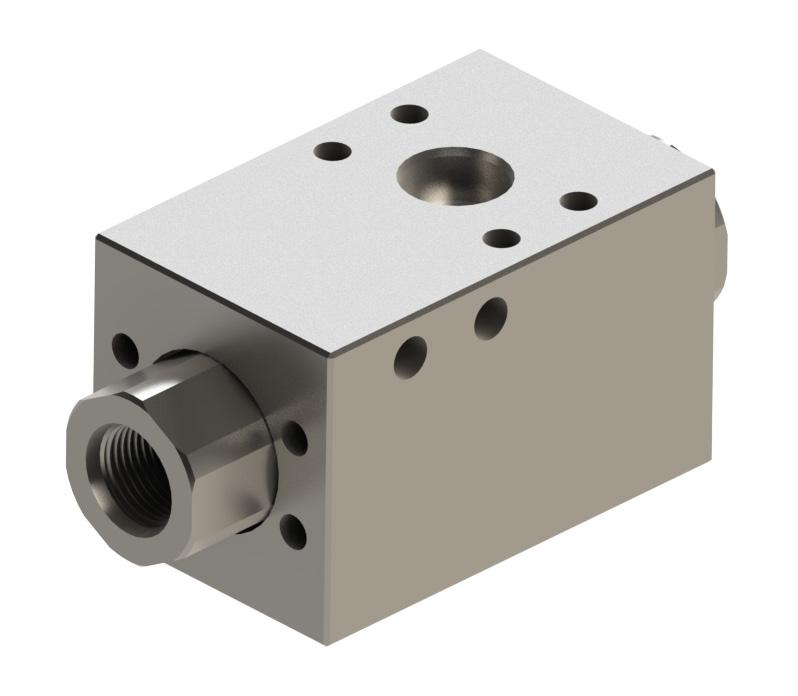

Mark IV Shuttle with Pressure Biased Attachment

Figure 3 GEN2 Shuttle 8. OUTLET INLET 2 INLET 1 INLET 2 INLET 1 OUTLET OUTLET INLET 1 INLET 2 INLET 3 INLET 4 SHUTTLE -042120-001-03 DRILLING | PRODUCTION | INDUSTRIAL

Available Configurations:

1/4” and 3/8” low interflow, SAE, and NPT configurations with customizable end connections and mounting.

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 5000 psi

Minimum Recommended Working Pressure 1500 psi

Recommended Maximum Operating Flow 8 GPM

Acceptable Leakage Rate

DRILLING

PSI,

or

drops per minute

GPM Flow Coefficient (Cv)

Minimum Shift Flow (Horizontal)

Cracking Pressure

psi

Hydrostatic Proof Pressure 7500 psi

Predicted Cycle Life 2500 cycles

Operating Temperature Range

Storage Temperature Range

Acceptable Operating Fluid Types

to 150˚F

to 150˚F

Water or mineral oil-based control fluid

Mounting Restrictions None

US Patent 10,133,282

Maximum Operating Depth 12,000 ft

BILL OF MATERIALS

Item Number Description Material

1 BODY

END CAP

CAGE-LI

A276 TP 316

A276 UNS S21800 (Nitronic 60)

A276 TP S21800 (Nitronic 60)

SEAL DISC PEEK

O-RING HNBR

SHUTTLE

A276 UNS S21800 (Nitronic 60)

Part Numbers*

Valve, Shuttle 1/4”

Low Interflow, Disc Seat

Valve, Shuttle 1/4” SAE, Low Interflow, Disc Seat

Shuttle, 3/8”

Shuttle,

Low Interflow, Disc Seat

Low Interflow, Disc Seat

Technical Sheet Disc Seal 1/4”

3/8” 5000

Low Interflow

0

.1

.6

<10

32˚F

32˚F

2

3

4

5

6

Description 29005

NPT,

29006

29007 Valve,

NPT,

29008 Valve,

3/8” SAE,

GEN2 Disc Shuttle Valve INLET 2 OUTLET INLET 1

| PRODUCTION | INDUSTRIAL INFO@Gilmore.com www.gilmore.com SHUTTLE -042120-001-04 *The repair kit part number will match the category part numbers with (-RK) at the end. *The seal kit part number will match the category part numbers with (-SK) at the end.

Available Configurations:

1/4” and 3/8” high interflow, SAE, and NPT configurations with customizable end connections and mounting.

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 5000 psi

Minimum Recommended Working Pressure 1500 psi

Recommended Maximum Operating Flow 8 GPM

Acceptable Leakage Rate

DRILLING

Disc Seal 1/4” or 3/8” 5000 PSI, High Interflow

drops per minute

GPM Flow Coefficient (Cv)

Minimum Shift Flow (Horizontal)

Cracking Pressure

psi

Hydrostatic Proof Pressure 7500 psi

Predicted Cycle Life 2500 cycles

Operating Temperature Range

Storage Temperature Range

Acceptable Operating Fluid Types

Mounting Restrictions

to 150˚F

to 150˚F

Water or mineral oil-based control fluid

None

US Patent 10,133,282

Maximum Operating Depth 12,000 ft

BILL OF MATERIALS

Item Number Description Material

1 BODY A276 TP 316

END CAP

CAGE-HI

A276 UNS S21800 (Nitronic 60)

A276 TP S21800 (Nitronic 60)

SEAL DISC PEEK

O-RING HNBR

SHUTTLE

A276 UNS S21800 (Nitronic 60)

Part Numbers* Description

- 2 Valve, Shuttle 1/4”

High Interflow, Disc Seat

- 2 Valve, Shuttle 1/4” SAE, High Interflow, Disc Seat

- 2 Valve, Shuttle 3/8” NPT, High Interflow, Disc Seat

- 2 Valve, Shuttle 3/8” SAE, High Interflow, Disc Seat

repair kit part

seal kit part number

category part

category part

GEN2 Disc Shuttle Valve

Technical Sheet

0

.1

.6

<20

32˚F

32˚F

2

3

4

5

6

29005

NPT,

29006

29007

29008

OUTLET INLET 2 INLET 1 SHUTTLE -042120-001-05

| PRODUCTION | INDUSTRIAL *The

number will match the

numbers with (-RK) at the end. *The

will match the

numbers with (-SK) at the end.

Available Configurations:

1/4” and 3/8” low interflow, SAE, and NPT configurations with customizable end connections and mounting.

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 5000 psi

Minimum Recommended Working Pressure 1500 psi

Recommended Maximum Operating Flow 4 GPM

Acceptable Leakage Rate

Minimum Shift Flow (Horizontal)

Flow Coefficient (Cv)

Cracking Pressure

Hydrostatic Proof Pressure

drops per minute

GPM

<20 psi

PSI,

or

Biased,

Interflow

psi

Predicted Cycle Life 2500 cycles

Operating Temperature Range

Storage Temperature Range

Acceptable Operating Fluid Types

Mounting Restrictions

to 150˚F

to 150˚F

Water or mineral oil-based control fluid

US Patent 10,133,282

Maximum Operating Depth 12,000 ft

BILL OF MATERIALS

Item Number Description Material

1 BODY

A276 TP 316

END CAP A276 UNS S21800 (Nitronic 60)

CAGE-LI

A276 TP S21800 (Nitronic 60)

SEAL DISC PEEK

O-RING HNBR

SHUTTLE

A276 UNS S21800 (Nitronic 60)

SPRING ELGILOY

Part Numbers* Description

- 1 Valve, Shuttle 1/4”

Low Interflow, Disc Seat, Spring Biased

- 1 Valve, Shuttle 1/4” SAE, Low Interflow, Disc Seat, Spring Biased

1 Valve, Shuttle 3/8” NPT, Low Interflow, Disc Seat, Spring Biased

- 1 Valve, Shuttle 3/8” SAE, Low Interflow, Disc Seat, Spring Biased

DRILLING

*The repair kit part number

with (-RK)

seal kit part number

category part

category

GEN2 Disc Shuttle Valve Technical Sheet Disc Seal 1/4”

3/8” 5000

Spring

Low

0

.1

.6

7500

32˚F

32˚F

None

2

3

4

5

6

7

29005

NPT,

29006

29007-

29008

OUTLET INLET 2 INLET 1 SHUTTLE -042120-001-06

| PRODUCTION | INDUSTRIAL

will match the

numbers

at the end. *The

will match the

part numbers with (-SK) at the end.

Available Configurations:

1/4” and 3/8” high interflow, SAE, and NPT configurations with customizable end connections and mounting.

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 5000 psi

Minimum Recommended Working Pressure 1500 psi

Recommended Maximum Operating Flow 4 GPM

Acceptable Leakage Rate 0 drops per minute

Seal

or

PSI, Spring Biased, High Interflow

Minimum Shift Flow (Horizontal)

GPM Flow Coefficient (Cv)

Cracking Pressure

psi

Hydrostatic Proof Pressure 7500 psi

Predicted Cycle Life 2500 cycles

Operating Temperature Range

Storage Temperature Range

Acceptable Operating Fluid Types

to 150˚F

to 150˚F

Water or mineral oil-based control fluid

Mounting Restrictions None

US Patent 10,133,282

Maximum Operating Depth 12,000 ft

BILL OF MATERIALS

Item Number Description Material

BODY A276 TP 316

END CAP A276 UNS S21800 (Nitronic 60)

CAGE-HI

A276 TP S21800 (Nitronic 60)

SEAL DISC PEEK

O-RING HNBR

SHUTTLE

A276 UNS S21800 (Nitronic 60)

SPRING ELGILOY

Part Numbers* Description

29005 - 3 Valve, Shuttle 1/4” NPT, Spring Biased, High Interflow, Disc

- 3 Valve, Shuttle 1/4” SAE, Spring Biased, High Interflow, Disc

- 3 Valve, Shuttle 3/8” NPT, Spring Biased, High Interflow, Disc

- 3 Valve, Shuttle, 3/8” SAE, Spring Biased, High Interflow, Disc

*The repair kit part number

with (-RK)

category part

the

seal kit part number

with (-SK)

match

category part

GEN2 Disc Shuttle Valve Technical Sheet Disc

1/4”

3/8” 5000

.1

.6

<20

32˚F

32˚F

1

2

3

4

5

6

7

29006

29007

29008

INLET 1INLET 2 OUTLET SHUTTLE -042120-001-07 DRILLING | PRODUCTION | INDUSTRIAL

will match the

numbers

at

end. *The

will

the

numbers

at the end.

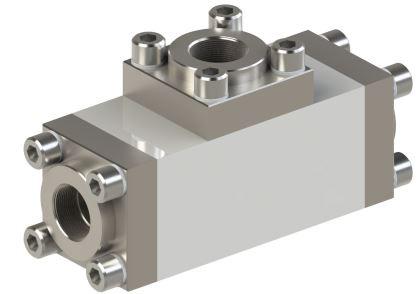

Mark

SINGLE

2 INLET 1 OUTLET

INLET 3

1

Available Configurations: 1/2”, 1”, and 1-1/2” in low interflow or high interflow, SAE and NPT configurations with customizable end connections and mounting.

2

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 5000 psi

Minimum Recommended Working Pressure 1500 psi

Recommended Maximum Operating Flow 45 GPM

Acceptable Leakage Rate

Minimum Shift Flow (Horizontal)

4 drops per minute

0.75 GPM

Minimum Shift Flow (Vertical) 2.0 GPM Flow Coefficient (Cv) 1.1

Recommended Full Shift Pressure 1500 psi

Hydrostatic Proof Pressure 7500 psi

Predicted Cycle Life 2500 Cycles

Operating Temperature Range

Storage Temperature Range

Acceptable Operating Fluid Types

Mounting Restrictions

1/2”, 5000 PSI, Non-Biased Low and High Interflow

32˚F to 150˚F

32˚F to 150˚F

Water or mineral oil-based control fluid

None

US Patent 9,915,275

Maximum Operating Depth 15,000 ft

BILL OF MATERIALS

Item Number* Description Material

1 BODY

A276 TP 316 (316 SS)

SHUTTLE, MKIV A276 UNS S21800 (Nitronic 60)

INSERT, THREADED A276 S21800 (Nitronic 60)

ADAPTER, SHUTTLE A276 TP S21800 (Nitronic 60)

ADAPTER, OUTLET A276 TP 316L (316 SS)

SEAL SUB A276 TP 316L (316 SS)

SHCS 5/16 - 18 UNC A453 GR 660

O-RING (ITEM* 8 - 11) BUNA N

Part Numbers** Description

Valve, Shuttle, MKIV, 1/2” Inline, SAE, Low Interflow, HD 29026 Valve, Shuttle, MKIV, 1/2” Stack, C62, Low Interflow, HD 29055 Valve, Shuttle, MKIV, 1/2” Inline, NPT, High Interflow, HD

kit

INLET

Technical Sheet

29025

2

3

4

5

6

7

8

STACKABLE OUTLET INLET

IV Shuttle Valve INLET

SHUTTLE -042120-001-08 DRILLING | PRODUCTION | INDUSTRIAL **The repair kit part number will match the category part numbers with (-RK) at the end. **The seal

part number will match the category part numbers with (-SK) at the end.

5000 PSI, Pressure Biased

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 5000 psi

Minimum Recommended Working Pressure 1500 psi

Recommended Maximum Operating Flow

Acceptable Leakage Rate

SINGLE

GPM (Inlet 1) 40 GPM (Inlet 2)

drops per minute

Minimum Shift Flow (Non-Biased Inlets) 0.75 GPM

Minimum Shift Pressure (Biased Inlets) 200 psi Flow Coefficient (Cv) (Inlet 1 and 2)

(Inlet 1) 1.0 (Inlet 2)

Recommended Full Shift Pressure 1500 psi

Hydrostatic Proof Pressure 7500 psi

Predicted Cycle Life 2500 Cycles

Operating Temperature Range

Storage Temperature Range

Acceptable Operating Fluid Types

Mounting Restrictions

32˚F to 150˚F

to 150˚F

Water or mineral oil-based drilling control fluid

None

US Patent 9,915,275

Maximum Operating Depth 15,000 ft

BILL OF MATERIALS

Number*

BODY

SHUTTLE

Configurations:

1”, and 1-1/2” in low interflow or high interflow

with

and

Material

A276 TP 316

A276 UNS S21800 (Nitronic 60)

INSERT, THREADED A276 TP S21800 (Nitronic 60)

SHUTTLE A276 TP 316 (316 SS)

SEAL, SUB A276 TP 316 (316 SS)

SHCS 5/16 – 18 UNC A453 GR 660

ADAPTER, OUTLET A276 TP 316 (316 SS)

COMPRESSION

N07500 (X-750)

ROD B637 N07718 (INCONEL 718)

A276 UNS S21800 (Nitronic 60)

AF

O-RING (ITEM* 12 - 15) BUNA N

Technical Sheet 1/2”,

45

4

1.1

32˚F

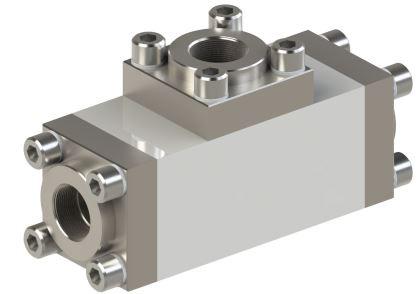

Continued on page 9.1 STACKABLE

OUTLET INLET 2 INLET 1 OUTLET INLET 3 Mark IV Shuttle Valve INLET 2 INLET 1

Item

Description

1

2

3

4 ADAPTER,

5

6

7

8 SPRING,

UNS

9 SPRING

10 PISTON

11 WEARBAND DELRIN

12

Available

1/2”,

configurations

customizable end connections

mounting. SHUTTLE -042120-001-09 DRILLING | PRODUCTION | INDUSTRIAL

SINGLE

OUTLET

1 OUTLET

3

1

Configurations:

1”, and 1-1/2” in low interflow or high interflow configurations with customizable end connections and mounting.

Part Numbers** Description

Valve, Shuttle, In-Line, MKIV, 2 Inlets, 1/2” SAE IN, 3/4” SAE IN, 1/2” SAE Out, 5000 psi, Pressure Biased, 200 psi Shift

1/2”, 5000 PSI, Pressure Biased

of Inlets

Valve, Shuttle, MKIV, 1/2” Stack, SAE, Pressure Biased, LI HD, 3 Inlets, 200 psi Shift

Valve, Shuttle, MKIV, 1/2” Stack, SAE, 2X Pressure Biased, LI HD, 4 Inlets, 200 PSI Shift 4

Valve, Shuttle, MKIV, 1/2” Stack, SAE, Pressure Biased, LI HD, 4 Inlets, 200 psi Shift 4

Valve, Shuttle, MKIV, 1/2” Inline, C62, Pressure biased, 200 psi Shift 2 29099 Valve, Shuttle, In-Line, MKIV, 2 Inlets, 1/2” SAE IN, 3/4” SAE IN, 1/2” SAE Out, 5000 psi, Pressure Biased, 350 psi Shift***

Mark IV Shuttle Valve Technical Sheet

(Cont.)

Number

29027

2 29028

3 29029

29038

29056

2

STACKABLE

INLET

INLET

INLET

INLET 2 INLET 2 Available

1/2”,

***Part Number 29099 - Pressure Biased, 350 psi Shift SHUTTLE -042120-001-09.1 DRILLING | PRODUCTION | INDUSTRIAL **The repair kit part number will match the category part numbers with (-RK) at the end. **The seal kit part number will match the category part numbers with (-SK) at the end.

INLET 2

Available Configurations: 1/2”, 1”, and 1-1/4” in SAE configurations with customizable end connections and mounting.

1

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 5000 psi

Minimum Recommended Working Pressure 1500 psi

Recommended Maximum Operating Flow (Inlet 1 and 2)

Acceptable Leakage Rate

Minimum Shift Flow (Horizontal)

GPM

4 drops per minute

GPM

Flow Coefficient (Cv) (Inlet 1 and 2) 1.1

Recommended Full Shift Pressure 1500 psi

Hydrostatic Proof Pressure 7500 psi

Predicted Cycle Life 2500 Cycles

Operating Temperature Range

Storage Temperature Range

Acceptable Operating Fluid Types

Mounting Restrictions

DRILLING

Biased

32˚F to 150˚F

32˚F to 150˚F

Water or mineral oil-based control fluid

None

US Patent 9,915,275

Maximum Operating Depth 15,000 ft

BILL OF MATERIALS

Item Number* Description Material

1 BODY

INSERT, THREADED

A276 TP 316 (316 SS)

A276 S21800 (Nitronic 60)

ADAPTER A276 TP S21800 (Nitronic 60)

SPRING COMPRESSION INCONEL (X-750)

ADAPTER, OUTLET

A276 TP 316L (316L SS)

SEAL, SUB A276 TP 316L (316L SS)

SHCS 5/16 - 18 UNC A453 GR 660

SHUTTLE, SPRING BIASED

GUIDE NUT

A276 TP S21800 (NITRONIC 60)

ASTM B169 C61400 (ALUM BRONZE)

O-RING (ITEM* 10 - 12) BUNA N

Part Numbers** Description

Valve, Shuttle, MKIV, 1/2” Inline, SAE, Spring Biased

repair kit part

with

seal kit part number

category part

category

Technical Sheet 1/2”, 5000 PSI Spring

45

2.5

2

3

4

5

6

7

8

9

10

Mark IV Shuttle Valve

29053

OUTLET

INLET

SHUTTLE -042120-001-10

| PRODUCTION | INDUSTRIAL **The

number will match the

numbers

(-RK) at the end. **The

will match the

part numbers with (-SK) at the end.

Available

1”, and 1-1/2” in low interflow or high interflow configurations with customizable end connections and mounting.

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 6000 psi

Minimum Recommended Working Pressure 1500 psi

Pressure Biased (Inlet 1) Maximum Recommended Operating Flow 175 GPM

Spring Biased (Inlet 2) Maximum Recommended Operating Flow 150 GPM

Acceptable Leakage Rate 4 drops per minute

Pressure Biased Inlet Flow Coefficient (Cv) (Inlet 4)

Non-Biased Inlet Flow Coefficient (Cv) (Inlet 1)

Pressure Biased Full Shift Pressure 400 psi

Pressure Biased Inlet Cracking Pressure 200 psi

Hydrostatic Proof Pressure 9,000 psi

Predicted Cycle Life 2500 Cycles

Predicted Cycle Life Biased Adapters 1000 Cycles Operating Temperature Range

32˚F to 150˚F Storage Temperature Range

Acceptable Operating Fluid Types

32˚F to 150˚F

Water or mineral oil-based drilling control fluid

None US Patent 9,915,275

Mounting Restrictions

Maximum Operating Depth 15,000 ft

BILL OF MATERIALS

BODY

A276 TP 316 (316 SS)

1” CODE

A276 UNS S21800 (Nitronic 60)

A276 UNS S21800 (Nitronic 60)

THREADED A276 UNS S21800 (Nitronic 60)

7/16-14

A286 (GR660)

A276 TP 316 (316 SS)

A276 UNS S21800 (Nitronic 60)

PSI SHIFT INCONEL (X-750)

INLET 2 Mark IV Shuttle Valve Technical Sheet 1”, 6000 PSI, Stackable Pressure Biased

4.7

5.4

OUTLET OUTLET INLET 1 INLET 2 INLET 3 INLET 1

Item Number* Description Material 1

2 ADAPTER,

62

3 SHUTTLE

4 INSERT,

5 SHCS,

UNC

6 ADAPTER, SEAL SUB

7 ADAPTER, PBS

8 SPRING COMPRESSION, 200

OUTLET INLET 5 INLET 3 INLET 1 INLET 4 INLET 2

Configurations: 1/2”,

Continued on page 11.1 SHUTTLE -042120-001-11 DRILLING | PRODUCTION | INDUSTRIAL

3

OUTLET

BILL OF MATERIALS (CONT.)

SPRING ROD

PISTON, PRESSURE BIASED

SHUTTLE, PRESSURE BIASED

B637 ALLOY NO7718

A276 UNS S21800 (Nitronic 60)

A276 UNS S21800 (Nitronic 60)

WEARBAND PRESSURE BIASED DELRIN AF

INSERT, SEAL SUB

A276 TP 316 (316 SS)

O-RING (ITEM* 14 - 19) HNBR

INLET

OUTLET

Part Numbers** Description Number of Inlets

1

2

Available Configurations:

1”, and 1-1/2” in low interflow or high interflow configurations with customizable end connections and mounting.

DRILLING

29015

Valve, Shuttle, MKIV, 1” SAE, Inline, Pressure Biased, 400 psi, 5000 psi 2 29019

Valve, Shuttle, MKIV, 1” C62, W/Seal Sub, LI, HD, Pressure Biased, 4 Inlets, 6000 psi 4 29031

Valve, Shuttle, MKIV, 1” C62 W/ Seal Sub, LI, HD, Pressure Biased, 200 psi shift, 3 Inlets, 6000 psi 3 29033

Valve, Shuttle, MKIV, 1” C62, LI, HD, Pressure Biased, 200 psi Shift, 4 Inlets, 6000 psi 4 29034

Valve, Shuttle, MKIV, 1” C62, LI, HD, 2X Pressure Biased, 200 psi Shift, 4 Inlets, 6000 psi 4 29035

Valve, Shuttle, MKIV, 1” C62, LI, HD, Pressure Biased, 200 psi Shift, 5 Inlets, 6000 psi 5

Valve, Shuttle, MKIV, 1” C62, LI, HD, Pressure Biased, 200 psi Shift, 6 Inlets, 6000 psi 6

Valve, Shuttle, MKIV, 1” C62, LI, HD, Pressure Biased, 200 psi Shift, 7 inlets, 6000 psi 7

*The repair kit part number will match the category part numbers with (-RK)

the

*The seal kit part number will match the category part numbers with (-SK)

the

INLET 2 Mark IV Shuttle Valve Technical Sheet 1”, 5000 PSI, Stackable Pressure Biased (Cont.)

29039

29040

1 OUTLET INLET 2 INLET 3 INLET 4 INLET 5 INLET 1

Item Number* Description Material 9

10

11

12

13

14

INLET

INLET

INLET

1/2”,

SHUTTLE -042120-001-12

| PRODUCTION | INDUSTRIAL

at

end.

at

end.

Available Configurations: 1/2”, 1”, and 1-1/4” in SAE configurations with customizable end connections and mounting.

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 5000 psi

Minimum Recommended Working Pressure 1500 psi

Spring Biased inlet Maximum Recommended Operating Flow 175 GPM

Pressure Biased 150 GPM

Acceptable Leakage Rate 4 drops per minute

Spring Biased Inlet Flow Coefficient (Cv)

Non-Biased Inlet Flow Coeffiecient (Cv)

5.4 Pressure Biased Inlet

Spring Biased Inlet Shift Pressure 200 psi

Spring Biased Full Shift Flow @ 1,500 psi 7.5 GPM

Hydrostatic Proof Pressure 7500 psi

Predicted Cycle Life 1000 Cycles

Operating Temperature Range 32˚F to 150˚F

Storage Temperature Range 32˚F to 150˚F

Acceptable Operating Fluid Types

Mounting Restrictions

Water or mineral oil-based control fluid

None

US Patent 9,915,275

Maximum Operating Depth 15,000 ft

BILL OF MATERIALS

A276 TP 316 (316 SS)

THREADED A276 UNS S21800 (Nitronic 60)

OUTLET A276 TP 316L (316L SS)

7/16-14 UNC A286 GR660

A276 UNS S21800 (Nitronic 60)

(X-750)

C61499

UNS S21800

A276 TP 316L (316

Technical Sheet 1”, 5000 PSI Pressure Biased and Spring Biased

5.4

4.7

Item Number* Description Material 1 BODY

2 INSERT,

3 ADAPTER

4 SHCS,

5 ADAPTER, PBS

6 SPRING COMPRESSION, 200 PSI SHIFT INCONEL

7 NUT GUIDE B169

8 SHUTTLE A276

9 INSERT, SEAL SUB

SS) 10 O-RING (ITEM* 10 - 11) BUNA N Mark IV Shuttle Valve OUTLET INLET 2 INLET 1 OUTLET INLET 2 INLET 1 Continued on page 13.1 SHUTTLE -042120-001-13 DRILLING | PRODUCTION | INDUSTRIAL

Part

Technical Sheet 1”, 5000 PSI Pressure Biased and Spring Biased (Cont.) Available Configurations: 1/2”, 1”, and 1-1/4” in SAE configurations with customizable end connections and mounting. Mark IV Shuttle Valve

Numbers** Description 29016 Valve, Shuttle, MKIV, 1” Inline, SAE, Spring Biased 5000 psi 29020 Valve, Shuttle, MKIV, 1” Inline, SAE, Pressure Biased 5000 psi, 200 psi Shift, 1-1/4” SAE OUTLET INLET 2 INLET 1 OUTLET INLET 2 INLET 1 SHUTTLE -042120-001-13.1 DRILLING | PRODUCTION | INDUSTRIAL **The repair kit part number will match the category part numbers with (-RK) at the end. **The seal kit part number will match the category part numbers with (-SK) at the end.

Mark

Shuttle Valve Technical Sheet

6000 PSI, Non-Biased, Low/High Interflow and Stacked

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 6000 psi

Minimum Recommended Working Pressure 1500 psi

Spring Biased Inlet Maximum

Recommended Operating Flow 175 GPM

Acceptable Leakage Rate 4 drops per minute

Minimum Shift Flow (Horizontal)

Flow Coefficient (Cv) (Inlet 1 and 2) 5.4

GPM

Recommended Full Shift 1500 psi

Hydrostatic Proof Pressure 9000 psi

Predicted Cycle Life 2500 Cycles

1

Operating Temperature Range

32˚F to 150˚F

Storage Temperature Range 32˚F to 150˚F

Acceptable Operating Fluid Types

Water or mineral oil-based drilling control fluid

Mounting Restrictions None

US Patent 9,915,275

Maximum Operating Depth 15,000 ft

BILL OF MATERIALS

Item Number* Description Material

Available Configurations: 1”, and 1-1/2” in low interflow or high interflow configurations with customiz able end connections and mounting.

1 BODY A276 TP 316 (316 SS)

SHUTTLE, LI, HD A276 UNS S21800 (Nitronic 60)

INSERT, THREADED A276 S21800 (Nitronic 60)

ADAPTER, 1” A276 S21800 (Nitronic 60)

O-RING (ITEM* 5 - 7) BUNA N

Part

29012

Description

Shuttle, MKIV,

psi, Inline, LI, HD

C62, Seal Sub,

of Inlets

DRILLING

repair kit

with (-RK)

with (-SK)

Valve, Shuttle, MKIV,

C62 Seal Sub, 6000 psi,

Valve, Shuttle, MKIV,

Inlets,

C62, LI, HD,

**The seal kit part number

match the category part

2.5

IV

1”,

2

3

4

5

INLET 2 INLET

SINGLE

Numbers**

Number

Valve,

1”

6000

2 29014

1”

90°, LI, HD 2 29032

1”

3

6000 psi 3 OUTLET STACKABLE INLET 2 INLET 1 INLET 3 OUTLET

SHUTTLE -042120-001-14

| PRODUCTION | INDUSTRIAL **The

part number will match the category part numbers

at the end.

will

numbers

at the end.

OUTLET

INLET 2 INLET 1

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 6000 psi

Minimum Recommended Working Pressure 500 psi

Maximum Operating Flow

275 GPM

Minimum Shift Flow (Low Interflow) 5 GPM

Minimum Shift Flow (High Interflow) 10 GPM

Acceptable Leakage Rate

Flow Coefficient (Cv) (Inlet 1 and Inlet 2) 12

1/2”,

PSI, Single Stack

Available Configurations:

1”, and 1-1/2” in low interflow or high interflow configurations with customiz able end connections and mounting.

drops per minute

Hydrostatic Proof Pressure 9000 psi

Predicted Cycle Life 2500 Cycles

Operating Temperature Range

Storage Temperature Range

Acceptable Operating Fluid Types

32˚F to 150˚F

32˚F to 150˚F

Water or mineral oil-based control fluid

Mounting Restrictions None

US Patent 9,915,275

BILL OF MATERIALS

Item Number* Description Material

1 BODY

INSERT, THREADED 1-1/2”

3 SHUTTLE

A276 TP 316 (316 SS)

A276 UNS S21800 (Nitronic 60)

A276 UNS S21800 (Nitronic 60)

4 ADAPTER, 1” CODE 62 A276 UNS S21800 (Nitronic 60)

5 O-RING (ITEM* 5 - 7) HNBR

Part Numbers** Description

29059 Valve, Shuttle, MKIV, 1-1/2” C62, Inline, Low Interflow, HD

29060 Valve, Shuttle, MKIV, 1-1/2” C62, 90°, High Interflow, HD

**The repair kit part number will match the category part numbers with (-RK) at the end.

**The seal kit part number will match the category part numbers with (-SK) at the end.

Mark IV Shuttle Valve Technical Sheet 1

6000

4

2

SHUTTLE -042120-001-15 DRILLING | PRODUCTION | INDUSTRIAL

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 6000 psi

Minimum Recommended Working Pressure 500 psi

Acceptable Leakage Rate

4 drops per minute

Flow Capacity (Inlet 1-6) 275 GPM Flow Capacity (Inlet 7) 200 GPM

Minimum Shift Flow (Inlet 1-6) 5 GPM

Minimum Shift Pressure (Inlet 7) 300 psi

Flow Coefficient (Cv) (Inlet 1 and Inlet 2) 5 Flow Coefficient (Cv) (Inlet 3) 5.3 Flow Coefficient (Cv) (Inlet 4) 6 Flow Coefficient (Cv) (Inlet 5) 7 Flow Coefficient (Cv) (Inlet 6) 8 Flow Coefficient (Cv) (Inlet 7) 10

Connection (Inlet 1-6)

1-1/2” Code 62 Seal Sub Connection (Inlet 7) 1-1/2” Code 62 Fixed Nose Outlet 1-1/2” Code 62 Seal Sub

Hydrostatic Proof Pressure 9000 psi

Predicted Cycle Life 2500 Cycles

Operating Temperature Range

32˚F to 150˚F Storage Temperature Range 32˚F to 150˚F

Acceptable Operating Fluid Types

Water or mineral oil-based drilling control fluid

None US Patent 9,915,275

Mounting Restrictions

Maximum Operating Depth 15,000 ft

BILL OF MATERIALS

A276 TP 316 (316 SS)

UNS S21800 (Nitronic

UNS S21800

Item Number* Description Material 1 BODY

2 INSERT, THREADED A276

60) 3 SHUTTLE A276

(Nitronic 60) 4 SCHS, 5/8 – 11 UNC A453 GR 660 Continued on page 16.1 Mark IV Shuttle Valve Technical Sheet 1 1/2”, 6000 PSI, Stackable and Pressure Biased OUTLET INLET 2 INLET 1 OUTLET INLET 1 INLET 3 INLET 2 Available Configurations: 1-1/2” in low interflow or high interflow configurations with customizable end connections and mounting. OUTLET INLET 1 INLET 2 INLET 4 INLET 6 INLET 3 INLET 5 INLET 7 SHUTTLE -042120-001-16 DRILLING | PRODUCTION | INDUSTRIAL

Available Configurations:

low interflow

6000 PSI,

Biased

BILL OF MATERIALS (CONT.)

SHUTTLE PRESSURE BIASED

SPRING ROD, PRESSURE BIASED

A276 UNS S21800

B637 Alloy N07718 (INCONEL 718)

PISTON, PRESSURE BIASED A479 UNS S32760 (Super Duplex)

DERLIN AF

COMPRESSION MP35N (UNS R30035)

ADAPTER 1” A276 UNS S21800

ADAPTER, PRESSURE BIASED A276 UNS S21800 (Nitronic 60)

ADAPTER, SEAL SUB A276 TP316

INSERT, SEAL SUB, TYPE 2, 1-1/2” MKIV A276 TP 316 (316 SS)

O-RING (ITEMS* 14 - 20) HNBR

of Inlets

Valve, 1-1/2”, Shuttle, MKIV, Stack, C62, Low Interflow, High Drag, Pressure Biased, 3 Inlets, 300 psi Shift

Valve, 1-1/2”, Shuttle, MKIV, Stack, C62, Pressure Biased, Low Interflow, High Drag, 5 Inlets, 300 psi Shift

Valve, 1-1/2”, Shuttle, MKIV, Stack, C62, Pressure Biased, Low Interflow, High Drag, 4 Inlets, 300 psi

Valve, 1-1/2”, Shuttle, Stack, Flange adapter, C62, Low Interflow, High Drag, Pressure Biased, 4 Inlets, 300 psi Shift

Valve, 1-1/2”, Shuttle, MKIV, Stack, C62, Pressure Biased, Low Interflow, High Drag, 6 Inlets, 300 psi Shift

Valve, 1-1/2”, Shuttle, MKIV, Stack, C62, Pressure Biased, Low Interflow, High Drag, 7 Inlets, 300 psi Shift

high interflow

seal kit

category

Mark IV Shuttle Valve Technical Sheet 1 1/2”,

Stackable and Pressure

(Cont.)

Item Number* Description Material 5

6

7

8 WEARBAND

9 SPRING,

10

11

12

13

14

Part Numbers** Description Number

29021

3 29022

5 29023

4 29063

4 29068

6 29069

7 OUTLET OUTLET INLET 2 INLET 1 INLET 1 INLET 2 INLET 3 OUTLET INLET 7 INLET 6 INLET 4 INLET 5 INLET 3 INLET 2 INLET 1

1-1/2” in

or

configurations with customizable end connections and mounting. SHUTTLE -042120-001-16.1 DRILLING | PRODUCTION | INDUSTRIAL **The repair kit part number will match the category part numbers with (-RK) at the end. **The

part number will match the

part numbers with (-SK) at the end.

INLET 2

Available Configurations:

1-1/2” in configurations with customizable end connections and mounting.

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 6000 psi

Minimum Recommended Working Pressure 500 psi

Flow Capacity (Inlet 1 and Inlet 2) 275 GPM

Acceptable Leakage Rate 4 drops per minute

Flow Coefficient (Cv) (Inlet 1 and Inlet 2) 12

Biased Inlet Minimum Shift Flow 10 GPM

Hydrostatic Proof Pressure 9000 psi

Predicted Cycle Life

Operating Temperature Range

1000 Cycles

32˚F to 150˚F

Storage Temperature Range 32˚F to 150˚F

Acceptable Operating Fluid Types

Water or mineral oil-based drilling control fluid

Mounting Restrictions None

US Patent 9,915,275

Maximum Operating Depth 15,000 ft

BILL OF MATERIALS

Item Number* Description Material

1 BODY

A276 TP 316 (316 SS)

2 SHUTTLE, FULL FLOW A276 UNS S21800 (Nitronic 60)

3 INSERT, THREADED A276 UNS S21800 (Nitronic 60)

4 ADAPTER, PRESSURE BIASED A276 UNS S21800 (Nitronic 60)

5 ADAPTER, SEAL SUB A276 TP316 (316 SS)

6 SPRING, COMPRESSION INCONEL (X-750)

NUT, GUIDE

ASTM B169 C61400 (BRONZE)

O-RING (ITEM* 8 - 12) HNBR

Part Numbers** Description

Valve, 1-1/2”, Shuttle, MKIV, C62, Inline, 2 Inlets, Spring Biased

**The repair kit part number

with (-RK)

match the category part

the end.

**The seal kit part number will match the category part

with (-SK)

Mark IV Shuttle Valve Technical Sheet 1 1/2”, 6000 PSI, Spring Biased C62

7

8

OUTLET

INLET 1

29062

SHUTTLE -042120-001-17 DRILLING | PRODUCTION | INDUSTRIAL

will

numbers

at

numbers

at the end.

INLET

Available Configurations:

in low interflow or high interflow, SAE and NPT configurations with customiz able end connections and mounting.

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 3000 psi

Recommended Working Pressure 500 psi

Recommended Maximum Operating Flow 150 GPM

Acceptable Leakage Rate

Minimum Shift Flow

Coefficient (Cv)

Hydrostatic Proof Pressure

Predicted Cycle Life

Temperature Range

Temperature Range

Acceptable Operating Fluid Types

Mounting Restrictions

Patent

drops per minute

GPM

psi

Cycles

to 150˚F

to 150˚F

Water or mineral oil-based drilling control fluid

Operating Depth 15,000 ft

BILL OF MATERIALS

Item Number* Description

BODY A276 TP 316

SLEEVE

SPACER, LI

CAP

V-SEAL

SHUTTLE

S21800 (Nitronic 60)

S21800 (Nitronic 60)

UNS S21800

TP 316

SHCS 1/2 - 13 UNC A286 (GR660)

NORD-LOCK, 1/2”

SMO

O-RING (ITEM* 10 - 12) BUNA N

Numbers**

Shuttle, GEN

Shuttle,

Shuttle,

Low Interflow, 3000 psi

IN,

Out, 3000 psi, Low

Face Seal Out, 3000 psi, Low

repair kit

seal kit part

GEN2 V-Seal Shuttle Valve Technical Sheet 1”, 3000 PSI, Low Interflow

1”

Minimum

0

1

Flow

5

4500

2500

Operating

32˚F

Storage

32˚F

None US

9,719,600 Maximum

Material 1

2

A276

3

POLYETHERETHERKETONE 4

A276

5

PTFE 6

A276

7 FLANGE A276

8

9

254

10

OUTLET INLET

Part

Description 29043 Valve,

2, 1” NPT,

29070 Valve,

GEN 2, 1” SAE

1” SAE

Interflow 29071 Valve,

GEN 2, 1” C62,

Interflow SHUTTLE -042120-001-18 DRILLING | PRODUCTION | INDUSTRIAL **The

part number will match the category part numbers with (-RK) at the end. **The

number will match the category part numbers with (-SK) at the end.

Available Configurations:

in low interflow or high interflow, SAE

NPT configurations with customiz able end connections and

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 3000 psi

Recommended Working Pressure 500 psi

Recommended Maximum Operating Flow 150 GPM

Acceptable Leakage Rate

Minimum Shift Flow

Coefficient (Cv)

Recommended Full Shift Pressure

Proof Pressure

Cycle Life

Temperature Range

Temperature Range

Acceptable Operating Fluid Types

Mounting Restrictions

Patent

drops per minute

GPM

psi

psi

Cycles

to 150˚F

to 150˚F

Water or mineral oil-based drilling control fluid

Operating Depth 15,000 ft

BILL OF MATERIALS

TP 316

S21800 (Nitronic 60)

HI POLYETHERETHERKETONE

S21800 (Nitronic 60)

UNS S21800

TP 316

1/2 - 13

A286 (GR660)

1/2”

(ITEM*

SMO

-

N

NPT, High Interflow, 3000

GEN2 V-Seal Shuttle Valve Technical Sheet 1”, 3000 PSI, High Interflow NPT

Minimum

0

5

Flow

5

500

Hydrostatic

4500

Predicted

2500

Operating

32˚F

Storage

32˚F

None US

9,719,600 Maximum

Item Number* Description Material 1 BODY A276

2 SLEEVE A276

3 SPACER,

4 CAP A276

5 V-SEAl PTFE 6 SHUTTLE A276

7 FLANGE A276

8 SHCS

UNC

9 NORD-LOCK,

254

10 O-RING

10

12) BUNA

OUTLET INLETINLET Part Numbers** Description 29041 Valve, Shuttle, GEN 2, 1”

psi

1”

and

mounting. SHUTTLE -042120-001-19 DRILLING | PRODUCTION | INDUSTRIAL **The repair kit part number will match the category part numbers with (-RK) at the end. **The seal kit part number will match the category part numbers with (-SK) at the end.

Available Configurations:

in low interflow or high interflow

with customizable end

and mounting.

FUNCTIONAL DESIGN SPECIFICATION

Maximum Allowable Working Pressure 5000 psi

Recommended Working Pressure 500 psi

Recommended Maximum Operating Flow 150 GPM

Acceptable Leakage Rate

drops per minute

Minimum Shift Flow Low Interflow 1 GPM

Shift Flow High Interflow

Coefficient (Cv)

Full Shift Pressure

Hydrostatic Proof Pressure

Predicted Cycle Life

Operating Temperature Range

Temperature Range

Acceptable Operating Fluid Types

Mounting Restrictions

GPM

psi

psi

Cycles

to 150˚F

to 150˚F

Water or mineral oil-based drilling control fluid

Patent 9,719,600

Operating Depth 15,000 ft

BILL OF MATERIALS

Number*

-

(ITEM*

Material

TP 316 (316 SS)

S21800 (Nitronic 60)

S21800 (Nitronic 60)

UNS S21800

TP 316

(GR660)

SMO

-

N

psi,

IN/OUT,

Technical Sheet 1”, 5000 PSI, High/Low Interflow NPT

1”

configurations

connections

GEN2 V-Seal Shuttle Valve

Minimum

0

Minimum

5

Flow

5 Recommended

500

7500

2500

32˚F

Storage

32˚F

None US

Maximum

Item

Description

1 BODY A276

2 SLEEVE A276

3 SPACER, HI POLYETHERETHERKETONE 4 CAP A276

5 V-SEAL PTFE 6 SHUTTLE A276

7 FLANGE A276

8 SHCS 1/2

13 UNC A286

9 NORD-LOCK, 1/2” 254

10 O-RING

10

12) BUNA

OUTLET INLETINLET Part Numbers** Description 29042 Valve, Shuttle, GEN 2, 1” NPT IN/OUT, 5000

Low Interflow 29044 Valve, Shuttle, GEN 2, 1” NPT

5000 psi, High Interflow SHUTTLE -042120-001-20 DRILLING | PRODUCTION | INDUSTRIAL **The repair kit part number will match the category part numbers with (-RK) at the end. **The seal kit part number will match the category part numbers with (-SK) at the end.

Gilmore 1231 Lumpkin Road Houston, TX 77043 +1 713 468 8778 INFO@gilmore.com www.gilmore.com