Gilmore Relief Valve

Ensuring safety systems are reliable and efficient.

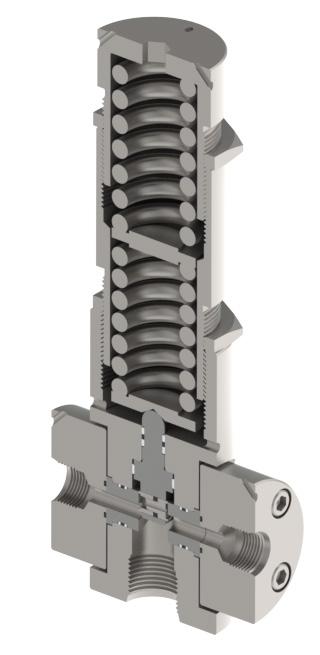

The new generation of relief valves, Gilmore’s GEN2 Relief Valve product line are highly reliable and quick acting, sensing and safely relieving pressure when it exceeds the desired setting within hydraulic control systems. Meeting industry requirements to prevent instrument and equipment failure, Gilmore GEN2 Relief Valves can be used in both topside and subsea applications.

Significant engineering enhancements

• Bi-directional Tungsten Carbide shear seal technology which prevents back pressure surge failure

• Extended life-cycle through wearband enhancement taking the radial force off the seal carrier

• Integral check valve option allows the testing of the GEN2 Relief Valve while still installed, eliminating the need to remove to recertify

Gilmore Relief Valve

Check Valve helps to test the integrity of the relief valve while in place, eliminating the need for removal to resertify

Port

Benefits

Qualified to API 16D requirements

Proprietary bi-directional Tungsten Carbide metal seal technology Ensures long life seal integrity and prevents back pressure surge failures

Suitable for panel mounting

Improved materials for offshore use:

• Tungsten Carbide (10% Ni) Hydro-Seals

• Inconel X750 Springs

• Nitronic 60 Seal Carrier

• 17-4 PH H1150DA Body

• PEEK / HNBR Soft Seals

• 316ss Flange

• A286 Gr 660 Cap Screws

Wide variety of set point ranges and vent port configurations

Wide variety of port styles to select from Optional inlet check valve and in situ SAE test port Drop-in replacement for legacy Gilmore relief valves

Auxiliary Test Port allows the user to pressure up the valve for verification and validity

GEN2 Hydro Seal Relief Valve

GEN2 Dual Vent Relief Valve

GEN2 Code 62 Relief Valve Auxilliary Test Port

GEN2 Code 62 Relief Valve Auxilliary Test