Health & Safety Pack For Construction Sites.

This pack has been produced for: Contents.

1. Company Statement

2. Company Health & Safety Policy

3. Company Environmental Policy

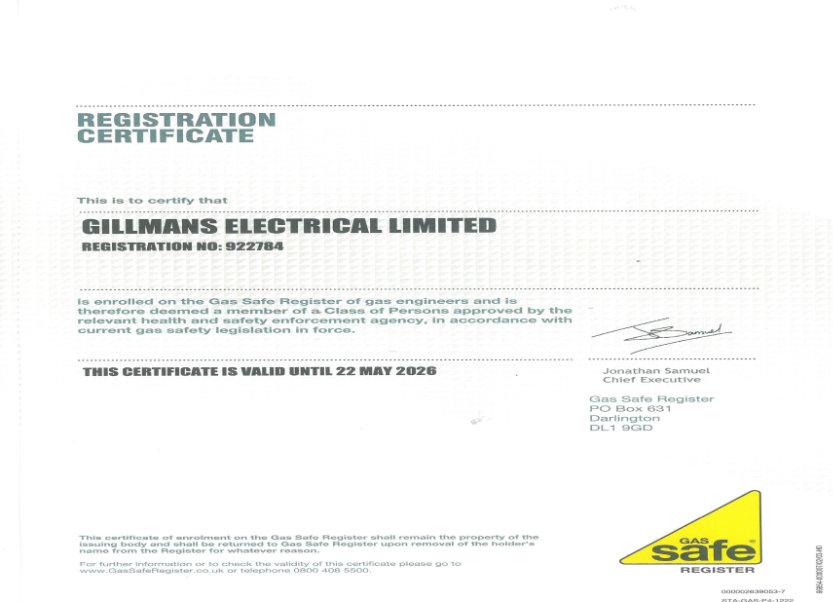

4. Company Certificates

5. Your Specific Method Statements

6. Your Specific Risk Assessments

7. Employee CSCS and Gas Safe Cards

Contacts:

Julie Cook 07761 635 036 julie.cook@gillmans.co.uk BDM - National Accounts

Charlotte Niblett 01452 509 059 tradesales@gillmans.co.uk Trade Supervisor

Rob Chappell 07551 154 270 rob.chappell@gillmans.co.uk Group GM, H&S & HR

Our Statement

Gillman’s Electrical Group limited recognises its obligations under the health & safety at work act 1974. In the conduct of its activities, it will implement “absolute” requirements as detailed in the relevant statutory instruments; and, in the conduct of its activities, it will, as far as is reasonably practicable:

The directors of the company understand the importance of having a safe and pleasant working environment which is risk free, they therefore support the below statement fully and work hard to ensure the high standards set by the company are reached.

• Protect the health and safety of its employees and all others who may be affected by its activities.

• Undertake appropriate assessments to enable the company to establish and maintain a safe, healthy working environment.

• Safeguard employees and all others from foreseeable risks with regards to health, safety and the environment in relation to existing processes or systems of work.

• Seek to eliminate or minimise risks to health or safety before the introduction of new substances, plant, machinery, equipment, or any change to existing processes or systems of work.

• Train all employees to carry out their agreed duties safely and to be aware of their responsibilities in respect of health, safety and environmental matters and seek their participation and co-operation in the identification of danger and the prevention of accidents.

• Ensure that contractors are informed of dangers present on the premises and of relevant company procedures and that they are monitored for compliance with those procedures without detracting from any contractual responsibilities.

• Establish lines of communication with the workforce with the object of creating an awareness of health, safety and environmental issues with particular references to their responsibilities.

• Maintain a relationship with appropriate organisations to enable changes in legislation and approaches to health and safety, to be considered and implemented as necessary.

The management of the company will implement this policy to ensure a safe environment for work and establish high standards of housekeeping, paying particular regards to:

• The provision of a safety statement, allocating responsibilities within the organisation.

• Following the “principles of prevention” as set out in the main policy, when implementing any preventative and protective measures.

• Providing sufficient resources to meet the requirements of health and safety and to support the health and safety plan.

• Ensuring that adequate information is available to all persons with regards to the hazards at the company.

• Providing adequate personal protective equipment and training employees in its use.

• Providing appropriate fire protection, first aid and welfare facilities and ensuring unimpeded access to and egress from the premises.

• The promotion of effective participation by all employees in health, safety and environmental issues.

• Regular review of this policy statement, which is to be revised annually or whenever a significant change in legislation, work processes, substances, equipment or staff make this necessary.

• A health and safety committee, made up of elected members of staff, from each department will meet bi-monthly, to look through and to deal with any issues that may arise. The meeting will always be chaired by a director, with the committee having the focus, training and power to implement changes and recommendations to ensure a risk and injury free environment.

• The board will review all accident statistics annually, with all follow up investigative information to reduce the risk of any further ‘same type’ accidents occurring in the future.

Company Intent.

Health & Safety Policy.

Gillmans Electrical Ltd aims for excellence in Health, Safety and Wellbeing of the group and all associated interests of the group.

The company will accomplish this by continually seeking to improve our Health and Safety management, systems and processes so that our expectations of having the safest working environment is achieved.

We will ensure that each and every obligation the group has under Health and Safety will be met to the fullest with a key focus on employee’s wellbeing.

Gillmans Electrical Ltd recognises that complying with The Health and Safety at Work Act 1974 and all pertaining regulations is a legal requirement, not a matter of choice. The group will act positively to minimise the incidence of all workplace risks and all activities will be carried out with the highest regard for the health, safety and wellbeing of all of our employees.

The company will empower all of its employees to assist, support and adopt the very best safety in all activities by providing training, high quality information and instruction, along with equipment and supervision to enable them to work safely while been competent and confident.

The company will ensure that all its activities are planned, risk assessment and instructed to reduce every level of risk. These will be reviewed at regular intervals to identify any hazards and to adopt corrective actions required to reduce any new risks.

We will encourage our employees to actively nurture a open and health attitude towards Health and Safety. We will work and consult with employees to support this.

Should there be any changes within the group or to legislation this policy will be reviewed, it will be reviewed annually in any case.

Company Introduction.

Gillmans Electrical Ltd is striving to create a positive and inclusive working environment and culture, providing the conditions for individuals and teams to thrive and achieve the highest standards of performance and service.

Positive contributions will be recognised by the group and encouraged.

The company will support its employees with learning and development through training and a positive culture. This will in turn empower employees to raise any Health and Safety concerns they have. The group will trust employees to be open and honest and adopt a full Health and Safety culture.

Scope.

This policy applies to all directly employed employees, those working from agencies or subcontractors on behalf of the company.

Contractors working on the behalf of the company who employ 4 or less employees will need to confirm they will adopt the standards of this policy or confirm in writing that they have a full written Health & Safety policy which maintains the same standards.

Contractors with 5 or more employees must confirm that they have a full written Health and Safety policy which is to the same standard as this.

All employees, including sub-contractors, agency staff and contractors’ employees have a duty to take reasonable care of health and safety at work for you your team and others, and to co-operate with their employer to ensure compliance with all health and safety requirements.

Roles & Responsibilities.

Employees:

Are reminded that they must take care of their own health and safety and that of others who may be affected by their work under the Health and Safety at Work Act 1974.

They must inform their employer of any danger to the health, safety or wellbeing of a person or persons posed by a work activity under the Management of Health and Safety at Work Regulations 1999.

Inform their employer of any shortcomings in the employer’s protection arrangements under MHSWR.

Employees must co-operate with their employer’s health and safety arrangements under the MHSWR.

Managers:

Managers will ensure that all activities their teams are required to complete will have been fully assessed and;

Each activity has a written risk assessment and method statement to cover the activity.

Employees have received the appropriate training so that they have a full and clear knowledge and understanding of the task they have been given to complete.

To ensure health and safety is always considered when planning activities.

Ensuring that employees are fully aware of the reporting and investigation of any suspected breaches within health and safety or following any incident.

Health & Safety Consultant:

To ensure the day to day management of health and safety is maintained at all times and all procedures are maintained in date and available to managers and employees.

Able to support managers and directors with the day to day advice required to ensure tasks can be completed as safely as possible.

Arrange suitable and sufficient training, training material and information for managers and employees so that they have suitable and sufficient advice on the Health and Safety at Work Act and can carry off their duties in the safest possible manner.

To monitor all reports and maintain records of any incidents, accidents and corresponding investigations.

Produce action plans and recommendations for directors and managers following any investigations.

Act as the link between the group and any third party company in the interests of health and safety, for example external third party insurers, EHO or HSE inspectors.

Directors:

The directors remain as the ultimate for responsibility for the Health, Safety and welfare of all employees for the business and to ensure that there are sufficient resources available to maintain high standards, reduce risk and injury to employees and to protect visitors and third parties.

Ensure that suitable risk assessments are maintained for all roles and activities that the Group is engaged with.

Ensuring that line managers are accountable for health and safety within their departments and areas of control.

Delivery of Policy.

This policy will be freely available to all managers and employees of the Group. Any employee can request a copy at any time.

It will be available through the company intranet site – Gillco and also available via each departmental manager.

Information posters, tool box talks and other training information will be displayed from time to time around buildings operated by the group to keep staff aware.

Monitoring of Policy.

This policy will be reviewed upon any significant changes to the Health and Safety ar Work Act 1974;

Any changes to any of the Regulations under the Act;

Any significant changes to working policies or practices of the group

Or; annually if none of the above apply.

Risk Assessments.

All activities that our employees are requested to complete must be properly assessed, the aim is to element as many risks to health or injury as possible, where we cannot eliminate the risk we will plan so that it is reduced as much as possible.

Once the risk has been assessed and the appropriate risk assessment completed all staff involved in the actions must be trained and briefed to the assessment to ensure that they have a good understanding of it and understand what is required of them to ensure that they will continue to ensure risks are reduced to the lowest level.

Employees will be given the opportunity to make suggestions, ask advise or clarify any part of the risk assessments prior to completing the task.

Method Statements.

Method statements will set out step by step the actions required by the employee to complete the task they have been asked to complete.

It will always flow with the risk assessment to ensure full compliance and again employees will be consulted on all method statements prior to completing the tasks.

Employees will fully complete all sections of method statements as required upon completion of the task and will undertake to follow fully the instructions laid out on the documents.

Training.

All staff will receive enough training to allow them to safely complete all the tasks they have been requested to do so in a safe manner.

Departmental managers will be required to assess the training needs for employees and to consult with the health and safety consultant to ensure that all training required is completed. The training can be in any of the below formats, subject to it been fully sufficient to ensure a safe conclusion to the task;

�� Classroom based training

�� E-learning

�� Module – on job training

�� Toolbox Talks / Training / Information sheets

Training may take into more than one option and may be spread over a period of time.

Managers will also consider regular update training to ensure employees remain refreshed.

Consultation.

The company recognises the importance of inclusion in the regard for health and safety, we understand and wish for employees to own the importance of good health and safety standards with the managers and directors ‘as one’.

The group will therefore regularly consult with all employees on health and safety matters and will take into account the importance of the information employees give when making decisions.

As a company we will invest in managers and staff receiving health and safety training to better enable them in helping and making suggestions.

Accident & Investigation.

The following should be reported through the online incident report form via Gillco. Reporting incidents allows the company to review, investigate and action, so we can prevent any reoccurrence.

�� Near Miss

�� Non-reportable incident / minor injury

�� Reportable incident / RIDDOR event

�� Incident involving a member of the public Near Miss:

This is an occurrence where someone may have been hurt but managed to escape injury –reporting this type of incident will allow the company to put actions in place to prevent it happening again.

Non-reportable / Minor injury:

A minor incident where local first has been required, or an employee has required the services of a local GP. A full incident report will enable the company to investigate and action plan a remedy to prevent a reoccurrence.

Reportable / RIDDOR:

An incident where the injury sustained or possible injury would be to the level that would require reporting under the RIDDOR regulations, such as a broken bone. These types of incidents must be fully reported within 24 hours of the incident and must be fully investigated within 14 days to enable a full RIDDOR report to be submitted.

Such incidents may warrant a follow up investigation from the HSE or local EHO.

Incident involving public:

Any incident that involves a member of the public or sub-contractor / agency work must be fully reported, the H&S consultant will review the incident within 24 hours and will confirm if a full investigation is required.

First Aid.

Each site has specifically trained first aiders who are always on duty, the number of first aiders will be dependent on the number of staff who are working at that time and if there are any special operations ongoing.

Each location has adequate supplies of first aid for its operations, each vehicle operated by the group also carries a first aid kit as standard.

Each main location also has a fully automated defibrillator with trained staff on how to use this equipment in an emergency.

Our aim is to provided fully stock facilities to aid in an emergency, preserving life and aiding in a fast recovery.

The names of first aiders is promoted at each location along with contact numbers.

The local accident and emergency departments are run by Gloucestershire health authority with a minor injuries unit based at Tewkesbury and a main 24 hour Accident and Emergency unit based in Gloucester. For Ross there is a minor injuries unit is Ross on Wye or the main A&E department at the County Hospital in Hereford.

Fire Safety.

The group takes fire safety very seriously and maintains regular training for fire marshals on all sites operated.

An annual fire audit is undertaken at each site with an action plan presented for any points raised during this period.

Gloucester Fire and Rescue Authority operate in all areas that the group have buildings , along with Hereford and Worcester Fire & Rescue Service for Ross on Wye.

Each building will complete regular fire alarm tests, these will be recorded in the fire register along with any actions required.

They will also complete at least two full emergency evacuations throughout each calendar year, these will also be recorded, and actions completed following these.

Fire marshals receive regular training and will always be on duty where operations are in progress.

Fire systems at sites that do not operate 24 hours will have a connection to an out of hours monitoring service.

Other emergencies that require an evacuation will be treated in the same manner as a full fire evacuation.

As part of their induction, all employees will receive fire procedure training on their first day and will be shown the fire assembly points.

Specific Arrangements.

Along with the above we recognise that there are also some specific arrangements that group needs to undertake, these will be in more detailed separate policy documents but are listed here for reference.

�� Display Screen Equipment

�� Eye Test Policy

�� Manual Handling

�� Pregnant Workers & New Mothers Policy

�� Drivers Policy

�� COSHH Policy

Third party Contractors.

Where appropriate any contractor that is authorised to work on any of the Groups sites will be required to submit a copy of their Health & Safety documents which will include:

�� Health & safety Statement

�� Risk Assessments

�� Method Statements

�� Job Specific Work Sheets Building Maintenance.

Where the group owns the buildings we will ensure that regular servicing of air conditioning systems, hot and cold water systems, electric gates and doors and site security systems are maintained regularly, ensuring that they remain in a good state of repair and fully working.

Fire safety equipment, intruder alarms, CCTV along with Sanitary equipment will be managed on a regular basis to ensure it remains operational for employees’ comfort, safety and security.

Building Security.

Appropriate security measures will be in place at each of the Groups locations, this will include services such as security personnel, CCTV systems and alarm systems or a mixture of the above.

Enough key holders will be available and updated to the alarm monitoring services on a regular basis.

Stress.

Managers will monitor all employees under their control for stress related symptoms or illness, the Group has adopted a reassurance policy for stress related illness and will help and support employees as much as possible.

The Human Resources department will work with all employees to ensure they have the support and resources required to help them.

Managers will work with HR to ensure that support is appropriate for the needs of the employee.

Home Working.

The Group is committed to providing an environment in which (where appropriate) employees have some discretion and flexibility to work from home.

This would normally take the form of occasional home working to assist in the delivery of a project or to assist the Group in time managed work activities.

Some employees will be encourage to ‘home work’ rather than travel to an office as it is recognised this can be the most beneficial method of working.

The Group will ensure that the welfare of any home workers is monitored and their line managers will keep in regular contact with the employee.

The employee will be aware of the Groups lone working policy and that they are still expected to work in a safe manner.

Monitoring and Review.

This policy will be reviewed each year or if there is any significant changes to the Groups operations.

It has been authorised as the Groups Health and Safety Policy at Director / Board level.

Authorised by Annabelle Gillman – Director

01/10/2025

Next review: 01/10/2026

Environmental Policy Statement

Gillmans Electrical Ltd

Gillmans Electrical Limited believe’s that every business should be working towards a fully sustainable supply and work chain.

We have therefore set out our responsibilities and guidance within this policy.

Introduction & Statement

We understand the profound implications of not managing our local, national and global environment. We recognise the importance of and ensure of aim is to;

• Reduce our Carbon exhausts and those of our suppliers and manufacturers.

• De-carbonise and reduce our energy uses to primarily reduce our needs on raw materials such as fossil fuels and water resources.

• Encourage our staff and visitors to use sustainable travel practices by providing extra resource to those who use public transport, car sharing or cycling as a method over single use of vehicles.

• Invest in technology to ensure our own vehicle use reduces year on year whilst maintaining a good customer service and meeting the demands of our customers.

• Minimise waste production from the work we do.

• Prevent pollution and environment damage from incidents or accidents.

• Ensure full compliance to legal and other requirements.

• Monitor our progress and report annually to the board of directors on projects.

Responsibility

Ensuring that, as a company, we all invest in our environment is paramount to our core business objectives, the board instil a strong will on all team members to ensure our principals are met. Any project that we undertake will be assessed against this and other policies to ensure it meets with or exceeds the minimum standards that we set out in our introduction. We aim to fund and maintain projects each year to ensure our principals are maintained, our funding for Environmental Projects will be listed later within this guidance. As a business we understand that we must lead our work force and those whom we work with to continually improve our systems to reduce our impact on the environment.

Our Core Actions

Understanding our core actions ensure that everyone works together, they are

• To work with manufacturers on transport and packaging - our aim is to reduce the amount of packaging we dispose of by 5% each year to a value of 15% by 2022. Working with manufacturers to identify better ways of packing, using more environmentally friendly ways of transporting appliances and goods and ensuring all manufacturers have a reduction plan at least equal to ours in place.

• Ensuring that we have a sound transport policy in place, ensuring that only full consignments are accepted ensures less vehicles on our roads - we have a transport and delivery system in place to ensure deliveries are timed and accurate, ensuring that waiting times are reduced ensures less carbon release into the environment.

• Group meetings, using technology such as Skype or Zoom to reduce travel to and from meetings where possible, or holding a meeting in a mutual location to reduce travel for all parties.

• Reduce our use of fossil fuels, by investing in new technology to produce the power required whilst reducing our harm to the environment. Such as solar power panels.

• Flexible working arrangements, so our staff have the freedom to arrange group transport to and from work or are able to use public transport or bicycle’s instead of a motor vehicle.

• By investing in a modern vehicle fleet, and ensuring they are well maintained and limit to set speeds will ensure we further reduce the carbon emissions.

With Manufacturers

We will complete site and factory visits on a regular basis to ensure that our manufacturers are working to and maintaining our core actions. Review meetings are held at least twice per year with each manufacturer where we look at the materials, they are producing / using and how they are reducing the impact on the environment whilst maintaining the standards we and our customers expect.

Our Core Projects

As a company we set core projects annually, this is our investment in new technology and proven equipment and materials that will actively help us to reduce our overall impact on the environment.

During 2019 / 20 we have allocated funds for the following projects / investments that fit within our environmental policy guidance to reduce our overall impact.

• New Service transport software - to ensure that miles travelled are reduced ensuring that our team remain efficient. It will also move from paper reports to electronic systems further reducing our impact on the rain forest and the local environment. With Completion by Mid2020.

• Installation of Solar Panels - At our 247,000 square feet warehousing to reduce our energy demands by 45% year on year. With Completion of the installation by Mid-2019.

• Trial of Electric Vehicles - To trial a local call all electric van to establish the reliability and distance of the vehicle with a view of a fleet roll out in 2021.

• Fleet Management - From the start of 2016. Roll out of only two models of van across the fleet, with more environmentally friendly engines and lower horsepower, the two vehicles will be Vauxhall Vivaro and Ford Connect vans. Replacement will be booked for 3 yearly cycles. Our offices are equipped with recycling boxes in every office & location - all staff are encouraged to separate all recycling and place in the correct containers, reducing our general waste by up to 80%. Our recycling is collected weekly and managed by Smiths.

Policy Overview

This policy will be reviewed on an annual basis and reported to the board of directors.

This policy was last reviewed and updated to Version V2 18/01/2024.

Signed:

Rob Chappell Health & Safety Consultant

Next review: January 2027

Authorised by the Board of Directors:

Annabelle Gillman – Company Director John Gillman & Son’s (Elec) Ltd 18/01/2025.

HEALTH AND SAFETY Managing Manual Handling Policy & Procedures.

INTRODUCTION

Manual handling operations currently account for approximately 35 % percent of all reported industrial accidents. Common types of injuries such as hernias and prolapsed discs can cause considerable pain, permanent disability and in some cases loss of experienced and valuable staff. Although such accidents and injuries will never be completely eliminated manual-handling tasks can be managed in order to reduce the likelihood of accidents.

REGULATION

The Management of Health and Safety at Work Regulations require an assessment of all risks to employees, if this general assessment indicates the possibility of a risk from the manual handling of loads then the requirements of the Manual Handling Operations Regulations should be followed.

WHAT IS MANUAL HANDLING?

The regulations apply to the manual handling of loads by human effort as opposed to mechanical handling by crane, clamp truck etc. Introducing mechanical assistance may reduce but not eliminate manual handling since human effort is still required to move, steady or position the load.

RESPONSIBILITIES

The responsibility for reducing the risk of injury from manual handling operations rests with the company and is met by departmental managers and key staff trained in manual handling safety.

The strategy which departments should adopt is:

• Identify manual handling operations, which involve a risk of injury.

• Carry out a risk assessment of the activity. This should detail the task and the risk reduction methods to be employed, in order of preference:

▪ Eliminate the task

▪ Automate or mechanise the activity

▪ Modify the activity and where appropriate provide training and information to handlers.

• Periodically review manual handling operations to ensure that developments and changes in the working environment can be accommodated.

STRATEGY

Where we identify that tasks our staff undertake involve risk of injury through manual handling we will complete a risk assessment of the task, from this we will aim to eliminate or at the very least reduce, the risks associated with manual handling.

Once we have the risk assessment signed off at director level, method statements will be produced and provided to staff as required.

Identification and assessment of manual handling tasks must be undertaken by a competent person trained in the techniques of manual handling.

TRAINING AND SUPPORT MATERIALS

All employees will complete manual handling training, this is provided in-house by our own trainer, and however, selected staff will also attend an external training company for refresher training.

The company uses a varied approach to the training form, these are:

• Online courses

• External third party training

• Internal training

• Tool box talks

External & online training – employees will receive a certificate once the course has been successfully completed.

Internal training – details of the course are held on the employees personnel file for reference.

Tool box talks are recorded on Gillco and an electronic log of when this has been opened by the employee is kept.