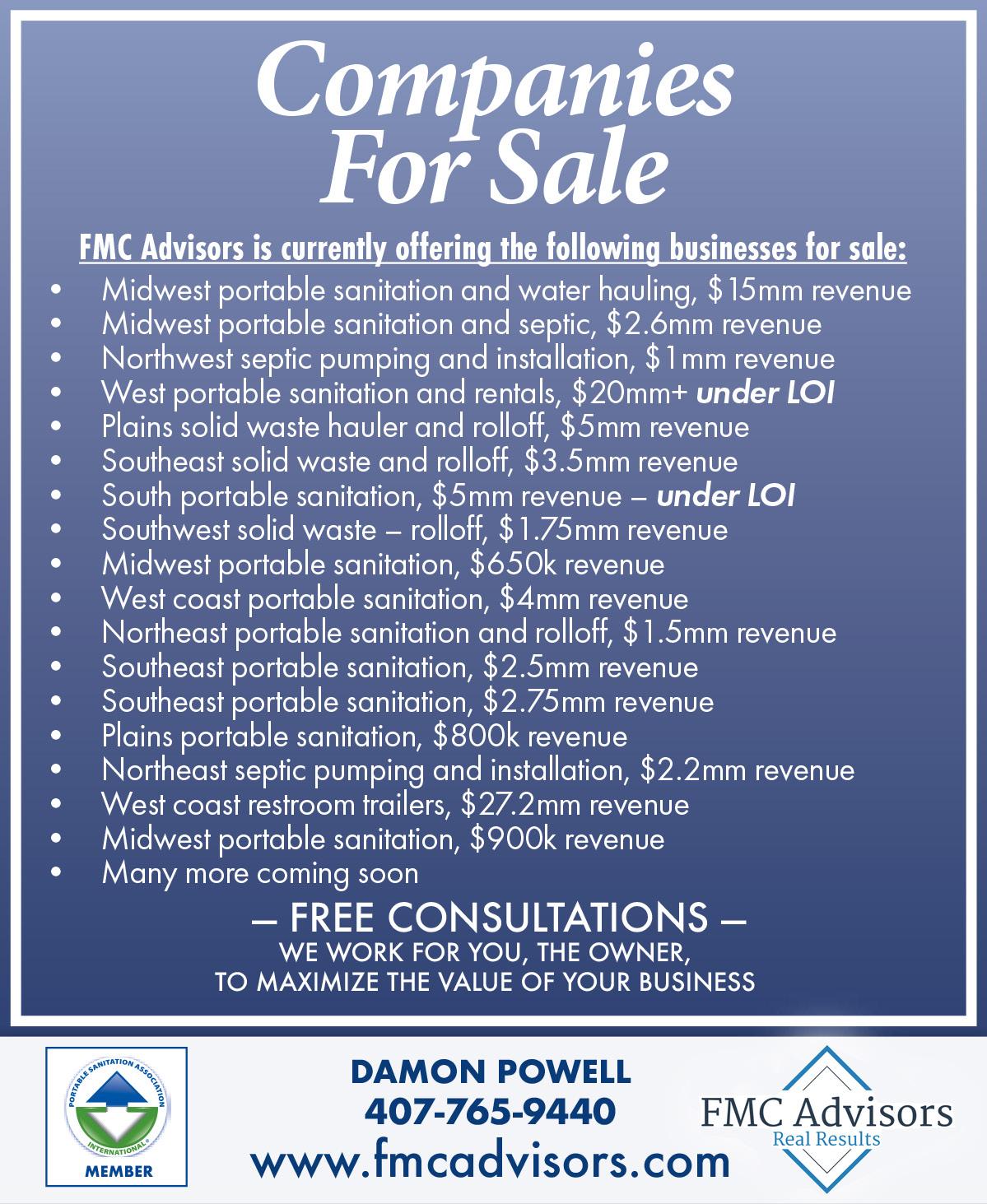

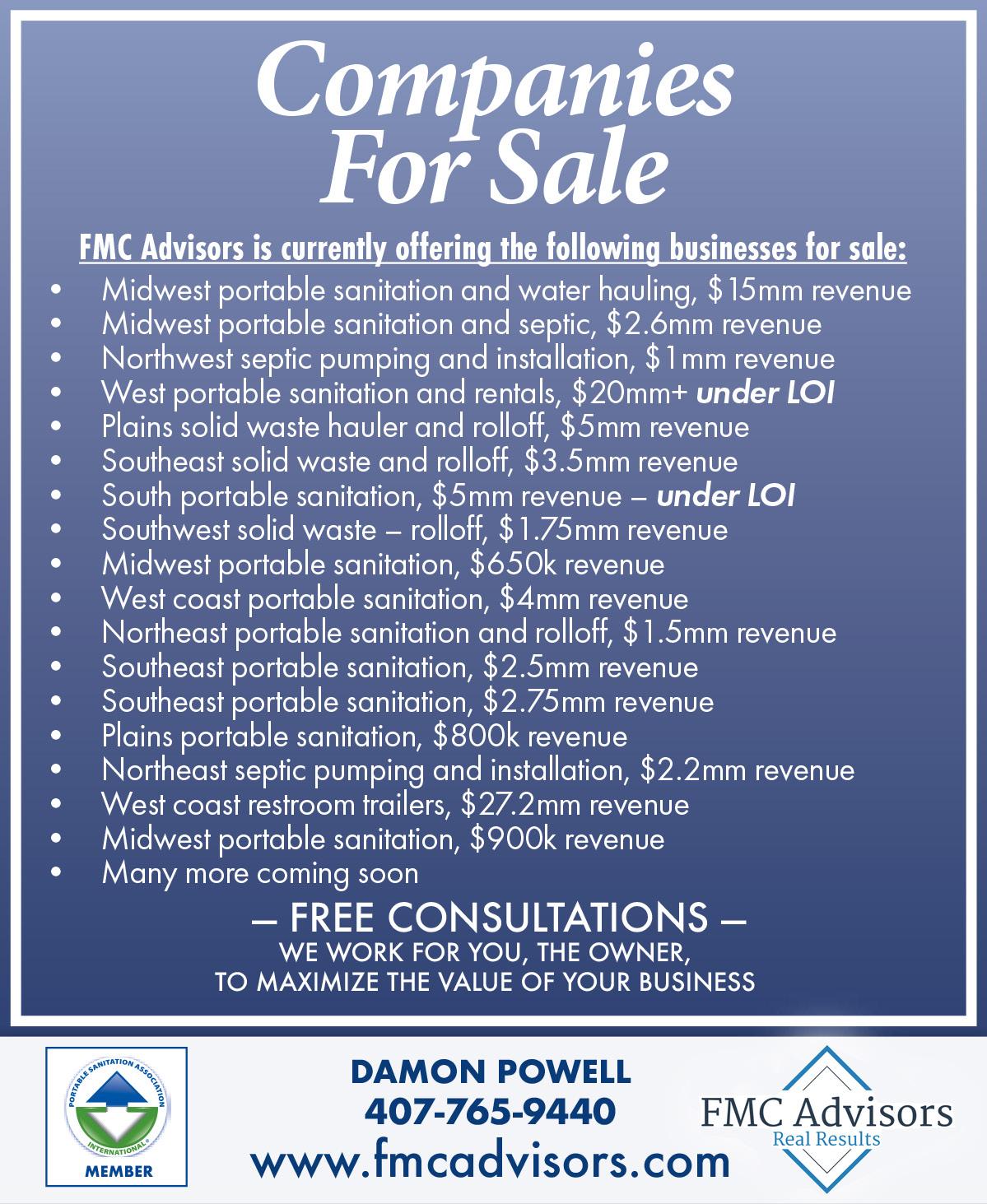

FMC Advisors is currently offering the following businesses for sale:

• West Coast

•

portable sanitation & liquid waste hauling, $16mm revenue

• Southcentral portable sanitation & rolloff, $15mm revenue – under LOI

• East Coast restroom & shower trailer rental, $11mm revenue

• West Coast Emergency Services, $8mm revenue

• Southcentral portable sanitation & rolloff, $7mm revenue

• Northeast septic pumping, installation & repair, $5mm revenue

• Plains solid waste hauler & rolloff, $5mm revenue

• West coast portable sanitation, $4mm revenue

• Southeast portable sanitation & rolloff, $4mm revenue

• Southeast solid waste & rolloff, $3.5mm revenue

• Southeast portable sanitation, $2.5mm revenue – under LOI

• Northeast septic pumping & installation, $2.5mm revenue

• Northeast portable sanitation, $2mm revenue

• Southeast portable sanitation, $1.5mm revenue – under LOI

• Northeast portable sanitation & rolloff, $1.5mm revenue

• Southeast portable sanitation, $1mm revenue – under LOI

• More coming soon!

CEO & PUBLISHER

Gideon W. Smith

SENIOR EDITOR

Katherine Nolan

ADVERTISING Tracy Rodean CREATIVE

Phoenix Global Media Inc.

P.O. Box 235, Stockton New Jersey 08559

866-418-4400 phone 973-532-0319 fax sales@americanliquidwaste.com American

The Guzzler Classic is the vacuum truck — the standard all others are measured against. Doing more in less time (and at less cost) defines this classic.

Safety-enhanced access to top of truck

Improved air routing and filtration

Easy maintenance with smart-design access points

Emergency stop and improved grounding

■ Straight Tri–Lobe

■ Performace: Vacuum up to 18 inHg; Flow up to 4805 cfm

■ Flexible Options & Installation

■ Coolest Blower Temperatures in it’s Class

■ More Energy Efficient vs. Other Straight Lobe Blowers

Ideal for:

■ Sewer Cleaning

■ Storm Sewers

■ Water Treatment Plants

■ Municipal Water Departments

■ Cleaning & Washing

Maynard’s Neat-N-Clean Portables is a thriving enterprise serving Milwaukee, Green Bay, Sheboygan, Oshkosh, Fond du Lac, Appleton, and greater Eastern Wisconsin. Never has there been a simpler and more fitting company slogan than theirs: “We're everywhere you gotta go!” Greg Grotegut, County Highway Commissioner and Business Owner of Maynard’s is an extraordinarily effective leader in the region.

Grotegut manages a staff of 50 people by day and runs Maynard’s as a robust side business during his off hours, supplying events and construction projects with high-end portable restroom units. It’s certainly impressive to observe — the level of commitment, the work ethic, the organizational talent. Yet, talking with Greg recently, he’s clearly taking it all in stride, cordial, unrushed, and consummately professional. We are

Never has there been a simpler and more fitting company slogan than theirs: “We're everywhere you gotta go!”

fortunate to have this busy government official share the story of his very successful side business in the industry:

HOW DOES GREG GROTEGUT DO IT ALL SO WELL?

He reflects on the progress of Maynard's: In 2004, I started the company. Before that, I was a heavy equipment operator, mainly excavators and bulldozers.

I was digging basements and was always the first one on the job site. I was aware of the need for the portable toilets. So, I did the rental toilet service by night for the first couple of years. I have always worked a full-time job besides running this business.

I’m a highway commissioner in Wisconsin. I work four 10-hour days at my full-time job. I have advanced through 16 years with our highway department.

After operating heavy equipment, I became a Paving Foreman. I always treated the restroom rental business as a hobby and always enjoyed this end of it. But, my hobby business reached a point in 2023 when I had 3 employees and 3 service trucks. I had over 200 toilet units and another 50 sinks. In 2023, I ended that larger operation. I sold two of the trucks I had at that time and all the plastics (toilets-sinks). I held the license up for about 2 years, until just a month ago for the new owner.

Now I just have one part-timer and the focus of the business for the future is concentrated on luxury restroom trailers. Commercial construction has taken off in luxury restrooms, and we still do a lot of events with trailers.

I have 3 of the luxury trailers being built right now and two more cycling to build. I currently have 2 20 ft sea containers with flushable toilets, two 4-stall, two 2-stall,

I have 3 of the luxury trailers being built right now and two more cycling to build... Those being built are already on long-term contracts too.

and a single-stall. The 4-stalls and the 2 containers are out on long-term contracts. Those being built are already on long-term contracts too.

The 3 being built are a 4-stall and 2-stall trailers. The other thing I started doing is fresh water and waste containers, heated all winter for office trailers. That’s the third trailer being built right now. It’s a custom office trailer. Everything is flushing and climatecontrolled.

When I wake up, I look over everything. I oversee everything. When I bring a trailer back, I manage everything involved in its preparation for the next rental. I have two younger daughters who are gaining some of that work ethic, helping with washing towels, cleaning restrooms, etc.

I’ve been between Manitowoc and Sheboygan and Racine this morning. [This was by the time of our 6:30 a.m. interview with Greg for this article.] The day starts early. On Fridays, I’m usually gone before 2:00 a.m. Right now (Wednesday at 6:30 a.m.), I’ll be home in 20 minutes and have my whole day ahead.

Before I scaled back the rental operation, I was starting at 3 a.m. and going to my regular job, going

continued on page 12

home at about 4:45 and helping the guys come in from the service calls. It was a lot. One of my daughters is in sports and both are busy with their own activities, but they are still helpful. And, by getting rid of the plastics, reducing the staff, and cutting the size of the operation overall, that kept me in the industry, and I’m enjoying it more.

The majority of contacts for renting the trailers come in via email. At lunch, I answer emails and I return phone calls in the evenings. On Fridays, I do a lot of my follow-up calls. A lot of my stuff is scheduled out in advance. It’s easier to schedule farther out in the future than meet the demands for fast delivery in basic portable toilet unit rentals, which very often require next-day service. If you can’t do that, the customer

quickly moves on to call the next person. It’s so much easier than my real job. [That’s Greg joking. So, we asked what kinds of responsibilities he has as a County Highway Commissioner.] I put together the whole road plan for our county. We have about 50 employees in our department. I have a great staff there. It’s about building that team. It’s not easy.

The website generates a lot of traffic. About threequarters of my business comes from my website vs. phone. It comes through links on the site and via email prompted by it. People plan a lot of weddings and events a year out. They’re often looking on the site during weekends, searching for information, getting a continued on page 14

Multiple products & configurations technology all cleaning functions are in a single control panel

Comprehensive Service Support

National authorized dealer network

OEM parts and options available

For Any Application. Municipalities and contractors, stormwater management, treatment plants, lift stations, underground utilities— there’s a Vactor for your job. And over 100 years of engineering, manufacturing and technical know-how go into each vehicle. Backed by service excellence and the support of the industry’s strongest dealer network, we uphold the Vactor promise every day — to be there for the life of your machine.

Have questions on equipment or applications?

ASK OUR EXPERTS

We need equipment to haul fresh water in winter. That’s one of the things we overcame, and we have been pretty successful with it.

try not to gaudy them up. I put a simple logo on the back and front. The trailers sell themselves. We have uniforms. They're black shirts with logos.

professional quote, etc. Event planners are working on filling their schedules for the following year.

All the work trucks are lettered. All trucks are black and trailers are all white. I try not to letter the trailers. They go to weddings and other special events, so I

My wife lets me do this expensive hobby. The overhead is crazy on what you need to operate, and it’s also challenging to figure out the trucks too. We need equipment to haul fresh water in winter. That’s one of the things we overcame, and we have been pretty successful with it. All my contracts are year-round, so we’re hauling water through all seasons. I have two trucks, and we have the ability to haul fresh heated water year-round. We do some RV tank pumping during the summer, and we do the regular holding tanks also.

continued on page 16

I plan on growing this business as the economy grows or shrinks, and, right now, maintaining the status quo. I see this restroom rental business as my early retirement job at 55 or so. That’s my game plan. That was my plan with the portable toilet rental operation, but it

continued on page 18

decide whether a gradual transition into full-time makes more sense for you than quitting your day job and jumping in full-speed from the start. The message is to be realistic about your priorities and map out a clear long-term plan that will take you on the path of least resistance to your ultimate goal for your business, your family, and yourself.

Not everyone can manage a key County government office with a staff of 50 by day and run a profitable and growing business on the side. In fact, it may be that Greg Grotegut is the only pro in the industry who can keep his arms around all of that.

However, if you look to emulate his operations model, be able to keep your life exceptionally well organized, make difficult practical decisions on what

to cut away and what to keep, embrace the hours and the work, and have the mindset to enjoy your life choice every day for the duration.

For information about Maynard’s Neat-N-Clean Portables in Newton Wisconsin, call (800) 701-4883 or (920) 726-4101, or visit Maynard’s Neat-N-Clean Portables.

Coxreels is proud to introduce a new line of three industrial duty LED lights now available on the PC10 reels. The new LED lights feature a variety of industrialgrade features and options, including: a 50,000 hour rating, internal light diffusers, and shatter-resistant polycarbonate lenses. Coxreels’ new LED lights also feature adjustable steel hooks for hands-free placement.

Whether you are looking for the compact LED light feature (-M), the LED light with the additional power source (-K), or the industrial-duty, UL Listed LED light (-H), these reels have the perfect features to complement a variety of applications.

Coxreels® has remained steadfast and focused on manufacturing high quality, industrial grade hose, cord, and cable reels with leading industry

The new LED lights feature a variety of industrial-grade features and options, including: a 50,000 hour rating, internal light diffusers, and shatter-resistant polycarbonate lenses.

innovation since 1923. Offering a full product line serving the industry in every channel and application, Coxreels® takes great pride in designing, building, and supporting each and every product made exclusively in the U.S.A.

For further information on Coxreels® industrial duty LED lights, contact Customer Service at (800) 269-7335 or visit www.coxreels.com.

COMPANY MAINTAINS ISO 9001 AND EARNS ISO 45001 AND ISO 14001

CERTIFICATIONS, DEMONSTRATING

Port Orange, FL (June 10, 2025) – Thompson Pump and Manufacturing Company , a leading manufacturer of heavy-duty dewatering and bypass pumps, proudly announces it has renewed its ISO 9001 certification and achieved ISO 45001 and ISO 14001 certifications, reinforcing its commitment to quality management, employee safety and environmental stewardship.

The ISO (International Organization for Standardization) certifications, awarded by a thirdparty auditor, place Thompson Pump among a select group of companies recognized internationally for operating with rigorous, measurable standards, highlighting its continued prioritization of delivering high-quality products, protecting employees’ well-being, and operating responsibly regarding environmental impact.

• ISO 9001 reaffirms Thompson Pump’s ongoing dedication to quality management principles, customer satisfaction and continual improvement.

• ISO 45001 demonstrates the company’s commitment to creating a safe and healthy workplace.

• ISO 14001 reflects Thompson Pump’s emphasis on sustainable practices, resources, efficiency and reducing its environmental footprint.

“Achieving and maintaining these certifications is a testament to the culture of excellence and accountability we’ve built across every level of our company,” said Chris Thompson, President of Thompson Pump . “From our manufacturing floors to our corporate offices, we are focused on continuous improvement, protecting our people, and doing our part for the planet.”

These certifications underscore Thompson Pump’s role as a leading and forward-thinking manufacturer, delivering reliable pumping solutions all over the world.

An ISO 9001, 45001, and 14001 Certified company, Thompson Pump and Manufacturing Company is an award-winning, full-service manufacturer and provider of high-quality, high-performance pumps, pumping equipment and engineering expertise for bypass pumping, dewatering, mining and flood control. Thompson Pump defines what is “state-of-the-art” in the industry and is dedicated to producing new and innovative dewatering and construction pump products. Family-owned and operated for 55 years, Thompson Pump continually seeks innovative and creative talent to join the team. For more, visit thompsonpump.com

The day-long event included group projects and interactive activities for students

ELYRIA, OHIO – June 30, 2025 – RIDGID® , a part of Emerson’s professional tools portfolio, held its annual “We Love STEM Day” in June for 60 local students in kindergarten through eighth grade. The day-long event, held at RIDGID global headquarters in Elyria, Ohio, let students experience the real-world role science, technology, engineering, and mathematics (STEM) plays in manufacturing.

STEM learning is a bit like solving a puzzle – you have the pieces and then it's up to you to figure out how they go together.

Students participated in a variety of hands-on activities, including making straw airplanes, rubber band powered cars, electroscopes and mini speakers. Each activity allowed students to learn about the importance of mechanical engineering, electrical engineering, renewable energy and natural resources in manufacturing.

“STEM learning is a bit like solving a puzzle – you have the pieces and then its up to you to figure out how they go together. I think that challenge, combined with the opportunity to bring their ideas

continued on page 26

to the project, is what makes STEM learning so fun for students and why our groups get larger each year,” said Stacey Varuolo, event chair and chapter lead, RIDGID Women’s Impact Network for Emerson “Our team loves getting to spend the day with the students and connect their projects with what we do in manufacturing.”

RIDGID is a proud supporter of local programs and education-based initiatives throughout Lorain County, including the Elyria school makerspaces that reinforce

STEM learning. The company also partners with current and future trade professionals and regularly invests and donates products. For years, its leaders have served on industry boards to help strengthen the trades.

Emerson’s professional tools business, which includes RIDGID as well as the Greenlee® and Klauke® brands, provides the industry’s broadest portfolio of advanced, reliable tools and technologies for the mechanical, electrical and plumbing trades globally. Visit emerson. com/professionaltools for more information.

RIDGID® , Greenlee® and Klauke® are trademarks of Emerson or its subsidiaries. All other trademarks belong to their respective holders.

Emerson (NYSE: EMR) is a global technology and software company providing innovative solutions for the world’s essential industries. Through its leading automation portfolio, including its majority stake in AspenTech, Emerson helps hybrid, process and discrete manufacturers optimize operations, protect personnel, reduce emissions and achieve their sustainability goals. For more information, visit Emerson.com.

RIDGID®, Greenlee® and Klauke® are trademarks of Emerson or its subsidiaries. All other trademarks belong to their respective holders.

Inquire today about these Orenco secondary safety barriers:

Tank Shield

•Secondary safety device

Tank Shield

•Durable polypropylene construction

•Secondary safety device

•Supports up to 250 lbs (113 kg)

•Durable polypropylene construction

•Supports up to 250 lbs (113 kg)

•Installs in new and existing access risers and pump basins

•Installs in new and existing access risers and pump basins

•Fits 24-in (600-mm) ribbed risers and Orenco 24and 30-in (600- and 750-mm) fiberglass risers

•Fits 24-in (600-mm) ribbed risers and Orenco 24and 30-in (600- and 750-mm) fiberglass risers For

•Secure, durable, watertight construction

Fiberglass Lids

•UV- and corrosion-resistant materials

•Secure, durable, watertight construction

•Supports 2500lb (1134kg) loads*

•UV- and corrosion-resistant materials

•Non-skid surface and molded-in caution statement

•Supports 2500lb (1134kg) loads*

•Non-skid surface and molded-in caution statement

•Fits ribbed PVC, HDPE, and Orenco FRP access risers and pump basins

•Fits ribbed PVC, HDPE, and Orenco FRP access risers and pump basins

*not recommended for vehicular traffic

*not recommended for vehicular traffic

For more information, contact your Orenco distributor. Or call Orenco at +1 541-459-4449 or (800) 348-9843.

As wastewater challenges continue to evolve, users need dependable pumping solutions that can adapt to demanding conditions. Tsurumi Pump provides a robust lineup of open channel and chopper pumps, engineered to handle specific wastewater conditions while minimizing downtime and clogging. Whether the need is high flow or heavy duty cutting, Tsurumi’s wastewater solutions

mitigate challenges to keep operations flowing.

Tsurumi’s open channel pumps are designed to move wastewater with large solids content such as rags and plastics. Engineered with widepassage impellers, open channel

Tsurumi’s open channel pumps are designed to move wastewater with large solids content such as rags and plastics. Engineered

with wide-passage impellers, open channel pumps allow debris to seamlessly pass through, thereby minimizing blockages.

Written by Ashleigh Johnson Municipal Engineer, Tsurumi Pump

pumps allow debris to seamlessly pass through, thereby minimizing blockages. The hydraulic design features an axial impeller adjustment system that maintains performance while reducing energy usage over time.

Ideal for dry-pit installations, wastewater treatment plants, and lift stations, open channel pumps deliver high flow rates and low shear, preventing the early

Ideal for dry-pit installations, wastewater treatment and lift stations, open channel pumps deliver high flow rates and low shear, preventing the early breakdown solids. Open channel pumps do not chop or grind solids, therefore they are most effective in applications where solids are relatively soft or have been pre-screened. flow municipal stations often prefer open channel pumps due to their reliable design and ease of access.

WRITTEN BY ASHLEIGH JOHNSON MUNICIPAL ENGINEER, TSURUMI PUMP

The moving parts of Tsurumi’s open channel pumps operate with minimal exposure to solids; in turn, this reduces wear and simplifies the maintenance process. When inspecting an open channel pump, it is recommended that users check impeller wear, bearing condition, seal integrity, and pump alignment.

As wastewater challenges continue to evolve, users need dependable pumping solutions that can adapt to demanding conditions. Tsurumi Pump provides a robust lineup of open channel and chopper pumps, engineered to handle specific wastewater conditions while minimizing downtime and clogging. Whether the need is high flow or heavy duty cutting, Tsurumi’s wastewater solutions mitigate challenges to keep operations flowing.

breakdown of solids. Open channel pumps do not chop or grind solids, therefore they are most effective in applications where solids are relatively soft or have been pre-screened. High flow municipal stations often prefer open channel pumps due to their reliable design and ease of access.

Open Channel Pumps: High Flow, Low Clog Risk

Chopper Impeller

The moving parts of Tsurumi’s open channel pumps operate with minimal exposure to solids; in turn,

Tsurumi’s open channel pumps are designed to move wastewater with large solids content such as rags and plastics. Engineered with wide-passage impellers, open channel pumps allow

Chopper Pumps: Cutting Power for Toughest Waste

Featuring a heavy-duty cutting system, chopper pumps macerate challenging solids and fibrous waste into small pieces. The rotating stationary cutters, in combination with high torque, reliable chopping while providing continuous flow. This leads to a reduced risk of clogging, ultimately prolonging pump life.

Chopper pumps are often installed in submerged applications where vertical space is limited, such as sumps or wet wells. When submerged, a chopper pump may require a lifting mechanism, impacting operational continuity.

Featuring a heavy-duty cutting system, chopper pumps

macerate challenging solids and fibrous waste into small pieces

this reduces wear and simplifies the maintenance process. When inspecting an open channel pump, it is recommended that users check impeller wear, bearing condition, seal integrity, and pump alignment.

Featuring a heavy-duty cutting system, chopper pumps macerate challenging solids and fibrous waste into small pieces. The rotating and stationary cutters, in combination with high torque, ensure reliable chopping while providing continuous flow. This leads to a reduced risk of clogging, ultimately prolonging pump life.

Chopper pumps are often installed in submerged applications where vertical space is limited, such as sumps or wet wells. When submerged, a chopper pump may require a lifting mechanism, impacting operational continuity.

Due to the cutting components and submersible nature, chopper pumps require increased maintenance compared to open channel pumps.

When completing inspections, users should focus on cutter sharpness, clearance between cutters and wear plates, motor condition, and condition monitoring of submersible seals and bearings.

From chemical composition of wastewater to physical site constraints, the choice between open channel and chopper pumps is seldom a one-size-fits-all decision.

Critical factors such as solid make up, accessibility, abrasion, flow rate, head, corrosion resistance, etc. aid in the decision for the best fitting pump. With increasing solid and fibrous content in wastewater streams, selecting the right pump is essential to balance investment, operational reliability, lifecycle cost, and compliance needs.

Tsurumi (America), Inc., a division of Tsurumi Manufacturing, was founded in 1979. Headquartered in Glendale Heights, Illinois, Tsurumi (America), Inc. has bases in Quebec, Canada; El Paso, Texas; and Salt Lake City. Globally, Tsurumi is active in 45 countries and has been an innovator in the pump industry since 1924. Tsurumi (America) is a provider of leading pumping technology in construction, civil engineering, mining, industrial wastewater, municipal wastewater, sewage treatment, flood control and scenery creation fields. Tsurumi products are backed by independent, third-party verification. Beyond leading pump technology, Tsurumi (America) is recognized for its robust distribution network and one of the largest on-hand inventories in North America.

Everything you need in a compact, efficient footprint.

The NEW Spartan Defender is a complete all-in-one skid-mounted system. Effective jetting coupled with a powerful vacuum pump puts everything you need to service and clean lines in one compact footprint.

With 3,000 PSI at 10 GPM jetting performance and a powerful suction pump, the Defender is ideal for grease trap maintenance, cleaning and maintaining small septic tanks, and removing waste from live sewers. Its compact footprint and new trailer mount version makes it easy to transport to the job site. Don't just clear the line, defend it.

WINTER ALWAYS COMES IN LIKE A LION, OUT LIKE A LAMB, OR VICE VERSA. SUMMER DOESN’T HAVE SUCH DESCRIPTIVE SIMILES, BUT THIS SUMMER IS COMING IN LIKE ITS OWN KIND OF BEAST. WITH YOUR PUMPER TRUCK(S) HEADING INTO THE PEAK SEASON, YOU’RE BRACED FOR A MULTITUDE OF PORTABLE TOILET UNITS

WAITING FOR SERVICE AT CUSTOMERS’ WORKSITES AND SPECIAL EVENTS. IN POTENTIALLY RECORD-BREAKING HIGH TEMPERATURES, A HEATRELATED EQUIPMENT BREAKDOWN COULD MEAN DISASTER. GET OUT AHEAD OF THAT RISK BY PRIORITIZING THE HOT-WEATHER PUMPER TRUCK MAINTENANCE ITEMS ON THE CHECKLIST BELOW.

If you haven’t yet made a checklist, you can use this one to build your own. In the meantime, this covers the basics of portable restroom pumper truck summer maintenance everywhere...

SUMMER PUMPER TRUCK MAINTENANCE CHECKLIST

Depending on your region of the country and any unique conditions in your state or local environment, you can modify this list of seasonal maintenance tasks. If you haven’t yet made a checklist, you can use this one to build your own. In the meantime, this covers the basics of portable restroom pumper truck summer maintenance everywhere: Fluid Levels

• Engine Coolant: Flush out coolant and replace it, if needed. Then, check levels frequently throughout the season to protect against engine overheating in hot weather.

Engine Oil: Top off the engine oil with a grade that

continued on page 36

Our new B1100 Spartan Pump Pack is built around the Battioni Ballast 11000 rotary vacuum pump. This pump is an absolute beast. The Ballast Pump is the perfect choice for heavy-duty applications, thanks to its innovative Crash Protection System. Featuring a sliding flange protection mechanism, this system prevents housing or rotor breakage in the event of vanes crashing. This ensures reliable and efficient operation, even in the toughest conditions.

With 3000 PSI of pressure and our premium aluminum cam-over box, our American made Jetter unit is reliable and tough enough for any job, including washing decking, driveways, or jetting out the toughest clogged pipes and drains.

• USA Made 24”x24”x48” Aluminum Box

• Stainless Steel Cam Over Latch with Padlock

• One Piece Gasket with Rain Gutter

• Jetter Stand with Anti-Vibration Pads

• Honda GX390 Gas Engine with Electric Start

• Rear Access Removable Panel with Vents

• Hannay Electric Reel with 200ft of Hose

• Guide Rollers and Electric Rewind Reel

• Wash Down Gun with Quick Connect Tips

PART NUMBER: 5000-8000

3,000 PSI

Inspect the radiator.

Clean it out with an appropriate cleaning agent if needed. Or, flush and refill it, if necessary.

• Vacuum Pump Oil: Check the vacuum pump oil level frequently during hot months, and top it off as needed.

• AC Refrigerant: Check AC refrigerant levels throughout the season and top it off as needed.

• Tank Deodorizer: Add extra pumper tank exhaust deodorizer liquid to help reduce odor in hot weather.

Cooling Equipment

• Radiator: Inspect the radiator. Clean it out with an appropriate cleaning agent if needed. Or, flush and refill it, if necessary.

• Fan Belt: Inspect the serpentine belt and hoses, and replace any worn ones. These parts are most vulnerable when running long hours in high external heat conditions.

• Air Filter: Replace the air filter, which can clog more quickly when driving daily during hot weather in high-dust areas.

• AC Belt: Inspect the AC belt, cab air vents, compressor functioning, and other air conditioning components.

Electrical and Battery

• Battery Terminals: Examine the condition of the battery terminals routinely for corrosion, and clean these as needed to prevent loss of voltage or disconnect.

Battery Voltage: Test battery voltage, because high summer heat under the hood can reduce battery life. Wiring: Inspect wiring throughout the vehicle for loose connections due to melting or drying out and becoming brittle from extreme heat exposure.

• Fuses: Check the fuses to ensure that all are working. Keep spares on hand for quick replacement if needed.

continued on page 38 provides the appropriate viscosity for summer temperatures in your climate zone.

• Vacuum Functioning: Check the vacuum pressure. Test its performance for ideal functioning to ensure prompt service to all customers during the busy summer.

Seals and Hoses: Examine hoses and seals. Heat can weaken and destroy these.

Pump Fittings: Use grease formulated for high temperatures to lubricate the vacuum pump fittings. This helps protect against rapid deterioration of connections in hot months.

• Tanks: Flush both wastewater and freshwater tanks, and clean them as needed, to minimize increasing bacterial growth and odor due to hot weather.

Safety

• Fire Extinguisher: Inspect the fire extinguisher, and have it recharged and otherwise serviced on schedule. Fire risk escalates during hot weather.

• ID and Safety Markers: Inspect license plates, other numbering and ID markers, and safety decals for damage from heat or direct sun exposure.

• Cameras: Check backup and other external cameras and alarms to ensure they’re working.

2025 Peterbilt 567 with 4200

2024 Ford F550 4x4 equipped with 1200-gallon 2C (300 water/950 waste), with a Masport HD4 hydraulic drive with a cooler, dual-sided service, 50’ hose spring rewind DC 10 water pump, dual-side bucket fill, dual 36” toolboxes, dual-side 2” x 30’ Tigertail suction hose, dual-side bucket holder, chemical holder drivers-side, dual-side wand holders

$130,000.00

2024 Ford F550 4x4 equipped with a 999-gallon 2C (300 water/699 waste), with a Masport HD3 engine drive, dual-sided service, 50’ hose spring rewind 45 PSI water system, dual-side bucket fill, dual 48” toolboxes (not shown), dual-side 2” x 30’ Tigertail suction hose, dual-side bucket holder, chemical holder drivers-side, dual-side wand holders

$107,000.00 (Gas Models starting at 96,000.00 complete)

2025 Peterbilt 537 Paccar PX-7 equipped with with an Allison 2500 RDS-P Transmission Gen 6, a 2500-gallon 2C (200 freshwater/2300 waste), Masport Titan 407 CFM’s, Masport water system PTO driven with 50’ rewind garden hose, 48” Toolbox

$168,950.00

Optional Add-on: Jetter Box $6,000.00

Brakes: Again, check brakes for wear more frequently during hot months.

General Inspection

• Daily: Inspect tires for damage from running on hot pavement.

• Weekly: And once again, inspect brakes and check tire pressure, because high heat increases wear on both.

• Monthly: Test engine idle for overheating, stalling, or other symptoms.

• Seasonally: Examine service logs for scheduled maintenance. Adjust intervals to increase frequency as needed in unusually hot summers.

Performing routine seasonal maintenance, of course, takes time during already busy days. And, it’s hot. So, it’s especially tempting to skip some of these chores. But, it’s worth it to maintain your equipment properly during the rough heat. It’s the way to greater peace of mind from improved safety and assurance of sustainable profitability during your biggest earning period of the year.

A SAFETY CULTURE BEGINS WITH TRAINING THAT PEOPLE REMEMBER AND USE EACH DAY. FOR SEPTIC, SEWER AND PORTABLE RESTROOM CONTRACTORS, THE WORK CAN BE RISKY. FALLS, CONFINED SPACES AND HEAVY EQUIPMENT ALL POSE REAL DANGERS. A STRONG SAFETY CULTURE CUTS INJURIES AND BOOSTS TEAM CONFIDENCE. HERE’S HOW TO MAKE TRAINING STICK!

A safety culture means everyone looks out for each other. When crews see that safety matters, they act more carefully. Injuries drop, equipment lasts longer and clients trust you more. Also important: you avoid costly fines or shutdowns. Training is the first step, but it must connect with real work. That makes lessons stay in the field.

TAILOR TRAINING TO THE JOB

Generic videos or slides can feel distant and impersonal. Instead, map each lesson to daily tasks. Show how to set up a trench box safely, then demo the

Pair short classroom talks with hands-on drills. For example, do a five-minute talk on ladder safety, then have each person climb a ladder and point out hazards.

steps on an actual jobsite. Walk through a confinedspace rescue drill right in the van before heading to the site. When people see the link to their work, they pay attention.

USE ON-THE-JOB PRACTICE

Theory only goes so far. Pair short classroom talks with hands-on drills. For example, do a five-minute talk on ladder safety, then have each person climb a ladder and point out hazards. Let crews swap roles: one spots risks while another works. This back-and-forth keeps them engaged and cements the lesson.

TRAINING SHORT AND SIMPLE

Long lectures lose focus. Break content into bite-sized pieces. A 10-minute toolbox talk on PPE fits before a morning run. A quick demo on trench shoring works during a lunch break. Keep sentences short and tasks

clear: “Check straps for frays.” “Place cones 10 feet from the hatch.” Clear tasks stick.

People learn in different ways. Rotate between brief talks, videos, hands-on drills and group discussions. A short clip on back-saver lifts can spark questions. Then, let the teams try to lift themselves. Having a few props — mock pipes or rescue dummies — adds a layer of realism. Changing formats keeps the mind on its toes.

Workers follow what they see. If supervisors buckle harnesses and run drills, crews will too. Walk the talk. Start each job with a quick hazard check, and point out what you see. When people see leaders catching unsafe moves and fixing them, they’ll do the same.

A safety culture thrives on open talk. After a drill, ask what went well and what felt odd. Maybe the harness was too stiff or the mock pipe too light. Take notes. Adjust the next session. When crews know their feedback shapes training, they stay invested.

Learning fades fast if you don’t revisit it. Use simple reminders: stickers on gear, posters by the time clock or text alerts before shift start. A weekly safety email can highlight one key point, like trench collapse warning signs. Short nods keep lessons fresh.

Positive feedback works better than fines. Spot someone tying off a ladder correctly? Tell them. A quick “nice catch” during a site walk builds confidence. At month’s end, a small reward or a shout-out in a crew meeting shows that you notice

the effort. This encourages others to follow suit.

Track incidents and near misses. Which hazards keep popping up? If confined-space entries still cause close calls, spend extra time on that topic. Swap out a video that didn’t land for a live demo. By tuning content based on real data, training stays sharp and relevant.

Building a safety culture isn’t a one-and-done task. It’s a cycle of training, practice and feedback. Start small with a quick demo or a toolbox talk. Then layer in hands-on drills and reminders. Lead by example and praise safe moves. Track what works and tweak what doesn’t. Over time, safety becomes part of every job and every decision.

That’s how training sticks. When safety is part of your daily routine, incidents drop and trust grows. For septic, sewer and portable restroom contractors, this means fewer injuries, smoother runs and a stronger reputation. Start today with a short session on a key hazard. A few minutes now can save weeks of downtime down the road.

AND THE LATEST INDUSTRY NEWS, SUBSCRIBE TO AMERICAN LIQUID WASTE MAGAZINE TODAY!

American Jetter ......................................................................... 44

866-944-3569 / americanjetter.com

American Tank Co.

254-721-5675 / atcvacuumtruck.com

Aqua-Zyme Disposal Systems Inc. 25 979-245-5656 / aqua-zyme.com

Bright Dyes 44 800-394-0678 / brightdyes.com

Bucher Municipal 45 704-658-1333 / buchermunicipal.com

Cam Spray 16

800-648-5011 / camspray.com

Chandler Vac

ChandlerVac.com

Coxreels

800-269-7335 / coxreels.com

Crane Pumps & Systems

cranepumps.com

Eljen Corp.

800-444-1359 / eljen.com

F.M. Manufacturing 11 877-889-2246 / fmmfg.com

FMC Advisors

727-486-0306 / 407-765-9440 / fmcadvisors.com

Fruitland Manufacturing 43 800-663-9003 / fruitlandmanufacturing.com

Guzzler 5 guzzler.com

Imperial Industries Inc 7 800-558-2945 / imperialind.com

J.C. Gury Company Inc. 6 800-903-3385 / jcgury.com

JD Brule. .......................................................................................

613-656-6663 / jdbrule.com

Key Commercial Corp.

877-333-4539 / keycommercial.com

Lane's Vacuum Tank, Inc.

800-592-3308 / lanesmobilejohn.com

McKee Technologies

866-457-5425 / mckeetechnologies.com MHC.

MHC.com

Mid-State Tank Co., Inc ...........................................................

800-722-8384 /midstatetank.com

Milwaukee Rubber Products

800-325-3730 / milwaukeerubber.com

National Vacuum Equipment, Inc.

800-253-5500 / natvac.com

Orenco Water

800-348-9843

Paul Swoyer Septics LLC

830-935-4936 Peterson Products .......................................................................6 800-669-1434 / pipeplug.com Porta Logix

585-484-7009 / portalogix.com Power Line Industries / Hot Jet USA

800-213-3272 / hotjetusa.com Presby Environmental Inc.

800-473-5298 / presbyenvironmental.com

800-656-4225 / rapidview.com

800-461-9200 / ratech-electronics.com