FMC Advisors is currently offering the following businesses for sale:

• West Coast portable sanitation & VIP trailers, $30mm revenue - under LOI

• Midwest portable sanitation & liquid waste hauling, $16mm revenue

• Southcentral portable sanitation & rolloff, $15mm revenue – under LOI

• East Coast restroom & shower trailer rental, $11mm revenue

• West Coast Emergency Services, $8mm revenue

• Southcentral portable sanitation & rolloff, $7mm revenue

• Northeast septic pumping, installation & repair, $5mm revenue

• Plains solid waste hauler & rolloff, $5mm revenue

• West coast portable sanitation, $4mm revenue

• Southeast portable sanitation & rolloff, $4mm revenue

• Southeast solid waste & rolloff, $3.5mm revenue

• Southeast portable sanitation, $2.5mm revenue – under LOI

• Northeast septic pumping & installation, $2.5mm revenue

• Northeast portable sanitation, $2mm revenue

• Southeast portable sanitation, $1.5mm revenue – under LOI

• Northeast portable sanitation & rolloff, $1.5mm revenue

• Southeast portable sanitation, $1mm revenue – under LOI

• More coming soon!

FREE CONSULTATIONS — WE WORK FOR YOU, THE OWNER, TO MAXIMIZE THE VALUE OF YOUR BUSINESS

CEO & PUBLISHER

Gideon W. Smith

SENIOR EDITOR

Katherine Nolan

ADVERTISING

Tracy Rodean

Phoenix Global Media Inc.

P.O. Box 235, Stockton New Jersey 08559 866-418-4400 phone 973-532-0319 fax sales@americanliquidwaste.com

American

CREATIVE

EDITORIAL

CIRCULATION Noah Aiden

SUBSCRIPTIONS

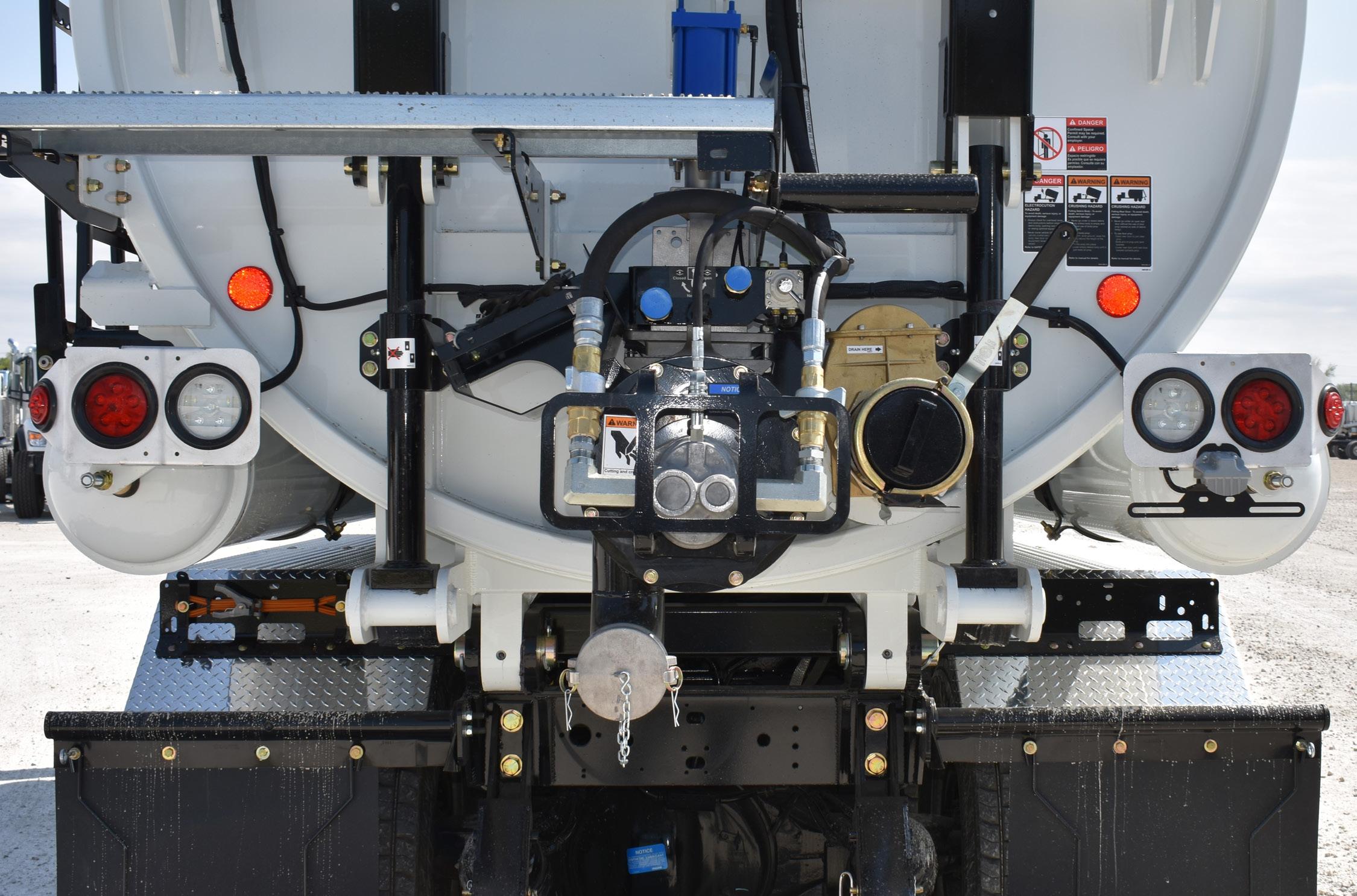

The Guzzler Classic is the vacuum truck — the standard all others are measured against. Doing more in less time (and at less cost) defines this classic.

Safety-enhanced access to top of truck

Improved air routing and filtration

Easy maintenance with smart-design access points

Emergency stop and improved grounding

■ Straight Tri–Lobe

■ Performace: Vacuum up to 18 inHg; Flow up to 4805 cfm

■ Flexible Options & Installation

■ Coolest Blower Temperatures in it’s Class

■ More Energy Efficient vs. Other Straight Lobe Blowers Ideal for:

■ Sewer Cleaning

■ Storm Sewers

■ Water Treatment Plants

■ Municipal Water Departments

■ Cleaning & Washing

At the heart of the Wisconsin Central Plain (10 miles from the exact center of the state) is Stevens Point. The vast rural expanse in all directions from the town is defined by the coastlines of Lake Superior and Lake Michigan, and the peripheral cities of Minneapolis, MN, Green Bay WI, and Milwaukee, WI. Thriving in this veritable open range between those three distant

major markets is Pro Septic Service LLC, owned and operated by Chris Sobczak. The story of his entrepreneurial achievement is fascinating. It’s about Sobczak’s success in the industry, and it’s a journey that started at an age among the youngest we’ve ever discovered. We were fortunate to talk with this remarkable business leader recently. Here,

I’ve been doing this type of work since I was 13 years old. I’m 51 now. I grew

up on a dairy farm. Coming from a dairy farm background means working from sun up to sun down seven days a week...

Chris shares some of his background, reflections, and professional insights with ALW readers:

I’ve been doing this type of work since I was 13 years old. I’m 51 now. I grew up on a dairy farm. Coming from a dairy farm background means working from sun up

to sun down seven days a week as a way of life. My uncle and his dad were septic system installers. They had a septic service business with one truck. From a young age, I helped them, and I learned a lot from that early experience.

Then, I got into pumping out tanks when I was 19 years old. I was pumping for about 2 years for one

company, then worked for another one for about 5 to 6 years, and then started my own company when I was 30.

CHRIS SOBCZAK AND PRO SEPTIC SERVICE LLC TODAY

Now I have 5 vacuum trucks. We have 3 full-time employees, and we have 2 part-time employees who

help with driving when needed. My wife, Amy, runs the

My wife and I built the company together all the way. We started from scratch, from nothing, with one truck and a blue sky and a dream.

office, takes care of all the calls, payroll — you name it. She does all the technical work. I’m in a truck all day, every day, not sitting with my feet up on the desk [Chris laughs].

My wife and I built the company together all the way. We started from scratch, from nothing, with one truck and a blue sky and a dream. So, we’re not like companies that have only grown through acquisition. But they don’t have anything on us in quality service and never will. There’s no replacement for our level of passion for service.

Amy runs the office, does the year-end taxes, marketing, retirement accounts, ordering employee uniforms, and everything that needs to be done administratively for the employees. She’s the technical person and I’m the hands-on guy. She takes care of all the emailing, printing work orders for the day, talking to the drivers about any concerns, routing, directions, all of it.

continued on page 12

My 20-year-old daughter, Claire, is also involved with the business. She works for us every summer when she’s home from college. She mostly helps in the office, working with Amy, doing DNR reporting, inspection notices, filing, etc., but even helps in the field if needed, helping take vehicles for maintenance, repairs, etc.

She can do much of what my wife does, booking customers and taking calls, and generally taking some of the pressure off during the busiest times. My goal for her has been to get her CDL and all the proper licensing and other credentials for working in and running the business. Hopefully, after she finishes college, she will become the next successor of the company.

continued on page 14

Multiple products & configurations technology all cleaning functions are in a single control panel

Comprehensive Service Support

National authorized dealer network

OEM parts and options available

For Any Application. Municipalities and contractors, stormwater management, treatment plants, lift stations, underground utilities— there’s a Vactor for your job. And over 100 years of engineering, manufacturing and technical know-how go into each vehicle. Backed by service excellence and the support of the industry’s strongest dealer network, we uphold the Vactor promise every day — to be there for the life of your machine.

Have questions on equipment or applications?

ASK OUR EXPERTS

with some large clients, like stores throughout the Fox Valley and the bigger markets. We have routes set up for clients who get routine service. But, the key to our success is that we are very well diversified. Not only are we a septic pumping service, we’re also a grease trap, commercial work, car wash, and pit cleaning service.

Our employees are all local guys right from my community. My longest-term technician, Rich, has been with me for 14 years. My other full-time technician, T.J., has been with me for 4 years. One employee, Brody, started working for us as a young teen who lived down the road. We just got him his CDL.

We’re always looking for new technologies and better tools out there to make things easier on the

technicians, like the lid pullers and jacks we’ve added. This year has probably pounded us harder than we ever have been. A big contractor needed us for a lengthy job that stretched us. But our team did what it took to make sure all our customers got the same top-quality service that they have always depended on us for.

Everyone has been so busy that I’ve switched to having a mobile washing and detailing company come in regularly to clean and detail the trucks. Image and cleanliness and top-notch equipment is Rule Number One for me. All our technicians wear uniforms, and I don’t go for sleazy slogans on trucks. Our slogan is “A class above the rest.” That’s the professional standard we work to uphold.

We don’t just hire anybody. We would not be here

But, looking back on the work side of that nightmare, we were only a two-truck operation at that time. The situation put us on our knees. We went from a strained two-truck operation down to one-truck with one employee in rehab and out of commission. So, it was all on me to keep us from going under. But we never missed a beat, never lost a customer. We did what we had to do to keep things rolling.

TREBCO helped us out for a few days during the worst time, while we were focusing on the injured employee. Imperial industries also stepped up and helped us get the replacement truck as soon as possible, within months.

The lady who hit our truck had no insurance and she took out a several hundred-thousand-dollar vehicle.

My insurance ultimately covered it all. We meet with our insurance company yearly to go over our coverages to make sure everything is good and that we’re well covered. But with all that Rich went through and what it took to keep the business running without him, it was brutal. I wouldn’t wish that kind of disaster upon anybody.

All our tanks are made by Imperial Industries. They’re 30 minutes from my shop, and they’re a one-stop shop. One call does it all. I call them, and things get taken care of. I’ve been with Imperial since the beginning, and they’ve always been good to me.

Two local auto service shops do all of our maintenance. We don’t do any of it in-house. They are

continued on page 20

Inquire today about these Orenco secondary safety barriers:

Tank Shield

•Secondary safety device

Tank Shield

•Durable polypropylene construction

•Secondary safety device

•Supports up to 250 lbs (113 kg)

•Durable polypropylene construction

•Supports up to 250 lbs (113 kg)

•Installs in new and existing access risers and pump basins

•Installs in new and existing access risers and pump basins

•Fits 24-in (600-mm) ribbed risers and Orenco 24and 30-in (600- and 750-mm) fiberglass risers

•Fits 24-in (600-mm) ribbed risers and Orenco 24and 30-in (600- and 750-mm) fiberglass risers For

•Secure, durable, watertight construction

Fiberglass Lids

•UV- and corrosion-resistant materials

•Secure, durable, watertight construction

•Supports 2500lb (1134kg) loads*

•UV- and corrosion-resistant materials

•Non-skid surface and molded-in caution statement

•Supports 2500lb (1134kg) loads*

•Non-skid surface and molded-in caution statement

•Fits ribbed PVC, HDPE, and Orenco FRP access risers and pump basins

•Fits ribbed PVC, HDPE, and Orenco FRP access risers and pump basins

*not recommended for vehicular traffic

*not recommended for vehicular traffic

For more information, contact your Orenco distributor. Or call Orenco at +1 541-459-4449 or (800) 348-9843.

both excellent. They know what we need and what we expect, so I stick with them. I’ve been with my tire guys for my trucks for 20 years. I consider them friends too. The same way with my truck repair centers. I’ve been with all my vendors forever. If you’re good to me, I’ll never leave you.

As far as I’m concerned, I offer excellent, topnotch, old-fashioned service. My word is my word. A handshake does it. My vendors know that’s how I roll, and so do my customers. With my vendors, it’s just like with my customers. We don’t lose a lot.

Since we started the company on April 1, 2004, growth has been steady. As far as plans for more

growth, I think we’re good where we are now, but I said that three trucks ago. With the stricter emissions regulations, climate conditions, and other impacts, you almost need to have a spare truck sitting around for repairs, or downtime if a Check Engine light comes on.

Parts aren’t always readily available. That said, we have no big plans to scale up.

Am I happy? That’s the magical question. The way things run in this business, it’s very hard on a family. There have been huge family sacrifices. My wife and I rarely go on vacation together, because one of us stays to man the office and oversee the operation. It’s a 7-day-a-week job. So, are we happy? I’m 150% in on my business. I’m 51 and have no plans to retire. I would feel guilty leaving my customers without quality

service. So, as long as my health and everything else holds up, I wouldn’t just walk away. Back on the farm, cows needed to be milked even when it was Christmas, Easter, or when you had the flu. That’s kind of how I run things here. I’m up at 3:45 a.m. every day. Every truck rolls out of the shop by 5:00 in the morning. If I try sleeping in on a Sunday, I’m wiped out for the rest of the day. I’m pacing without something to do.

Before starting my own business, as I said, I worked for a couple of other companies where I had major responsibilities. So, I had a lot of experience before I ventured out on my own. I ran businesses before I started my own. I came into ownership very well trained.

I knew the ins and outs. It took me till I was 30 years old to make that leap. I didn’t just jump into it. I finally decided — I can do this.

Today, one of those former employers, Ed Trzebiatowski, the Owner/Operator of TREBCO Services, is a very close friend. We’ve known each other for 35 years. We help each other and cover for each other, as needed. We usually talk at least once daily. He’s like family. It’s good to have that relationship of mutual support with a competitor. You know that one of them has always got your back.

During my startup, it was pretty easy for me to build relationships. People knew me by name or by face. I made connections with people. I knocked on doors, but word of mouth was what helped us most. That’s how I

grew it, how I made it. [Though Chris recalls a smooth transition in developing relationships for his new business, he likens the startup years, overall, to the experience of fighting for his life clawing his way out from under the cracked ice with bloody fingers when he fell in while ice fishing alone at about age 18.]

One of my accounts today is a big service company. They called me once, and I helped them in a pinch, and they were so impressed with how we did it in a pinch that they stuck with me. We take on a lot of very big jobs and very big accounts. But clients change. Businesses get sold. New customers come in from out of state.

One

of my accounts today is a big service company. They called me once, and I helped them in a pinch...

These days, you don’t have that advantage of being friends in our hometown with all our customers. A lot of that has gone by the wayside. You’re dealing with more management companies now. We still have those long-time customers we’ve kept through the relationships we’ve built with them. But, I will still sell sometimes. I say that when things are good, just don’t always think it’s going to last forever.

The Dos and Don’ts on our website are also printed in our pamphlets that we hand out to every customer. We’re constantly educating our customers

Everything you need in a compact, efficient footprint.

The NEW Spartan Defender is a complete all-in-one skid-mounted system. Effective jetting coupled with a powerful vacuum pump puts everything you need to service and clean lines in one compact footprint.

With 3,000 PSI at 10 GPM jetting performance and a powerful suction pump, the Defender is ideal for grease trap maintenance, cleaning and maintaining small septic tanks, and removing waste from live sewers. Its compact footprint and new trailer mount version makes it easy to transport to the job site. Don't just clear the line, defend it.

on their septic systems and on a good service plan for their specific needs. If we come to their property and find it’s very thick and there’s a lot of garbage, sludge, and scum getting out to the drainfield, we know the customer needs to make changes in the care of their system.

Our county requires a pump-out every three years. However, the customer may need to have it done every two years or every year, depending on their usage, environmental factors, and other considerations. I’m a big advocate of every-year pumping. My parents did that. I recommend that customers get that waste and sediment out of there as frequently as needed to take the best care of the system and keep it functioning smoothly.

We’re here walking the walk. We’re very passionate about what we do. The challenges we’ve taken on and things we’ve accomplished in our career can seem unbelievable to people who haven’t had that kind of experience. We’re here for our customers, like this morning, fired up at 3:30 am to help with an urgent need, after finishing up last night at 8:00 pm. But that’s not an example of how things are done for unknowing customers elsewhere in our area. We deal with problems created for them all the time: Septic service scams: Through the years, poorquality operators have always been in our rearview mirror, undercutting, trying to take customers and trade secrets. But, one big thing in our area now that

we’re fighting is that some plumbers found some loophole in the codes that allows them to not pump, or just to inspect without pumping and have the customers come out and just sign off. So, they never clean the filters or inlet baffle, where the sewage comes in from the house.

Then, they end up calling us as backup. The inspectors sign off to meet the county requirements, and the customers are not getting anything for what they’re paying them. A customer last week had an inspection a year ago, and now sewage is backed up in their basement, in their finished basement, on the rugs. Every customer that has told us they did that inspection option has said they never should have done that and that they will never go that route again.

Our biggest dilemma right now is trying to educate people about this. These guys don’t offer any other service, just inspection. The situation started ramping up about three years ago, and this year it’s really gotten out of control.

Inexperienced Operators: We learned through years on the job. Now, some newer operators watch a YouTube video and think they know what they’re doing. People trust them to do a professional, highquality job, but things that go on now without the customers knowing any better are increasingly causing serious consequences to many septic systems and homes. The unqualified technicians are leaving a lot of sludge in the tanks, leading to sewage backups into finished basements, damaged

Learn it before you get into it. Don’t just buy a truck and hop into it. There’s so much more to it.

Learn it before you get into it. Don’t just buy a truck and hop into it. There’s so much more to it. It’s one thing to run a truck and pump. But you’d also better know where you’re going for disposal sites, and have a second, and a third, and a fourth option for it.

equipment, damaged drainfields, and other costly problems.

Another big issue for us has become disposal location shortages. The treatment plant facilities were built 30 to 50 years ago. They were built for a certain capacity of waste stream at that time. Those plants are aging, and the cities that use them have grown. So, now more waste is coming into the plants. The cost to renovate those facilities is astronomical. Treatment plants in big cities have a lot of money. But out in areas like mine, small cities with only 20 to 30 thousand people have very limited money, and the sewer plant is the last place the money goes.

We used to be able to take as much as we wanted to the treatment plants, but now they have to treat their rate payers’ sewage as their priority. Though they want to work with everyone who needs it, they have to restrict the loads from us area outliers. It’s a common problem. In northern Wisconsin and in many places throughout the country, it’s even worse. Some operators are having to drive as much as 300 miles for disposal. We’re fortunate to have land app licensing, so we’re much better off than other operators.

You’d better know how to do your accounting, know the DNR regulations, how to get licensing, and how to troubleshoot the gamut of odd problems. You need to make sure you have enough insurance. It’s a very important part of a business. There are a lot of uninsured and underinsured motorists out there.

There’s a lot more to know to build a successful company that stands the test of time. It’s a constant battle. But if you love what you do, you’ll probably want to keep doing it. I’ve told my family that on my grave stone, I want it to say, “I wish I could have pumped one more.” [Chris laughs with his contagious hearty laugh.]

On the Pro Septic Company

It’s a big question: how does a company owner remain steady in facing the many unique entrepreneurial challenges of his industry in this particular locale? First, factor operating in the veritable wilderness of central Wisconsin, the northern US climate conditions, limited waste disposal resources, great travel distances, high costs of heavy equipment, relentlessly long hours, and the staggering physical and financial risks of operating in the daunting region.

Then, as Chris Sobczak has reflected, the question becomes, “Are we happy?” (He’s referring to himself and his team, the people in the literal trenches with him.) The answer appears to be YES . He seems to be very happy, maybe one of the happiest business

owners we’ve met across the national septic services industry.

Throughout the half dozen or so times we’ve spoken with Chris over the past three months, he’s been consistently upbeat and always exhibits that admirable quality of seeming moderately amused with what’s happening around him.

But did he ever get that elusive vacation? We’re glad to report that just the following week after our first meeting with Chris, he answered our call from a deer blind in Saskatchewan, and we talked to him while he was on vacation there! He sounded very happy indeed. (He brought home a big 10-point buck from that trip.)

But applying Chris’s question of happiness more broadly: Do we recommend his strenuous work life

for new entrepreneurs entering the industry in such exacting markets? Uh, not for the average human. It’s not for the easily discouraged. But, if you’re made of that rare stuff, equal to the team under the direction of Chris Sobczak and their rugged and smart strategic business leader, then go ahead into the open country up north to pursue a happy life in the industry. Our advice: Be extraordinarily well prepared

BY KATE ZABRISKIE

SOMETHING GOES SIDEWAYS AT WORK—MISSED DEADLINES, BAD CUSTOMER FEEDBACK, YOU NAME IT— AND THE FIRST SUGGESTION IS, “WE NEED TRAINING!” SOUND FAMILIAR?

IT’S LIKE REACHING FOR A BAND-AID WHEN WHAT YOU REALLY NEED IS A LIFESTYLE CHANGE. TRAINING CAN BE POWERFUL, BUT IT SHOULDN’T BE YOUR KNEE-JERK SOLUTION TO EVERY WORKPLACE HICCUP.

Here’s the hard truth: Training is the last stop, not the first. If you’re jumping to training without laying the groundwork for great performance, you’re wasting time, money, and effort. Let’s break down what you need to be doing instead—and why it matters.

Think of hiring as the foundation of your performance “house.” If you’re building on shaky ground, even the best training program won’t save you. You need the right people in the right roles from the get-go.

Here’s how to hire smarter:

• Be Crystal Clear About What You Need: Don’t

Think of hiring as the foundation of your performance “house.” If you’re building on shaky ground, even the best training program won’t save you. You need the right people in the right roles from the get-go.

settle for generic job descriptions like “good communication skills.” Define what success looks like in the role.

• Ask About Real Situations: Look beyond polished résumés and ask candidates how they’ve handled challenges in the past.

• Prioritize Cultural Fit: Skills can be taught, but a mismatch with your team’s vibe or values is much harder to fix.

Smart hiring sets the stage for performance, minimizing the need for “fix-it” training later.

You know what drives me up the wall? Leaders who say, “They should just know what to do.” Really? Since when are we hiring mind readers? If you want great performance, you need to spell it out—clearly and consistently.

Here’s how to set expectations that stick:

• Be Specific: Don’t say, “Do better.” Say exactly what “better” means: “Respond to all customer inquiries within 24 hours.”

• Write It Down: Memory is unreliable, and verbal instructions are easy to forget (or misinterpret). Document everything.

• Keep the Conversation Going: Expectations aren’t oneand-done. Reinforce them regularly in meetings and one-on-ones.

If you want great performance, you need to spell it out—clearly and consistently.

Clarity eliminates confusion, giving your team a clear path to success—and fewer excuses for poor performance.

Here’s a truth bomb: Your team is watching you. If you

Expecting great performance without giving people the tools to succeed is like asking someone to build a house with a toy hammer. Before blaming performance, ask yourself: “Do they have what they need?

yourself: “Do they have what they need?”

Here’s what to check:

• Technology: Is their software up to date? Slow tech kills productivity and morale.

• Time: Are workloads reasonable, or are you stretching people too thin?

• Knowledge: Do they know where to find information and resources? If not, create guides, FAQs, or training documents.

When people have what they need, they’re empowered to succeed—and training becomes less of a crutch.

preach punctuality but show up late to meetings, you’ve already lost the plot. Leadership isn’t just about what you say—it’s about what you do. To walk the talk:

• Practice What You Preach : Whether it’s meeting deadlines, showing respect, or staying organized, lead by example.

• Own Your Mistakes: Perfection isn’t the goal. When you mess up, acknowledge it and show how you’ll fix it.

• Live Your Values: If collaboration is a core value, show it by inviting diverse input and recognizing contributions.

When you model the standards you expect, you set the tone for everyone else to follow.

Expecting great performance without giving people the tools to succeed is like asking someone to build a house with a toy hammer. Before blaming performance, ask

Here’s the thing about accountability: Without it, even the best plans turn into wishful thinking. It’s like signing up for a gym membership and never going—you have the potential, but nothing’s happening. How to make accountability work:

• Address Issues Quickly: Problems don’t get better with time. If something’s off, call it out immediately.

• Give Actionable Feedback: Be specific about what went wrong and what needs to change. “The report was late” isn’t as helpful as “The late report delayed our project timeline and caused extra work for others.”

• Follow Through: Empty threats are worse than no accountability at all. If you set consequences, enforce them consistently.

Accountability bridges the gap between expectations and results, ensuring everyone stays on track.

Not every performance issue requires formal training. Sometimes people just need guidance from someone who’s been there, done that. It’s like using GPS instead of fumbling with an old-school map.

Ways to provide coaching:

• Regular Check-Ins: Use these to offer targeted advice and discuss progress.

• Peer Mentoring: Pair experienced team members with newer ones to share knowledge and skills.

• Shadowing Opportunities: Let employees observe high performers in action. Coaching creates a supportive environment for learning and growth—without the need for a formal training program.

If you’ve done everything above and still see performance gaps, then—and only then—should you consider training. But make it count. Here’s how:

Skip generic courses and focus on the specific skills or knowledge your team needs.

• Identify the Root Cause: Don’t train for the symptoms; train for the actual problem.

• Keep It Relevant: Skip generic courses and focus on the specific skills or knowledge your team needs.

• Follow Up: Training doesn’t end when the session

does. Monitor progress and ensure the learning is being applied.

Training is most effective when it’s part of a broader performance strategy—not a standalone fix.

Training isn’t a magic wand. It’s more like the cherry on top of a well-built sundae. If you’re relying on training to solve performance issues without addressing the bigger picture, you’re doing it wrong.

To build a high-performing team, focus on the fundamentals: hire well, set clear expectations, model excellence, provide the right tools, hold people accountable, and offer coaching. Then, if gaps still exist, use training strategically.

Remember: Great performance isn’t trained—it’s built.

Step by step, with the right pieces in place, you’ll create an environment where people can thrive without leaning on training as a crutch.

ABOUT THE AUTHOR:

Kate Zabriskie is the president of Business Training Works, Inc., a Virginia-based talent development firm. She and her team provide onsite, virtual, and online soft-skills training courses and workshops to clients in the United States and internationally. For more information, visit www.businesstrainingworks.com.

IRVING, Texas – Liquid Environmental Solutions (“LES”) today announced it has acquired Grease Masters a leading provider of grease trap, commercial drain line cleaning and plumbing repair, used cooking oil and kitchen exhaust hood cleaning.

Based in St. Louis and founded in 2006, Grease Masters will be added to LES’s extensive network of non-hazardous wastewater collection facilities, providing customers with more options for the collection and recycling of non-hazardous wastewater, drain line cleaning and plumbing repair.

“Grease Masters has a tremendous reputation in the waste management industry, and I’m very pleased to welcome the Grease Masters team and their loyal customers into LES's footprint,” said Jerry Sheridan, Chief Executive Officer of LES . “We look forward to working closely with them to help expand their reach and incorporate their outstanding services into our business.”

“We have always prided ourselves on applying the finest equipment and technology to service our broad base of clients, and we’re thrilled that LES shares our commitment to creating a positive experience for our customers,” said John Remstedt President of Grease Masters and Pam Remstedt CEO of Grease Masters who, along with other members of the Grease Masters, will assist with the integration. Both Grease Masters and LES are industry leaders committed to delivering

a high level of safe and compliant services to our St. Louis customers.

Brian Bidelspach, Executive Vice President of Corporate Development for Liquid Environmental Solutions, added, “Grease Masters and the St. Louis area represent a compelling growth opportunity for LES , and we’re thrilled to be able to help Grease Masters grow as part of the LES family of brands.”

LES, one of the nation’s most trusted recyclers of liquid waste, focuses on the collection, treatment and beneficial reuse of non-hazardous liquids from a wide variety of waste sources, including grease traps & interceptors, used cooking oil, oil water separators & grit traps and industrial & third party wastewater. With over 1000+ team members, 650 state-of-the-art fleet vehicles, 65 collection branches, and 25 wastewater treatment plants, LES is positioned to meet customers’ diverse, non-hazardous liquid waste needs from coast to coast. For more information about our company, our solutions and our people, please visit liquidenviro.com or call 866.MY.GREASE.

INDUSTRY EXPERT, WILL NICCOLLS, OWNER, GREEN LATRINE, SEATTLE, WA, ATTENDED THE 2025 PORTABLE SANITATION ASSOCIATION

INTERNATIONAL (PSAI) SHOW IN FLORIDA IN EARLY NOVEMBER. BETWEEN THE MANY EQUIPMENT AND SUPPLY VENDORS AND SERVICE COMPANY OPERATORS, A VAST WEALTH OF KNOWLEDGE WAS SHARED ACROSS THE GAMUT OF INDUSTRY INTERESTS, FROM TECHNOLOGICAL INNOVATIONS TO IMPROVED SERVICE PRACTICES. HERE, WILL REFLECTS ON HIS EXPERIENCE AT THE TRADESHOW AND OFFERS ALW READERS AN ABUNDANCE OF EXCEPTIONAL TAKE-AWAY INFORMATION FROM DISCUSSIONS OF ONE OF THIS YEAR’S MOST POPULAR TOPICS FOR DISCUSSION AT THE EVENT — WORKPLACE SAFETY AND OSHA COMPLIANCE:

Unit placement is probably the most important piece of the process. There are lots of considerations from the users’ side and technicians’ side.

WILL NICCOLLS – A WORD ON THE NATIONAL PSAI EVENT

Unparalleled Learning Opportunities for Portable Restroom Services Teams

We’ve had great success taking people from our company to this and other PSAI events. (Like “the Edge PSAI in Scottsdale, AZ. We took 7 people to that one.) Exposure for our team to the learning opportunities at these events has been a wonderful investment for us. Instead of just taking the senior people, having more of the team getting exposed to

the concepts presented is very valuable to us. They’ve been getting to hear solutions from other operators in other parts of the country who are experiencing the same challenges and are interested in the same issues.

PSAI Takeaway & Wisdom from Industry Expert, Will Niccolls

Combining discussion points from the PSAI event and Will’s deep knowledge of worksite safety in portable restroom placement, use, and maintenance, he recommends that operators focus on these five key points:

Unit placement is probably the most important piece of the process. There are lots of considerations from the users’ side and technicians’ side. The more factors considered in advance, the better the placements of units will be.

Easy Access: Toilet units can be placed farther from users where it’s preferred that they’re out of sight at events where people don’t want to see them, such as weddings, parties, etc. But, on jobsites, it’s a very good idea to provide handy access. Per OSHA, toilets must be readily accessible, and never unreasonably restricted, within 200 feet horizontally from every worker on the jobsite.

• Hazard-free: Where there is potential for hazards to develop from weather, such as mud, ice, or snow in northern climates, both users and service techs need to be able to access them safely, and with as little disruption to others as possible. For example, a big portable toilet service truck should not be in the way of neighbors.

• Lighting: Ideally, you can place units under a streetlight, work light, or other overhead light. Or, you’ll need to employ some other means of bringing light into areas where toilet units are placed to prevent trip or fall hazards. Per OSHA, toilet units must be well lit, including during evening work.

• Hose Length: Most portable toilet trucks carry 2060 feet of hose. The toilet units have to be placed within one vacuum hose length, where the pump truck can be parked on level ground for servicing each unit on the site. If not, the volume of waste in the tank won’t allow optimal filling and the operator may have issues servicing all the units.

Your company policy on PPE may differ from the job site requirements of a specific client. High-visibility clothing, such as a vest, T-shirt, or jacket may be required, as well as eye protection and/or ear protection. One client we have specifies the kind of hard hat our technicians are required to wear. Another

You may be bringing standard portable toilets or rolling elevator units on casters that you can wheel into an elevator in a high rise. Whatever units you have, they are probably built to comply with federal OSHA rules and regulations.

requires our techs to get certified by their safety officer and to put their job site safety sticker on our hard hats.

Under OSHA regulations, employees servicing portable toilet units on worksites must wear the proper PPE. That includes safety glasses, boots, and gloves. In some cases, it may also include face shields, or even respirators.

You may be bringing standard portable toilets or rolling elevator units on casters that you can wheel into an elevator in a high rise. Whatever units you have, they are probably built to comply with federal OSHA rules and regulations. But, individual state requirements may vary. They may require, for example, that the units be completely enclosed. So, your units may meet OSHA

regs but not meet your own state’s legal requirements. Ensure the units you order comply with all laws from all governing oversight agencies — local to federal. Another caveat, different requirements may apply to the design, placement, and maintenance of units for some purposes. For example, an OSHA-approved flyable toilet unit may be required to have handwash containment trays. Or, there may be specs on how it is to be connected for lifting on a tower crane (metal harness, etc.)

Or, where units are used on some large building sites, like a new hospital, skyscraper, public works project, bridge construction job, etc., the project is likely to have its own safety compliance officer. Your portable sanitation team should coordinate with that individual to ensure you are abiding by any unique safety requirements of that individual site.

Association guidelines, industry Best Practices, other industry standards, and certification training criteria for service technicians are all critical to safety on job sites and to ensuring OSHA compliance. From laws on adequate ventilation to mitigate odors to PPE and safety training for service workers handling the units, to equipment maintenance training, to keeping clean, sanitary, stocked units, your team should be familiar with all federal regulations to ensure compliance. That may come, in part, from PSAI or other organizations. Larger construction contractors often do their own training. They may even require toilet rental providers to send their techs to their in-house safety compliance training.

As for the pump truck itself, it’s a top priority to keep

continued on page 40

Our new B1100 Spartan Pump Pack is built around the Battioni Ballast 11000 rotary vacuum pump. This pump is an absolute beast. The Ballast Pump is the perfect choice for heavy-duty applications, thanks to its innovative Crash Protection System. Featuring a sliding flange protection mechanism, this system prevents housing or rotor breakage in the event of vanes crashing. This ensures reliable and efficient operation, even in the toughest conditions.

With 3000 PSI of pressure and our premium aluminum cam-over box, our American made Jetter unit is reliable and tough enough for any job, including washing decking, driveways, or jetting out the toughest clogged pipes and drains.

• USA Made 24”x24”x48” Aluminum Box

• Stainless Steel Cam Over Latch with Padlock

• One Piece Gasket with Rain Gutter

• Jetter Stand with Anti-Vibration Pads

• Honda GX390 Gas Engine with Electric Start

• Rear Access Removable Panel with Vents

• Hannay Electric Reel with 200ft of Hose

• Guide Rollers and Electric Rewind Reel

• Wash Down Gun with Quick Connect Tips

PART NUMBER: 5000-8000

3,000 PSI

Violating OSHA requirements for portable toilet management on a jobsite can lead to substantial financial penalties.

the trucks safe by doing all preventive maintenance promptly and all other tasks to keep the pump and the truck’s overall functioning in excellent condition.

Because no jobsite supervisor would allow an oil leak from a portable toilet service truck, or, worst-case, a waste compartment leak. OSHA requires a strict routine of waste disposal that is in compliance with local laws.

Before You Place and Maintain Portable Rental Toilets on Jobsites

OSHA regulations govern portable rental toilet operations on worksites, and those supersede generally accepted industry practices, contractors’ internal site safety policies, and toilet rental businesses’ operating standards. Violating OSHA requirements for portable toilet management on a jobsite can lead to substantial financial penalties. NOTE: It is

recommended that you obtain adequate portable restroom business liability insurance to protect your company and yourself in cases of adverse outcomes due to accidental noncompliance. Teaching the specifics of how to achieve and consistently maintain industry Best Practices and OSHA compliance is the domain of experts across the field of well-experienced portable toilet rental business owners, PSAI professionals, and other industry specialists. You are strongly advised to keep your knowledge updated from all these resources to capture the best and most current information and ensure the highest quality of performance by your team.

For information on future PSAI events, visit psai.org. For information about Will Niccoll’s Green Latrine eco-friendly solutions in portable toilet rental service, call 206-984-6931, or visit gogreenlatrine.com.

The Vactor Ramjet Trailer now features the option of a dual hose reel for increased efficiency, versatility and convenience for a variety of sewer cleaning jobs.

“The Vactor Ramjet Trailer already provides a multitude of configuration choices including water tanks up to 1,000 gallons, pull-out and pivoting hydraulic reels, and mounted accessories. The

addition of a dual hose reel means our customers can truly expand the Ramjet Trailer’s capacity for effective cleaning of many types of sewers, drains, and culverts,” said David Brockman, Vactor product manager.

The dual hose reel option features the main sewer hose plus one smaller hose designed for lateral pipes. This allows the operator the ability to tackle a wider

variety of drains. Generally, the lateral hose has a diameter of 1/2” while the vertical hose is 3/4” or larger.

The most popular model of jetting unit with dual reels would be the 3000PSI at 36-40GPM. With two hose reels, one hose allows the jetter to run 3000PSI at 36-40GPM while the second smaller reel is capable of 3000PSI at 18GPM. Having this versatility means

The Vactor team has been driven to develop the most capable I and versatile equipment for our customers...

the jetter can combat heavy debris and sludge in city mains and culverts while also navigating smaller lateral pipes with blockages too.

The Ramjet Trailer’s advanced hydraulic controls, including pay-in/out and speed control, help operators to easily maneuver the hose reels.

“The Vactor team has been driven to develop the

most capable and versatile equipment for our customers,” said Brockman. “The Ramjet Trailer’s dual hose reel is another example of our team anticipating and innovating the tools our customers need.”

Beyond the Ramjet Trailer, Vactor offers a variety of solutions for sewer cleaning including the combination sewer cleaner – an industry first at the time.

With more than a century as an American manufacturer, Vactor’s lengthy expertise and leadership in sewer cleaning dates back more than fifty years. As an innovator, Vactor created the first combination sewer cleaner – saving time and money while improving productivity and safety for operators. With an array of reliable tools and equipment, Vactor is committed to providing value for each customer. Learn more at Vactor.com.

FOR MORE INFORMATION ABOUT VACTOR, VISIT VACTOR.COM..

It’s all here:

High energy networking & industry-focused mixers

A 300,000+ sq. ft. action-packed expo hall with products and demos of the latest trenchless technology

100+ accredited conference sessions led by industry experts

Inclusive, community-focused receptions

Inspiring awards programs celebrating industry excellence

For more information, visit www.wwettshow.com

Industrial vacuum systems are essential for various sectors, from cement plants to oil refineries. However, a significant challenge has always been offloading the materials vacuumed by these machines. Traditional methods often result in inefficiencies and missed opportunities to reclaim, reuse or recycle valuable materials. Fortunately, Guzzler Manufacturing

has revolutionized the process with its advanced offloading solutions, offering a range of systems designed to optimize performance, reduce downtime and promote sustainability.

Guzzler’s innovative offloading systems, including continuous and batch solutions, allow businesses to not only handle waste and process materials efficiently

but also reclaim valuable resources, enhancing their environmental footprint. From dense-phase offloading for dry bulk materials to sludge pump systems for liquid recovery, these versatile technologies enhance industrial vacuuming

KEY OFFLOADING SYSTEMS

Guzzler offers both continuous and batch offloading

Guzzler’s innovative offloading systems, including continuous and batch solutions, allow businesses to not only handle waste and process materials efficiently but also reclaim valuable resources

solutions to suit different operational needs, all engineered to provide seamless, high-performance material handling.

CONTINUOUS OFFLOADING SYSTEMS

These systems enable simultaneous vacuuming and offloading, drastically reducing downtime and improving operational efficiency. They are ideal for

• Description: A system that allows continuous vacuuming and discharge of materials simultaneously.

• Best Used For: Reclaiming recyclable materials and containing hazardous materials as well as catalyst recovery applications or any operation where uninterrupted vacuuming is essential.

Application/Advantage: Material containment and reclaiming recyclable materials maximize operational uptime and efficiency.

• Description: A powerful, hydraulically driven pump

designed for liquid or semi-liquid materials, such as water, sewage and mud.

• Best Used For: Pumping high volumes of liquid or solid-laden sludges while continuing to vacuum, particularly in wastewater, oil & gas and industrial applications.

Application/Advantage: Considering it can be used as a continuous or batch system, productivity is enhanced. Hydraulic pumping of water, mud, sewage, silt and other semi-liquid materials maintains flow while the 4” discharge also contributes to increased efficiency.

Batch offloading systems are designed for situations where materials are vacuumed first and offloaded

continued on page 50 applications where uninterrupted operation is critical.

2025 Peterbilt 567 with 4200

2024 Ford F550 4x4 equipped with 1200-gallon 2C (300 water/950 waste), with a Masport HD4 hydraulic drive with a cooler, dual-sided service, 50’ hose spring rewind DC 10 water pump, dual-side bucket fill, dual 36” toolboxes, dual-side 2” x 30’ Tigertail suction hose, dual-side bucket holder, chemical holder drivers-side, dual-side wand holders

$130,000.00

2024 Ford F550 4x4 equipped with a 999-gallon 2C (300 water/699 waste), with a Masport HD3 engine drive, dual-sided service, 50’ hose spring rewind 45 PSI water system, dual-side bucket fill, dual 48” toolboxes (not shown), dual-side 2” x 30’ Tigertail suction hose, dual-side bucket holder, chemical holder drivers-side, dual-side wand holders

$107,000.00 (Gas Models starting at 96,000.00 complete)

2025 Peterbilt 537 Paccar PX-7 equipped with with an Allison 2500 RDS-P Transmission Gen 6, a 2500-gallon 2C (200 freshwater/2300 waste), Masport Titan 407 CFM’s, Masport water system PTO driven with 50’ rewind garden hose, 48” Toolbox

$168,950.00

Optional Add-on: Jetter Box $6,000.00

One of the key benefits of Guzzler’s offloading solutions is their contribution to environmental sustainability... Guzzler’s dense-phase and continuous offloading technologies help businesses reclaim and reuse these materials...

later. These systems are perfect when distance to the offloading point is long, or precise flow control is needed.

• Description: Combines pressure and high airflow to pneumatically convey dry materials in a dense-phase stream, capable of lifting materials up to 120 feet vertically.

• Best Used For: Cement, bulk powders and dry materials that need to be conveyed over long distances, such as to silos or railcars. Ideal for industries like construction and mining.

Application/Advantage: Controlled, efficient material conveyance of dry bulk materials up to 120 vertical feet helps avoid contamination.

• Description: Uses a rotary vane pump to pressurize the debris tank and enables offloading at up to 14.5 psi. It can also reverse to vacuum up to 28.5 in. Hg.

• Best Used For: Liquids, slurries and thick sludges in industries like oil & gas, grease removal, septic services and tank clean-outs.

• Application/Advantage: Rotary vane pump ensures high pressurization for handling liquids, slurries and thick sludges while reducing the risk of contamination and the need for air filtration.

Hi-Dump Into Roll-Off Containers

Description: Designed for operators to dump debris directly into roll-off containers up to five feet tall. The

system is controlled via an electronic sequence, ensuring stability and safety.

• Best Used For: Sites where large containers are available, and fast offloading without material conveyance is preferred, making it ideal for waste management and construction cleanup.

• Application/Advantage: Direct dumping into rolloff containers simplifies waste management and minimizes labor and material handling, especially on construction and demolition sites.

One of the key benefits of Guzzler’s offloading solutions is their contribution to environmental sustainability. Many industries generate valuable materials that, without proper offloading systems, would go to waste. Guzzler’s dense-phase and continuous offloading technologies help businesses reclaim and reuse these materials, reducing environmental impact while boosting operational efficiency.

For instance, cement manufacturers are using dense-phase offloading to recycle spillages of dry bulk powders that would otherwise end up in landfills. Similarly, in the plastics industry, acetate flakes that were once discarded are now being reclaimed and reintegrated into the production process, reducing material costs and waste.

Guzzler’s offloading solutions provide industries with cutting-edge technology to maximize operational efficiency, reduce downtime and embrace sustainable practices. Whether through continuous offloading

systems like the XCR Swing-Out Loading Cyclone or batch solutions such as dense-phase offloading, Guzzler has redefined the way industrial vacuum systems handle material recovery and disposal. By making it easier to reclaim, reuse and recycle valuable materials, Guzzler is not just improving productivity but also helping industries reduce their environmental footprint.

About Guzzler Manufacturing

Guzzler Manufacturing is a leader in industrial vacuum loaders, offering solutions for cleaning, material recovery and waste management across a wide range of industries. As part of Federal Signal Corporation’s Environmental Solutions Group, Guzzler continues to set the standard for innovation and reliability in industrial vacuuming. For more information, visit Guzzler.com or call (815) 672-3171.

American Jetter 52 866-944-3569 / americanjetter.com

American Tank Co. 31 254-721-5675 / atcvacuumtruck.com

Aqua-Zyme Disposal Systems Inc........................ 33 979-245-5656 / aqua-zyme.com

Bright Dyes 52 800-394-0678 / brightdyes.com

Bucher Municipal 53 704-658-1333 / buchermunicipal.com

Cam Spray 16 800-648-5011 / camspray.com

Chandler Vac 39 ChandlerVac.com

Coxreels 27

800-269-7335 / coxreels.com

Crane Pumps & Systems 55 cranepumps.com

F.M. Manufacturing .................................................... 11 877-889-2246 / fmmfg.com

FMC Advisors 3, 4

727-486-0306 / 407-765-9440 / fmcadvisors.com

Guzzler 5 guzzler.com

JD Brule. 12

613-656-6663 / jdbrule.com

Key Commercial Corp. .............................................. 27 877-333-4539 / keycommercial.com

Lane's Vacuum Tank, Inc. 29 800-592-3308 / lanesmobilejohn.com

McKee Technologies 35 866-457-5425 / mckeetechnologies.com

MHC. 2 MHC.com

Mid-State Tank Co., Inc ............................................. 31 800-722-8384 /midstatetank.com

Milwaukee Rubber Products 15 800-325-3730 / milwaukeerubber.com

Orenco Water 19 800-348-9843

Peterson Products 6 800-669-1434 / pipeplug.com

Porta Logix 33 585-484-7009 / portalogix.com

Portable Restroom Trailers 6 855-416-6789 / portablerestroomtrailers.com

Power Line Industries / Hot Jet USA 52 800-213-3272 / hotjetusa.com

Presby Environmental Inc. ......................................... 3 800-473-5298 / presbyenvironmental.com

RapidView BC 800-656-4225 / rapidview.com

Ratech Electronics 54 800-461-9200 / ratech-electronics.com RCS II Inc 6 518-812-0000 / septicdrainer.com

Ritam Technologies LLC .......................................... 40 925-478-2730 / ritam.com

Vacuum Tanks

814-933-0927 / robinsontanks.com

877-296-2555 / wee-engineer.com