LIME PRODUCTION

Lime-making from shells was an early industry in the St George area. The General Muster undertaken in 1800 showed that the number of lime burners in Sydney was 11, with 12 employed in this trade along the Georges River.

Lime, essential in making mortar, was in short supply in the colony. Lime-burners exploited Aboriginal shell middens along the Georges River and Botany Bay, sites of cultural significance, traditional knowledge, ritual and ceremony as well as the remains of generations of feasting. Middens were important for coastal Aboriginal communities who ate shellfish in large numbers before Europeans arrived. Today historical oyster shell middens remain along the Georges River, at Salt Pan Creek, Lime Kiln Bay,

Oatley, Lugarno, Sans Souci and around Port Hacking. Shells were crushed and burnt in pits or kilns, in alternative layers with timber and then set alight. The length of time it took to burn the shells was unknown, but it often took several days. Kilns were established at several locations around the region, including at Sans Souci, Port Hacking, Lugarno and Lime Kiln Bay in Oatley.

By the 1840s ships transported the lime from Botany Bay or it was hauled to Sydney by bullock teams. As these supplies were exhausted, live oysters were scraped from rocks and tidal mudflats. Men, women and children gathered oysters for lime production. This ‘inexhaustible’ supply was depleted and by 1868 the burning of live oysters for lime was prohibited.

The discovery of limestone in inland New South Wales gradually led to the demise of lime burning.

Lime burning was a simple process; shells were piled on top of or inter-layered with timber and burnt in the open. Some shell heaps were plastered with mud or clay before being set alight, with the shell burning taking several days. It is reputed that the ex-convict, John Alford, who had a 60-acre land grant upstream from Lime Kiln Bay in 1832, produced lime from abundant shells in Georges River middens that was used to build the Lansdown Bridge, near Liverpool.

Kiln for burning shell lime, 1899. Reproduction of etching. Australian Town and Country Journal

Cook’s River Dam and Lime kiln, c. 1860, Photograph Courtesy of Bayside Library Service

In 1851 it was estimated that ‘50 to 100 carts of timber and lime crossed the Cooks River Dam daily’. The burning of shells, however, destroyed many culturally significant Aboriginal shell middens.

The early building of Colonial Sydney required lime for mortar, plaster, lime wash and for agricultural purposes. As there were no limestone deposits along the coast, seashells were gathered and burnt. Some of the first settlers in the Georges River area were lime burners.

Shells were simply burnt in large heaps on site or transported to centralised kilns for burning. Shells from Botany Bay and Point Hacking was transported by ships to kilns in Sydney, and on the Cooks River. The demand for shells for lime accounted for ‘a considerable percentage of the NSW coastal shipping trade from early in the century until the 1850s’.

BOAT BUILDING, TOBACCO AND OSTRICHES

As the population of the Georges River region expanded during the mid-19 th century so too did the range of industries and businesses.

In 1870 it was noted that within the district ‘over 1,400 acres were under cultivation of which 620 acres were occupied by market gardens, orchards and vineyards’ in what is now Bexley, Kogarah, Rockdale and Peakhurst. Crops, including maize, oats and potatoes, were cultivated and there were paddocks for cattle, horses, sheep and pigs. Blacksmiths, farriers and coachbuilders flourished. The availability of land also led to the establishment of some unique farming ventures during this time.

Kingsgrove became the site of Smithson’s tobacco farm and factory, manufacturing tobacco and snuff for the Sydney market for twenty years. An Ostrich farm existed for several years during the 1880s on Stoney Creek Road in Hurstville, when the bird’s feathers were a highly sought after commodity. Blakehurst’s development was aided by its proximity to the water.

Shell midden of oyster shells, Georges River, undated. Photograph. Georges Riverkeeper collection

, ebony, glass eyes, two parts Made in France, ‘Sarge’ brand.

Hurstville Museum & Gallery collection, H2004.7.1-3

Boat and shipbuilders prospered, and many hired out boats for recreational use, a popular pastime on the Georges River. Most early Australian-built vessels, including those made along the Georges River, were small coastal traders. These were ‘vital for the establishment and expansion of settlement throughout the newly founded colonies’, with many built during the 1830s to 1870s.

Among the businesses in the area were Daniel Callaghan who built schooners on the shores of Townson’s (Kogarah) Bay; Thompson’s yard at O’Connell’s Bay; J.J. Mildwater and Sons who had a business at Shipwrights Bay; partners Alexander Kyle and James Merriman, boatbuilders at Kyle Bay, Peake and Rose boat builders in Oatley Bay and later Harry Linmark, a Danish boat builder, who offered cedar rowing boats for hire and managed the ‘tea gardens on the

river’, the Oatley Pleasure Grounds. The Parkesvale Pleasure Grounds also operated at Como and the Henley Pleasure Grounds in Lugarno during the late 19th and early 20th centuries.

Briar wood (Erica arborea) was commonly used to make tobacco pipes, knife handles and other specialty timber items, such as this smoking pipe and pipe holder in the shape of an owl perched on a branch. It had very good heat-resistant properties, so was favoured for use in making the bowls of tobacco pipes, along with its decorative grain.

Among the types of boats built on the Georges River were the ketch and schooner, both suitable for use on rivers. Boats built on the Georges River were often constructed out in the open, on ‘gently sloping ground close to the river… the vessels were side on to the river for ease of launching’. Abundant local timber was used, and the boats were made with the frame first, followed by the planks. While there is some knowledge of the methods used to build the boats, less is known about those who were employed to build them. This photograph is unusual in that it documents the makers, noting ‘Mr. Mahalan and Mrs. Mahalan building a launch at Neverfail Bay, Georges River’.

While the commercialisation of ostriches originated in South Africa during the 1860s, Ostrich farming spread to Australia during the late 19th century. By the beginning of the twentieth century ostrich feathers were a highly valuable and sought after commodity, used in clothing, hats, fans and

for decoration. ‘Kimberley Park’ operated by Captain J.W. James is significant for being the first, although little known, commercial ostrich farm in New South Wales. James’ ostrich farm operated between 1881 and 1885 and was located near the corner of Croydon Road and Stoney Creek Road on the property of Alfred Gannon, ‘Gannon’s Grove’ in Hurstville, on 31 acres of land. James’ managed his farm while continuing to practice as an engineer and his wife assisted with the business by entering ostrich feathers into NSW Agricultural Society shows.

The history of the ostrich farm reveals insights into some of the unique early farming ventures in the Georges River area and the district’s past.

Boatbuilders, Neverfail Bay, Georges River, Oatley NSW c. 1912. Georges River Council Libraries Local Studies collection, SNR-871.

Smoking pipe and pipe holder early 20th century Briar timber (Erica arborea)

BAKER’S DELIGHT

Bakeries were once widespread in the St. George region. They were often only streets apart, some on main streets, but many located between or behind private houses. Bread was baked daily and delivered fresh to homes via horse and cart and later motorised bread vans.

Prior to the advent of mass-produced, factory made bread, there were many small family owned bakeries which operated in the area. Centennial Bakery on Forest Road was managed by the Packham family, who had a lengthy association with the baking industry from the late 19th century. Syd Packham became prominent Australia wide in the bread industry. In 1885 George Greig had a large two-storey bakery on the same road, which was described as the ‘only bakery in the township, and is a model establishment, both in regard to the cleanliness of the premises and the excellence of the bread it turns out’.

Bread packaging, c. 1960s

Printed plastic packaging for Buttercup brand

Raisin and Fruit bun, 340g net

Hurstville Museum & Gallery collection, H1980.1819

Francis Elliott similarly occupied a bakery on the corner of Gloucester and Forest Roads Hurstville from 1908 to 1916. He built an additional bakehouse in 1914 with a ‘modern bread-making plant’ to cope with local demand. Several successful bakeries in the area added supper and tea rooms, with large seating capacities, to their businesses by start of the 20th century. Brett’s Bakery on Railway Parade in Kogarah did so in 1907 and Orr and Sons ran ‘pastrycook enterprises’ in Hurstville, Kogarah, and Rockdale by the 1920s. By this decade, however, the industrialisation of the bread making process was underway and large manufacturing companies began to sell bread in packaged form.

Sliced and packaged bread was introduced in America as early as 1928. It was initially described as ‘startling’, but a ‘refinement that will receive a hearty and permanent welcome’. The earliest sliced bread in

Australia was made by the Sunshine Bread Company in Newtown. Commercial bread makers often had strict guidelines to adhere to regarding production and distribution of their products. In 1926 The Day Baking Act (New South Wales) was introduced, which legislated for weekday baking times to start at 5.30am with deliveries allowed only between 6am and 6pm. Among the many brands of wrapped bread sold in the following decades was the Buttercup brand. During the Second World War, due to ‘wasteful’ packaging, bread was no longer available sliced or wrapped. By 1958 Tip Top bread was launched and became Australia’s first national bread brand.

Packham’s Bakery was originally established by Syd Packham at 319 Forest Road, Hurstville in 1908. It had first operated from an 1888 building on the corner of Bridge Street and Forest Road before its expansion along Bridge Street in subsequent years. The operation was later expanded and became known as the Sunbeam Bakery, until it was sold in 1957, making way for a modern business known as Buttercup Bakeries the following year. It was noted in 1913 that ‘Mr. J. Packham, of Sunbeam Bakery, wishes to state that he has secured the services of a first-class pastry cook, from Sargents, Sydney, in order to supply the public with the best pastry that can be made’. Following Mr. Packham’s death, his wife Clarice Vida assumed control of the business in the 1930s. The site was sold in 1985 and the land adjoining the original bakery building was later redeveloped as a multi-level residential and commercial complex.

Packham’s Bakery staff, Bridge Street, Hurstville NSW, believed to be 1930s. Photograph Georges River Council Libraries Local Studies collection, GRLS22-340

WARTIME COMMERCE AND INDUSTRY

Although suburbs such as Hurstville and Kogarah were established during the 1880s, the region did not experience rapid growth until the 1920s. Individual suburbs, such as Mortdale, were further expanded through houses built for returned soldiers after the First World War, which brought an influx of new residents. Other suburbs, such as Beverly Hills experienced real estate developments during the 1930s and 1940s. In 1936 The Propeller noted that ‘a careful investigation of local industrial activity has revealed that there are over fifty factories within the St. George and adjoining areas’. The range of manufactured goods produced in the area at this time included furniture, chemicals, brushes, baskets, soft drinks, car batteries, knitted apparel, rubber floor coverings, springs and screws.

Expanding suburbs were important in the reconstruction of social and economic life after the War and integral to the rise of domestic industries such as tiles, timber and plaster. The Second

World War led to the further expansion of local industries. Grange Worsted Mills, in Talbot Street, Herne Bay (Riverwood) operated from 1943 as a partnership between Charles Hannam and Alan Gill. Hannam later operated Hannam’s Textile Mills in Hearne Street, Mortdale. At Mortdale a camouflage factory was also established while camouflage nets were made by many local volunteers across the St George region as part of the war effort. The Wonderbord Company, makers of fibrous plaster from sisal and gypsum, operated in Peakhurst and Mortdale during the 1940s. Businesses and industries during the war greatly expanded manufacturing jobs in the area, frequently providing employment for skilled and unskilled workers.

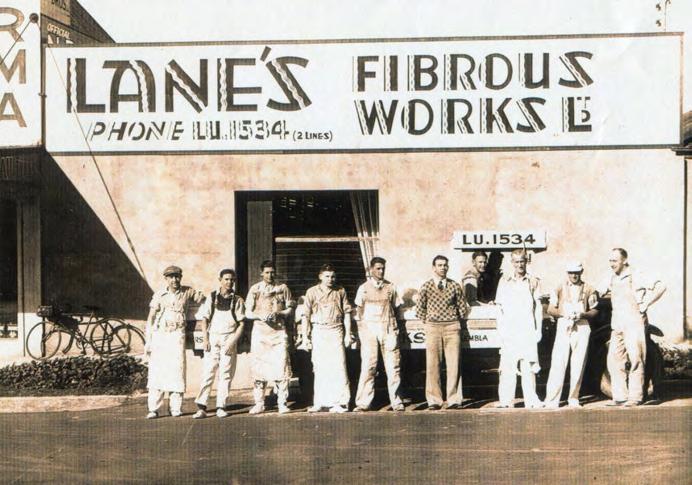

Lane’s Fibrous Works was established in Treacy Street, Hurstville by Mr. E Lane in 1925. The following year the business was

praised for ‘manufacturing tons of excellent plain and fancy sheets every month’. The factory supplied plaster products for the local district and beyond. The business underwent an extensive expansion in 1935, with The Propeller noting that it was ‘now one of the largest plaster-sheet works in the State utilising two floors…the firm’s activities are statewide, and many contracts have been executed in far-away leading country towns’. By 1940 it was described as a ‘progressive local industry’, employing a ‘big staff of local men…contributing considerably to the importance of Hurstville as an industrial centre’. The company was a large supplier of materials for public buildings and homes in the St George region.

During the Second World War many factories in Australia turned to war production, manufacturing everything from widgets to warships. Women took on new

Employees of Lane’s Fibrous Works, c.1920s. Photograph. Georges River Council Libraries Local Studies collection, GRLS22-184

Camouflage netting class during Second World War, Hurstville NSW, 1941. Photograph. Georges River Council Library Local Studies collection, GRLS19-0033

roles in essential industries, working in what had previously been male-dominated areas, and many people engaged in voluntary work to help the ‘war effort’ . Making camouflage netting was an activity that was easily done on the home front. Newspapers and magazines published detailed instructions for net making. Schools and organisations came together to create a vast number of nets for use overseas, while sporting and business organisations, department stores, churches, hospitals and municipal councils all similarly contributed to making nets. In the St George region, many groups made camouflage nets, including those at Diment’s Lane netting class in Hurstville photographed here. An Australian record was made when the Kogarah Branch of the National Defence League was the ‘first camouflage net making centre in the Commonwealth to have completed its 10,000th net’ in 1942.

Camouflage nets were an essential device during the Second World War. They were ‘decorated’ with abstract patterns made of pieces of material matching the colour of the surroundings, to conceal the object underneath and to diffuse any shadows that might be visible from the air. Large, flat hardwood netting needles or shuttles were used to make camouflage nets. Many people volunteered to make nets as part of their civic and patriotic duty, from children to the elderly. The largest netmaking centre in the St George region was in Kogarah. Volunteers threaded the needles with twine, ready for others to make the nets, tie knots

EXPANSION AND CHANGE

The Second World War had been a stimulus to the growth of the private sector and an expansion of manufacturing throughout Australia. The rapid industrialisation that occurred after the War continued during the 1950s, 60s and 70s. Federal and corporate funding for major industries together with government policies for population growth enabled programs that shaped urban environments into modern industrial landscapes.

and attach the pieces of fabric. In addition to the Kogarah Camouflage Netting Centre, several sub-branches existed at Penshurst, Hurstville, Sans Souci, Bexley, Ramsgate, Kingsgrove and Carlton. Community organisations, such as the CWA (Country Women’s Association), similarly assisted in making camouflage nets, and established netting annexes at Oatley and South Hurstville during the war. In 1942 students at Hurstville Central Technical School were acknowledged for their contributions, when it was noted that the ’manual training section turned out hundreds of camouflage netting needles and boards’.

In the St. George region, this was reflected in the establishment of new businesses and industrial development. The Wonderbord Company purchased a site in Mortdale in 1948, becoming the ‘only fibre teasing specialists in Australia’, producing fibrous plaster. Dunlop Australia Ltd expanded its range of consumer goods after the War and in 1948 opened a tennis racquet factory in Beverly Hills. In 1947 the Hurstville Council took the ambitious step of a £30,000 loan for the purpose of acquiring, planning and subdividing 90 acres of land to develop a ‘modern industrial area’ in Kingsgrove. A town planning study had previously highlighted that the Hurstville Municipality was ‘lacking very badly in industrial space’. By 1955 the Council had sold off 17 acres at the site and many new manufacturing businesses had been established.

Companies such as Coca-Cola, J. Fielding & Co, makers of fibreboard, boxes and containers, and International Resistance Co. were among the first to open factories in the estate. Sales of lots continued in 1959 when companies such as Cyclops & Lines Bros Ltd, Tyree Holdings Pty Ltd, Tapex and Frank G. Spurway Properties Ltd purchased land. The Kingsgrove site became the ’second largest industrial and consolidated estate within the local government

area’. From the 1960s onwards, new technologies continued to impact on the way goods were produced, and further specialist manufacturers were established in the St George region.

The Oliver brand of tennis racquet was established in South Australia in 1934. By the mid-1930s the small company was also making table tennis bats and tool handles. Sales outlets for the tennis racquets opened in Melbourne, Sydney, Brisbane and Perth and they were exported to Europe, Canada and the United States after the Second World War. Tennis equipment was designed and built by the Oliver company in house to ensure uniformity. There were 78 processes required to construct and finish a racquet . Until the 1920s most racquets in Australia were imported from England

and the USA, but the popularity of tennis at this time reached levels which justified local production of racquets and balls. The Dunlop Sports Co Pty Ltd factory in Beverly Hills employed men and women in all aspects of tennis racquet production. By 1951 it was noted that the factory had ‘modern machinery [which] treated the timbers, turning out 240 Maxply racquets a day’.

The Peakhurst Timber yard was located at the intersection of Boundary Road and Norman Streets, Peakhurst. The business was previously known as J.A. Letchford and Co. from 1949 and was subsequently acquired by Tanner and Middleton in July 1968. It was one of several timber yards and merchants that had operated in the forested St. George region from the late 19th century. Walters and Middleton, timber merchants,

opened a sawmill and joinery works at Carrington Avenue in Hurstville in 1912. They became the largest suburban timber merchants in Sydney the following year. Peakhurst Timber Yard’s business involved the processing and production of timber products and provision of hardware items for the local community. During the 20th century there were several timber yards in Peakhurst and Narwee with The Propeller in 1942 reporting on the ‘unsightliness and …noise’ of some of the yards, despite operating circular saws only two hours a day.

The development of land for industrial purposes in the Hurstville municipality increased rapidly after the Second World War. By 1946 the Council was receiving 40 to 50 building applications per week. It was reported that Hurstville Council still had ‘miles of undeveloped areas to be used for homes and industries’ in 1953. Containers Limited was granted approval in principle for the construction of a factory on Forest Road. In 1960 it was reported that the company’s factory was under construction at the site, would manufacture tin cans, and accommodate a workforce of about 350 people. The factory went on to partly occupy the former Federal Brick Company (Carlton Brick and Pottery Works) site and operated between 1961-2012. Parts of the Containers’ area later became Kempt Field and today the East Quarter residential apartments.

Peakhurst Timber, yard staff, Boundary Road, Peakhurst NSW, 1961. Photograph. Georges River Council Libraries Local Studies collection, SNR-403

Containers Limited premises, Forest Road between Durham and Hill Streets, Hurstville NSW, c. 1982. Photograph. Georges River Council Libraries Local Studies collection, JHP6-031.

OBJECT LIST

THE FORESTS OF ST. GEORGE

Laden timber jinker with two individuals alongside, undated

Photograph Georges River Council Library Local Studies collection, LHP587

Cleveland land, Ponderosa Place, Lugarno NSW, 1920s

Photograph Georges River Council Library Local Studies collection, LMG15-065

Cross cut saw, late 19th century Metal and timber Hurstville Museum & Gallery collection, H1980.1341

Broad or Squaring axe head, c. 1890 Steel, embossed with ‘7’ on front Hurstville Museum & Gallery collection, H1980.879

Photograph illustrating charcoal production, 1930-50

‘Charcoal being removed from a kiln’, photographer unknown, for the Sydney Morning Herald, Sydney, 1930-1950. Powerhouse collection

Charcoal tooth powder, late 19th century Timber and lithographic decal Hurstville Museum & Gallery collection, H1980.243

OYSTER FARMING

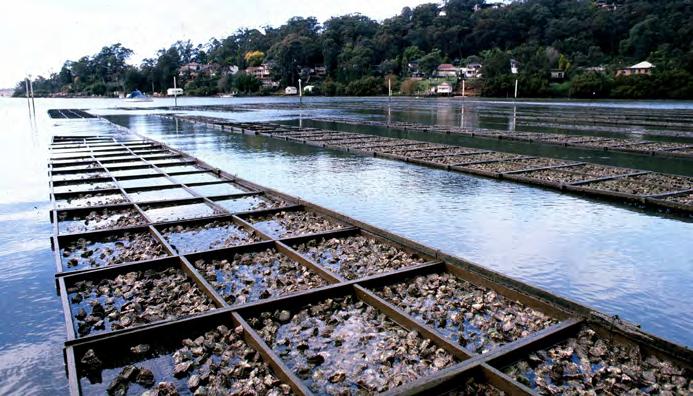

Oyster farming, Georges River, NSW, August 1989

Robert Kerton (CSIRO) photograph, via Wikimedia Commons https://commons.wikimedia.org/wiki/ File:CSIRO_ScienceImage_2901_ Oyster_Farming.jpg

Oyster covered stick, early 20th century Timber and oyster shells Hurstville Museum & Gallery collection, H1980.1487

New South Wales Oyster Fisheries, 1883 Etching by Arthur Collingridge (18531907)

Reproduction of page from the Australasian Sketcher, 14 March 1883, p. 49

Oyster Culture on the Georges River, New South Wales, 1922 Book, ‘Oyster Culture on the Georges River, New South Wales’, Technical Education Series, No. 25, paper / textile, written by Theodore Cleveland Roughley.

Produced by the Technological Museum, Sydney, printed and published by William Applegate Gullick, Government Printer, Sydney, New South Wales, Australia, 1922 Powerhouse collection, purchased 1986

Oyster farmers David Corstorphine of Tuncurry, aged 78 and Fred Selmon of Georges River, aged 70, enjoy oysters at Dolls Point, c. 1930

Photograph, Sam Hood (1872-1953) photographer, Sam Hood Collection part II. State Library of New South Wales collection

Oyster jar, c.1950s

Glass and paper label

Oyster pick, c. 1930s

Timber and metal

Culling tool, c.1960s

Hardened steel

Oyster sack, c. 1980s Hessian Derwent family collection

Bob Drake, veteran Georges River oyster farmer, 2012

Photograph, Jane Dyson

Image from ‘Flashback Friday: Good and bad times for oyster growers in Georges River and Botany Bay’, St George and Sutherland Shire Leader, 16 July 2018, p. 7

Thomas Andrew ‘Darby’ Derwent with Ron Derwent (son) in background, c. 1950s

Photograph

Derwent family collection

Derwent female family members, c. 1912

Photograph Derwent family collection

Derwent family home, Wyong Street, Oatley, early 20th century

Photograph Derwent family collection

Derwent and Mahalm family members, Neverfail Bay, Georges River, Oatley NSW, 1912

Photograph Georges River Council Library Local Studies collection, SNR-870

LIME PRODUCTION

Cook’s River Dam and Lime kiln, c. 1860

Photograph Courtesy of Bayside Library Service

Burning shells to make lime, 1899

Reproduction of etching

Australian Town and Country Journal, Saturday 6 May 1899, p.29

Shell midden of oyster shells, Georges River, undated

Photograph

Georges Riverkeeper collection

Model furnace, lime kiln, c.1880

Periodical furnace for limestone burning, wood / metal, made by J Schröder Actien-gesellschaft, Darmstadt, Germany

Powerhouse collection, purchased 1884

BOAT BUILDING. TOBACCO AND OSTRICHES

T. Thompson working on a launch, Neverfail Bay, Georges River, Oatley NSW, March 1927

Photograph

Georges River Council Library Local Studies collection, SNR208

A and J Pryor at Pryor’s Boatshed, Jewfish Bay, Georges River, Oatley NSW, 1930

Photograph

Georges River Council Library Local Studies collection, SNR-828

Boatbuilders, Neverfail Bay, Georges River, Oatley NSW, c. 1912-14

Photograph

Georges River Council Library Local Studies collection, SNR-871

Rope, early 20th century

Hemp and wire

Hurstville Museum & Gallery collection, H1980.1072

Round bottom plane, late 19th century

Wood and steel

Australian National Maritime Museum collection, 00008921

Firmer chisel, boat building tool, Titan, 1900 -1940

Brass, stainless steel, wood

Australian National Maritime Museum collection, 00015165

Marking gauge: boat building tool, 1914

Manufactured in England

Wood and metal

Australian National Maritime Museum collection, 00005719

50ft tape measure, boat building, Treble, 1900-1940

Manufacturer in England

Brass, leather, cotton

Australian National Maritime Museum collection, 00008416

Carpenter’s square, six-inch blade, boat building, 1900 - 1940

Wood, mild steel, brass

Australian National Maritime Museum collection, 00008417

Boat builder’s bevel, 1900-1925

Wood and brass

Australian National Maritime Museum collection, 00006434

George Linden (1857-1927)

[Georges River Boat shed scene], not dated

Oil on board

Signed lower right ‘G LINDEN/ 26/2’, in blue paint.

Hurstville Museum & Gallery collection, H00.173

Como, Georges River, c. 1890s

Reproduction of postcard

Sutherland Shire Library, Local Studies collection.

Lugarno Picnic Grounds and Tea Rooms, c. 1910s

Photograph

Sutherland Shire Library, Local Studies collection.

Parkesvale Pleasure Grounds, Georges River NSW, likely to be 1900s

Postcard

Georges River Council Library Local Studies collection, LMG15-712

Como Boat Letting Company Shed, Georges River, Como NSW, October 1924

Photograph

Georges River Council Library Local Studies collection, SNR-880

Oatley Pleasure Grounds, Annette Street, Oatley NSW, believed to be 1935

Photograph

Georges River Council Library Local Studies collection, LHP166

Charles H. Kerry (1857-1928)

Baling and sampling tobacco, New South Wales, c. 1900

Photograph, PIC Box PS 1435

#PIC/13562/2 copy

National Library of Australia collection

Tobacco cutter, hand operated, c.19th century iron / brass / wood, maker unknown, place of production unknown

Powerhouse collection, purchased 1978

Tobacco coils (2), c.1890s

Nicotiana tabacum (tobacco plant), place of origin unknown

Powerhouse collection, acquired by exchange from the Royal Botanic Gardens Sydney, 1896

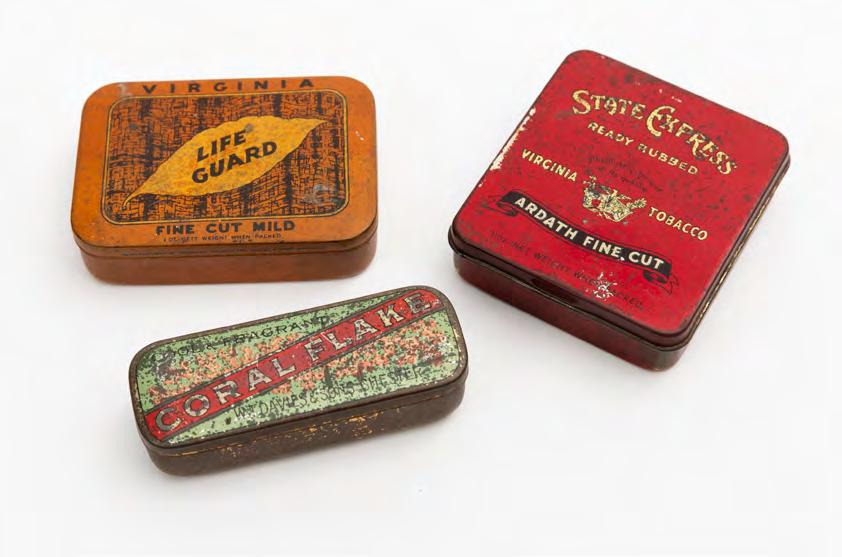

Tobacco tins, 20th century Coral flake brand tobacco tin, c. 1930s State Express brand tobacco tin, pre-1939

Virginia – Lifeguard fine cut brand tobacco tin, c. 1920s

Metal and decals

Hurstville Museum & Gallery collection, 1980.1311, 1980.1080 and 1980.1862

Smoking pipe and pipe holder, early 20th century Briar timber (Erica arborea), ebony, glass eyes, two parts Made in France, ‘Sarge’ brand. Hurstville Museum & Gallery collection, H2004.7.1-3

Ostriches, 19th century

Glass lantern slide image

OSU Special Collections & Archives Research Centre, via Wikimedia Commons https://commons. wikimedia.org/wiki/File:Ostriches_ (4750360156).jpg

Fan (1 of 3), c.1890-1900

Ostrich feather / bone / metal, maker unknown, probably England

Powerhouse collection, gift of G D Ellis, 1973

Jacket, womens, c. 1890-1892

Velvet / satin, textile / feathers, maker unknown, place of production unknown

Powerhouse collection, purchased 1959

BUTCHERS AND SLAUGHTERMEN

Meat cleaver, early 20th century Wooden handle and iron blade, 2014.206.1

Don Bank Museum, North Sydney Heritage Centre, Stanton Library collection

Cattle Branding iron, c. 1880s

Cast iron

Hurstville Museum & Gallery collection, H1980.880

Letter regarding Training Scheme Qualification, 10 January 1950

Typed text and ink on paper Letter signed 10 January 1950 from the Ministry of Post-War Reconstruction regarding Mr. K.C. (Kenneth Charles) Hamilton, 55 Washington St Bexley, completing the Commonwealth Reconstruction Training Scheme and qualifying as a general butcher. Hurstville Museum & Gallery collection, H00.174

Training Scheme Qualification certificate, 10 January 1950 Printed paper and ink

Certificate for Mr. K. C. (Kenneth Charles) Hamilton, Bexley, on completion of the Commonwealth Reconstruction Training Scheme and qualifying as a general butcher. Hurstville Museum & Gallery collection, H00.175

Smithson’s butcher shop and staff, Forest Road, Hurstville, c. 1936

Photograph

Georges River Council Libraries Local Studies collection, GRLS 19-0029

J Burnett and Burnett’s Butcher Shop, Hillcrest Avenue and Laycock Road intersection, Hurstville Grove NSW, c. 1936-37

Photograph

Georges River Council Libraries Local Studies collection, GRLS20-362

C J Stone’s slaughter yards, with Herbert Smithson driving cart, c. 1890s

Photograph

Kogarah Historical Society Inc collection, Carss Park Museum

BAKERS’ DELIGHT

Baker’s Oven door, c. 1888

Cast iron oven recessed hinged door

Hurstville Museum & Gallery collection, H1980.1151

Junior Social Studies Series No. 3: A

Loaf of Bread, 1949

Black and white film

Director, Malcolm Otton and Producer, Stanley Hawes National Film and Sound Archive collection

Bread proving basket, c.1950s

Coiled cane and metal staples

Hurstville Museum & Gallery collection, H1980.1058

Married loaf bread tin, c. 1950s

Pair of square based metal tins, joined, slightly flared sides, corrugated metal, black exterior paint. Embossed ‘HOVIS’ on base. Hurstville Museum & Gallery collection, H1980.1035

Advertising brochures for commercial bakery products and machinery, c. 1950s-60s

American Machine and Foundry Co., paper

Big Batch Mixing advertisement; advertisement for AMF end labeller

Hurstville Museum & Gallery collection, H00.179c and H00.179d

Bakery recipe, c. 1960s

Typed and printed bakery recipe on paper for ‘Soya/ Raisin Bun Loaf “No Time”

Hurstville Museum & Gallery collection, H00.180.1

Cake plate trophy, 1961

Silver cake tray, with floral pattern cut into the outer rim of the of the tray

Engraved on the rim; ‘Newcastle 1961

Show Best 2 loaves (1 roll & 1 single condensed) / 1st Prize/ Sunbeam Baking Co. (Hurstville)’; Crusader silver, (manufacturer)’.

Hurstville Museum & Gallery collection, H1980.1506

Unknown artist

Bread for Energy, c. 1920s-1940s Oil on board

Hurstville Museum & Gallery collection, H00.176

Packham’s Bakery, delivery van and driver, Sunbeam Bread, c.1950s

Photograph

Georges River Council Libraries Local Studies collection, LMG15-183

Packham’s Bakery staff, Bridge Street, Hurstville NSW, believed to be 1930s

Photograph

Georges River Council Libraries Local Studies collection, GRLS22-340

Packham’s Bakery site, delivery vehicles, Bridge Street, Hurstville NSW, c. 1940

Photograph

Georges River Council Libraries Local Studies collection, LMG15-181

Packham’s Bakery, Bob Alexander in bread room, Bridge Street, Hurstville NSW, believed to be c. 1960

Photograph

Georges River Council Libraries Local Studies collection, LMG15-188

Bread vendor’s jacket, c. 1950s-60s

Beige drill cotton jacket, double fronted wrap over style, with ties and logo on left pocket, ‘Swing to Sunbeam bread’.

Hurstville Museum & Gallery collection, H1980.1210

Bread packaging, c.1960s

Printed plastic packaging for Buttercup brand Raisin and Fruit bun, 340g net.

Hurstville Museum & Gallery collection, H1980.1819

Trompp Bakery horse drawn delivery cart and driver, likely to be Penshurst area, NSW, c. 1920s

Photograph

Georges River Council Libraries Local Studies collection, GRLS21-1584

DAIRIES

Cowbells, 19th century

Metal and leather

Moruya and District Historical Society Museum collection

Butter pats, early 20th century

Pair of wooden butter pats

Hurstville Museum & Gallery collection, H1980.1541

Butter wrap, c. 1940s

‘Choicest creamy butter’, ‘1 lb nett’, blue ink printed on greaseproof paper

Hurstville Museum & Gallery collection, H2001.11

Cream skimmer, 1880

Metal, hand made

Hurstville Museum & Gallery collection, H1980.28

8-inch Metal ruler, 1926

Metal; printed text on ruler

‘Compliments of L.S. Reynolds, Regent Park Dairy, Regent St, Bexley.’

Hurstville Museum & Gallery collection, H1980.1853

Here’s looking at You! Dairy Farmers Milk, 1925-1940

Reproduction of cardboard advertisement by Dairy Farmers, Australia, 86/1397

Powerhouse collection

Hill Top Dairy, horse drawn milk cart, Hurstville NSW, 1920

Photograph

Georges River Council Libraries Local Studies collection, GRLS19-0233

Regent Park Dairy, Bexley NSW, believed to be 1919

Photograph

Georges River Council Libraries Local Studies collection, GRLS19-0010

Pott’s Dairy, The Groves, Hurstville [Hurstville Grove], early 1900s

Photographic reproduction

Kogarah Historical Society Inc collection, Carss Park Museum

Rosa Street Dairy, Oatley, c. 1915

Photographic reproduction

Kogarah Historical Society Inc collection, Carss Park Museum

Milk measure (1 of 4), part of Dairy Farmers Collection, 1910-1950 Tin, maker unknown, used by Dairy Farmers Pty Ltd, Sydney, New South Wales, Australia Powerhouse collection, gift of Dairy Farmers Co-Operative Ltd, 1986

MADE FOR WALKING

Boot-stitching machine, 1878-1890

Treadle operated, cast iron / wood, made by Bradbury & Co Ltd, Wellington Work, Oldham, Greater Manchester, England, 18781890, used by the Hamey family of boot-makers in New South Wales, Australia, c. 1880-1979

Powerhouse collection, gift of E J Hamey, 1973

Shoe lasts, c. 1920s-1940s Hardwood and metal Men’s shoe last, stamped ‘3270’, size ‘7E’; Woman’s last with instep attached with cord; Women’s last with missing instep and ‘3270 US’, Children’s last, stamped, ‘6’ and small child’s shoe last.

Hurstville Museum & Gallery collection, H00.181, H00.182, H00.183, H00.184, H00.185

Men’s and women’s shoes and boots, c. 1920s-40s

Leather, timber heels and metal Hurstville Museum & Gallery collection, H1980.943.4, H1980.943.6 and H1980.943.15

Lawrance’s boot making depot, Kogarah, c. 1913

Photographic reproduction

Kogarah Historical Society Inc collection, Carss Park Museum

Lawrance’s boot making shop, Kogarah, c. 1913

Photographic reproduction

Kogarah Historical Society Inc collection, Carss Park Museum

Glass advertising slides, Lawrance Bros, c. 1920s-30s

T.W. Cameron Slide specialists, 430 Bourke Street Melbourne and Whitford’s Theatre Ads Ltd., Sussex Street, Sydney

Kogarah Historical Society Inc collection, Carss Park Museum

Business archive, J. Lawrance bootmaker, 1920s-30s

Lawrance Bros, bootmakers, Railway Parade, Kogarah invoices, paper and ink, 1923 and 1932

Lawrance Bros, bootmakers, Railway Parade, Kogarah business cards, paper and ink, c. 1920s-30s

Lawrance Bros, bootmakers, Railway Parade, Kogarah, Master Bootmakers & Repairers Association NSW, Approved member Certificate of Competence, printed paper and ink, c.1920s-1930s

Kogarah Historical Society Inc collection, Carss Park Museum

Mrs Mary Rate and Mr Thomas Rate with some of the employees from Mrs Rate’s shoe factory in Short Street, Carlton. c. 1900s

Photograph Courtesy of Bayside Library Service

Selection of boot and shoe making tools, c. 1920s-40s

Shoe and bootmaker’s tools, metal and timber; shoehorns, leather scraps, shaped head tool, lasting pliers, two awls, shoe talc, stitch marker and shoemaker’s twine Hurstville Museum & Gallery collection, H1980.368

POTTERIES AND BRICKWORKS

Stoneware Jardiniere, 1932

Made by George Day of Mashman Brothers pottery, Auburn, New South Wales, Australia.

Powerhouse collection, purchased 1997

Glazed earthenware vase, c.19301940

Possibly made by Mashman Brothers Ltd, New South Wales, Australia Powerhouse collection, purchased 1977

Carlton brickworks, c. 1920s

Photograph

Kogarah Historical Society Inc collection, Carss Park Museum

R. Carroll

Judd’s Brickworks, c.1950s-60s Oil in board

Hurstville Museum & Gallery collection, H00.22

Judd’s Brickworks, Mortdale NSW, 1970s

Photograph

Georges River Council Libraries Local Studies collection, JHP1365

Federal Brick Company demolition site, Hurstville NSW, 1957

Photograph

Georges River Council Libraries Local Studies collection, JHP3016

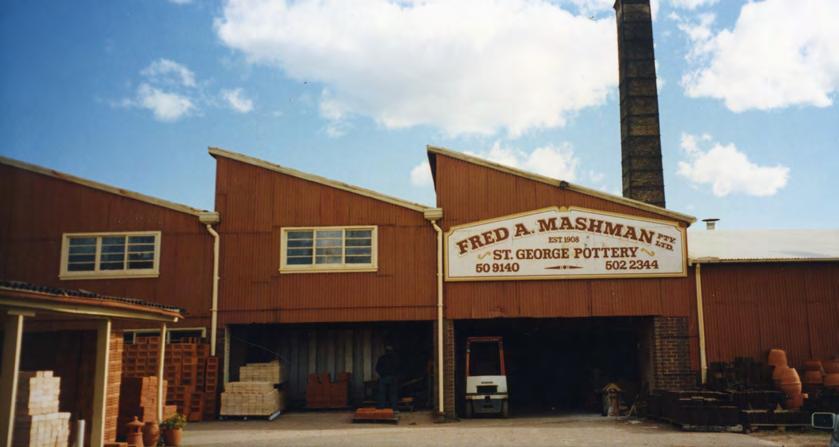

Mashman Pottery Works, Kingsgrove NSW, c. 1995

Photograph

Georges River Council Libraries Local Studies collection, LMG14-786

Mashman Pottery Works, Kingsgrove NSW, c. 1995

Photograph

Georges River Council Libraries Local Studies collection, LMG14-788

Brick making equipment, undated Attributed to Judd’s brickworks, metal and timber frog and brickmaking equipment, handmade models.

Hurstville Museum & Gallery collection, H1980.562

Letter Box cover, c. 1900-1920s

Terracotta

Made by Fred A Mashman , Mashmans Pottery

Hurstville Museum & Gallery collection, H1980.1832

Regal Mashman drip glazed vase, c. 1930s

Made by Mashmans Pottery, brown glaze streak pattern

Hurstville Museum & Gallery collection, H00.172

WARTIME COMMERCE AND INDUSTRY

Hurstville street procession, Hurstville Ice Works truck, Hurstville NSW, c. 1920s

Photograph Georges River Council Libraries Local Studies collection, JHP1841

Ice chest, early 20th century Timber and metal, unknown manufacturer

Hurstville Museum & Gallery collection, H1980.1478

Employees of Lane’s Fibrous Works, c.1920s

Photograph

Georges River Council Libraries Local Studies collection, GRLS22-184

Parkinson Bros account books, 1915-1943

Paper, ink and cardboard

Bound accounts books of Parkinson

Bros., builders and contractors, July 1915 to June 1943

Georges River Council Libraries Local Studies collection

Forest Road and Kenwyn Street intersection, including W J Smith Manufacturing premises, Hurstville NSW, c. 1982

Photograph

Georges River Council Libraries Local Studies collection, JHP6-022

Camouflage netting class during Second World War, Hurstville NSW, 1941

Photograph

Georges River Council Library Local Studies collection, GRLS19-0033

Nets that Save Lives, National Defence League of Australia, 1943

Black and white newsreel film

Cinesound Movietone Productions National Film and Sound Archive collection

Weaving needle for making camouflage nets, c.1940-45

Wood

Hurstville Museum & Gallery collection, H1980.1568

EXPANSION AND CHANGE

Dunlop tennis factory, Beverly Hills, April 1949

Home and Away– 32487: Dunlop tennis factory, Beverly Hills, 8/4/1949 photograph

Mitchell Library, State Library of New South Wales collection

Dunlop tennis factory, Beverly Hills, April 1949

Home and Away – 32478: Dunlop tennis factory, Beverly Hills, dated 8/4/1949 – photograph

Mitchell Library, State Library of New South Wales collection

Dunlop Maxply Tennis Rackets and Tennis Balls, 1920-1930

Photographic reproduction

Dunlop Australia Limited (1899 -)

advertisement

Deposit 31 - Dunlop Rubber Company of Australia Limited deposit 1, NBAC 31-37-98

Noel Butlin Archives, Australian National University collection

Tennis racquet, c. 1930s-1940s

Timber, lacquer and gut strings, Oliver brand tennis racquet. Hurstville Museum & Gallery collection, H2008.3.1

Peakhurst Timber, yard staff, Boundary Road, Peakhurst NSW, 1961

Photograph Georges River Council Libraries Local Studies collection, SNR-403

Two factory workers making decorative trim for sandals at Dunlop Footwear plant, Kingsgrove or Mortdale, 17 July 1968

Photograph by John A. Mulligan (1927-1996)

National Library of Australia collection

Female factory workers at sewing machines, Dunlop Footwear plant, Kingsgrove or Mortdale, 17 July 1968

Photograph by John A. Mulligan (1927-1996)

National Library of Australia collection

Machinists at the Dunlop Footwear plant, Kingsgrove or Mortdale, 17 July 1968

Photograph by John A Mulligan (1927-1996)

National Library of Australia collection

How Pix maps are made at H. E. C. Robinsons, City and Kingsgrove, 4 November 1964

ON 388/Box 100/Item 045,

Photograph by David Cumming (1933-2016)

Mitchell Library, State Library of New South Wales collection

Containers Limited premises, Forest Road between Durham and Hill Streets, Hurstville NSW, c. 1982

Photograph Georges River Council Libraries Local Studies collection, JHP6-031

J Fielding & Co. premises, Vanessa Street, Kingsgrove NSW, believed to be 1962

Photograph Georges River Council Libraries Local Studies collection, GRLS190160