CNC

March 2022

M AC H I N E RY & EQ U I P M E N T A FURNITURE & JOINERY PRODUCTION SUPPLEMENT

Epicon CNCMarch Cover2022 2022.indd CNC Supp JA.indd1 1

15/02/2022 28/02/2022 16:14 16:53

E VE NT S this April and June

EVEN TS ● NESTING vs CUT, EDGE & DRILL

7 – 9 JUNE 2022

EVENTS ● THE PROFITABLE WORKSHOP

5 – 7 APRIL 2022

Balancing time, space and cost. Your production needs answered. Event opening hours: 10am - 4pm. Location: Weinig UK, Abingdon.

Small and mighty: Compact automation designed to improve workshop efficiencies. Event opening hours: 10am - 4pm. Location: Weinig UK, Abingdon.

• WATCH TAILORED MACHINERY DEMONSTRATIONS • MEET THE EXPERTS • EXPERIENCE THE LATEST INNOVATIONS • ENHANCE YOUR MANUFACTURING PROCESSES • GROW YOUR INDUSTRY KNOWLEDGE • CONNECT WITH INDUSTRY To register your attendance and to book your dedicated arrival time please visit

weinig.co.uk CNC Supp March 2022.indd 2022 JA.indd Connect A4 Advert 1 2

28/02/2022 18:07 16:53 14/02/2022

2 18:07

3

EDITOR John Legg Tel: 01424 834973 john@media66.net ADVERTISING MANAGER Lisa Williams Tel: 01424 834829 lisa@media66.net ADVERTISING EXECUTIVE Conor O’Brien Tel: 01424 834962 conor@media66.net PRODUCTION James Ash studio@media66.net DIGITAL CONTENT Nyall McCurrach digital@media66.net COPY ADMINISTRATION & DATA Steve Merrick Tel: 01424 776108 production@media66.net ACCOUNTS Wendy Williams accounts@media66.net SUBSCRIPTIONS UK: free with sign-up Europe-£85 RoW-£95 lisa@media66.net PROOF READER Paul Farley REPRO, PRINT and DISTRIBUTION Stephens & George

DISCLAIMER: All material submitted for inclusion in Furniture Production is done so entirely at the contributor’s own risk. No responsibility is accepted for the safe-keeping of contributors’ materials. Whilst all attempts are made to ensure accurate reproduction, Furniture Production accepts no responsibility for variations. Artwork undertaken by our studio remains the copyright of Media66 and may not be reproduced or stored without prior permission. Some articles in Furniture Production have been submitted by companies and organisations. Monies may have been accepted in some instances to offset production costs. All rights reserved. In respect of artwork originated free of charge as part of a booking, clients should know that excessive work (more than one set of corrections, known as ‘authors corrections’) is chargeable at £55 per hour. DATA PROTECTION “OPT OUT” STATEMENT: Readership data held by Media66 may be shared with any member of the Media66 and associated companies for the purposes of customer information, direct marketing or publication. Data may also be made available to external parties on a list rental/lease basis for the purposes of direct marketing. If you do not wish data to be made available to external parties for list rental or lease please write to: Data Protection Co-ordinator, Media 66 Ltd, 36 Stirling Road, Castleham Business Centre East, St Leonards-on-Sea, East Sussex TN38 9NP. SUBSCRIPTIONS: Refunds on cancelled subscriptions will only be provided at the publisher’s discretion, unless specifically guaranteed within the terms of the offer.

Comment In recent decades, the deployment of CNC machinery has become a standard fixture for most progressive furniture and joinery manufacturers – not necessarily the impressive, five-axis machining centres, but entry-level boring machines, for instance, which represent an ideal entry point into the world of programmable, highly accurate production. It’s perhaps worth reminding ourselves just how transformative computer numerically controlled machinery and equipment has been across the furniture and joinery industry since its inception in the 1940s. For those of us old enough to remember the classic workshops and factories before the mass appropriation of advanced technology, what went before was created using classical methods, with lots of individual, manual processes, with tremendous man hours, and at a considerable cost to the end-user. True furniture democratisation requires a completely different approach. Depending on where you take your reference point, CNC can trace it origins back to the 1940s, when John T Parsons, working as a machinist producing helicopter rotors in his father’s company, effectively developed Numerical Control (NC). Working with Frank Stulen, the duo designed a method of creating co-ordinates in an X and Y axis on a rotor (for two machinists would ultimately make the cut). Following this, they worked with the Massachusetts Institute of Technology (MIT) to create punch cards that could be programmed with reference points to provide automated machining. Into the 1950s, MIT developed a programmable language that could create co-ordinates for machined parts automatically, reducing the time required to feed machines with instructions. The key step for CNC machining came in 1959 when MIT demonstrated a completely automated machine producing aluminium ashtrays. This Computer Aided Design (CAD) program empowered designers to ‘draw’ their creations into the computer interface, bypassing the paper drafting process. Since 1970s, CAD programs have been in use throughout industry. So, within just 50 years or so, CNC machining has progressed to such an extent that it has become the standard for most furniture and joinery firms across the UK. The requirement for time and labour cost savings has driven the majority of businesses to truly democratise furniture and joinery production, providing goods for a fraction of the cost of the hand-made items our forbears would have known. In this supplement, you will find a multitude of superb examples of the kind of machinery and equipment which would have been the stuff of fantasy 50 years ago – I hope you enjoy the issue.

www.furnitureproduction.net ISSN 2396-9024 © Media 66 Ltd 2022

CNC Supp March 2022 JA.indd 3

John Legg, editor

28/02/2022 16:53

40

VWM Woodworking Machines Lodge Holme, Skipton Road, Trawden, Nr Colne, Lancashire, BB8 8RA

YEARS

01282 870077

info@vwm.co.uk VWM TECHNOS CNC MACHINING CENTRES – ALWAYS IN STOCK www.vwm.co.uk

CALL US FOR SPECIAL DEALS ON OUR EX DEMONSTRATION MACHINES

TECHNOS FLEX •

Various table sizes, including Euro sheets

•

Nesting, automatic loading and unloading

•

Standard 9Kw spindle

•

Automatic tool changers

•

Minimum of 250cm/hr vacuum pumps

•

PC controller with in-built graphics

•

Fully guarded and light beams on the working side, to comply with CE and Health and Safety

•

And many more options available

3 YEAR WARRANTY

(conditions a

pply)

CAD/CAM software included

TECHNOS ECO •

Less expensive (dip your toe in the water machine)

•

Various table sizes, including Euro sheets

•

Nesting, automatic loading and unloading

•

Standard 9Kw spindle

•

Automatic tool changers

•

Minimum of 250cm/hr vacuum pumps

•

Hand-held controller

•

Fully guarded and light beams on the working side

www.vwm.co.uk T 01282 870077 F 01282 870088 E info@vwm.co.uk VWM Ltd, Lodgeholme, Skipton Road, Trawden, Nr. Colne, Lancashire, BB8 8RA CNC Supp March 2022 JA.indd 4

28/02/2022 16:53

March Open House Throughout the month, come and view our extensive showroom and workshop. Talk with us to undertand how your next CNC machine can be built to your exacting spec, for your specific application requirements.

Call in and see us!

What’s on show? In addtion to the amazing Technos CNC machines, there is a wide selection of sliding table panel saws, and a choice of edgebanders, sanders, thicknessers and planers, routers, borers and dust extraction … and much, much more besides!

CNC Supp March 2022 JA.indd 5

28/02/2022 16:53

6 CNC machinery & equipment

Contents 8

Homag’s next generation of nesting solutions deliver greater efficiency, flexibility and performance

10 Maxicam Excitech offers complete solutions for nested based furniture 12 An iconic family – Holz-Her indroduces Epicon³, a new five-axis CNC series from Holz-Her 16 Consistent growth and a widening porfolio from experienced supplier VWM 18 Kimla replaces three CNC routers at GeeTee Signs

M H

20 New software for SCM CNC machining centres 24 The Tekcel EXR from Complete CNC Solutions

Un ho pr

26 Service and impressive engineering underpins AES’ growth in UK market

Fr of so fo

30 CNC in the joinery production arena – a brief vacuum guide 32 Think CNC – think Masterwood

CN W ax

34 New MultiCam CNC router reduces lead times

Cu re

36 Maka’s five-axis and multi-axis CNCs deliver

N Ne of an

increased productivity 38 Comec Group – CNC manufacturing solutions – not just CNC machines

A off

40 A speedy solution for Seamless 42 Improve productivity with Palamatic’s handling solutions

CNC Supp March 2022 JA.indd 6

H Te 28/02/2022 16:53

FP - Feb;

Market CNC technology. technology. Market leading leading CNC Highly efficient efficient production. Highly production. Understandablythe thedecision decision of of choosing choosing the the right at at firstfirst glance, Understandably right CNC CNC machining machiningcentre centremay mayseem seemdaunting daunting glance, however, HOMAG’s approach is designed to ensure each and every customer gets the right machine for theirtheir however, HOMAG’s approach is designed to ensure each and every customer gets the right machine for production requirements. production requirements. From the initial consultation, HOMAG works in partnership with each customer to make sure the specification From the initial consultation, HOMAG works in partnership with each customer to make sure the specification of their machine is exactly right for their needs. Together, ensuring that the combination of tools, machine and of their machine is exactly right for their needs. Together, ensuring that the combination of tools, machine and software match up to provide a solution not only for the current demands of the business, but also one that allows software match up to provide a solution not only for the current demands of the business, but also one that allows for future growth. for future growth. CNC Processing Centres CNC Centres WithProcessing the demand for faster production times and more bespoke manufacturing requirements increasing, HOMAG’s 3-, 4- & 5With the demand for production timesofand more including bespoke routing, manufacturing increasing, HOMAG’s 3-, 4- & 5axis CNC processingfaster centres offer a variety functions sawing,requirements drilling and edge banding. axis CNC processing centres offer a variety of functions including routing, sawing, drilling and edge banding. Customisable for any level of the market and tailored to suit any customer requirements, these processing centres can Customisable for any level of the market andrunning tailored to low suitand anyyetcustomer requirements, these with processing centres reduce the amount of equipment needed, keep costs maintain high quality production fast output rates. can reduce the amount of equipment needed, keep running costs low and yet maintain high quality production with fast output rates. Nesting Solutions Nesting Solutions is a very efficient art of converting raw boards into sized and drilled components. Specifically designed for the creation Nesting of carcass furniture, dividing refining raw of furniture nesting the operations of designed two machines, to creation one Nesting is a very efficient art ofand converting boards fronts, into sized andCNC’s drilled combine components. Specifically for the and are particularly useful for the efficient production of shaped parts that require cutting, drilling, grooving or routing. of carcass furniture, dividing and refining of furniture fronts, nesting CNC’s combine the operations of two machines, to one and are particularly useful for the efficient production of shaped parts that require cutting, drilling, grooving or routing. A number of options can also be added to automate the production process further, such as a robot to load raw panels and off load processed A number of optionsparts. can also be added to automate the production process further, such as a robot to load raw panels and

off load processed parts.

HOMAG UK Tel. 01332 856500 | Email. info-uk@homag.com | www.homag.com

HOMAG UK Tel. 01332 856500 | Email. info-uk@homag.com | www.homag.com FP - Feb; CNC Technology.indd 1

YOUR SOLUTION

YOUR SOLUTION 18/02/2022 13:27:33

CNC Supp March 2022 JA.indd 7

28/02/2022 16:53

FP - Feb; CNC Technology.indd 1

18/02/2022 13:27:33

8 CNC Machinery & Equipment

Homag’s next generation of nesting solutions deliver greater efficiency, flexibility and performance The demands on modern CNC nesting machines are extensive. On the one hand, they must be efficient to help save materials and resources – on the other, they need to provide increased performance and be highly versatile. It is precisely these demands that Homag has responded to with the design of its new generation of CNC nesting machines. Improving sustainability, flexibility and performance were all guiding factors in the development of the new models. Homag’s nesting machines are engineered to make easy work of machining and dividing panel-shaped materials for carcass furniture production and the dividing and finishing of furniture fronts. They also make the processing of stair stringers and door leaves effortless. With the release of the Centateq N-210 and N-510 CNC machining centres in November 2021, Homag has truly redefined nesting. Clever revisions and creative engineering, with a focus on waste reduction and sustainability, have significantly increased the value proposition of these machines. More flexible workflow configurations The new CNC machines not only handle the classic nesting tasks, but their 5-axis processing capabilities also provide added flexibility. The maximum total height in the

CNC Supp March 2022 JA.indd 8

Z-direction on these new machines has been extended, enabling the processing of material thicknesses up to 260mm. The new generation of machines is available in both standalone and automated configurations. They can be specified with updated matrix table arrangements to increase both performance and flexibility. In addition to the table structure, the vacuum, air cushion concept and material handling components have been rethought and further optimised. To improve non-productive times and set-up, the toolchanging system has also been updated. Automation adaptations for changing performance demands Performance requirements often change as Homag’s customers grow their businesses. To accommodate this, the base machines can be upgraded to meet shifting performance demands with 14 automation options. The performance-enhancing automation programs for the new series were developed for high-volume workflow demands. They include, for example: the addition of lifting tables for easier loading of material; automatic belt conveyors for pushing out finished parts; and complete integrations with saw and storage-system combinations or materialhandling robots.

Dynamic shuttle operation The pendulum mode, which allows the operator to continuously swap out parts while the machine runs at the other end of the bed, is extended using a separate vacuum supply and ventilation of the table sections. This highly efficient and seamless alternation between the left and right table sections is extended by ‘dynamic pendulum operation’. In a similar way to the Homag console table machines, the vacuum fields are assigned to the table sections and can be controlled individually. Homag has also created the ability to dynamically control the machines’ air cushion functions. This means that individual workpieces of different sizes and surface finishes can easily be processed in pendulum mode. Material yield utilisation and part identification drives production Sustainability is at the forefront of the utilisation of these machines. They were designed to generate as little material waste as possible. Thus, the nests are optimised via intelligent software solutions to deliver the best possible yield. To ensure parts are identified for secondary processing, such as edge banding, and for assembly after production, barcode labels can be applied to each item. These labels provide

28/02/2022 16:53

9

Homag’s Centateq N510 CNC processing centre

valuable information for transporting parts through the production process. For example, the type of material, edge banding information, part size, order number and even part-related graphics and company logos can be added.

table sections has been redesigned so that this transition point is always constant and suction cups can be positioned across these segments without restriction. This is a very beneficial feature for 5-axis machining.

Active vacuum solutions – new valve technology The new series of nesting machines provide many different table sizes to suit specific needs and requirements. Independent of the table size, three configurations of the automated vacuum field layouts are offered – Classic, Advanced and Premium. The Classic layout is the standard for Homag’s earlier nesting models. The field sizes are designed in such a way that the underlying vacuum zones can be applied to concentrate vacuum pressure to any number of common panel sizes. The Advanced layout creates a more balanced machine. The vacuum field sizes are engineered at both the front and back of the machine to allow for flexible fixturing of a wide range of panel sizes, as well as smaller preformatted parts. The Premium layout consists of many small, symmetrical vacuum fields that are controlled individually. With this variant, the operator can activate only one field, for even more flexibility and efficiency in the future. New valve technology has been installed in the table for this purpose. It generates the vacuum output required for nesting workpieces and precisely maintains that vacuum pressure throughout the nesting process so that no excess energy is required. The matrix table option consists of a raised island and groove pattern that has a consistent grid dimension to provide optimal vacuum flow. The transition between the individual matrix

More options for tool changes and drilling gears For short changeover times, the eight-place toolchanger riding along the X-axis of the machine can be selected as standard. Depending on the variety of machining and application requirements, different versions can also be selected to accommodate 14 or 22 tools. The previous benchmark for toolchanging times on the Homag nesting machines has been significantly reduced, and the chip-to-chip toolchange times have been improved. Within some of the automated configurations, the changing of the tools can be carried out in parallel with the loading of panels, saving additional time. For those requiring advanced toolchanging technology and speed, an X/Y ride-along toolchanger is available, which can be paired with a second toolchanger to provide a combination of speed and flexibility. The new nesting series provides a wide selection of drilling gears, with up to 21 different drilling gear units. Various combinations of vertical and horizontal drilling, as well as grooving, can be handled by these units without the machine requiring a tool change. Homag’s patented quickchange system for drill bit changes is also incorporated.

CNC Supp March 2022 JA.indd 9

5-axis processing on the Centateq N-510 brings added value For additional versatility, the proven Homag DRIVE5CS 5-axis head is now provided

with the Centateq N-510 series. As well as traditional nesting, this series can be used as a conventional CNC machining centre. Parts can be elevated, referenced, and machined on five sides. The new model provides further nesting operations in addition to the typical ones such as part sizing, shaping and vertical drilling. The extra functions include horizontal drilling for dowels, the creation of mitres with a 350mm saw blade, and the efficient machining of solid wood components such as stair stringers and door components. Greater sustainability and service life Commenting on the innovative design of the newly released models, Simon Brooks, Homag UK’s MD, says: “As well as configuring the new nesting machines to meet specific technical and functional applications, these nesting CNCs are engineered with a focus on conserving resources and achieving sustainability. “Times for toolchanging have been shortened, whilst the extraction of dust and the cleaning of the spoil board have been significantly improved. Both the new Centateq models are highly efficient, increasing yield and decreasing waste. “Engineering advances have minimised the use of electricity and compressed air, and maximised dust collection. “Where possible, machine movements and operating sequences have been combined and shared to increase the service life of machine components and bring additional value to Homag customers.” For a demonstration or more information on Homag’s machinery or software, contact Adele Hunt at Homag UK on 01332 856424. 01332 856500 www.homag.com

28/02/2022 16:53

10 CNC Machinery & Equipment

Maxicam Excitech offers complete solutions for nested based furniture Maxicam CNC has grown rapidly since its first introduction to the UK and Irish market in 2010 as the exclusive dealer for Maxicam/ Excitech CNC technology. Now in its 12th year and offering an everexpanding product range, Maxicam Excitech has cemented a reputation for quality products that offer maximum performance with industry-proven reliability. A changing market, driven by increased costs, has meant customers are increasingly looking at automation. Maxicam Excitech has the ability to supply complete CNC solutions as a batch size 1 smart factory, with fully connected modules including automatic material warehousing, automatic nesting, edgebanding, six-sided drilling and board storage. Along with these connected solutions, Maxicam Excitech also supplies each machine type as standalone or in a standalone production cell format. Production cells reduce manpower and human error, allowing automation of highdemand areas such as edgebanding with return conveyors or high-speed, six-sided drilling of flat panels with manual or robotic loading and unloading. As well as automated solutions for nested furniture, Maxicam Excitech also supplies highquality five-axis machining centres, with large work volumes from 1200 x 1200 x 500mm up to large-format five-axis with 6000 x 3600 x 2000mm working volume. 2021 showed further growth in five-axis sales, with many installations across the woodworking market with the popular E8 and E9 models. Both machining centres come in multiple table configurations, including single- or twin-

Smart factory nesting solution with robotic unloading

CNC Supp March 2022 JA.indd 10

Maxicam Excitech E4 Below: An M9 CNC router was installed at CNC Projects London

looking to process complex 3D shapes. Flagship nesting machine, the Maxicam Excitech E4, has recently arrived in the London showroom. This flatbed three-axis machine is perfect for kitchen and furnituremakers and comes with drill bank, high-powered 12kW HSD automatic toolchange spindle, and a state-of-the-art Italian OSAI controller. table models. The fixed-gantry moving table design increases rigidity at the cutting tip whilst allowing a larger working volume in full five axis, perfect for woodworking companies

To book a demonstration or discuss requirements in more detail, call the sales team on +44 845 689 0294 or contact sales@maxicamuk.com.

Installation of multiple six-sided drilling machines

28/02/2022 16:53

NestIng, EdgIng, DrIllIng Cutting edge technology from Maxicam Excitech As part of the Maxicam Excitech’s large catalogue of innovative products is a range of solutions developed to handle the complete manufacturing process from start to finish for the joinery industry. Developed to shorten lead times, improve finish quality and lower production costs. Maxicam Excitech’s complete range are accessible to all sizes of manufacturers, from entry level workshops to industrial production. EF583 EDGEBANDER 6 SIDED DRILLING WITH RETURN

E9 5 AXIS PROCESSING CENTRE

E4 NESTING BARCODE, LOADING UNLOADING

E6S DRILLING 6 SIDED DRILLING WITH RETURN

MAXICAM EXCITECH

INNOVATION IN WOODWORKING t: 0845 689 0294 - e: sales@maxicamuk.com - w: www.maxicamuk.com

CNC Supp March 2022 JA.indd 11

28/02/2022 16:53

12 CNC Machinery & Equipment

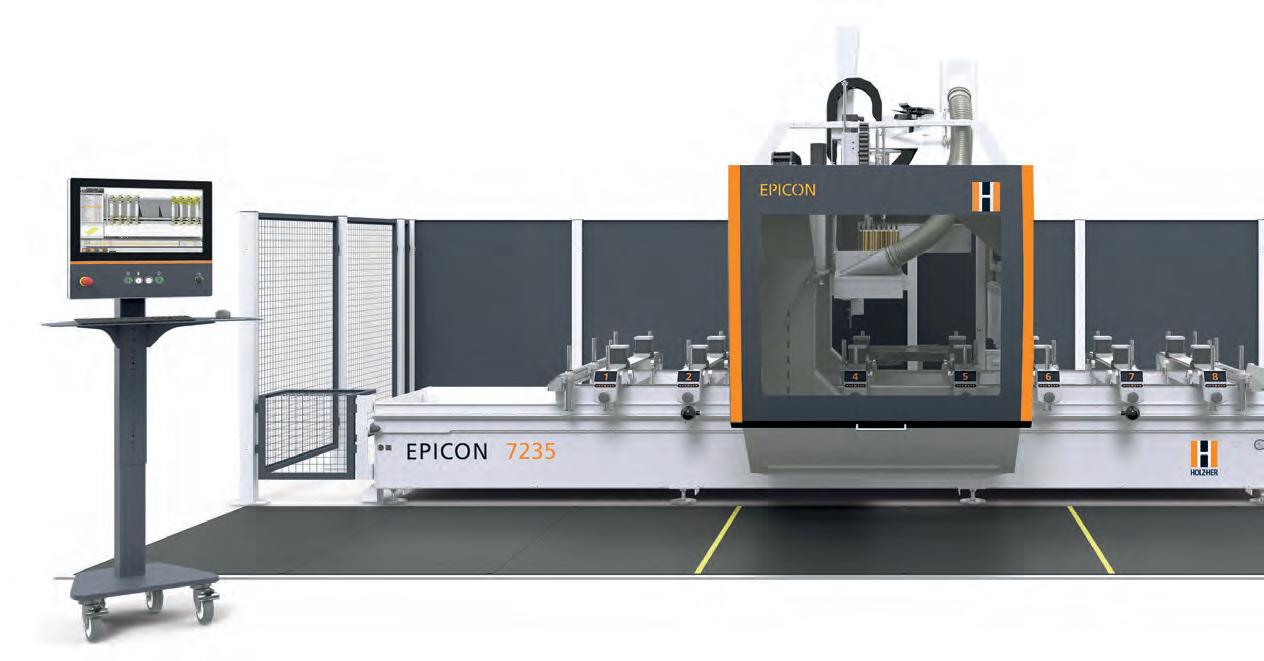

An iconic family Introducing the Epicon³, the new five-axis CNC series from Holz-Her …

Following the successful launch of the Epicon 7235 last year, the Epicon range has expanded to include two further highperformance, high-precision five-axis CNC machining centres and two new optional console tables. While varying in size, the new Epicon 7135 and Epicon 7335 – which have machining depths of 1500mm and 2100mm respectively – have been designed to offer exceptional machining flexibility and fast and effective milling on panels, solid wood and composite materials. In addition to machining lengths of 3680 to 7280mm in the X direction, all three Epicon models offer a true 300mm of clearance above the top of the suction cup for extreme machining heights, as well as a generous 565mm Z stroke – an ideal solution for those working with complex workpieces, stairs, windows and doors.

CNC Supp March 2022 JA.indd 12

Sitting on a tolerance-free, plasma-cut base, Holz-Her’s Epicon³ series has been built to withstand vigorous use. The family’s fiveaxis performance package is equipped with a powerful, liquid-cooled 13 kW direct-drive, five-axis head as standard, that can also be combined with Holz-Her’s new Bluetooth Chip Control for data capture and spindle monitoring. An optional 18kW Pro-Torque electro-spindle for high machining performance is also available, along with a variety of automatic toolchanging options and space for up to 97 tools, making it suitable for every configuration and application. An optional chip conveyor, which is available on the 7235 and 7335, and designed to be integrated into the machine base to save space, can also be specified, to ensure even large quantities of chips are reliably transported to the extraction manifold. Offering adaptable machining capabilities,

three drilling units are available. As standard, the Epicon comes equipped with 10 vertical and four horizontal drills, plus a grooving saw, with the option of two further horizontal drills in the X. An optional XL drilling head, designed for more drill-intensive projects such as adjustable shelving, offers 15 vertical and six horizontal drills. A further four horizontal drills and an extra grooving head can also be integrated into the machine. A larger XXL unit offers even quicker drilling operation and comes equipped with 25 vertical drills, six horizontal drills and a grooving saw. Four additional horizontal drills and an extra grooving head can also be specified. For maximum flexibility, the Epicon³ series can be equipped with various machine tables. A manual positioning table with two laser pointers for the exact positioning of vacuum cups and display of workpiece contours comes >>

28/02/2022 16:53

xxx 13

A high-powered 13kW direct-drive, five-axis head comes as standard. An optional 18kW Pro-Torque electrospindle is also available

The VISE LED table highlights the correct position of the console and suction cups using coloured LED strips for quick and easy set-up

Holz-Her’s new synchro-drive table moves all consoles and suction cups to their optimum position automatically within seconds, while taking into account the tool contours, passage and pockets

CNC Supp March 2022 JA.indd 13

28/02/2022 16:53

14 CNC xxx Machinery & Equipment

The Epicon³ series offers SafeDetect – a new safety monitoring system that automatically slows and stops the machine when required. It also continues machining where it left off once it is safe to do so

>> as standard. Alternatively, Holz-Her’s new synchro-drive table – which comes equipped with loading aids – moves all consoles and suction cups to their optimum position automatically within a matter of seconds, while taking into account the tool contours, passage and pockets. Suction cups for solid wood and special materials are also available for machining operations that require an extreme holding force. All Epicon models can also be equipped with a VISE LED table that highlights the correct position of the console and suction cups using coloured LED strips. Designed for error-free positioning and millimetre accuracy, the VISE LED table even displays the angle of rotation needed and, for frequently recurring parts, the operator can save the suction cup position together with the workpiece, to ensure fast and simple set-up every time. The Epicon’s software offering has also been designed to reduce set-up time and costly downtime. The CAMPUS Plus software package – which includes new pre-programmed macros for effective fiveaxis machining – features BetterSim cutting simulation as standard. This allows the cutting steps to be checked even during work preparation, ensuring collision-free operation

CNC Supp March 2022 JA.indd 14

between the machine’s tools, non-cutting area and workpiece. Additional simulations are also available of the suction cups and consoles, for even more control over the machining process. When using CAD software, the operator also has the option to create a tool path before machining. The professional DXF import of components from CAD software allows workpieces to be positioned on the work centre directly from the CAD software. The only prerequisite for this is a matching layer in the design software. This allows for even complex five-axis machining operations to be realised simply. The Epicon³’s intelligent features do not stop there. When it comes to safety, the Epicon offers new, state-of-the-art sensor technology with automatic distance control. The introduction of SafeDetect means that, while the operator can benefit from free access to the machine, the space above the machine table, as well as the area in front of the machine, is monitored for all-round protection. Laser lines projected on the floor in real time continuously show the operator the safe zone surrounding the machine head. If this is encroached, the machine will stop safely and securely. What is even more impressive is that unlike a bumper system that needs to run at a

very slow speed, SafeDetect runs at full speed until it gets within 1400mm of the operator. It then automatically reduces the 131m/min vector speed to traverse at 30m/min. When within 700mm of the operator, it will stop and, when ready, continue where it left off. A guard fence also prevents access to the machining centre’s operating area at the side and rear. Paul Nightingale, national sales manager for Holz-Her UK, says: “I’m excited to take this machine to market. The Epicon³ range has been expertly designed and engineered to offer a wealth of different machining solutions without compromise. Not only does it represent German build quality at its best, the level of innovation within the machine is second to none. “Featuring what I believe to be the best and most intuitive machine software on the market, you can’t fail to engage with these easy-to-use, powerful Epicon CNCs. Our market share grew significantly in 2021, and with the introduction of the new Epicon family, Holz-Her’s continued growth is assured.”

To book a virtual demonstration or talk to a Holz-Her CNC expert, call 01235 557600 or visit www.holzher.co.uk.

28/02/2022 16:53

xxx 15

The Epicon comes equipped with a hands-free, knee-activated vacuum for ergonomic loading and easy handling

CNC Supp March 2022 JA.indd 15

28/02/2022 16:53

16 CNC machinery & equipment

MARCH OPEN HOUSE Call for details 01282 870077 www.vwm.co.uk

Consistent growth and a widening porfolio from experienced supplier Based in Trawden, Lancashire, VWM is a well-known woodworking machinery supplier with a reputation for providing cost-effective and highly capable solutions for furniture and joinery manufacurers across the UK. The company is well placed to support its comprehensive product line-up within the UK market thanks to deep engineering experience. “Where most machinery suppliers need to have interaction from their supplier, we are the opposite, as we have manufactured CNC machinery in the past – so if or when a problem arises with a machine, support is given from VWM alone,” explains VWM’s sales director, Jason Varey. “We have four dedicated CNC technicians who are all very familiar with all our machines, and between them have a combined knowledge of over 60 years, so we have a vast wealth of knowledge and experience to cope

CNC Supp March 2022 JA.indd 16

with any application.” For many manufacturers, the last 24 months will have been a challenge, but in many ways it will also have been a period of opportunity, with increased desire for home improvements and rising property prices fuelling demand for furniture and joinery. “The time to invest is now,” says Jason. “Funding is readily available for machinery, and finance rates are low – and when you are investing in CNC, you are investing in the future. These machines will save time and money, as you have guaranteed production times, accuracy, and a quality of finish you will never get by machining manually. “Investing in a CNC for any business will immediately improve productivity, and this will benefit businesses both large and small. Noticeably,” says Jason, “we now have smaller companies with typically five employees or

less buying CNC machines, as they are the ones that want to be more competitive, and the only way to achieve this is by investing in CNC technology.” VWM has been with its partners for 20 years now, and the first CNC it installed back in 2002 is still going strong today. Jason says: “The relationship with our suppliers is long-standing and based on mutual respect – we call them our partners, as we are not agents. We have developed our range of Technos machines with them over time – we don’t only produce our standard range, but special-purpose machines as well. “Last year we installed two machines with a table size of 15 x 3m with a 25kW head, twin toolchanger and a 700mm diameter indexing saw unit – so we don’t just supply standard machines, we are about providing the correct and most appropriate solution for a customer’s

28/02/2022 16:53

17

“This year will see VWM add a new and exciting range of wallsaws, as well as further developing its impressive Technos range with a brand-new model being added”

individual requirements. All our machines are very user-friendly, and again, we have had a hand in developing them to make them more accessible to all markets. A typical installation would take part from Monday to Friday, and by the Friday, a customer will be running his product off the machine – that’s how easy we have made CNC for our users,” says Jason. “We only offer full installation and training carried out by VWM engineers, not some third party, as we believe if you buy a machine from us then we should be the ones training you and looking after you to get the best from your machine! We have two teams who carry out the installations, and any of these engineers will leave their contact number with the customer so they can be contacted any time of day, giving the customer great confidence in our company and product.” How has business been during the Covid era? “The last two years have been phenomenal! It’s the only way I can explain it,” says Jason. “In 2020 we supplied and installed over 23 machines, in 2021 we did even better with 26 machines, and even 2022 has started great – we have only installed three so far this year, but have six paid for and waiting to be installed, so 2022 looks like being another very good CNC-fuelled year at VWM. “We are a family-owned business with over 40 years of trading, offering some new and innovative products within our range – we also offer some very lean manufacturing processes which we have gained through our experience. “In terms of opprtunities,” Jason says, “linking up with VWM, customers can enjoy a great range of products – we have some very unique machines within our portfolio and can offer a wealth

of experience in all aspects of wood-based manufacturing. “This year will see VWM add a new and exciting range of wallsaws, as well as further developing its impressive Technos range, with a brand-new model being added later this year. We have an open house in March which will be showcasing the new Omaksan 1030 Holemaster CNC boring machine and a new bench-top CNC from Technos, along with a new exciting product from our Casolin range,” concludes Jason. 01282 870077 www.vwm.co.uk

CNC Supp March 2022 JA.indd 17

28/02/2022 16:53

18 CNC machinery & equipment

Kimla replaces three CNC routers at GeeTee Signs GeeTee Signs creates visually exciting signage for some big household names including Boots, Next, M&S and Five Guys. Operating since 1978, the Nottingham-based company set itself apart in the industry with its levels of customer service and creativity. Furniture & Joinery Production interviewed Darren Wombwell, accounts director, to find out why the company replaced three CNC machines with just one Kimla CNC from Daltons Wadkin. “We produce everything from internal to external signage, illuminated and nonilluminated large-format signage, from a varied range of different materials,” Darren explains. The mix of materials GeeTee Signs processes includes aluminium, acrylic, Foamex and MDF. GeeTee’s three antiquated CNC machines, dating as far back as 25 years, were noticeably lacking in speed and ability. “We went over to Daltons Wadkin’s showroom, and they demonstrated to us what the machine could do in real-world conditions – how we’d be using it back at our base.” Darren and his team took sample materials and their own CNC files for a thorough demonstration on the Kimla BPF CNC router. Daltons Wadkin was able to show them exactly how the CNC would operate for their projects, and the added opportunities it could offer combined with the iVision extraction system. Production time and quality of cut means GeeTee Signs can now produce its own prototypes, further expanding its product portfolio. Darren explains the key benefits: “The speed, the materials it can cut, the quality of the cut, and the ability to send our files straight through

our network as opposed to having to put it on memory sticks and physically take them down to the old CNC machines we had.” Replacing three CNC routers with just one machine has been a huge development for GeeTee Signs, but it also means the company relies on Daltons Wadkin for backup and support. “If the machine goes down then we can’t produce anything that’s CNC – and most of our work has got CNC cutting in it somewhere – every time we’ve needed Daltons Wadkin for support, we’ve got great service. Every time we’ve ordered something it’s come promptly, and the guys on the other end of the phone are fantastic,” enthuses Darren. The future for GeeTee Signs is looking bright. With an extensive client base which continues to grow, it is able to offer more than ever before. Darren concludes the interview by saying: “I would recommend Kimla that Daltons Wadkin supply. It’s a great machine, it does everything we need it to do, especially in this industry, and more, and the service we get from Daltons Wadkin is brilliant.” Daltons Wadkin is the sole distributor for Kimla CNC routers in the UK and Ireland. For more insight, watch the YouTube interview with GeeTee signs https://youtu.be/BlIHVODe698. For further information, expert advice or to arrange a demonstration, contact the company directly. 0115 697 1423 info@daltonswadkin.com www.daltonswadkin.com/brands/kimla/

CNC Supp March 2022 JA.indd 18

28/02/2022 16:54

CNC ROUTERS

|

WATERJETS

|

FIBER LASERS

Simply Powerful CNC Solutions

Take your CNC machining to the next level with Kimla. Processing speed, build quality, operating system and ease of use are unsurpassed. The multi-purpose capabilities of Kimla CNC machines make them suitable for almost any business working with wood, MDF, Plywood, metals, composites, cardboard, plastics, foam, rubber to name a few. >

3/ 4/ 5 axis machining

>

Z axis from 200 – 700mm

>

Customisable working areas

>

Unlimited software licences

>

Leading UK support

WWW.DALTONSWADKIN.COM Sole UK and Irelend Distributors CNC Supp March 2022 JA.indd 19

0115 986 5201 28/02/2022 18:35

20 CNC machinery & equipment

New software for SCM CNC machining centres There are many new features related to SCM software and digital services, with particular reference to CNC machining centres, and they are part of a truly integrated ecosystem – the “Digital Integrated Woodworking Process”. This is a collection of digital and integrated technologies – ie, software and digital services – that interact to define what products are to be manufactured, as well as how and when they are to be manufactured. Within this framework, SCM software and digital services can support customers at every stage of their process in creating furniture. The company’s innovations for 2022 concern all these stages. Preparation – Maestro CNC The first step is to prepare the information, data and programs for the production. Design, CAD-CAM software and simulators can dramatically shorten time and reduce errors from the office to the machines. According to Maestro’s software

CNC Supp March 2022 JA.indd 20

mission, SCM provides specific software to support customers in the design, optimisation and data generation for the machines in the shop floor. In the office, before the production, design and programming system Maestro CNC presents new updates and features. Maestro CNC is the CAD-CAM software for the design of the workpiece, and it ensures that all the machining operations are quickly and easily programmed, thanks to smart functions – app and macro libraries – built to program with just a mouse click. Another click, and CNC programs are automatically generated. Maestro CNC offers large graphic previews of the workpiece with the machine operations, the machine and of the tools, together with immediate functions which are able to deliver the most comfortable use and best result. Also in evidence is Maestro proview, the 3D simulator software that allows users the access to a three-dimensional model of their machine in their office, and to overview the operations that will be carried out during the production in

advance on their PC. Planning and optimisation Once all production data have been defined, it is time to optimise, schedule and plan the jobs and the production. Production scheduling and planning can be handled with dedicated software, the so-called MES (Manufacturing Execution System). On the other hand, optimisation has to do with incrementing processes such as cutting, drilling or routing. • Maestro easyFLOW is the newborn plug&play MES software powered by SCM that ensures well-executed production plans, complete visibility and optimisation of production and processes across the enterprise. Maestro easyFLOW is extremely simple to use and able to support even small businesses with programming and production flow management as well as 4.0 interconnection. • Maestro Power TMS is the new software of the new Accord 500/600 CNC machining centres for solid wood machining. It further optimises and >>

28/02/2022 16:54

21

CNC Supp March 2022 JA.indd 21

28/02/2022 16:54

22 CNC machinery & equipment

>> simplifies tool management. Thanks to this program that maximises the ability of the storage and optimises programming, there is no need for the operator to waste time and energy in looking for the most suitable tool – the software will identify and indicate the tool’s exact position in the storage, thus minimising machining times. Production – Maestro Active CNC Smart manufacturing employs different technologies to make machines more and more intelligent, smart and interactive. In this concept, a smart factory has machines provided with HMI software facilitating the user experience and interaction with the machine. Maestro active is the unified operator interface software for all SCM technologies, including CNC machining centres. A single operator can easily and safely manage multiple machines at a time, thanks to the consistency maintained between all interfaces – regardless of the machine, Maestro active maintains the same look and feel, thus ensuring the same approach to interaction. The new interface has been specifically designed and optimised for immediate use via touchscreen. Graphics have been redesigned for simple and comfortable navigation, with tablet-like icons on touchscreen controllers. Productivity has been improved thanks

CNC Supp March 2022 JA.indd 22

to integrated help and recovery procedures that reduce the possibility of error from the operator’s side. Monitoring and servicing – Maestro connect Once the production has been started, and for the whole lifecycle of the machine, the Maestro Connect Digital Service platform ensures machine status monitoring, maintenance optimisation, issue management, spare parts suggestions and smart learning, as well as augmented reality service support with Smartech. The Maestro Connect IoT platform is linked to the new My SCM portal. This is a new

service where customers and partners can open tickets for technical assistance and track the status of their requests. By tracking all support requests, SCM Service can manage the cases in an easier and more effective way, cutting down waiting times and providing faster solutions. The ticketing service is just one of the many services available on the portal, and all customers and partners which have connected machines can enter the IoT Maestro Connect platform through it. 0115 977 0044 scmuk@scmgroup.com www.scmgroup.com

28/02/2022 16:54

SCM

OUR WOODWORKING TECHNOLOGIES, YOUR VISION Simplify work and improve performance with the widest range of woodworking solutions. Flexible and modular machines and cells, integrated with state-of-the-art systems and automation, such as anthropomorphic robots, cobots and autonomous mobile shuttles. Smart technologies to increase efficiency and flexibility, reduce scraps and waste, optimize the quality of your products with the latest software and digital services. A human approach to help you achieve your vision, with a team of specialists always ready to support you, even from afar. SCM: your Smart and Human Factory.

SCM UK Tel. +44 (0)115 9770044 scmuk@scmgroup.com www.scmwood.com

CNC Supp March 2022 JA.indd 23 SCM_ADV_S&H_A4_EN.indd 1

is more

28/02/2022 16:54 16/02/21 09:21

24 CNC machinery & equipment

The Tekcel EXR from Complete CNC Solutions When companies look to invest in a new Flatbed CNC system for the first time, or maybe in addition to other machinery, there is sometimes a misconception that they all have the same function. Not all CNC flatbed routers are alike, however, and the Tekcel EXR 2m x 3m from Complete CNC Solutions is one such exceptional machine. It has been favoured by many prestigious companies over the years for its ease of use, abundance of innovative features and, above all, its ability to machine so many different types of materials, all from the one machine. Some CNC suppliers can only offer a ‘singletype material’ machine, which is dedicated to wood or metal, for example, but Tekcel continues to manufacture CNC machines that are highly versatile. These solutions also have attractive add-ons and options, allowing customers to diversify into new and lucrative opportunities. The EXR system has gained a growing reputation as one of the most well-respected, versatile and reliable three-axis CNC flatbed routers on the market today. With over 6000 Tekcel units installed worldwide and with 500+ installations in the UK and Ireland alone, these world-class CNC systems continue to deliver high-quality output and performance, while returning excellent profits in some of the most demanding and diverse market sectors. These include woodworking and joinery, decor and interior design, plastics and metal fabrication, packaging, shopfitting, architectural and cladding, 3D model making, sign, graphic and display, point of sale, exhibition, print finishing,

CNC Supp March 2022 JA.indd 24

and TV and film prop design. Tekcel EXR routers are fully capable of running at high speeds and dealing with the most demanding of material, including MDF, MFC, chipboard, HPL, OSB, plywoods, soft and hardwoods, industrial plastics, cast and extruded acrylics, polycarbonates, ABS, rigid PVC, HD foams and model boards, aluminium composite material, aluminium, brass, copper and thin stainless steel. Whatever customers’ requirements, the Tekcel EXR 2m x 3m system makes light work of it, processing popular sheets sizes of 8 x 4ft, 10 x 5ft, Jumbo Boards and metric 2 x 3m. With a standard gantry height of 150mm, this allows a maximum material cut thickness of 100mm. In order to cut these various types of materials efficiently, a high-quality performance machine and spindle is desired, which is why all of Complete CNC Solutions’ Tekcel routing systems are equipped as standard with vacuum table hold down, tool length indexing, hide away pop-up/ down 17-bay auto toolchangers, along with industry standard high-performance HSDmanufactured spindles. Tekcel routers only use the best recirculating ball screw and brushless, digitally encoded servo motors on all axes. These drive formats will give high cutting and positional accuracy at speed, with outstanding strength, longevity and very low maintenance when compared to standard or helical rack-and-pinion drives used on other lesser-performing systems. The EXR comes with a state-of-the-art,

podium-mounted 15in touchscreen controller interface as standard, conforming to health and safety regulations, as well as the added HSE requirement of safety light guarding, which interacts seamlessly with the ‘machine pause and restart’ feature. The EXR also boasts a ‘hole and pocket’ vacuum table top and high-powered auto on/off vacuum pumps for superior material zoned hold down, accurate Z-depth control via tool indexing for consistent routing, drilling, bevelling and grooving of all sheet materials. If required, Tekcel systems can also be fitted at any stage with various options and add-ons, including ‘cut-to-print’ camera registration systems for seamless registration cutting around rigid sheet printed or laminated graphics. Machines can also be fitted with the latest knife cutting technology in the form of the Tekcel Opticut, producing clean, sharp cuts on many types of flexible or semi-rigid materials using either oscillating or fixed blade processes. Complete CNC Solutions supplies awardwinning Vectric CAD/CAM software with every Tekcel EXR system, and offers a secondto-none on-site training programme to get users cutting right away. With its fully stocked range of dedicated solid carbide tooling and accessories, service, support and spare parts departments, the company has every requirement covered. 01934 742186 info@completecnc.co.uk www.completecnc.co.uk

28/02/2022 16:54

If you’re dealing with the most demanding of materials like woods, plastics, metals & composites you’ll need a CNC to step up to the challenge. Look no further than the Tekcel EXR system.

Tekcel EXR

The Tekcel EXR is powerful and precise thanks to its servo driven precision ball screw technology on all axis. Its unbelievably productive too thanks to its unrivalled list of features for maximum output with minimum effort.

Solidly engineered to endure the biggest workloads.

When your workload is heavy and your deadlines are tight, your CNC needs to work hard for you. The Tekcel EXR does just that… It’s more than a System…It’s a Solution.

APPLICATIONS

Woodworking, Cabinet Making & Joinery Décor, Screening & Interior Design Plastics & Metal fabrication Shopfitting & Exhibition Architectural & Cladding 3D Model Making Packaging & Point of Sale Sign, Graphic, Display & Print Finishing TV & Film Prop Design.

15” Touch Screen Operator Interface

Accurate Ballscrew Drives on all Axis

TOOLING FROM COMPLETE CNC SOLUTIONS

Auto Tool / Blade Length Sensing

17 Bay Auto Tool Change System

HSE Required Safety Guarding System

We have carefully selected and commissioned the manufacture of high quality tools made from solid micrograin carbide. Our tooling delivers the optimum combination of performance and service life compared to others. We also offer you technical help and application advice you may need to get the job done.

Telephone: 01934 742 186 E-mail: info@completecnc.co.uk www.completecnc.co.uk CNC Supp March 2022 JA.indd 25

28/02/2022 16:54

26 CNC machinery & equipment

Service and impressive engineering underpins AES’ growth in UK market In a competitive marketplace dominated by big brands and multi-product conglomerates, and where sales are driven and service often forgotten, AES has introduced its products steadily into the market and is fast becoming one of the big names in the world of industrial CNC manufacturers. AES’ secret is more akin to common sense – which is to always remain customer focused. From design to production, the AES products offer heavy-duty solutions using top-quality, branded products during the construction of the machines. Where many manufacturers are taking away the value to compete, AES is

giving uncompromised value in the products’ strength, quality of build and customer support. Such is the vast nature of the range, AES will definitely have a machine to cater for the most demanding of user. The flat-bed nesting machines start with the popular Flexa Pro, which is available in various bed sizes, all complete with auto toolchanger. The newly launched Extreme Ultra is available as a standalone machine or as a through-feed line machine, and offers a number of options to allow a machine to be custom built. The flagship of the flat table nesting machines is the AES Raptor Ultra, designed for continual use and again available as a standalone machine or a through-feed line machine. There are also the Vega series of pod-andrail-style machines for both modular furniture and joinery companies. Particularly popular is the Vega Ultra, fitted with the dedicated double-sided horizontal router head commonly used for processing fire doors. The Vega 5X is a true five-axis machine, which is complete with Alphacam Ultimate software to allow simultaneous machining in all five axes. The machine also has endless movement in the A and C axes, so does not need to keep unwinding once turned >> through 360°.

CNC Supp March 2022 JA.indd 26

28/02/2022 16:54

J&C2022

T: 01704 893109 E: info@ukwoodworkingmachinery.co.uk WOODWORKING MACHINERY SPECIALISTS

www.ukwoodworkingmachinery.co.uk

AES Go 1300M ATC

CNC Drilling machine with 6 position tool changer.

In stock and ready to demonstrate.

AES SUPER NOVA

AES RAPTOR ULTRA NESTING LINE

AES SIRIUS CNC DRILLING MACHINE

AES ALPHA PS04 BEAMSAW

AES EXTREME ULTRA

AES ALPHA PS05 BEAMSAW

AES FLEXA PRO

AES VEGA ULTRA

AES VEGA 5X

J&C O’Meara Ltd, Unit 4A Dakota Business Park, Dakota Way, Burscough L40 8AF

J&C2022_JA1.indd 1 JA.indd 27 CNC Supp March 2022

14/02/2022 28/02/2022 16:5410:39

28 CNC machinery & equipment

>>

All AES CNC machines are driven by industryleading and machine-neutral Alphacam CAD/ CAM software. All AES machines are also complete with a LIFETIME manufacturer remote technical support. Also in the AES range are the Sirius and Go! 1300 CNC drilling machines. The Sirius was first introduced in 2017 and has since become very popular amongst cabinetmakers, as the machine also has the option of a router head, making it a mini-CNC as well as a fast and accurate drilling machine. Finally, there is the Alpha series of heavy-duty beamsaws. These are serious heavyweight machines, giving fast processing times and available with cutting heights to allow a stack of six 18mm boards to be cut. Carl O’Meara says: “Since the introduction of the AES machines into the UK, we have seen demand for the products increase year on year. We have installed and commissioned a vast array of machines to customers who have adopted CNC technology for the first time, to the high-volume producers needing automated solutions, and to the bespoke manufacturer looking to produce in a fast and efficient manner. The AES Group are a pleasure to work with, and we would rate their machines amongst the best we have seen.” 01704 893109 www.ukwoodworkingmachinery.co.uk

CNC Supp March 2022 JA.indd 28

The J&C O’Meara HQ in Burscough – home to the best AES showroom in the UK

28/02/2022 16:54

Cabineo Time-saving furniture connector without edge drilling and with very high clamping force

No edge drilling High clamping force

Advantages and features

One-piece and pre-installed

– Process optimisation due to clean surface machining; No horizontal boring required! – Reduced height of 10 mm for panel thicknesses of 12 mm or more – One-piece connector without dowel; no need for preassembly of screws or dowels in the side sections – Flat-pack delivery with preassembled connectors – Possibility of disassembly for transportation or if the fixed shelves need to be adjusted – Possibility of retrofitting shelves or vertical partitions in a cabinet that has already been installed

Lamello AG | Joining technology | Hauptstrasse 149 | CH-4416 Bubendorf Shaye Chatfield | Area Sales Manager International | M +44 789 1025 646 | s.chatfield@lamello.com | www.lamello.co.uk

CNC Supp March 2022 JA.indd 29

28/02/2022 16:54

30 CNC machinery & equipment

CNC in the joinery production arena – a brief vacuum guide Vacuum is a key component when using CNC equipment, as precise machining can only take place though precise clamping. Having the correct vacuum applied to a vacuum bed or jig is therefore essential – and if it is not working correctly, throughput can suffer or stop altogether. Experts in the field such as Vacuum Pumps UK (www.vacuumpumpsuk.com) can help. Its team will consider what clamping force is required, while also considering substrate porosity and air leakage, among a variety of factors – not least on larger vacuum beds. Often clamping force issues can be diagnosed as a deficiency of vacuum, when the same symptom can manifest itself due to inadequate flow. After this assessment, the company would then utilise one of several pump types to suit the conditions and application. Dry running rotary vane vacuum pumps have become the foundation of most woodworking CNC routing machines. New technologies are starting to appear such as claw units, which are an interesting option, as reduced running costs can be attractive. Centralised air systems are also a consideration for the progressive company, providing energy efficiency along with reduced shopfloor noise and heat. Once a vacuum unit or system is in place, the key to reducing downtime is preventative

PA.155 claw unit

maintenance or scheduled servicing. Ultimately, vacuum cannot be ignored – it will always be ever-present in the production environment of many industries, and is a key component within CNC production processes.

“So, why not look at your machinery vacuum requirements? There are probably savings to be made, in terms of cost of supply, energy efficiencies and less down time!” www.vacuumpumpsuk.com

VTLF2.250 rotary vane

“Dry running rotary vane vacuum pumps have become the foundation of most woodworking CNC routing machines. New technologies are starting to appear such as claw units, which are an interesting option, as reduced running costs can be attractive”

CNC Supp March 2022 JA.indd 30

Mas Mas Mas

28/02/2022 16:54

Untitled-4 Untitled-4 Untitled-4

Lorem Ipsum Lorem Ipsum Lorem Ipsum

Masterwood GB GB Ltd Ltd Units Units 18-23, 18-23, Hollybush Hollybush Business Business Centre, Centre, Shipley Shipley Bridge Bridge Lane, Lane, Horley, Horley, Surrey Surrey RH6 RH6 9TL 9TL Masterwood Masterwood GB Ltd Units 18-23, Hollybush Business Centre, Shipley Bridge Lane, Horley, Surrey RH6 9TL

T: +44(0) +44(0) 1293 1293 402700 402700 E: E: office@masterwoodgb.co.uk office@masterwoodgb.co.uk www.masterwood.com www.masterwood.com T: T: +44(0) 1293 402700 E: office@masterwoodgb.co.uk www.masterwood.com Untitled-4 1 Untitled-4 1 Untitled-4 CNC Supp1March 2022 JA.indd 31

07/02/2022 11:51 07/02/2022 11:51 07/02/2022 16:54 11:51 28/02/2022

32 CNC machinery & equipment

Think CNC – think Masterwood Masterwood GB will be hosting its first open house event at its Gatwick showroom, from 18th-21st May 2022. After the cancellation of the W Exhibition in Birmingham, the open house will provide an exceptional opportunity to view the latest machinery and software packages that Masterwood can offer. Over the four days, visitors will be able to see a whole range of demonstrations in the showroom, featuring the debuts of the Masterwood beam saw and high-speed drilling machine, the Project TF600. Together with the new additions in the Masterwood range, there will be a five-axis pod and rail, four-axis nesting flat bed, and a compact CNC drilling/routering machine. Masterwood also offers a fully compatible software package, all of which will be on show during the open house. There will be demonstrations on: • Solid core and timber-frame doorsets • Windows/traditional box windows • Cabinets and face framing • Stairs • Nesting panels and shapes • Full five-axis/3D Machines on show will include: • Project 385L – five-axis pod and rail • MW 15.38 – nesting flatbed • Speedy II – drilling + routering • MW320S – beam saw • TF600S – high-speed drilling + routering TF600S In addition to the original Project TF100/ Speedy, Masterwood now offers a wider range of drilling machines for the panel market. The Master Drill series, which is available in three versions, has the advantage of working above and below simultaneously, thanks to the

Smart table, for continuous workpiece support and patented airbed tables. The machines can have vertical and horizontal drilling heads above and below the bed, plus the option for vertical routers. These combinations, and the twin gripper feed system, ensure fast and accurate machining. Programs are easy to generate in the Masterwood CAD/CAM software, and can be used with barcodes and scanners for fast, automated production. Options of infeed and outfeed tables, to help speed-up production time, are available among the three models.

Beam saw Having already been sold around Europe since its release, the first beam saw by Masterwood will be arriving in the UK this year. The machines are available in three levels to suit all requirements of production and workshop. These are heavy-build machines, using leading manufacturers’ parts to ensure high and long-lasting accuracy. To register interest in attending the open house, or for more information, contact Masterwood GB. office@masterwoodgb.co.uk +44 1293 402700

HEA TO

• S • T

Untitl

CNC Supp March 2022 JA.indd 32

28/02/2022 16:54

e In Hous ery Machin Show st 29th-31 March

MD

TOP

series

HEAVY DUTY CNC WORKING CENTRES CONFIGURED TO SUIT CUSTOMERS INDIVIDUAL REQUIREMENTS • SHAPING • MILLING • DRILLING • CUTTING • • TWIN WORKING FIELDS • AUTOMATIC LOADING •

Untitled-1 1

CNC Supp March 2022 JA.indd 33

04/02/2022 09:22

28/02/2022 16:54

34 CNC machinery & equipment

New CNC router reduces lead times and improves quality BikeStow creates bike racks for homes, offices and vans. These feature a unique wooden design which folds away when not in use, and secures the wheel rather than the frame, reducing potential damage to the bike. Initially BikeStow was outsourcing all of its machining work to another company, but with the business growing, and a move from its home garage to a proper dedicated unit, the company decided the time was right to buy its own CNC machine. “Outsourcing the machining was the biggest cost to the business, so we wanted to buy our own CNC machine and bring this in-house,” explains George Laight, BikeStow. “This also meant we were able to have better control over the quality of what was being produced, and the timescales.” Why did you choose a MultiCam? “When we were looking there were a few factors,” says George. “We needed something immediately, a machine at the right price and the support package involved. As it was our first machine, we knew we would need some hand-holding.” The team at BikeStow chose a refurbished MultiCam 3000 Series Router after going to see the machine in action at CNC World. They were impressed with the exceptional finish and the support package. What benefits have you seen since your MultiCam machine was installed? BikeStow has been up and running with the machine for over a year now. “We had planned to bring designs in-house one at a time over a six-month period, but it was so easy to get started with our new MultiCam that we had brought all four designs in-house within two months,” says George.

This has allowed for tighter quality control over BikeStow’s designs, as well as reducing the time between the customer’s order and the product being delivered. What advice would you give to someone looking to buy a new CNC machine? “Make sure that the company you are buying from can offer the support you need,” suggests George. “The best thing about buying our machine from CNC World has been the people and the support they’ve given. John, our engineer, has always been super quick with answers and solutions, which has meant little downtime for our machine and business.” Where do you buy your tools from? “We buy most of our tools and accessories from Cutter Shop,” says George. “Initially, we received some tools when we bought our machine, as Cutter Shop are part of CNC World, but we have continued to buy from them for several reasons. “Pete, part of the customer services team, has been so helpful, especially when we were starting out with our MultiCam in offering advice on the best tools – he knows a lot! The selection of tools is good, it’s great to have a choice of the cheaper own-brand tools as well as the more expensive branded tools, and the free next-day delivery helps too!” For more information, call one of CNC World’s machine experts on 01953 668899 or visit www.cnc-world.co.uk. To speak to the cutting tools customer services team call 01329 246070 or view the product range at www.cutter-shop.com.

CNC Supp March 2022 JA.indd 34

28/02/2022 16:54

Vac ad.in

www.vacuumpumpsuk.com

Providing vacuum is key to your production - We are the Vacuum Experts We are a leading independent supplier to the UK vacuum industry, with a huge inventory of pumps and spare parts. Our prices are always competitive, and our years of technical expertise and dedicated service mean we offer unrivalled support – all with ISO9001:2015 Quality Assurance

NEW AND REFURBISHED PUMPS • PARTS • SERVICE & REPAIRS • HIRE PUMPS • TECHNICAL SUPPORT

VTLF2.250 Rotary vane

FILTERS

PA.155 Claw Unit

SERVICE AND REPAIRS

SPARE PARTS FOR MOST MAKES from www.vacair-superstore.com

www.vacair-superstore.com

Vacuum Pumps UK and our sister company Vac-Air Superstore have been leaders in the supply of vacuum pumps, service and spare parts for many years. Contact us now to see how much you could save!

0113 2088 407 Vac ad.indd 1 CNC Supp March 2022 JA.indd 35

VACUUM PUMPS UK

www.vacuumpumpsuk.com

sales@vacuumpumpsuk.com 03/02/2022 10:50 28/02/2022 16:54

36 CNC machinery & equipment

Maka’s five- and multi-axis CNCs deliver increased productivity Exciting innovations from the five-axis specialist, Maka Systems, now provide greater flexibility and productivity. Enhanced machine features reduce downtime and reduce cycle times, while Maka’s new rapid toolchangers and quick-setting fixtures reduce non-productive setting times. Machines remain robust, and reliability is maximised. Higher-power drive motors, particularly on rotary drives, enable larger and heavier tools to be employed, and reduce cycle times. Further innovations also enable Maka users to cut development times for design and programming too. Enhanced productivity CNC-positioned fixtures and clamps, and material handling systems available on the renowned PM-Modular and other models – including the twin-table MM7t and moving beam BC range – reduce setting times for complex joinery components. This simplifies the setting process, and provides a reliable and secure clamping system to ensure machining is precise, and results in the components being produced having the highest-quality surface finish. Post-machining secondary operations, such as sanding and finishing, are reduced, boosting productivity further. Offline innovations now available with Maka’s Siemens-ONE include modern networked

CNC Supp March 2022 JA.indd 36

production and control technology, providing open access to all CAD/CAM tools. This enables users to incorporate clamping devices and handling systems into the setting. ‘Simulation’ not only illustrates, but provides a real-time virtual testing facility to enable users to prove-out new products, manufacturing strategies and specific CNC programmes, even before the machine is available. Maka’s ‘Digital-Twin’ is a complete virtual Maka, not just a 3D model. This new option enables real programs to be run and viewed

(on a PC) as they would on the actual machine. Running the Twin reduces setting times, collision risks and running costs. This has never been possible before, and eliminates the need for third-party simulation software and the associated time and costs involved. Reliability is even more important, as the machine must be as per the perfect virtual model. The stability and high precision provided by Maka are essential, allowing the actual processes to be undertaken exactly as the Digital Twin. Security and protection, specifically network protection, is also addressed with integrated IT. Modibase network protection simultaneously protects the shopfloor-based Maka from possible threats from the network. Modibase provides a secure gateway for remote maintenance and, for the first time, offers the option of automatically backing up all data, programmes and machine parameters. Energy efficiency advances on new machines includes new drive systems, delivering higher productivity and better energy efficiency. Maka has increased its personnel and created new structures to provide even higherquality support and service for the end-user. For further details, contact Maka at info@ makauk.com, telephone 01952 607700, or call Iain Young directly on 07836 295434. www.maka.com

28/02/2022 16:54

37

MAKA PM-Modular 5-Axis CNC routers The

NEW

benchmark!

5-Axis CNC machine centres

for stairs, windows, bespoke joinery and timber engineering!

MAKA Machinery UK Ltd

Tel: 01952-607700

C5 Horton Park IE., Hortonwood 7, TELFORD, Shropshire TF1 7GX

CNC Supp March 2022 JA.indd 37

Web: www.MAKA.com Email: info@makauk.com

28/02/2022 16:54

38 CNC machinery & equipment

Comec Group – CNC manufacturing solutions, not just CNC machines The Comec Group, based in the Udine region of Northern Italy, has over 50 years of experience in the design and manufacture of high-quality woodworking machinery. In the early days the company employed just five people and concentrated on building special mechanical drilling machines, shapers and clamps, that were mainly sold to local chair manufacturers. Fast-forward to 2022, and Comec now employs 100 people, with worldwide exports accounting for over 90% of its production. In addition, production of its range of specialist CNC machining centres has significantly jumped in recent years, by +50%. The three model lines consist of the Frontal Series, MD Series and Driver. Unlike many woodworking machinery manufacturers, Comec has the philosophy of designing machines to suit customers’ individual production requirements, rather than having a one-size-fits-all approach. As a result, it has been able to implement some unique features into its machines, such as automatic hopper feed loading systems, piece return systems and multiple CNC machining heads. The Frontal CN series of machines consists of a vertical automatic hopper feed loader, with a step-by-step through-feed system which delivers the component to different machining stations, which can include saw units, horizontal/vertical drilling, routing and end/ face milling. This particular model of machine

CNC Supp March 2022 JA.indd 38

can be used for producing general furniture components, rails, tenoning/slotting window and door parts, and also for machining drawer fronts. The MD series of CNC machining centres are available in three different versions, MD Classic, MD Top and MD Jamb. All of these can be configured with a number of different machining heads, including vertical and/or horizontal milling heads, and NC drilling groups which can be specified to work on all the faces/ends of a furniture rail. In addition, a C-axis can be added, meaning it is possible

to cut components to size with either straight or angled cutting, plus making a dowelled or mortised joint at the same time. The MD is ideal for machining a wide range of solid wood, plastic or composite components that need drilling, shaping and cutting for finished items such as garden seating, garden structures, benches and chairs from reclaimed plastics, bed frames and much more. The tandem loading option also makes it an extremely productive machine. The five-axis Driver series is the latest machine in the Comec range, and is capable of machining complex-shaped components, particularly solid wood furniture parts. The machine can be configured with two crossed router heads (giving four useable spindles), tandem loading operation, and an optional vertical automatic vertical loading system for volume production. Clamping can either be pneumatic or vacuum, depending on the type and shape of the part to be produced. To find out more about the Comec CNC range, contact JJ Smith directly. Alternatively, attend the forthcoming In House Machinery show on the 29th, 30th and 31st March, where an MD TOP XL CNC will be on demonstration – simply register to visit via the JJ Smith website. 0151 548 9000 sales@jjsmith.co.uk www.jjsmith.co.uk

28/02/2022 16:54

39

www.ferwoodgroup.com

Tel: 0113 2866689

The World’s Biggest Brands Reconditioned to the Highest Standards

Find out how some of the largest companies in the UK and Ireland have already realised the quality and value, without compromise, of machines supplied by Ferwood.

PROFESSIONAL CNC TOOLING T: 01580 890500 E: sales@wealdentool.com

NEXT DAY FROM STOCK

A long-established company with an increasing presence in the CNC tooling market, Wealden Tool Company has at least 95% of its range in stock at any time, meaning that orders can be dispatched the same day, offering customers a rapid source of supply. The wide range features traditional solid spiral cutters including larger sizes and many innovative cutters hard to find elsewhere. Some cutters feature replaceable tips, offering the benefits of constant geometry and easy maintenance. All cutters plus toolholders, collet nuts and collets available online or call Wealden for technical advice or to discuss a particular requirement.

www.wealdentool.com 2 Clinton Business Centre, Lodge Road, Staplehurst, Kent, TN12 0QF

Wealden_JA.indd 1

CNC Supp March 2022 JA.indd 39

PROFESSIONAL CNC TOOLING NEXT DAY FROM STOCK

14/02/2020 09:57

28/02/2022 16:54

40 CNC machinery & equipment

A speedy solution for Seamless When faced with a broken-down CNC machine, the options very quickly narrow down. You can’t afford to halt your production line, so do you take a gamble with your quality and outsource your work, or do you revert to manufacturing by hand while you wait for a spare part to arrive? Either way, it’s going to cost you. But, for established fabricator, Seamless Solid Surfaces, the first port of call was reconditioned machinery specialist, Ferwood UK – and within four days of its breakdown, a Ferwood Functional CNC was sourced, financed and installed … “We’d just found out that our old CNC machine had an electrical fault and the spare part was going to take up to three weeks to arrive,” begins Gary Wade, MD of Seamless Solid Surfaces. “We couldn’t afford to be without a CNC for three weeks. It would have costs us up to £2000 for every week the machine was out of action.” The Wakefield-based business needed to find a solution, and quickly. “The engineer that came out to try and repair the CNC suggested that Ferwood might be able to find me a replacement machine quickly. They talked me though a suitable machine on the Tuesday, I saw the CNC in action on the Wednesday and it was delivered and fully installed on the Friday. All I had to do was make room for the machine in the workshop and supply some wires. It was unbelievable. I’d never experienced anything like it.” The CNC needed to work effectively on acrylic and solid surfaces such as Corian, Staron, TriStone and Hi-MACS, and work seamlessly with an existing template laser. It would also need to work quickly and effectively on commercial batch orders and a growing number of domestic worktops each week. The four-axis, 12-tool SCM Record 100 AL ticked all the boxes, and after being function-tested by a Ferwood specialist, it was ready to be installed. Once installed, an engineer spent three days

CNC Supp March 2022 JA.indd 40