1.586.777.6250

1.586.777.6250

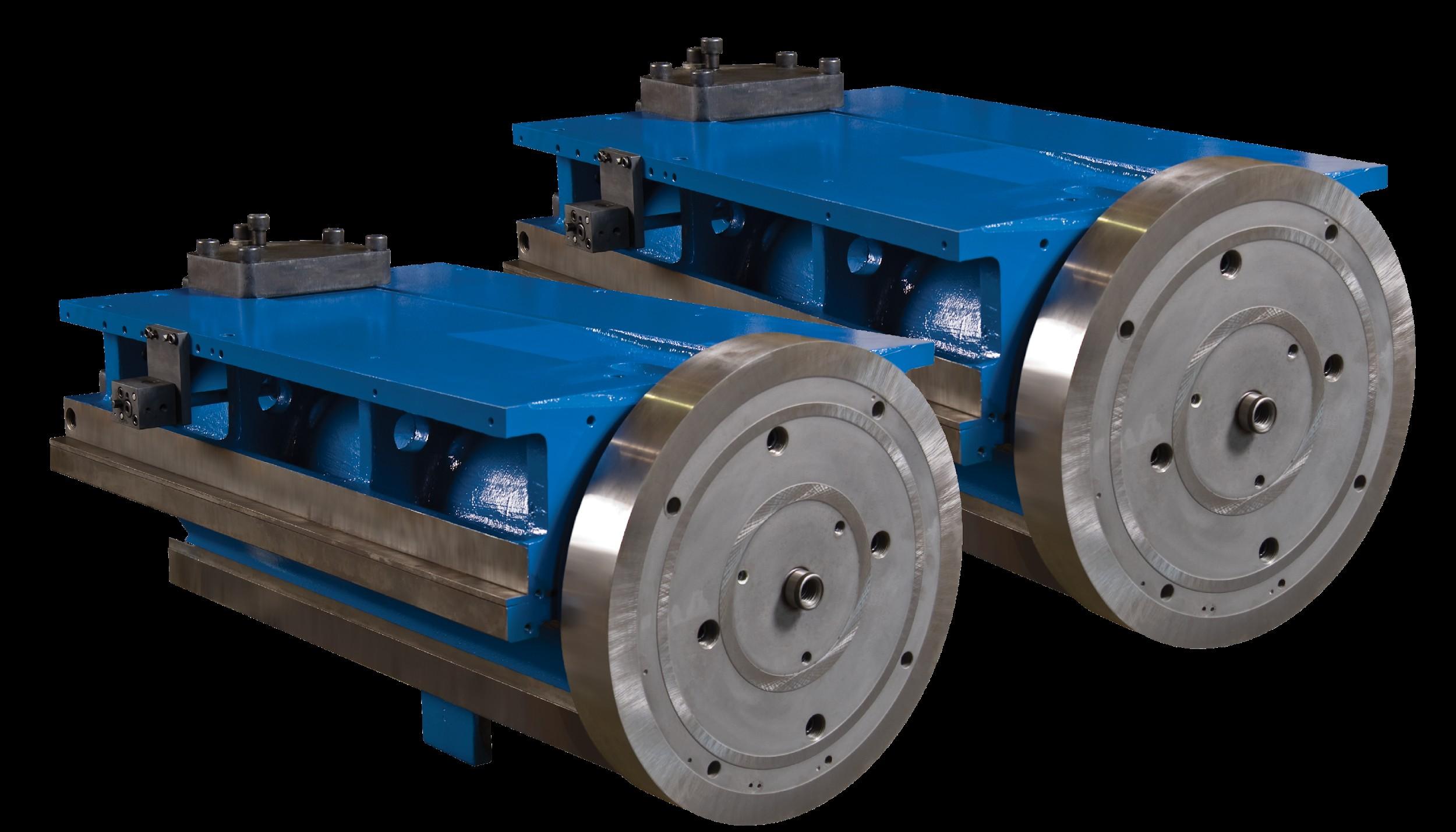

• Grinder performance is crucial in industries like automotive, aerospace, and manufacturing.

• Spare parts can be expensive, impacting budgets and productivity.

• Learn smart strategies to save costs while maintaining

• Essential for machine longevity and smooth operation.

• Worn-out parts lead to downtime, inefficiency, and costly repairs.

• Investing in quality components ensures durability and precision.

• Use High-Quality Aftermarket Parts – Reliable, cost-effective alternatives to OEM components.

• Bulk Purchasing – Reduces unit costs and ensures consistent supply.

• Work with a Trusted Supplier – Expertise and competitive pricing improve efficiency.

• Opt for Refurbished Parts – Restored to industry standards, ensuring reliability.

• Preventive Maintenance – Regular servicing extends component life and prevents breakdowns.

• Consolidate Purchases – Partnering with one supplier helps streamline logistics and secure discounts.

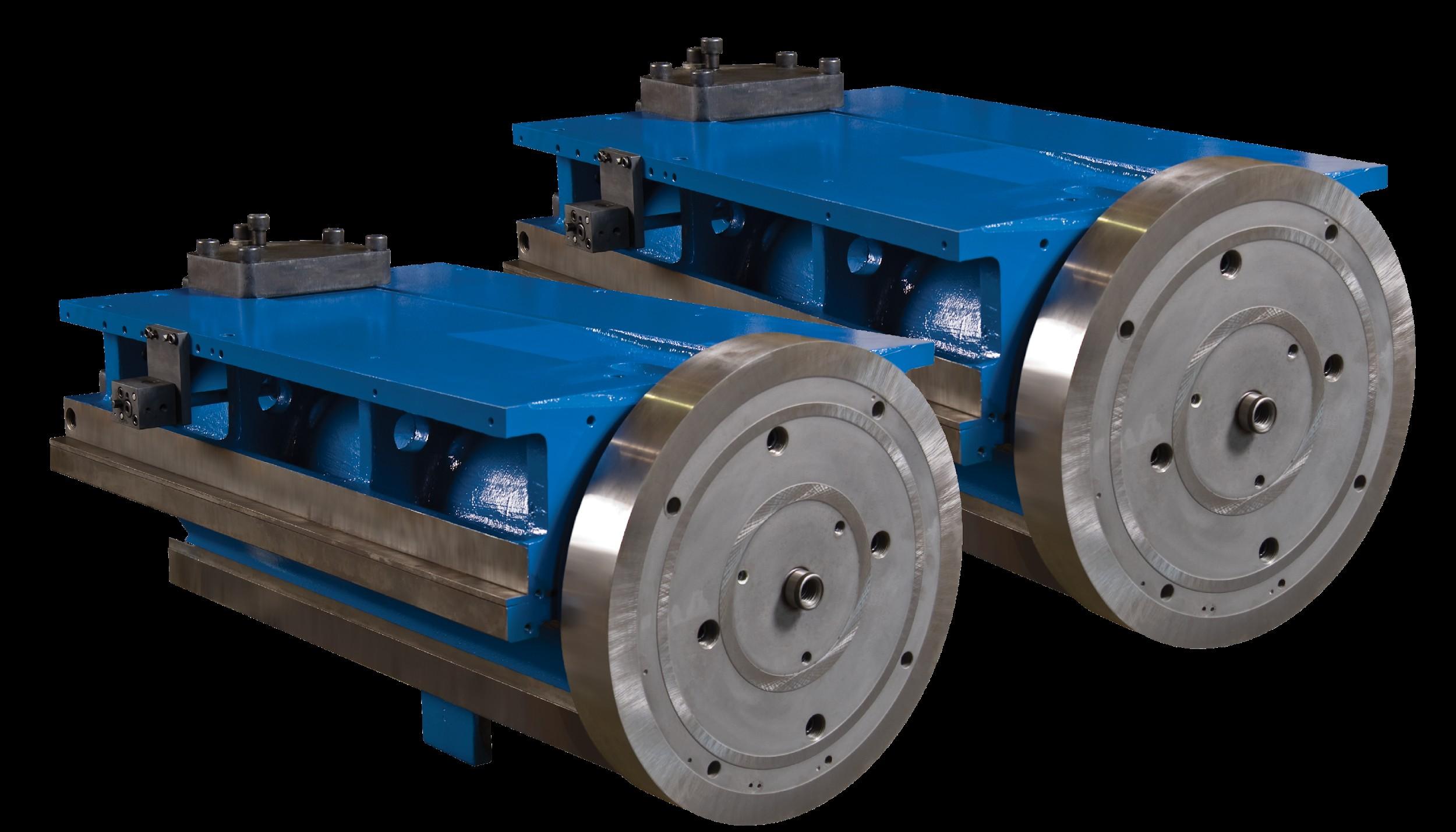

Grinding Spindles : Opt for remanufacturing instead of full replacements.

Bearings & Bushings: Choose highquality aftermarket alternatives.

Grinding Wheel Dressers: Buy in bulk or select long-lasting options.

Hydraulic Components: Consider refurbished parts for cost efficiency.

• Extensive Inventory: Aftermarket and refurbished parts for various grinder models.

• Competitive Pricing: Cost-effective solutions without compromising quality.

• Expert Guidance: Industry professionals help select the best parts for your needs.

• Custom Engineering: Tailored solutions to meet unique operational requirements.

• Extended Machine Lifespan: Reduce wear and boost operational longevity.

• Improved Productivity: Minimize downtime and maintain efficiency.

• Significant Cost Savings: Invest in durable, long-lasting parts to cut expenses.