SEE THE WINNERS OF THE 2025 CONSTRUCTION EXCELLENCE AWARDS!

SEE THE WINNERS OF THE 2025 CONSTRUCTION EXCELLENCE AWARDS!

How landmark projects, industry innovation, and union craftsmanship are shaping the future of construction

Excellence is the cornerstone of everything we do in construction. It’s reflected not only in the buildings we deliver, but also in the collaboration, innovation, and craftsmanship that bring those projects to life. Every day, GBCA members set the bar higher—driving quality, safety, and professionalism across our industry.

Each year, the GBCA Construction Excellence Awards give us the opportunity to pause and recognize the incredible people and projects that embody those values. The honorees featured in this issue of Construction Today represent far more than outstanding construction achievements. They reflect our industry’s relentless commitment to progress—demonstrating how thoughtful planning, teamwork, and technical expertise can transform the built environment and the communities we serve.

Behind every award-winning project is a story of collaboration. Contractors, design teams, labor partners, and clients come together to overcome challenges and deliver results that stand as testaments to what’s possible when we work with purpose and precision. That spirit of partnership is what defines the GBCA community and continues to strengthen our region’s construction landscape.

As we celebrate this year’s finalists and winners, we also celebrate the collective strength of our industry. Every success story featured here is a reminder that excellence doesn’t happen by chance—it’s built through dedication, partnership, and a shared commitment to doing things the right way. Together, we are building a legacy of integrity, innovation, and craftsmanship that defines the Greater Philadelphia construction community.

It is an honor to serve as Chairman of the GBCA Board of Directors and to witness firsthand the passion and perseverance that drive our members. The future of our industry is bright because of your commitment to excellence, and I look forward to seeing what we will continue to achieve together.

Congratulations to all of this year’s Construction Excellence Award winners, and thank you to every GBCA member for the work you do to make our industry stronger every day.

Maura C. Hesdon, LEED AP Chairman of the Board, GBCA General Manager, Shoemaker Construction Co.

Dear Members,

The construction industry is no stranger to change — but every so often, a shift comes along that truly reshapes demand. That shift is happening now, driven by the explosive growth of artificial intelligence.

At GBCA’s recent Fall Membership Dinner the panel discussion featured experts from the Data Center Coalition, Governor Shapiro’s office, PSE&G, and a leading engineering firm, the message was clear: AI is fueling a massive surge in demand for both power generation and data centers — and the timelines are aggressive.

Let’s be honest — we’re not here to debate the ethics of AI. We’re here to build what powers it. Data centers are massive, energy-hungry facilities that require complex infrastructure and must be delivered quickly. That means opportunity for contractors who are ready to meet the moment.

Pennsylvania has a real chance to lead. While Virginia remains the data center capital of the country, the number two spot is wide open — and we have the workforce, natural resources, and technical capacity to compete. Make no mistake: without strategic intervention, energy costs will rise. And here’s the catch — because of our interconnected regional energy grid, we’ll feel the effects of increased demand whether the facilities are built here or not. The question is whether we also get the jobs, revenue, and economic activity — or just the strain without the benefit.

Of course, opportunity doesn’t come without risk. As with any boom, there’s the potential for a bubble. If financing dries up or demand cools, contractors — especially those entering late in the game — could be left holding the bag. These projects demand precision, deep resources, and a readiness to perform under pressure. Additionally, data centers — and the billions of dollars in economic activity that flow through them — are opening previously unfathomable amounts of liability. Contractors must be vigilant in protecting themselves, ensuring that if a center they helped build falters, they aren’t exposed to claims tied to lost digital or economic output.

Here’s what it all means: once again, contractors are being asked to deliver what society needs — when and how it needs it. And as always, it will fall on contractors and the associations fortunate enough to represent them to think not just about how to build, but how to build responsibly and protect their interests.

GBCA is here to help. Let us know how we can support you as you explore this space — and we’ll keep advocating for more opportunities, better protections, and a smarter path forward for our members.

Sincerely,

Ben Connors President & CEO

PUBLISHER/EDITOR

Nicole Catrambone

ADVERTISING/SALES

Nicole Catrambone

CONTRIBUTING WRITERS

William Graves / Ryan Klinicki / Daphene Koch, PHD / Ryan Monkman / Erin O'Brien-Hofmann / Matt Pentz / Angelina Perryman / Jessica Matase Slattery

DESIGN Punch Garage

ACCOUNTING Jeremy Pease

EDITORIAL OFFICE

General Building Contractors Association, Inc.

36 South 18th Street Philadelphia, PA 19103

P: 215-568-7015 F: 215-568-3115

© Copyright CONSTRUCTION TODAY® registered in U.S. Patent and Trademark Office Copyright ©2004 by the General Building Contractors Association. All rights reserved. Submissions for editorial review should be sent to the editorial office address. Neither the publisher nor any individual associated with any branch of production, nor the advertisers will be liable for misprints or misinformation contained herein.

2025 GBCA BACKYARD SOCIAL

2025 GENERAL CONTRACTORS RECEPTION

2025 FALL MEMBERSHIP DINNER

CASUAL CONVERSATIONS WITH ARMOR MASONRY, DAVIS CONSTRUCTION, AND TEMPLE UNIVERSITY

RYAN KLINICKI, HEALTHCARE GROUP LEADER | HSC BUILDERS AND CONSTRUCTION MANAGERS

A major transformation took place in the heart of Philadelphia. Two whole floors—14,631 square feet—of a behavioral health unit in a century old hospital building were set to be reimagined into a cutting-edge medical space. The challenge was significant and demanded not only technical precision and expertise, but also a forward-thinking vision that seamlessly blended innovation with compassionate care

At the core of this transformation was the integration of advanced technology. The Intelligent Room Integration System (IRIS) became the brain of each patient room, automating functions to enhance both comfort and efficiency. Medical staff could operate more effectively in a streamlined environment while patients would have control over lighting, climate, and entertainment with the touch of a button. To improve the patient experience, a 75-inch monitor was installed in each patient room, allowing patients or families to simultaneously see information about their medical care and stream television, play video games, or listen to music. A sophisticated lighting, temperature, and shade controls system via pillow speaker was also introduced, allowing patients to adjust these systems for their comfort.

Beyond the sleek, high-tech upgrades, critical infrastructure improvements ensured the unit would function at the

highest standard. A new air handler unit was installed to maintain pristine air quality, an essential factor in preventing infection and ensuring patient safety. Additionally, three automatic transfer switches (ATS) were strategically placed, guaranteeing uninterrupted power in case of an electrical failure.

What had once been a space in need of revitalization was now a beacon of modern healthcare and technology. Rich Carroll, Associate Principal at E4H, captured the spirit of the collaboration best: “E4H Architecture and HSC Builders collaborated seamlessly on the conversion of the fourth and fifth floors of the Wright Saunders building from behavioral health to medical-surgical beds. E4H provided innovative design solutions to ensure the space met the needs of Penn Medicine, while HSC Builders efficiently managed construction. The team effort resulted in a state-of-the-art facility that enhances patient care and supports healthcare providers with a functional and modern care environment.”

The project’s success was more than just a testament to cutting-edge technology and construction expertise—it was a demonstration of adaptability, teamwork, and an unwavering commitment to exceptional patient care. Today, the two transformed floors stand as a testament to what’s possible when vision meets execution, offering patients and healthcare professionals a space that is not only functional now, but truly future-ready.

ANGELINA PERRYMAN, VICE PRESIDENT | PERRYMAN CONSTRUCTION

JESSICA MATASE SLATTERY, REGIONAL DIRECTOR, MARKETING | LF DRISCOLL

The Cobbs Creek Foundation is leading a visionary restoration of the historic Cobbs Creek Golf Course in West Philadelphia—an ambitious effort to reimagine the 340-acre site as a dynamic center for recreation, education, and community connection. Once complete, the revitalized campus will include a fully restored 18-hole course, a redesigned nine-hole Karakung Course, short course, a youth education center, a two-story driving range complete with a restaurant, pro shop, event space, and club house.

LF Driscoll, in partnership with Perryman Construction, has played a pivotal role in the preconstruction and construction of the Smilow Woodland TGR Learning Lab and Lincoln Financial Center. The team spent nearly a year in detailed planning and value management sessions to align the project’s ambitious vision with budget goals without compromising quality, innovation, or efficiency.

At the outset of the projects, extensive sitework and utility installations were required to prepare the former golf course for redevelopment. This included designing and installing a campus-wide underground electrical system strategically routed to avoid interference with the golf course greens. The LF Driscoll/Perryman team worked closely with PECO, civil engineers, and the design team to precisely map manholes, transformer vaults, and modules. Using drone technology, the team surveyed elevation changes and existing utilities to ensure accuracy and efficiency during installation.

Beyond the buildings themselves, the construction team collaborated with the Cobbs Creek Foundation to address additional infrastructure needs, including a private-cost sewer installation and the integration of a new force main.

The 30,000-square-foot Smilow Woodland TGR Learning Lab was the first structure to take shape and quickly became a bright spot in the community, offering free, year-round STEAM programming for students in grades 1 through 12. From site preparation to final finishes, the construction team worked with precision to deliver a space that supports hands-

on learning in robotics, engineering, digital media, and more.

The construction of the Lincoln Financial Center, a twostory golf entertainment and practice center, introduced another layer of complexity with two distinct design teams—, one focused on the core and shell, and the other on the interior fit-out. Regular design charrettes and pull- planning sessions were instrumental in aligning efforts, resolving design conflicts, and maintaining project momentum. The Lincoln Financial Center’s expansive construction scope included excavation and grading, foundations, stormwater management, paving, sidewalks, landscaping, and site utilities. A defining feature of the work was the installation of a prefabricated pedestrian tunnel beneath Lansdowne Avenue, enhancing connectivity across the campus and linking key elements of the revitalized site.

The success of Cobbs Creek’s revitalization is rooted in collaboration between LF Driscoll/Perryman, the Cobbs Creek Foundation, and a network of skilled union trades and subcontractors. Together, we worked to ensure the project not only delivered technical excellence but also reflected community priorities and values.

Union labor played an essential role, with craftspeople delivering high-quality work across all trades, from concrete and steel to mechanical systems and interior finishes. The project also partnered with workforce development programs such as Everybody Builds and Women in NonTraditional Careers, providing Philadelphia residents with training opportunities and pathways to rewarding careers in construction.

The restoration of Cobbs Creek Golf Course stands as a testament to what’s possible when thoughtful design, strategic planning, and inclusive building practices converge. More than just a revitalization, it’s a reimagining of a historic landmark—one that will serve generations of golfers, students, and community members for years to come.

GBCA’s 7th Annual Project Safety Awards honor the member companies and project teams who set the standard for safe, responsible union construction. This year’s record achievements—20 companies and 57 zeroincident projects—demonstrate the unwavering commitment our industry brings to every jobsite.

C.H. Schwertner & Son, Inc.

Clemens Construction Company, Inc.

Hispanic Ventures, Inc.

Rycon Construction, Inc.

| Armor Masonry Restoration Inc.

Project: Bellevue Exterior Restoration – Broad Street Façade

| C. Erickson & Sons, Inc.

Project: Glenmede Headquarters, Floors 38, 39 & 40

| Clemens Construction Company, Inc.

Project: Broad + Noble

| D.M. Sabia & Co., Inc.

Project: Princeton Graduate Hotel

| D’Andrea Bros. Concrete Co., Inc.

Projects:

• Elmwood Park Zoo Welcome Center and Animal Hospital

• University of Pennsylvania OTT Center – Indoor Training Facility

• J & J Horsham Campus – Commons Building

| DWD Mechanical Contractor, Inc.

Projects:

• 1701 Market

• 3201 Cuthbert

| Geppert Bros., Inc. Projects:

• Penn Presbyterian Hospital Parking Garage

• Princeton University Art Museum-Marquand Phase 2

• Borgata Asian High Limit Gaming Renovation

• PHA Fairhill Apartments Development Project

• Nemours Children’s Hospital 3CE Moseley Outpatient

• Haverford Township Free Library Renovation & Additions

| Gilbane Building Company

• Projects:

• CHOP King of Prussia Parking Garage Expansion

• Make the World Better Foundation Vare Recreation Center Rebuild

| Guthrie Glass & Metal Inc. Projects:

• Joseph’s University – Maguire Athletic Center

• University of Pennsylvania SAS Vagelos Lab for Energy Science & Technology

| Hispanic Ventures, Inc.

Project: University of Pennsylvania SEAS Science Building

| Hunter Roberts Construction Group, LLC Projects:

• Princeton University – Meadows Campus Graduate Student Housing

• 1620 Sansom Street – Josephine

| Independence Steel and Erectors Projects:

• UPHS 3600 Civic Center Boulevard Overbuild 2.0

• Princeton University Health Service Project

• City of Passaic Municipal Parking Deck

| INTECH Construction, LLC Projects:

• Holy Family Home Phase 2 & 3

• EwingCole Office Renovation

• Germantown Friends School

• Fox Rothschild

• Center City District

| LF Driscoll Projects:

• HOSUP – Dulles 4 Endoscopy

• TGR Education Center

• CHOP Main 4 – OR Boom and Blanket Replacement

• Procedure Room

• Interventional Neurosurgery CT

• Farm Journal Infusion Pharmacy

| Madison Concrete Construction Projects:

• Calder Gardens

• Private Office Building

• Cobbs Creek Education Center

• Penn Terminals Container Stacking Foundations

| Mara Restoration, Inc. Projects:

• William H. Gray III 30th Street Station Redevelopment Project-Expansion Joint Replacement

• Longwood Gardens Longwood Reimagined Cascade Gardens

• Rehabilitation of East Schuylkill River Wall

| P. Agnes, Inc. Projects:

• Maguire Athletic Center

• Meadows Neighborhood Site Development

• Meadows Neighborhood Parking Garage

• Cape Regional Radiology & ED Renovation

• YouthBuild Philadelphia Charter School

• Franklin Field Team Operations

• Jane and David Ott Center for Track & Field

| Premier Building Restoration, Inc.

Project: Independence Blue Cross

| Rycon Construction, Inc.

Project: Chick-Fil-A Cedarbrook Plaza

| Turner Construction Company Projects:

• University of Pennsylvania SEAS, 10th Floor Fit-Out

• Penn Medicine, One uCity Square 2nd Floor Fit-Out

• Agilent Technologies – Project Odin

• Integral Molecular, One uCity Square

• Netrality Data Center – 10th Floor Expansion

New Research by GBCA highlights how its members are setting the standard for jobsite safety through significantly lower incident rates compared to non-members.

The General Building Contractors Association (GBCA) conducted a comprehensive analysis of over 2 million OSHA 300 logs from 2016 onward and found that its members experience significantly lower incident rates than non-members across various categories. An incident is defined as any health or safety event that results in unwanted consequences, including bodily injury or property damage.

By maintaining lower rates of these incidents, GBCA members demonstrate a strong commitment to jobsite safety, supported by union-backed training, dedicated safety resources, and proven best practices. These efforts contribute to making the construction industry safer for everyone.

GBCA member contractors set the standard for safety, with fewer injuries, illnesses, and job transfers than nonmembers. Their commitment protects workers and strengthens the industry—benefiting businesses and the broader economy.

GBCA continues to enhance workplace safety through strong leadership, comprehensive training, and a commitment to best practices, resulting in a steady reduction of injuries and incidents from 2016 through 2023.

GBCA members consistently reduced incident rates across all categories.

The rate of cases involving job transfers or restrictions among GBCA members decreased by 62.61% during the study period.

Rates of less common but significant incidents, categorized as “Other Cases,” dropped by 54.72%

The rate of jobsite injuries among GBCA members improved by 61.59%.

ERIN O'BRIEN-HOFMANN | INTERNATIONAL UNION OF PAINTERS AND ALLIED TRADES DISTRICT COUNCIL 21

I’ve been a commercial painter since 2007. I joined because I was a waitress and a barmaid, just trying to get by while I waited to figure out whatever I’d do next. While working, I couldn’t help but notice that so many of my customers were union members. I didn’t totally understand what they did, but I knew they always had money, and I wanted that for myself too. I became a commercial painter with the International Union of Painters and Allied Trades District Council 21, and I haven’t looked back. I was a painter for 12 years, then became a commercial paint instructor, then commercial paint coordinator. I kept moving up the ranks to Assistant Director of Training, then Director of Training, and now I’m the Director of Member Engagement.

Being a woman in construction hasn’t always been easy. It’s a male-dominated industry, obviously, and I’ve had to work harder than a lot of the guys around me to prove that I belong. But I’m a damn good painter, and I always say that this job may not be for every woman, but it’s for any woman. Women have the exact same ability that men do to paint, finish drywall, set glass, and work in any other trade – a lot of us just need encouragement to get started and feel like we belong. This is why I run our Women in Nontraditional Careers (WINC) pre-apprenticeship program, designed to show young women all of the different career opportunities available to them in the union construction industry. You can’t be what you can’t see, which is why it’s so important for women who are already in the trades to mentor those who are coming in behind us.

That’s why Women’s Committees and conferences like Tradeswomen Build Nations are so important. Tradeswomen Build Nations is the largest conference of tradeswomen in North America, bringing thousands of construction worker women together to strategize, brainstorm, and inspire one another. This year’s conference was in Chicago, and our District Council was proud to send about 20 members, some for the very first time. We heard amazing speakers, marched in a Banner Parade, and had a caucus with IUPAT members from District Councils across the U.S. and North America. Many IUPAT members spoke about how joining our union changed their lives and gave them confidence and the ability to be truly independent. That’s exactly how I feel. I have a great husband, and I love him, but I don’t need him – I make my own money and now that I have my trade, I always will.

I’m one of the founders of the DC 21 Women’s Committee, and our work is all about bringing more women into our union and keeping those who join. Some people think our biggest issue is recruitment, and obviously that’s part of it, but it’s also retention – making sure our women members feel comfortable, safe, and that we have policies that support them. One big issue for our female members is obviously related to family planning. Construction is hard, physical work, and because the vast majority of our members are men, we were slow to prioritize benefits related to pregnancy and birth. But I am proud to share that our International Union is taking big steps to change that. A few years ago, we adopted a policy that provides IUPAT members who have given birth 6-8 weeks of paid leave, and up to 6 months of paid leave for those unable to work during pregnancy.

The IUPAT is committed to having our union reflect our broader society. That’s why, at our 2024 General Convention, we voted to pass a resolution to increase our percentage of female members to 20% of our overall membership. I’m really proud to be part of a union that prioritizes members like me. But this progress, and that of our Women’s Committee and Tradeswomen Build Nations, is at risk under the current administration’s policies.

Recent federal policies have made it harder to advance the kinds of programs that make the building trades more inclusive and forwardthinking. But instead of letting that slow us down, it reminds us why our work and our unity matter more than ever.

Programs like our Women’s Committee, Tradeswomen Build Nations, WINC, and other initiatives that open doors for women and underrepresented workers are not just good for individuals; they strengthen our entire industry.

When opportunities are taken away or delayed, it’s not just projects that stall. It’s paychecks, local businesses, and community progress. Every home, bridge, and power plant we build supports families and neighborhoods. That’s why we must continue to invest in people, in all people who want to put their skills to work building our future.

Our industry’s success depends on the diversity, drive, and expertise of its workforce. We know that talent doesn’t come from one background or one story. It comes from every corner of our community. So, let’s keep recruiting, mentoring, and championing new workers. Let’s make sure every person who wants to build has a pathway to do it, and a union that’s ready to welcome them.

What all construction workers want, men and women both, is steady work, fair pay, and respect so we can take care of ourselves and our families. That’s why I’m so proud to be a member of District Council 21, and I hope more women follow in my footsteps. I’ll be there to support them the whole way through.

MARYBETH GERDELMANN, COORDINATOR, EDUCATION & WORKFORCE DEVELOPMENT | GBCA

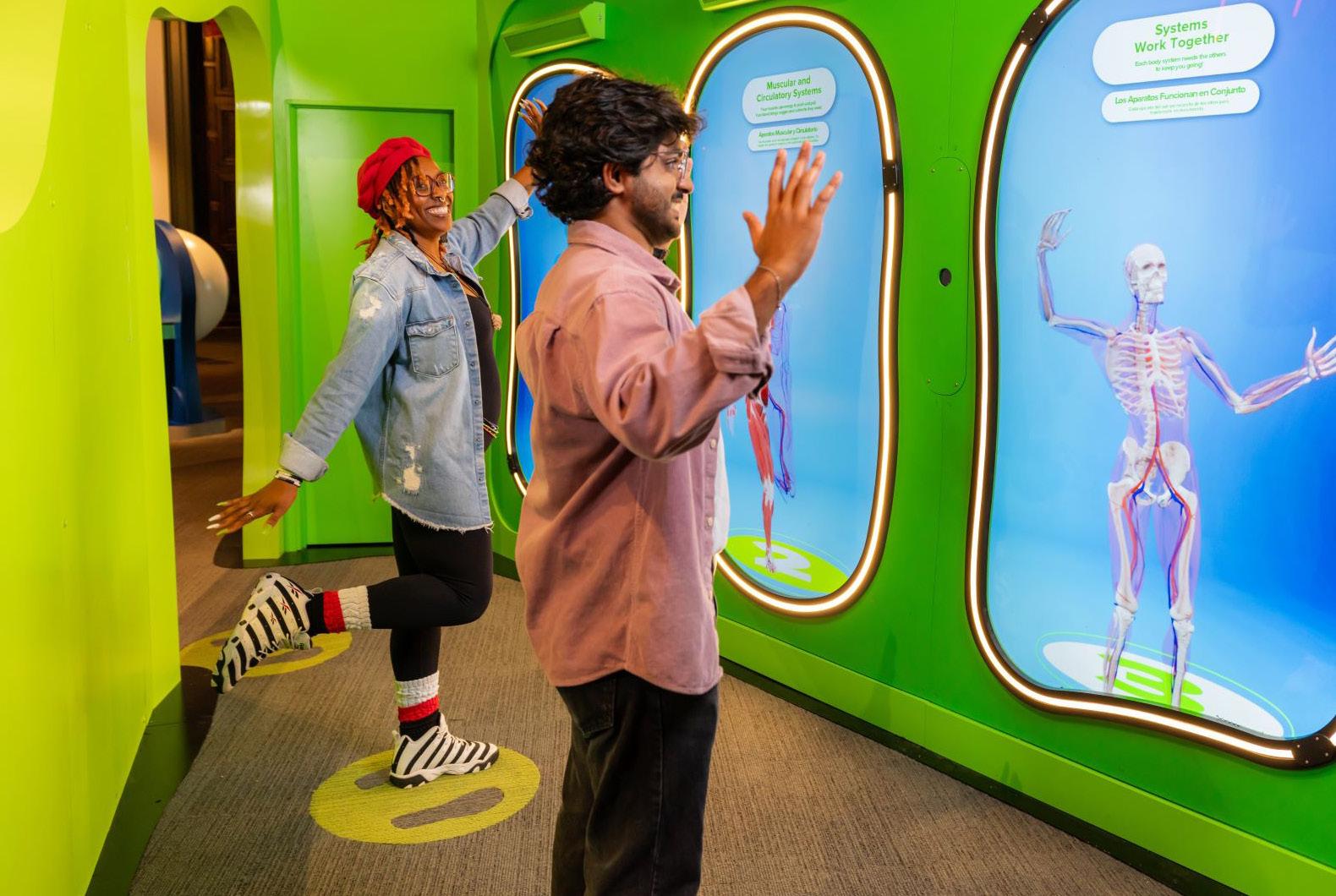

On October 8 and 9, hundreds of students from across the Philadelphia region gathered for GBCA’s Build My Future 2025—an interactive, two-day showcase designed to introduce young people to rewarding careers in the construction industry.

The success of this year’s event builds on the foundation established in 2024, when Angelina Perryman, Vice President of Perryman Construction, helped bring the Build My Future initiative to life in Philadelphia. Working in collaboration with The Bellwether District, The School District of Philadelphia, and Clayco, Perryman played a key role in organizing the city’s first-ever Build My Future event. Her leadership and vision helped create an engaging experience that introduced hundreds of students to hands-on career pathways in construction—setting the stage for GBCA to expand and elevate the program in 2025.

Held at the Sheet Metal Workers Local 19 Training Facility, the event brought together contractors, training centers, and labor organizations to demonstrate the many opportunities available in the union construction industry. For two full days, students explored what it takes to build Philadelphia—one skill, one trade, and one career pathway at a time.

Before students entered the main exhibit area, GBCA Safety Consultant Jim McGugan welcomed each group and set the tone for the day. He introduced the event’s purpose, outlined the range of opportunities within the trades, and

emphasized the importance of safety as the foundation of every successful construction career.

McGugan explained that safety isn’t just a rule—it’s a culture that defines how the industry operates and how workers protect themselves and one another on every jobsite. His remarks helped students understand that the skills they were about to see in action were built on a shared commitment to safety, professionalism, and teamwork.

With that context, students entered the event energized and ready to explore the world of construction from a new perspective.

Throughout the event, students rotated through a variety of interactive exhibits, each designed to highlight technical skills, teamwork, and safety practices that define professional construction work. Guided by experienced tradespeople and industry professionals, they learned about the tools and equipment used on jobsites and the importance of safety in every aspect of the work.

Demonstrations included CPR training, electrical hazard simulations, scaffolding and fall protection displays, and even a smoldering demonstration that reflected the skills of plumbers and HVAC technicians and offered a close-up look at how the trades handle heat, smoke, and fire safety. Each exhibit emphasized practical skills and gave students the chance to ask questions, test equipment, and experience a bit of what life on a jobsite feels like.

The goal was to make the experience as hands-on and engaging as possible—allowing students to do more than observe. They could interact directly with professionals who shared what their typical day looks like, what training or apprenticeship is required, and how those skills translate into lifelong, well-paying careers.

Beyond the demonstrations, exhibitors shared information about apprenticeships, training programs, and career pathways in the building trades. Many students left with a clearer understanding of how to get started in construction and the wide range of options available to them—from carpentry and electrical work to safety management, project coordination, and more.

For teachers, counselors, and chaperones accompanying their students, Build My Future offered an invaluable opportunity to connect classroom learning to real-world career options. The event showcased how construction blends technical skill, problem-solving, and teamwork, while also offering long-term stability and professional growth.

The event served as an important reminder that career readiness can take many forms, and that the union construction industry continues to provide pathways to success that are accessible, diverse, and sustainable.

Council member Katherine Gilmore Richardson joined the event on October 8, welcoming students and emphasizing the vital role construction plays in Philadelphia’s continued development. She encouraged students to take full advantage of the opportunity—to visit every exhibit, ask questions, and explore what the industry has to offer.

On October 9, State Senator Joe Picozzi addressed attendees, underscoring how the construction trades help strengthen local communities and build a foundation for the region’s economic future. Both leaders reinforced the idea that construction is more than a job—it’s a chance to contribute to the growth, safety, and resilience of the city and its people.

Their presence helped connect the dots between workforce development, education, and civic engagement—reminding students that they are not just future workers, but future leaders and changemakers within their communities.

Adding a creative twist to the two-day event, Mayfair Middle School students recorded a live episode of their Dope Student Podcast right on the show floor. The young hosts interviewed fellow students, exhibitors, volunteers, and elected officials to capture their perspectives on what they learned and what inspired them most about the construction industry.

The podcast recordings captured authentic reactions from students seeing the trades up close for the first time— moments of curiosity, discovery, and pride. From learning how to operate tools safely to hearing personal success stories from professionals in the field, students came away with a stronger appreciation for the value of skilled labor and the teamwork that drives every project.

The enthusiasm surrounding Build My Future 2025 reflects the construction industry’s ongoing commitment to workforce development and education. As the need for skilled labor continues to grow across the Philadelphia region, events like this serve as a crucial bridge between students and the opportunities waiting for them in the field.

By engaging directly with students and showcasing the real people behind the industry, GBCA and its partners are helping young people see construction not just as an option, but as a pathway to purpose, stability, and professional growth.

GBCA extends its sincere appreciation to the event’s sponsors, exhibitors, and volunteers for their time, creativity, and commitment to inspiring the next generation. Their participation made Build My Future 2025 an unforgettable experience for hundreds of students and a powerful demonstration of what’s possible when the industry comes together to invest in its future workforce.

Located at the heart of campus on Polett Walk, across from the iconic Bell Tower, Temple University has unveiled a new home for its Barnett College of Public Health (CPH). With Rycon Construction serving as general contractor, and PZS Architects (AOR) alongside SLAM Collaborative leading the design, the university transformed the former library into a dynamic academic hub.

Previously spread across 10+ separate buildings, CPH is now consolidated into a single centralized facility through a comprehensive expansion and renovation of Paley Hall. The building supports education, research, and community engagement, while aligning with the architectural character and flow of the surrounding urban campus. Notably, the project is designed to achieve both LEED and WELL Fit certification - marking Temple’s first WELL-certified building.

Given the complexity of this multi-prime, public bid project, Rycon prioritized transparency, collaboration, and proactive problem-solving. With MEP prime contractors held directly by the university, Rycon’s ability to foster strong relationships was essential. The team managed over 1,000 RFIs and 680 change orders, emphasizing real-time communication with Temple and trade partners to maintain momentum.

Rycon’s Philadelphia presence proved invaluable, with team members leveraging existing relationships with subcontractors to build trust and ensure seamless coordination. Weekly OAC meetings, trade coordination sessions, and foreman huddles helped identify issues early and keep the project aligned.

To minimize conflicts and enhance coordination, BIM technology was used for model federation, clash detection, and issue tracking. Solution Driven Workshops brought stakeholders together to resolve challenges collaboratively. Rycon also self-performed select scopes, including millwork, wood soffits, and specialty ceilings.

Spanning 27 months, the project was strategically planned to meet the Fall 2025 semester deadline. It encompassed a 150,000-sf interior renovation and a 160,000 sf vertical expansion, paired with a full infrastructure upgrade. Together, these efforts created a cutting-edge environment designed to foster interdisciplinary learning and collaboration, reinforcing Temple’s commitment to advancing public health.

Beneath the polished result was an intricate construction process that demanded innovation, precision, and seamless coordination. The project combined three major efforts: renovating an existing facility, adding a two-story vertical expansion, and constructing a new ground-up addition. Each component was tightly interwoven, with the progress in one area often dependent on the successful advancement of another, demanding a tightly synchronized schedule to ensure milestones aligned, and momentum continued across the site.

Existing building conditions added complexity. The team encountered inconsistent slab depths and varying rebar densities when tying existing elevations and concrete structures into the addition. Additional challenges included cutting through three original concrete decks to create a

dramatic multi-story atrium. This new light well, anchored by a learning stair, now serves as a centerpiece drawing daylight deep into the building’s core. Integrating new structural elements into the legacy frame required meticulous field verification and detailing to ensure alignment and stability.

Adding to the challenge was the building’s unconventional geometry. Far from a standard rectangular footprint, the design featured radius conditions, a curved floor plan, and a layered, high-performance exterior envelope. The façade incorporated sunshades, curtain walls, and a mix of terracotta and granite finishes - each requiring sustained, trade-by-trade coordination.

The building envelope was redesigned with a bold new entrance featuring two light wells, an atrium, and a modern skin of stone, terracotta rainscreen, masonry veneer, ACM panels, and curtainwall glazing. The steel-framed addition includes CMU walls, concrete foundations, EPDM roofing, and two vegetated green roofs for sustainability and stormwater management.

Inside, flexible classrooms, research labs, faculty offices, café, event space, sensory room, and a dramatic green wall foster learning and collaboration. At its core, the state-ofthe-art Simulation Center replicates real-world environments including: a park, a row home, an ambulance bay, and a hospital floor, with observation and control spaces for realtime feedback.

The Aramark Community Teaching Kitchen features induction cooktops and commercial-grade support spaces, offering community education programs like SNAP-focused instruction. On the first floor, two large classrooms convert into four smaller rooms via Skyfold motorized, acoustically rated partitions for maximum flexibility and space utilization.

Constructing a major facility at the center of Temple University’s active campus required precise logistics and heightened security coordination. The Rycon team met these demands by implementing controlled access with dedicated security personnel, coordinating hourly with campus police during peak class transitions, and managing lock and gate operations throughout the project’s duration.

On a landlocked site with limited laydown space, deliveries were scheduled “just in time”, trailers staged in the mezzanine, and the crane positioned within the tight fence line. Minimal off-site storage kept critical materials accessible while reducing double handling.

Despite the constraints, the project achieved phased occupancy: basement areas were operational by August 8, classes began in newly completed spaces on August 25, and the grand opening, featuring a public dedication with local and state legislators, was held on October 10.

Designed for LEED and WELL certification, the building integrates wellness and sustainability throughout. Green roofs mitigate heat and manage stormwater, while a living wall in the atrium enhances air quality and aesthetics. Installing the wall required close coordination of irrigation, drainage, roofing, and grow light systems to ensure plant viability.

The new facility unifies CPH’s satellite programs into a five-story (plus basement and mezzanine) academic home. Located steps from the library and core services, it offers students and faculty a centralized, interdisciplinary environment. Flexible classrooms, advanced labs, and immersive simulation suites prepare students to deliver care across the full continuum—from community settings to clinical environments and back again.

The project exemplifies how thoughtful planning, technologyenabled coordination, and union craftsmanship can deliver a complex, beautiful building on a tight urban site. It’s a powerful investment in student success and community wellness - and a new campus beacon for public health.

Thank you to our GBCA project team members; A.T. Chadwick Company, Inc., Anthony Biddle Contractors, Inc., BrandSafway Services, LLC, Chesco Coring & Cutting, Inc., ClarkDietrich Building Systems, Concrete Cutting Systems, Inc., Creative Surfaces, Inc., EDA Contractors, Inc., Fizzano Bros. Concrete Products, Inc., Graboyes Commercial Windo and Glass Solutions, Guthrie Glass & Metal, Inc., Hilti Inc., Hispanic Ventures, Inc., Independence Steel and Erectors, Joseph Dugan, Inc., PDM Constructors, Inc., Revolution Recovery, LLC, Torrado Construction Co., Inc., Tri-State Construction Inc., Unified Door & Hardware Group, LLC, Tru-Fit Frame and Door.

RYAN MONKMAN, SENIOR PROJECT MANAGER | GILBANE BUILDING COMPANY

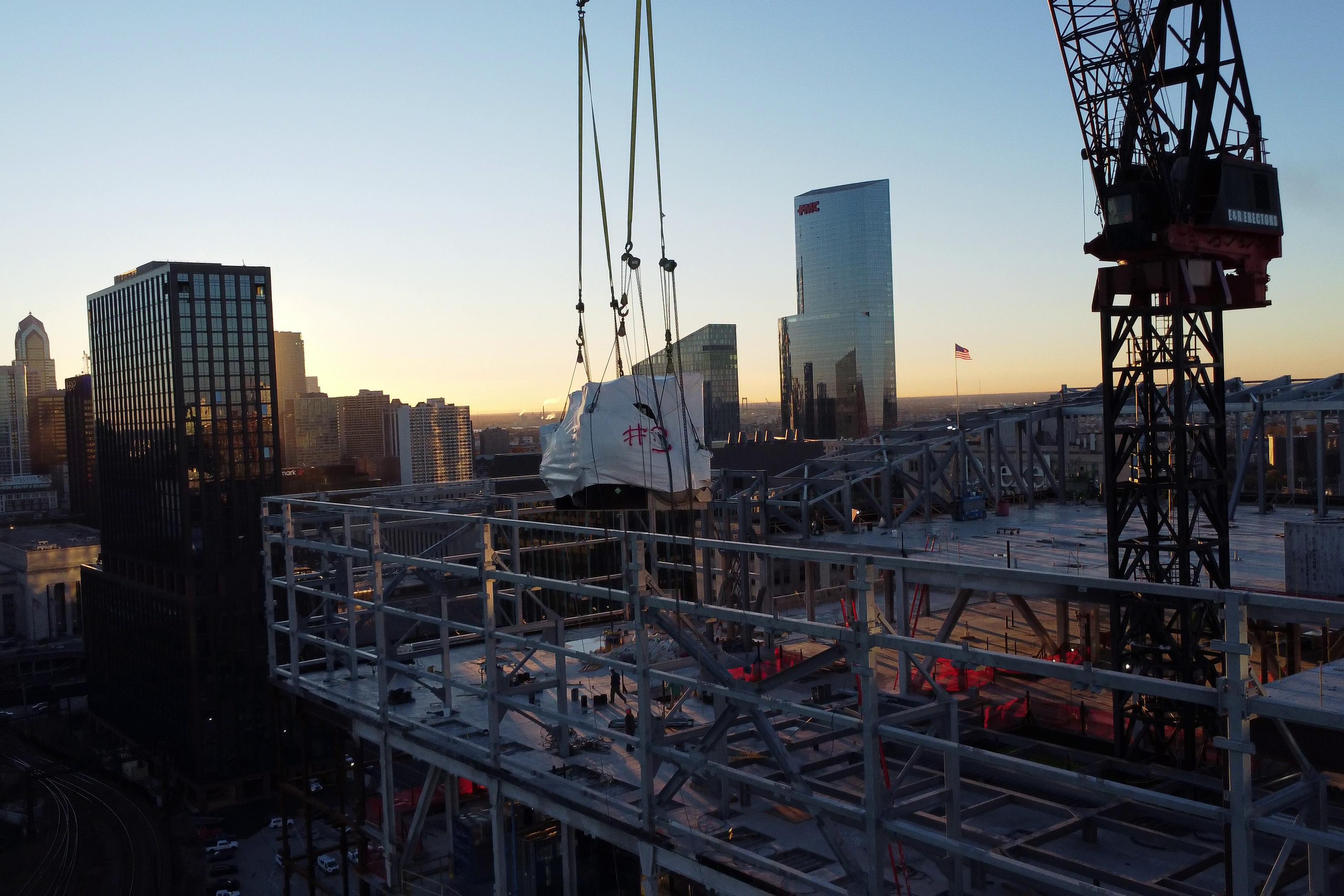

Since breaking ground in 2023 significant progress has been made at Amtrak’s William H. Gray III 30th Street Station redevelopment project in Philadelphia. But as with any project of this size and scope, there’s much more that goes into it than meets the eye.

This transformative initiative is aimed at modernizing Philadelphia's historic rail hub – a challenging task considering the age of the station at nearly 100 years old and the fact that the station must remain open and operational throughout the extent of the project. As the third-busiest station in Amtrak's network, serving more than 5 million customers in 2024, this project will enhance functionality, improve traveler experience, and stimulate economic development in the surrounding area.

This project is delivered through a public-private partnership between Amtrak and Plenary Infrastructure Philadelphia, which includes Plenary Americas, Vantage Group, and Johnson Controls, with Gilbane Building Company and Skidmore, Owings and Merrill (SOM) as the design-build team. Gilbane, as the project’s design-builder, is playing a key role in bringing this ambitious vision to life. A crucial component in achieving the Philadelphia 30th Street Station District Plan is the significant redevelopment and restoration work, which will maintain the station’s place as a top transit hub and community resource while retaining all the historic elements that make the station so unique.

So far, we’ve made massive strides updating the Historic Main Concourse, the South Concourse and Food Hall, the Building Systems Infrastructure, as well as modernizing Amtrak’s Corporate offices. Our construction has been focused on addressing a backlog of deferred maintenance items, enhancing the customer experience to support future growth in ridership, reviving the building’s historic character, and improving operations and retail opportunities at the station.

Restoring and modernizing this nearly 600,000-squarefoot historic facility while allowing the station to remain operational during construction has required a significant amount of planning, partnership, and construction expertise. In our experience, successfully executing a historic renovation project of this scale comes down to four key characteristics:

adaptability, partnership, innovation, and culture.

Successfully renovating a nearly 100-year-old building in 2025 requires plenty of modern technology and innovation. At Gray 30th Street Station, we’ve implemented numerous digital tools to safely, efficiently, and effectively work on areas needing modernization while preserving the building’s historic character. For example, we utilize mobile wearable scanning devices that continuously scan the site as we walk. Creating an immersive view of existing conditions makes logistics, subcontractor coordination, and scheduling significantly easier.

We’ve also leveraged a digital logistics management platform to streamline construction site deliveries and enhance operational efficiency. On urban sites like Gray 30th Street Station, there’s minimal room for material laydowns and limited hours for deliveries. By replacing outdated scheduling methods like whiteboards and spreadsheets, digital logistics management platforms allow trade partners to book delivery slots online, while managing approvals to prevent congestion and ensure smooth site operations.

To push technological adoption even further, we’re also leveraging artificial intelligence (AI) tools to improve project efficiency, transparency, and decision-making. With AI technology, teams gain instant access to project documents and receive proactive alerts for key milestones, helping reduce delays and improve schedule performance in ways that are essential to success on a complex historic restoration project.

Historic restorations often present unique construction challenges that require flexibility and adaptability. This building was constructed in the early 1930s using materials and techniques different from those used today. The most high-profile restoration is in the ceiling in the Main Concourse – one of the most delicate tasks on the project. Restoring the ceiling required artisans qualified in historical painting techniques to recreate and preserve 100-year-old plasterwork

with painstaking accuracy. Mockups, historic brushes, and hand-mixed plasters are just a few of the specialized tools in use, reflecting an unmatched level of care and craftsmanship.

Flexibility was also required when updating the station’s electrical systems, all while limiting disruptions to transit service. Gilbane was tasked with installing new high-voltage systems, including utility company switchgear, and a highercapacity, longer-running emergency power backup system. Doing so required weeks of careful and flexible planning with transit operators to maintain power supply to areas in need and ultimately eliminate unnecessary transit disruptions.

Gilbane is committed to bringing diverse, local talent to our job sites. Considering the sheer volume of work required on Gray 30th Street Station, we thought strategically from the beginning about which specialty subcontractors would be needed to complete the renovation project. We knew from the start that hiring Philadelphia-based talent would be essential to preserve the local character and identity of this facility. Thankfully, we’ve been investing in local partnerships for decades and have the deep relationships required to source this work from Philadelphia-based companies that understand the cultural significance of the station.

On a complex job with many shifting pieces, it’s important for the construction lead to ensure everyone is moving in the right direction. This is where culture can play a significant role in setting the tone for the project at hand. On a Gilbane

job site, you can feel the energy – and the Gray 30th Street Station project is no different. Everyone from the trades workers to the engineers to the specialty contractors understands the importance of safety, professionalism, and teamwork. This cohesion creates an environment of camaraderie and enthusiasm for outstanding work that fuels the success behind every task at hand. It is this dedication to excellence, discipline, and integrity that makes Gilbane uniquely qualified to coordinate and execute a complex historic restoration like Gray 30th Street Station.

Additionally, utilizing a design-build model enables greater coordination and efficiency. Throughout construction (and even before the project started), we formed close partnerships with the long-term operators of the building – Johnson Controls for overall building operations and Vantage Group for the retail program – to ensure this culture permeates every aspect of the job and final constructed conditions meet our shared goals.

On a historic restoration job as complex and important as Gray 30th Street Station, working with a construction partner with the right mix of resources, relationships, and culture is crucial to success. At Gilbane, we’re thankful for the opportunity to put our strengths to the test and are thrilled with the results thus far. The PIP and Amtrak partnerships look forward to reopening the South Concourse and Food Hall as we continue to advance this important project that will benefit Philadelphia, Amtrak customers, and the greater region for generations to come.

WRIGHT SAUNDERS | CLEMENS CONSTRUCTION COMPANY, INC.

In Philadelphia’s union-driven construction market, collaboration is the difference between projects that struggle and those that succeed. From healthcare expansions to higher-ed renovations, it has become clear that the delivery method chosen at the outset determines how a project ends. For GBCA members, and for the owners and institutions we serve, finding the right balance between cost, collaboration, and flexibility is critical.

In the beginning of my career the default for construction contracting was hard bid. On the surface, it made sense: soliciting multiple bids drove competition, lowered prices, and ensured fairness. It makes sense when construction procurement can be treated like a commodity. But most projects are not commodities. They are fast-tracked, budgetsensitive, and operationally complex. Hard bid is perilous for an owner if the documents are less than 100%, even with contingencies. There is minimum collaboration and maximum friction. Everyone on the team works to protect themselves rather than work together.

Integrated Project Delivery (IPD) works beautifully for those who can commit, but very few owners can afford the complexity. I spent 8 years on an IPD team, and it was a great experience. However, from a contractual and practical standpoint, IPD can be a challenge. Getting the contract executed is time-consuming, owners need an in-house leader for IPD, and the subcontractor community with the resources to participate effectively is limited. The IPD team and contract need to be in place at the very conception of a project — a threshold many owners are not prepared to meet.

Many projects in our region utilize the Competitive

Guaranteed Maximum Price (GMP). On paper, this looks like an upgrade from lump sum bidding, but the reality is different. A GMP delivered late in design is still essentially a lump sum with a cap. By the time a CM is engaged, opportunities for collaboration and constructability review are already gone — the GMP simply locks in an incomplete plan. Owners often believe they are buying cost certainty, but what they are really buying is a cap on an imperfect process.

Another procurement model invites CMs to compete on Fee and General Conditions while the trade costs are carried later. This moves the focus away from chasing the lowest GMP number and emphasizes team selection. But here, too, there are pitfalls. To stay competitive, CMs often undervalue staffing, offering leaner project teams than they know are truly required. This risks slower decision-making and weaker coordination. I have seen many projects awarded on a staff basis that is clearly less than the effort required for success. Undervaluing staff may win the work, but it rarely wins the project.

The real key to building a successful project is getting the right people in the same room early. That means experienced CM staff, a few key subcontractors, the design team, and the owner sitting together in structured planning sessions. This is the essence of design-assist. The effort is relatively inexpensive, but the payoff is enormous. During these sessions, constructability can be vetted, logistics planned, budgets aligned, and risks identified. Everyone has a seat at the table: owners and facilities staff, design professionals, the CM, and key trades.

We’ve seen this approach deliver real value on projects across the Philadelphia region in hospitals, universities and in our high rise and multi-family commercial construction.

The early planning sessions establish expectations, define the unknowns, minimize disruption, and build a definition for project success that the team lives by.

Team surveys are followed up with fully vetted schedules and logistics plans that are completed alongside the design development drawings. The result is a workable plan that drives value by fully defining the scope and building trust among all participants.

Conclusion

Contract structure sets the tone for behavior. Lump sum creates adversaries. Competitive GMP and fee-only models

try to soften the process but don’t always bring the builder in early enough with the resources to change the game. IPD holds great promise, but for many owners it remains too complex. Design-assist, on the other hand, is practical, flexible, and proven. For GBCA members, it represents a delivery method that leverages our region’s greatest strength — skilled trades and collaborative partnerships — while protecting owners’ interests. If owners truly want comprehensive planning and predictable outcomes, designassist is the most economical path forward.

Board Champion: Dale E. Lintner, Jr.

GOAL

y Position GBCA members as industry leaders and establish GBCA as the foremost authority on industry issues. This involves understanding growth and efficiency challenges, enhancing political engagement, and fostering collaboration among owners, designers, and contractors.

KEY MILESTONES

y GBCA members and staff were appointed by the Mayor and City Council to the Mayor’s Transition Team, the Mayor’s Business Roundtable, the Philadelphia Housing Authority Board of Commissioners, the L&I Task Force, and the Mayor’s Stakeholder Advisory Group for the H.O.M.E. Initiative.

y Member of staff has been appointed to the Philadelphia Industrial Development Corp Board.

y Engaging directly with key city departments—including L&I, Streets, and Water— in collaboration with members to resolve issues and strengthen working relationships between GBCA contractors and city agencies.

y Hosted a successful fundraiser for Mayor Cherelle Parker, exceeding the fundraising goal and strengthening GBCA’s relationship with the Mayor and her administration.

y Concluded owners’ and developers’ focus group.

ONGOING INITIATIVES

y Actively working with City Council and the Mayor’s administration to ensure GBCA members play a leading role in delivering the 30,000 new and renovated housing units under the HOME initiative.

Board Champion: Pat Pasquariello III

GOAL

y Build a collaborative and synergistic partnership with labor unions.

y Position GBCA as the labor management think tank, working alongside the trades to create a competitive advantage for signatory contractors.

KEY MILESTONES

y Regional OSHA 300 analysis

y Market indicators analysis

y CBA Matrix analysis

y L&I Relations analysis

ONGOING INITIATIVES

y Two GBCA/Carpenters Think Tank meetings were held in 2025

Board Champion: Shawn Carlin

GOAL

y Create and implement workforce development initiatives to positively impact 25,000 school-aged individuals.

y Increase opportunities for Minority Business Enterprises (MBE), Women Business Enterprises (WBE),and underrepresented populations within the workforce.

KEY MILESTONES

y GBCA is hosting Build My Future, a two-day event for middle and high school students that showcases educational opportunities and careers in the construction industry.

y GBCA launched a Construction Fundamentals tuition reimbursement program, where members and IAP contributors can get reimbursed for courses.

y Construction Leadership Council membership has increased by 23% so far in 2025.

y 54% of the 2024 CARP graduates were hired by GBCA members.

y As a partnering association for the CARP 3-1-1 Summer Program, GBCA supported participants by providing hard hats and SEPTA transit passes.

EVERYBODY BUILDS PHILADELPHIA

y Supported to five workforce development programs and provided direct assistance to pre- apprenticeship programs, including community awareness, recruitment support, barrier reduction, and contractor/industry engagement.

y Assisted CARP and WINC in obtaining over $200,000 in new investments.

Board Champion: Maura Hesdon

GOAL

y Execute a strategic plan to enhance members, committees, and board engagement, and achieve more efficient organizational outcomes.

KEY MILESTONES

y The Leadership Preparation Program (LPP), designed to enhance leadership and professional skills among GBCA members, has successfully increased member engagement and fostered significant skill development.

y Increased duties and responsibilities for the Board of Directors have led to greater board engagement and encouraged more member involvement.

y The Long Term Planning Committee is evaluating future member services, revenue opportunities, and strategies to strengthen GBCA’s long-term impact.

y Created an Active Member Engagement Report to identify and re-engage at-risk members.

ONGOING INITIATIVES

y Review of committee structures and missions.

Name: Andrew Shinn

Title: Preconstruction Manager

Age: 32

Company, City: Rycon Construction, Philadelphia

Years in Field: 12

Education: Bachelor of Arts in Architectural Studies, Hobart College; Post-Baccalaureate Certificate in Construction Management, Louisiana State University

What inspired you to pursue a career in construction?

My father worked his entire career in utility construction, and for whatever reason it pushed me to pursue something different; so, I set off to college with architecture in mind. By my senior year I started to realize that architecture maybe wasn’t what I wanted to do in the long term. I was fortunate that my college was building a new Performing Arts building, so as a “senior project” I petitioned the college’s Director of Construction for an internship and was able to work under him for a full semester as a liaison for the college. Seeing the process of construction firsthand, interacting with stakeholders and subcontractors, and seeing the impact the project had on the campus community around it pushed me into wanting to make that a career.

How has the construction industry changed since you started your career, and how have you adapted?

Owners’ budgets are consistently shrinking or are under scrutiny creating a domino effect on the quality of designs that come out resulting in pressure for precise proposals. I think a combination of diligence in review of the documents we’re given and utilizing the resources around me, between our team at Rycon and our relationships with the subcontractors in the area, help to shape strong proposals and keeping our team informed on what is needed.

What has been the most fulfilling moment of your career so far?

The first project I was the lead estimator on with Rycon was the Birthing Center at Virtua in Vorhees, New Jersey. It was such a unique project and cemented my interest in healthcare construction and gave me confidence that I was doing what I wanted to. I often think back to that project as a benchmark of success from bidding, to being in the descope, and seeing it turn into reality.

What unique challenge do you face in your role, and how do you overcome it?

It’s easy to get into a bit of a black hole in estimating where you just shut out everything around you and become transactional in dealing with your own

team and the bidding subcontractors. This is especially heightened with the churn of constantly reviewing different sets of drawings and specifications. Getting out to that job you bid, stopping by a subcontractor’s or owner’s office, or getting out for a drink with people from the office breaks up that silo.

What advice would you give to someone just starting out in the construction industry?

Get in the field! I started my construction career as an APM/assistant superintendent and was fortunate to work on a handful of projects that gave me a good understanding of the communication and coordination that happens on a project site before moving into estimating. Being on the preconstruction side, it is sometimes difficult to visualize or understand how buildings really go together so I emphasize spending time on site talking to the superintendent or foreman or seeking out the funky detail that was on a plan set and seeing it in person.

What leadership principles guide you in your professional life?

A mentor of mine told me that there are learning opportunities up and down the construction, and what he meant by that is that everyone in the process can bring up valid points or insights from an APM to the executive VP. He ultimately emphasized that leading with surety in what you know, but an open mind for what you don’t know will make you successful. I am the first to admit when I don’t know something, but I will immediately work to understand it and share my experience from that.

How has being part of the CLC contributed to your personal and professional growth?

Being apart of the CLC has helped push me beyond my comfort zone a little and stay engaged with the happenings of our industry. The opportunities for growth and development that are available because of the CLC are invaluable and the friendships that have grown from being a part of CLC help show the most important part of construction, that it is a human industry.

What’s a recent accomplishment or skill you’ve developed that you’re proud of?

I was able to complete a Dale Carnegie course in the past year that really helped shape my understanding of what it means to be a leader – to be recognized by Rycon as someone that should take a course like that and now have the skillsets from the course are both something that I carry with pride.

How do you stay motivated and inspire those around you?

Staying motivated in preconstruction and estimating can certainly be tough. It’s a position of constantly hearing “no” or “we went with another firm”. I try to remain positive, with a dash of being a realist, and treat every project as a must-win. Celebrating the small victories the same as the big ones is a good way to stay grounded and maintain positivity with others around me.

What qualities do you think are most important for the next generation of construction leaders?

Tenacity and understanding that construction is tangible. I think tenacity, carrying that sense of “no quit”, is both a mindset and personality that helps push individuals ahead in construction. Not backing down from a challenge but figuring out three different ways to conquer it goes a long way. Understanding that construction is tangible goes to what I mentioned earlier. This is a human industry, and staying engaged with the people of the project builds trust and confidence.

What’s your favorite CLC event or initiative, and why?

The first CLC event I really got engaged with was Camp Out for Hunger and as someone who has always valued philanthropy, it was great to see the group together and give back to the community.

How has participating in CLC activities impacted your career?

Participating in CLC has allowed me to build relationships that I otherwise don’t think I would have as easily. Being able to get insights from leaders in our industry from Coffee Chats or simply having the chance to chat with them at a membership dinner is invaluable. Additionally, I have been able to see some great projects through the hard hat tours and even show off one of Rycon’s as well.

What makes GBCA membership valuable to you?

The network that GBCA opens doors to is unparalleled and not to mention that network is filled with great people that are willing to help each other. I enjoy the fact that you can often shed that sense of being a competitor at GBCA events and enjoy what our industry has to offer (or sometimes commiserate together too…).

We all know the issue; there is a shortage of qualified workers in the construction industry and a huge number of the qualified workforce is going to retire soon, (over 20% of the workforce is over 55 according to the US Bureau of Labor Statistics).

What can we do about this?

We can encourage and support professional development opportunities to recruit a new generation and retain those who are starting out. A Gallup poll showed that 87% of millennials value professional development as much as company culture.

To support this initiative, AGC of America has been educating construction leaders for decades. While their Construction Supervision Fundamentals (CSF) program helps to educate transitioning supervisors, The Supervisory Training Program (STP) has been educating field leaders of all levels for over 40 years and is celebrating the 10th edition release in 2025. One of the most overlooked yet critical components of successful construction projects is leadership at the field and craft levels. These are the individuals on the front lines—the carpenters, electricians, foremen, welders, and other skilled tradespeople—who often have the most direct influence on productivity, safety, quality, and team morale. Investing in leadership training for these workers isn't just a good idea; it's essential for the long-term success of construction companies.

For the past 20 years, I have facilitated training for over a thousand construction workers and know firsthand that leadership training works. Some of the major topics that attendees have mentioned were the most impactful include:

1. Bridging the Gap Between Management and the Field

This alignment leads to fewer misunderstandings, improved workflow, and a stronger sense of accountability

2. Improving Safety Outcomes

Safety is paramount in construction, and leadership at

the field level plays a major role in ensuring a safe work environment.

3. Enhancing Communication and Collaboration

Poor communication can lead to mistakes, rework, and even injury. Leadership training equips field leaders with tools to communicate clearly and constructively with everyone on the project team from owners to specialty contractors

4. Building Future Leaders from Within

By investing in leadership training for craft workers, companies can develop a pipeline of qualified individuals ready to move into supervisory or management roles.

5. Driving Productivity and Quality

A well-trained field leader knows how to organize tasks efficiently, motivate their crew, and address challenges in real time. These skills lead to better time management, fewer errors, and higher-quality work—ultimately contributing to the profitability and reputation of the company.

6. Fostering a Culture of Respect and Inclusion

Modern construction sites are increasingly diverse, with workers from varied backgrounds and cultures. Leadership training includes elements of emotional intelligence, cultural competency, and respectful communication.

Conclusion

Leadership is not confined to the office or the boardroom. On a construction site, leadership at the field and craft levels is just as vital—if not more so. By investing in leadership training for these workers, construction companies can improve safety, productivity, communication, and job satisfaction while building a resilient workforce ready to meet the challenges of today and tomorrow. It's time to recognize that every worker has the potential to lead—and to give them the tools to do so effectively.

This issue features the standout projects and teams recognized at the 28th Annual Construction Excellence Awards, celebrating the achievements that elevate Greater Philadelphia’s union construction industry.

Check out this year's winners!

Founded in 1989 by Stephen Wouch, CPA, CFF, and John F. Maloney, CPA, CFF, CVA, ABAR, Wouch, Maloney & Co., LLP was established to provide specialized accounting services tailored to the construction industry. Known as construction accounting, this field addresses the unique financial requirements of construction projects. The firm assists contractors in securing projects by delivering accurate financial statements, including Income Statements, Balance Sheets, Cash Flow Statements, and Work-in-Progress (WIP) schedules. Beyond reporting, Wouch Maloney provides training for clients’ accounting teams, ensuring seamless year-end and tax seasons. More than 70% of the firm’s revenue is derived from construction clients.

At Turner Construction Company, safety is a core value embedded through our Building L.I.F.E.® (Living Injury Free Every Day) philosophy. In Philadelphia, we foster active caring, proactive risk mitigation, and frontline engagement. Over the past 18 months, Turner delivered more than 370,000 hours without a single OSHA recordable incident. In 2024, its Self-Perform Operations (SPO) team—responsible for carpentry, drywall, and concrete—achieved 250,000 hours without a recordable, earning Turner’s Golden Hard Hat Award. In May 2025, we marked our 20th Annual Safety StandDown with engagement, training, and recognition across all jobsites, demonstrating the impact of a proactive, systems-based safety approach.

Over the past 18 months, Gilbane has advanced construction innovation in the Philadelphia region through the strategic deployment of cutting-edge technologies. From autonomous robotics and AI-powered safety platforms to mobile laser scanning and digital logistics tools, Gilbane has enhanced project delivery, safety, and stakeholder engagement. Notable successes include accelerating delivery at the CHOP Morgan Center by using 4D modeling and robotics, and improving site logistics at major urban projects through Voyage Control. These efforts reflect Gilbane’s commitment to smarter, safer, and more inclusive construction practices.

Over the past 18 months, Guthrie Glass & Metal, Inc. has advanced workforce development through its structured Assistant Project Manager (APM) training program. The program has successfully onboarded three new team members from unique backgrounds, including no glazing experience, no U.S. work experience, and a transition from field to office. Over a 90-day period, participants receive technical training, industry education, jobsite exposure, and progressive project ownership. As a result, all three trainees are now self-sufficient APMs running their own projects. This program reflects Guthrie’s commitment to professional development and preparing employees to excel in a demanding commercial glazing environment.

Turner Construction Company’s Philadelphia office demonstrates a deep, sustained commitment to community service through active volunteerism, workforce development, and economic inclusion. Over the past 18 months, Turner has supported over 60 nonprofits, hosted more than 50 service events, packed 55,000+ pounds of food, and donated over $130,000 to organizations advancing healthcare equity, education, and workforce diversity. Founder's Month alone mobilized over 20 employees to prepare 1,300+ meals and engage 800+ students. Through intentional partnerships, employee-led initiatives, and a culture of “active caring,” Turner is helping shape a stronger, healthier, and more inclusive Greater Philadelphia.

PROJECT DESCRIPTION

Marble is timeless. The unique characteristics within each block make it a highly sought-after interior finish material. The tighter tolerances and the visual nesting from one piece to another require exceptional attention to detail. These demands often price marble out of most commercial projects and limit its use to an exclusive client base. When D.M. Sabia & Co., Inc. was presented with the opportunity to furnish and install this marble work, the team ensured it was delivered with precision, craftsmanship, and care—meeting the highest standards expected for such a distinguished and challenging material.

OWNER/CLIENT

Glenmede Wealth Management

CONSTRUCTION MANAGER

C. Erickson & Sons, Inc.

WINNER

PROJECT DESCRIPTION

The Borgata B Bar Refresh was a fast-paced install with stunning custom details. Guthrie Glass & Metal, Inc. and Baumgardner Finishes Co. partnered to deliver high-end finishes fabricated in Guthrie’s South Jersey shop. Working against a tight schedule, the team coordinated and executed custom fabricated screens featuring 16 art glass panels and four upholstered inserts, water jet marble flooring and bar tops, and specialty bronze mirrors with precise cutouts for integrated lighting. Additional details included a brass-finished radius handrail with low iron glass and custom carpet tying the design together. Exceptional craftsmanship brought the project vision to life.

OWNER/CLIENT

• Massett

• MGM

ENGINEER(S)

Landmark

1 MILLION – 10 MILLION

PROJECT DESCRIPTION

Cippco demolished 500,000 square feet of underutilized office space at 1701 Market Street, beginning its transformation into 299 residential units known as 17 Market West. The project’s unique technical, logistical, and schedule challenges required careful planning, coordination, and innovative solutions. A custom saw rig was developed to secure, cut, and modify 1,560 limestone façade panels in place. An unconventional bottomup demolition sequence enabled early tenant leasing, while crews removed 840 loads of debris using a single elevator and coordinating closely with other trades. With over 35,000 manhours and no lost-time incidents, Cippco delivered multiple floors ahead of schedule.

OWNER/CLIENT

• Alterra Property Group

• Clemens Construction Company, Inc.

ENGINEER(S)

• Bala Consulting Engineers

• Eileen Tognini Design

• NORR

GBCA MEMBER SUBCONTRACTORS

• Eureka Metal & Glass Services, Inc.

• Revolution Recovery, LLC.

1 MILLION – 10 MILLION

PROJECT DESCRIPTION

Superior Scaffold took on the largest supported scaffold project in Philadelphia’s history: the historic Bellevue Hotel. At 254 feet tall and spanning two city blocks, it is the largest contiguous scaffold job ever built in the city. The owners chose to complete the exterior renovation all at once, requiring extraordinary planning and execution. Years of negotiations preceded the project, as suspended scaffold or alternative means could not be used. Sidewalks needed shoring to support the enormous weight, while the scaffold itself was too heavy to stand without reinforcement. The project’s complexity and scale read like a best-selling story.

OWNER/CLIENT

Lubert-Adler

ENGINEER(S)

Alternate Design Solutions

GBCA MEMBER SUBCONTRACTORS

Armor Masonry Restoration, Inc.

FINALIST

DWD Mechanical Contractor, Inc.

PROJECT DESCRIPTION

3201 Cuthbert stands out as a benchmark for innovation and coordination in mechanical construction. The project featured complex mechanical systems, including high-efficiency HVAC, advanced controls, and seamless integration within tight structural constraints. DWD Mechanical Contractor, Inc. delivered precision prefabrication, reduced field hours, and achieved aggressive scheduling goals without compromising quality. Collaboration with all trades ensured clash-free installation and exceptional energy performance. This project exemplifies forward-thinking design, sustainability, and craftsmanship, setting a new standard for urban development in Philadelphia. With its technical achievements and strong collaboration, DWD demonstrated how mechanical excellence can drive both project efficiency and long-term value.

OWNER/CLIENT

Gattuso Development Partners

ENGINEER(S)

Burro Happold Engineering

PROJECT DESCRIPTION

Southland Industries provided design-assist mechanical and plumbing services for Amy Gutmann Hall, the University of Pennsylvania’s new hub for cross-disciplinary collaboration. The facility is the tallest new mass timber building in the Philadelphia region. To anticipate procurement challenges and establish a target value, Southland was formally onboarded during design development, enabling early and detailed coordination. Prefabricated HVAC risers and equipment skids improved labor efficiency and quality while minimizing hot work near the timber assemblies, ensuring a cleaner, safer site. Each full-height HVAC riser was installed in less than a single day, showcasing precision, innovation, and project efficiency.

OWNER/CLIENT

• Gilbane Building Company

• University of Pennsylvania

ENGINEER(S)

Buro Happold Engineering

GBCA MEMBER SUBCONTRACTORS

• All Trades Mechanical

• MAS Construction Services, LLC

PROJECT DESCRIPTION

BrandSafway provided a wide range of innovative access solutions for the Gattuso Life Science project, a premier facility in Philadelphia’s expanding life sciences sector. Services included a personnel hoist, loading dock, sidewalk protection, rolling scaffold, power swing, and QuikDeck suspended scaffolding. Operating in a dense urban environment, the team navigated complex site logistics while prioritizing safety, efficiency, and minimal disruption to other trades. This project highlights BrandSafway’s ability to deliver customized, highperformance solutions that support cutting-edge development. With its scale, complexity, and successful execution, the project stands as an exceptional example of access innovation for next-generation scientific research.

Hunter Roberts Construction Group, LLC

WINNER

PROJECT DESCRIPTION

Trinity Hall is a private high school for girls in the Catholic tradition. The Trinity Hall additions totaled over 30,000 square feet across two new buildings, along with renovations to 15,000 square feet of existing space. A major challenge was ensuring the school remained operational during the academic calendar, requiring careful coordination among all team members to maintain student and faculty safety with zero disruptions. The state-of-the-art design and construction introduced new arts, athletics, labs, and academic spaces. These enhancements elevated student facilities and performing arts areas, supporting the school’s mission of delivering a well-rounded, high-quality education for future women leaders.

OWNER/CLIENT

Trinity Hall

ENGINEER(S)

• The S/L/A/M Collaborative (SLAM) Architecture, Structural, Landscape

• Bala Engineering

• Colliers Engineering and Design

GBCA MEMBER SUBCONTRACTORS

• Capitol Steel

• Commercial Wallcovering

• City Newark Glass

• Material Distributors

• MO Flooring

• Northeast Fireproofing

• Sealing Concepts

PROJECT DESCRIPTION

The Lisa Dean Moseley Foundation Institute for Cancer and Blood Disorders is a 24,000-square-foot inpatient unit at Nemours Children’s Hospital, Delaware, purpose-built to advance pediatric oncology and hematology care. Designed by HDR and constructed by Turner Construction Company, the facility blends architectural precision with compassionate, family-centered design. Each patient room features custom millwork and seamless integration of complex MEP systems. From age-specific play areas to research-driven care environments, the project showcases exceptional craftsmanship, clinical functionality, and healing design. The result is a transformative facility that sets a new benchmark for pediatric healthcare in both form and function.

OWNER/CLIENT

Nemours Children's Health

ENGINEER(S)

BR+A Consulting Engineers

GBCA MEMBER SUBCONTRACTORS

• Eureka Metal & Glass Services, Inc.

• Independence Steel and Erectors

• Liberty Flooring, LLC

• M. Schnoll & Sons, Inc.

• Oliver Fire Protection & Security

• Restoration Solutions LLC

PROJECT DESCRIPTION

LF Driscoll and Perryman Construction delivered an exceptional mixed-use project at 3935 Walnut Street, skillfully navigating complex stakeholder interests, tight urban constraints, and active transit lines. Collaborating with Mosaic, the University of Pennsylvania, McDonald’s, SEPTA, and a dual design team, the builders ensured safety and seamless logistics at a dense, high-traffic intersection. This turnkey development is a cornerstone of Penn’s 40th Street Corridor revitalization, featuring a McDonald’s on the ground floor and flexible office space above for Penn’s Career Services, University Life, and Penn Global programs. The project demonstrates innovation, coordination, and community impact—hallmarks of urban construction excellence.

OWNER/CLIENT

• Mosaic Development Partners

• University of Pennsylvania

ENGINEER(S)

• HF Lenz

• Keast & Hood

PROJECT DESCRIPTION