PRODUCT CATALOGUE

HIGH PRESSURE GAS CYLINDER VALVES EXPORT

EDITION

HIGH PRESSURE GAS CYLINDER VALVES EXPORT

Tekno Valves is a leading manufacturer of high pressure gas cylinder valves for Industrial, Medical, Speciality, Firefighting, CNG, SCBA, Refrigerants & Corrosive gases.

Established in 1971, Tekno Valves is proudly family-owned, with the first and second-generation working with a shared vision to put Indian gas equipment at the global centre stage.

With long-term and sustainable decision-making at the core of all activities, our journey of 51 years has led to Tekno Valves being accepted and used in 65+ countries worldwide.

Our integrated manufacturing facility based in Kolkata, India, is equipped with the latest technology and inclusive of a tool & die shop, forging unit & ISO 17025-certified laboratories in the field of calibration, mechanical & chemical testing. The infrastructure is sustainably designed to minimize environmental impact.

Cylinder valves are designed, certified, and manufactured to exceed the requirements of national & international standards. Valves bear Pi, Rho and CGA V-9 marks for exports and are approved by Federal Institute for Materials Research & Testing (BAM), Germany and Arrowhead UK.

Through active participation, we contribute towards the development of technical standards in the International Organization for Standardization (ISO) / Compressed Gas Association (CGA) / Chlorine Institute (CI) / Bureau of Indian Standards (BIS) cylinder valve committees. Our association with the gas industry includes membership in IOMA, CGA, GAWDA, CI, ASTM & AIIGMA.

“Tekno” is synonymous with safety in handling high pressure, and our dedicated team of valve experts remain committed to delivering reliable valving solutions to our customers.

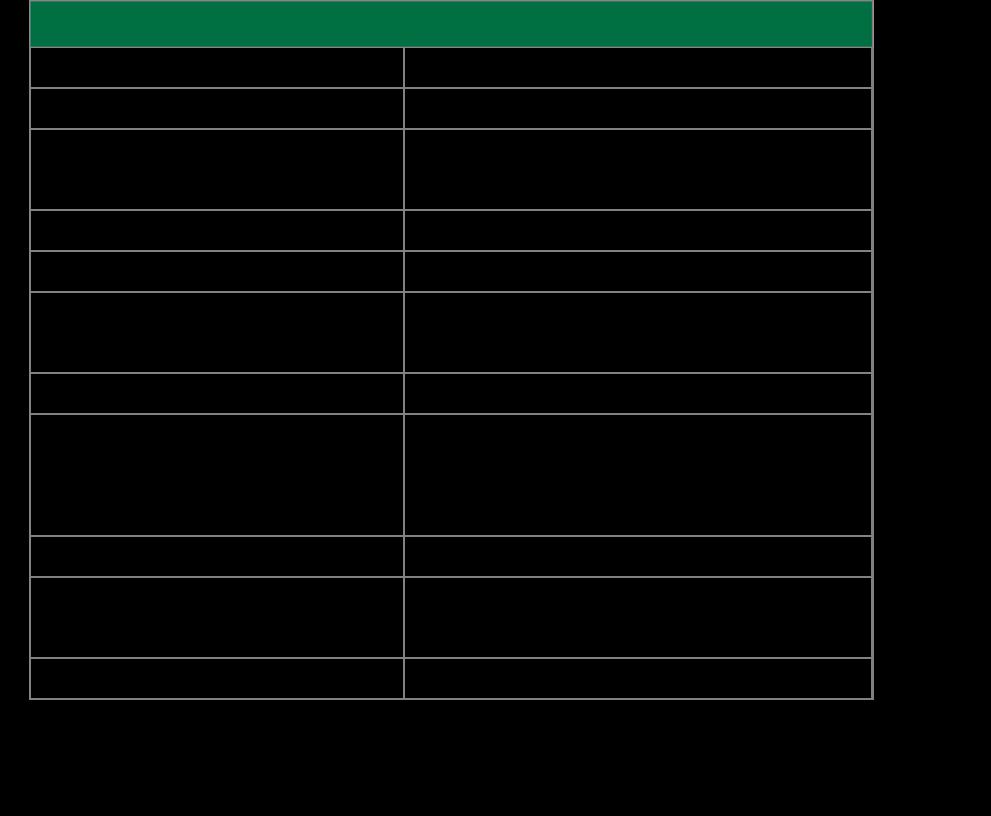

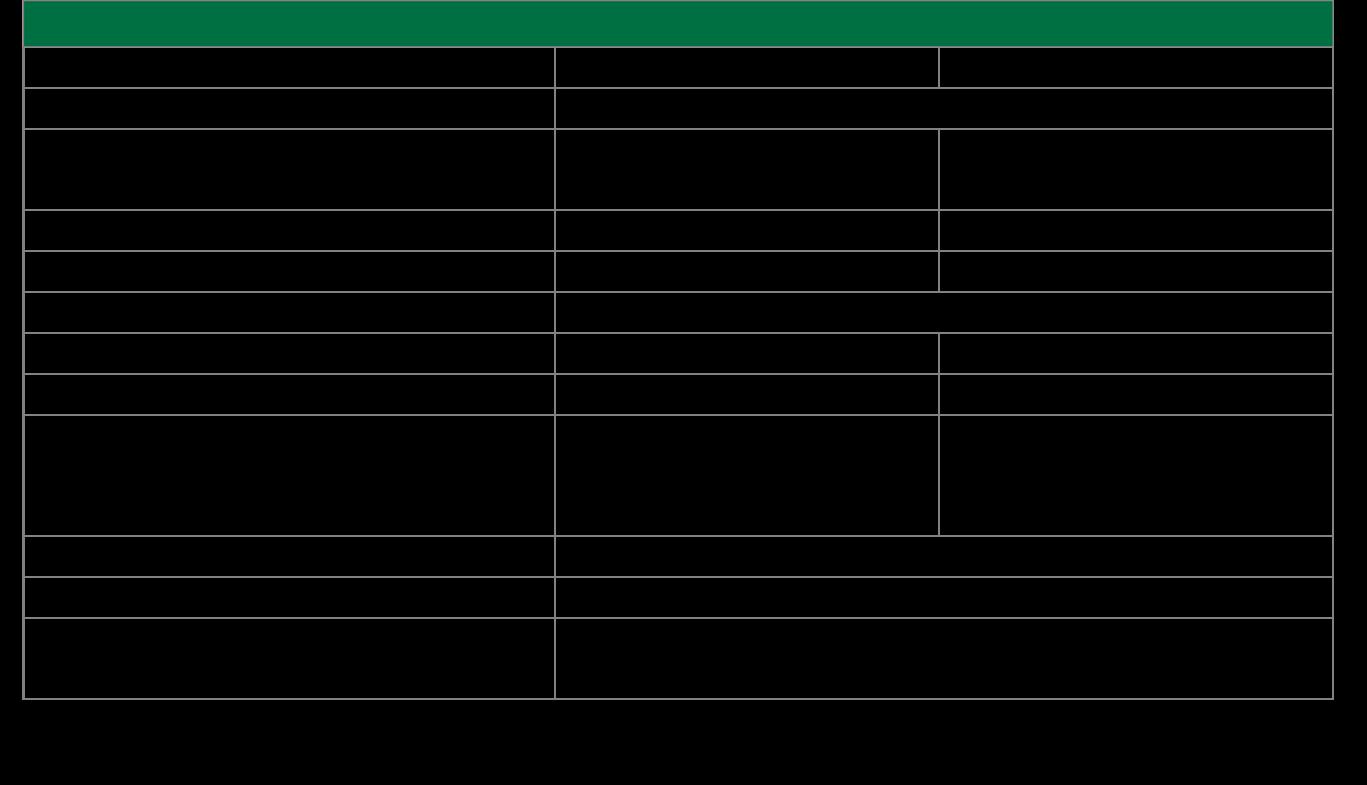

Oxygen,

BSKN-12/O & BTKN-12/O…………………………26.1.2

SWN-12/O & SWN-12/N……………………………26.1.3

TWN-12/O…………………………………………………..26.1.4

SWN-12/45…………………………………………………26.1.5

BOWN-12/O & BOWN-12/N……………………..26.1.6

Acetylene BSKM-21/O…………………………………………………26.1.7

KHO-10/D & KVO-10/D……………………………..26.1.8

BSKN-12/D & BAKN-12/D…………………………26.1.9

BSWN-12/D-30 & BAWN-12/D-30…………26.1.10

SWN-12/D & TWN-12/D………………………….26.1.11

Carbon Dioxide

SKN-12/C………………………………………………….26.1.12

SWN-12/45……………………………………………….26.1.13

SWN-12/C…………………………………………………26.1.14

BOWN-12/C………………………………………………26.1.15

BSKM-21/O ……………26.2.1

BSKN-12/O & BTKN-12/O ……………26.2.2

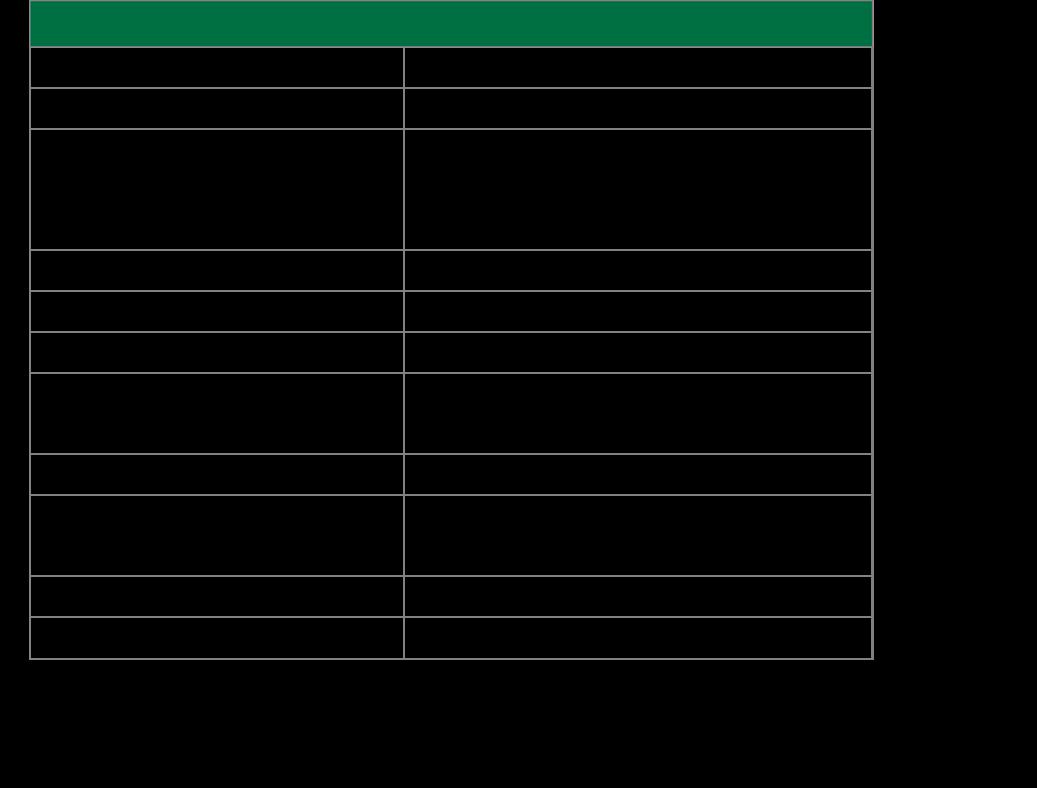

BPKN-12 & BPTN-12 …………26.2.3

PBN-12 ………..26.2.4

SWN-12/O ………..26.2.5

TWN-12/O………………………………………….………..26.2.6

SWN-12/45 ………26.2.7

BOWN-12/O ……..26.2.8

Cylinder valves are designed to meet national and international specifications, tested and certified by a European notified body. Product development is aided by the CAD/CAM software, which seamlessly integrates with manufacturing.

Modern tool room assists design and production activity by developing forging dies, trimming punches, jigs and fixtures, packaging trays and other utilities.

Integrated forge shop is equipped to produce in-house customized forgings using energy-efficient induction furnaces and carry out subsequent heattreatment processes.

Our state of the art machine shop uses multi-axis CNC machines to carry out simultaneous operations of valve bodies and components in a single setup to minimize loading time and ensure accuracy.

Valve bodies and components are degreased in a close circuit using vacuum solvent technology to remove oil and grease, cutting fluid and particulate matter.

Automated equipment used for O-ring fitment, lubrication dispensation, PTFE taping and wheel assembly. Torques are imparted using DC nut runners and each valve is pressure tested prior to despatch.

Valves are packed in customized foam trays made on-site to provide cushioning and protection during transport. The foam compacts to approximately 10% of its original volume in a landfill. It is biostable and will not degrade to pollute air or groundwater. Valves for Oxygen service are heat sealed to maintain the integrity of the cleaning process.

Our dedicated Mechanical, Chemical, and Calibration laboratories are ISO 17025 certified and NABL accredited, allowing us to carry complete chemical and mechanical tests of raw materials and in-house calibration of measuring instruments, torque wrenches and pressure gauges.

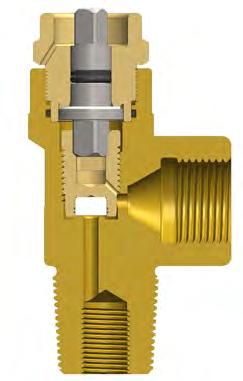

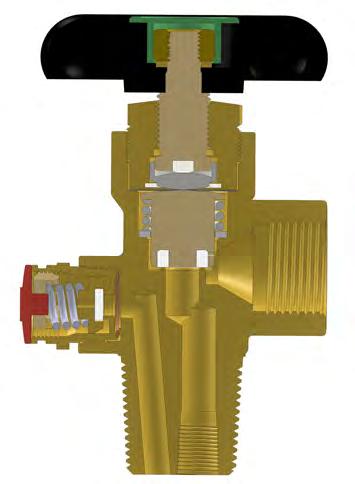

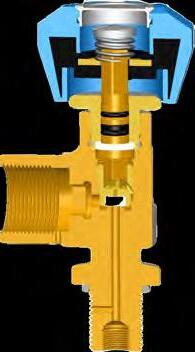

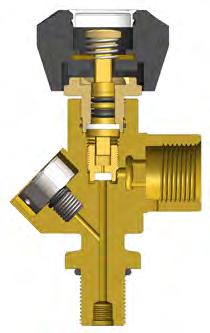

Valve Operating Mechanism

Mechanism which opens & closes the valve orifice.

Residual Pressure Device (RPD)

Device that is designed to prevent ingress of contaminants by maintaining a positive pressure within the cylinder relative to atmosphere by closing off its internal gas passages in the discharging direction.

Pressure Relief Device (PRD)

Device used to prevent the pressure in a normally charged cylinder from rising above a predetermined maximum, thereby preventing rupture of the cylinder in case of fire & / or overfilling.

Component which actuates the valve operating mechanism – handwheel, key, knob or actuator.

Valve Operating Device Seat

Sealing surface surrounding the orifice in the valve body

Outlet

Portion of the valve body through which gas is introduced or discharged.

Portion of the valve that contains the orifice, seat, inlet & outlet connections. It is machined to accept the components to create the valve assembly & sealing system.

Valve Body Inlet

Portion of the valve body that connects to the cylinder.

(Key

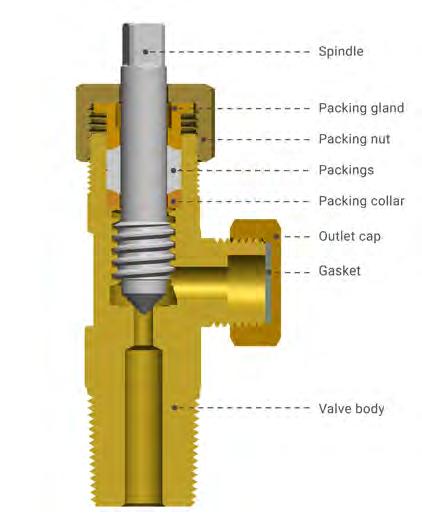

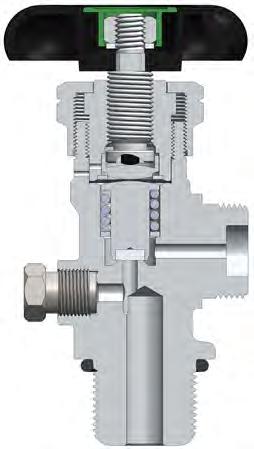

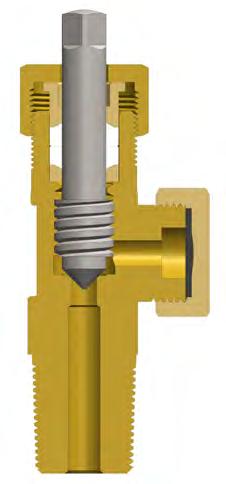

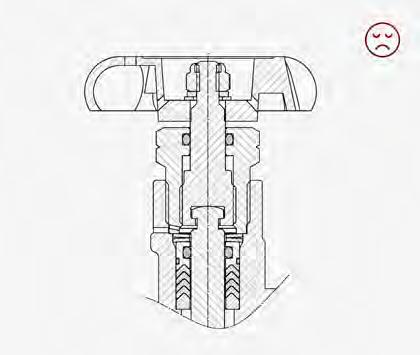

These valves, available in Brass, Al-Si Bronze and Carbon Steel, use compressed packing to make a seal around the valve spindle & body. To ensure a good seal, the packing nut is tightened to compress the packing against the spindle. As this results in higher torques, the valve is operated with wrench. The design allows for tightening of the gland nut in case of leakage past the packings. These valves are used for corrosive gases because of the ability of the operating mechanism to withstand higher torques to overcome any build-up of salts or contaminants in the seating area. These valves are generally used up to valve test pressure of 50 bar & not preferred for high purity applications because of particulate generation from valve seat & packing wear.

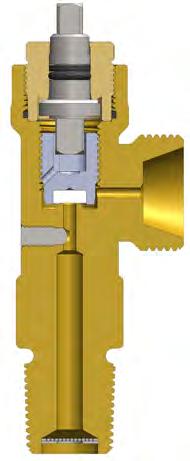

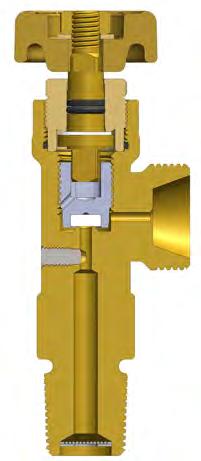

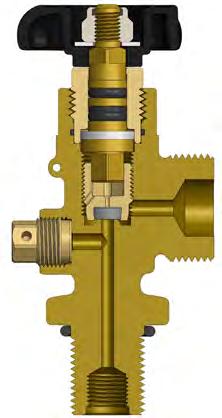

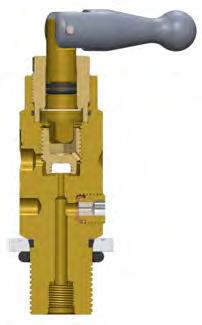

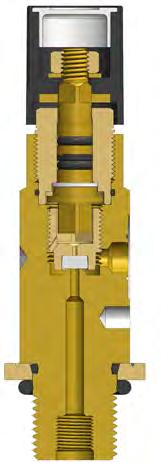

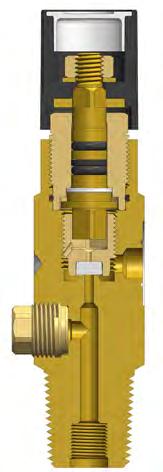

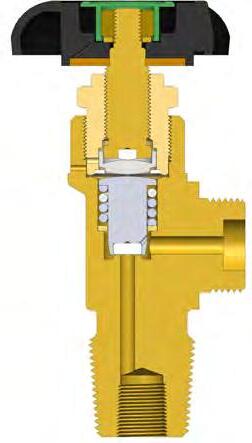

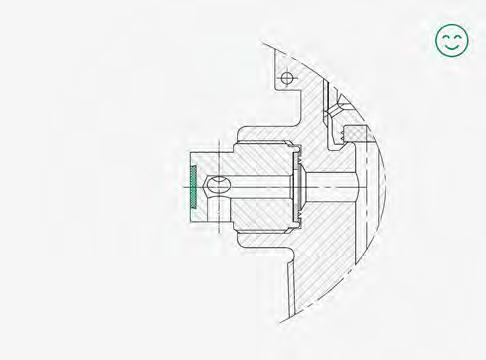

(Two-piece

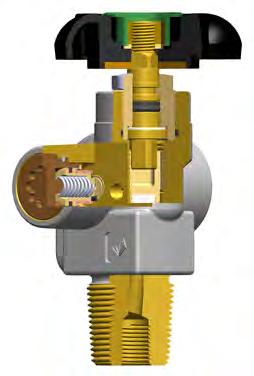

These valves, available in brass body, have a non-rising upper spindle & threaded lower spindle. It uses O-ring/s to create a seal around the upper spindle. These valves are easier to operate than packed valves due to absence of packing load on the upper spindle & hence used for a wide range of pressure & non-corrosive gas applications where low torque operation is desired. The top spindle is designed to fail first, allowing valve maintenance & package content recovery in the event of a failure, even when the cylinder is full. These valves come in key, toggle, handwheel & handle operation.

Key Operation Handwheel Operation

a) Key Operation

The upper spindle is usually manufactured from Stainless steel as the valves are expected to withstand high torques in the field.

b) Handwheel Operation

The upper spindle is fitted to a handwheel to operate the valve by hand. This restricts imparting of high torques by the user to operate the valve, preventing damage to the operating mechanism & facilitating high cycle life.

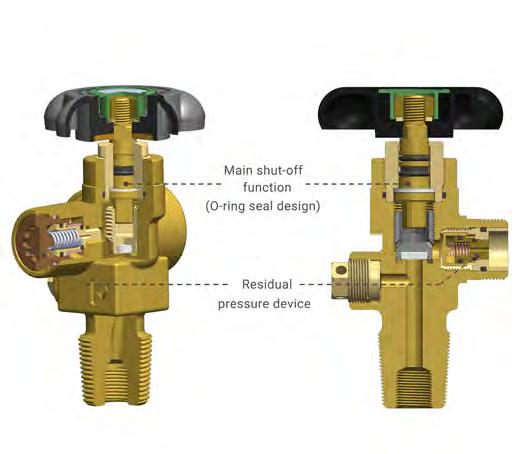

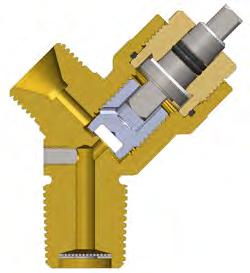

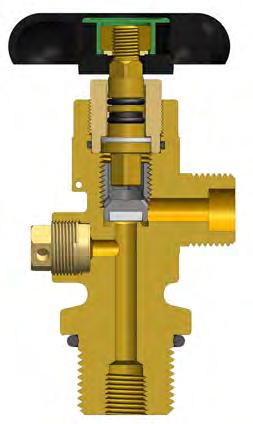

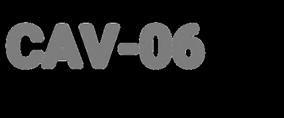

These are handwheel operated O-ring seal valves fitted with an offline or inline Residual Pressure Device (RPD). The RPD has a built in Non-Return Valve (NRV) function to prevent backflow of downstream contents preventing contamination risks as a result of positive pressure always present in the cylinder. RPV technology provides improved safety of the cylinder & ensures purity of gas contents eliminating the need to purge cylinder each time it comes back for filling. The user needs a filling connector consisting of a projected “Pin” during filling & evacuation to neutralize the NRV function.

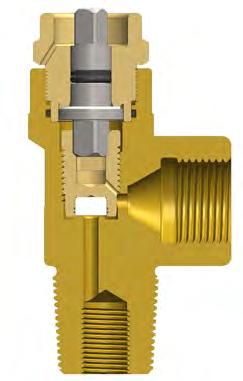

Inline RPV

The RPD is contained within the outlet & therefore is mainly used for external threaded outlet requiring sealing on the face. Due to limitation of the volume within which the inline RPD have to be accommodated, they have greater flow limitation than the offline version.

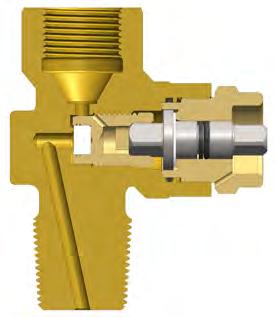

Offline RPV

The outlet is offset with respect to the inlet plane & the RPD is backside of the outlet. Offline valves can be designed for any outlet connection but are mainly used for outlet with internal threads & for external threaded outlet requiring sealing in the cone. They are less restrictive on the flow passage of the valve.

These valves, available in brass & stainless steel body, use diaphragms for gland sealing. The gland nut threads into the valve body & clamps the outer edges of the diaphragms against a ledge in the valve body to form a seal. The lower spindle assembly is non-threaded & encased in a spring which forces it away from the seat when the valve is opened. The upper spindle is threaded into the gland nut.

The replacement of elastomeric seals with metal diaphragms gives the valve superior leak integrity. The lower spindle is nonthreaded & non-lubricated making the design highly suitable for toxic, pyrophoric & high purity gas. The valve opening is restricted by the stroke of the diaphragm, limiting the flow through the valve. Due to high torque required to close the valve by overcoming cylinder pressure X area of the diaphragm plus the spring force, the use of these valves is limited to cylinder pressure up to 200 bar.

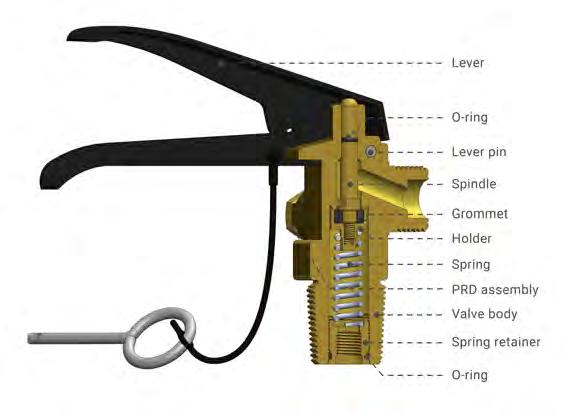

These are brass valves & use an O-ring to seal around the valve spindle. Pressure tends to keep the valve shut & as the cylinder pressure decreases, the total force available to sustain valve shut-off also decreases & seat closure is achieved by spring force. If there is a leak at the seat when the valve closes, there is no way to manually apply more force.

This design is used for squeeze grip carbon dioxide valves for firefighting application where quick release of gas content is desired.

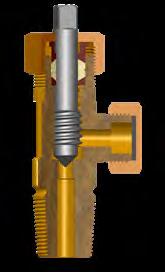

These valves, available in Brass, Al-Si Bronze, Carbon Steel & Stainless Steel body, combine compressed gland packing & O-ring technology to gland seal the valve. The lower spindle connects to the upper spindle via a slip joint. The lower spindle assembly seals against the seat without rotating, reducing wear & particle generation. The gland nut is usually secured by a lock nut having threads in the opposite direction to prevent accidental loosening of the gland nut.

Unlike the single spindle packed valve, the packing is smaller, better contained, spring loaded & backed by O-ring/s. This allows the mechanism to seal with handwheel up to 200 bar & eliminates the need to retighten gland nut making the design very suitable for toxic & corrosive gases.

Pressure & / or temperature activated device installed on cylinders to prevent the pressure in a cylinder from rising above a predetermined maximum, thereby preventing rupture of the cylinder in case the cylinder is exposed to fire, high temperature & / or overfilling.

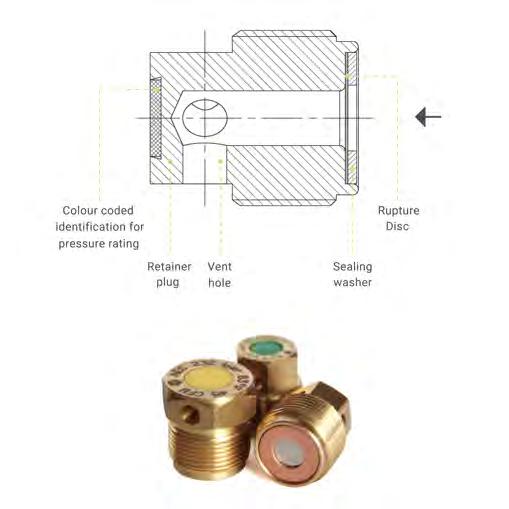

Pressure operated non-reclosing device designed to function by the bursting of a pressure containing disc. Once the disc ruptures, it completely releases the content of the cylinder. It is equipped with colour coded safety for easy identification of its set pressure.

For compressed gas UN cylinder, test pressure of the cylinder is 1.5 times the working pressure of cylinder. For liquefiable gas UN cylinder, test pressure & the corresponding filling ratio is given in P200 of ADR. Test pressure of a DOT cylinder is 5/3 times the working/service pressure.

Thermally operated non-reclosing device designed to function by the yielding of a fusible metal at a set temperature. These devices do not protect from overpressurization at temperatures below their melting point. In the event a cylinder is exposed to fire or excess heat, the fusible plug is designed to melt & release the cylinder contents preventing product within the cylinder from creating excessively high pressures, caused by high external temperatures & rupturing the cylinder.

These devices are limited for use up to 500 psig service pressure due to risk of extrusion of the alloy.

CG-2 plug yields at a temperature between 157°F to 170°F (69.4°C to 76.7°C). Nominal temperature 165 °F (74 °C).

CG-3 plug yields at a temperature between 208°F to 224°F (97.8°C to 106.7°C). Nominal temperature 212 °F (100 °C).

Combination of pressure & temperature operated non-reclosing device consisting of a rupture disc backed by fusible alloy on the atmospheric side of the disc. In case of fire or high temperature, the fusible metal yields & cylinder overpressure is relieved by the bursting of the rupture disc. Both the pressure & temperature requirements of the device must be satisfied for the device to actuate. This device will not protect a cylinder from overpressurization if the fusible alloy is not heated to its yield temperature. The fusible metal prevents premature rupture disc failure from momentary overpressurization & also protects the disc from external corrosion.

CG-4 plug yields at a temperature between 157°F to 170°F (69.4°C to 76.7°C). Nominal temperature 165 °F (74 °C).

CG-5 plug yields at a temperature between 208°F to 224°F (97.8°C to 106.7°C). Nominal temperature 212 °F (100 °C).

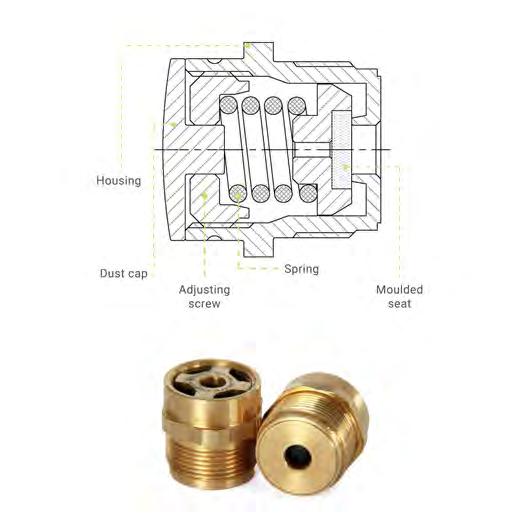

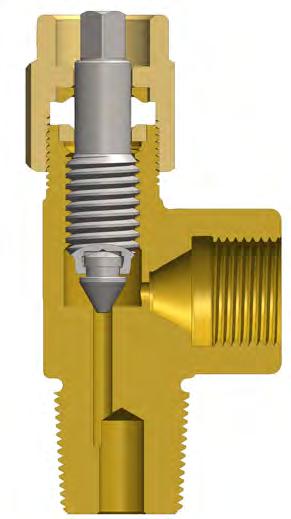

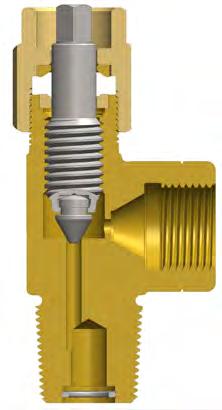

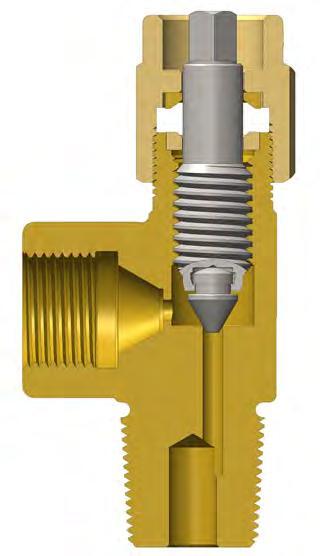

Spring-loaded device designed to relieve excessive pressure & reclose & reseat to prevent further flow of gas or fluid from the container after resealing pressure is achieved. When the cylinder pressure exceeds the pressure setting of the spring in the relief valve, the valve opens to discharge the cylinder contents. Once the cylinder pressure decreases to the Pressure Relief Valve’s (PRV’s) pressure setting, it reseats above the pressure in a normally charged cylinder at 130°F (54.4 °C) after venting sufficient gas to control the internal cylinder pressure.

The pressure setting of the pressure relief valve is normally between 75% & 100% of the minimum test pressure of the cylinder.

This device does not protect against rupture of the container when the application of heat weakens the container to the point where its rupture pressure is less than the operating pressure of the device. These devices are limited for use up to 500 psig charging pressure cylinders.

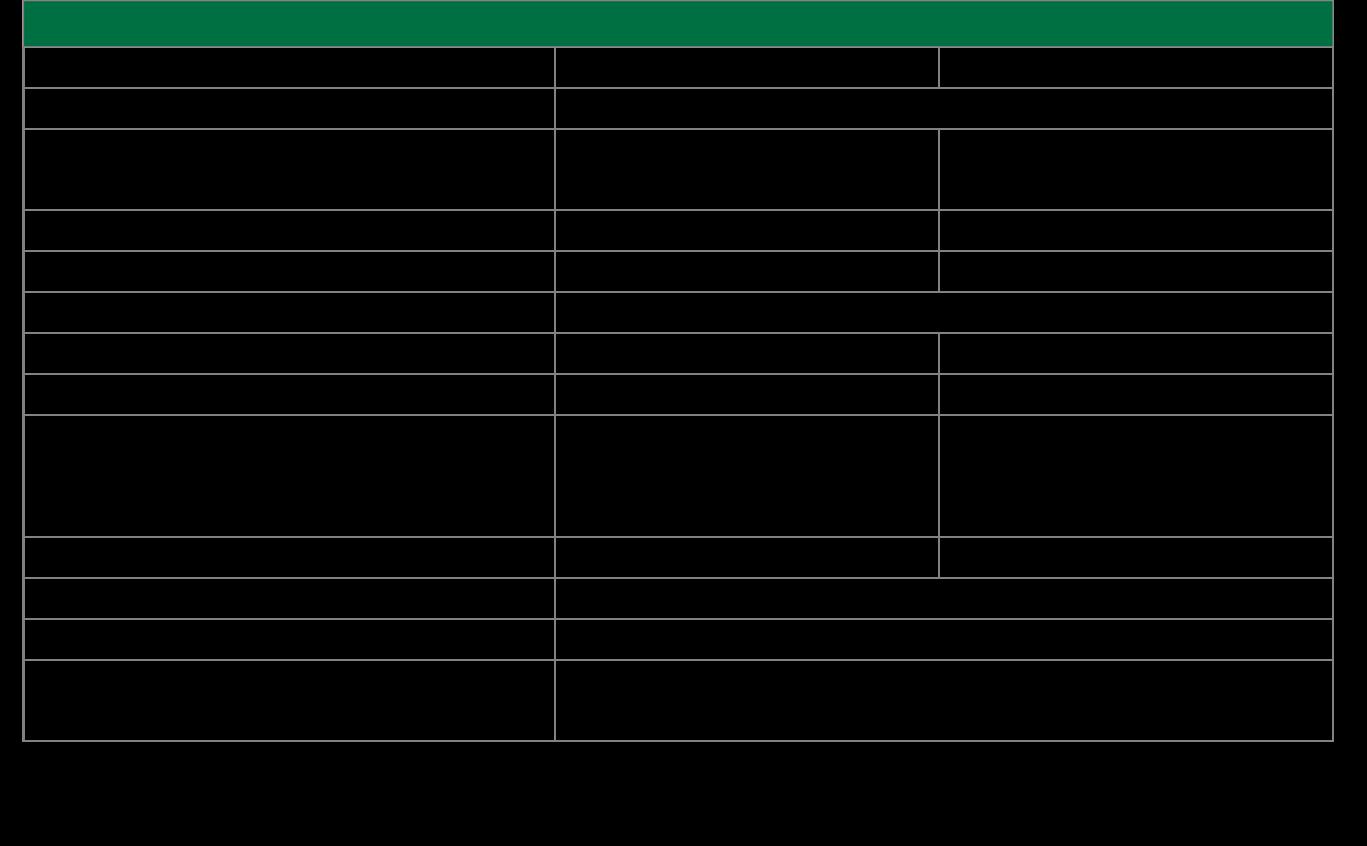

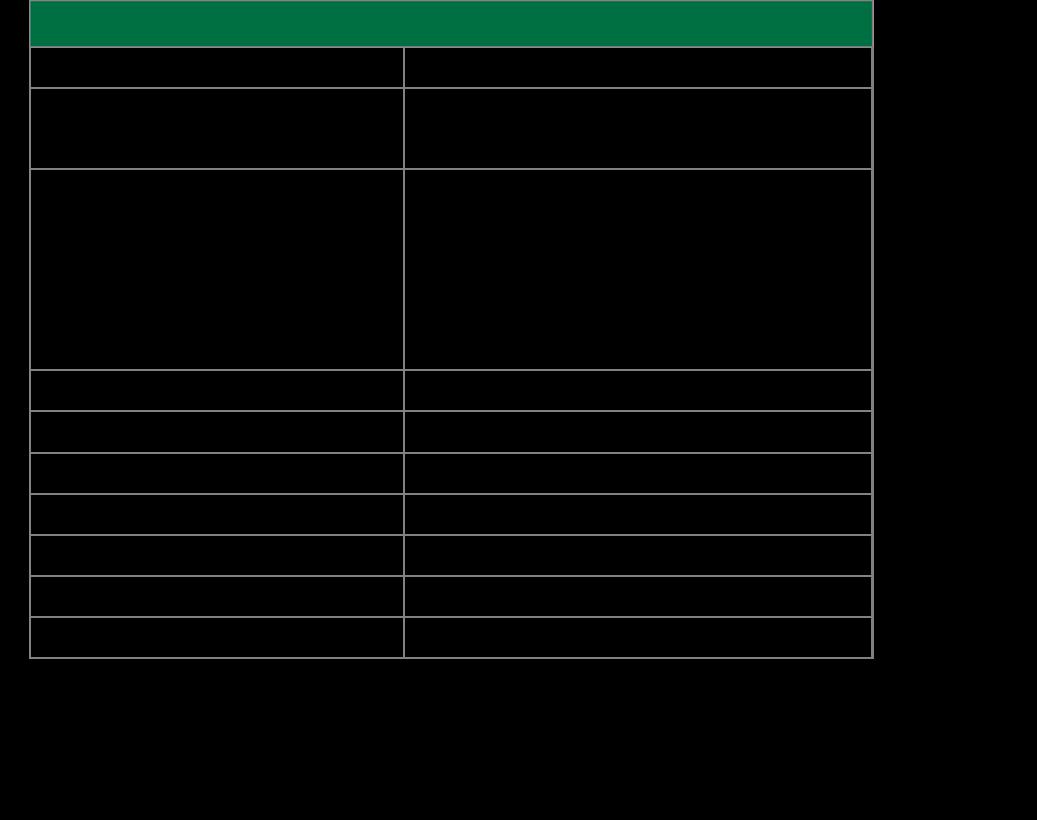

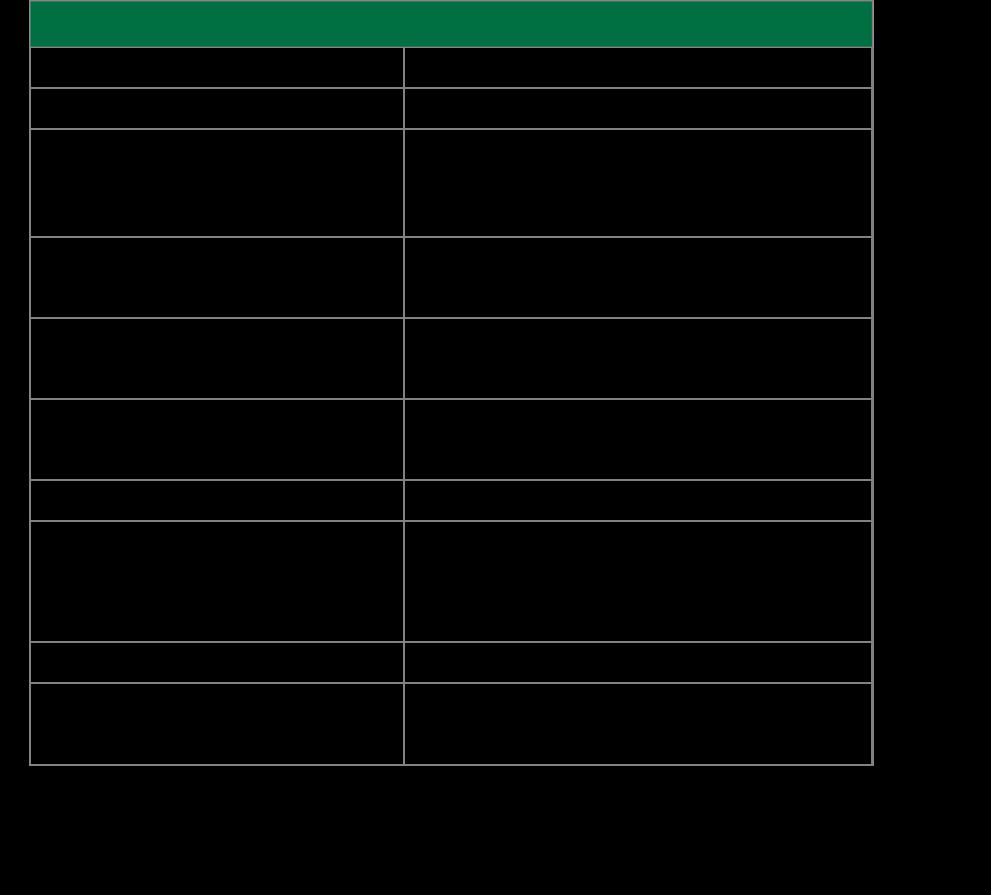

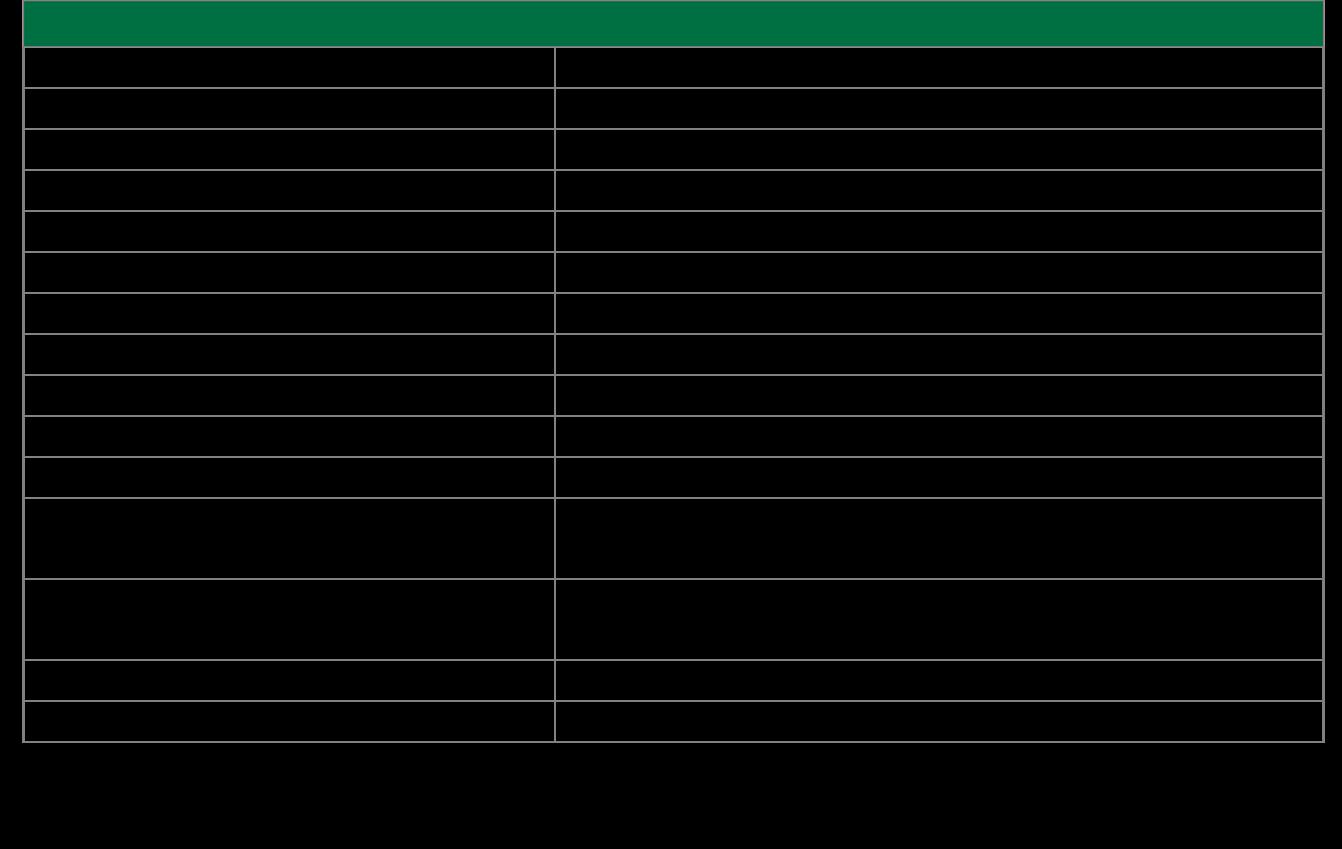

Pi marking

Compliance to European Transportable Pressure Equipment Directive, TPED 2010/35/EU

Identification of notified body

Four digit identification number for TPED notified body

FRONT VIEW

Standard compliance

Compliance to EN ISO 10297 standard. If ISO VB is marked on the valve, it indicates that the valve has been tested for Oxygen pressure surge test for use as a main valve

Inlet identification

Valve inlet connection which engages with the cylinder neck

Outlet identification

Valve outlet connection which engages with the filling / discharge connection

REAR VIEW

Manufacturing date

YYYY/MM - Year & month of manufacture of valve

Total package mass

Total package mass (combined mass of a gas cylinder, its valve, its permanent attachment(s) including valve guard & its maximum allowed gas content) for which the valve can be used without valve protection

Manufacturer’s identification

Markings shown are as per ISO 10297 & for illustration purpose.

Cylinder Valves Markings

Temperature range

Operating and storage temperature range if the valve has been design tested for extended temperature range

Country of origin

Country where the valve is manufactured

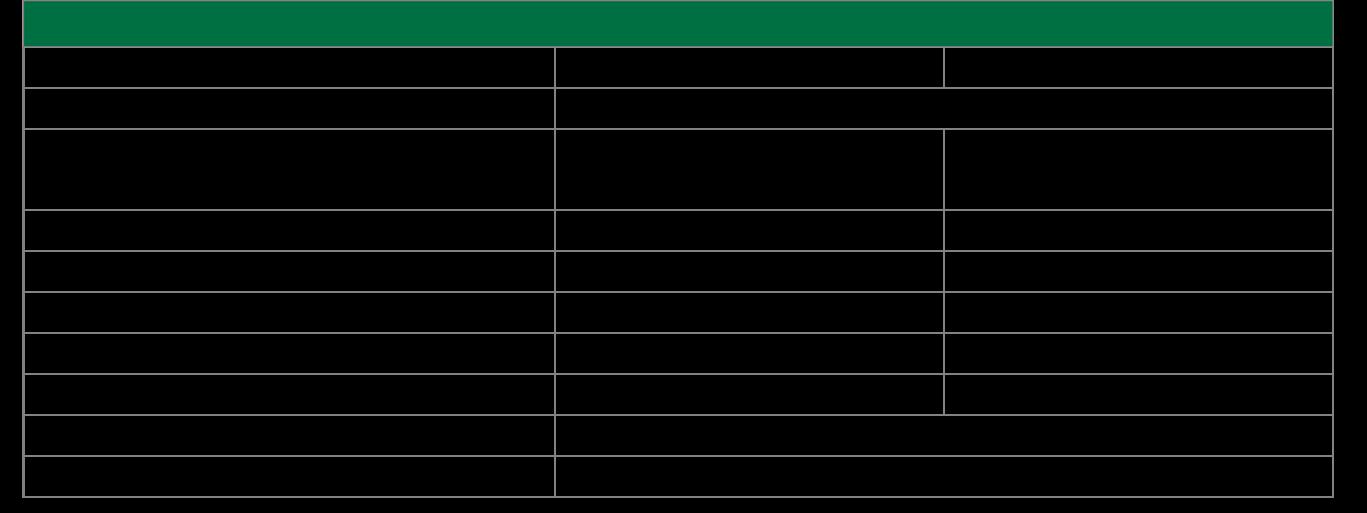

FRONT VIEW

Item code

Alpha numeric valve identification

Series

Model number of the valve with unique design features

Gas service

Gas service for which the valve is certified, compatible & intended to be used

Batch number

Traceability to the raw material used to manufacture valve body

REAR VIEW

Valve working pressure (WP)*

Settled pressure of a compressed gas at 15 °C in a full gas cylinder or cylinder bundle for which the valve is intended to be used

OR

Valve test pressure (TP)*

Minimum pressure of the valve used for endurance test, Oxygen pressure surge test & leak tightness test during type & production testing

* For compressed gas , test pressure = 1.2 x working pressure. For liquefied gas, test pressure shall be at least equal to the minimum test pressure corresponding to the applicable filling ratio.

Markings shown are as per ISO 10297 & for illustration purpose.

O-ring seal

TWN-12/O

SWN-12/45

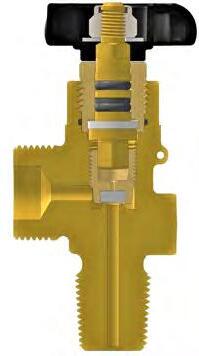

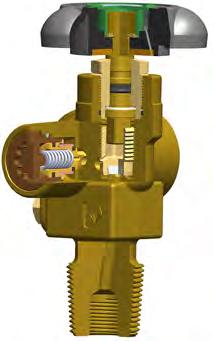

O-ring seal (Offline RPVs) BOWN-12/O & BOWN-12/N

O-ring seal

Handwheel

BSWN-12/D-30 & BAWN-12/D-30

SWN-12/D & TWN-12/D

Carbon Dioxide

SWN-12/C

O-ring seal (Offline RPVs) BOWN-12/C

MEDICAL GASES

Compression packed

Key / Toggle

O-ring seal Soft seated Two-piece

O-ring seal (Offline RPVs)

Handwheel

BSKN-12/O & BTKN-12/O

BPKN-12 & BPTN-12

SWN-12/O

TWN-12/O

SWN-12/45

BOWN-12/O

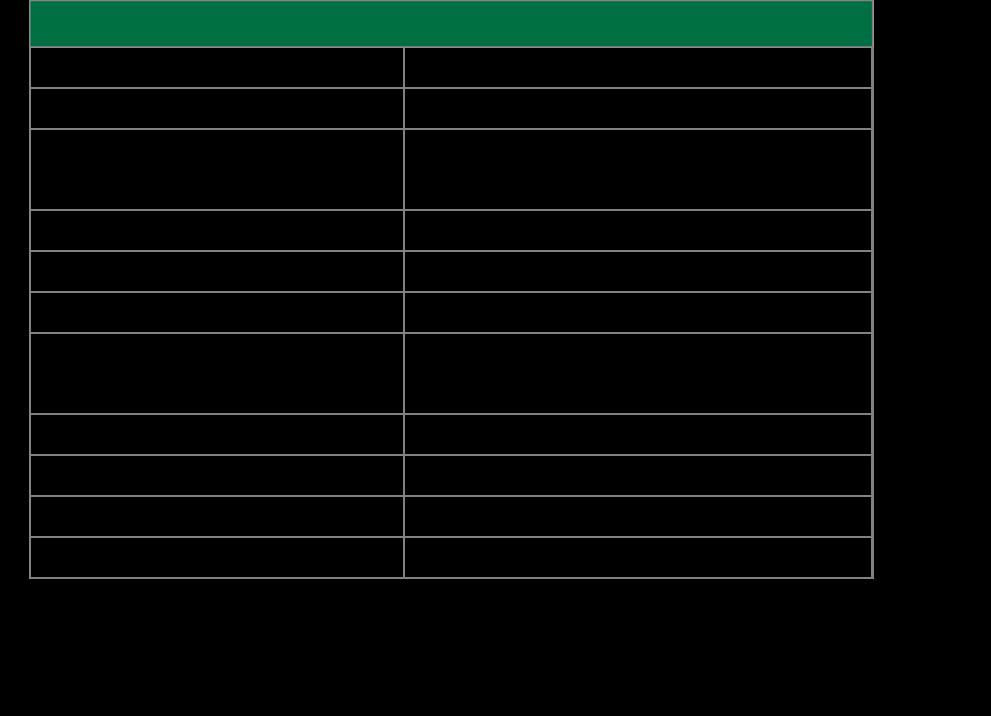

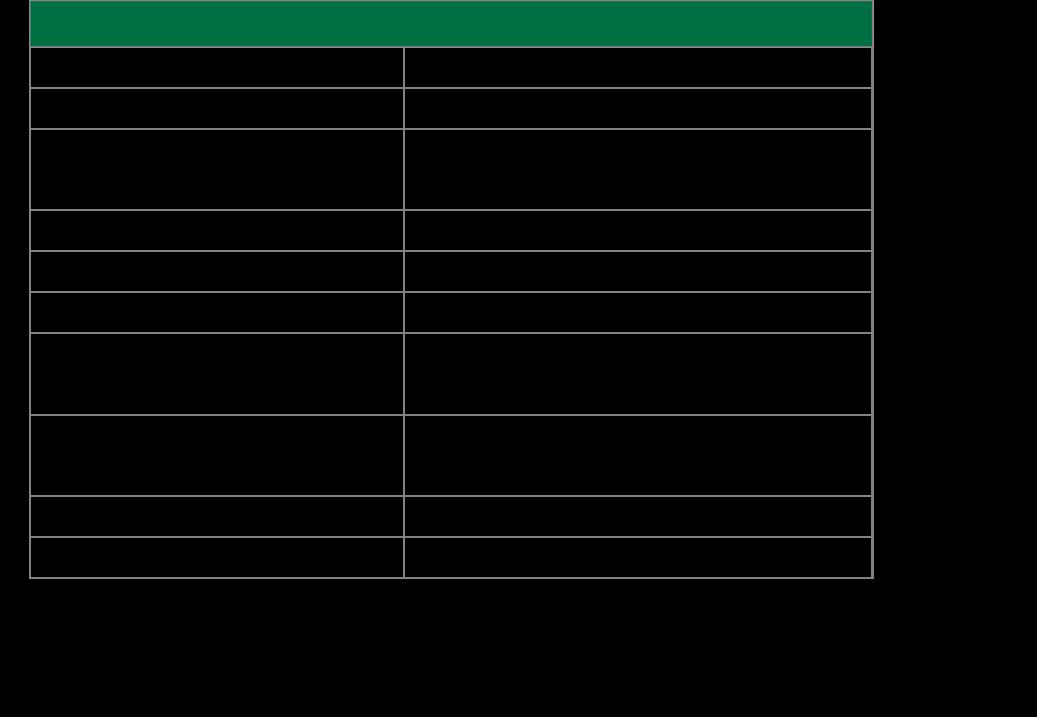

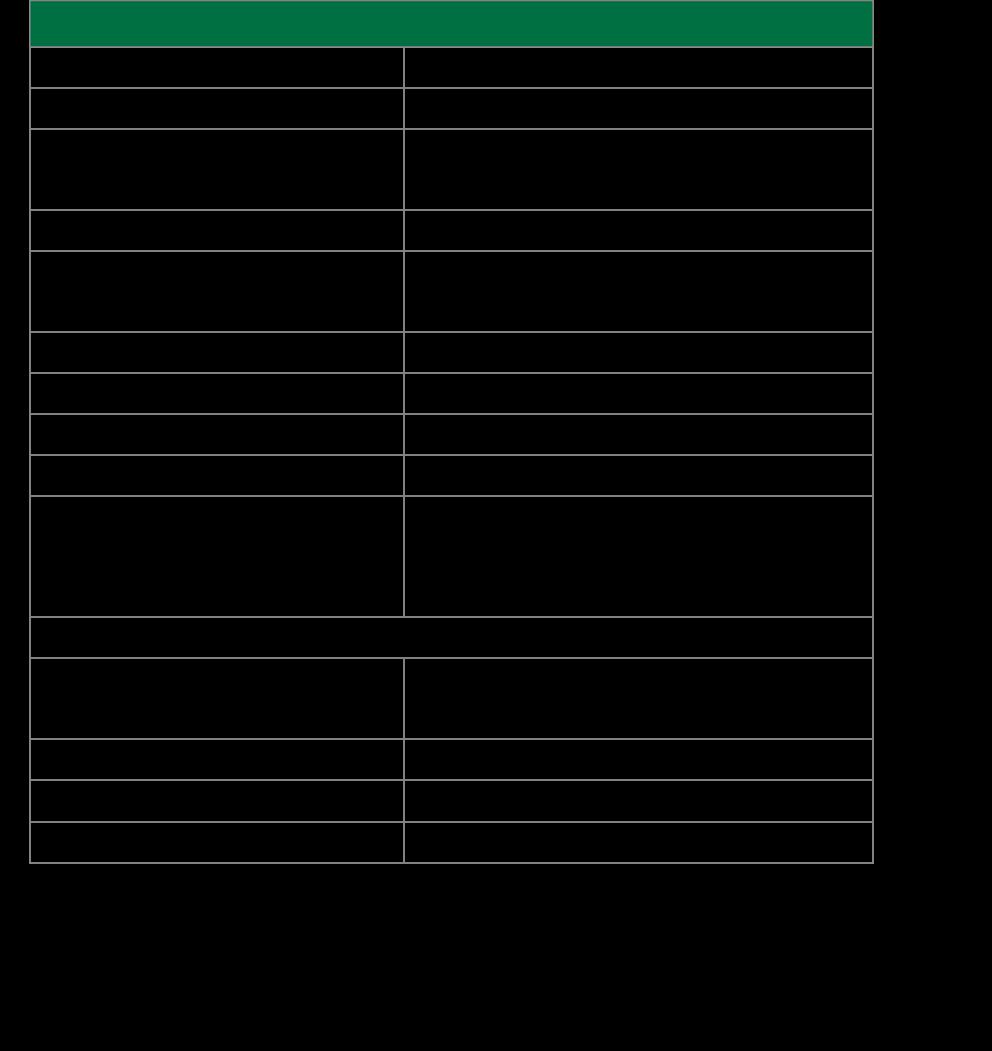

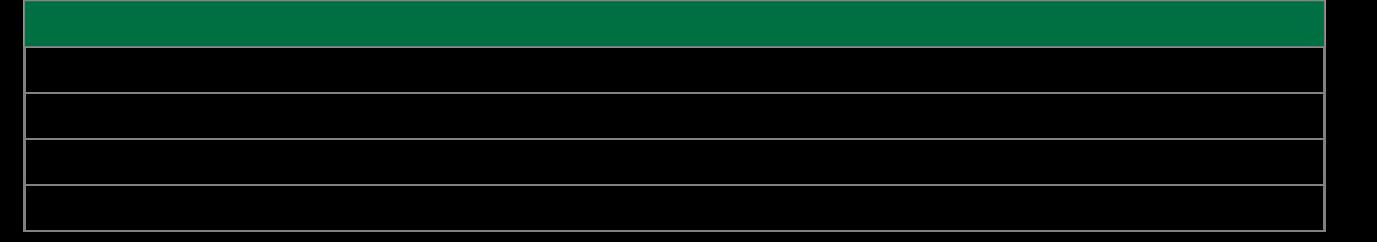

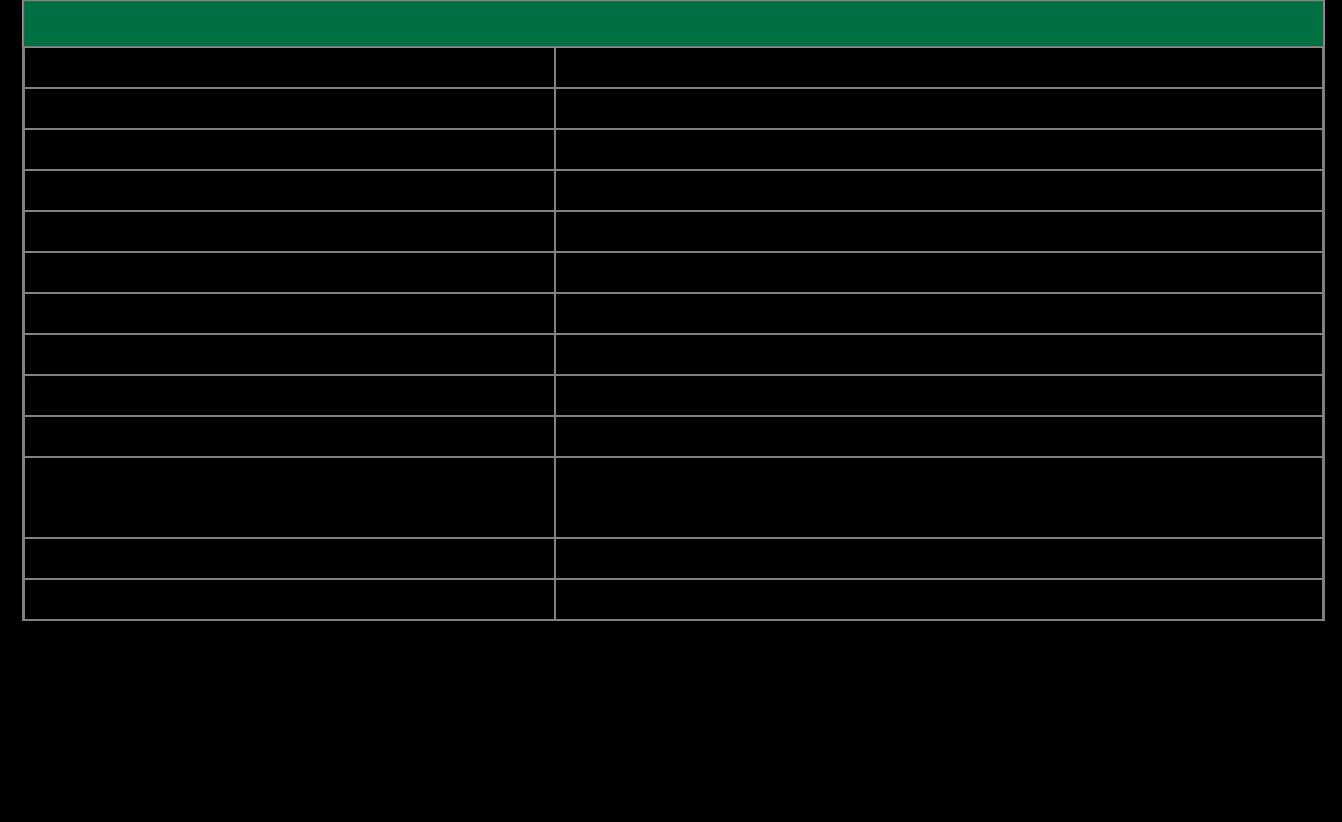

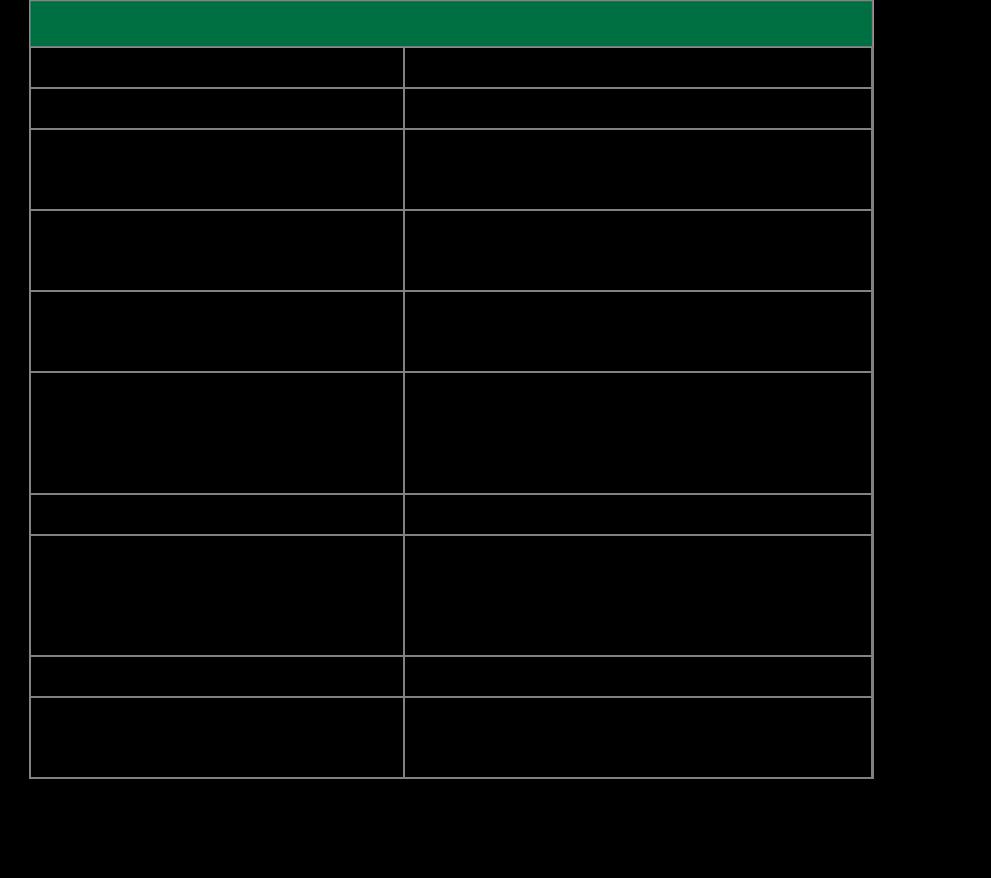

Select the suitable series based on design/application/materials/orientation/flow requirement/operating device/ pressure rating etc. for your application from ‘Series Selection Table’. Scan the QR code from the product page to download the detailed series catalogue, if applicable. Choose the appropriate three-digit valve series code given in the ‘Product Selection Guide’ of the detailed series catalogue for item code creation.

Select the appropriate valve body material from the options given in the ‘Product Selection Guide’. Choose chrome plating option if available and required. The choice of valve body material with or without plating is reflected in the next two digits of the item code.

Select inlet connection to match the cylinder neck thread. Distinguish between taper & parallel threads. Taper threads seal by a combination of thread sealant & metal deformation. Parallel thread seal is created by O-ring. Select the applicable three-digit code from the options. Customer specific inlet size / respective oversize are offered on request.

Choose dip tube thread if required on inlet connection. Dip tubes are used for quick withdrawal of the liquid content of the cylinder. Select the corresponding single-digit for the dip tube thread. Choose “X” if dip tube thread is not required. Customer specific dip tube thread can be offered on request.

Select the outlet connection required. Outlet connection changes based on the gas service / pressure rating and the country of use. Outlet connections are referred in the national / international outlet connection standard (e.g. CGA/BS/DIN/AFNOR/UNI/AS/IS/ISO). Select the applicable three-digit code for the outlet. Outlet connection not listed can be provided on request.

Select the applicable two-digit code from the available list of gases.

If PRD is required, select the applicable single digit for the PRD type taking into consideration the material option of the burst disc (if provided). Choose “X” if PRD is not required.

Select the PRD rating (temperature &/or pressure) from the two-digit code. Choose “XX” if PRD is not required. Pressure rating of the PRD depends upon the working pressure of compressed gas, filling ratio used for liquifiable gases and the test pressure of the cylinder.

Select the applicable single-digit code for the standard to which the cylinder valve compliance is required (e.g. ISO 10297/ CGA V-9/IS 3224).

Select the applicable single digit for the inspection requirement (e.g. In-house/third party).

Options:

Select the applicable single digit for the soft seat option. Ensure the soft seat is compatible with the gases for which the valves shall be used.

Select “WP” (Working pressure) or “TP” (Test pressure) to reflect in the item code. WP is the settled pressure of a compressed gas at 15 °C in a full gas cylinder.

Note - As per ISO 10297, the term WP is only applicable for compressed gases & does not apply to liquefied or dissolved gases.

For compressed gases, TP = 1.2 x WP

For liquefied gases, TP shall be at least equal to the minimum test pressure given in ADR.

Select the three-digit code to correspond to the pressure rating required for the valves.

Handwheel material & colour, filter, seal nut, gasket, dip tube, chain & keeper ring, EFV- are generally not unique to the item code & need to be specified separately.

Note:

Four-digit number following the item code is the drawing number & marked on the valve body representing the unique combination of selected technical parameters from 1-13

* Oversize of 18.16 & 31.75 are also available as per IS 3224

2. Equivalent to 3/4-14 NGS-2A as per AS 2473.2

NOTE The list contains commonly used Cylinder Valve Inlet Connections & is not exhaustive. Refer ISO/TR 11364, for additional connections used worldwide

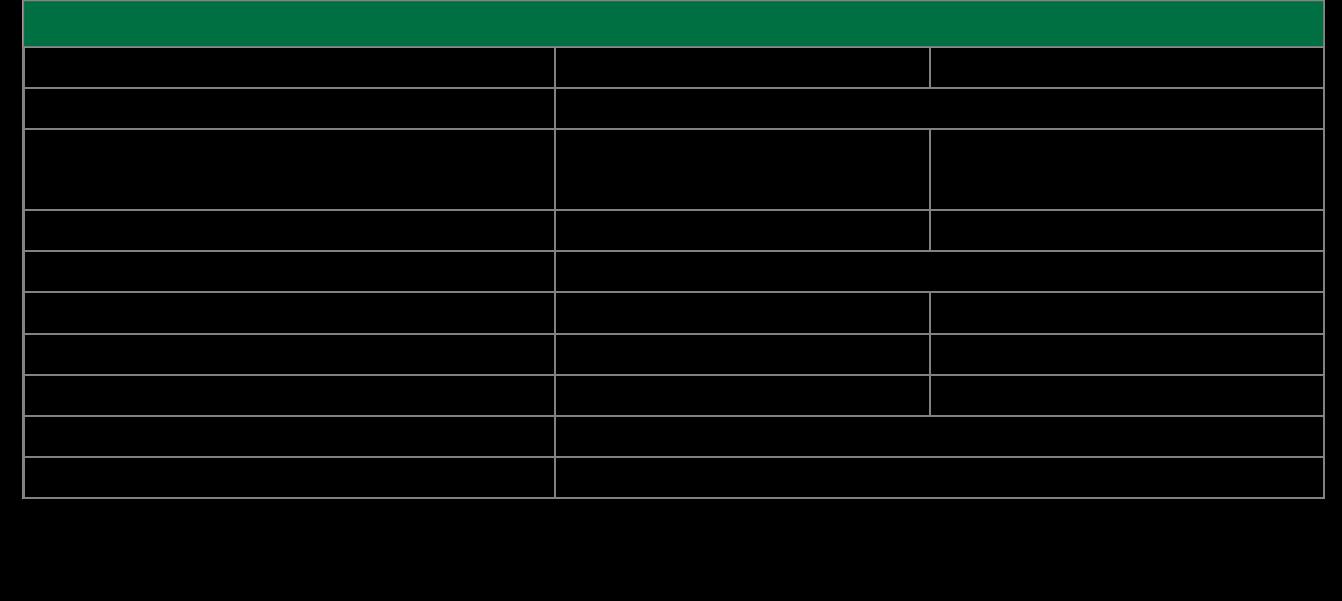

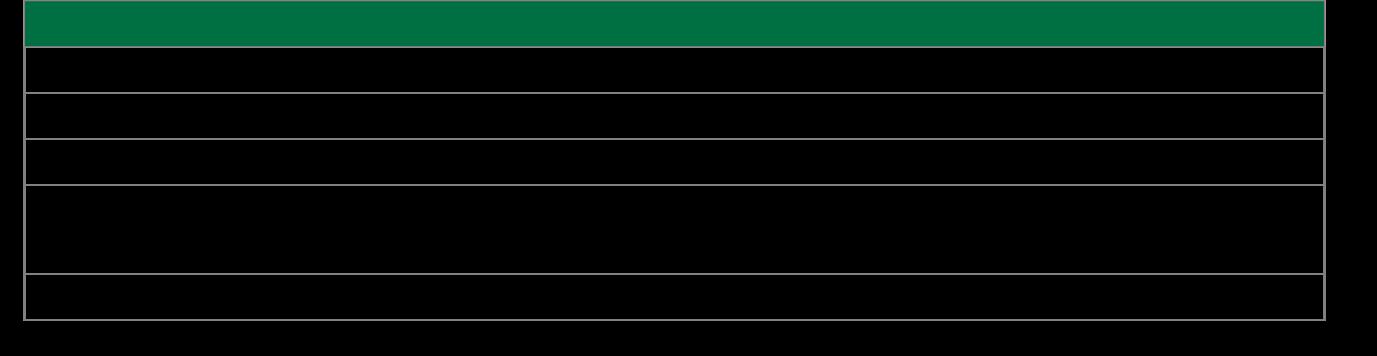

OXYGEN, HYDROGEN & OTHER GASES

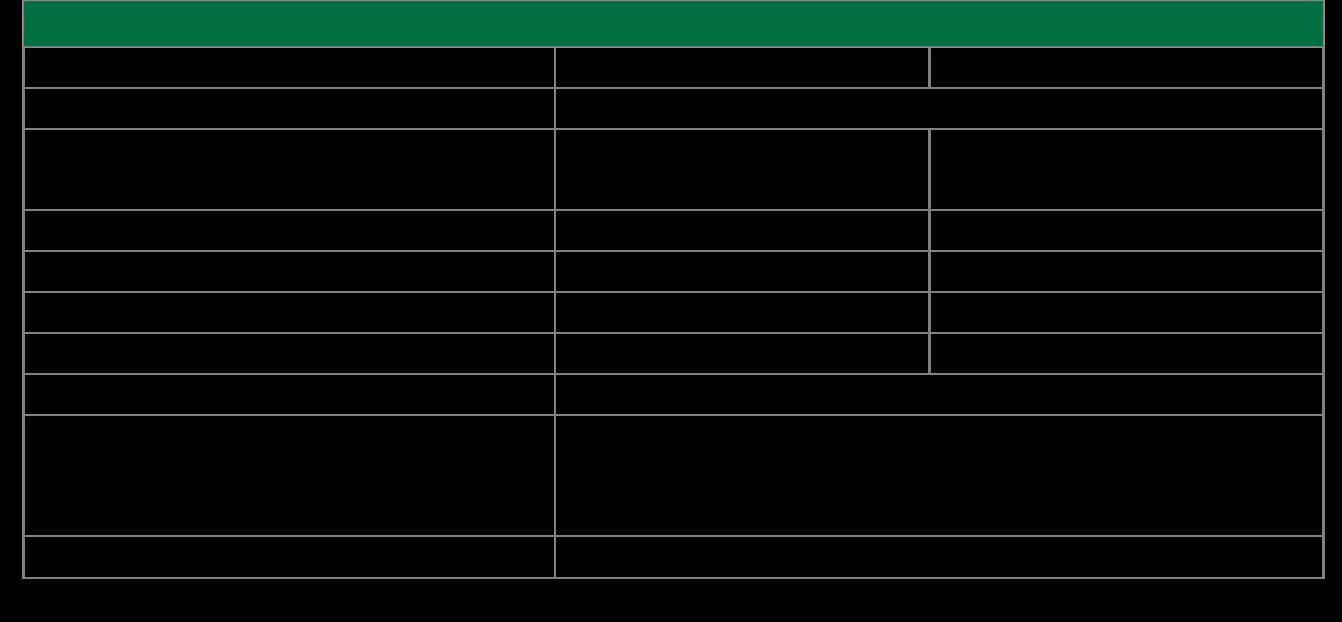

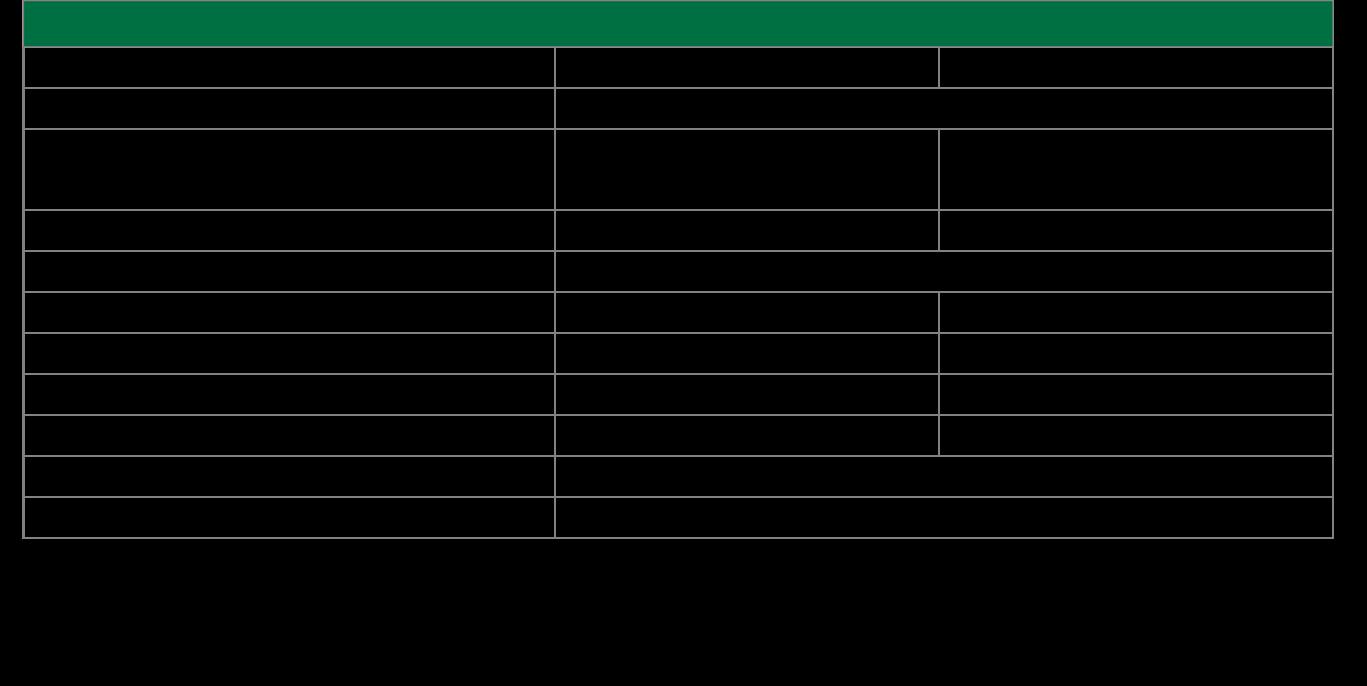

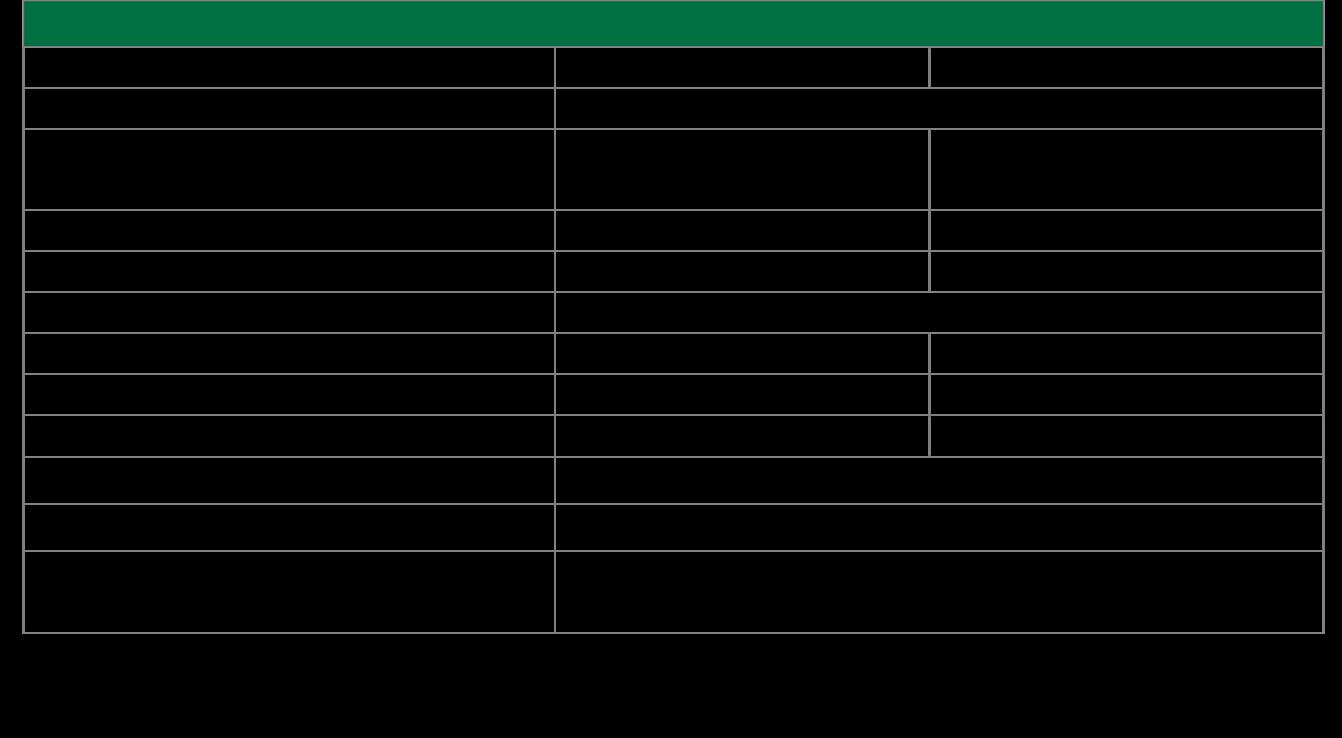

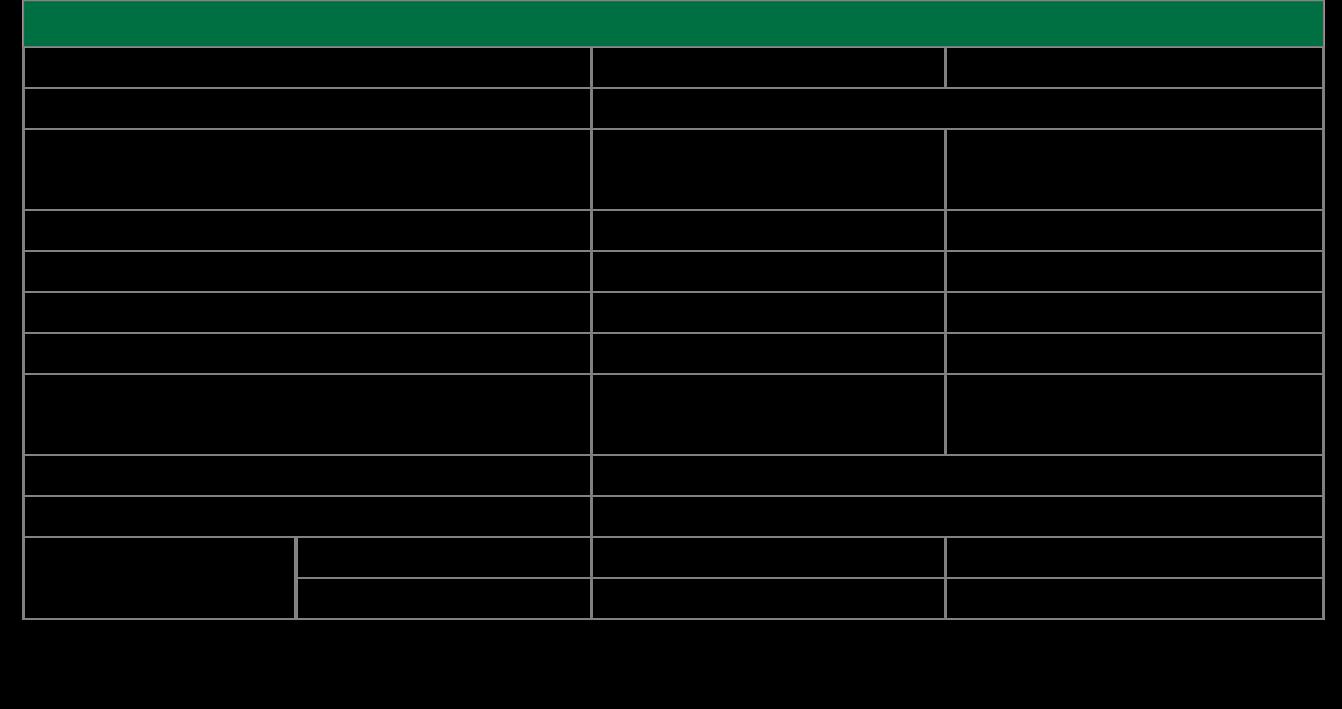

Series Name

BSKM-21/O

BSKN-12/O & BTKN-12/O

SWN-12/O & SWN-12/N

TWN-12/O

SWN-12/45

BOWN-12/O & BOWN-12/N

BSKM-21/O

KHO-10/D & KVO-10/D

BSKN-12/D & BAKN-12/D

BSWN-12/D-30 & BAWN-12/D-30

SWN-12/D & TWN-12/D CARBON

a - Higher torques may be required to operate the valve in service

(Maximum recommended 25 Nm)

b - Retightening may be required in service

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED & available with Pi ( ) mark

• Valves meet IS 3224:2021, approved by PESO & supplied under BIS inspection c for Indian market

c - Available only with 7.1mm spindle square valves

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED & available with Pi ( ) mark

• Valves meet IS 3224:2021, are approved by PESO & supplied under BIS inspection b for Indian market

• PRD complies with CGA S-1.1

b - Available only with 7.1 mm spindle square valve

SWN-12/O - Oxygen, Hydrogen & Other Gases

SWN-12/N - Inerts & Argon + CO2 Gas Mixtures

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED, available with Pi ( ) mark & UK TPE, available with Rho ( ) mark

• PRD complies with CGA S-1.1

For features, benefits & ordering information, refer detailed catalogue

SWN-12/N

shown with taper inlet & PRD)

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED, available with Pi ( ) mark & UK TPE, available with Rho ( ) mark

Valve with taper inlet

Valve with parallel inlet (shown with PRD)

b - For parallel inlet connection only

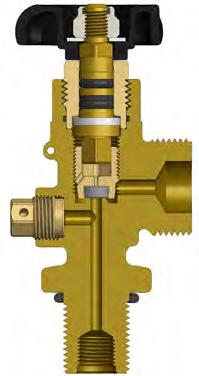

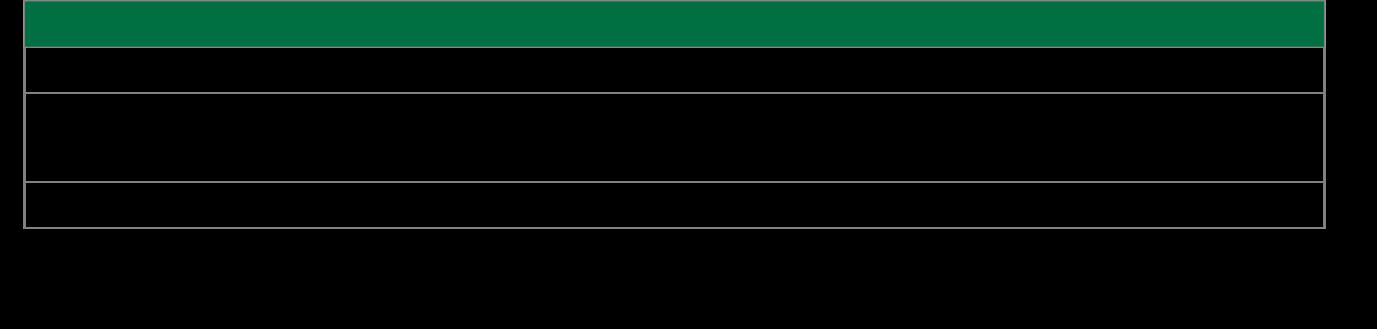

Compliance & Certification

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED & available with Pi ( )mark

• PRD complies with CGA S-1.1

BOWN-12/O - Oxygen, Hydrogen & Other Gases

BOWN-12/N - Inerts & Argon + CO2 Gas Mixtures

RPV Filling Adapters

Free cutting brass

BOWN-12/N SS 303

Seat insert PA 66

O-rings, Back-Up Ring & Quad ring EPDM

Housing Dezincification resistant brass

RPD O-rings PUR

Thrust washer PEEK

Handwheel Aluminium (CED coated) / Glass filled PA with brass insert

Spring Copper beryllium

Burst disc Nickel / Copper

Burst disc sealing washer Copper

Inlet O-ring b EPDM

b - For parallel inlet connection only

Compliance & Certification

• Valves meet EN ISO 10297:2017, ISO 15996:2017 & CGA V-9:2019

• Valves are certified to European TPED, available with Pi ( ) mark & UK TPE, available with Rho ( ) mark

• Valves are approved by PESO & supplied under Lloyd’s inspection for Indian market

• PRD complies with CGA S-1.1

• Available with CGA XXXR outlet connection as per CGA V-1

For features, benefits & ordering information, refer detailed catalogue

a - Optional

b - Higher torques may be required to operate the valve in service

(Maximum recommended 25 Nm)

c - Retightening may be required in service

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED & available with Pi ( ) mark

• Valves meet IS 3224:2021, approved by PESO & supplied under BIS inspection d for Indian market

• Fusible plug complies with CGA S-1.1

d - Available only with 7.1 mm spindle square valves

* Optional

KHO-10/D Side outlet valve shown with fusible plug

KVO-10/D Top outlet valve

– Integrated fusible alloy/plug

– Integrated fusible alloy

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves without fusible plug are certified to European TPED & available with Pi ( ) mark

• Fusible plug complies with CGA S-1.1

BSKN-12/D – for ‘B’ cylinder

* Valves for manifold application shall be supplied without fuse metal

– for ‘MC’ cylinder

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves without fuse metal are certified to European TPED & available with Pi ( ) mark

• Fuse metal complies with CGA S-1.1

For features, benefits & ordering information, refer detailed catalogue

Acetylene Valves with integrated fuse metal for “B” & “MC” Style Cylinders

- for ‘B’ cylinder

- for ‘MC’ cylinder

* Valves for manifold application shall be supplied with Red handwheel & without fuse metal

mm Zinc base alloy (Powder coated)

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves without fuse metal are certified to European TPED & available with Pi ( ) mark

• Fuse metal complies with CGA S-1.1

SWN-12/D

Side outlet valve shown with integrated fuse metal

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

Valves are certified to European TPED, available with Pi ( ) mark & UK TPE, available with Rho ( ) mark

• Fuse metal complies with CGA S-1.1

TWN-12/D Top outlet valve

Compliance & Certification

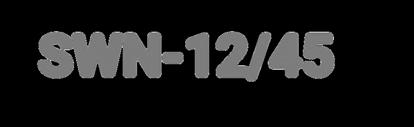

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED & available with Pi ( )mark

• PRD complies with CGA S-1.1

For features, benefits & ordering information, refer detailed catalogue

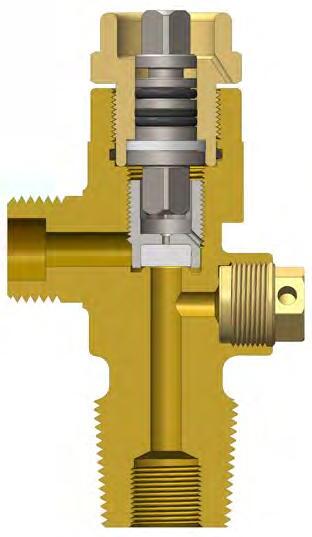

SWN-12/45

Valve with taper inlet

Valve with parallel inlet

Compliance & Certification

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED & available with Pi ( ) mark

• PRD complies with CGA S-1.1

* For parallel inlet connection only

Thrust washer PA 66

Handwheel

Compliance & Certification

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED & available with Pi ( ) mark

• PRD complies with CGA S-1.1

Aluminium (CED coated) / Glass filled PA with brass insert

Burst disc Nickel

Burst disc sealing washer Copper

Inlet O-ring * EPDM

* For parallel inlet connection only

• Valves meet EN ISO 10297:2017, ISO 15996:2017 & CGA V-9:2019

• Valves are certified to European TPED & available with Pi ( ) mark

• Valves are approved by PESO and supplied under Lloyd’s inspection for Indian market

• PRD complies with CGA S-1.1

• Available with CGA 320R outlet connection as per CGA V-1

For features, benefits & ordering information, refer detailed catalogue

a - Higher torques may be required to operate the valve in service

(Maximum recommended 25 Nm)

b - Retightening may be required in service

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED & available with Pi ( ) mark

• Valves meet IS 3224:2021, approved by PESO & supplied under BIS inspection c for Indian market

c

- Available only in 7.1mm spindle square

For features, benefits & ordering information, refer detailed catalogue

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED & available with Pi ( ) mark

• Valves meet IS 3224:2021, are approved by PESO & supplied under BIS inspection b for Indian market

• PRD complies with CGA S-1.1

b- Available only in 7.1mm spindle square

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED & available with Pi ( ) mark

• PRD complies with CGA S-1.1

• MRI approved upto 3 tesla as per ASTM F2052-15 & stamped as per ASTM F2503-13

b

Material

Flange ring b &

plug

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED, available with Pi ( ) mark & UK TPE, available with Rho ( ) mark

• PRD complies with CGA S-1.1

For features, benefits & ordering information, refer detailed catalogue

Knob

mm Glass filled PA (V-0) moulded with brass insert

Burst disc Nickel

Burst disc sealing washer Copper

b - For 3/4-16 UNF parallel inlet connection

c - For parallel inlet connection

O-rings & Back-Up Ring

Handwheel Aluminium (CED coated) / Glass filled PA with brass insert

Burst disc Nickel

Burst disc sealing

washer Copper

Inlet O-ring b

Compliance & Certification

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED, available with Pi ( ) mark & UK TPE, available with Rho ( ) mark

• PRD complies with CGA S-1.1

/ PTFE

b - For parallel inlet connection only

Handwheel Aluminium (CED coated) / Glass filled PA with brass insert

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED, available with Pi ( ) mark & UK TPE, available with Rho ( ) mark

• PRD complies with CGA S-1.1 For features, benefits & ordering information,

Valve with parallel inlet (shown

b - For parallel inlet connection only

Compliance & Certification

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED & available with Pi ( )mark

• PRD complies with CGA S-1.1

RPV

b - For parallel inlet connection only

Compliance & Certification

• Valves meet EN ISO 10297:2017, ISO 15996:2017 & CGA V-9:2019

• Valves are certified to European TPED, available with Pi ( ) mark & UK TPE, available with Rho ( ) mark

• Valves are approved by PESO & supplied under Lloyd’s inspection for Indian market

• PRD complies with CGA S-1.1

• Available with CGA XXXR outlet connection as per CGA V-1

For features, benefits & ordering information, refer detailed catalogue

a – Applicable for cylinder valve only

b - Higher torques may be required to operate the valve in service

recommended 25 ft.lb)

c - Retightening may be required in service

Compliance & Certification

• Valves meet performance requirements of Pamphlet 17 of the Chlorine Institute (CI)

• Valves meet CGA V-9:2019

• Fusible plug complies with CGA S-1.1

• Cylinder valve compatible with CI Emergency Kit A

For features, benefits & accessories, refer detailed catalogue

Ton Container Valve (5/16” orifice)

Material

of Construction

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED & available with Pi ( ) mark

Material of Construction

Part Material

Valve body Forged AlSi Bronze / Forged HT brass

Gland nut, Lock nut & Outlet cap a Free cutting brass

Upper spindle & Packing gland SS 303

Lower spindle & Body seat insert Monel metal

Seat insert, Tip blank & Gasket a PVDF

O-rings FKM

Packing X 4 PTFE

Packing collar Al-Si Bronze

Belleville spring X 3 EN 42

Handwheel Zinc base alloy (Powder coated)

a - Optional

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED & available with Pi ( ) mark

• Valves are approved by PESO & supplied under Lloyd’s inspection for Indian market

Material

Valve body Forged SS 316L (Electropolished) Lock nut & Packing

Upper spindle, Gland nut, Packing gland & Outlet cap* SS 303

Lower spindle Monel metal

Seat insert PCTFE

Tip blank & Gasket* PVDF

Packing X 2 PTFE

O-rings FKM

Belleville spring X 3 EN 42

Handwheel Zinc base alloy (Powder coated)

Chain & keeper ring* Stainless steel

* Optional

Valve with parallel inlet (shown with PRD)

Compliance & Certification

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED, available with Pi ( )mark

• PRD complies with CGA S-1.1

Valve with taper inlet

Seat insert PA 66 / PCTFE

Diaphragm X 5

301

302 Handwheel

(CED coated) / Glass filled PA with brass insert

Retainer plug Free cutting brass

Burst disc Nickel / Copper

Burst disc sealing washer Copper

Inlet O-Ring b PTFE / NBR

b - For parallel inlet only

Valve with parallel inlet (shown with PRD)

Valve with taper inlet (shown with chain & keeper ring)

Compliance & Certification

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED & available with Pi ( )mark

• PRD complies with CGA S-1.1

a - Higher torques may be required to operate the valve in service

recommended 25 ft.lb)

b - Retightening may be required in service

Compliance & Certification

• Valves meet CGA V-9:2019

Material of Construction

Part Material

Valve body Forged Low carbon steel (Phosphated)

Upper & Lower spindle, Packing gland & Packing collar SS 303

Gland nut, Lock nut & Outlet cap* Carbon steel

Seat insert PCTFE

Packing X 4 PTFE

O-rings EPDM

Belleville spring X 2 EN 42

Handwheel Aluminium (CED coated)

Gasket* PA 6

* Optional

Valve shown with chain & keeper ring

Material of Construction

Part Material

Valve body Forged SS 303 (Electropolished)

Lock nut, Packing collar, Upper spindle, Lower spindle, Gland nut, Packing gland & Outlet cap*

Compliance & Certification

• Valves meet EN ISO 10297:2017

• Valves are certified to European TPED & available with Pi ( ) mark

SS 303

Seat insert & Gasket* PCTFE

Tip blank PA 66

Packing X 2 PTFE

O-rings EPDM

Belleville spring X 3 EN 42

Handwheel Zinc base alloy (Powder coated)

Chain & keeper ring* Stainless steel

* Optional

a - Higher torques may be required to operate the valve in service (Maximum recommended 20 ft.lb)

b - Retightening may be required in service

Compliance & Certification

• Valves meet CGA V-9:2019

For features, benefits & accessories, refer detailed catalogue

tube a (1/2” X 3/8” X L b)

Spring SS 302

Sealing washer Copper

b – As per customer requirement Compliance

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves without PRV meet IS 3224:2002, approved by PESO & supplied under BIS inspection for Indian market

• PRV complies with CGA S-1.1

For features & benefits, refer detailed catalogue

Compliance & Certification

• Valves meet EN ISO 10297:2017 & CGA V-9:2019

• Valves are certified to European TPED & available with Pi ( ) mark

• PRV complies with CGA S-1.1

Valve with parallel

(shown with

Compliance & Certification

• Valves meet EN ISO 10297:2017, EN 144-1:2018 & EN 144-2:2018

• Valves are certified to European TPED & available with Pi ( ) mark

• EFV with anti-dust tube tested for 2000 pressure shocks by BAM

• Valves without PRD meet IS 7302:1974, approved by PESO & supplied under Lloyd’s inspection for Indian market

• PRD complies with CGA S-1.1

For features, benefits & ordering information, refer detailed catalogue

Valve with taper inlet (shown with Self-locking handwheel)

66

O-rings, Inlet O-ring & Back-Up ring

Spring SS 302 Handwheel (Blue / Black)

mm PA coated with FR Thermoplastic PU & brass insert Burst disc Nickel Burst disc sealing washer Copper

Compliance & Certification

• Valves meet EN ISO 10297:2017, EN 144-1:2018 & EN 144-2:2018

• Valves are certified to European TPED & available with Pi ( ) mark

• EFV with anti-dust tube tested for 2000 pressure shocks by BAM

• PRD complies with CGA S-1.1

For features, benefits & ordering information, refer detailed catalogue

b

Compliance & Certification

• Valves meet EN ISO 10297:2017, EN 144-1:2018 & EN 144-2:2018

• Valves are certified to European TPED & available with Pi ( ) mark

• EFV with anti-dust tube tested for 2000 pressure shocks by BAM

• PRD complies with CGA S-1.1

Compliance & Certification

• Valves meet EN ISO 10297:2017, EN 144-1:2018 & EN 144-2:2018

• Valves are certified to European TPED & available with Pi ( ) mark

• EFV with anti-dust tube tested for 2000 pressure shocks by BAM

• Valves meet IS 7302:1974, approved by PESO & supplied under Lloyd’s inspection for Indian market

• PRD complies with CGA S-1.1

For features, benefits & ordering information, refer detailed catalogue

BHN-12/N

Handle Operated Soft Seated Valves in O-ring

Master Shut-off Valves (Main Valves) for Bundles, Manifold & Panels

WHY: Aluminium handwheel is prone to atmospheric corrosion when exposed to natural elements. Corrosion leads to surface degradation involving pitting and flaking. Flaking is particularly risky in oxygen service and may act as fuel if it comes in contact with the gas.

HOW: CED (Cathodic Electro Deposition) coating is a process of painting using electrical current to deposit the paint on the surface of a part connected to the cathode. The paint primarily consists of epoxy resin with suitable pigment for colour.

WHAT:

WHY: Cylinder valves with identical outlet connections are commonly equipped with PRDs whose rating depends upon the service pressure corresponding to the cylinder test pressure. The different rated PRDs (e.g., 3000 psig, 3360 psig) are not easy to distinguish visually, leading to a mix up of cylinders.

HOW: Each pressure rating is assigned a unique colour code for easy identification of cylinders with different test pressures.

WHAT: A colour-coded cap corresponding to the pressure rating is fitted to the retainer nut of the PRD.

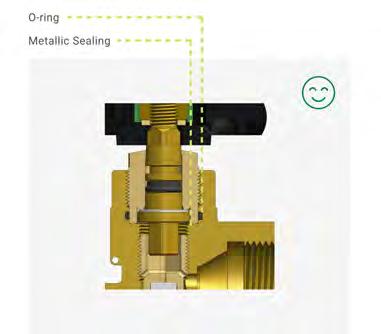

WHY: Some cylinder valve designs (e.g., O-ring seal) have a metal-tometal seal between the gland nut and the valve body to prevent external leakage past the threads. The sealing works till there is no external damage to the gland nut. Any impact on the gland nut may lead to leakage through the threads, which the users generally struggle to arrest.

HOW: Secondary protection is provided by an O-ring in case the metallic seal is compromised.

WHAT: Gland nut O-ring is introduced in the valve body below the gland nut threads to prevent leakage.

Metallic Sealing

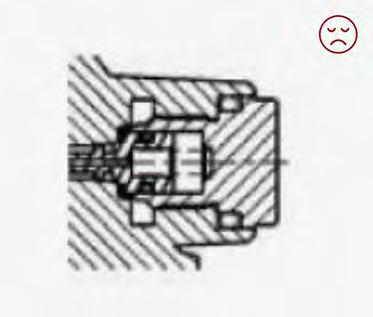

WHY: Parts of cylinder valves (e.g., retainer nut and gland nut) manufactured from Brass are susceptible to stress corrosion cracking or over-stressing, especially if installed in tensile stress.

Gland nut in tensile stress

O-ring Metallic Sealing

Retainer nut in tensile stress

HOW : Components are designed to be assembled in compressive stress and torque values optimized to limit stresses below the material strength. Refer EIGA Safety Info 21/19

WHAT:

Gland nut in compressive stress

Retainer nut in compressive stress

WHY: Plating on cylinder valves is done for aesthetics but carries the risk of flaking and particle generation, which is risky for oxidizing gases. Further, the plating and the substrate material may be incompatible with the gas content, and machining tolerances need to take plating thickness into account to ensure gauge compliance.

HOW: The inlet, outlet & the internal surface of the valve body & components are plugged during the plating process to ensure plating is only deposited on non-gas wetted areas to avoid any chance of plating contamination.

WHAT:

WHY: Stainless steel valves are often used in corrosive environments making the surface prone to degradation and discolouration. Therefore, surface treatment of the valve body is critical to ensure corrosion resistance and aesthetics.

HOW: Electropolishing removes free iron, embedded contaminants and oxide scale from the surface of the submerged valve body forging in an electrolyte and passing an electric current. Electropolishing also reduces roughness by levelling micro-peaks and valleys and removes free iron to enhance chrome/nickel content, making the surface corrosion-resistant.

WHAT:

Electropolished valve body

WHY: Brass soft seat retention skirts having high-stress concentrations are susceptible to stress corrosion cracking (SCC) [Refer EIGA Doc. 21/19]. SCC occurs when stresses, corrosive environment & time act together and is observable in gases like Carbon Dioxide and Acetylene in the presence of moisture.

WHY: Failures in Residual Pressure Valves (RPVs) can result from design and operational issues and stress corrosion cracking.

HOW : Fail-safe design ensures that in case of failures, the valves would still function at a basic level (i.e., open and close safely), and no unsafe gas release or ejection of parts occurs.

WHAT: The Residual Pressure Device (RPD) housing threads are placed after the O-ring groove, which is the critical area.

HOW: The lower spindle material is constructed from 300 series Stainless Steel to eliminate the possibility of SCC.

WHAT:

WHY: Some cylinder valve designs (e.g., diaphragm, packed etc.) have a threaded upper spindle engaging with the gland nut internal threads. These designs may witness loosening of the gland nut due to the applied torque on the operating mechanism.

HOW: The gland nut is secured by a lock nut having threads in opposite direction to the gland nut threads to avoid the risk of loosening in service.

WHAT:

WHY:

Design issues may cause pressure-activated PRDs to actuate prematurely. The resultant thrust can lead to the cylinder getting propelled dangerously, causing safety issues and product loss.

HOW: Internal plug capsule design uses a washer for secure sealing, reducing torsional stress on the burst disc and preventing the PRD from loosening, damage or premature failure. Cross-flow design diverts the escaping gas in a plane parallel to the cylinder’s longitudinal axis to balance the thrust forces and prevents cylinder tipping.

WHAT:

Sealing washer

Burst disc

Vent

Forging dies and Brass hot forgings are manufactured in-house to close tolerances. Induction heating of the slugs ensure better ductility, finer grains and superior resistance to Dezincification.

Brass valve body forgings are stress relieved to remove residual stresses to improve impact performance and resist stress corrosion cracking in the field.

Valve body and components are precision machined inhouse in latest technology CNC machines in single set up for unparalleled accuracy.

Valve body and parts are cleaned to a much higher level of cleanliness than required by industry standards.

Brass valve body is shot blasted and not acid pickled for surface treatment to avoid problems of stress corrosion cracking and, unsightly marking if exposed to rainwater.

Foam Trays used for packaging are eco-friendly reducing environmental footprint by cutting greenhouse gas emissions. The foam compacts to 10% of its original volume, is biostable and will not degrade to pollute air or ground water.

Abbreviation Full Form

ADR Agreement Concerning the International Carriage of Dangerous Goods by Road

Al-Si Bronze Aluminium Silicon Bronze

ASTM American Society for Testing & Materials

BAM Federal Institute for Materials Research & Testing

BIS Bureau of Indian Standards

BS British Standard

BSB British Standard Brass

BSP British Standard Pipe

CED Cathodic Electro Deposition

CGA Compressed Gas Association, Inc.

EFV Excess Flow Valve

EN European Standards

EPDM Ethylene Propylene Diene Rubber

European TPED European Transportable Pressure Equipment Directive

FKM Fluorocarbon Rubber

FR Flame Retardant

ft.lb Foot-Pound

HDPE High Density Polyethylene

HEX Hexagon

HT High Tensile in Inch

IS Indian Standard

ISO International Organisation for Standardization

kgf/cm2 Kilogram-Force Per Square

Centimetre

L Length

l Litre

LH Left Hand

LT Low Tensile mm Millimetre

MRI Magnetic Resonance Environment

NBR Nitrile Butadiene Rubber

NGT National Gas Taper

Nm Newton-Meter

NPT National Pipe Taper

Abbreviation Full Form

OPST Oxygen Pressure Surge Test

PA Polyamide

PCTFE Polychlorotrifluoroethylene

PEEK Polyetheretherketone

PESO Petroleum And Explosive Safety Organization

psig Pounds Per Square Inch Gauge

PTFE Polytetrafluoroethylene

PU Polyurethane

PUR Polyurethane Rubber

PVDF Polyvinylidenefluoride

RH Right Hand

SCBA Self-Contained Breathing Apparatus

SS Stainless Steel

TPI Thread Per Inch

UK TPE United Kingdom Transportable Pressure Equipment

UNF Unified National Fine

Standard Title

ISO 407 Small medical gas cylinders - Pin-index yoke-type valve connections

ISO 5145 Cylinder valve outlets for gases & gas mixtures - Selection & dimensioning

ISO 9001 Quality Managements Systems - Requirements

EN ISO 10297 Gas cylinders - Cylinder valves - Specification & type testing

IS ISO 11114-1

IS ISO 11114-2

Transportable gas cylinders - Compatibility of cylinder & valve materials with gas contentsPart 1: Metallic materials

Transportable gas cylinders - Compatibility of cylinder & valve materials with gas contentsPart 2: Non-metallic materials

EN ISO 11363-1 17E & 25E taper threads for connection of valves to gas cylinders - Part 1: Specification

ISO 12209 Gas cylinders - Outlet connections for gas cylinder valves for compressed breathable air

EN ISO 14246 Gas cylinders - Cylinder valves - Manufacturing tests & examination

EN ISO 15001

Anesthetic & respiratory equipment - Compatibility with oxygen

ISO 15245-1 Gas cylinders - Parallel threads for connection of valves to gas cylinders - Part 1: Specification

EN ISO 15996 Gas cylinders - Residual pressure valves - Specification & type testing of cylinder valves incorporating residual pressure devices

ISO 17025

IS 3224

IS 3745

IS 5903

IS 7302

IS 13497

General requirements for the competence of testing & calibration laboratories

Valve fittings for compressed gas cylinders excluding Liquefied Petroleum Gas (LPG) cylinder

Specification for yoke type valve connections for small medical gas cylinders

Recommendation for safety devices for gas cylinders

Valve fittings for Self Contained Breathing Apparatus (SCBA) & Self-Contained Underwater Breathing Apparatus (SCUBA) - Specification

Fusible plug for dissolved acetylene gas cylinder - Specification

CGA G-4.1 Cleaning equipment for oxygen service

CGA S-1.1 Pressure Relief Device standards - Part 1 - Cylinders for compressed gases

CGA V-1

CGA V-9

Compressed Gas Association standard for compressed gas cylinder valve outlet & inlet connection

Compressed Gas Association standard for compressed gas cylinder valve

EN 144-1 Respiratory protective devices - Gas cylinder valves - Thread connections for insert connector

EN 144-2

ASTM F2052

ASTM F2503

BS 341-1:1991

BS 341-3:2002

Respiratory protective devices - Gas cylinder valves - Outlet connections

Standard test method for measurement of magnetically induced displacement force on medical devices in the magnetic resonance environment

Standard practice for marking medical devices & other items for safety in the magnetic resonance environment

Transportable gas container valves - Specification for industrial valves for working pressure up to & including 300 bar

Transportable gas container valves - Valve outlet connection

ADR (Volume I & II) European agreement concerning the international carriage of dangerous goods by road

AFNOR NF E 29-650 Gas cylinders - Valve outlet connections

AS 2473-2

CI Pamphlet 17

DIN 477-1

JIS B 8246

2010/35/EU

UNI 11144

Valves for compressed gas cylinders - Part 2: Outlet connections (threaded) & stem (inlet) threads

Pamphlet 17 - Packaging plant safety & operational guidelines

Gas cylinder valves for cylinder test pressures up to 300 bar - Part 1: Valve inlet & outlet connections

Valves for high pressure gas cylinders

Transportable Pressure Equipment Directive (TPED)

Transportable gas cylinders - Cylinder valves for working pressure ≤ 250 Bar - Outlet, Inlet valve connections & fittings: Shapes & dimensions

( ‘Pi’ mark/TPED Directive + ‘Rho’ mark/TPE Directive) -

Cylinder valve designs are tested to relevant ISO standard/s by an ISO 17025 accredited test laboratory, resulting in Type approval certificate issued by the European/UK notified body.

The combination of type approval and periodic audits form the basis of the Authorization Certificate, which lists all the type approval certificates covered under the scope of TPED / TPE directives. Our In-house Inspection agency, authorized by the Notified body, is responsible for the surveillance of manufacture and initial inspection and test for all valves.

( PESO Approval)

The Petroleum and Explosives Safety Organization (PESO) is India’s statutory body for approving gas cylinder valves. Valves for the Indian market are approved by PESO and duly inspected by BIS or Lloyds Register as per Indian or International standards.

NABL ACCREDITED LABORATORY

ISO 17025

To Know more

Members since 2019

Members since 2008

Members since 2017

Members since 2004

Member since 1975

Member since 2019

Approved Supplier since 2020

1971

Commenced business to manufacture Chlorine Cylinder Valves

1975

Expanded portfolio by developing Cylinder Valves for Industrial Gases

1978

Commenced production of Brass Forgings as backward integration

1985

Established Tool Room to manufacture In-house Forging Dies

Y.K. Behani was awarded ‘Udyog Patra’ by the Vice President of India as recognition for being a self-made industrialist

Started using 300 bar 3-stage reciprocating compressors for testing of Cylinder Valves

2003

Second generation joined the business (Rohit Behani)

Received ISO 9001:1994 Certification from Lloyds Register

Introduced CNC Machines for machining of Cylinder Valve Body & Components

2005

Entered North American market with export of Chlorine valves

2006

Introduced DC Nut Runner Torque Tools for Assembly and Testing

2007

Received EN ISO 10297:2006 certification for three valve designs by BAM

2008

Awarded ‘Pi’ mark in compliance with European Directives (TPED)

Tekno Valves North America Incorporated

2010

Developed Residual Pressure Valves (RPV) as per EN ISO 15996:2007

Established state-of-the-art integrated manufacturing unit

Quality lab granted NABL certification as per ISO 17025

Recognized as ‘One star Export house’ from Government of India

Export footprint enlarged to 50+ countries

Started testing of Cylinder Valves using Differential Pressure Technology

Declared Essential Manufacturer for Medical Oxygen Cylinder Valves amidst COVID-19 pandemic

2023

Received ISO 45001:2018

Certification from DNV” Green Initiative - Solar Power Plant of 715 kW commissioned

Awarded ‘Rho’ mark in compliance with UK TPE