Service Repair Manual Models

325D

and 325D L Excavator

Previous Screen

Product: EXCAVATOR

Model: 325D L EXCAVATOR SCR

Configuration: 325D & 325D L Excavators SCR00001-UP (MACHINE) POWERED BY C7 Engine

Disassembly and Assembly

C7

Engines for Caterpillar Built Machines

Media Number -RENR9218-13

Shutdown SIS

Publication Date -01/06/2014 Date Updated -04/06/2014

Rocker Shaft and Pushrod - Install

SMCS - 1102-012; 1208-012

Installation Procedure

Table 1

Required Tools

NOTICE

Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life.

i02303869

Tool Part Number Part Description Qty A 8T-2998 Lubricant 1

Illustration 1

1. Apply Tooling (A) to both ends of pushrods (6) .

g01153544

2. Lubricate pushrods (6) with clean engine oil. Install pushrods (6) and inlet valve bridges (5) .

3. Position rocker shaft (3). Install bolts (1) and bolts (2). Finger tighten bolts (1) and bolts (2). Tighten bolts (2) and bolts (1) to standard torque.

4. Apply Tooling (A) to each of the button faces of the rocker arms.

5. Adjust the valve lash of the rocker arm by turning rocker arm adjustment screws (4). Refer to Testing and Adjusting, "Engine Valve Lash - Inspect/Adjust".

End By: Install the valve mechanism cover. Refer to Disassembly and Assembly, "Valve Mechanism Cover - Remove and Install".

Copyright

Private Network For SIS Licensees. Wed Jun 3 15:41:31 UTC+0800 2020

1993 - 2020 Caterpillar Inc. All Rights Reserved.

Previous Screen

Product: EXCAVATOR

Model: 325D L EXCAVATOR SCR

Configuration: 325D & 325D L Excavators SCR00001-UP (MACHINE) POWERED BY C7 Engine

Disassembly and Assembly

C7

Engines for Caterpillar Built Machines

Media Number -RENR9218-13

Shutdown SIS

Publication Date -01/06/2014 Date Updated -04/06/2014

Cylinder Head - Remove

SMCS - 1100-011

Removal Procedure

Start By:

i02303932

A. Remove the valve mechanism cover base. Refer to Disassembly and Assembly, "Valve Mechanism Cover Base - Remove and Install".

B. Remove the rocker shaft and pushrods. Refer to Disassembly and Assembly, "Rocker Shaft And Pushrod - Remove".

C. Remove the unit injectors. Refer to Disassembly and Assembly, "Unit Injector - Remove".

D. Remove the fan drive mounting group. Refer to Disassembly and Assembly, "Fan Drive Mounting Group - Remove and Install".

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

NOTICE

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and mandates.

Illustration 1

g01153598

1. Disconnect harness assemblies (1), (2), (3), (4), and (5) .

Illustration 2

g01153599

Illustration 1

g01153598

1. Disconnect harness assemblies (1), (2), (3), (4), and (5) .

Illustration 2

g01153599

2. Disconnect hose assembly (6) and tube assembly (7) .

.

4. Attach a suitable lifting device to cylinder head (11). The weight of cylinder head (11) is approximately 175 kg (385 lb).

Illustration 3 g01153600

3. Disconnect tube assembly (8) and tube assembly (10) from turbocharger (9)

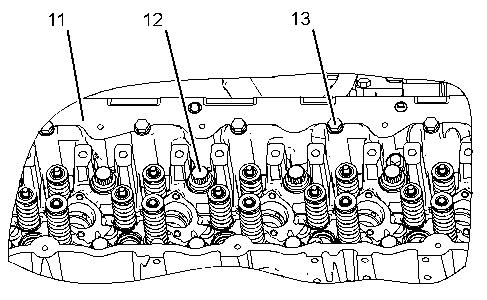

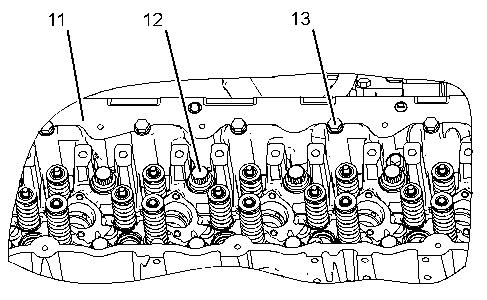

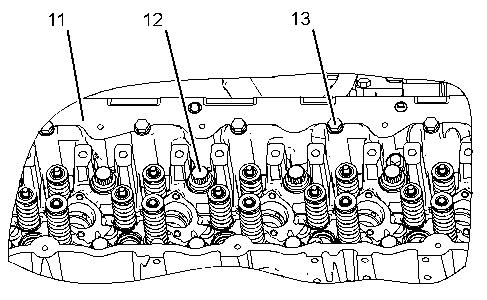

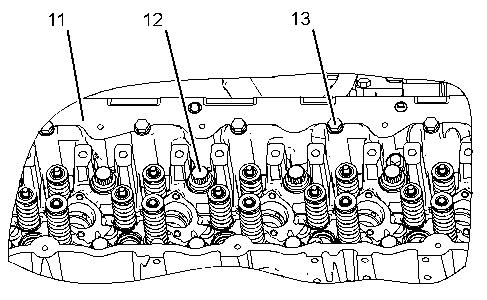

Illustration 4 g01153645

5. Remove bolts (12) and bolts (13). Remove cylinder head (11) and the gasket from the cylinder block. Copyright

1993

2020 Caterpillar Inc. All

Private Network For SIS Licensees. Wed Jun 3 15:42:26 UTC+0800 2020

-

Rights Reserved.

Previous Screen

Product: EXCAVATOR

Model: 325D L EXCAVATOR SCR

Configuration: 325D & 325D L Excavators SCR00001-UP (MACHINE) POWERED BY C7 Engine

Disassembly and Assembly

C7

Engines for Caterpillar Built Machines

Media Number -RENR9218-13

Cylinder Head - Install

SMCS - 1100-012

Installation Procedure

Table 1

Required Tools

Shutdown SIS

Publication Date -01/06/2014 Date Updated -04/06/2014

i02304034

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

1. Install a new cylinder head gasket.

Tool Part Number Part Description Qty A 6V-4876 Lubricant 1 B 4C-5590 Anti-Seize Compound 1

Illustration 1 g01153645

Illustration 2 g01153662

Note: To avoid damage to the cylinder head gasket, use guide bolts of an appropriate size to install the cylinder head.

2. Attach a suitable lifting device to cylinder head (11). The weight of cylinder head (11) is approximately 175 kg (385 lb). Position cylinder head (11) onto the cylinder block.

3. Apply Tooling (A) to the threads and both sides of the washers of bolts (12). Apply Tooling (B) to the threads and both sides of the washers of bolts (13). Install bolts (12) and bolts (13) .

4. Tighten the cylinder head bolts according to the following procedure:

a. Tighten Bolt (1) through Bolt (14) in a numerical sequence to a torque of 300 ± 15 N·m (221 ± 11 lb ft).

b. Loosen Bolt (1) through Bolt (14) until the washers are loose under the bolt heads.

c. Tighten Bolt (1) through Bolt (14) in a numerical sequence to a torque of 130 ± 15 N·m (95 ± 11 lb ft).

d. Tighten Bolt (1) through Bolt (14) again in a numerical sequence to a torque of 130 ± 15 N·m (95 ± 11 lb ft).

e. Turn Bolt (1) through Bolt (14) in a numerical sequence for an additional 90° (1/4 turn).

f. Tighten Bolt (15) through Bolt (20) in a numerical sequence to a torque of 55 ± 7 N·m (41 ± 5 lb ft).

Illustration 3

g01153600

5. Connect tube assembly (8) and tube assembly (10) to turbocharger (9) .

Illustration 4 g01153599

6. Connect hose assembly (6) and tube assembly (7) .

Illustration 5 g01153598

7. Connect harness assemblies (1), (2), (3), (4), and (5) .

End By:

a. Install the fan drive mounting group. Refer to Disassembly and Assembly, "Fan Drive Mounting Group - Remove and Install".

b. Install the unit injectors. Refer to Disassembly and Assembly, "Unit Injector - Install".

c. Install the rocker shaft and pushrods. Refer to Disassembly and Assembly, "Rocker Shaft And Pushrod - Install".

d. Install the valve mechanism cover base. Refer to Disassembly and Assembly, "Valve Mechanism Cover Base - Remove and Install".

Copyright 1993 - 2020 Caterpillar Inc. All Rights Reserved. Private Network For SIS Licensees. Wed Jun 3 15:43:22 UTC+0800 2020

Previous Screen

Product: EXCAVATOR

Model: 325D L EXCAVATOR SCR

Configuration: 325D & 325D L Excavators SCR00001-UP (MACHINE) POWERED BY C7 Engine

Disassembly and Assembly

C7

Engines for Caterpillar Built Machines

Media Number -RENR9218-13

Shutdown SIS

Publication Date -01/06/2014 Date Updated -04/06/2014

Lifter Group - Remove and Install

SMCS

- 1209-010

Removal Procedure

Start By:

i02304097

A. Remove the rocker arms and pushrods. Refer to Disassembly and Assembly, "Rocker Shaft and Pushrod - Remove".

B. Remove the unit injector hydraulic pump. Refer to Disassembly and Assembly, "Unit Injector Hydraulic Pump - Remove".

C. Remove the speed/timing sensors. Refer to Disassembly and Assembly, "Speed/Timing Sensor - Remove and Install".

D. Remove the electronic control module (ECM). Refer to Disassembly and Assembly, "Electronic Control Module - Remove and Install".

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Illustration 1 g01125745

1. Remove bolts (1) .

2. Remove side covers (2) .

Illustration 2 g01125748

3. Place identification marks on each lifter in order to identify the proper location on the side cover for installation.

Note: Ensure that the sleeves of the side covers remain in the side covers.

4. Remove bolts (3) and the dowels that hold lifter arms (4) and lifter shaft (5) to each side cover. Remove seal (6) .

Installation Procedure

Table 1

Required Tools

Tool Part Number Part Description Qty

A 9S-3263 Thread Lock Compound 1

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

g01125748

(3). Tighten bolts (3) to a torque of 13 ± 3 N·m (10 ± 2 lb ft). Tighten the two center bolts. Then tighten the end bolts.

Illustration 3

1. Install seal (6) .

2. Install lifter arms (4) on lifter shaft (5) .

3. Position lifter shaft (5) over the dowels on the side cover. Ensure that the oil holes in the lifter shaft are facing the side cover. Apply Tooling (A) on the threads of bolts (3) that hold lifter shaft (5) to the side cover. Install bolts

4. Lubricate the lifters with clean engine oil.

Illustration 4

5. Position the gaskets and side covers (2). Install bolts (1) .

End By:

g01125745

a. Install the electronic control module (ECM). Refer to Disassembly and Assembly, "Electronic Control Module - Remove and Install".

b. Install the speed/timing sensors. Refer to Disassembly and Assembly, "Speed/Timing Sensor - Remove and Install".

c. Install the unit injector hydraulic pump. Refer to Disassembly and Assembly, "Unit Injector Hydraulic Pump - Install".

d. Install the rocker arms and pushrods. Refer to Disassembly and Assembly, "Rocker Shaft and Pushrod - Install".

Wed Jun

15:44:18

Copyright 1993 - 2020 Caterpillar Inc. All Rights Reserved. Private Network For SIS Licensees.

3

UTC+0800 2020

Previous Screen

Product: EXCAVATOR

Model: 325D L EXCAVATOR SCR

Configuration: 325D & 325D L Excavators SCR00001-UP (MACHINE) POWERED BY C7 Engine

Disassembly and Assembly

C7

Engines for Caterpillar Built Machines

Media Number -RENR9218-13

Shutdown SIS

Publication Date -01/06/2014 Date Updated -04/06/2014

i02304162

Camshaft - Remove

SMCS - 1210-011

Removal Procedure

Table 1

Required Tools

Start By:

A. Remove the vibration damper and the pulley. Refer to Disassembly and Assembly, "Vibration Damper and Pulley - Remove and Install".

B. Remove the rocker arms and the pushrods. Refer to Disassembly and Assembly, "Rocker Shaft and Pushrod - Remove".

C. Remove the front cover. Refer to Disassembly and Assembly, "Front Cover - Remove and Install".

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Tool Part Number Part Description Qty A 136-4632 Timing Pin 1 139-7063 Timing Pin Adapter 1 B FT-2730 Puller 12

1. Use Tooling (B) to reposition the valve lifters out of the way.

2. Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston". Install Tooling (A) in the flywheel.

3. Ensure that the timing marks on the following gears are aligned: the camshaft drive gear, the idler gear and the crankshaft gear.

5. Remove thrust plate (3) .

6. Remove camshaft (4) from the cylinder block. Copyright 1993 - 2020 Caterpillar Inc. All Rights Reserved.

Illustration 1

g01125899

4. Rotate camshaft gear (1) in order to access bolts (2). Remove bolts (2) .

Licensees. Wed Jun 3 15:45:13 UTC+0800 2020

Private Network For SIS

Previous Screen

Product: EXCAVATOR

Model: 325D L EXCAVATOR SCR

Configuration: 325D & 325D L Excavators SCR00001-UP (MACHINE) POWERED BY C7 Engine

Disassembly and Assembly

C7

Engines for Caterpillar Built Machines

Media Number -RENR9218-13

Camshaft - Install

SMCS

- 1210-012

Installation Procedure

Shutdown SIS

Publication Date -01/06/2014 Date Updated -04/06/2014

i02304177

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Illustration 1

1. Carefully install camshaft (4) in the cylinder block.

2. Install thrust plate (3) .

g01125899

3. If necessary, rotate camshaft gear (1) in order to access thrust plate (3). Install bolts (2) .

4. Ensure that the No. 1 cylinder is at the top center compression stroke. Refer to Testing and Adjusting, "Finding Top Center Position for No. 1 Piston".

5. Ensure that the timing marks on the following gears are aligned: the camshaft drive gear, the idler gear and the crankshaft gear.

End By:

a. Install the front cover. Refer to Disassembly and Assembly, "Front Cover - Remove and Install".

b. Install the rocker arms and the pushrods. Refer to Disassembly and Assembly, "Rocker Shaft and Pushrod - Install".

c. Install the vibration damper and the pulley. Refer to Disassembly and Assembly, "Vibration Damper and Pulley - Remove and Install".

Copyright 1993 - 2020 Caterpillar Inc. All Rights Reserved. Private Network For SIS Licensees. Wed Jun 3 15:46:09 UTC+0800 2020

Previous Screen

Product: EXCAVATOR

Model: 325D L EXCAVATOR SCR

Configuration: 325D & 325D L Excavators SCR00001-UP (MACHINE) POWERED BY C7 Engine

Disassembly and Assembly

C7

Engines for Caterpillar Built Machines

Media Number -RENR9218-13

Shutdown SIS

Publication Date -01/06/2014 Date Updated -04/06/2014

Camshaft Gear - Remove and Install

SMCS - 1210-010-GE

Removal Procedure

Start By:

A. Remove the camshaft. Refer to Disassembly and Assembly, "Camshaft - Remove".

i06290358

1. Wrap the camshaft with a protective covering in order to prevent damage to the camshaft.

1 g00987675

Illustration

NOTICE

Do not allow the camshaft to fall to the floor when pressing it from the drive gear. Also make sure that the camshaft lobes do not catch on the press plates.

2. Place the camshaft assembly in a suitable press. Press camshaft (2) from camshaft gear (1) .

3. If necessary, remove key (3) from the camshaft.

Installation Procedure

1. Raise the temperature of the camshaft gear from 200° C (392° F) to 250° C (482° F).

Note: Do not use a torch to heat the camshaft gear.

Illustration 2 g00987675

2. Align key (3) in the camshaft with the groove (keyway) in the camshaft gear.

3. Install camshaft gear (1) on the end of camshaft (2) .

End By: Install the camshaft. Refer to Disassembly and Assembly, "Camshaft - Install". Copyright

- 2020 Caterpillar Inc. All

Private Network For SIS Licensees. Wed Jun 3 15:47:05 UTC+0800 2020

1993

Rights Reserved.

Previous Screen

Product: EXCAVATOR

Model: 325D L EXCAVATOR SCR

Configuration: 325D & 325D L Excavators SCR00001-UP (MACHINE) POWERED BY C7 Engine

Disassembly and Assembly

C7

Engines for Caterpillar Built Machines

Media Number -RENR9218-13

Shutdown SIS

Publication Date -01/06/2014 Date Updated -04/06/2014

Camshaft Bearings - Remove and Install

SMCS - 1211-010

Removal Procedure

Table 1

Required Tools

Start By:

a. Remove the camshaft. Refer to Disassembly and Assembly, "Camshaft - Remove".

i02232381

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Note: Note the oil hole orientation in each camshaft bearing prior to removal for assembly purposes.

Part Number Part Description Qty A 8S-2241 Camshaft Bearing Tool Group 1

Tool

Illustration 1 g00989974

1. Use Tooling (A) to remove camshaft bearing (1) from the front of the cylinder block. Remove the remaining camshaft bearings (2) from the cylinder block.

Installation Procedure

Table 2

Required Tools

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Tool Part Number Part Description Qty A 8S-2241 Camshaft Bearing Tool Group 1 NOTICE

Illustration 2

g00990062

1. Use Tooling (A) to install all of the camshaft bearings (2) except for the front camshaft bearing. Locate the oil hole in each bearing so that oil hole (3) is located at the top of the bore. Refer to Specifications for more information.

Illustration 3

g00989938

2. Use Tooling (A) to install front camshaft bearing (1). Align oil hole (5) in the front camshaft bearing with the oil hole in the cylinder block. Locate joint (4) in the front camshaft bearing in the proper position. Refer to Specifications for more information.

End By:

a. Install the camshaft. Refer to Disassembly and Assembly, "Camshaft - Install".

Suggest:

If the above button click is invalid.

Please download this document first, and then click the above link to download the complete manual.

Thank you so much for reading

Previous Screen

Product: EXCAVATOR

Model: 325D L EXCAVATOR SCR

Configuration: 325D & 325D L Excavators SCR00001-UP (MACHINE) POWERED BY C7 Engine

Disassembly and Assembly

C7

Engines for Caterpillar Built Machines

Media Number -RENR9218-13

Shutdown SIS

Publication Date -01/06/2014 Date Updated -04/06/2014

Engine Oil Pan - Remove and Install

SMCS - 1302-010

Removal Procedure

Start By:

A. Remove the engine.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

i05954439

NOTICE

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.

Dispose of all fluids according to local regulations and mandates.

1. Drain the engine oil into a suitable container for storage or disposal. Refer to Operation and Maintenance Manual, "Engine Oil and Filter - Change" for the correct draining and filling procedures.

Illustration 1

g01153839

Note: Do not pry or gouge the sealing surface of the engine oil pan. Use a rubber mallet to tap lightly on the engine oil pan, if necessary.

2. Remove bolts (2) . Remove engine oil pan (1) and the gasket.

Installation Procedure

Table 1

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Tool Part number Part Description Qty A - Loctite 598 1 NOTICE

Illustration 1

g01153598

1. Disconnect harness assemblies (1), (2), (3), (4), and (5) .

Illustration 2

g01153599

Illustration 1

g01153598

1. Disconnect harness assemblies (1), (2), (3), (4), and (5) .

Illustration 2

g01153599