Corrugated Board & Box MachinesMaking www.friendsenggco.com

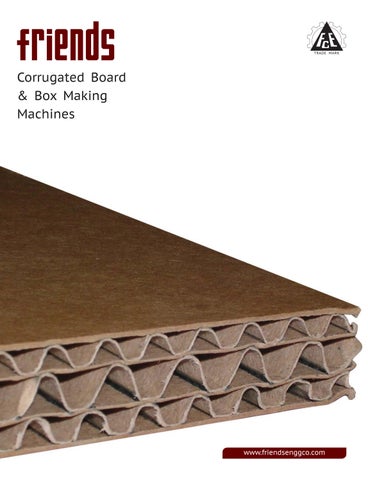

The 3ply, 5ply, 7ply, and multi-function corrugated cardboard production line has high middle and low grade with different-specification and different-quality equipment. On the base of understanding the requirements of the customers and the advanced skills at home and abroad, our company has developed and designed these production lines with the speed 100-220m/min; the paper width 1400-2200mm and four fluting UV type A, B, C, E for all the customers to choose from.

Purpose and Characteristics

Slitter Scorer Cutoff Stacker Double Facer Single Facer Splicer

N.C.

Pre Heater Reel Stand Bridge Gluer

Corrugated Board Production Line

Corrugated Cardboard Production Line is the professional equipment for producing corrugated cardboard. The 3ply, 5ply, 7ply and multi-function corrugated cardboard production line mainly consist of the following equipment: Mill Roll Stand, surface paper (core-paper) pre-heater, single facer, Conveying Bridge, Glue Application Machine, Double Facer, Slitter Scorer, Cut-off, Conveyer and Stacker, Heating System, Air compression system and Glue Making System, etc.

SpaceMin.SlotMax.MaxMax.SizesMin.Max.ProductionColorControlPrintingParameterFRIENDS-900FRIENDS-1200FRIENDS-1400RollerDia300mm408mm480mmModePLC/TouchScreen/ButtonGroupEverythingcanbequippedaccordingtousers’needsSpeed120/150/200PaperSizes900x1800/2000/2200/2400/2600mm1200x1800/2000/2200/2400/2600mm1400x1800/2000/2200/2400/2600mmPaperPositiveknife300x640mm350x720mm400x720mmNegativeknife300x720mm350x740mm400x740mmPrintingSizes900x1600/1800/2000/2200/2400mm1200x1600/1800/2000/2200/2400mm1400x1600/1800/2000/2200/2400mmdie-cuttingSize900x1700/1900/2100/2300/2500mm1200x1700/1900/2100/2300/2500mm1400x1700/1900/2100/2300/2500mmPrintingPlateThickness7.2mmWidthxMax.depth7mmx220mm7mmx300mm7mmx350mrnSlotPositiveknife150*150*150*150mm170170170170mm170*170*170*170mmNegativeknife250*90*250*90mm260*90*260*90mm260*90*260*90mmMotorlistNameSizeFeedingunitMainmotorSIEMENS/ABB1.5KW(Frequency)Separationandreunionofthemachine1.5KW1/60GearreducespeedLeftandrightbaf fle plate0.2KW RV-30 Suction motor7.5KW Dust exhausting fan1.5KW Printing unitPhase adjustment0.2KW RV-30(Frequency ) Anilox roller / Ceramic roller0.4KW 1/30(Gear reduce speed) Slotting unitPhase adjustment0.2KW RV-30 Knife seat horizontal movement (by maunal / by electrical) SIEMENS / ABB 0.37KW RV-50 1/80 Die—cutting unitPhase adjustment0.2KW RV-30 Left and right tensile0.18KW RV-50 1/80 Repair of rubber roller0.37KW RV-40-50 1/900 Stacking unitConveying belt3.0KW (electromagnetic controlling speed) Lift of stack table2.2KW RV-135 1/80 Automatic High Speed Printing Slotting and Die Cutting Machine Technical Parameter Printing Unit Rotary Slotting Rortary Die Cutting

Rubber roller (top roller) can move automatically, move range ±40mm.

Chain Feeding Rotary Slotting Machine (RS4)

Driving part uses pull pump to lubricating (motorized phase adjustment type used spray lubricating).

High quality 48 CrMo slotting knife with induction hardness. Frequency conversion motor drive, save power. Equipped with the photo electricity counter, display production amount

Rotary Die Cutting Machine

MAIN

Oil box made of thick iron plate to avoid oil leakage.

Semi-automaticFEATURES chain feeding system, side lay gauge adjust feeding position, ensure feeding accurately.

Technical Parameter

The machine adopts chain feeding system and double roller rotary type. It can perform all process of slitting, creasing , corner cutting and hit special whole at one time. It has advantage of high precision, easy to operate, long service life and low Papercost.Feeding Unit

Cutter die diameter ModelFRIENDS(mm)4054802200FRIENDS2400FRIENDS2200FRIENDS2400FRIENDS 2600FRIENDS 2800 Max. Sheet Size (mm)1200 x 22001200 x 24001400 x 22001400 x 24001400 x 26001600 x 2800 Min. Sheet size (mm)350 x 500350 x 500400 x 500400 x 500400 x 500400 x 500 Min. Slot distance (mm)190 x 50 x 190 x 50 Slot width (mm)777 Sheet thickness (mm)3 - 103 - 103 - 10 Work speed (Pcs/min)0-600-600-60 Power

Full machine gear made of 45# steel have been quenched treatment, Adopts lock-alx key less and cross-head system connect with shafts finish no gap adjustment.

FQK Series rotary slotting machine is a kind of comprehensive equipment that slotting, slitting, cutting corner, creasing. Its main feature is feeding single piece cardboard by hand, common card board also OK.

Manual adjust former block board and computer control lateral block board, dial indicator.

All of shaft precision gring, chrome plated. High quality 48CrMo slotting knife with induction hardness. Speed variable motor drive machine, speed is adjustable. Equipped with the photo-electricity counter, display production amount. Slotting crease joint movement by hand control.

Electric adjusting box height (or PLC adjust).

Leading paper roll have groove glue surface to prevent the crushed card board and increase the accuracy of feeding.

Function and Uses

Phase adjustment by manual operate with micro-adjustment (or motorized adjust in 360º)

Die Roller (bottom roller) lift-down adopts pneumatic control, manual or automatic operation.

Motorizedsmoothly,UsedcardfeatureequipmentFRIENDS(kw)2.22.22.2UsesandFeaturesseriesrotaryslottingmachineisakindofcomprehensivethatslotting,slitting,cuttingcorner,creasing.Itsmainisfeedingsinglepiececardboardbyhand,commonbendboardarealsoOK.MainFeaturesleadedgefeederwithvacuumfeedingsystem,fastand(orkickfeederoption).(orPLC)adjustsideandfrontbaf fle, manual adjust black buffer (motorized).

Rubber roller (top roller) fix overrunning clutch to compensate line speed automatically, and avoid one position Equippedcutting.withanvil cover repair device, prolong use life.

The drum made of high quality steel tube, thickness 30mm, do balance treatment, plated chrome.

Sheets/Hr, die-cutting precision: ±0.75mm.

Main Characteristics

Rubber roller (top roller be wrapped anvil cover from “Maxdura” Brand from Taiwan (or CUE, DAY option), long use life.

Uses and Features

Slotting crease joint movement by motorize control (PLC option).

Adopt lead edge feeding system with vacuum adsorption auxiliary feed, (optional equipment kick feeding Speed:system)10000

Planet gear type motorized observe and reverse adjustment in All360°.of shaft precision grind, chrome plated.

Planet gear type motorize observe and reverse adjustment in 360° Manual adjusting four box height cutter synchronous (motorize adjusting is option).

Rotary Slotting Machine (RS4)

ControlPLC&TouchPaperboardPowerTotalDimensions(mm)L11000*W3000*H1600LlMin.Cardboard(mm)300*900300*900Max.Cardboard(mm)900*22001200*2500ModelTS-2400TS-25002500*W3200*H1600weight5500kg6500kgRequired12KW380V3Phase50HZ12KW380V3Phase50HZthickness3or5layerpaperboard3or5layerpaperboardScreenPLC&TouchScreenBlankSizeMax.(mm)Min.(mm)W450180L650270D2900300G4034 MaxMin1500mm90mm 50 mm1515Max Max 606 mm Min 90mm mm250Min Max 2600mm Min 606mm Automatic Folder Gluer Machine Semi-Automatic Folder Gluer Machine Technical Parameter

ModelFRIENDS - 1300FRIENDS - 1450FRIENDS - 1600 Maximum size (mm)1100 x 13001100 x 14501400 x 1600 Minimum size (mm)350 x 350350 x 350450 x 450 LaminateSpeed6000precision±1.5mm±1.5mm±1.5mmSheets/h6000Sheets/h6000Sheets/h Total power (kw)121213 Length (m)12.512.515 Total weight (T)6.87.28.0 ModelFRIENDS - 1300FRIENDS - 1450FRIENDS - 1600 Maximum sheet size (mm)1300 x 13001450 x 13001600 x 1300 Minimumsheet size (mm)350 x 450350 x 450350 x 450 Speed (mt/min)0-900-900-90 Total power (kw)777 Overall dimensions (m)8.8x2.2x1.78.8x2.35x1.78.8x2.5x1.7 Total weight (T)3.54.04.5 Automatic Flute Laminator Semi-Automatic Flute Laminator Technical Parameter Technical Parameter

Machine Size (mm) FRIENDS 1400 - 2300 Roller Dia. (mm) 280 320 / 360 380 Heating type Steam / electric / oil Corrugated roller material 48CrMo alloy steel / 52CrMo alloy steel Wallboard type Oblique / square Transmission type Gear box / chain Feeding type Fingerless / finger Design speed 100m/min 150m/min 200m/min Pneumatic working pressure 0.4-0.9Mpa “Upper corrugated roller diameter” 0280mm 0320mm 0350mm “Lower corrugated roller diameter” 0280mm 0320mm 0380mm Pressure roller diameter 0280mm 0320mm 0385mm Glue roller diameter 0242mm 0242mm 0268mm Paste fixed roller diameter 0127mm 0127mm 0140mm Preheat roller diameter 1402mm 1402mm 1402mm Main driving motor 11KW 15KW 30KW Wind suction motor 11KW 11KW 11KW Control type SIEMENS / SCHNEIDER Bearing SKF / NBC / NACHI Fingerless Type Single Facer Technical Parameter Double Profile Corrugation Machine Size 42” 52” 62” 72” Motor (H.P.) 9 11.5 11.5 14 Heating Load KW 19 18 21 25 Wt. Approx. 5 5.5 6 6.5 Floor Space 7.5’×15’ 8.5’×15’ 9.5’×15’ 10.5'×15’ 84” 16.5 25 7.5 11'×18’

OBLIQUE TYPE MACHINECORRUGATINGPAPERSize36”42”46”52”62”Motor(H.P.)23355HeatingLoadKW1519182125Wt.Approx.3.03.544.55FloorSpace7’×15’7.5’×15’8’×15’8.5’×15’9.5’×15’ FOUR BAR ROTARY CUTTING & CREASING MACHINE Size 65”75”85”95” Motor (H.P.) 2223 Wt.Approx. (Tons)1.722.22.8 Floor Space 7’×4’8’×4’9’×4’10’×4’ ECCENTRIC SLOTTER Size 65”75”85”95” Motor (H.P) 2335 Max. Slot17”18”18”18” Wt. FloorApprox.1.82.22.43Space7'×4'8'×4'9'×4'10'×4' BOARD PRINTER Size 50”×75”50”×85”50”×95” Motor (H.P.) 3 3 3 Wt. Approx. (M.T.)2 2.32.6 Floor Space 7'×12'7'×13'7'×14' SHEET MACHINEPASTINGSize45”55”65”75”85”Motor(H.P.)11111Wt.Approx400450500600700FloorSpace5'×3'6'×3'7'×3'8'×3'9'×3 BOX48”20”Sizes:BottomFlapSTITCHINGMACHINESealing&SealingStitcher30”36”42”60”Size54”Motor(H.P)2Wt.Approx1.8M.T.FloorSpace6’×8’ REEL TO SHEET CUTTER

BSCIC 390-B, FOCAL POINT, AMRITSAR- 143001 P : (+91-183) 2701931, 2580419 M : +91-9937 000000, 98884 44440 e : fec@friendsenggco.com w : www.friendsenggco.com w : www.diecuttingmachine.in