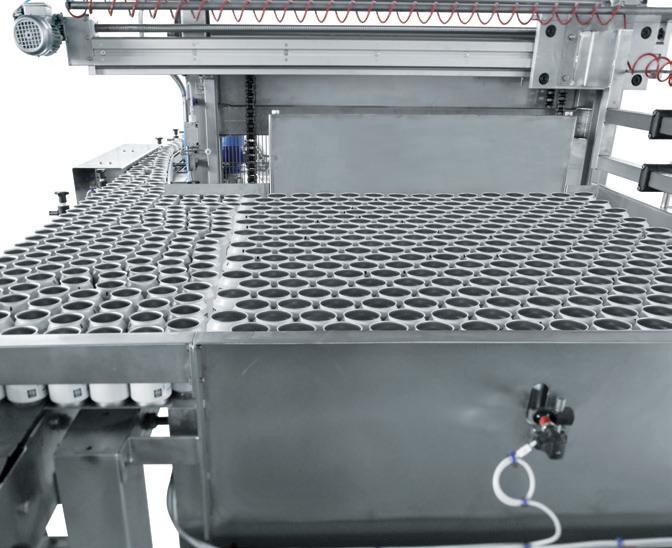

Automatic cans depalettizer, full stainless steel construction, complete with automatic layerpad removal and cans aligning system to single lane conveyor.

Technical details:

• Standard pallet dimensions: mm 1120x1420 (other sizes on request);

• Heavy duty extremely robust stainless steel structure;

• Standard unloading height: 3200 mm (lower available on request);

• Production: max 1 layer/minute

The machine consists of:

• Completely enclosed pallet lifting compartment;

• Door for closing the machine complete with safety sensors;

• Electromechanical pallet lifting system by means of reduction gear with self-breaking motor;

• Automatic layer level by means of photocell and encoder system allowing for different can heights;

• Electromechanical group for the movement of the layer including layerpad removing system and storage.

• Multiway conveyor with differentiated speed chains, for aligning to single lane;

• Stainless steel AISI 304 electric panel;

• Manual loading of pallet inside the machine and top frame removing;

• Fixed safety protections to the pallet lifting chains;

• Management with Siemens or Vipa PLC;

• Recipe management system for different cans heights;

Gravity rinsing unit:

• Including stainless steel inlet and outlet twists;

• Available for rinsing with water, sterile air or Ionized sterile air;

• Single channel or multi-channel, allowing to process up to 3 cans sizes without change parts (including automatic can size change);

• Rinsing electro-valve controlled by the machine’s PLC.

FRAMAX srl - Via Marlianese, 31 51030 Serravalle Pistoiese (PT) Italy

Ph./Fax +39 0573 51435 - Fax +39 0573 079907

email: info@framax.com

For additional information visit: www.framax.com

Layerpad remover. Multiway conveyor to single lane. Gravity rinser. Control panel. Automatic layer transfer. Stainless steel twists.