SAWLINES

Skidders

Shredders

NEW SENSORS, NEW SYSTEMS, NEW SOLUTIONS!

SAWLINES

Skidders

Shredders

NEW SENSORS, NEW SYSTEMS, NEW SOLUTIONS!

The Log Max 5000V is a modern and reliable harvesting head that can handle a wide range of logging challenges. This is the perfect mid-range head for both thinning and nal felling. The head can be equipped with a 82 cm saw bar and has a maximum cutting diameter of 74 cm. It also features Log Max’s multi-stemming MK2, that is agile and lightweight, making thinning work easier. The Log Max 5000V is suitable for those who seek the perfect balance between agility, capacity, and durability.

Quote from test driver Erik Wiik:

“The cutting and feeding are brutally good, and in combination with the new length measuring unit, Log Max becomes unstoppable ; )”

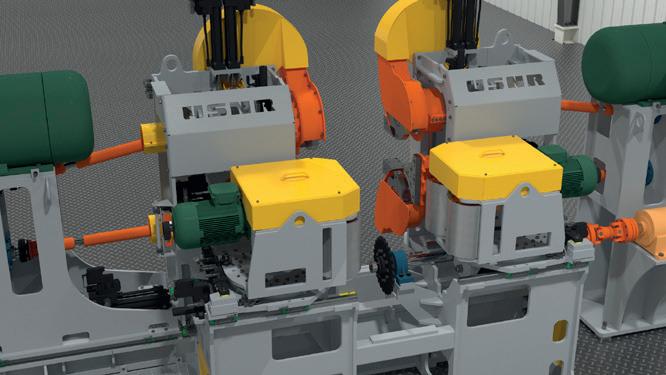

USNR presents the next generation 4900 family of sensors for transverse edging, trimming, and grading applications. Based on the same proven technology of the BioLuma 3900 sensor, the 4900 captures higher density scans with improved resolution. The 4900 sensor is part of the Bioluma scanning system which uses high-speed hubs to gather scan data and defect recognition data through advanced

AI, and solutions from the MillGenius Optimizer, for extremely accurate grade processing solutions at high speeds. Combining color vision technology with high density geometric scanning, the BioLuma grading optimizer offers sawmills the highest value optimized decisions with grade and recovery performance.

www.usnr.com

In the ever-evolving landscape of Artificial Intelligence (AI), BID stands as a pioneer in robotic automation, transforming the trim block production handling process for sawmills worldwide.

20

The sawn timber production of the wood products company Koskisen’s new processing unit started as planned at the beginning of July.

J.D. Irving’s Truro Sawmill, also known as Sproule Lumber, recently completed a major upgrade which will greatly improve operations and productivity.

26

Södra’s

After 43 years of servicing the wood industry, MiCROTEC today is the only provider offering scanning and optimization solutions from the logyard to secondary processing both for the softwood and hardwood sectors.

Recent mergers and acquisitions have solidified USNR’s leadership position in providing equipment and technology for the global wood processing industry.

The QC Assist gives me quantifiable data to know that the products our mill is sending out are consistent.”

SUBSCRIPTIONS

SUBSCRIPTIONS

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Annual Subscription

Annual Subscription

U K and Europe £160, € 230 Rest of the world US$270

U K and Europe £160, € 230 Rest of the world US$270

EDITORIAL

EDITORIAL

T: +44 (0)1442 877 583

T: +44 (0)1442 877 583

F: +44 (0)1442 870 617 www.internationalforestindustries.com

F: +44 (0)1442 870 617 www.internationalforestindustries.com

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

Editor Robin Peach robin@internationalforestindustries.com

Publisher Robin Peach robin@internationalforestindustries.com

Editorial Board

Dr Patrick Moore – Chairman and Chief Professor Piotr Paschalis-Jakubowicz –Warsaw Agricultural University (Poland)

Mr Kim Carstensen

Director General

Forest Stewardship Council

As anticipated, the turnout to the second Residues2Revenues 2023 was a standout for the industry. Around 250 delegates attended the wood residues event, principally forest owners and managers, harvesting and log cartage contractors, those looking at utilising surplus residues from wood processing and manufacturing operations and aggregators, who were extracting, transporting, processing, drying and selling ever-increasing volumes of woody biofuels that are being sought by larger industrial heat and energy users.

• An investment of NZ$10.4 million into woody biomass research including maximising the management of woody debris, including slash as well as support being given to develop a pilot bioenergy plant to turn woody debris into a mix of biodiesel and electricity (https:// woodresidues.events/bioenergyfunding-to-better-utilise-forestry-slash/).

• Co-investing more than NZ$2 million with Air New Zealand into two studies to consider the feasibility of producing sustainable aviation fuel.

Eduardo Morales

Email: lapham@jpmediainc.com

South American Forestry Consultant

WEB OPTIMIZATION

Jo

jo@internationalforestindustries.com

ADVERTISING AND PROMOTIONS

ADVERTISING AND PROMOTIONS

International Forest Industries Ltd

International Forest Industries Ltd

Advertising Manager

Advertising Manager

Emma Smith emma@internationalforestindustries.com

Emma Smith emma@internationalforestindustries.com

+44 (0)1442 877 583

+44 (0)1442 877 583

Associate Editor

And it wasn’t only New Zealand companies. A good contingent from Australia attended again and a raft of international delegates were able to join those in Rotorua, New Zealand and participate in the event remotely.

• A NZ$10 million dollar investment was made to replace all remaining coal boilers in New Zealand schools with renewable woody biomass or electric heating sources by 2025.

Robin Peach robin@internationalforestindustries.com

Associate Editor Robin Peach robin@internationalforestindustries.com

Advertising Production Enquiries

Advertising Production Enquiries

Emma Smith emma@internationalforestindustries.com

Emma Smith emma@internationalforestindustries.com

Studio Manager

Luke Evans luke@lecreative.co.uk

Last year’s event, Residues2Revenues 2022 (R2R22), barely scratched the surface. Feedback clearly told the organisers that the event was long overdue, that the networking provided was invaluable and that the industry didn’t want the momentum built up at R2R 2022 to diminish. It didn’t.

• and Fonterra announced that they were continuing to progress their decarbonisation work with the coal boilers at its Hautapu site being converted to wood pellets. Other projects underway at the time included the Waitoa and Stirling sites which were both in the process of installing wood biomass boilers to transition out of coal.

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK

Accounts

Nicola Shukla nicolas@internationalforestindustries.com

International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA, 17B South Middlesex Avenue, Monroe NJ 08831 and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTE R: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831

© International Forest Industries Ltd 2007 – 2019 I FI uses, as preference, SI units throughout. All dollars are US unless otherwise stated.

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in

Interest, particularly from forest owners who were looking to better utilise forest residues, slash, bin wood, offcuts left on landings, short length or malformed logs not meeting MDF, pulp-mill or chip export log specifications and the almost weekly announcements by the NZ Government encouraging business and consumers to switch from fossil fuels to renewables ensured that interest just ramped up. As evidenced by the photos collected over the two days, the event met and exceeded all expectations.

To reflect the speed of change, in just the three months leading up to Residues2Revenues 2023, the NZ Government announced;

• A ban on new coal boilers and phasing out by 2037, of all existing coal boilers.

Announcements and initiatives like these ensured that the Residues2Revenues 2023 conference, pre-and post-conference workshops and exhibitions (inside and outside the venue) were perfectly timed.

It provided an independent platform showcasing new innovations and smart operating practices being used, locally and internationally, to harvest and process wood residues and explore further, through a series of case studies, a raft of options being used to successfully aggregate regional fuel supplies to ensure consistency of product quality, quantity and supply.

FIEA delivers world class technology events for Australasian forest products companies.

This year, Ponsse and Konehuolto P. Kula Oy, which operates as a Ponsse contract service center in Southwest Finland, will celebrate their 20th year of partnership.

The trade name Petri Kula and Ponsse started working together in the spring of 2000. First, Kula operated as a service car entrepreneur until the company was transformed into a limited company in 2003. Today, Konehuolto P. Kula’s work in Ponsse service is up to the same level as any other Ponsse customer service center. The company is in Pöytyä, Finland, and it employs five mechanics.

“I would like to thank the entrepreneur himself, Petri Kula, for the 20 years of partnership! Ponsse wants to make sure that our customers get the best service and spare

part availability, and Kula has done their part perfectly! Congratulations to Petri for 20 years as an entrepreneur and future success is certain because of Petri’s brave and enthusiastic attitude”, says Ponsse’s country director, Jani Liukkonen.

The number of customers has increased over the years in Southwest Finland. There are approximately 100 Ponsse machines in the area and most of the customers with whom P. Kula works with are within a 50-kilometer radius.

“The 20 years have certainly been a great journey! There could not be a better partner than Ponsse, for sure. Matters are solved with common sense and it is easy to negotiate and work with the Ponsse people. We share the same values: The interests of the customers

comes first,” says entrepreneur Petri Kula.

In early June Konehuolto P. Kula Oy celebrated the 20-yearanniversary of the company by arranging a market day at their service center in Pöytyä, Finland.

Australia’s archaic road rules, and its unique weight restrictions on trucks, have emerged as a major stumbling block to moves to transform the country’s heavy duty truck fleet to fully electric.

Volvo Trucks – the world’s biggest maker of heavy-duty electric trucks, and Australia’s biggest vehicle manufacturer –wants to start selling its heavyduty electric trucks now and to build them at its Wacol factory near Brisbane from 2027 – but says arbitrary weight limits stand in its way.

The weight rules – unique in the world – put a 6.5 tonnes limit on the front axle of the truck’s prime mover, ostensibly to protect Australian roads. Volvo says this makes it impossible to load enough batteries to where they are needed. They want it lifted to at least 7.5 tonnes.

And ironically, even an empty heavy duty electric truck, which normally weighs up to 44 tonnes when the trailer is fully loaded, would not be allowed on Australian roads under current rules.

Volvo has sold more than 5,000 electric trucks and is the first in the world to build heavy duty electric trucks at scale. It has brought in its first FH heavy duty electric truck to Australia, in time for the Brisbane Truck Show – the industry’s flagship event – but can only drive it on local council roads, and not the freeway, after getting special permission.

“This is the biggest transformation ever,” Roger Alm, the head of the Swedish truck maker said a launch event at Wacol on Wednesday. Volvo claims 50 per cent of the electric truck market in both Europe and the US, and has

set a target of lifting electric trucks to half of its production by 2030, and 100 per cent by 2040.

But – despite 18 months of talks, and agreement from other trucking companies and the industry’s main lobby group – there has been little or no movement on the weight limit problem, and it was not even mentioned in the National Electric Vehicle strategy released late last month by the federal government.

“The barrier we have right now is legislation,” the head of Volvo Group in Australia, Martin Merrick said. “If we don’t get legislation change, then we won’t meet these targets. Everyone feels it should be done, it is just taking time.”

» Diverse line of models ranging from 14” to 45” capacity

» Cuttermill processes material utilizing less fuel

» Wide variety of teeth and screen sizes available

» Produces a high-quality end product

» Top notch aftermarket support

WATCH IT RUN!

40 YEARS OF QUALITY TREE CARE AND RECYCLING EQUIPMENT

MODEL 3680T 35” Capacity Horizontal Grinder

MODEL 3680T 35” Capacity Horizontal Grinder

The logging industry demands reliable and efficient equipment to tackle the toughest challenges in harvesting operations. Introducing the Log Max 5000V, a state-of-the-art harvesting head that combines durability, agility, accuracy, and intelligence to revolutionise logging worldwide. With its reinforced design, advanced features, and improved servicing capabilities, the Log Max 5000V sets a new standard for modern and powerful harvesting heads.

The Log Max 5000V boasts a reinforced frame designed to withstand the most demanding logging applications. The slimmed-down saw box enhances performance in snowy conditions, ensuring optimal cutting efficiency. Equipped with the new 318 MK2 - 30cc saw, this harvesting head delivers fast and troublefree cutting up to 74cm, guaranteeing exceptional cutting performance.

Measuring Precision and Simplified Maintenance: Accurate measurement results are crucial in today’s harvesting operations, and the Log Max 5000V meets this requirement

with its redesigned measuring unit. The length measuring unit incorporates smart features, including a contactless sensor, easier lubrication, and durable tapered bearings. Furthermore, the harvesting head’s improved accessibility, wellorganised hoses, and grease nipples facilitate simplified maintenance and servicing.

To enhance the Log Max 5000V’s durability and longevity, several updates have been implemented. The design of the measuring wheel hole has been improved, reinforcing the stoppers for the feed roller arms inside the frame, thus increasing strength and stability. The length measurement function has been significantly improved through the introduction of a new measuring wheel unit with a larger wheel, ensuring superior measurement accuracy.

Advanced Saw Unit:

The Log Max 5000V incorporates the enhanced saw unit 318 MK2 19 cc (True-Cut) or 30 cc, carefully designed to optimise work processes. Upgrades include a more robust saw bar mount with protective covers and rubber seals, ensuring protection against dirt and moisture. The saw bar holder now utilises premium-grade Hardox 450 material, offering increased strength and longevity. Additionally, the placement

of the “saw bar home” sensor has been optimised for easy access during maintenance. On the 30cc version the saw valve is mounted directly to the motor which greatly increases responsiveness.

Improved Multi-Stemming Unit MK2:

The Log Max 5000V’s multistemming unit has undergone a redesign, resulting in reduced weight, increased lifespan, and simplified serviceability. The relocation of cylinders and improved hose protection increase durability and minimise the accumulation of snow and dirt.

Enhanced Four-Point Measuring MK2:

The Log Max 5000V’s fourpoint measurement MK2 features new components and functions to excel in harsh conditions. The introduction of a contactless encoder in the lower delimbing knife enhances its lifespan and simplifies maintenance. The lower delimbing knife now incorporates an “Active Lower Knife” function, increasing lifting power and optimising tree holding capability. Additionally, the design modifications, such as a new axel nut and improved cable routing, enhance durability and reduce the risk of snow and ice packing.

Conclusion:

The Log Max 5000V represents a groundbreaking advancement in the logging industry. With its unparalleled durability, cutting performance, precise measurement capabilities, and simplified maintenance, this harvesting head sets a new benchmark for productivity, efficiency, and reliability. Experience the power of the Log Max 5000V and unlock its potential to revolutionise your logging operations.

Slash has huge potential to be used as biofuel when salvaged, recycled, and repurposed.

away from coal and fossil fuels to cleaner energy sources, it says.

Cyclone Gabrielle has had a devastating impact on Aotearoa, bringing major concerns to the fore about climate change and forestry management. The news reports from February will stay long in the memory, particularly the huge volumes of slash that contributed to our worst floods this century. As managing slash becomes an urgent nationwide issue, one company has devised a solution that can turn the problem into a positive.

Forestry and timber company OneFortyOne is a business with a plan to turn New Zealand’s unwanted forestry slash into biofuel. According to the business, slash has huge potential to be used as biofuel when salvaged, recycled, and repurposed. The biofuel made from slash can also help organisations move

Based in the Nelson, Marlborough and Tasman regions at the top of the South Island, OneFortyOne recognises that slash can cause significant environmental problems. The business is on a mission to harness classic Kiwi ingenuity and turn unwanted waste into a fuel source that can power communities into a cleaner future.

OneFortyOne collects binwood, the larger pieces of slash measuring over 600mm long and 100mm wide that don’t meet the required log grades or dimensions for sawmills or pulp mills. After salvaging the wood from skid sites, OneFortyOne stores it

The new COMBi-CB70E electric forklift is the most compact 7,000kg counterbalance truck on the market. It is loaded with a host of features that greatly enhance operator comfort, including excellent all-round visibility, a spacious gas-strut suspension cab, independent electric traction and our newly developed Auto Swivel Seat which intelligently swivels 15O in the direction of travel. To find out how Combilift can help you unlock every inch of your storage space.

performance, extensive battery life and unrivalled ergonomics combined with all the advantages of the Combi-CB range make the CB70E the most powerful, compact multidirectional forklift yet.

in safe storage sites across its estate. The binwood is then dried over many months. Once moisture content is at the right level, it can be chipped and used as an energy source.

Since November 2021, OneFortyOne has invested almost $500,000 into its binwood collection project, accumulating 15,000 tonnes of wood. That’s enough to fill 405 logging trucks or cover two rugby pitches piled three metres high. Not an insignificant amount.

The slash initiative requires meticulous care and attention. The removal of wood has to be balanced with wise management of soils and slopes, and enough biomass has to be left on the slopes to provide nutrients for future planting. The extraction of logs and binwood must also be done in a way that prevents erosion of the slopes until the next rotation of trees is established.

Removing binwood reduces the amount of slash on-site post-harvest, which

significantly decreases the likelihood of skid failures and potential damage by slash in the event of intense weather events, such as Cyclone Gabrielle.

OneFortyOne’s binwood collection project delivers an energy source that can help NZ businesses move away from coal and has removed 15,000 tonnes of slash from our forests. The group is keen to work with industries across the country to reduce the impacts of slash and mitigate climate change by embracing biofuels that are less damaging to our environment.

The timber business initiated this project because it believed it needed to continually look for ways to improve how slash was managed, it also knew it had a valuable product that was previously only viewed as a problem.

Replacing fossil fuels with bioenergy alternatives can help New Zealand meet its greenhouse gas emission targets and create new

opportunities for the local economy. The business says the project, when scaled up, could be a game-changer for New Zealand in creating a sustainable, endlessly renewable source of bioenergy.

As it looks to the future and further innovation to help the environment, OneFortyOne is ready to work with other organisations to reduce the impact of slash, prevent climate damage, and turn a negative into a positive. The business is on the lookout for partners to collaborate on

slash reduction and mitigate the genuine threat of climate change.

Trimble (NASDAQ: TRMB) announces the launch of LIMS PRO, a new cloudhosted version of its widely used Log Inventory and Management System (LIMS) to manage sawmill raw material procurement. As a cloud-based log settlement solution, LIMS PRO is designed to improve operational visibility for mills. It enables small- and mediumsized forest product companies to realize productivity and growth gains that only large companies have historically been able to afford by digitizing lumber supply chain workflows.

Taking the power of LIMS and creating a more accessible Software-as-aService (SaaS) version, this robust business management software streamlines contracts, receiving, inventory and settlement processes into a single platform, providing forestry companies with a complete picture of their operations. In addition, the software assists with mobile ticketing in the woods before the logs make their way to sawmills, eliminating the need for manual recordkeeping.

Comprised of a mobile application, web-based applications and an onsite

receiving application connected to the weigh scale, LIMS PRO provides an easily accessible reporting dashboard that shows exactly what is happening from forest to sawmill. Whether in the woods or at the weighing scale, this new software simplifies the complete process for sawmills—taking it from days to hours through improved data accuracy, real-time reconciliation, minimization of processing errors and faster truck turn times.

“At Trimble, we work closely with our customers to digitize their supply chain data,” said Kevin Toohill, general manager of Trimble Forestry. “LIMS PRO enables partners and others along the value chain to digitally transform their operations—moving from paper tickets, log sheets and manual data entry to modern workflows. This means increased accuracy and less time spent tracking down paper copies or entering data multiple times.”

“Leveraging our work with more than 500 large forestry customers, we have developed a hosted, cloud-based solution that gives small- and medium-sized businesses

the opportunity to benefit from our enterprise expertise while having digital workflows tailored to meet their needs,” said Toohill. “This takes the complexity out of managing and maintaining a dedicated on-prem log and inventory management system.”

In addition to digitizing the supply chain, this new software enables forestry organizations to:

• Simplify load reconciliation by syncing the weigh scale to the settlement system within minutes

• Automate invoicing and financial settlements

• Track yard inventory while monitoring costs to procure timber inventory

• Manage key performance indicators and assess the overall health of the business

• Seamlessly share data with partners

• Eliminate need for additional IT infrastructure as the solution is hosted and managed in Trimble’s secure AWS cloud environment

I• ntegrate mobile tickets, using the LIMS mobile application, with weigh scales to replace handwritten tickets and log sheets

The ultimate timber resaw blade. Lasting twice as long as LENOX Woodmaster C and 3 times longer than the nearest competitor.

The wait is over for professional sawyers, as Dakin-Flathers proudly unveils the latest innovation in timber resawing technology - RIPPER37 QUANTUM! Engineered to redefine the limits of bandsaw blades, RIPPER37 QUANTUM promises unmatched precision, efficiency, and above all, durability for resawing lumber like never before.

RIPPER37 QUANTUM outperforms all other resaw blades, lasting twice as long as the current market leader LENOX Woodmaster C and 3 times longer than the nearest competitor!

“The exit of LENOX Woodmaster C from the market presented us with a big challenge. We wanted to provide an alternative for the market, and specifically for Lenox customers, which is not only as good as LENOX Woodmaster C, but which is a MASSIVE improvement. We invested huge resources into R&D, innovation, new technologies and rapid prototyping. And we SUCCEEDED!

In independent tests, Quantum lasts twice as long as Woodmaster C and three times as long as the nearest competitor. We have patented the new technology and the product, and really look forward to working with our

Using cutting-edge materials and manufacturing techniques, RIPPER37 QUANTUM is designed to withstand the most rigorous resawing applications. Produced in aerospacecontrolled temperature conditions using the world’s first gaseous phase control. The new heat treatment

resaw applications. Customers can order the product through our authorized global network of distributors.

For additional information, technical specifications, and pricing, interested parties can contact our sales team on +44 (0) 1977 705 600 or email info@ dakin-flathers.com.

Dakin-Flathers is the world’s largest manufacturer of carbon bandsaw blades dedicated to delivering innovative, highperformance bandsaw blades to woodworking professionals and hobbyists worldwide. With a legacy of excellence and a commitment to quality, Dakin-Flathers is continuously pushing the boundaries of what’s possible in bandsaw blade manufacture.

RIPPER37 QUANTUM marks a significant advancement in timber resaw bandsaw blade technology, promising unmatched performance and durability. Whether you’re

Say goodbye to inefficient resawing processes and premature blade changes.

RIPPER37 QUANTUM boasts an unprecedented blade life significantly increasing productivity, especially on multi-head sawmills, along with boosting profit margins.

partners to help them grow their sales and market share.”

Oliver Garside, Managing Director

Oliver Garside, Managing Director

Why is it so Good?

It’s down to Dakin-Flathers patent pending TOP-SECRET manufacturing process!

process results in exceptionally low levels of oxidization producing a near-perfect grain structure for exceptional longevity and cutting performance.

RIPPER37 QUANTUM is currently available in 1” x 2 hook to cater predominantly for pallet manufacturing with multi-head sawmills, though it is suitable for many other

a seasoned professional or a passionate woodworking enthusiast, RIPPER37 QUANTUM is set to transform your resawing experience. Embrace the power of innovation and take your resawing to new heights with the RIPPER37 QUANTUM!

Find out more at www.dakin-flathers.com/ sawmill-bandsaw-blades/ ripper37-quantum-resaw-blade

HSM offers the right skidder for every need. Designed for jobs from thinning to harvesting in deciduous forests under difficult conditions. What they all have in common is their robust design with central torsion and compact dimensions, with tyres as wide as 940 mm at outside dimensions of less than 3 metres. For every performance class, HSM offers the perfect selection of cranes with internal hoses, attached low on the vehicle. State-of-the-art engine technology, high-performance hydraulics and innovative drive technology, such as the High Speed Drive or Twin Power Drive transmission, round off the range.

Södra has decided to investigate the conditions for a new large-scale sawmill in Kinda in Östergötland, Sweden. A preliminary project will be undertaken and serve as a basis for a future investment decision.

Södra’s assignment is to improve and renew the value of forest estates. A key part of the association’s Group strategy is a future-proof industrial structure that continuously creates a leading offering for customers and consumers. Our sawmills play a central role in this work and Södra has therefore now decided to launch a preliminary project to study the conditions for the construction of a new largescale sawmill.

The preliminary project started in the spring and is investigating the potential to replace Södra’s current sawmill in Kinda in Östergötland Municipality, Sweden. The new facility under investigation would be constructed using the latest technology in the industry and mark a

technological leap that would benefit health and safety and productivity.

“Our industrial structure has created our current strong position and is key to Södra’s development moving forward,” said Peter Jhaveri, President of the Södra Wood business area. “An advanced sawmill structure strengthens the association and our ability to create more value from members’ forest raw material, and to contribute further to the climate transition. This preliminary project at Södra Wood Kinda will investigate opportunities to take this work to the next level and we hope to contribute

with more processed forest raw material in an even more efficient industry,”

Södra Wood Kinda is one of Södra’s eight sawmills and the unit is strategically located to contribute to wood sales in the area and Södra’s customer offering.

“Södra Wood Kinda plays a key role in Södra’s industrial structure and I am pleased that there is great development potential. For us, it is vital with a viable industry that it constantly improves and develops so we can meet market demand. I look forward to studying the findings of the preliminary project,” said Patric

September 1st, Marcus Åsgärde will be the new President of the Södra Wood business area. Marcus has an extensive background in Södra and will succeed Peter Jhaveri, who has decided to step down from the role to take on other assignments.

Åsgärde most recently served as manager of a sales and operational planning project at Södra, prior Mill Manager of Södra Cell Värö (2020 to 2023) and has extensive experience from several roles and business areas at Södra, including Mill Manager of Södra Wood Värö. Marcus studied at Chalmers University of Technology in Gothenburg and the Stockholm

School of Economics.

“I am delighted to welcome Marcus as Executive Vice President of the Södra Wood business area. Marcus has an extensive background from Södra and is a highly valued and competent leader. Södra’s sawn timber business will play a key role for the association moving forward, and Marcus will make a substantial contribution to the continued development of Södra Wood,” said Lotta Lyrå, President and CEO.

Takes effect September 1st

Marcus Åsgärde will take on his new role on September 1st and will accede to Södra’s Group Senior Management.

“I am looking forward to

being a part of Södra Wood and to develop the business area together with all my colleagues. Our sawn timber products are in high demand and play a key role in driving the climate transition, while we also need to maintain our long-term focus on operational safety and efficiency.

This is an important trend to continue pursuing and I am looking forward to doing that with a focus on people and culture,” said Åsgärde.

Marcus will succeed Peter Jhaveri, who has decided to step down from the role to take on other assignments.

During the autumn, Peter will continue to perform separate assignments for Södra and

work with organisational development.

“I would like to thank Peter for his fantastic efforts in Group Senior Management and at Södra Wood, where he contributed with several major successes, outstanding results, and a solid work effort. Peter’s competence and great commitment have been important for the association’s development,” said Lotta Lyrå.

In the ever-evolving landscape of Artificial Intelligence (AI), BID stands as a pioneer in robotic automation, transforming the trim block production handling process for sawmills worldwide. With unrivaled precision, efficiency, and profitability, BID’s AI-powered robots continue to revolutionize the way trim blocks are picked and sorted, ensuring no valuable piece goes to waste.

This innovation comes just at a perfect time where industries face daily challenges around the workforce attraction and retention, safety, cost control, and sustainability and growth. People do not want to do dull and dangerous jobs anymore. Robotic automation, mainly the AI-powered one, eliminates the need for employees to perform unfulfilling or dirty jobs and addresses challenges arising from low unemployment rates and an aging workforce in remote locations.

At the heart of this innovation lies a sophisticated AI-powered system that employs cuttingedge scanning and tracking capabilities. The first step in the trim block line involves presorting, where sawdust and undersized trims are efficiently removed, ensuring the purity and quality of the blocks. BID’s system then arranges the blocks into a single layer, setting the stage for subsequent steps with ease and accuracy.

The true brilliance of BID’s technology lies in its AI-powered robots, which swiftly identify valuable blocks, separating them from rejects destined for the chipper. This advanced technology enables the robots to make precise decisions, guaranteeing that each piece meets the desired grade. However, BID’s AI-powered system goes beyond mere identification. It utilizes AI scanning, optimization, and tracking to fine-tune each block’s solution thus maximizing its potential value. Depending on the mill’s production, the system will either have one pick and place robot with a pace of up to 30 blocks per minute, or two robots with a capacity of up to 48 blocks per minute. Three or more solutions are also available for a higher piece count.

The process continues with stamping and tier generation, ensuring an organized and efficient workflow. Notably, BID’s robotic solutions excel in stacking not only trim blocks but also boards, enhancing overall production capabilities. At BID, each solution layout is specific to the customer’s needs.

The robotic system can handle wood products that are up to:

• Thickness: 8’’

• Width: 12’’

• Cross section: 8x8’’ or 2x12’’

• Length: 12’

The robotics system can be smartly connected to BID’s digital platform, OPER8TM, to provide real-time feedback on the trim block line’s operations.

BID’s robotic system is built for durability and safety, with concrete bases providing stability in case of an emergency stop. The robotic system area has a lock door switch on all doors, a push button box to ensure safe access, and a push button to restart the line.

Installation and start-up are hassle-free, requiring no specific expertise. Training on the global process is provided by BID, while robotic training is handled by specialized partners. BID’s PLC standards enable programming without the need for internal robotic knowledge.

The advantages of AI-powered robotic automation

There are various advantages of choosing BID’s robotic automation. Firstly, it surpasses traditional laborbased methods by operating at a faster rate, delivering results with remarkable speed.

During BID’s research and development phase, it has been assessed that yields could be increased up to 50% in comparison to human sorting and stacking which often leads to inaccurate categorizing and high-quality blocks sent to chipper.

Secondly, BID’s system leverages sophisticated AI algorithms to analyze data and boards, making informed decisions based on real-time information. By identifying and handling blocks more efficiently than standard robotic applications that use photocells only, BID’s vision scanner and grading rules

ensure precise decision-making for higher-quality and yield outcomes.

Moreover, BID’s robotic automation operates continuously without breaks, maximizing production output and efficiency. With precision and consistency, businesses can streamline their operations, reducing labor costs while increasing profits. Thanks to its strategic partnership with Yaskawa Motoman, BID Group robotic systems are supported 24/7 ensuring peace of mind and an uninterrupted workflow.

The decision to embrace robotics in manufacturing is driven by several key factors. One of the most crucial considerations is safety. Robotics eliminates the need for employees to engage in dangerous tasks, ensuring a safer work environment. Additionally, with a scarcity of available skilled labor, robotics offer a solution by taking over repetitive and physically demanding tasks.

Cost-effectiveness and reliability are other significant advantages of using robotics. BID’s complete solutions, which are fully integrated with mechanical, PLC, optimization, and robotic elements enhanced by Artificial Intelligence, handle complex problems with efficiency and precision.

Consistent decision-making and maximized production and revenue make BID’s system a superior choice.

BID’s AI-powered robotic automation has ushered in a new era of trim block production. Its precision, efficiency, and profitability are unmatched, making it the ultimate choice for sawmills looking to stay ahead in the race for progress. By

integrating the transformative power of BID’s technology, businesses can revolutionize their operations and secure a competitive edge in the industry.

Contact BID today to experience the future of trim block production and take your business to new heights. Do not miss this opportunity to shape the future of your industry.

info@bidgroup.ca

The sawn timber production of the wood products company Koskisen’s new processing unit started as planned at the beginning of July. Production of the new unit will be ramped up gradually during the second half of the year, and full operating capacity will be reached in early 2024. The new unit will significantly improve the productivity of the Sawn Timber Industry starting next year.

The new production line will increase sawmilling productivity by up to 40 per cent and enable the use of smaller log diameter. This way, we will be able to serve our customers with new products and the wood raw material will be used even more precisely in end products that bind carbon for a long time,” says Jukka Pahta, CEO of Koskisen.

Sawn Timber Industry segment’s EBITDA will improve by approximately EUR 8 million annually once full production capacity has been reached. The EBITDA improvement consists of, among other things, higher sales volumes, increased side streams, as well as improved material efficiency and quality yield. The unit’s significantly higher degree of automation and more efficient logistics will also improve profitability.

The total investment in the new unit is approximately EUR 50 million in 2021–2024.

In the first phase of the investment, the unit’s

production capacity will increase from the current 300,000 cubic metres to 400,000 cubic metres. In the second phase, it is possible to increase volumes up to 500,000 cubic metres. In addition to increasing volumes, product quality is also improving.

“The new wood processing unit represents the latest world-class technology and efficiency, which is also in line with our high-quality driven strategy. We have succeeded in the project in accordance with the set goals on schedule and budget, which in part says a lot about our expertise and capability. Thanks for this go to both our own project organization and external contractors,” says Tommi Sneck, Director, Sawn Timber Industry.

Koskisen manufactures high-quality standard sawn timber as well as dimensioned and strength-graded sawn timber from spruce and pine. Koskisen further processes approximately 40 per cent of

the sawn timber it produces, mainly by planing and, to a lesser extent, painting. A significant part of the sawn timber and processed products is sold to markets outside Finland, especially Japan.

Additional information:

Sanna Väisänen, Director, Sustainability and Communications, Koskisen Corporation

sanna.vaisanen@koskisen.com

Tel. +358 20 553 4563

Koskisen is an international wood processing specialist with more than a century of experience and known for its agility and ability to listen to the customer. They utilise their valuable wood raw material as thoroughly as possible, up to the last particle of sawdust. They manufacture high-quality and sustainable products that store carbon for decades. The Group’s revenue in 2022 was EUR 318 million.

J.D. Irving’s Truro Sawmill, also known as Sproule Lumber, recently completed a major upgrade which will greatly improve operations and productivity. The extensive modernization project, spanning over

During the seven-week shutdown, the mill underwent intensive mechanical, civil and electrical work, with more than 100 contract workers involved at the peak.

Key upgrades included the replacement of outdated equipment with new, state of the art machines. Replacing these machines results in faster saw operation thanks to

larger motors and advanced scanning technology. These upgrades will also result in better log recovery. This refers to how many board feet that can be recovered from the log and how many chips the log can provide to ensure maximum usage of every log. The new machine scans the logs and sends data to ensure the log is cut appropriately to maximize value.

A new planer and associated infeed and sticker handling systems were installed, further streamlining the production process. The trimmer/sorter line underwent multiple upgrades, allowing it to run up to 180 boards per minute. The sorter was expanded with 15 additional bins for dressed lumber and a second stacker was relocated from Deersdale. These machines will ensure that the sorting process of boards by length will be faster and smoother. To complete the upgrades, the mill also added an automated wrapper to allow for less manual labor and a safer workplace.

WE HAVE INSTALLED 250 OF THESE SYSTEMS AROUND THE WORLD!

TNT Wholesalers, a wholesale distributor of lumber and plywood goods has announced its acquisition of Sierra Forest Products in Terra Bella, California, by Sierra Forest Products Holdings, Inc, a sister entity.

TNT Wholesalers was founded by Dave Thomas and soon partnered with lumber industry veteran, Greg Mitchell. Through their business and industry experience TNT has made a name as a premier resource to fellow wholesalers, lumber distributors as well as end-users of industrial lumber products.

Together Dave and Greg have diversified TNT’s product line, broadened its customer base and grown their sales

team establishing itself as a multi-million-dollar sales company.

“This important step forward will ensure the continued success of TNT’s scalability,” said Dave Thomas. Greg Mitchell continues, “We are humbled and honored by the torch of Sierra Forest’s unparalleled reputation of quality softwood lumber products being passed on to us.”

Dave and Greg will be joined in partnership by Seth Hokit, current sales manager at Sierra Forest Products, as owners of Sierra Forest Products Holdings, Inc. Seth’s experience in sawmill sales has earned him a reputation as a creative and talented

lumberman. He has built his lumber career on the development and maintenance of business relationships. His insight and knowledge of the workings of the industry will allow Sierra Forest Products to continue being a market leader.

Sierra Forest Products President Kent Duysen will continue to be an integral part of Sierra Forest’s success and will remain on staff as a mentor and leader with the company. With Kent’s 46 years of industry experience, he will help to lead SFP into the future.

TNT’s wholesale distribution arm will be led by Greg Mitchell and his team of traders that include industry veterans with over 35 years of wholesale lumber trading.

Sierra Forest Products was established in 1967 and boasts over 300 acres of sawmill and forest land in Central California. This centrally located site will allow statewide distribution for just in time buying clientele. With abilities to service throughout the SouthWestern United States as well as Mexico, Sierra Forest Products’ reach will be greatly expanded. The sawmill will continue to produce dimensional lumber, pine commons and industrial grades of softwoods

Pukepine Sawmills is planning a major upgrade for their planer mill with the help of USNR. The project includes an overhaul of existing equipment that will be completed in two stages.

The first stage will come with a number of new installations, including USNR’s Occlusionless THG, along with the infeed and associated handling equipment. Pukepine will also install a refurbished USNR Revolver Lug Loader, a Tray Sorter, and a new planer that operates at 550m per minute. All this will come with the

trusted engineering and project management services offered by Skookum, USNR’s partner based in New Zealand.

The second stage, to be implemented later on, will see the installation of a new Multi-Track Fence and a new dry stacker.

And when this is all said and done, Pukepine can look forward to advanced

automated grading, improved productivity, and more efficient labor distribution. The mill will produce higher quality boards at a faster rate while providing more opportunities for their team to work more effectively.

USNR and Skookum look forward to being part of this initiative and are proud to support Pukepine Sawmills in achieving its production goals

Södra’s new crosslaminated timber (CLT) facility was recently inaugurated on the west coast of Sweden. The facility is one of the largest in Sweden and marks a tenfold increase in Södra’s production capacity. Guests at the inauguration included Brittis Benzler, County Governor in Halland Municipality, and AnnCharlotte Stenkil, Chair of Varberg’s municipal council.

Akey part of Södra’s Group strategy is a future-proofed industrial structure that creates a leading offering for customers and consumers. The new CLT facility broadens the market for construction materials while also promoting sustainable construction and more sustainable communities.

“Södra’s assignment is to renew and improve the value of forest estates and our new CLT facility is one way to do exactly that. This is a proud moment for Södra’s entire organisation – members, employees and customers are continuing to work together to build stronger value chains that enable us to meet society’s demand for sustainable and innovative products from family forestry,” said Lotta Lyrå, CEO of Södra.

The plant at Värö is one of the largest in Sweden for the production of CLT with the capacity to supply framing materials for just over 4,000 homes per year, a tenfold increase in Södra’s production

capacity. By investing in production at Värö, Södra is close to several developing regions for CLT in the Nordic region. Logistically, the product can also be easily shipped to international markets from the port in Varberg. CLT production is completely fossil free as it uses green energy produced at Södra’s pulp mill at Värö.

Guests of honour included the County Governor and Chair of the municipal council 150 curious guests attended the inauguration, from both the local area and abroad. During the day, the inauguration was celebrated with speeches and a guided tour of the facility. Guests of honour included Brittis Benzler, County Governor in Halland Municipality.

“One prerequisite for meeting the emissionsreduction targets is broadbased cooperation among companies, authorities and politicians – when we work together towards the same objective. Another is that we

show that it is possible to achieve the targets, which will instil hope and in turn create engagement and a sense of responsibility. I am therefore delighted to take part in this inauguration,” said Brittis Benzler, County Governor in Halland Municipality.

The investment in a new plant at Värö has led to recruitment of 90 new Södra employees to the company’s Building Systems segment, which is responsible for producing CLT. This was welcomed by Ann-Charlotte Stenkil, Chair of Varberg’s municipal council, who was also a guest at the inauguration.

“This type of establishment is very important for Varberg. It creates many jobs. It also makes sustainable and largescale timber construction possible – both housing and commercial premises. The plant is also very impressive in terms of its size, logistics and efficiency,” said Ann-Charlotte Stenkil, Chair of Varberg’s municipal council.

Södra’s goal is to be the leading CLT producer in the Nordic region

CLT has many different applications and has become increasingly prevalent in Swedish buildings within a short period of time. The material can be used to construct high-rise buildings, industrial halls and schools in timber, and by using Södra’s CLT the building’s carbon footprint can be reduced by up to 80 percent. Södra’s goal is to be the leading operator in the Nordic region in solid timber construction by increasing the value of the raw material for family forestry in an innovative manner – from seedling to finished product.

After 43 years of servicing the wood industry, MiCROTEC today is the only provider offering scanning and optimization solutions from the logyard to secondary processing both for the softwood and hardwood sectors

Committed to providing customers with economical and sustainable wood utilization, MiCROTEC provides a wealth of accurate data for sorting and cutting optimization. Earlier this year, MiCROTEC introduced MiCROTEC Connect, offering optimized solutions for each step of the process. MiCROTEC Connect is the real fingerprint system based on CT-scanned logs. Through the innovative scanner and software solutions and the implemented MiCROTEC Ai platform, each log can be traced from virtual to real boards.

CT Log provides complete reconstruction of the logs’ internal features. The scanner allows logs to be graded and sorted by quality, optimizing the cutting solution with the highest value in real-time. Powered by MiCROTEC Ai, CT Log provides exact threedimensional internal wood defect detection in size and position. Providing the size and location of each defect of a log, MiCROTEC’s cutting optimizer finds the best cutting solution by grading each virtual board

in advance. Internationally, CT Logs are installed in different lines and applications for a variety of wood species. Depending on the sawmill’s production, the value uplift provided by the CT Log starts at 5% to more than 20%.

When CT Log ins’t installed in transverse applications, the MiCROTEC Connect concept continues lineally with the Logeye Stereo

MiCROTEC’s patented stereoscopic imaging system, Logeye Stereo, is the only worldwide scanner that provides a full 360° scan of a log as it’s rolling into the carriage, headrig, end dogger, or from a transverse to lineal conveyor. Operating internationally, the Logeye Stereo makes sure logs are fully optimized and ready for sawing the instant it’s dogged or sent through the sawline.

Specialized for the sawmill, the optimization is based on overbark and underbark diameter, length, curvature, and taper, as well as internal quality features. Logeye Stereo provides high-precision 360° shape visualization of logs to detect defects within the log. Using proprietary technology, the Logeye Stereo is integrated

with MiCROTEC Ai, opening the possibilities of detection among many softwood and hardwood species.

The Logeye Stereo leads to higher throughput speed and vastly improved recovery, as the entire surface of the log is imaged without shadows or occlusions. Previously only possible on lineal scanning lines, the scanning can also detect the current rotation of the log at any point in the process, allowing for full rotation optimization and turn correction. Logeye Stereo also includes the ability for operators to change a cut solution board by board during the cutting process.

When integrated into the MiCROTEC Connect concept, Logeye Stereo performs geometric matching at the carriage to achieve CT-based optimization. Combined with MiCROTEC’s optimization software Maxicut and Optiline, the Logeye Stereo provides full transparency of the optimized solution overlayed on the live image of the real log.

Through the MiCROTEC Connect solution, the Logeye Stereo and CT Log integrate with Truespin, the log rotation control and movement

compensation scanner. Measuring the rotation and uncontrolled movements of logs in real time, Truespin detects and tracks the external texture of the log acquired with digital cameras without

the aid of additional marks. Increasing yield due to rotation accuracy, the system measures in real-time the rotation of the log during the clamping process and log turning in the log turner in front of

the saw. Truespin provides reliable data about the actual log movements. MiCROTEC

Connect is a modular concept and can connect with various scanners based on the customer need.

Recent mergers and acquisitions have solidified USNR’s leadership position in providing equipment and technology for the global wood processing industry, and we are sharing some of it with you at the Forest Products Machinery & Equipment Expo this August in Nashville, TN, hosted by the Southern Forest Products Association.

Innovations in machine design bring an elegant efficiency to primary breakdown equipment, with less moving mass and more control, these systems operate smoothly and efficiently.

See the world’s most advanced primary breakdown log profiler on display. This new design includes smart anvils that allow precise positioning

against sideboards cut at any angle, which reduces defects and improves chip containment while still allowing the flexibility to cut sideboards at an angled solution.

USNR’s new log profiler allows more volume through the mill while capturing equal recovery. It delivers higher quality finished products and reduces edger demand.

The world’s first standalone knuckle-style log turner, dubbed the Sidewinder, will also be displayed. Based on our proven knuckle turner infeed technology, this unique unit provides more versatility in new and existing primary line applications and requires less infrastructure thus reducing installation costs.

The Sidewinder offers higher turn accuracy and lower operating and maintenance costs. Its wide operational envelope handles 3” to 24” diameter logs with feed speeds up to 700 FPM. Two sets of turning rolls mounted to shifting carriages enable it to be mounted behind slewing and skewing infeeds.

Experience the future of efficient lumber manufacturing technology in USNR’s booth where you can learn how to capture more recovery and produce higher value products by applying our advanced grade optimization technology upstream in the sawmill.

USNR presents the next generation 4900 family of sensors for transverse edging, trimming, and grade optimization applications. Based on the same proven

technology of the Bioluma 3900 sensor, the 4900 captures higher density scans with improved resolution.

See first-hand the power of the Bioluma sawmill grade optimizer system on display in a trimmer application. The system uses high frame rates and high-resolution imagers to gather stunning visual images and precise geometric measurements. From there, the information is processed with the powerful MillGenius optimization to give mills extremely accurate grade processing solutions at high speeds for the highest value optimized decisions.

The Bioluma sawmill grade optimizer offers sawmills the highest value optimized decisions based on grade and recovery performance. It can also boost drying capacity by identifying defects in green boards and trimming the ends before they’re sent to the kilns.

We are also pleased to showcase the highly innovative optimized grading solutions from our VAB-brand lineal planer mill scanner and lumber grading system. This system is designed to increase premium lumber grades while decreasing economy grades. It increases production, decreases trim loss, and reduces the need for labor by eliminating the time required for manual graders to analyze boards.

The VAB-brand lineal grading system easily manages multiple grades in one recipe. Mills capture more wood volume. Its small footprint simplifies installation and easily integrates into existing production lines.

Visit us in booth # 929 at Forest Products Machinery & Equipment Expo and let us share advances that will make your process more efficient and improve your bottom line. 800-BUY-USNR, +1 360.225.8267, usnr.com

USNR’s new Sidewinder log turner handles 3” to 24” diameter logs at speeds up to 700 FPM with higher turn accuracy and lower maintenance costs.

The difference with Delta is measurable. Precisely coordinate multi-axis

will diminish, throughput will rise, and profits will stack up as a result.

RemaSawco AB has signed an agreement with Älvsbyhus AB regarding an upgrade of the company’s sawmill in Älvsbyn. The upgrade affects various systems in the saw line.

Älvsbyhus AB has its own sawmill in direct proximity to the factory in Älvsbyn. It is this sawmill that now needs an upgrade of the saw line, and RemaSawco was once again trusted to deliver the necessary systems. The order includes products for optimization, measurement control and a 3D measuring frame.

“We are very pleased that Älvsbyhus chooses to renew its trust in RemaSawco. Satisfied customers is the best acknowledgement we can get for the work we do and it gives us new energy to continue working for the good of our customers!”

Says Emilien Saindon, CEO of RemaSawco.

Delivery is planned for the turn of the year 2023/2024.

Wood Technologies International (“Wood Technologies” or “the Company”), a comprehensive supplier of modern lumber processing equipment, technology, and essential tooling, announced President Dale Brown has been appointed CEO of the Company, effective June 30, 2023.

Outgoing CEO Craig Tompkins will serve as a Strategic Advisor to the Board of Directors of Wood Technologies to help continue to guide the company.

“We are proud to have Dale step into this role after eight years of leadership at the Company,” said Rob Sivitilli, Chairman of the Board of Wood Technologies. “We thank Craig for his efforts at leading the effective integration efforts after the merger of USNR and Wood Fiber Group and for helping drive two subsequent complementary acquisitions, all which built Wood Technologies into an industry leader today.”

Brown has had a 37-year tenure with Wood Technologies and predecessor company USNR, starting his career there in 1986 as an accounting data entry clerk, working his way up through various roles in USNR’s accounting, sales and executive operations

departments. Past positions included Chief Accountant, Controller, Vice President, Senior Vice President, and CEO of USNR in 2018. Brown was named President of Wood Technologies upon the USNR/ Wood Fiber Group merger in 2021.

“I thank the Board for entrusting me as the next leader of Wood Technologies, and I look forward to working with our great team whose hard work has contributed to our success,” said Brown. “Craig has been a first-rate colleague over the last year as we’ve built an industry leader with tremendous potential. I thank him for his efforts and wish him well in retirement.”

Tompkins helped spearhead the merger of Wood Technologies’ predecessor companies: mill automation, equipment supplier and technology system integrator USNR, and sawmill parts supplier/manufacturer Wood Fiber Group, in November 2021. This combination of highly complementary product offerings and customer bases enabled Wood Technologies to become a leading supplier in the industry, with 1,500 employees and 30 operating sites.

Tompkins also helped lead and integrate Wood Technologies’ July 2022 acquisitions of Timber Automation, a provider of custom engineered equipment, aftermarket parts, controls and optimization systems; and The Knife Source, a manufacturer of machine knives used in waste wood chipper machines and brush chipper equipment.

“Craig’s skill in uniting Wood Technologies’ predecessor businesses created a leading wood processing brand well positioned for future growth,” said Brown. “Craig fostered a positive business culture enabling strong performance, evidenced by strong revenue growth and record levels of backlog over the last few years. He leaves a great legacy at Wood Technologies that we will work steadfastly to maintain.”

“I am immensely proud of my time at Wood Technologies, where I got to work with fantastic people— including Dale—over the past eight years,” Tompkins said. “With Dale at the helm, I can walk away confident that the company is in great hands and that it will achieve even greater success.”

About Wood Technologies International Wood Technologies International was created through the transformational combination of USNR with Wood Fiber Group. Wood Technologies International is a leading engineered automation equipment and solutions platform, delivering sophisticated systems, consumable products, parts, and services to wood processors. From saws and machinery to automation and engineering consultation, industry professionals can turn to Wood Technologies International for their wood processing needs. To learn more, visit woodtechnologies.com.

The argument goes that green products, particularly green and renewable energies, will be favoured as governments use increased stakes in enterprise to force the environment to the front of the business agenda.

This is likely to be a boon for forestry in general, particularly for biomass production. And while high-level chippers may be the primary recipient of this new desirability, all size-reduction technologies could potentially have an angle into new business.

Here, we present some of the leading products in this technology space that could turn forest waste into money for entrepreneurs.

grinders as wood waste recycling machines. This industry-changing innovation made sustainable forestry practices more attainable.

1

1 Safety Guards

Peterson horizontal grinders are built with safety in mind, including the projectile guard.

1 Safety Guards

Using horizontal grinders to process bark waste from in-field chipping into a value-added product means leaving less waste

4 Adaptive Feed System

Astec Industries is an industry leader in producing a full line of Peterson grinders, disc and drum chippers, flail debarkers, and blower trucks. A history of innovation and reliable manufacturing has established a reputation for equipment of the highest quality. Astec equipment is manufactured in Eugene, Oregon, where each machine is engineered and built to exact standards.

Peterson was one of the first to develop portable horizontal

2 Sloped Feed Walls

Peterson horizontal grinders are built with safety in mind, including the projectile guard.

Allow better visibility while loading and smoother feeding for more production in a wide variety of materials.

2 Sloped Feed Walls

Allow better visibility while loading and smoother feeding for more production in a wide variety of materials.

3 Feed Chain Conveyor

3 Feed Chain Conveyor

A robust feed chain conveyor efficiently feeds the rotor.

Monitors the grinding load and varies the speed of the feed system to keep the engine working at its optimal power curve. It accelerates the feed when the engine load is light, slows when the load is high, and reverses feed when the load is excessive.

5 Impact Cushion System Absorbs energy shocks component life and helps severe impact.

6 Rotor Placement

Optimum rotor placement reduces the potential of rotors are available.

A robust feed chain conveyor efficiently feeds the rotor. A hydraulic drive motor synchronizes with the feed roll for near continuous feeding and massive throughput.

5 Impact Cushion System

A hydraulic drive motor synchronizes with the feed roll for near continuous feeding and massive throughput.

4 Adaptive Feed System

Monitors the grinding load and varies the speed of the feed system to keep the engine working at its optimal power curve. It accelerates the feed when the engine load is light, slows when the load is high, and reverses feed when the load is excessive.

Absorbs energy shocks and spikes to extend grinding system component life and helps prevent catastrophic damage from severe impact.

7 Mobility Options Astec horizontal grinders or stationary electric versions. an optional tow dolly for be towed with a dump truck.

8 Multiple Engine Options Depending on emission both Tier II, Tier IV, and

Size-reduction technology is looking more and more profitable as a secondary revenue stream or primary business

and site clean-up. Grinding slash into hog-fuel or nutrient-rich forest bedding can lessen logging impacts to an operation site. Reducing materials before it leaves the job site can increase payload and reduce truck traffic, fuel usage, and road erosion.

Astec’s continued commitment

to sustainability and innovation has developed specialized delivery and processing equipment that turns low-grade organic materials into high-value products. The company’s strong foundation of innovations, one built upon the next, culminates into a premium product.

The Astec Industries

Peterson 4710D Horizontal Grinder is a track mounted horizontal grinder designed for high-volume producers with very demanding end-product specifications

“Not only are they built to withstand the harsh conditions of forestry operations, but they also offer the lowest operating cost per tonne,” the company said.

Astec’s three-stage grinding process starts with its patented upturn rotor, drawing material into the grinding chamber. The anvil is positioned for optimum sizing and the large grate area offers high production. The upturn process provides better material fracturing and Astec’s four-grate sizing system makes it easy to produce the sized material customers demand.

This grate system offers unparalleled customization to tool the machine to fit output needs. Grates are removed through an easy-access door on the side wall. Combined with Astec’s heavy-duty bits, and robust anvil, their horizontal grinders have an

exceptional wear life and accurate product sizing.

All Astec grinders feature an adaptive feed system. This system monitors the grinding load and varies the speed of the feed system to keep the engine working at the top of its power curve. A patented Impact Release System allows contaminants to be ejected from the grinding chamber to reduce the risk of catastrophic damage from ungrindable objects like rocks and metal, a system unique to Astec.

13

Powerful cross-belt magnets pull tramp metal off of the conveyor, producing cleaner, profitable material. Earn additional income from scrap metal!

6 Rotor Placement

System and spikes to extend grinding system helps prevent catastrophic damage from

Optimum rotor placement ensures positive feeding and reduces the potential of thrown material. Pinned or drum rotors are available.

placement ensures positive feeding and thrown material. Pinned or drum

7 Mobility Options

Options grinders are available in wheeled, tracked, versions. Larger tracked grinders have for easy transport, while the 1700D can truck.

9 Telematics gives connectivity

8 Multiple Engine Options Available

10 Continuous Discharge Conveyor

13 Optional Cross Belt Magnet

New D-Model grinders feature Remote Monitoring Analytics, including a wireless display for operators and offsite analytics.

Depending on emission standards for your region, Astec offers both Tier II, Tier IV, and EU Stage V engine configurations.

10 Continuous Discharge Conveyor

One continuous discharge conveyor reduces materiel loss, increases uptime, and lowers maintenance.

Astec horizontal grinders are available in wheeled, tracked, or stationary electric versions. Larger tracked grinders have an optional tow dolly for easy transport, while the 1700D can be towed with a dump truck.

Options Available standards for your region, Astec offers EU Stage V engine configurations.

11 Guard Rails

9 Telematics gives connectivity

One continuous discharge conveyor reduces materiel loss, increases uptime, and lowers maintenance.

Powerful cross-belt magnets pull tramp metal off of the conveyor, producing cleaner, profitable material. Earn additional income from scrap metal!

14

14 Optional Magnetic Headroll

11 Guard Rails

Peterson grinders feature a magnetic headroll that allows for effective metal separation and high capacity production.

Peterson grinders feature a magnetic headroll that allows for effective metal separation and high capacity production.

15 Optional Tracked Stacking Conveyor

With safety in mind, guardrails are high-visibility yellow, reducing potential slip & fall hazards when servicing the machine.

12 IQAN Operating System

Fine-tune adjustments for maximum productivity.

New D-Model grinders feature Remote Monitoring Analytics, including a wireless display for operators and offsite analytics.

With safety in mind, guardrails are high-visibility yellow, reducing potential slip & fall hazards when servicing the machine.

Add an optional Peterson stacking conveyor to pile material even higher.

15 Optional Tracked Stacking Conveyor

12 IQAN Operating System

Fine-tune adjustments for maximum productivity.

Add an optional Peterson stacking conveyor to pile material even higher.

Peterson+ is a telematics system that is now available on all new Astec grinders. It gives the owner and operator a live view of their equipment performance and GPS location details. Loading operators can see common machine analytics right from their cab. Peterson+ includes a host of other features, including a maintenance log, directions to the machine site, and historical machine data.

The most recent model release, the 4700D Horizontal Grinder, is designed for high-volume producers with very demanding end-product specifications. The 4700D is powered by a Tier IV Caterpillar C18 engine rated at 755 HP (563 kW).

The machine uses an upturning rotor in combination with a down-force compression roll to grind the feed material in a three-stage process, resulting in a more accurate and consistent finished product.

Opposing rotational forces create an aggressive shearing action. The upturn rotor draws material into the grinding chamber and minimizes bit wear, providing the first stage in material size reduction. Available with pinned or drum rotors.

2 Anvil

Positioned for optimum sizing and production, the anvil provides the second stage in the sizing process.

3

The last step in the three stage sizing process, the large grate delivers highproduction capacity for a wide variety of materials and end products.

Optional features, like work lights, cold weather kits and a magnetic cross belt conveyor increase the grinder’s flexibility between jobs. The liquid injection system is a high-flow water option that’s great for mulch coloring and dust control, and an optional transportation dolly is available on many Astec grinder models.

With an eye on innovation, Astec has added several models to the lineup.

Astec’s most significant addition to the horizontal grinder lineup brings big power in a small package. This compact grinder has a 44 ft 1 in (1,344 cm) operating length but packs an impressive 455 hp (339 kW) Caterpillar C9.3B Tier IV engine and a large feed opening of 54 ft x 27 in (137 x 69 cm).

The 1700D Horizontal Grinder is available with wheels, while the 1710D Horizontal Grinder is a tracked model. The 1700D has a pintle hitch and can be transported between job sites with a dump truck.

The 2750D Electric Horizontal Grinder is powered by a single 600 HP (450 kW) electric motor. An on-site electric machine may be the answer for grinding mill residuals to increase profits since electric power costs are typically much lower than diesel fuel costs.

With a feed opening of 60¾ in x 32 in (154 cm x 81 cm) combined with Astec’s high lift feed roll for an optional opening up to 44 in (112 cm) high, the 2750D can reduce a diverse range of raw materials.

While Astec brought the industry-changing horizontal grinder to the marketplace to process wood waste from in-field chipping operations, sustained growth and a focus on customeroriented products continue to keep the manufacturer at the forefront of the market.

The company is constantly looking at ways to improve their equipment to make the machines more durable and easier to maintain. In response to recent trends, Rawlings is thinking outside the box and recommends systems that incorporate a combination of equipment. For example, utilizing horizontal high-speed and slowspeed grinders as the primary grinder for processing larger-size materials such as railroad ties, pallets, construction, demolition, and hurricane debris, while using the vertical grinders and hammermills to produce a smaller, more consistent particle size.

By splitting the material loads through different grinders and incorporating product screening, it allows the equipment to process the material more effectively while producing consistent feedstock,” says Judi Tyacke, Rawlings project manager.

The company’s solid steel Super Hi Inertia Rotor TM is designed from rock crusher technology, making it extremely tolerant of contaminants, rocks, and metal without catastrophic maintenance costs if metal enters the grinding chamber. The Rawlings rotor is also designed to maximize inertia while minimizing its weight.

“With the increase of inertia, our machine runs at lower rpms than competitor machines and half the speed of conventional hammermills, resulting in overall savings of electricity and maintenance costs. The cam profile of the Rawlings rotor prevents feed surges by keeping material closer to the cutting edge of the bits. This translates to better productivity as the in-feed conveyor is stalled less frequently, and less down time, as the increased energy reduces the number of motor drive stalls.

During Rawlings’ 45 years of designing wood grinding systems, our company has learned that most of its clients are asking for grinders to

obtain the smallest finished product on a single pass or one-stage pass through the grinder. We often suggest that this is not always the most economical option long term, running the grinder and related equipment at full surge capacity results in frequent equipment breakdowns, high consumption of spare parts and costly maintenance repairs. Incorporating several types of equipment into the system allows the customer to protect their investment while producing a high-quality, consistent end product.

For that reason, Rawling’s engineers have made significant changes to the hog case that allow its customers’ maintenance teams easier access to the hog rotor, sizing grates and internal case liners. Over the years, several customers have wanted a Rawlings solid rotary hog but did not have the overhead clearance in their existing footprint to allow for a clam shell opening type of machine, Rawlings says. “Our engineering team took this feedback and did a redesign of

the hog case. This new model opens hydraulically from the rear of the machine, allowing full access to the hog’s internal wear components and rotor for ease of maintenance.”

More recently, a customer contacted the company looking for a 2-inch minus product, as his feedstock was 12-inch minus with approximately 40 percent of the material already sized to 2-inch minus. “After thoroughly looking over the project parameters, we suggested a vibratory shaker deck to screen off and separate the material, removing the 2-inch accepts prior to grinding it through a Rawlings vertical drop feed hog,” Tyacke says. “This is a common practice to reduce the amount of tonnage to the machine, resulting in cost savings of spare parts, maintenance, and overall electricity costs. Simply put, it’s less expensive to screen it than grind it.”

www.wastewoodhogs.com

Since 1983, Bandit has manufactured equipment for a multitude of wood waste processing markets. The vision since the beginning, is to build quality, highly productive, easy to maintain equipment providing years of dependable service.

The commitment for quality, innovation, and dedication is instilled in every employee and is one of the main reasons why Bandit became an Employee-Owned Company (ESOP) in 2018. These core values ensure each Bandit machine will leave the factory ready to exceed your expectations.

Bandit’s line of horizontal grinders known as “The Beast”, are the most versatile grinders available on the market today. These units are the most efficient way to process wood waste and here is why:

The heart of each Beast Recycler is the Cuttermill, allowing the machine to efficiently cut material apart opposed to the beating action of a hammermill grinder. This process is best described by comparing an axe to a sledgehammer, which would you prefer to use to cut down a tree?

The mill in each Beast is larger in diameter compared to most competitive grinders. These larger diameter mills will turn at a slower RPM, generating a tremendous amount of torque to process material using less horsepower and fuel. Since the cutting action is much smoother and efficient, vibration is minimized