PEMO PUMPS:

Horner’s FREE Intuitive Programming and HMI Design Software is easy-to-use with a wide range of features.

The Horner Automation Group is pleased to announce the release of Cscape 10 software - a major new release of Horner’s FREE Windows-based Application Development software for their line of OCS All-in-one Controllers and PLCs.

Horner All-in-one Controllers combine the functionality of a PLC with a built-in Operator Interface - and are available with a variety of screen size and built-in I/O options.

As a major new release, Cscape 10 features a redesigned user interface and among its dozens of improvements includes the newly developed Advanced Graphics Engine.

This Advanced Graphics Engine supports several graphic building blocks for user

interface design that have been reimagined from the ground-up. These include (but are not limited to) Trend, XY Graph and Scatter Graph objects, a Recipe object, Alarm objects and a Video playback object.

User Interface Upgrades

t Ribbon Bar

t Editing in Tabs

t Graphics Toolbox

t Ladder Graphics

t Combined Settings

t Backup Improvements

t New File Wizard

t Project Navigator Updates

Graphic Object Upgrades

t Background Selection

t Slide & Rotary Objects

t Data & Indicator Objects

t Menu & Recipe Objects

t Trend & Graph Objects

t Switch & Selector Objects

t WebMI Plus

t Extensive Symbol Library

t Video Object and more!

Cscape can be downloaded free from www.hornerautomation.eu. It has no costly licensing fees, so you don’t have to pay for software upgrades. With fully integrated hardware and software, OCS offers easier programming, installation, development, and set-up.

Contact: Olivia Flynn T +353 021 4321266 olivia.flynn@horner-apg.com www.hornerautomation.eu

Magog Industries are long established UK designers, manufacturers and suppliers of processing, mixing and conveying screws and barrels. Based in Hertfordshire, the company operate across the UK, Ireland and Europe.

Coatings and materials available are designed to enhance longer life and greater wear resistance in for increasingly demanding processing using recycled material.

“We constantly strive to offer solutions from optimal design to reduce wear to offering a wide range of surface technologies, explained Michael Bate, General Manager.

“We design everything in-house but also work closely with specialist partners to

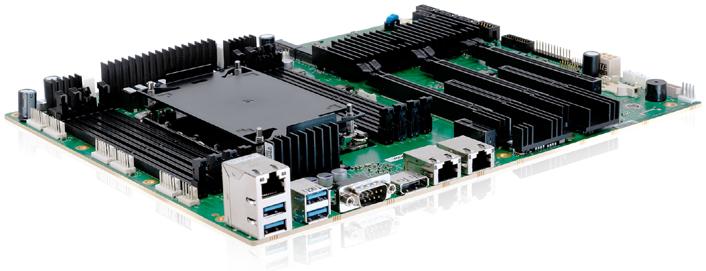

Powerful and scalable industrial server motherboard for AI and industrial applications

Kontron, a leading global provider of IoT/Embedded Computer Technology (ECT), has launched the K9051-C741, a server-class ATX motherboard for scalable 4th and 5th generation Intel® Xeon® processors. Featuring the Intel® C741 chipset and supporting Intel® LGA4677 socket processors with 350W TDP and up to 768GB of memory, the motherboard is ideally suited for demanding AI applications.

Designed for industrial, imaging, medical, AI and robotics applications, the system addresses the growing demand for high-core and high memory throughput computing platforms. The 5th generation Intel® Xeon® processors, equipped with AI accelerators such as Intel® AMX, provide optimised performance for deep learning applications.

The K9051-C741 ATX is the ideal choice for memory-intensive applications in continuous operation, supporting processors with up to 64 cores and eight memory channels. Its high expandability and integrated Intel® X710 10 GbE dual LAN with teaming function set new standards for demanding network applications in medical technology, data centres and high-performance computing.

The Kontron K9051-C741 supports DDR5 memory with speeds up to 5,600 MT/s RDIMM and capacities up to 768 GB. Five PCIe Gen 5 expansion slots allow for future expansion, while advanced thermal management and OpenBMC integration ensure efficient management and maintenance.

Following its launch in North America, the motherboard is now available in EMEA.

Contact www.kontron.com/en/products/ k9051-c-atx/p180464

meet our customers’ specific processing and production requirements. Our three core competencies run through everything we do: process experience, manufacturing expertise and engineering excellence”

Enhanced coatings include: Thin Dense Chrome (TDC) to enhance wear with low friction and is FDA Approved for food process environments. Ceramic Seal coatings reduce porosity and increase plating/coating life 4 to 10 times longer in corrosive environments, HVOF (High Velocity Oxygen Fuel) provides a crackfree 98% density with hardness of 62 to 72 HRC. This scratch-resistant tungsten carbide coating has gained much interest among plastics moulders.

Magog also specialise in refurbishment of pre-used parts which extends the life of screws and barrels by re-honing, partial re-line of barrel bores and hard welded re-build of screw flights in bimetallic alloy as standard. This provides a cost-effective option and ensure lower operating cost.

For more information, contact Magog Industries: T 01920 465201 enquiries@magog.co.uk www.magog.co.uk

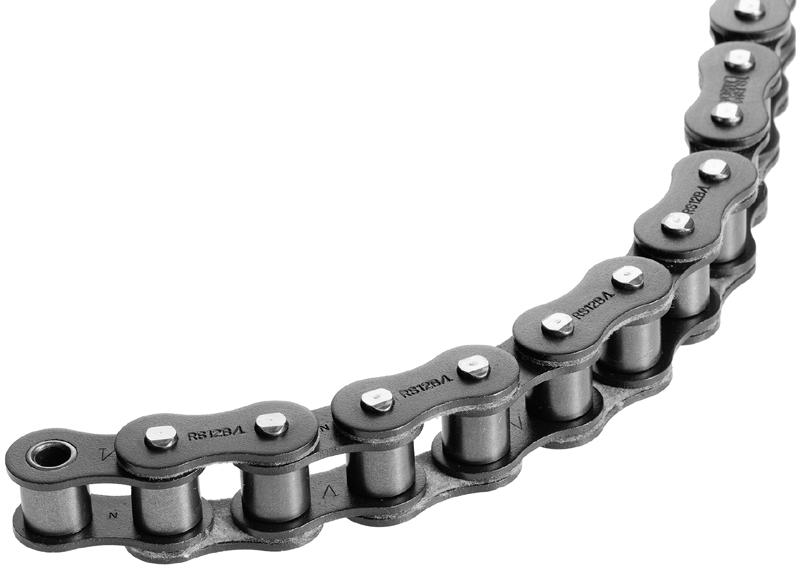

In this issue of Industry Update, we are delighted to welcome Tsubakimoto UK Ltd as our Industrial Chain Manufacturing Company of the Month

Tsubakimoto UK is a member of the Tsubaki Group, the global leader in power transmission products and automotive timing chain systems as well as new mobility solutions. Tsubakimoto has steadily built a reputation of delivering high quality service and cutting-edge technology since 1917. Tsubaki is a major player in the power transmission industry: supplying to the automotive, food & beverage, packaging and other manufacturing sectors.

Tsubakimoto UK was founded in 1985 and is based in Sherwood Business Park, Nottingham, East Midlands.

Tsubaki is an industryleading manufacturer of a wide portfolio of products, encompassing industrial drive chains, attachment chains and large size conveyor chains. Additional related products include; cam clutches/freewheels, sprockets, shaft couplings, safety devices & linear actuators complement the programme. With a wide application base, the products are utilised across automotive, paper & pulp, waste-to-energy, materials handling, food & beverage and many more.

the following applications: tray packing, chocolate moulding, thermoforming, can feeding, gable top carton filling, and yoghurt filling industry. This year’s PPMA fair was a great way to showcase innovative solutions to the UK audience and reinforce our position in the market.” explained Jake Yamamoto, Director Sales & Marketing.

In the Food industry hygiene is paramount and regular lubricants cannot come into contact with the food products. Tsubaki Lambda Chains lubricate themselves internally with NSF-H1 food grade lubricant, negating the need for any external lubrication. This solution significantly reduces the risk of contamination or produce mixing with the lubrication, affecting the chain’s articulation. In the unlikely occurrence that the food touches the chain, the use of NSF-H1 food safe lubricant eliminates potential health risks.

Tsubaki’s chain range is also perfect for accurate and hygienic Gable Top Filling Machines for cartons in the beverage industry. The SS and AS chains contain robust stainless-steel construction and inbuilt corrosion-resistance for optimised longevity.

be applied. Available in nickel plated and stainlesssteel executions, these high corrosion-resistance chains are designed for wash downs, safeguarding continuous hygienic compliance. In combination with our in-house Match & Tag service this solution offers exceptional accuracy, reducing downtime and batch waste.”

With their Match & Tag service Tsubaki ensures chains to be within a specific length tolerance for those applications where chains run in parallel lines with special attachments connecting the two. For these types of applications, even pairs and multiple chain lengths are matched and tagged for easy identification and installation. Tsubaki can guarantee a maximum chain length differences of 0.50mm independent of the total chain length.

The Tsubaki Titan, Lambda and Neptune value-added solution products act as an effective alternative to standard carbon steel chains. With a customercentric approach, Tsubakimoto UK offers an initial site visit by expert engineers to determine the best solutions for each application and the corresponding requirements. As part of an ongoing after service, Tsubakimoto UK also offers periodical follow-up visits to measure elongation and assess the performance of the chain to reassure the client. This maintenance support ensures each investment is protected and benefits from longer performance.

To contact Tsubakimoto UK Ltd, see details here: T +44 (0)1623 306600 https://tsubaki.eu/contact/about

“Tsubaki attended the PPMA Show 2024 at the NEC in Birmingham to meet food and packaging clients from the UK and Ireland. We promoted solutions for

“Our Gripper chain is specially designed for thermoforming applications where film needs to

Setting new standards for the dairy industry

Product quality, product safety. The guiding mantra in dairy production. That’s why the world’s leading dairy producers rely on the products and solutions developed by DMNWESTINGHOUSE. Our rotary valves and diverter valves offer the highest level of precision engineering, preventing bridging and possible contamination during conveying processes. At the same time, they guarantee unparalleled cleanability, drastically increasing product safety while reducing downtime for maintenance and repairs.

Taking up the challenges

Through years of experience and valuable partnerships, DMN-WESTINGHOUSE has gained a deep understanding of the global dairy industry

and its challenges. We have earned the trust of an industry where hygiene, cleanability, and safety are paramount. In our R&D department, we leverage innovative technology, setting the dairy industry standard. In our factories, we control every step in the manufacturing of heavy-duty rotary valves and diverter valves.

Always compliant

Just like you, we strive for unparalleled quality and consistency. A commitment underscored by our compliance with current certifications, including USDA, EHEDG-ED Class II and ATEX.

Whether it’s about infant formula, lactoferrin, (plant-based) milk powders, caseinates or probiotics, at DMN-WESTINGHOUSE, we help you maintain the highest quality standards in dairy.

Many producers of dairy products, ranging from baby formula to lactoferrin, rely on our renowned heavy-duty rotary valves. These valves come in two types and various sizes: the drop-through type (AL/ AXL/AML) and the blow-through type (BL/BXL/BXXL). They comfortably comply with the stringent hygiene standards the dairy industry needs to maintain. All product contact surfaces consist of food-grade material, polished to perfection. They are all radiused and polished to an astonishing 0,8 μm Ra (150 grit), and the rotor vanes have precisely chamfered edges preventing the build-up of conveyed dairy powders.

MZC-series: standard for safety, hygiene and cleanability

Cleaning intervals will vary depending on which dry dairy substances are processed. To reduce cleaning time and resulting downtime, we developed the MZC rotary valves based on our AL- and BL-series.

The MZC-I and MZC-II are equipped with supporting rails so the rotor and end cover can be removed. The MZC-II opens on two sides for unprecedented easy access and superior cleanability.

These valves facilitate premium process handling, raising the bar in cleanability, hygiene, and safety. The rotor body clearances are set automatically when the rotary valve is closed after cleaning.

Options for ultimate safety and reliability

Adding innovative solutions can take your dairy production to the next level. We offer:

t Rotor Interference Detection (RID 3.0) is our third generation, detecting unwanted contact between the rotor and body or end covers. This prevents major damage and provides insight into product contamination. RID 3.0 offers 50 times more accurate resistance measurement than its predecessors.

t Shaft seal flow control boosts the reliability of our AL and BL heavy-duty rotary valve series even more. Precise flow control prevents the build-up of powder residue on the shaft seals, minimising the risks of seal failure, contamination, leakage, damage and downtime.

t Rotary valves equipped with the Sanitary Air Seal (SAS) outboard bearing shaft seal minimise leak risks due to pressure changes inside the valve, thus maintaining the right airflow.

Cleaning-in-place (CIP)

For maintaining hygiene and preventing contamination, cleaning-in-place (CIP) is indispensable. CIP is about cleaning the interior of pipelines, valves, tanks and other equipment without the need for disassembly. In the dairy industries it’s a necessary, often automated method to maintain the highest levels of hygiene and prevent contamination.

Your perfect Niro replacement

Handling dry dairy solids is about maintaining the strictest standards and requirements 24/7. Are you currently operating Niro rotary valves needing replacement any time soon? Our NR347 rotary valves (NR = Niro replacement) match the outer dimensions of the Niro valves operating within your system,

which means they are usually a perfect fit. The NR347 is based on our heavy-duty AL250 model and is made of stainless steel. Meeting all hygiene and safety standards, the NR347 will prove its value day in and day out.

Our diverter valves: boosting efficiency and hygiene

Diverging and converging powders or granulates is a daily routine in dairy production. Safety, efficiency and maximum hygiene are key. That’s why our 2-TDV, 3-TDV, M-TDV, and GPD diverter valves are very much in demand.

t Our 2-TDV and 3-TDV diverter valves are designed for quick disassembly and streamlined distribution. The 2-TDV effortlessly handles two

destinations, while the 3-TDV targets three.

t The M-TDV efficiently handles the pneumatic transport of powders or pellets, diverging and converging flows to multiple destinations. Available in different sizes, offering up to 14 ports.

t Our diverter valves are the perfect choice for systems needing regular, quick cleaning with minimal downtime.

Would you like to know more about DMNWESTINGHOUSE rotary valves or diverter valves and discover why we are the dairy industry’s choice worldwide?

Please get in touch with DMN-WESTINGHOUSE: T +44 (0)1249 818400 dmn.uk@dmnwestinghouse.com

By provisioning preventative maintenance programs in good time, plant operators avoid costly downtimes. This is all the more important for nonstandard configurations.

An Argentinian steel mill operator commissioned Menzel Elektromotoren to build a special motor based on an existing motor having the type of construction IM 7311. In order to future-proof and since this is a considerable investment, the old, still operational motor is to be stored as backup.

Therefore, the new machine must replicate it in every detail, although, due to modern design techniques, Menzel implemented a performance increase at the customer’s request. The new slip ring motor provides a nominal torque

of 43,245Nm at 6,600V rated voltage and 1,345kW rated power. The format is unusual: at a total weight of 21.9 tons, the rotor alone weighs full 10.4 tons. Various accessories were installed, including HALL effect current transformers to measure the rotor current, customerspecified accelerometers on the bearings, and a level sensor for the electrolyte in the starter.

The motor features IP23 protection and IC 01 cooling (open-circuit ventilation). It has to withstand ambient temperatures up to 45°C in the rolling mill.

The German, family-run company counts special motors among its core business and also designed the starter in such a way that it caters for the new motor and the original one equally.

Before shipping, the motor underwent a complete type test with additional tests according to customer specifications, including partial discharge and dissipation factor measurement (tan δ). Menzel will also handle the mill drive commissioning, which the operator will schedule to suit production planning.

More information about customised motors: www.menzel-motors.com/ modification

In this issue of Industry Update, we are proud to select Anua Clean Air UK as our Sustainable Environmental Solutions Company of the Month

Anua Clean Air UK Ltd leads the way in air pollution control, specialising in advanced biological treatment solutions for air and biogas. Our expertise is exemplified by our patented Biofiltration and Bio Trickling technologies, which provide highperformance, costeffective emission control using innovative recycled media.

Our flagship technologies, Mónashell® and CrumRubber , are sustainable breakthroughs that utilise reclaimed materials as core filtration components. These materials not only excel in pollutant capture and treatment but also offer significant environmental advantages, contributing to the circular economy and reducing carbon footprints through minimal water and energy consumption, with zero consumables.

wastewater treatment works, municipal solid waste and composting facilities, sludge-handling and treatment processes, industrial facilities and the treatment of airflows ranging from 50m3/hr to 500,000m3/h. It carries many benefits such as: up to 67% footprint reduction compared to conventional biofilters, no short circuiting, low water consumption and many more.

The Mónashell™ biofiltration system is a proven and cost-effective alternative to chemical scrubbing or carbon adsorption, designed like a biotrickling system yet incorporating many benefits of traditional biofilters. It is ideal for sustainable odour and VOC treatment across the following applications: wastewater pumping stations,

The shell-based media is fully sustainable and renewable, with the in-built ability to maintain a neutral pH within the biofilter. This safeguards optimal odour performance across a wide range of odour producing compounds, while essentially simplifying operation and streamlining system reliability. There has been growing concerns about the control of odourcausing compounds from wastewater and industrial treatment processes. With more houses being built on once-remote treatment facilities, it’s increasingly prioritised to have effective odour control technology.

Both Mónashell® and CrumRubber™ have been rigorously tested and have a long track record in numerous applications with unparalleled capabilities in air purification and odour control across a wide range of applications.

In recent years, we have expanded our presence across the UK, Ireland, and globally in partnership with our parent company, Anua Clean Air International Ltd, and our Italian sister company, Air Clean SRL. Our international portfolio includes notable projects such as Dual Pass Monashell® installations in Riyadh, Jeddah, Laguna Lake in the Philippines, Coimbatore in India, and Sindos in Greece. CrumRubber technology has been successfully deployed

in the Canary Islands, China, Oman, and the UK and Ireland. Exciting collaborations with Air Clean SRL and Air Clean USA are also underway, bringing Dual Stage CrumRubber™/Monashell® systems to Puglia, Southern Italy, and across Massachusetts, Connecticut, Maine, and Rhode Island in the United States.

Anua Clean Air UK is also renowned for maintaining the performance and efficiency of existing odour control units. Our services include thorough equipment health checks, process upgrades, and media replacement, ensuring the continued operation of hundreds of biological air treatment systems worldwide.

Join us in our mission to purify the air and safeguard the environment through innovative and sustainable solutions.

Contact us today at +44 (0)1450 420017. www.anuacleanair.co.uk

The 2024 Environmental Services and Solutions Expo (ESS) took place at the NEC, Birmingham from 11-12 September 2024. Featuring five colocated expos that make up the ESS Expo family –Resource & Waste Management Expo (RWM), Energy, Fuels & Decarbonisation Expo (EFD), Water Resource Management Expo (WRM), Air Pollution Control Expo (APC), and Contamination & Land Remediation Expo (CLR) – the event drew thousands of industry experts, suppliers, and thought leaders under one roof. A true highlight of the environmental services calendar, ESS 2024 delivered cutting-edge innovations, insightful panels, and invaluable networking opportunities across two jam-packed days at the NEC, Birmingham.

ESS Day One: A buzzing start

From the moment the doors opened on day one, the energy in the halls was palpable. Halls 17-20

were teeming with exhibitors showcasing the latest technologies across resource management, recycling, energy, air quality, land remediation, water management, and everything in between. The newly launched APC Expo, focusing on air quality solutions and emissions monitoring, added an exciting dimension to the 2024 show. Delegates had the opportunity to explore everything from innovative recycling methods to decarbonisation strategies across all four halls.

ESS Day Two: Continuing the momentum

Day two saw even more industry leaders sharing their expertise. The Summit stage hosted multiple insightful panels addressing the most pressing challenges currently facing the sector.

Enabling Net Zero: Re-use shops at HWRCs

SUEZ UK led a fascinating panel discussing consumer attitudes towards reuse shops at household waste and recycling centres (HWRCs). Their research showed that 95% of people were satisfied with their local reuse shop, highlighting the importance of public awareness and the need for visually appealing

shops. Anna Scott from Keep Britain Tidy, who worked alongside SUEZ UK on the research, emphasised the role these shops play in reducing waste and promoting sustainability.

A Platform for the future

ESS and RWM Expo 2024 brought together a comprehensive range of sectors, from waste management and recycling to decarbonisation and water solutions. The event was more than just an exhibition – it provided a critical platform for the exchange of ideas, the showcasing of groundbreaking innovations, and the celebration of industry leaders. From cutting-edge technology to vital discussions on policy and sustainability, ESS 2024 reaffirmed its position as the UK’s largest and most essential environmental gathering.

For those who attended, the event offered a wealth of knowledge, connections, and inspiration. As we look ahead to ESS 2025, the conversations and collaborations started here will undoubtedly continue to shape the future of the environmental sector.

If you missed out, mark your calendars for next year – the 2025 ESS Expo promises to build on this year’s success with even more innovation and leadership across the environmental services spectrum, and takes place on 10-11 September 2025. This is our pick of the best exhibitors from this year’s show, listed here in alphabetical order: PEMO PUMPS, SoluForm & Waste Logics Software. Further details can be found on this page and the next.

www.ess-expo.co.uk

Waste Logics provides innovative software solutions designed to streamline waste management operations by enhancing efficiency, boosting profitability and promoting sustainability. Our platform equips businesses with transparent insights into their waste activities, empowering them to make informed decisions that drive growth and positive environmental change.

Waste Logics supports waste management businesses and is specifically designed for:

t Skip Hire

t Waste Brokers

t Trade Waste

t Material Recycling Facilities

t Tippers & Aggregates

t Commodity Trading

t Scrap Metal Processors

Cloud-based platform for flexibility and growth

Waste Logics is cloud-based which enables users to access data and manage operations from any location, at any time. This provides the flexibility and scalability necessary to drive business growth, without the constraints of being tied to a specific location or device.

In addition to convenience, this offers robust data security,

automatic backups, and seamless updates, allowing you to focus on business operations without worrying about IT maintenance or security risks.

Simplified booking and order management

With Waste Logics, booking orders is quick and hassle-free. Our intuitive interface allows users to easily manage customer orders, track their progress, and ensure timely completion. This streamlined process helps reduce administrative workload while ensuring better service delivery.

Optimised transport planning and driver tools

Waste Logics offers advanced transport planning tools to help businesses optimise routes and manage jobs efficiently. Our Driver App provides real-time job updates

and routing information, allowing drivers to capture electronic signatures, photos, 3rd party weighbridge ticket information and raise problems on-site.

Automated invoicing and seamless accounts integration

Waste Logics automates invoice creation based on completed and signed off jobs, reducing manual effort and minimising invoicing errors. With two-way integration into accounting software like Sage and Xero, Waste Logics ensures real-time updates of account balances, statuses, and credit limits. This helps businesses mitigate financial risk by providing alerts when potential issues arise.

Real-time data for informed decision-making

Waste Logics provides real-time insights into KPIs and detailed reporting features. These data-driven insights allow businesses to make informed decisions that can improve operational efficiency and positively impact profitability.

Waste Logics is the ultimate solution for waste management businesses seeking to improve efficiency, streamline operations, and make data-driven decisions. Ready to transform your operations? Contact us today to schedule a demo and see Waste Logics in action!

Contact T 0330 120 0721 info@wastelogics.com www.wastelogics.com

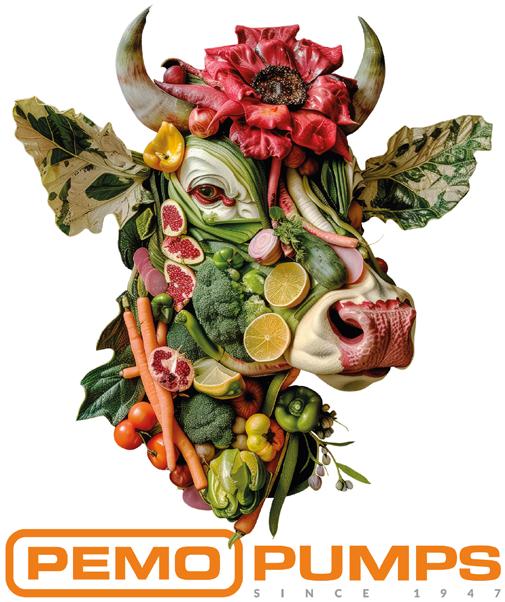

PEMO PUMPS was back at the illustrious Environmental Services & Solutions (ESS) Expo 2024 at the NEC Birmingham from the 11-12 September. With a centrifugal pump proudly on display and eye-catching visual merchandising, the stand was inundated with enquiries from the biogas sector.

PEMO PUMPS already has an emerging presence in the aggregates, tunnelling and stone processing sectors, across the UK and French markets where the pumps are used for transferring slurry and feeding filter presses. Through more recent trade fairs, PEMO PUMPS has been reaching out to biogas and biomethane production chains, showcasing its range of robust pumps.

“Certainly, our pump naturally caught many attendees’ attention but it was our quirky, artistic bull poster that turned the most heads. The bull’s face was decorated with fruit, vegetable and flowers, showing our advancement into the biogas sector. Our robust centrifugal pumps are designed for many transfer applications including the biogas production sector, where

pumps are used to load and recirculate OFMSW to anaerobic digesters. This drives both methane recovery and sustainability,” explained Massimo Ghio, Sales Area Manager at Perissinotto S.p.A. PEMO PUMPS.

Anaerobic digestion (AD) is a leading approach to managing and stabilising biodegradable waste and produces biogas: a prized renewable energy source. Also importantly, AD systems capture methane, reducing greenhouse gases in the process- a leading cause of climate change.

PEMO PUMPS are routinely used in waste water treatment plants, OFMSW or liquid manure treatments, supporting the global move to greater sustainability.

PEMO PUMPS is a brand of Perissinotto S.p.A. and was established in 1947 by Antonio Perissinotto. The pumps were first primarily used in marble and granite cutting processes across the construction sector before diversifying into the steel industry, then chemical and wastewater treatment. In the last twelve months, the company has expanded its warehouse by 2,000m² to aid further pump production for growing global demand.

SoluForm provides industry-leading solutions for the hand placement of bagged concrete or soil across civil engineering applications in and out of watercourses. Adhering to environmentally sustainable guidelines, both bagwork solutions can be cleanly handled and safely placed in concrete or soil.

The Derbyshire-based experts in scour protection and river-work design recently attended the Water Resource Management Expo (WRM), as part of ESS Expo 2024 at the NEC, Birmingham from 11-12 September to showcase the new SoluForm prefilled sandbag range.

These sandbags are designed for

erosion protection and flood control, providing robust fortification against rising water. The 20kg polyester sandbags are filled with silica sand and have UV-resistant properties.

Available in a lightweight, dark green colour, the sandbag is despatched prefilled and ready to use. Compliant with ISO 9001 and 14001 quality systems, these sandbags offer industry-leading protections against the devastating increasing impacts of erosion and floods. Other applications include: traffic management, trench and excavation safety, embankment stabilisation, retaining wall construction, and temporary structures and site protection.

To view the whole product range including: concrete filled bagwork, sand filled bagwork, topsoil filled MSE bagwork and the prefilled sandbags, click here: www.soluform.co.uk

To contact SoluForm directly, see the details below: Head Office 01629 541066 sales@soluform.co.uk

“We can offer over 3,000 pump models with fully customised hydraulics and materials to our customer base across more than 100 countries. Furthermore, we have a warehouse with over 10,000 components, which allows us to solve customer requests quickly and without delay.

PEMO PUMPS offers flagship advanced centrifugal pumps, with semi-open impellers and anti-clogging volutes that enable the transfer of highly viscous substrate containing fibres, filaments and large solid parts. This is highly advantageous over standard single-screw pumps, with the unique ‘HARDALLOY PEMO’ wear-resistant superalloy.

It was lovely to meet lots of new faces at ESS 2024. Don’t hesitate to contact our expert sales team if you have any further queries about how our pumps can support the biogas sector.”

www.pemopumps.com

In today’s industry, briquetting is a growing solution for waste management, efficiency, and cost savings. By compacting loose waste— like dust and shavings—into highvalue fuel briquettes, companies gain an efficient heating source for internal use or a sellable byproduct, creating new revenue and lowering disposal costs.

Petroleum Oil Residue (POR) briquettes, made from petroleum byproducts, are a popular coal alternative in heavy industry. With high calorific value and lower emissions, POR briquettes are an efficient and eco-friendly fuel choice.

Briquette Tech has over 25 years’ experience selling and servicing POR briquetting machines, helping clients with the environmental sustainability of their manufacturing models. Its large range of machines can help to convert your costly waste stream into extra revenue.

Briquette Tech is now the exclusive distributor and re-seller for the POR Micucci System SRL range of briquetting and shredding machinery across the UK and Ireland. Designed with the needs of small to medium-sized businesses in mind, this advanced equipment offers an efficient solution for converting wood waste into valuable resources.

To support potential customers in evaluating the benefits of briquetting, Briquette Tech has installed a demonstration briquetting machine at its facility in Kettering. This allows businesses to bring in their own material for testing, providing a practical and hands-on way to assess the potential of transforming waste from a disposal cost into a revenuegenerating asset.

T 01536 414401

M 07837 632080

bertie@briquettetech.com www.briquettetech.com

Alison Handling Limited is the UK’s largest independent stockist of new, reusable, and recyclable plastic storage solutions, including boxes, trays, totes, pallets, and pallet boxes. They also offer a range of metal products, such as roll cages, lockers, and dollies.

With 35 years of experience, Alison Handling prides itself on providing the right products at competitive prices, promptly delivered from their extensive warehouses, often within 24 hours of order receipt.

Renowned for exceptional customer service and technical expertise, Alison Handling is committed to environmental responsibility, with the majority of their storage solutions being fully recyclable. As part of their commitment to the environment, Alison Handling also buy and sell used plastic storage boxes, which means you can purchase your items at an even lower price or if you have some plastic boxes you wish to sell, you can even make

some money too!

Alison Handling make sure to offer a wide range of boxes that are versatile and specific to your sector.

Whether you work in the food and catering industry, manufacturing, retail, healthcare, or simply need some extra plastic storage boxes for your business, home or a range of other sectors, there is a wealth of choices available from Alison Handling.

Alison Handling Limited offers high-quality storage products ideal for commercial, industrial, and domestic use. From large containers for bulk storage, stack and nest containers to maximise space, to small parts storage boxes and pallets, Alison Handling understands its customers’ needs. They also manufacture wheeled dollies that complement their boxes.

Their products come in a wide selection of colours and sizes, catering to various sectors such as food and catering, horticulture, agriculture, entertainment and hospitality, manufacturing, retail, waste management and recycling, healthcare, and education.

Alison Handling exhibited at the Resource & Waste Management Expo 2024 from 11-12 September, NEC Birmingham on Stand CT-F220.

You can view the extensive Catalogue here: https://alisonhandling.com/download/flip/ catalogue_2019

For more information or to speak to a member of their Customer Services Team today, see below: T 01772 687940 enquiries@alisonhandling.com www.alisonhandling.com

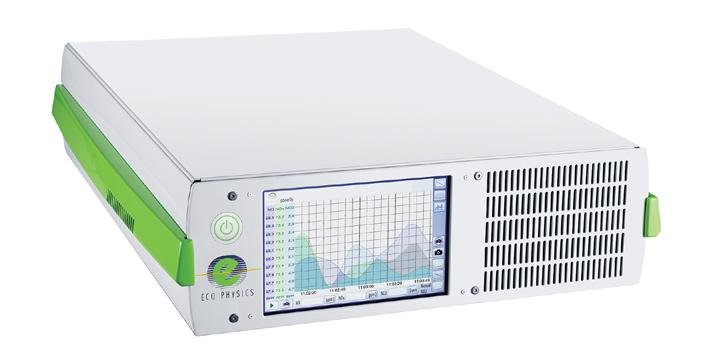

ECO PHYSICS AG offers innovative analytical solutions for measurement tasks in the fields of environment, health and process control. Using its vital expertise and technology to contribute towards environmental preservation, human health, and industrial innovation, ECO PHYSICS’ interdisciplinary research and development team work tirelessly to deliver the best customer orientated and tailor-made products and services for the industry.

Founded in 1990 through a management buy-out, ECO PHYSICS stands strong today as an independent Swiss shareholder’s company with an active board of members who are committed to the future growth and success of the company. We spoke to Dr. Grischa Peter Feuersänger, Head of Sales & Marketing who explained how the past 12 months have fared.

“We have received a positive recovery post pandemic. Many public projects were reopened which generated a lot of opportunities for new references. The war in East Europe is a new tough challenge to overcome, especially for companies that rely almost completely on importing parts and exporting their finished products. But the main challenge for all of us has particularly been the manufacturing costs, shipping routes and exchange rates. Since 2022, we have used this time to expand our product portfolio and modernise our production line. New staff has been hired for production and R&D, and we have rearranged

the supply chain due to the rise in production costs. We have adapted our yearly forecast to cater to this, we know it will be hard, but optimisation is our current goal.”

Knowing there is no quick fix to economic changes, ECO PHYSICS is determined to continue innovating and has developed a new three-channel analyser based on chemiluminescence. As an upgrade from the The nCLD AL2, The nCLDAL3/8555 CY analyser is the next generation in high precision nitrogen oxide measurement. Unique in speed and reliability, the nCLDAL3/8555 CY is modular designed and capable of simultaneously NO, NO2, NOX, NH3 and NOXAmines. The new and intuitive graphical user interface also individually displays and connects to other instruments’ data.

Overall stability and reliability are lifted to a new level. The optional electro-mechanical bypass system balances out even the fastest of pressure variations

occurring in the sample flow. Furthermore, the analyser is adaptable to numerous non-standardised applications and the calibration of the unit runs quickly and automatically with all necessary data available anywhere at any time. Its user friendly, compact, modular, and intelligent hosting its own CPU whilst enabling interaction with other CPUs by BUS-communication.

Additionally, ECO PHYSICS has also been developing upgrade kits for all its existing products to help counteract some of the problematic complications the supply chain has caused. “We have used this chance for some substantial upgrades in hardware, software and gas flow controls,” added Dr. Grischa Peter Feuersänger.

Going forward, ECO PHYSICS is excited to continue working on optimising production workflow whilst simultaneously expanding its current portfolio and developing new technologies.

In closing, we asked Dr. Grischa Peter Feuersänger how the company felt receiving our award. He responded, “We are extremely honoured to be nominated, thank you.”

Contact T +41 55 220 22 22 info@ecophysics.com www.ecophysics.com

Kemtile, a division of Stonhard, has recently completed the installation of a new hard-wearing and chemically resistant flooring solution for Wessex Water at their Food Hall Facility.

The regional water and sewerage business – which serves 2.9 million customers across the south-west of England – had recruited Kemtile to provide a suitable flooring solution for their ‘food to power’ facility in Avonmouth.

Corrosive elements contained in the domestic waste treated on-site by Wessex had attacked the concrete floor surface to leave it ‘pitted’ and uneven. A subsequent ‘overlayment’ installed to combat the problem had also failed within a short period of time leaving the floor needing a complete rethink in terms of a solution.

a chemically resistant, hard-wearing floor finish capable of withstanding the movement and ‘scaping’ from a 25-tonne mechanical loader.

Kemtile visited the site over 18 months and undertook testing works of the existing finishes and structural slab by taking ‘cores’ and having these examined by a concrete testing laboratory. Assisteds by Sean McIntyre, Stonhard Coatings and Lining Manager, Kemtile developed a specification that included the removal of all the existing finishes back down to the structural slab and the installation of a new fit-for-purpose floor. This included – a new concrete overlay to ‘falls’, new surface drainage and

Kemtile installed Stonhard’s Stonclad UT – a highimpact polyurethane-based floor screed which exhibits excellent abrasion, thermal shock, thermal cycling and chemical-resistant characteristics. Stonclad UT was installed at 12mm thick, it incorporated a ‘unique’ wear-indicating layer that shows if maintenance is required given the extremes of use in this facility. The system was further reinforced with a layer of Stonhard’s Stonchem 601 chemical-resistant lining system to further enhance its chemical-resistant properties.

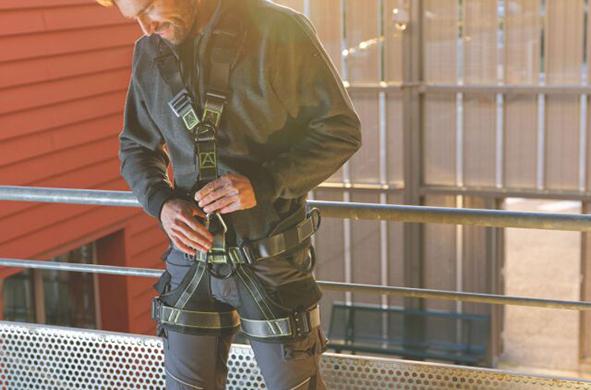

A proactive approach to health and safety was maintained throughout the installation with the installation teams complying with the site CDM regs which included the mandatory use of gas monitors at all times.

Dan Owen, Project Engineer of GENco/Wessex Water Enterprises, said, “Kemtile brought great expertise to the table from day one dealing with a significant level of deterioration and providing immediate support – as well as supplying the final flooring fix over the 18 months that we worked together. I commend them on seamless delivery with minimum disruption to the rest of the plant which remained in operation throughout.”

Kemtile’s David Priest commented, “This was a significant project for us – in a sector with huge potential – involving a number of external stakeholders for sign-off including the original structural engineers.

“We drew on expertise from across the Stonhard group globally working with colleagues based in Canada and Portugal who had completed similar projects and had an excellent understanding of the requirements of the industry.”

https://kemtile.co.uk

Union Industries, the UK’s leading manufacturer of bespoke industrial doors, has helped Sonoco introduce more efficient operating procedures with the installation of its high speed Ramdoor.

It represents a first for the paper mill in Halifax, West Yorkshire, which recycles wastepaper and cardboardconverting it into a range of useful products.

With efficiency in mind, Union’s rugged Ramdoor replaced a slow and outdated roller shutter door, at the same time helping with the segregation of pedestrian and vehicular traffic.

Sited in a section of the warehouse leading to the waste yard, the newly installed Ramdoor has enabled Sonoco to increase the frequency of both large machinery and forklift traffic through this entranceway, in line with changes to their operating procedures.

Due to the large volumes of wastepaper processed, it is important that the Ramdoor seals quickly, preventing the ingress of debris. A Class 5 wind resistance rating provides extra benefit - helping maintain operations during more challenging weather conditions.

Sonoco, a multi-billion-dollar global provider of consumer packaging, industrial products and packaging supply chain services, has been a customer of Union Industries for almost 30 years, having previously fitted four Matadoors.

This is the first Ramdoor to be installed at the site - features include a variable speed drive motor with frequency inverter for greater control, thick Ramhide door blade material with anti-static additive and a ‘Crash Out’ system which reduces the potential of bottom beam damage - helping to minimise downtime and repair costs.

The heavy-duty wind-bar system, combined with the extra-deep side-guides, provides added strength, and contributes to the Ramdoor’s ability to cope with high wind loads and pressures.

Paul Hindley, Engineering Manager at Sonoco, said, "The installation of the Ramdoor at our Halifax facility is a game-changer. It allows for quicker, safer, and more efficient movement of our large machinery and vehicles. This has enabled us to introduce changes to our operational procedures, creating more

Independent Access Sales (IAS) provide industry-leading manufactured platforms, such as Easylift Spider Platforms and SOCAGE Truck Mounting Platforms across the UK.

Spotlight on SOCAGE

The SOCAGE 24D double-articulated truck platform has been expertlydesigned with safety in mind, with standard automatic stabilisation. It can reach a working height of 23.60M and a lateral reach of 12,70M with a maximum load of 300kg: perfect for all jobs at height without risk of collision and with improved precision for tricky manoeuvres.

From early next year, the SOCAGE 75M – the largest SOCAGE access platform in the UK will be available from IAS.

Spotlight on Easylift

For arborists or specialist cleaners at height, the Easylift srl Piattaforme

Aeree R360 has a turret rotation of 360°, coupled with a working height of 35.4M. It is an ideal platform for working with heritage or historical buildings with limited space.

The R260 model has a maximum height of 26M, with an outreach of 13.5M. This is the ideal choice for maintenance and installation jobs.

The Easylift Spider Platforms have a range from 13M up to 53M and give operators great manoeuvrability in tight spaces and at height.

Contact IAS to scale the heights today: speak to owner Richard Martin.

M 07483 246878 enquiries@iasales.co.uk www.iasales.co.uk

(L-R) Paul Hindley, Engineering Manager at Sonoco and Rob Howe, Technical Sales Engineer at Union Industries.

efficiency. This upgrade is part of our commitment to continuously improve both our operational processes as well as our safety standards."

Rob Howe, Technical Sales Engineer at Union Industries, said, "We are delighted to continue our long-standing partnership with Sonoco by providing them with a flexible and highly effective solution.

“The Ramdoor offers superior performance and durability, and in this instance has allowed Sonoco to ensure that this external entrance can cope with increasing traffic flows, effectively future proofing its requirements and allowing for future growth.”

T 0113 244 8393 enquiries@unionindustries.co.uk www.unionindustries.co.uk

Conduct remote licence checks using our innovative technology for just £1.60 per check.

With a direct link to the DVLA ADD service our new Drivers Licence Checking Service offers a completely remote solution to streamline your fleet management and compliance requirements in one cost effective, user-friendly app!

Simple to use: It’s the same platform as you use now, fully integrated into the existing staff area of the app!

Pay-as-you-go: Add as a pay-as-you-go service based on a risk evaulation of drivers

Remote use: Remote use of software makes this ideal for businesses with dispersed workforces.

OCR technology: The app uses Optical Character Recognition (OCR) with over 95%accuracy rate.

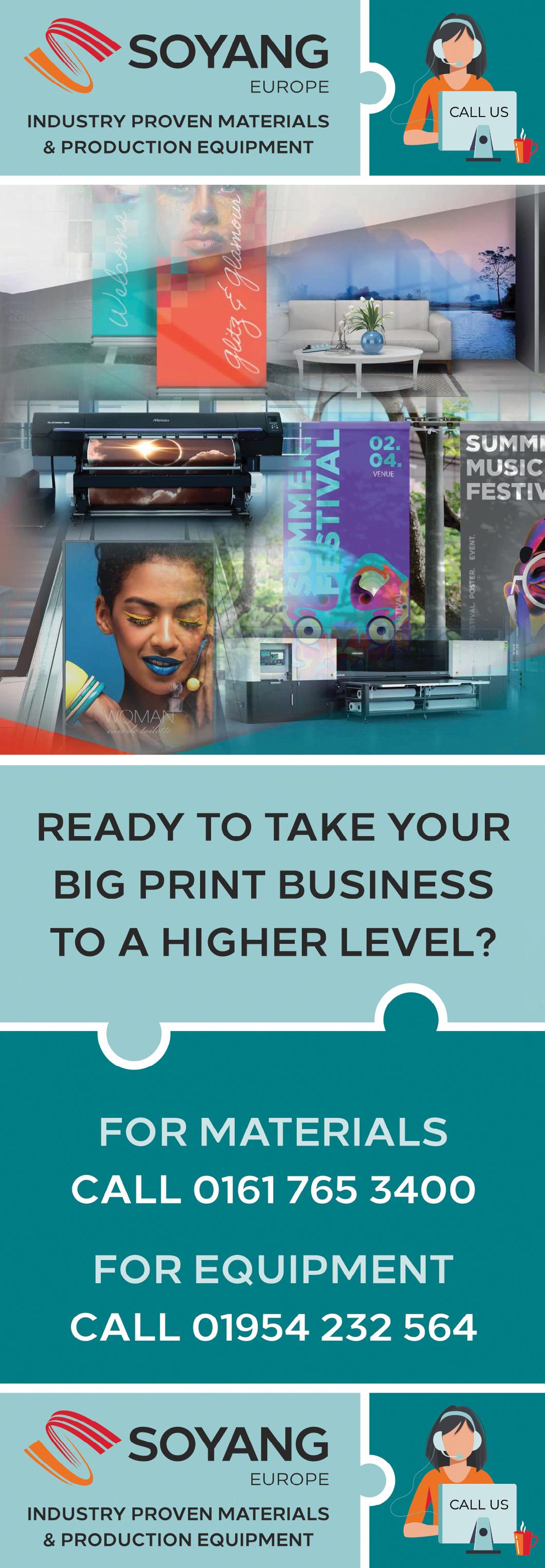

Soyang Europe has been working with Reconomy to offer customers access to environmentally focused and responsible waste management services.

International circular economy specialist

Reconomy has revealed how its relationship with wide-format and superwide-format media manufacturer and distributor Soyang Europe is helping UK print service providers to improve their environmental credentials.

Reconomy combines technology and skills to enable businesses to better manage their resources, helping to reduce waste, optimise their supply chains, and contribute in a meaningful way towards the circular economy.

While this involves working directly with print companies, Reconomy is also partnered with several leading manufacturers and distributors, supporting their customers with textile waste management. One such partnership is with Soyang Europe, whereby printers using materials from Soyang Europe can responsibly dispose of their waste.

This partnership came about three years ago with the support of FESPA UK. Reconomy was working on various sustainability initiatives with FESPA, while Soyang Europe is a long-term member of the association.

The process works with Reconomy providing customers with a baler to prepare their textile waste. Soyang Europe then collects the bales when delivering new products to customers, with the waste taken to its facility in Altham in Lancashire ready for bulk collection and transportation to a recycling facility for processing.

“It was a perfect fit,” said Reconomy Director, Jon Hutton. “Soyang has always been proactive in wanting to offer their customers, and the wider industry, waste management solutions for their products.

“Sustainability is a hot topic for several reasons. Brands and consumers are looking down the supply chain for environmental credentials, so it’s therefore a driving factor in how to not only maintain and gain business, but how a printer positions themselves for the long term.”

Mark Mashiter, Managing Director at Soyang Europe, added, “It provides our customers with an outlet for their waste. This works well with local customers when we deliver orders to them; we can bring any textile bales back with us and store them in our yard until they are collected.”

Originally, Reconomy had sourced a solution for recycling PVC banner and polyester fabrics at a UK site, whereby waste was blended with other polymers to produce low grade products. While this process ended when more desirable material became available to the market, a recovery route was soon set up and, with the support of Wheeldon Brothers, waste could now be diverted from landfill to renewable energy.

Reconomy combines technology and skills to enable businesses to better manage their resources, helping to reduce waste, optimise their supply chains, and contribute towards the circular economy

However, recycling has since been reestablished and material is again being used in manufacturing processes. Coupled with its use for renewable energy, all of this is helping work towards a circular economy.

An additional benefit to the service is that Soyang Europe is willing to take other supplier’s waste textiles along with its own. This option is available to customers using their own transport within a set radius of Soyang Europe’s facility and when making deliveries.

“Soyang Europe wants to be part of the environmental solution and not the problem,” Jon said. “The take-back scheme provides a platform for printers to demonstrate their sustainability by providing customers with an outlet for their recycling waste.

“Several customers have engaged with Reconomy further and are now collecting their own clients’ end-of-campaign textiles, integrating this with the collection of their materials. All loads are tracked, and Certificates of Recycling can be issued once the material has been processed.”

The work does not stop here for Reconomy, with Jon saying the company will continue to work with Soyang Europe, FESPA UK and its wider membership base to provide more sustainable solutions to the UK industry.

“It’s our aim to continue to be a driving force in educating the industry on the importance of recycling and developing circular economies,” Jon said. “This, with the continued support of Soyang Europe, will ensure more customers take up this service.”

T +44 (0)161 765 3400 sales@soyang.co.uk https://soyang.co.uk

The safe laser scanner UAM-05LP offers maximum vewrsatility for safe area monitoring

The Schmersal Group continues to expand its range of products for safe area monitoring: the company is now selling the UAM-05LP safety laser scanner from Japanese manufacturer Hokuyo in Europe, beginning with markets in Germany, France, Austria and Switzerland. The safety scanner is characterised by its extremely compact design and low weight, as well as its flexible integration options and high safety standards. This helps it to ensure maximum personal protection in logistics, manufacturing & the process industry.

Contactless protective devices, such as laser scanners, offer many benefits in the implementation of safety requirements. In contrast to guard fences and guard doors, there is no manual opening and closing requirement, and they do not impede materials transport. In addition, they also enable a clearer view of machinery and processes.

infrared beams to scan the environment and detect the entry of people and objects into the safety zone. This also allows the Hokuyo UAM to achieve a wide range: with a detection range of up to 270°, a safety clearance of up to

The UAM safety laser scanner handles presence control on stationary machinery and robot systems, with the UAM’s sensor utilising

5m and a warning detection area of 20m, the laser scanner can be used in various machinery safety applications.

The laser scanner can be easily configured for

Maintaining a safety shower is crucial for ensuring its optimal performance and effectiveness during emergency situations. Here are several reasons why maintaining a safety shower is essential:

1) Reliable Emergency Response

Regular maintenance ensures that the safety shower is in proper working condition and ready to be used when needed. By conducting routine inspections and maintenance activities such as testing water flow, checking water temperature, adjusting controls, and inspecting valves, any potential issues or malfunctions can be identified and addressed promptly, ensuring that the safety shower will function reliably during an emergency.

2) Employee Safety

The primary purpose of a safety shower is to provide immediate decontamination in case of exposure to hazardous substances. Regular maintenance helps ensure that the safety shower delivers the appropriate water flow rate, temperature, and coverage necessary for effective decontamination.

3) Compliance with Regulations

Safety showers are often subject to regulatory requirements and standards that specify their maintenance and inspection. By adhering to these regulations, organizations demonstrate their commitment to compliance and workplace safety.

4) Extended Lifespan

Proper maintenance and care can significantly extend the lifespan of a safety shower. By promptly addressing any

issues, replacing worn-out components, and conducting regular cleaning, you can prevent major breakdowns and costly repairs.

5) Reputation and Employee confidence

Demonstrating a commitment to maintaining safety showers indicates a strong safety culture within an organization. Regular maintenance instils employee confidence in the workplace safety measures and shows that their wellbeing is a top priority.

Conclusion

Maintaining a safety shower is essential for its reliable performance, employee safety, regulatory compliance, and overall operational readiness. Regular maintenance and inspections help identify and address any issues promptly, ensuring that the safety shower is always ready for use during emergencies.

For more information on service and maintenance, please contact Aqua Safety Showers on: +44 (0)1942 318096 or sales@aqua-safety.com

a wide range of uses and also has the ability to monitor two hazardous areas at the same time, eg. two adjacent robots. Each of the two safety zones switches its own OSSD output.

Furthermore, the safety laser scanner is also able to undertake access control as well as arm and hand protection for safety-critical areas in work zones, eg. as part of insertion and assembly workflows.

Another advantage of the Hokuyo laser scanner is its encoder input: with the help of encoders, the speed and direction of travel of automated guided vehicles (AGVs) are transferred to the laser scanner, so that the safety zones can be dynamically adjusted to stop the AGV in case of danger.

The Hokuyo UAM-05LP is suitable for use in machinery safety applications up to PL d, Cat. 3 in accordance with EN ISO 13849 and SIL 2 in accordance with IEC 61508.

Contact: Steve Watkins, Marketing Manager T 01684 571987 swatkins@schmersal.com www.schmersal.co.uk

In this issue of Industry Update, we are delighted to showcase ARCoptix as our Manufacturing Optical Measurement System Company of the Month

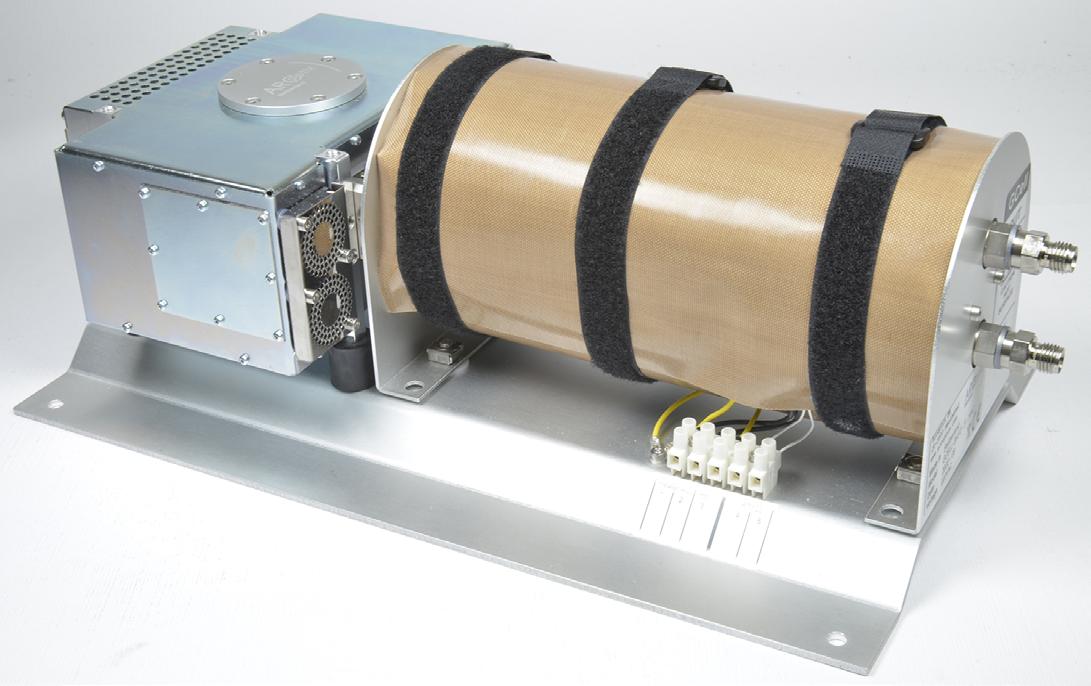

ARCoptix is a renowned Swiss manufacturer of optical measurement systems, with popular products such as the FTIR spectrometers and liquid crystal systems.Established by a team of engineering experts in 2005, the company is privately owned and located in Neuchâtel, Switzerland. The picturesque area is an hour from Geneva in the heart of the Jura mountains, known famously as ‘Watch Valley.’ Over the last 19 years, the Swiss company has fostered powerful partnerships with the Swiss Federal Insitute of Technology Lausanne (EPFL), Bern University of Applied Sciences (BFH) and of course the globally renowned Swiss horological (watch) industry. With cutting-edge R&D facilities, ARCoptix has established a wealth of expertise in optics and microtechnology, with a loyal, broad customer base.

spectrometer, covering a spectral range from 5,000 to 850cm-1. The system is compact and optimised for system integrators. In addition to the OEM solutions, ARCoptix also offers a range of standard desktop products primarily focused on optical fibre applications,” proudly outlined owner, Gerben Boer.

The OEM010 module is integrated to a low volume (0.2L) heated (up to 200°C) gas cell, where light experiences multiple reflections, giving an integrated optical path of 5m with more than 50% transmission. The cell's internal optics is rhodium and gold coated, meaning it is highly resistant to most chemicals such as acid gases HF, HCl, HBr.

“We work in the niche market of FTIR spectrometers and in addition, carry out bespoke optical systems for individual companies. We offer a unique range of FTIR OEM instruments, ideal for system integrators. The ARCoptix GASEX FTIR system for example, is specifically designed for the gas analytics industry.

“The GASEX system consists of a 5 metre path cell combined with a high-resolution 0.5cm-1 FTIR

The Gasex System contains an interferometer module with the MCT detector, an IR light source and a multi-reflection gas cell. The light is made by a black body radiation module and modulated by a dual corner cube interferometer. The light is then integrated into the Gas cell, followed by the injection of the gas under analysis, where this is reflected back and forth multiple times. Lastly, the light is focused on the MCT detector. This is perfect for the fight against climate change such as ambient air (pollution) monitoring, exhaust emissions and continuous emissions monitoring (CEM).

“Other applications include combustion monitoring,

toxic gas detection, mining, aerospace, through to agriculture, petrol-chemistry, cement kilns and much more”

The GASEX MODULAR: ARCoptix FTIR GAS is a portable gas analyser and one of our leading spectrometer products. It offers a fully configurable solution for gas spectroscopy applications such as air pollution for environmental research, through to pharmaceutical, forensic, food and drink, and medical applications. It is a ‘research and laboratory product of choice’ loved for its user-friendly properties. Due to its aligned interferometer, it conveniently doesn’t require realignment and stands firm against temperatures, drifts and vibration variables. The multiple reflection cell is perfect for analysing gases with low concentrations and the single-pass cell conversely analyses gases with high concentrations.

For more information, click here: https://arcoptix.com

Like all industries, pressure to decarbonise is imminent. And glass manufacturing is no exception, with the objective to attain carbon neutrality by 2050. Not only does decarbonisation benefit wider industry and society, but when done correctly, also provides efficiency and cost benefits.

A proven technology

It’s recognised that electrical melting and boosting are not the only technologies available to reduce GHG emissions. The two other main energy options being investigated by the industry are hydrogen and biofuel. There is plenty of research into this and there are some very promising tests and industrial implementations on glass furnaces.

In terms of technological readiness, infrastructure, production and capacity, hydrogen and biofuels are unlikely to be suitable short-term or even midterm solutions for the industry’s energy and CO2 challenges. Therefore, it’s believed that the future systems will be based on a hybrid mix of solutions varying by region and industry.

The benefit of electrical melting is that it is not only a proven technology, but it’s already available today for large-scale glass furnaces all over the world. As a result, we expect that by between 2030 to 2040, electrical boosting, or melting, will represent more than 50% of the total melting energy for most new and cold-repaired glass furnaces, including for float glass.

Power boxes

Looking specifically at electrical boosting and melting,

there are different ways to implement this. A traditional solution using large variable step-up/step-down transformers has been a robust technique used for a long time, but it lacks flexibility. After carefully considering the design, Eurotherm developed a new power solution in the form of power boxes (power skids).

These power boxes bring versatility and efficiency with much shorter lead-times and finer granularity of control, as well as easier installation, using cables instead of large busbars. With power skids located close to the electrodes, or even underneath the furnace in a few instances, this solution keeps the voltage as high as possible, for as long as possible.

The key benefit is that it significantly reduces the line current and the corresponding heat loss. Plus, instead of expensive copper busbars running over 20 to 40 metres to the electrodes, it uses much smaller cables.

Energy savings

With a variable transformer design, there is usually a significant difference between the kWs needed to melt the glass and the kilo volt amperes (kVA) rating of the transformer. This means that this type of system must be oversized, typically by up to 50 per cent, which increases cost.

For example, for a two MW at 200V system with three single boosting zones, the system would typically be designed at three mega-volt amperes (MVA). For only 2,000kW power needed to melt the glass, the system needs to be designed at typically a minimum of 3,000kVA, with three 5,000A at 200V busbar systems to

the electrodes.

With Eurotherm’s power box solution, an alternative design using a much more standard medium voltage transformer with a secondary voltage between 400 and 480V is possible. Power skids can be placed as close as possible to the electrodes to control and step down the voltage to the desired operating range.

The high amperage is only after the power skids and therefore on much shorter cable distances to the electrodes. The power skids include power controllers operating in automatic load tap changer mode, which provides control of power on the full operating voltage range at very high-power factor and without the traditional mechanical wear.

The glass industry is searching for ways to decarbonise. Here, not only will electric boosting and melting play a large role in the decarbonisation of the glass industry, but design methodology such as power skids, placed close to the electrodes, is the more efficient way to go.

To learn more about Eurotherm and its solutions for glass manufacturing, visit: www.eurotherm.com – to learn more about Watlow’s thermal solutions, head to: www.watlow.com

At

Cable Services, the UK’s trusted supplier of electrical cable and specialist equipment, we have invested in an automatic winding and measuring cable cutting machine at our Wrexham facility. This £90,000 investment reflects our commitment to offering an economically valuable and highly efficient service for our valued customers.

We are known for providing tailored solutions that meet the exact needs of our customers. We recognise the growing demand for a flexible service that eradicates waste and delivers cost efficiencies. The efficiency and precision of this new machine support the industry’s commitment to operational sustainability and allow us to pass on cost savings to our customers.

Commenting on this latest investment, Jason Bostock, Managing Director of Cable Services Group, said, “We continue to make significant investments in our operations across the Group to better serve our customers. This new machine more than doubles our capacity, and it also enhances our ability to meet the specific needs of our customers promptly and efficiently. Customers can order custom-cut cable lengths to suit the exact needs of their projects,

providing flexibility beyond the traditional supply of full drums to sites.”

Installing the advanced Loimex TRG250 alongside our existing cutting machine has significantly boosted our cut-to-length capability. To achieve seamless integration and optimise performance, expert trainers from Loimex conducted an intensive three-day training programme for all warehouse operators at our Wrexham facility. This highly engaging, practical training course equipped our team with the skills needed to operate the machine efficiently, ensuring consistent quality and precision.

Warren Hughes, Warehouse Manager, praised the training provided by Loimex. He said, “We were impressed with Loimex’s training, and the support received to date has been exceptional. Having direct access to the manufacturer’s training experts was invaluable, allowing us to ask questions that directly relate to

Electric vehicles are a decisive factor in reducing CO2 emissions in road traffic. They store the energy required for propulsion in batteries and an electric motor converts it into motion. In contrast to combustion engines, no fossil fuels are required. If the batteries are charged with electricity from renewable energy sources, they even have a completely CO2-free energy balance. Today, lithiumion batteries are used almost exclusively as accumulators. Vacuum technology is indispensable for their production.

Tracer gas leak detection ensures quality The proper functioning, quality and safety of lithium-ion batteries, which are used as accumulators in impermeability to external influences such as moisture ingress. For this reason, leak detection systems are used in battery production to check the batteries.

Pfeiffer Vacuum supplies the necessary vacuum solutions from a single source.

One of the world’s leading battery manufacturers for the automotive industry is currently using test gas leak detection systems from Zeltwanger Leak testing & Automation GmbH, which are equipped with complete solutions from Pfeiffer Vacuum. The systems must meet stringent requirements. The decisive factors here are achieving the required cycle time and high reproducibility of the battery cell test.

Enabled by Pfeiffer Vacuum technology, even the smallest leaks can be quantified and localized with the help of Zeltwanger’s testing systems. This makes it possible to quickly eliminate leaks in a downstream production step.

Changes to geometries and improvements to production methods and processes can be initiated based on the results obtained. This leads to quality improvements, increases the yield and reduces manufacturing and testing costs.

T +49 6441 802 0

www.pfeiffer-vacuum.com

our day-to-day operations. With this training, we are confident in our ability to use this technology to its full potential, ensuring we provide a highly responsive and agile service that meets the needs of industry.”

The new automatic TRG250 from Loimex handles electrical cables with the utmost accuracy. It accommodates cables ranging from 1 to 100mm in diameter, wire ropes from 1 to 33mm, and wooden drums up to 2,500mm, with a maximum weight capacity of 5,000kg. With its advanced safety features, the machine complies with CE directives, reflecting our consistent delivery of safe and reliable products that meet the highest industry standards.

For more information about our cable cutting capabilities or to place an order, please contact us at: www.cableservices.co.uk

WielandElectric presents the latest generation of highly efficient safety light grids and safety light curtains.

The importance of occupational safety grows in modern industrial and logistical environments as machines and systems become more complicated. Against this backdrop, Wieland Electric introduces its next generation of safety light curtains and safety light grids, which complement the existing array of optoelectronic protection devices and are distinguished by a high level of safety, flexibility, and use.

The new SLG4 series safety light grids were designed for applications requiring dependable access protection over wide areas on machines or in production sites. While withstanding temperatures as high as 70°C, the light grids may be put into action swiftly thanks to their simple software configuration and plug-and-play installation. Clearly visible LEDs also enable immediate on-site diagnostics, reducing downtimes.

Furthermore, the durable aluminium housing and protection rating IP65/67 in accordance with EN 60529 ensure that the optoelectronic protective devices perform reliably even in adverse environmental situations.

The SLC4 series safety light curtains are perfect for protecting fingers and hands in the machine's danger zone. When the machine is used frequently, they cut access times compared to physical guards, increasing production. Advanced functionalities like muting ensure safe material flow and contribute to cost-effective material supply and removal.

Cascading two devices enables vertical access and horizontal presence monitoring in a single system. The SLC4 safety light curtains, like the SLG4 safety light grids, have a simple software-free configuration and the ability to do quick on-site diagnostics. This improves productivity and safety in industrial applications.

www.wieland.co.uk

Connected Britain is the UK’s most important digital economy event, bringing together stakeholders from across the connectivity ecosystem, featuring over 7,500 attendees, 350 speakers, and 2,000 organisations from every aspect of the UK telecoms sector and beyond.

Excellent digital connectivity is crucial for unlocking positive socioeconomic benefits for the UK’s people, businesses, and communities. Connected Britain, held at London’s ExCeL from 11-12 September 2024, explored how the UK can capitalise on the opportunities that digital infrastructure and emerging technologies bring and showcased the leaders who are making innovation happen.

Where is the UK connectivity sector headed? How can the UK position itself as a technology leader? How is digital infrastructure benefitting communities and businesses across the UK? What obstacles lie ahead for

delivering ubiquitous connectivity and how does the industry overcome them? Visitors could find out at the Connected Britain keynotes.

In an increasingly digital world, the future of work is changing. New skills are needed, new mindsets, new partnerships. Is the UK taking the right steps to close the ‘skills gap’? What is needed both from government and the private sector to ensure that the UK remains a technology and business leader?

New for 2024, the Connected Networks Stage explored strategies for building, expanding, and future proofing communications infrastructure while also exploring the technologies which are driving innovation. Digital connectivity is the cornerstone of the UK’s ambitions when it comes to an intelligent transport system, smart utility networks, EV charging and more. The potential is huge, so how can the UK capitalise on these exciting opportunities?

Taking a strategic look at the commercial and regulatory context for the deployment of next-

Founded in 1948, E-T-A pioneered the development of precision performance circuit breakers which provide overload and short circuit protection for equipment and assets. Today, we now offer the most comprehensive product portfolio of devices, whether mechanical or electronic solutions, single components or complete systems, standardised or for customer-specific applications. All our products are designed and manufactured to exacting performance and quality standards; produced in our own production facilities and supplied by our world-wide network of E-T-A subsidiaries and channels.

Our intelligent power distribution systems capabilities for server and network cabinets include flexible power distribution units as standard products and customised solutions. From purely electronic overcurrent protection to a fully integrated complete system with remote access - thanks to its flexibility, the system covers all needs and guarantees maximum system availability. Using our unique circuit breaker technology ensures precise overcurrent protection and also enables remote control, monitoring and analysis. Many customers from the telecommunications, data center, industrial, energy and railroad infrastructure sectors place their trust in us. Please do not hesitate to get in touch.

T +44 (0)1296 420336 info@e-t-a.co.uk www.e-t-a.co.uk

generation communications infrastructure in the UK. Gigabit Britain was the best place to learn about the state of play for the fixed and mobile sectors while also understanding what new technology opportunities might be around the corner.

Focusing on the realities of building communications infrastructure. Key themes included the technologies enabling network rollout, engineering strategies, supply chain issues and public-private partnerships.

Keeping people connected has never been more important. Tackling the digital divide, promoting digital inclusion, developing the provision of digital public services, providing support for those who need it most is crucial to delivering a more connected and inclusive Britain.

Connected Britain returns next year to London’s ExCeL from 24-25 September 2025. This is our pick of the best exhibitors from this year’s show, listed here in alphabetical order: E-T-A Circuit Breakers & FTTx. Further details can be found on this page.

www.terrapinn.com/conference/connected-britain/ index.stm

FTTx and Energy Warehouse is a specialist wholesaler and distributor of fibre optic communication technologies. The leading Manchester company was one of our Top Exhibitors at Connected Britain 2024: the UK’s leading digital economy event held from 11-12 September at the ExCeL, London.

Company CEO, Paul Johnson, Director, Henry Wilkens and Warehouse Manager, Richard Llewellyn were on hand to demonstrate leading products such as the Van Scan, Blue Dragon and Splice Machines. There was plenty of interest in the home drop solutions and the team answered queries regarding the warehousing, logistics services and lock box service.

The Blue Dragon Jet Extended is a blowing machine with directional switch: primarily designed to blow micro cables. This blower model has extended range and directional switch to allow cable retraction. The cable diameter is: Ø 2.5-12,0mm, with a duct diameter of: 5, 7, 10, 12, 14, 16, 20mm.

The Swift KF4A Fusion Splicer is a cladding alignment fusion splicer with design functionality for stripping, cleaning, cleaving, splicing and protecting.

This model is ideal for fusion splicing and fusion splice-on connectors (SOC) of FTTx network applications.

To explore the full product range for industry-leading fibre optic technologies, contact FTTx and Energy Warehouse today: T +44 (0)330 088 9796 info@fttxenergy.com www.fttxenergy.com

The new single-use Quattroflow® Microdosing QB2-SD Pump operates entirely differently from the legacy line of Quattroflow products. Using the principle of positive displacement with a rotary action, the lightweight QB2-SD gently transfers fixed cavities of liquid of 25μl with a maximum flow rate of 2.7L/hr around a rotor from inlet to outlet. This provides high levels of accuracy without the need for additional sensors that are typically combined with peristaltic pumps. The pumps also generate a high vacuum capability and handle high viscosities.

The system allows easy and rapid changeovers since the single-use pumps simply click in and out of a motor drive, which is especially convenient when wearing full PPE.

The QB2-SD Microdosing Pump can be gamma irradiated up to 50kGy with USP <88> Class VI certified materials, making it an ideal solution for handling biologics, including cells, proteins, mAbs, etc.

Approved Biopharma Certifications

t Particulate Testing (Sub-visible testing per USP 788)

t Microbial Ingress

t Endotoxin (USP 85)

t Bioburden (ISO 11737-1)

Also available from PSG Biotech, Quattroflow is a plug-and-play drive device called Q-Drive-Alpha. The device is intuitively easy to use and can allow commercial use of the pumps in laboratories and similar environments.

Features & Benefits

t Single-use – Rapid changeovers with no cross-contamination

t Lightweight, compact design – Saving valuable space

t Dosing with a minimum flow rate of 75μl/s (at 1rps) – For precision microdosing

t Suitable for single transfer of cells with low shear – Protecting product integrity

t Self-priming, high vacuum capabilities – For positioning flexibility & higher product recovery

Criteria

Examples for QB2

Max. flow rate 45 ml/min (2.7l/hr)

Resolution 25μl

Operating Speed

1-10rps

Baseline Accuracy ±6% 3SD

Maximum Pressure 0.2bar

Max Vacuum -0.6bar

Maximum Torque 100mNm

Maximum Fluid Viscosity 500cP

Operating Temperature 2-40°C

Dimensions (mm) 38W, 30L, 17H

Weight 6.4g

Wetted Materials

Connector Sizing

Longevity

MBS, HDPE, SIL

Hose barb for pump inlet and outlet. For use with 2mm ID flexible tubing

Up to 5L @ 5rps (Up to 3L @10rps)

Shelf Life 1 year

Longevity 1 x 50kGy

t Bi-directional pumping – Avoids drips during filling

t Gamma compatible – Up to 1 x 50kGy

t USP <88> Class VI certified materials –Ensuring biocompatibility

Technical Specifications

Using the principle of positive displacement with a rotary action, the QB2-SD has a 6mm rotor that carries three cavities of fluid, each with a volume of 25μl. This lightweight, in-line pump features

hose-barbed connectors, making it easy to attach tubing to the inlet and outlet. A stepper or DC motor drives the pump at a maximum operating speed of 10rps. The QB2-SD simply clicks in and out of the motor drive in seconds, making it quick and easy to swap fluids without cross-contamination. It is bi-directional, high-vacuum, and self-priming with a low dead volume.

www.psgdover.com www.quantex-arc.com

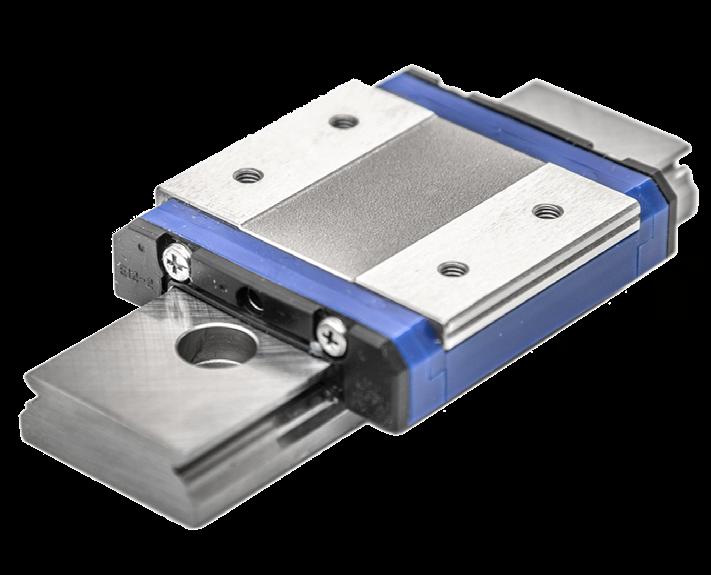

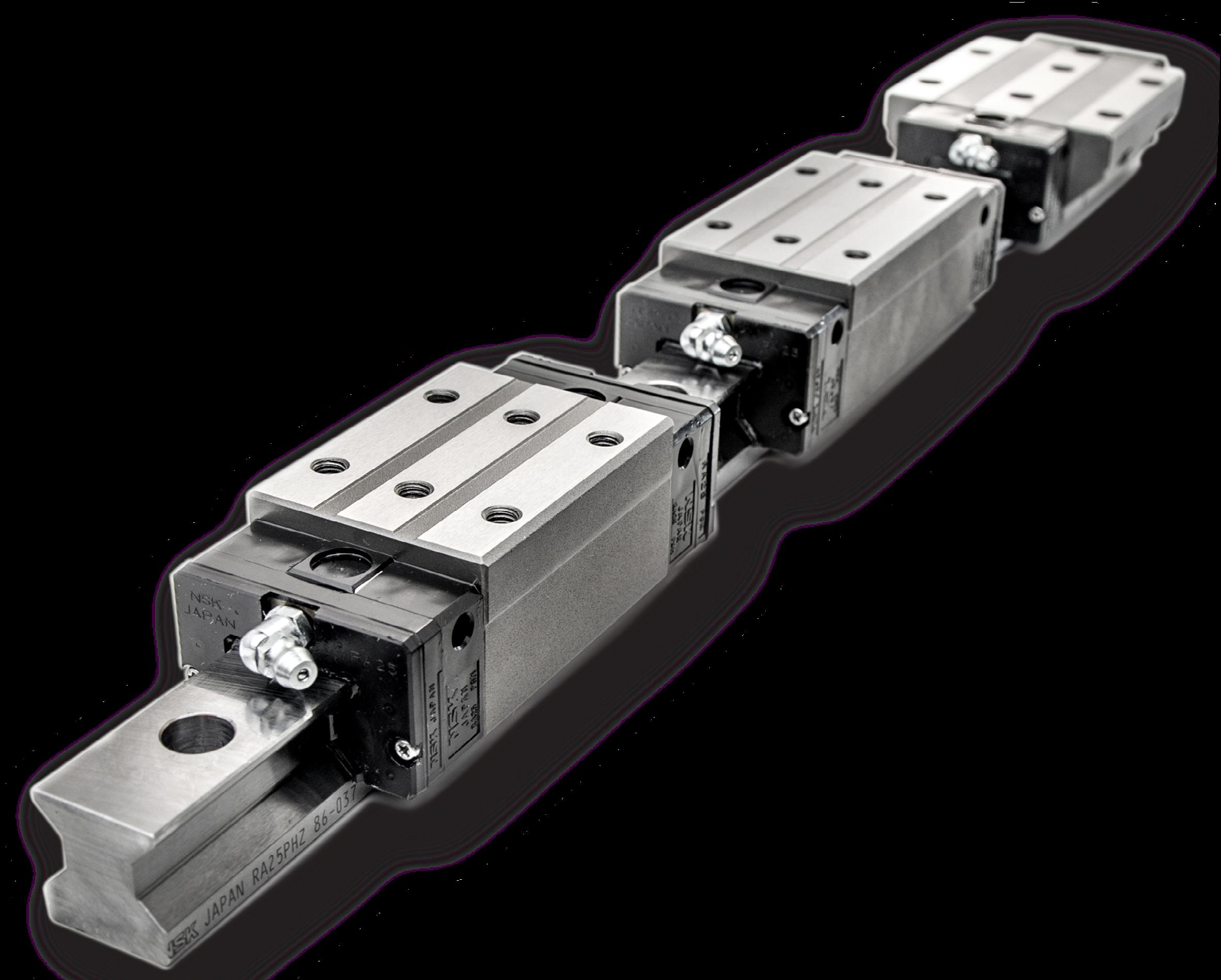

Linear guides and ball screws

Large stock, fast delivery

Specialist cutting facilities

Authorised NSK UK distributor

Authorised NB distributor

Informa PLC, the world’s largest exhibition organiser, have announced that the co-located exhibitions; Facilities Show, FIREX, IFSEC and Safety & Health Expo will now become part of newly launched Anticipate London, taking place from the 2nd to the 4th December 2024 at ExCeL London.

Anticipate London emerged as a result of insightful conversations with members of a future-focused advisory board which includes leaders in security, safety, FM and property from both FTSE 250 organisations and the wider public sector.