In this

issue

of Industry Update, we’re delighted to select Plas-fit UK Ltd as our Water Fittings Company of the Month

The longevity of Polyethylene Pipes (PE)

Over thirty years ago, the UK

PE pipe had its defining watershed moment, when Severn Trent Water declared it frontrunner for extended design life following extensive testing. PE pipes are distinguishable by leading built-in durability, corrosion and chemicalresistance features, coupled with lightweight, easy handling and installation. Ergonomically designed for toughness, the pipes are able to withstand ground movement without cracking and the smooth interior surface ensures fluid flow, while simultaneously reducing the chance of blockages. With a long service life surpassing fifty years, PE pipes are integral to the circular economy and with its recyclable features, offer a sustainable construction practice moving forward.

“We have been supplying our leading WRAS-approved fittings in Germany and The Netherlands for decades, where PE pipes are commonly used for domestic, industrial and commercial buildings for over sixty years. Over the years, we developed our range to meet the very high German certification standards.

“Historically, the existing UK Water Fittings market for PE pipes has been well catered for by a few established companies. To successfully break into this market, we knew we needed a strategic triangular approach: superior products, huge warehouse stock investment and customer-centric philosophy at the heart of operations.

The secret to success: quality water fittings During the recent Utility Week Live back in May, Plas-fit was a Top Exhibitor and magnet for new and existing customers.

“We are market disrupters, for a long time the UK has been dominated by two suppliers but we now offer an alternative product supply, mirroring the success in Germany and The Netherlands.

“We supply an extensive product portfolio of WRAS-approved fittings including: 250/350 series, universal fittings, stop cocks, pipe liners and spare parts and tools. Our universal fittings are particularly popular, due to its small, compact design, which allow for minimal disruption across all jobs.

Leading water fittings for PE pipes

Safe drinking water is a leading priority for homes and businesses across the UK, therefore having access to WRAS-approved water fittings help comply with stringent water fittings regulations.

As part of our spotlight feature on emerging UK wholesale building materials, we spoke to Managing Director and Chairman of Plas-fit UK, Ian Grant, to find out more about the company’s rise and future trajectory.

“In November 2023, we took a leap of faith and launched our range to the UK market at the National Drainage Show.

“Seven months in and you can now buy Plas-fit UK products all across the country, solidly backed up by our located warehouse in Stoke-On-Trent, ensuring reliable next-day delivery. This location gives unrivalled connections to the rest of the UK, with close proximity to the M6 for road transport links. We have our own transport and can quickly deliver to customers, on the same day if needed.

“Unlike the more established companies which ship the products from as far afield as Australia and Israel, Plas-fit UK manufactures the majority of its products in the Greek region of Cyprus.

“Not only does the shipping avoid delays due to geo-political hotspots but the carbon footprint is dramatically lower: a huge advantage to European-based manufacturing.

“We’ve been bowled over by huge scale of response, with enquiries even coming in from national groups and water companies. Looking ahead, we're looking to build-up our network of traders/ merchants further and are particularly interested to hear from interested parties in Northern Ireland.”

“We’ve been inundated by enquires after exhibiting at the National Drainage Show and Utility Week Live, proving that we’re not just the new kids on the block but we’re here for the

Want to find out more about the extensive range of water fittings for PE pipes from Plas-fit?

Contact: Andrew Day, Director of Operations T +44 (0)1782 894912 andrew.d@plas-fit.co.uk https://plas-fit.co.uk

UNISIG is an industry-leading American producer of deep hole drilling machines. The company supplies a large variety of customers from aerospace and automotive to energy, firearms, hydraulic cylinders, military, medical sectors, smaller bespoke companies and large original equipment manufacturers (OEM.)

With unparalleled installation capabilities across Europe, Asia and America, UNISIG has the expertise to provide advanced precision-driven machinery for all jobs, with its complete deep hole drilling solutions that range from machinery to tools and automation.

The drilling capabilities include: Gun drilling, BTA, counterboring/reaming, trepanning, pull boring, skiving and roller burnishing, bottom forming, bottle boring and much more. With a wide range of stock machinery lines for diverse manufacturing needs, UNISIG can also provide bespoke-engineered machinery across all applications.

The American heavyweight was established in 1981 and since that time, has built up to a pole position across the global industry with its renowned production of gun drilling and deep hole drilling machines. Entrust Manufacturing Technologies acquired UNISIG in 1995 and then moved the company to its purpose-built headquarters in Milwaukee, USA.

Their US Milwaukee facility was expanded by over 100,000ft2 in 2019 to keep up with increased

production capacity demand levels. The CNC grinding machine also supports greater production, alongside regular upgrading across the production facility. The dedicated design engineers at the UNISIG Tech Centre in Milwaukee are more than happy to build customised drilling machine orders, from prototypes to finished machines.

We spoke to Philipp Steimle, Sales and Service Manager for Europe, to ask more about company developments, “Due to ongoing supply issues, our company is expanding its own manufacturing department. The Kellenberger CNC grinding machine we have installed will allow us to finish all the drilling spindles in-house. We have also installed a laser-cutting machine, a CNC press brake and welding stations so that we can do all the guarding

and coolant reservoirs in-house to avoid delays in our machine building.”

“The UNE6 series for medical instrument drilling with its fully integrated automation is a game changer for the industry and is proving highly popular in the market. We have, and continue to invest in more inhouse production rather than external third parties to keep on top of our orders.”

UNISIG is a clear market leader with a commitment to excellence to all customers. From quick machinery and part shipping orders delivered around the world, to meticulous service and repair jobs (conducted on-site and remotely), all jobs are carried out by an expert installation team made up of UNISIG engineers.

The recent addition of two new SSI Schaefer LOGIMAT® vertical lift modules (VLM) in the parts warehouse have further enhanced the alreadyexcellent customer service. The storage units hold up to 28 tons of spare parts each providing welcomed streamlined organisation and tracking. UNISIG operators can now effortlessly access parts inventory on the touchscreen and the VLM moves the correct tray forward, while a laser then selects the precise bin and location of the required part. This use of automated technology has optimised the inventory storage capacity and created a smoother, more accurate retrieval system.

UNISIG leads the way in expertly engineered, high-performance gundrilling. Another prime example of this is through the use of the Dual-Spindle gundrilling machine that comes with counter-rotation (UNE12-2-750-CR). This has impressive features that include the two spindles for advanced-precision gundrilling to 12mm in diameter and 750mm in depth, at 12,000rpm. And, with capabilities to produce over 2,000psi coolant pressure, with integrated chip collection system and a touchscreen control panel, the characteristic counter-rotation of cylindrical workpieces provides next-level hole straightness that you’ve never seen before.

Contact UNISIG to discuss how deep hole drilling equipment would support your business venture today: www.unisig.com

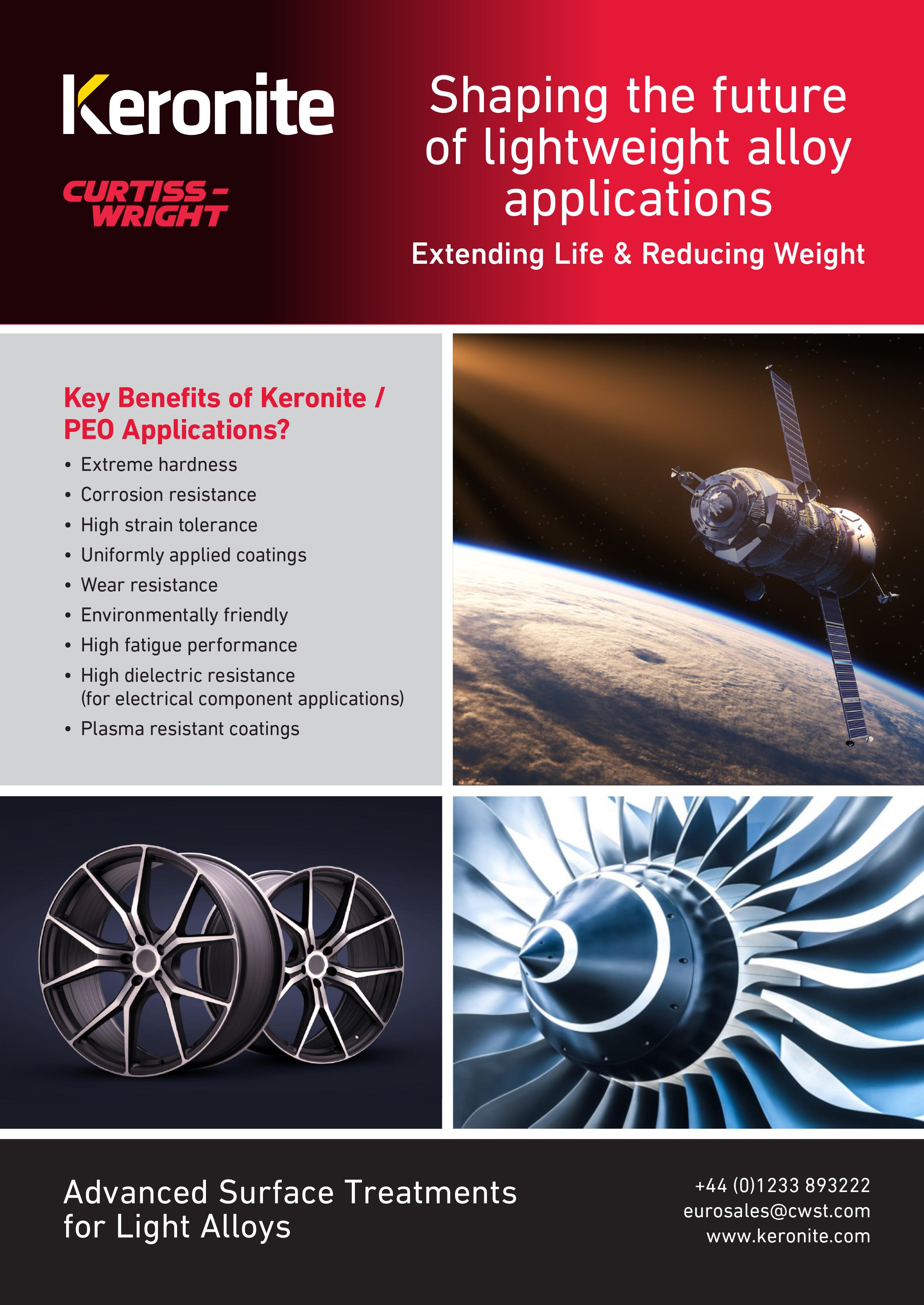

Innovative design, rigorous testing and high precision engineering are why Oliver Hydcovalves are the most trusted valves for Hydrogen and Carbon Capture applications.

The range has grown rapidly to include instrumentation, Double Block and Bleed, Pipeline, and Subsea Gate Valves. Shown here is the 1” Hydraulic Gate Valve with manual override, DBB with 20mm bore, 3” Flange, and the ½” Hydraulic Gate Valve equipped with Remote Operated Vehicle bucket capability.

These valves, showcased for their

diverse features, are en route for deployment in Carbon Capture (CC) injection applications.

For information on how Oliver Hydcovalves can provide Hydrogen and Carbon Capture valve solutions for your green renewable energy project, telephone: +44 (0)1565 632636 or visit our website at: www.valves.co.uk

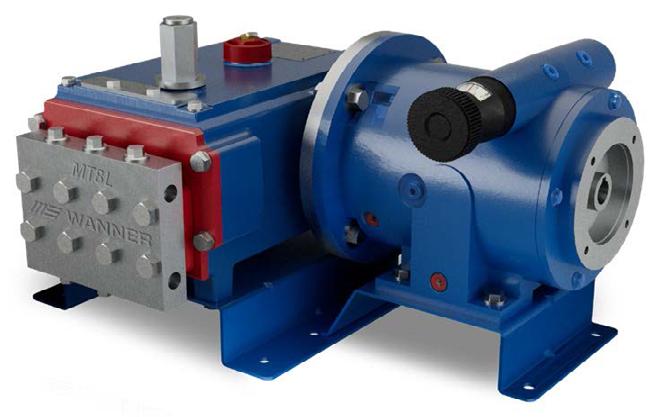

WANNER has designed and developed a metering pump range that integrates Hydra-Cell Pro seal-less pump technologies for the highest levels of volumetric and energy efficiencies across the full turndown – 100% to 1% of rated flow – for accurate metering performance.

The Hydra-Cell Pro MT8 series exceeds API 675 standards with a steady-state accuracy of ±1%, linearity ±3%, and repeatability ±3% over a wide adjustable range.

Unlike single diaphragm metering pump technologies, WANNER’s metering design with multiple diaphragms in a single pump head eliminates the need for pulsation dampeners and associated risks of pipe strain in most applications, with reduced acceleration head losses and a wider process window. The extremely low pulse flow from this design delivers a much more even distribution of injected chemicals.

For superior accuracy and reliable operation at low- and high-suction pressures, the hydraulic oil management system replenishes on every back stroke, also ensuring a more consistent process. In

addition, the patented Advanced Diaphragm Position Control (ADPC) protects the diaphragms under closed or restricted inlet conditions; if an operator runs the HydraCell pump by accident with a closed suction line isolation valve, the diaphragms are not damaged.

With WANNER’s valve set design and material options, this reliably handles a wide range of viscosities and shear sensitivities, plus corrosive liquids, abrasives, slurries and suspended solids. And the compact design of the MT8 saves valuable plant space.

www.hydra-cell.co.uk/metering

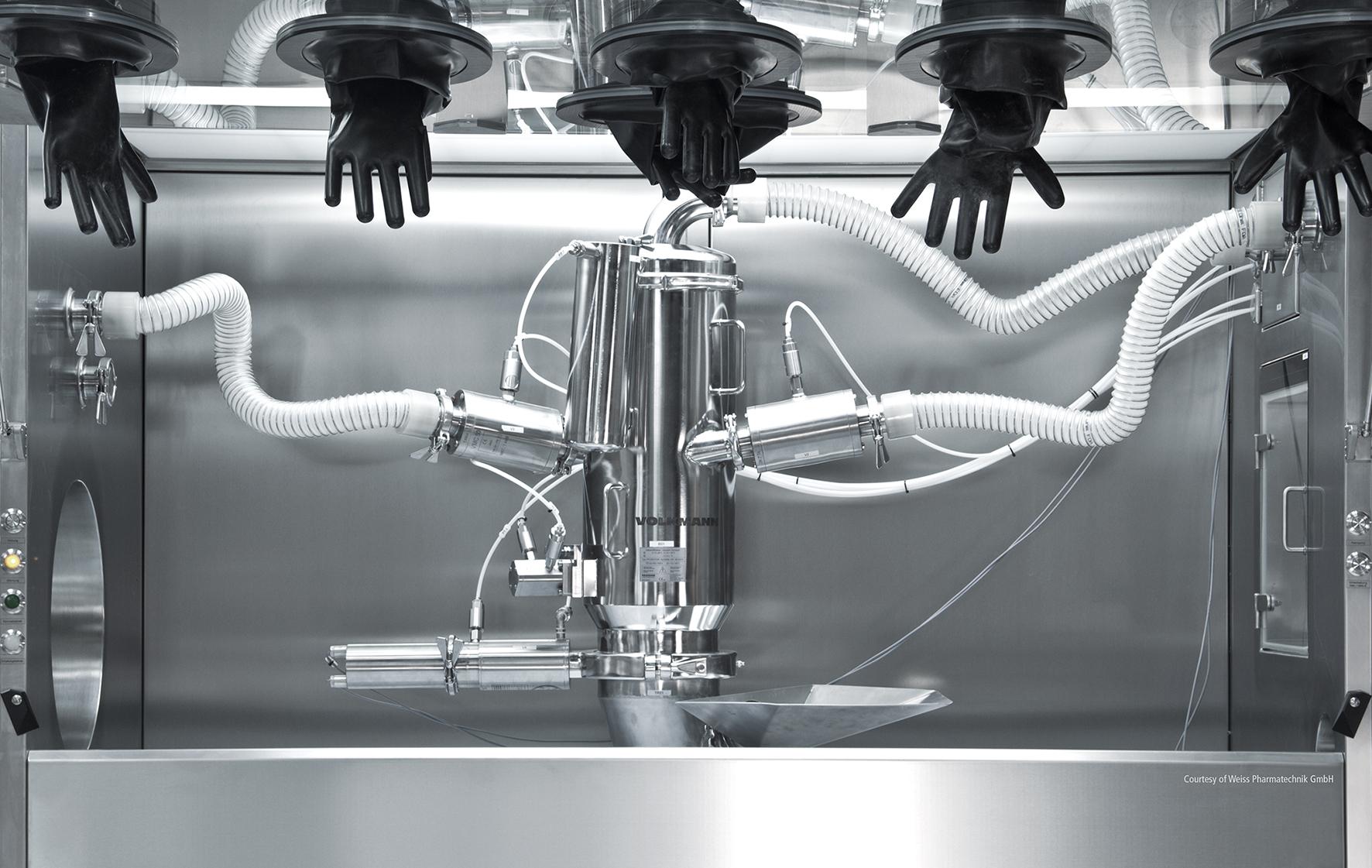

Volkmann supports customers in solving their conveying tasks, from the idea right up to the finished plant. This is our strength. We act responsibly and pay particular attention to the perfect interaction between our and other systems applied in the process. Our expertise in consulting and design, together with the high quality of manufacture and flexibility within the company, offer the best recipe for the success of a project as well as for the satisfaction of the users, thanks to equipment and plants that can be operated simply and safely.

During the planning or improvement of process and filling-lines, the question occurs of how to optimise the material flow. Nowadays, the product flow downstream of packaging units is highly automised, however, the supply side often shows weakness. Volkmann have a loading

system, which combines the advanced Multijector®Vacuum Conveyors with a level-controlled buffer hopper.

With this transfer unit, first the respective powders, granules and other bulk materials to be packed are safely transported by vacuum and it is then used to supply the packaging and filling process on demand. The result is an interactive, enclosed transfer system, which is also suitable for pellets, capsules or tablets. This conveying method has considerable advantages over conventional, old fashioned, manual or mechanical transport technologies. Apart from supplying packaging lines, Vacuum Conveyors safely load mixers, tablet-presses or any other kind of process equipment or vessels (containers, silos etc.) (figure 1).

Conveyable bulk materials even include difficult and sensitive powders. The cyclic vacuum-plug-flow conveying set up usually results in no product separation or

segregation. When introducing small amounts of powders into the system either manual suction lances or feeding hoppers are used. For larger quantities bag rip & tip stations or big-bag unloading devices are more common. In addition, the available ATEX certificates for all Multijector®-Vacuum-Conveyors make them the perfect choice for potential EX areas (powders and gasses) and with that they are unique in the European market.

Nearly any type of bulk-materials, ranging from A for Activated Carbon to Z for Zeolithe, are conveyable with vacuum.

T +49 2921 96040 mail@volkmann.info https://uk.volkmann.info

Founded in 1970, the company is headquartered in Nordhorn, Germany. Reinert-Ritz GmbH has established itself as a leading provider in the field of polyethylene (PE) and polypropylene (PP) piping systems, which are widely used in various industries including water supply, gas distribution, wastewater management, and industrial applications.

“Our primary role is the production of specialised fittings. Our service encompasses the entire process, from planning new pipelines to final installation. Where conventional suppliers halt, we begin, assisting engineers and municipalities with their needs. Reinert-Ritz offers custom-made, pressureclass compliant fittings made from polyethylene and polypropylene, with sizes up to 2,500mm,” said Nico Hindriks, Area Sales Manager.

One of its most iconic and popular innovations is the QUICK-PIG – a station that simplifies and enhances the pigging process, ensuring ease and safety by allowing operation from the ground surface. With its specialist design, it is seamlessly integrated into the pipeline as a fitting, providing a range of options that

In this issue of Industry Update, we are pleased to feature Reinert-Ritz GmbH as our Equipment & Pipeline Construction Company of the Month

make the construction and operation of a pressure pipeline both economical and sustainable.

“QUICK-PIG is specifically designed for rising mains, offering swift access without the need to descend into a manhole. Its key advantages, particularly in terms of health and safety, make it a standout solution for utilities. We're proud to announce the successful sale of the initial units to South West Water, as well as ongoing detailed discussions with additional utilities,” added Nico.

QUICK-PIG is compact for efficient operation, economical to purchase and operate and fully safe to operate. Furthermore, all components of the QUICKPIG station that come into contact with the medium, such as wastewater, are manufactured from the proven PE 100-RC (resistant to crack) and stainless steel 1.4571 (V4A). This ensures that QUICK-PIG is corrosion-resistant and durable.

Reinert-Ritz GmbH invests largely in research and development to innovate and improve its product offerings, staying at the forefront of technological advancements in the plastic piping industry. “We believe that Quick-Pig has the chance to be state of the art in the global wastewater market,” trust Nico. We at Industry Update support the manufacturer who has demonstrates since the beginning his strong reputation for reliability, quality, and customer service in the global utilities market.

Unlike other companies that may serially produce

products, Reinert-Ritz GmbH offers tailored fabrication services to meet specific project needs, including custom dimensions and unique configurations.

Reinert-Ritz GmbH is continually enhancing its product portfolio, and its latest innovation is the QUICK-PIG with an Integrated Air Release Valve. This multi-tool for pressure lines offers comprehensive capabilities, including checking, pigging, flushing, and suctioning – all in one efficient device.

Where others stop, Reinert-Ritz GmbH begins, and we are excited to see what the rest of 2024 and beyond has in store for the company.

T +49 (0)5921 83 47-883 nico.hindriks@reinert-ritz.com www.reinert-ritz.de www.quick-pig.com/en

St Andrews Links Trust has appointed sustainable water and purification experts Bluewater as its Official Hydration Supplier to provide a nextgeneration drinking water solution for golfers and visitors to the Home of Golf.

The pioneering agreement will see Bluewater, a global leader in sustainable water purification & beverage solutions, provide purified drinking water across the St Andrews Links estate through its innovative refill stations, supporting a commitment for the removal of singleuse plastic bottles from the Trust’s facilities.

The stations utilise the Swedish company's advanced SuperiorOsmosis™

treatment process, which removes more than 99% of known contaminants from water, to provide locally purified and chilled drinking water at the point of consumption.

The refill stations will initially be installed in both the Old Pavilion next to the first tee of the iconic Old Course and at the Halfway House serving the Old, New, and Jubilee Courses with further installations at the Links Clubhouse, Golf Academy, and Castle Course Clubhouse.

Each unit will provide free-of-charge refills of chilled and purified water.

The units also feature high-bright digital TV screens to communicate key information to visitors concerning wider sustainability initiatives across the world-renowned venue.

For more information, visit: www.bluewatergroup.com, or call David Noble on +44 (0)7785 302694 or email: david.noble@bluewatergroup.com

Electric vehicles are a decisive factor in reducing CO2 emissions in road traffic. They store the energy required for propulsion in batteries and an electric motor converts it into motion. In contrast to combustion engines, no fossil fuels are required. If the batteries are charged with electricity from renewable energy sources, they even have a completely CO2-free energy balance. Today, lithiumion batteries are used almost exclusively as accumulators. Vacuum technology is indispensable for their production.

Tracer gas leak detection ensures quality The proper functioning, quality and safety of lithium-ion batteries, which are used as accumulators in impermeability to external influences such as moisture ingress. For this reason, leak detection systems are used in battery production to check the batteries.

Pfeiffer Vacuum supplies the necessary vacuum solutions from a single source.

One of the world’s leading battery manufacturers for the automotive industry is currently using test gas leak detection systems from Zeltwanger Leak testing & Automation GmbH, which are equipped with complete solutions from Pfeiffer Vacuum. The systems must meet stringent requirements. The decisive factors here are achieving the required cycle time and high reproducibility of the battery cell test.

Enabled by Pfeiffer Vacuum technology, even the smallest leaks can be quantified and localized with the help of Zeltwanger’s testing systems. This makes it possible to quickly eliminate leaks in a downstream production step.

Changes to geometries and improvements to production methods and processes can be initiated based on the results obtained. This leads to quality improvements, increases the yield and reduces manufacturing and testing costs.

T +49 6441 802 0 www.pfeiffer-vacuum.com

Veolia Water Technologies has launched the latest generation of Polaris, its leading highcapacity water distillation and steam generation solutions, developed for the pharmaceutical industry. Using a range of standard options, the skid-mounted PoIaris 2.0 Multiple Effect Distiller (MED) and Polaris 2.0 Pure Steam Generator (PSG) systems have been engineered to reliably deliver the required volumes of water for injection (WFI) and pure steam in line with European, Japanese and US Pharmacopoeia standards.

The new Polaris 2.0 range includes an array of standard units with different capacities and a list of options to meet all customer requirements. The design and construction of the Polaris 2.0 units comply with ASME Bioprocessing Equipment (BPE) standards. In addition, for simple compliance with FDA CFR 21 Part 11 and GAMP V, Polaris 2.0 is equipped with a Siemens HMI Comfort Panel that includes new validated and certified software.

The PoIaris 2.0 Multiple Effect Distiller units have capacities from 250 l/hr to 4,500 l/hr and have been designed to guarantee high-quality WFI. The units include between three and eight columns depending on the size to reduce utility consumption and the ‘falling film’ distillation process helps ensure high efficiency and a fast start-up. Furthermore, the PoIaris 2.0 MED achieves blowdown levels of just 10%, meaning a small water footprint.

The Polaris 2.0 Pure Steam Generators offer rapid-response steam supply and can produce between 300kg/hr and 3,000kg/hr of pure steam depending on the unit selected, and up to 4 barg for autoclave supply. It also features an integrated thermal degasser for the removal of non-condensable gases for compliance with EN285.

The Polaris 2.0 range has been designed and built to allow easy maintenance throughout the system’s lifespan. This minimises downtime and reduces the costs and lost production for the customer. Veolia Water Technologies offers comprehensive programs of servicing and after-sales support including preventative and predictive maintenance.

Finally, the Polaris 2.0 is compatible with Hubgrade, Veolia’s cloud-based remote monitoring and optimisation solution. Hubgrade provides customers with live

operational information, alerts and advanced data analysis, as well as enabling faster issue resolution in collaboration with Veolia’s engineers.

Commenting on the launch of the new range, Luca Danesi, Chief Sales Officer Europe –Pharma Division, at Veolia Water Technologies, said, “Our Polaris distiller and steam generation units have long been the go-to solution for pharmaceutical businesses around the world. Polaris 2.0 is an evolution of this tried-andtrusted solution for WFI and pure steam generation with improved performance and efficiency.”

Contact www.veoliawatertechnologies.co.uk

In response to recent findings exposing the presence of harmful PFAS contaminants in the tap water of 70 million Americans, Bluewater, a pioneering brand delivering water purification solutions and beverages, is urging for increased public vigilance and intervention from national health and water authorities this World Water Day 2024. Committed to a plastic-free planet and ending the need for single-use bottles, Bluewater is spotlighting the intensifying global crisis of water contamination by PFAS persistent chemicals, now widely detected in tap water worldwide and posing a threat to human health.

“Our mission at Bluewater is to protect people by preventing hazardous chemicals such as PFAS from getting into their bodies. PFAS isn’t a localised issue. It’s a global health crisis spiralling out of control,” says Bengt Rittri, a leading Swedish environmental entrepreneur who founded and leads Bluewater as CEO. Rittri believes there is an urgent need to amplify public awareness about the risks tied to these toxic ‘forever chemicals’ still being produced and used in numerous industries – and leaching into environments such as rainwater, surface water, and ground soil where they won’t break down for hundreds of years if ever.

“Every mother, father, and concerned citizen on our planet, from Europe to North America, Asia, and Africa, should be demanding action from their local and national health and water authorities,” Mr Rittri says. “At Bluewater, we’re dedicated to developing

and offering solutions that purify tap water for home, work, and play, helping consumers and businesses to end their reliance on bottled water while restoring trust in the water flowing directly from their taps.”

Bluewater believes the severity of PFAS contamination of drinking water underscores why governments worldwide must promptly establish or finalise national drinking water standards for PFAS and set science-based limits for these chemicals in water. Bluewater’s ground-breaking purification solutions have been verified in independent tests to remove 99.7% of all toxic PFAS chemicals from tap water, providing customers with healthier and great tasting drinking water.

In recent investigations to raise public awareness of the problem in London and Stockholm, Bluewater found evidence in both cities of worrying levels of the most hazardous PFAS chemicals, PFOA and PFOS. The company also champions sustainable practices, partnering with many of the world’s leading events and venues in plastic reduction initiatives and promoting reusable bottles. Bluewater hydration and bottle solutions are used widely in fan-facing events like golf’s The Open and by teams competing in the America’s Cup,

Founded in 2013, Bluewater is forging ahead with its purpose-driven mission to end the need for singleuse plastic bottles by developing and harnessing planet-friendly technology. Bluewater purification solutions for home, work, and play are available to tens of thousands of consumers and hospitality businesses concerned about what’s in their tap water worldwide, including the Middle East, North America, Europe, Southeast Asia, and Africa.

“As we commemorate World Water Day 2024, Bluewater encourages everyone to consider tap water quality and to take action towards better health and a sustainable planet. We also urge the manufacturers of PFAS chemicals to take responsibility for the pollution they are causing and –preferably – stop their production of such chemicals entirely,” said Bengt Rittri.

M 07785 302694

david.noble@bluewatergroup.com www.mynewsdesk.com/bluewater www.bluewatergroup.com

From rising levels of noise pollution in urban areas to concerns over air quality, these issues have a profound impact on the well-being of citizens and the sustainability of industries. To address these challenges, the field of environmental monitoring has emerged as a critical sector within the broader technology and engineering landscape.

Environmental monitoring solutions encompass a range of sophisticated technologies and data-driven approaches aimed at tracking and mitigating environmental factors. This includes monitoring noise levels in cities, assessing air quality in industrial zones, and measuring vibrations caused by construction activities. Such monitoring is not only essential for regulatory compliance but also for the overall quality of life and safety of individuals living and working in these environments.

In this context, companies like Cirrus Research play a pivotal role by developing innovative and reliable monitoring solutions. These solutions provide real-time data, enabling businesses and government authorities to

make informed decisions to improve the environment and safeguard health.

Cirrus Research’s mission revolves around creating innovative solutions that enhance the way we monitor and manage noise and other environmental impacts. They have not only revolutionised the field of noise monitoring but also expanded their expertise in air quality, vibration, and more.

Cirrus Research’s Cloud-based monitoring solutions, Quantum Indoor and Quantum Outdoor, have had a profound impact on businesses and communities across the UK. By providing real-time data on noise, air quality, and vibrations, they empower businesses and local authorities to make informed decisions. This data-driven approach not only ensures compliance but also fosters healthier, quieter, and more sustainable living and working environments.

These Cloud-based monitoring solutions have not only changed the way we perceive data but have also transformed the way we live and work in the UK.

Find out more at: www.cirrusresearch. co.uk/blog/2023/11/ quantum-award-ofexcellence

Michell Instruments, part of the Process Sensing Technologies Group, has launched an advanced new portable compressed gas dew-point hygrometer.

The new Easidew PDP Dryer Portable is designed for use by OEMs, maintenance engineers and independent service companies. It is lightweight, rugged and easy to use, enabling trace moisture levels to be measured and data logged in compressed air and gas streams as they exit refrigerant or PSA dryers.

Measuring trace moisture levels in compressed air and specialized gases, such as nitrogen, oxygen and hydrogen, is becoming increasingly important. This is especially true in healthcare and advanced manufacturing applications, where the need to ensure consistent gas quality, traceability and compliance is essential.

The new Easidew PDP (Pressure Dew Point) Dryer Portable has been developed to enable service and maintenance engineers to quickly and safely prove moisture content compliance in the outlet feed from the different types of dryers commonly used in industry.

The Easidew PDP Dryer Portable offers:

t Air-quality compliance to ISO 8573-1 Class 1–4

t Pressure dew-point monitoring to 20 barg t Multiparameter datalogging/ downloading

Michell Instruments has been manufacturing advanced moisture measurement sensors, analyzers and portable instruments for 50 years. The development of the new Easidew PDP Dryer Portable draws on this combined knowledge and experience, creating an instrument that the company believes will become the gold standard for portable dew-point (meters) devices.

T +44 (0)1353 658000 info@processsensing.com www.processsensing.com

KADANT PAAL DESIGN AND MANUFACTURE EFFICIENT SOLUTIONS for volume reduction to optimise transportation of recyclable materials, helping to reduce environmental impact and transportation costs.

WE ARE RECOGNISED

AS EUROPE’S PREMIER MANUFACTURER of baling presses including Channel, Twin Ram, Closed End and Metal Balers. Kadant PAAL work globally within the recycling industry whether it is with national waste carriers, independent waste companies, local authority, or FM distribution centres.

The Kadant PAAL Group is a result of the merger of four European Companies, PAAL, COMDEC, FAES and DICOM, with the recent addition of BALEMASTER USA.

The experience within the group ensures that Kadant PAAL are best placed as a provider of proven, tried, and tested baling solutions.

Kadant PAAL UK manufacture its own DICOM Product range of popular vertical balers and waste compactors, distributing and installing the PAAL range of fully automatic horizontal balers and conveyors manufactured in Germany. With their own Technical and Design Team they can provide bespoke solutions with fabrication work manufactured at the factory based in Alfreton to suit all requirements. Our mobile engineers are strategically placed across the country in the event of any mechanical difficulties providing a rapid response call out. Furthermore, the Remote Service Support (RSS) system remotely connects technical experts to the machine in question, with the ability to quickly diagnose the cause of faults, alarms or any performance related issues to avoid unnecessary downtime.

WE PROVIDE COMPREHENSIVE BALING SOLUTIONS. Over the last 150 years we have learnt that each application is unique, each operation having its own particular requirements and needs, processing varied materials.

WE UNDERSTAND EACH PROJECT IS UNIQUE, therefore we have a wide range of options that have been developed to ensure once the customers’ needs have been assessed and identified, we can offer an option that will fulfil the baling requirements, supplying a well-designed, robust and reliable solution. It is inconceivable to produce an individual bespoke baler for each application in the same way that one size does not fit all. With our extensive range of waste management options which are used in applications from MRF’s to retail stores, we are also able to offer bespoke adaptations to provide solutions for your environment.

dicom.sales@kadant.com

www.kadantpaal.com

www.dicompaal.co.uk

Why add a coat of varnish to your print materials? What are the advantages and disadvantages of varnish printing? And what techniques are available to you? Here’s the Soyang guide.

Why use a varnish?

Print varnishing has a dual purpose. A coat of varnish can help protect the printed material, making it less likely to rip and tear and more likely to withstand a moist environment or a splash of water. Where the substrate isn’t especially absorbent (and where inks are therefore less likely to penetrate), varnish can help seal the product and protect against smudging.

The other great benefit of varnish printing is impact. Varnishing makes print more eye catching. Then it helps your print last, so it can deliver that impact for longer. Precisely what impact you make depends on the varnish printing techniques you choose.

Is varnish printing suitable for all applications?

No, but it is suitable for many.

Paper, cardboard, metal: you’ll find varnishing effective across a wide range of substrates. Where it tends to have limited effect is with print materials designed to have large degrees of stretchy flexibility (eg. mesh banners or flags). A varnish coating will gradually crack and flake on such materials.

What are the disadvantages of print varnishing?

We’re not quite sure you’d call them disadvantages as such. You need to get varnishing right first time, as there’s little to no chance of rectifying a mistake. The same is true of many print techniques though.

It’s also the case that varnish needs time to dry, and that inevitably slows the productivity of any print shop. Again, we’d argue that the pros of the technique far outweigh the cons – we’re not sure any printer is printing brochures/flyers/ business cards etc and not offering varnishing on the basis that drying can take a while.

Varnish printing techniques

All of the following techniques are applied postprint using a press or varnishing machine. Once the varnish has been applied, the material will need to be cured or left to dry depending on the

specific technique (see below).

The ‘entry level’ print varnish is a basic machine seal that prevents inks on less absorbent materials from marking. In terms of visual impact, well, that’s not really the point of a simple sealant. This technique is all about the protection. For impact, you’ll want to apply one of the following:

Gloss varnishing

A gloss varnish delivers big visual impact, especially on printed photographs or graphics. The coating reflects light, boosting the oomph of imagery and making it ideal for brochures, flyers, magazines and similar.

Inevitably, gloss can lead to glare, though, so where a print material will be subject to harsh lighting (for example, a banner or poster) you may be better choosing an alternative finish or risk the imagery being obscured by glare.

Matt varnishing

The opposite end of the spectrum to gloss varnish. If gloss brings the shine, matt removes it, delivering a warm, soft finish. Importantly, matt varnish makes text easier to read than gloss typically will.

Silk varnish

A halfway house between gloss and matt, delivering reduced glare (although not as reduced as matt) but greater image impact thanks to the soft sheen finish.

UV varnish

A UV varnish is great for helping colours ‘pop’. It also has a knack of making print feel substantial, giving projects a prestige finish. As the name suggests, the coating needs to be cured under UV light once applied.

Spot UV

UV varnish is effective across a whole page but can be even more impactful when applied to specific elements of your print. Confine it to specific images or lettering, for example, and you create an even more eye-catching cover to your book, brochure or report.

Textured varnish

All of the techniques we’ve explored so far have distinct visual appeal but don’t offer much in the way of tactile excitement beyond lending the print a general sense of prestige.

Textured varnish, however, changes that. Once applied and cured, the finish creates a sort of rippled effect that encourages inquisitive fingers.

Particularly effective when used as a spot varnish.

Talk to Soyang

Of course, there’s more to a great printed product than the varnish. Your choice of print material is a crucial ingredient too.

For all your printing material needs, talk to Soyang at: https://soyang.co.uk/contact-us

Soyang Europe has been working with Reconomy to offer customers access to environmentally focused and responsible waste management services.

International circular economy specialist Reconomy has revealed how its relationship with wide-format and superwide-format media manufacturer and distributor Soyang Europe is helping UK print service providers to improve their environmental credentials.

Reconomy combines technology and skills to enable businesses to better manage their resources, helping to reduce waste, optimise their supply chains, and contribute in a meaningful way towards the circular economy.

While this involves working directly with print companies, Reconomy is also partnered with several leading manufacturers and distributors, supporting their customers with textile waste management. One such partnership is with Soyang Europe, whereby printers using materials from Soyang Europe can responsibly dispose of their waste.

This partnership came about three years ago with the support of FESPA UK. Reconomy was working on various sustainability initiatives with FESPA, while Soyang Europe is a long-term member of the association.

The process works with Reconomy providing customers with a baler to prepare their textile waste. Soyang Europe then collects the bales when delivering new products to customers, with the waste taken to its facility in Altham in Lancashire ready for bulk collection and transportation to a recycling facility for processing.

“It was a perfect fit,” said Reconomy Director, Jon Hutton. “Soyang has always been proactive in wanting to offer their customers, and the wider industry, waste management solutions for their products.

“Sustainability is a hot topic for several reasons. Brands and consumers are looking down the supply chain for environmental credentials, so it’s therefore a driving factor in how to not only maintain and gain business, but how a printer positions themselves for the long term.”

Mark Mashiter, Managing Director at Soyang Europe, added, “It provides our customers with an outlet for their waste. This works well with local customers when we deliver orders to them; we can bring any textile bales back with us and store them in our yard until they are collected.”

Originally, Reconomy had sourced a solution for recycling PVC banner and polyester fabrics at a UK site, whereby waste was blended with other polymers to produce low grade products. While this process ended when more desirable material became available to the market, a recovery route was soon set up and, with the support of Wheeldon Brothers, waste could now be diverted from landfill to renewable energy.

Reconomy combines technology and skills to enable businesses to better manage their resources, helping to reduce waste, optimise their supply chains, and contribute towards the circular economy

However, recycling has since been reestablished and material is again being used in manufacturing processes. Coupled with its use for renewable energy, all of this is helping work towards a circular economy.

An additional benefit to the service is that Soyang Europe is willing to take other supplier’s waste textiles along with its own. This option is available to customers using their own transport within a set radius of Soyang Europe’s facility and when making deliveries.

“Soyang Europe wants to be part of the environmental solution and not the problem,” Jon said. “The take-back scheme provides a platform for printers to demonstrate their sustainability by providing customers with an outlet for their recycling waste.

“Several customers have engaged with Reconomy further and are now collecting their own clients’ end-of-campaign textiles, integrating this with the collection of their materials. All loads are tracked, and Certificates of Recycling can be issued once the material has been processed.”

The work does not stop here for Reconomy, with Jon saying the company will continue to work with Soyang Europe, FESPA UK and its wider membership base to provide more sustainable solutions to the UK industry.

“It’s our aim to continue to be a driving force in educating the industry on the importance of recycling and developing circular economies,” Jon said. “This, with the continued support of Soyang Europe, will ensure more customers take up this service.”

T +44 (0)161 765 3400

sales@soyang.co.uk https://soyang.co.uk

We are a leading provider of pumps, power equipment, and fluid handling solutions to a wide range of industries throughout the UK and export markets. Our expertise extends to manufacturing and selling pressure washers, pumping systems, and component assemblies. With a deep understanding of our products and a network of industry experts, we can cater to the specific needs of our customers.

We are recognised as offering exceptional service, characterised by speed, accuracy, & flexibility. Our customers can count on us for support & assistance, allowing them to focus on serving their clients.

We value open communication and respect in all our interactions and strive to be helpful, personable, and friendly. We take responsibility for our actions and always follow through on our commitments.

With over 48 years in the industry, a dedicated team, and our own warehouse, production, and testing facilities, we are well-equipped to meet the demands of our partners and stock a wide range of quality products.

Located in Melton Mowbray, Leicestershire, in the heart of the East Midlands, we have good transport links and offer next-day delivery to most of the UK. Good access to East Midlands, Birmingham, and London Stansted international airports enables easy travelling for overseas visitors.

We pride ourselves on long-lasting relationships with our customers and suppliers built on trust and excellent service

t Customer Care & Sales team are ready to take your orders and help with enquiries.

t Technical experts to offer advice.

t Dedicated export sales advisor for European and international export matters.

t Dual Pumps has a proud tradition of long-serving staff.

t 99% of customers surveyed, rated our service as good or excellent.

t In a typical month, 99% of more than 2,400 calls are answered within a minute.

t More than 96% orders fill on active products over a typical monthly period.

Our experienced distribution team ensures you and your customer’s consignments are despatched securely and on time Unrivalled stocks are ready for your choice of delivery. Optional plain cover delivery direct to your customer.

Our purchasing team liaises with suppliers daily, placing orders and negotiating the best possible prices

The warehouse team receives daily deliveries from suppliers and replenishment of stock is constant.

T +44 (0)1664 567226 info@dualpumps.co.uk www.dualpumps.co.uk

Union Industries, the UK’s leading manufacturer of bespoke industrial doors, has helped food importer and distributer, Taj Foods, improve efficiency through the installation of high-speed freezer doors – the Eiger Door.

Taj Foods, specialists in frozen exotic food and prepared meals, was established in 1980 and recently expanded its cold storage at its Sheffield warehouse to meet growing demand. The project undertaken by EJM refrigeration, involved improving its energy efficiency and carbon footprint with the installation of a new CO2 refrigeration system.

L-R: Rob Howe, Technical Sales Engineer at Union Industries and Anil Solanki, Anil Solanki, managing director at Taj Foods

The two Eiger Doors will enhance operational efficiency in the high-demand environment and will maintain consistent freezer temperatures, while ensuring unimpeded access to cold stores.

Since its launch in 2002, the Eiger Door has been installed as a fast-access traffic door at major food

retailers, 3PL cold storage and distribution, and frozen food manufacturers across the UK.

The Eiger Door ensures that consistent temperatures can be maintained and features an innovative dehumidification system, which prevents snow and ice build-up on the door blade and frame. This feature tackles a consistent issue plaguing other door types, as the freezer encounters humid ambient air entering the cold store.

Minimising downtime is also supported by the Eiger Door’s robust construction and its tried and tested crash-out and reset system. Due to the modest difference in size between Forklift Trucks and the door opening, as well as the busy nature of this freezer, this is of particular benefit at this depot when considering the long-term reliability of the Eiger Door.

Rob Howe, Union Industries’ Technical Sales Engineer, said, “The installation of the Eiger Doors at Taj Foods showcases our commitment to providing cutting-edge solutions that prioritise efficiency and reliability.

“Over the past 20 years, the Eiger Door has consistently proven to be a superior and effective innovation for cold storage access, overcoming challenges such as ice build-up and excessive energy use to maintain consistent temperatures.

“We are confident that the Eiger Door will significantly contribute to Taj Foods’ operational success.”

Anil Solanki, managing director at Taj Foods, said, “We were looking for a reliable door solution to fit in with the redevelopment of our Sheffield warehouse, and after reading about the success of the Eiger Door we approached Union Industries to assist us to improve operational efficiency as we doubled our capacity.

“We believe that the advanced features of the Eiger Door will not only enhance the efficiency of our cold storage but also contribute to long-term reliability, minimising disruptions in our day-to-day operations.”

Contact T +44 (0)113 244 8393 enquiries@unionindustries.co.uk www.unionindustries.co.uk

Union Industries, the UK’s leading manufacturer of bespoke industrial doors, has utilised virtual reality (VR) to help Leeds-based Met Fab Solutions maintain comfortable working conditions with the installation of a Bulldoor.

Union Industries has successfully deployed its innovative new VR software to assist Met Fab Solutions, a leading UK manufacturer of aluminium panels and aluminium pressings, specify and configure the correct door suited to its needs.

This innovative tool allows Union to immerse prospective clients in a 3D showroom where they can experience their high-speed door offerings and interact with the products in a virtual environment. The software, comprising a VR headset and handheld units representing the customer’s hands, showcases the extensive features, specifications and benefits of Union Industries’ products.

Met Fab’s powder coating facility contains an extraction unit which draws the temperature outside of the building

to keep the area cool during hotter periods. However, when windy, the extraction unit causes a wind-chill resulting in employee discomfort, hence the company’s need for a fast acting and reliable door.

The Bulldoor not only ensures the integrity of Met Fab’s facility but also significantly reduces the impact of adverse weather conditions. Operated conveniently via remote control, the door incorporates a ‘Crash-Out & AutoReset’ feature as a standard safety measure, minimising costs associated with door impacts.

Renowned for their reliability and efficiency, Union Industries’ doors, including the Bulldoor, have become the preferred choice for manufacturers dealing with heat loss and escalating energy prices. With a robust design requiring minimal maintenance, these doors can withstand constant high-volume operations, making them an ideal solution for industrial settings.

Rob Howe, Union Industries’ Technical Sales Engineer, said, “Once again, the Bulldoor is the first choice for those

in the manufacturing industry who aim to address heat loss and wind chill through open doorways.”

“The Bulldoor is one of our best-selling doors and has been developed by our own R&D team over the years to become the reliable workhorse that it is today. Its robust design ensures minimal maintenance and can withstand constant high-volume operations.”

“We are also thrilled with the success of our new virtual reality configuration tool. This software enables us to immerse prospective customers into our world, providing a first-hand experience of the advanced features and capabilities of our rapid roll doors.”

Steve Cockerham, managing director at Met Fab Solutions, said, “The collaboration with Union Industries has proven invaluable in addressing our specific needs.”

“In utilising the VR software, Union was able to demonstrate to us in detail how the Bulldoor was best placed to serve our specific needs and address the challenges we faced.”

“The Bulldoor has not only enhanced the integrity of our facility but has also significantly improved working conditions for our employees.”

Please see our video: www.youtube.com/watch?v=C_pZjPdKGwg&t=4s T +44 (0)113 244 8393 enquiries@unionindustries.co.uk https://unionindustries.co.uk

Electrical heating systems have several safety features built in to prevent dangerous situations. High-limit sensors, or safety sensors, are one of the most important. Not only do they protect people, they help keep manufacturing lines running by limiting damage to equipment and product. In this article, Jeremy Ohse (pictured) at industrial heater, temperature sensor, and controller manufacturer, Watlow, explores best practice and considerations for high-limit safety sensors.

Understanding safety sensors

Thermal loops consist of a heater, temperature sensor, and heater controller. The controller has a temperature setpoint, receives a signal from the temperature sensor, and modulates power to the heater to maintain the temperature setpoint.

If there is a failure in the primary thermal control loop, the redundant safety sensor can tell the controller to reduce power to the heater or shut down the entire system. The most common failures are physically damaged sensors, worn out components, and pinched wires.

In an application away from industry, a hot tub uses a high-limit sensor to prevent the water from getting too hot. If the primary control loop fails, the heater will continue to heat the water. When the water temperature reaches a certain level, usually between 110 and 120°F, the highlimit sensor disables the heater to keep the water at a safe, enjoyable temperature.

To provide additional safety, when the high-limit sensor trips the system, users are ‘latched out’ until the system is inspected and reset by an operator, system designer, or

manufacturing engineer. Once the system is repaired and reset, it will operate normally again. In the hot tub example, the highlimit sensor will likely disable the pump in addition to the heater. A technician may need to inspect the hot tub and replace the primary sensor – or other defective parts – before resetting the system. This safety latch is often achieved in industrial systems through a programmable temperature controller and mechanical relay.

High limit applications

The high limit sensor in these scenarios are often thermistors, resistive temperature detectors (RTDs), or thermocouples (TCs). The best type of high-limit sensor is application dependent. The controller is often programmable so the user can adjust the primary control loop and the safety control loop temperature setpoints.

Location is essential

For the safest operation, the safety sensor should be attached directly to or immediately adjacent to the heat source. The farther the safety sensor is from the heat source, the more likely unwanted damage will occur when the safety control loop is engaged. For this reason, Watlow offers many heating products with sensors already embedded in the heaters.

Multiple high-limit sensors are used on large heating systems. A very large circulation heater may have several safety sensors to help identify failures in different sections of the heater. This approach allows operators to identify potential issues before they become a bigger problem.

Additional considerations

While the primary sensor and safety sensor are often two separate physical objects, they both plug into a single

heater controller. Just as there could be a failure in the sensor, there could be a failure inside the heater control. If the heater controller is agency certified (UL, CE, or ETL), it’s likely there are two independent micro-controllers inside the heater control box, one for the primary thermal loop and one for the safety loop. This second safety microcontroller is an important often forgot about distinction when selecting a heater controller. Look for the agency marking and inquire with the manufacturer if in doubt. Runaway thermal systems create risk of both fire and electrical shock.

Some systems involve a chemical reaction. Even after the heater is turned off, the chemical reaction may continue. If it becomes exothermic and continues to produce heat, shutting down the heaters will not stop the temperature from continuing to rise. In this example, the safety sensor could activate a fire suppression system.

A less accurate, lower cost method to provide safety could utilise a resettable thermostat or thermal fuse instead of a high-limit safety sensor. These devices are wired in series with the heater and create an open circuit when a manufacturer pre-defined temperature is exceeded. These alternatives can be good solutions in some applications, but nearly always have lower performance and are driven by cost.

Watlow integrates all types of thermal safety sensors into our heaters: TCs, RTDs, thermistors, thermostats, and thermal fuses.

High-limit safety sensors are a critical part of safe heating systems. By using the most suitable safety sensor and following best practices, your system will have the best opportunity to prevent unforeseen accidents and damages.

Watlow provides a range of industrial thermal sensors. Discover them at: www.watlow.com

“Biogas… It’s Happening” will be the overarching theme of this year’s World Biogas Expo and Summit taking place in Birmingham, UK, on 10-11 July 2024.

Organised by the Anaerobic Digestion and Bioresources Association (ADBA) and the World Biogas Association (WBA), the event is the only trade show solely dedicated to the anaerobic digestion (AD) and biogas sector. This year, it will bear testimony to the rapid growth of the industry as forecast by the International Energy Agency (IEA) in its World Energy Outlook 2023 report*.

Human activity generates 105bn tonnes of organic waste annually, which could provide homegrown biogas, biofertilisers and other bioproducts to secure energy and food self-sufficiency around the world and deliver 50% of the Global Methane Pledge now

signed by over 150 countries.

Currently, only 2% of those wastes are treated through AD. Fully deployed, the global AD and biogas could grow into a $34trn industry and create 10-15 million new green jobs.

Key industry players will gather at the NEC Birmingham to hear about market trends and policy in the conference areas and explore the busy exhibition where over 150 AD and biogas companies will showcase their products, services and innovations. Debates will focus on how decarbonisation through AD can be rolled out through finance, transport, agriculture and other key sectors of the economy.

“The World Biogas Expo and Summit represents a fabulous opportunity for people to come together and collectively identify the opportunities and challenges that we’ve got in delivering for the industry and the world,” explains Charlotte Morton OBE, WBA Chief Executive.

Registration to the World Biogas Expo and Summit is free and can be completed at: www.biogastradeshow.com www.world-biogas-summit.com

*Between 8% and 22% per year by 2030.

Source: IEA, World Energy Outlook 2023

Unlock the full potential of your organic by-products with Mavitec Green Energy! We specialise in food waste recycling and depackaging solutions, offering exceptional separation efficiency.

Our machines ensure that organic material is meticulously separated from its packaging, delivering a remarkably clean (>99.7%) organic output ideal for biogas & compost installations and compliant with the latest European legislation. The Paddle Depacker processes up to 30m³ of material per hour per machine and

also produces a clean plastic fraction.

Curious to see how it works with your own material? Our Paddle Depacker Roadshow is available for rental. Installed on a trailer, this mobile unit can be set up at your site for a convenient and thorough demonstration.

If you are visiting The World Biogas Expo in Birmingham, come visit us at Stand E41 to see the new Paddle Depacker live. Contact us at: info@ mavitec.com or +31 (0)72 574 59 88 to learn more.

We are delighted to launch Toucan Eco Auto, the latest innovation in our groundbreaking Toucan Eco range. The revolutionary bio-cleaning system marks a significant leap forward in sustainable commercial cleaning, offering a robust solution for operators of medium to large facilities aiming to reduce their chemical use and environmental footprint.

Toucan Eco Auto is an automated disinfectant generator, capable of producing 20 litres of multipurpose disinfectant cleaner in just 30 minutes using just salt and water.

Designed for direct dispensing into containers for comprehensive surface cleaning, the fully automatic system simplifies operations by requiring only the periodic refilling of salt as indicated by its LED display.

This innovation not only enhances the efficiency of cleaning regimes while saving money, but also helps companies to reduce their carbon footprint by eliminating the need for up to 80% of conventional cleaning chemicals, as well as their associated singleuse plastic bottles, packaging, and manufacturing and transportation emissions.

An independent carbon footprint audit has indicated that producing one litre of ready-to-use solution with

Toucan Eco Auto generates the equivalent of just 3.07g CO2. To put this into context, this means that five litres of activated solution can be created with the system for the same carbon emissions as one boiled kettle.

Steve Courtney, product lead for Toucan Eco at Robert Scott, states, “The Toucan Eco range is at the forefront of sustainable commercial cleaning innovation. With the introduction of Toucan Eco Auto, we’re catering to the demands of busier environments where quick, effective, and environmentally conscious cleaning solutions are paramount. This addition to the range

highlights our commitment to providing versatile and sustainable cleaning solutions across various sectors.”

The British-made system uses a specialised electrolysis cell to activate a mixture of salt and water with a small electrical current, producing a powerful combination of hypochlorous acid (an effective disinfectant) and sodium hypochlorite (a cleaning agent). The result is a potent yet naturally occurring disinfectant cleaner that is non-toxic, hypoallergenic, environmentally friendly, and effective against a broad spectrum of germs with an efficacy rate of up to 99.999%.

Certified to EN 14476, EN 16777, EN 1276, and EN 13697 standards, and registered as a UK biocide, the cleaning solution boasts a pH level of approximately 7.8 to 8.5, making it gentle yet effective without the need for protective clothing or PPE.

Despite its substantial output capacity, the Toucan Eco Auto boasts a compact design, making it an ideal addition to various commercial settings. Measuring 48x25x65 cm and weighing 25kg, it offers an unobtrusive, powerful, and sustainable cleaning solution.

For more information or to arrange a demo, please call 01457 819400, email: info@robert-scott.co.uk or visit: www.robert-scott.co.uk

Vision Engineering, the world-leading provider of innovative inspection, metrology, and digital 3D visualisation solutions, is celebrating the 30th anniversary of its best-selling and awardwinning Mantis range of ergonomic optical stereo microscopes.

In 1994, Vision Engineering revolutionised the field of microscopy by introducing the first-ever 'eyepieceless' stereo microscope, Mantis. This innovative instrument was meticulously crafted to bridge the gap between a bench magnifier and a traditional microscope, offering users an unparalleled ergonomic experience.

Its pioneering design not only earned Mantis widespread acclaim but also secured numerous industry-recognised design and innovation awards. As a result, Mantis quickly established itself as the industry standard for highperformance ergonomic stereo magnification, redefining precision and user comfort in industrial microscopy applications within the electronics, medical device, aerospace & automotive industries.

In 2005, Vision Engineering unveiled the second generation of Mantis. Soon after its introduction, Mantis manufacturing moved from Woking to a new manufacturing facility in Connecticut, USA. This iteration featured notable enhancements, such as a sleek and modern design, improved LED lighting, an expanded field of view, increased magnification capabilities of up to 20x, and stand and accessory options. In 2009, Vision Engineering expanded the Mantis range by introducing the Mantis Elite HD Cam with a built-in camera for image capture.

The third generation Mantis was

introduced in June 2023. The newest edition includes improved optics for both hand-to-eye coordination and excellent depth perception, a 3-position turret to house up to 3 objectives ranging from 3x to 15x, an 8x super long working distance lens, and five different illumination options providing flexibility to optimise the lighting to view the perfect image. The Mantis PIXO offers an improved, higher-resolution image and ‘designed-in’ integrated video camera. The system also features an option to switch between white and UV light.

Mantis is designed for precision engineering, electronic engineering, medical device manufacture, and a wide range of other applications that require high-quality images and superior ergonomics and is used in tens of thousands of R&D, manufacturing, and analytical sites worldwide.

Contact