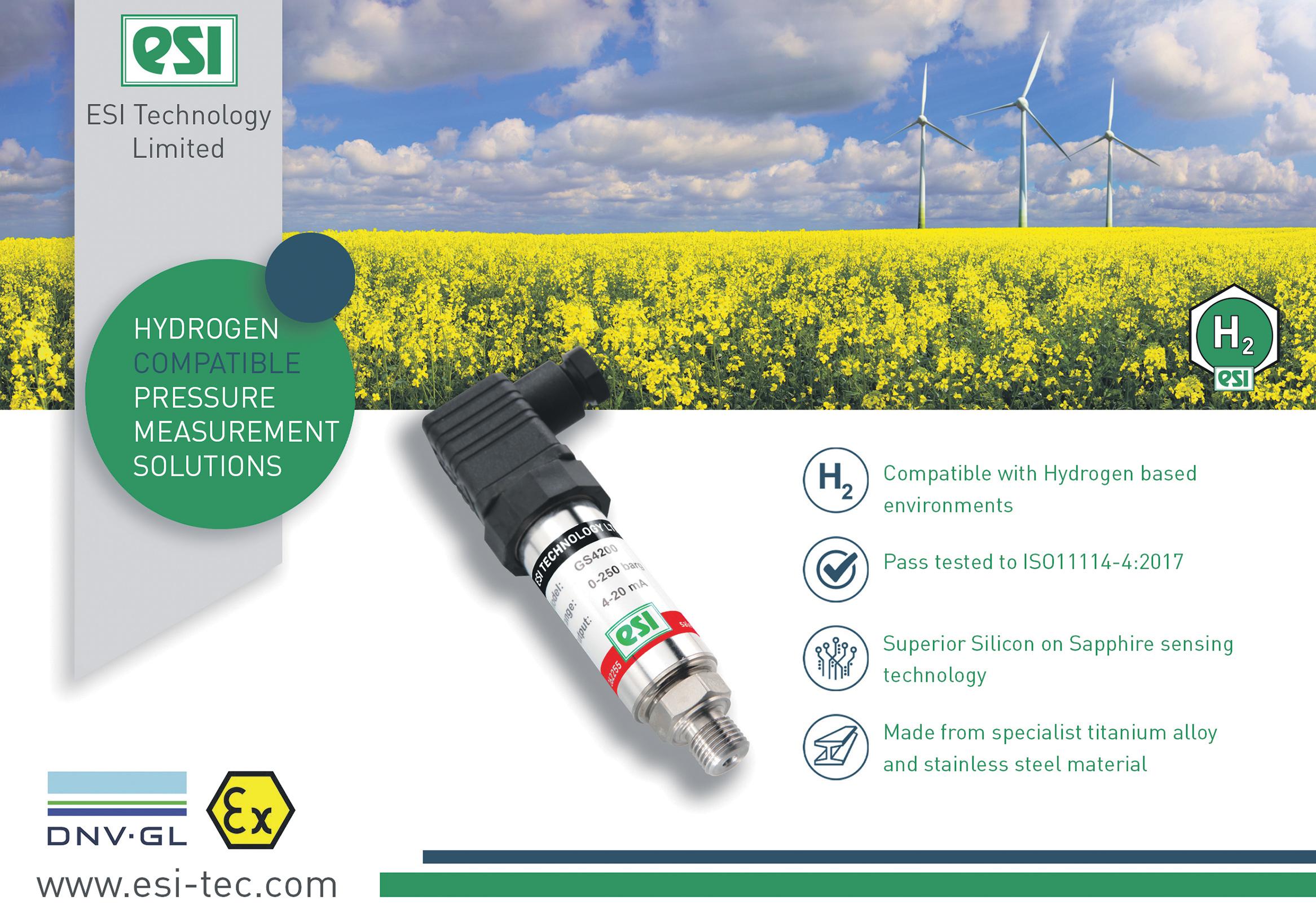

Hydrogen offers a cleaner, secure and more affordable source of energy with the potential to drastically reduce and tackle CO2 emission levels.

With that in mind ESI are committed to offering a product range that is not only versatile and environmentally friendly, but also offers the same outstanding performance and stability that they are known for.

What is Hydrogen Compatibility?

Samples of the materials used in the manufacture of the range were tested based on ISO 11114-2:2017 in accordance to the European Regulations EC 79/2009 and EU 406/2010 to determine an ‘embrittlement index’ of the material when placed in a saturated environment over extended periods of time. Results have provided a pass rating to the compatibility of the material against Hydrogen.

Vision Engineering, a 64 year old British leading designer and manufacturer of high-quality visual instrumentation and a significant supplier of machined components/sub assembly services to other industrial sectors, has today announced the acquisition of Milturn Precision Engineering, of Hinckley, Leicestershire, a precision engineering specialist.

The acquisition of Milturn fulfils a strategic objective to significantly improve Vision Engineering’s position global position as a leading designer and manufacturer, by adding scale and capability to the company’s existing UK and USA manufacturing base.

Established in 2001 and one of the first UK firms to achieve ISO 9001 2015, Milturn Precision Engineering has 21 highly skilled machinists and anodisers specialising in high quality components, including high performance lens cases for the optical /movie/ camera industries, marine and automotive engineering and high end shop/hotel fitting, Milturn also has an anodising facility to improve the quality and durability of finished components.

Mark Curtis, Vision Engineering CEO said “The strategic acquisition of Milturn Precision Engineering strengthens Vision Engineering’s global manufacturing capability, and improves our ability to deliver high quality precision manufactured parts, assemblies and finished products to our combined existing and new customers. It also consolidates our Manufacturing Services division with substantial high end milling, turning and anodising skills and experience.”

Ian Mustard, Milturn Owner and Director said “Milturn has worked with Vision Engineering for years and I know their commitment to highly skilled operators, whether machinists or anodisers, producing quality components. We have built up a demanding, high end customer base in specialised sectors. I am confident that Vision Engineering will implement strategy and investment to take Milturn Engineering and Bowfran, our anodising division, forward and continue the success built on the capabilities of our staff”

For more information: www.visioneng.com

The Material

The pressure diaphragm and threaded pressure port are machined from a specialist Titanium alloy specifically designed to withstand harsh and demanding environments.

This, along with the non-oil-filled sensor and high integrity stainless steel housing results in a robust and versatile unit that offers excellent media compatibility across a range of environments.

The Hydrogen range also benefits from the same Silicon on Sapphire (SOS) sensor technology used throughout the ESI brand, providing outstanding performance, stability and highly accurate pressure measurement.

Applications

Hydrogen is already used in a growing variety of industries, and

although the Oil & Gas sector still remains the predominant source of energy supply and usage, there are significant efforts being made to find an alternative.

Applications for ESI’s newest range include:

t Hydrogen storage

t Hydrogen production

t Hydrogen re-fuelling

t Hydrogen engines

t Marine propulsion

t Hydrogen fuel cells

t Laboratory environments

t Industrial applications

For more information on Hydrogen, contact ESI on 01978 262255 or email: sales@esi-tec.com

Interface Force Measurement Solutions (Interface) is a UK company specialising in the supply and distribution of high-quality sensors and associated electronics and displays for a wide variety of

industries. Working previously with clients such as Airbus, BAE Systems, and Formula One Teams, we spoke with Tony Rokins, Business Development & Pressure Mapping Specialist, who explained some

of the companies well known products.

“Our product portfolio is applicable to many industries. For instance, we are well known for our high-quality pressure mapping systems that are used by many of our automotive and motorsport customers. Our sensors deliver highly accurate, repeatable measurements and many of our load cells are used by calibration houses as calibration reference devices. Our high-quality, yet competitively priced 3 and 6 axis load

cells are used for many R&D, renewable energy and robotic applications.”

Reflecting on last year, Interface has faced much adversity from COVID-19. Fortunately, its sturdy business model and reliable service has enabled the company to pick up the pace and continue projects that were left postponed. “Trading conditions have been tough, but business levels picked up strongly towards the end of the year. I think we came out of it stronger than we could have reasonably expected.”

In terms of recent developments, Tony continued, “we’ve taken some time to review our business model, how we operate on a day-to-day basis. Being responsive to our customer’s needs and being able to offer a high-quality product with strong product knowledge at a competitive price with the best possible lead times is our number one priority.”

2021 also welcomed the launch of the G-Series Load Cells. The range comprises of miniature and small sensors for industrial applications, with capacities starting from just 4.5N Newton up to 200kN with metric threads. “These are high-performance devices but aimed at more cost-conscious applications. This is a new market for us, but we are seeing increasing interest. We are launching an e-commerce website for the G-Series in the next couple of weeks. Competitive pricing and availability from stock will be key to this new venture’s success,” stated Tony.

In the future, Interface is keen to continue its growth trajectory for 2022. We asked Tony how he felt receiving the award and what their plans are going forward, he answered, “we work hard for our customers to offer the best measurement solutions. The recognition is greatly appreciated. Long term, we are strengthening our position with our customers in our more traditional markets of aerospace, automotive, motorsport, Universities and alternative energy research.

We are also working on new, wireless force and vibration sensors for remote monitoring in systems such as luggage carousels. One more area we are pushing for growth is with XSensor’s pressure mapping systems, particularly in the Hi-speed systems designed for high-speed impact or crash testing and tire foot-print research. These systems are capable of capturing data up to 2,500 frames per second. The tire sensor can be driven over at speeds of up to 140kph. I believe this is a unique capability we can bring to the industry.”

For more information, see below.

T 01344 776666 info@interface.uk.com

www.interfaceforce.com

NEW StopTite Industrial range has been launched to provide high-quality premium solutions for thousands of applications across industry. Products are available in colour-coded categories, and include threadlockers, retainers, pipe sealants, gasketing and adhesives for mechanical assemblies.

StopTite products offer outstanding mechanical properties with a temperature range of -50 to 200°C+. The threadlocker product helps to prevent the loosening of bolts, studs and screws, due to vibration and shock loads. It can also be used to permanently lock threaded components. The Retainer products offer excellent resistance to shear and compression and can be used for

Aico have expanded their educational offering with the launch of their City & Guilds Assured qualification on Domestic Fire & Carbon Monoxide (CO) Alarm Systems.

As the European Market Leader in home life safety, Aico place education at the forefront, promoting best practice and delivering a range of free training for their supply chain across the UK. To further support their customers, Aico are proud to introduce their City & Guilds Assured qualification – a global quality benchmark that recognises excellence in training and learning.

The qualification is a continuation of Aico’s FIA CPDaccredited Expert Installer training, which provides Installers with the essential knowledge to correctly install Aico Fire and Carbon Monoxide Alarm Systems and Environmental Sensors.

To provide participants with a detailed understanding, this one-day course, AA2426-01, focuses on the design, installation, maintenance, interconnection, siting, and electrical connection of Aico domestic alarm systems.

The qualification has a mixture of theory-based and practical sessions and concludes with a multiple-choice assessment, that must be successfully completed to earn the City & Guilds qualification.

Duncan Orr, Regional Specification Manager for NI & IOM and Supply Chain Education Lead comments “At Aico we are passionate about education. It is a cornerstone of our business, with tens of thousands of participants having received our award-winning, FIA accredited, Expert Installer training. In an ever changing and fast-moving landscape, the City & Guilds assured AA2426-01 course builds on this foundation and takes our educational offering to the next level. It is our privilege to bring this City and Guilds Assured qualification to the market and continue to promote the raising of standards, knowledge, and competence in the life safety industry.”

AA2426-01 will officially launch on Friday 6th May, with the first session taking place at Aico’s Centre of Excellence in Oswestry and delivered by a member of their expert Technical Team.

For more information please contact Alex Garmston – Marketing Manager on alex.garmston@aico.co.uk or 01691 664100. For all the latest news please visit our website www.aico.co.uk

To be eligible for the City & Guilds Assured qualification, participants must have completed Aico’s Expert Installer training and be a member of the Aico Installer Community – a connected online platform built to support Expert Installers.

To find out more and to sign-up, please visit: https://www.aico.co.uk/our-services/ domestic-fire-co-alarm-systems/

To find out more about Aico Expert Installer, please visit: www.aico.co.uk/our-services/ expert-installer-training/

the permanent fixture of bearings, shafts, splines and keys.

The ST27 Pipe Sealant product offers an instant lowpressure seal on tightened fittings up to 150psi.

The ST31 Muilty Gasket offers resistance to low pressures after the assembly of mating flange faces. Seal joints between metal faces and flanges. Ideal for motoring and industrial applications.

The 007 and 006 high-strength adhesives have been designed to bond metal and composite applications, offering high-impact resistance while remaining quick and easy to use.

Made in Britain, the StopTite range has been developed by S2-lube, which has been formulating a wide range of industrial products with partner companies for over 40 years. The company’s products are popular with various industries, including renewables, water, electronics, construction, military, aircraft, farming, leisure, automotive and all types of production lines.

Product is supplied to stockists as retail display boxes of 6 to 20 items. Free samples are available and can be requested by emailing sales@stoptite.co.uk or calling 01584 874220.

www.stoptite.co.uk

In this issue of Industry Update, we are pleased to announce OnRobot as our Automation Machinery Manufacturing Company of the Month.

OnRobot is a One Stop Shop for Collaborative Applications where its main role as a company is to help small and mid-sized manufacturers through its solutions to optimise their processes and to ultimately, grow their businesses with greater flexibility, higher output and improved quality.

“Collaborative Automation has levelled the playing field for small and mid-sized manufacturers, and as robots become easier to buy and implement, the tooling has become the vital element in adapting for a wide range of applications,” stated Vikram Kumar, General Manager.

Since its establishment in June 2018 by Enrico Krog Iversen, the need for Collaborative Automation within businesses has increased. Collaborative Automation is

facilities networks located in Odense, Denmark, Dallas, Los Angeles, Soest (Germany), Aalborg (Denmark), Barcelona, Warsaw, Shanghai, Tokyo, Seoul, Singapore and Budapest. “We offer everything manufacturers need from one supplier, providing even more value from the automation investment. The OnRobot solutions are compatible with a wide range of major robot brands. We have made it simpler than ever to deploy collaborative applications by providing out-of-the-box solutions that are easy to customise and can be seamlessly integrated,” said Vikram Kumar.

2022 has been a year of innovation for OnRobot with the welcome of two new products to its already extensive range of solutions. It makes great sense to automate material handling processes, and if you want to reduce physically straining work or increase productivity without having to worry about recurring labour shortages then OnRobot has the solutions for you. In January 2022, OnRobot released the 2FGP20, an electric gripper used for palletising and slip sheet handling that is highly versatile with wide stroke and customisable arms for handling heavy or open boxes and even shelf-ready products such as Euro containers that usually cannot be handled with traditional vacuum grippers.

important as it equips organisations and businesses to easily scale up or down, switch SKUs, and expand into new markets more quickly. OnRobot has a full line of innovative Plug & Produce solutions for all collaborative robot applications, alongside its award-winning Gecko technology that is used to help manufacturers gain the full advantages of automation, including ease of use, cost-effectiveness and safety alongside human workers.

To support this service its full product range includes “a wide assortment of tools and software for collaborative applications, including electric, vacuum and magnetic grippers, the award-winning Gecko gripping technology, force/torque sensors, a 2.5D vision system, screwdriver, sander kits and tool changers. Supported by the free, Learn OnRobot e-learning platform, OnRobot makes it easy to deploy collaborative automation on tasks such as packaging, quality control, materials handling, machine tending, assembly, and surface finishing regardless of skill level or previous robotics experience,” said Vikram Kumar.

OnRobot’s services provide compatibility and versatility beyond compare that are supported by its global

Following suit to the OnRobot electric gripper range, the 2FGP20 provides out-of-thebox deployment with intuitive programming and an integrated vacuum gripper that places slip sheets negating the need to change the gripper or the

Not long after, in March 2022, OnRobot then released the new 7th axis robot elevator named the Lift100, which gives additional reach for your robot and enables you to handle more types of pallet sizes, box sizes, and palletising patterns. Other features include a long-stroke, high-payload robot elevator that adds a versatile seventh axis to light-industrial and collaborative robot arms, a durable design that has been tested and certified to work reliably under all typical

use of another handling method. The flexible solution is cost-effective as it provides fast deployment with the complexity and cost of external air supply, and costsaving solutions as it saves significant engineering effort whilst shortening deployment time.

manufacturing conditions, a robust design that ensures precise positioning of boxes, even at high speeds, and a versatility that means it can be used for any application where additional vertical reach is needed for the robot. Essentially, the Lift100 provides out-of-the-box integration with the Pallet Station and can be deployed with any leading robot brand.

A notable new release, OnRobot has developed software for the palletizer. Offering a complete, configurable, and modular palletizing solution, supports leading robot brands and is able to fit in existing floorplan. The software is intuitive and requires no process or robot knowledge to quickly configure new palletizing tasks.

OnRobot is an ambitious company that is always looking for its next innovation. “In November 2021, we launched our first remote monitoring and diagnostics software for collaborative applications. By implementing this new software we can now focus on both hardware and software,” said Vikram Kumar. WebLytics is the first remote monitoring and diagnostics software to optimise production and minimise downtime for collaborate applications.

Its intuitive, customisable dashboards transform raw data into actionable application and deliver device-level insights using industry standard KPIs. Furthermore,

WebLytics also automatically collects, analyses, and reports on collaborative applications, including data from any OnRobot tool and any leading cobot or light industrial robot.

It remains evidentially obvious that OnRobot is leaps ahead of any competition in delivering the most innovative and ground-breaking solutions to the industry of automation. Harked as just the beginning for the company, Vikram Kumar ended by telling us what the company plans for the future. “OnRobot is an ambitious company and strives to expand our global presence gradually. We will achieve this by remaining the top solution provider enabling our customers to increase their revenue. If they strive, we strive.”

With the dawn of smarter, more adaptive tooling, robots can now function with greater speed, strength, safety and precision, accomplishing a wide range of tasks, while maximising ROI. If you’re interested in how to grow your business with Collaborative Applications, OnRobot has devised a FREE EBOOK that is accessible to download via the website.

For more information and access to the FREE EBOOK, see below.

T +45 53 53 57 37

North-europe@onrobot.com www.onrobot.com

Swiss-based UPS manufacturer, CENTIEL SA, has announced its plans to expand its manufacturing facility further, to support continued growth in demand for Centiel’s existing product family and to accommodate a new production line.

CENTIEL is a Swiss-based technology company designing, manufacturing and delivering industry-leading power protection products for critical facilities worldwide. The Company’s range of class leading, energy efficient, UPS systems offers the highest availability and reliability developed by the innovators of the industry’s first transformerless UPS and the world’s first three-phase modular UPS. CENTIEL’s network of channel partners and subsidiaries is also growing, providing class leading power protection products worldwide.

Filippo Marbach, founder of CENTIEL SA confirms: “The continued and rapid rise in data use has meant more datacentres are being developed and they all need quality, critical power protection provision. We originally took over our current factory based

should ensure the corresponding metal part for the heater is clean and smooth – metallic ‘burrs’ could penetrate the heater surface and cause a malfunction.

A critical step before heater placement is to remove any labels from the part. Failure to remove labels can create heat-related problems that impair heater function and even cause a fire hazard.

If a label is not rated for a heater’s operating temperature, the label becomes a fuel source. Certain types of labels can cause a chemical reaction that releases chlorides and breaks down the silicone rubber. Over time, this can lead to arcing or combustion.

Prior to installation,

To

in Lugano, Switzerland in 2018, as we expanded and have now extended its capacity to meet the increased global demand for our leading UPS products.

“We have also increased our sales, technical support and operational teams over the past few years and therefore added to the office space to accommodate our larger team. The factory which also incorporates CENTIEL SA’s global headquarters, houses our R&D, production, final test, sales and marketing, logistics and finance departments, in addition to quality control of all CENTIEL’s UPS products.

“It is an exciting time in the development of the Centiel brand across the globe and we look forward to continuing to lead the world in the development of critical power protection equipment for the datacentre industry and beyond.”

For further information please see: www.centiel.com

One of the common requirements for fans is low noise, selecting the correct bearing in the fan is key to minimising noise levels.The low cost choice is usually Sleeve bearing, which initially should offer low noise levels. However after some time of operation, due to the nature of the bearing, the fan will become gradually noisier.

At a higher price is Ball bearing, this bearing is preferred for high end applications requiring faster speeds (higher airflow), longer life expectancy and the freedom to mount in all orientations without the risk of premature failure. Ball bearing is however not renowned as the lowest noise option. If low noise is the target there are alternate bearings available.

One example is Sunon patented MagLev bearing, a near frictionless bearing system. One of the key features of this is the use of a magnetic plate to remove the contact between the impeller and the bearing wall. This versatile bearing offers life expectancy closer to a Ball bearing at

a cost closer to Sleeve. If located in a harsh environment, then added levels of protection should be considered for the fans. These can start from simple IP21 to fully enclosed IP68 rated fans. Sunon can also offer environment specific protection, such as GR47 Salt Fog for marine applications. If the correct level of protection is not considered, then the life expectancy of the fan will be compromised. If there is concern regarding fan failure, most are now available with additional wires for Tacho Feedback or Locked Rotor Detection which can alert to any issues.

www.gelec.co.uk

In this issue of Industry Update, we are proud to announce that we have selected Constant Power Services Ltd as the recipient of our Commitment to Excellence Award.

For over 30 years, Constant Power Services Ltd has been a solutions provider supporting businesses seeking quality, uninterruptible power supplies, installation and aftercare.

“We appreciate the complexities of a specification, the time constraints on finalising a project and understand that it can all change in a second, which is why we are the best support for progressive businesses looking to manage, maintain and protect their business from power failure,” stated Chris Cowley, Commercial Manager.

Finding smart ways to help customers to manage their operations is always at the forefront of the company’s mind which is why some of its clients have stayed with them for over 20 years. Its portfolio consists of a range of products from smaller 700va uninterruptible power supplies to 6.4mva systems, containerised units for hire or purchase, generators, switchgear, and maintenance contracts. Chris added, “if you are looking for an uninterruptable power supply for a new building, inherited a UPS from a recent acquisition or simply want to upgrade to a new system so that you can get the service and support you require, we can help.”

Establishing strong relationships with a mutual respect, Constant Power Services Ltd.’s years of expertise in taking full ownership of the task at hand has meant it has been maintaining business continuity since the late 80’s.

“Our turnkey solutions are tailored to our customers’ requirements, and we provide a vital link to business continuity. Working with our customers requires great communication and this is something we pride ourselves on. Support is integral to our business which is why communication, respect and ownership form our internal values, as they come so naturally to us,” said Chris.

In recent developments, Constant Power Services Ltd has opened a new office near Glasgow, Scotland which boasts 4000sqm of warehouse space to which the company is able to hold products and spares inside delivering a swifter response to customers’ requirements. Chris stated, “we have also expanded our Multibox product range by introducing the Multibox 800, a 20ft containerised solution. This enhancement to our fleet means we can provide temporary rental solutions for larger projects that require a UPS while building works are being carried out. Additionally, we have launched a new service to complement our existing service packages, offering customers four- and seven-year remedial packages. Our new service offers maintenance works alongside customers’ existing service contracts and should be seen as an enhancement and extra security, prolonging the life span of customers’ equipment and ensuring that it is working to its optimum.”

Power is critical for businesses, and it is of the upmost important to Constant Power Services Ltd to provide a quick, reliable and proven service that its customers feel supported by. Boasting years of expertise and experience in the industry, the knowledge of its staff is of the highest quality. Add to that the support of its parent company, Riello Electronnica, which adds another string to its bow having the full support and expertise of the manufacturer at its disposal.

In closing, we asked Chris what commitment to excellence means to the company, he replied. “We are constantly appraising and reviewing our performance with customer input. We ensure that our ISO9001, 14001 and 18001 accreditation is on point giving us the added commitment to upholding the standards across the business. We are also committed to ensuring our environmental positivity is clear by not only reducing the business’s carbon footprint, but by giving energy through our solar panels on the building back to the grid.”

T 0330 1230125

sales@constantpowerservices.com

www.constantpowerservices.co.uk

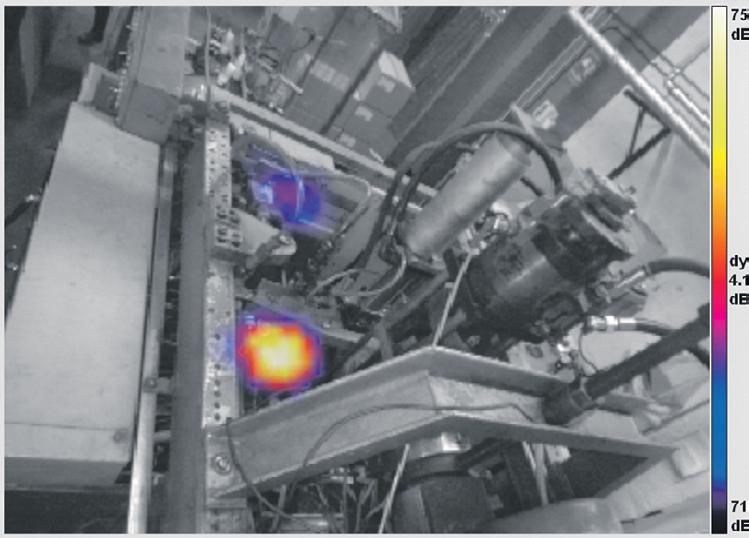

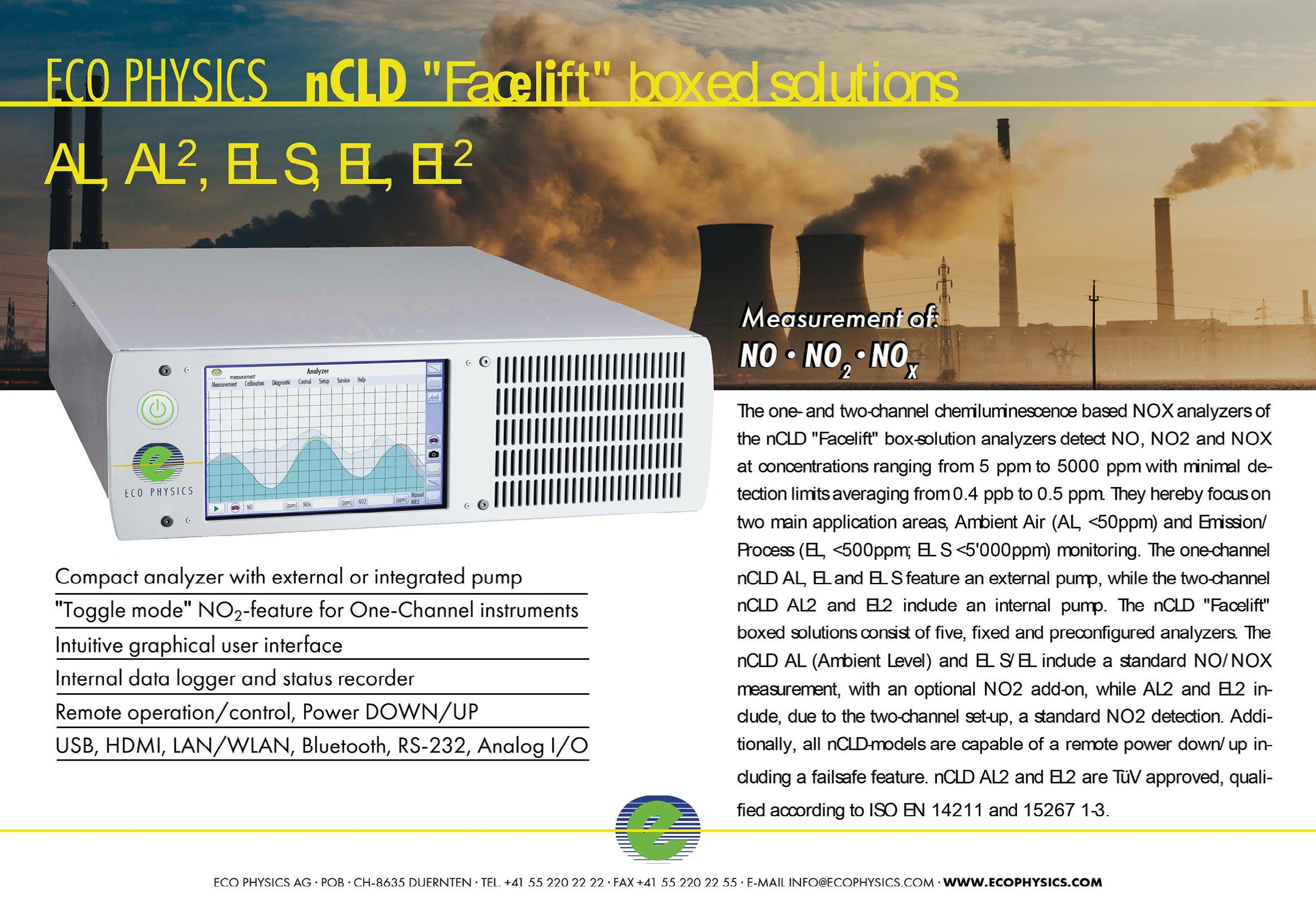

In this issue of Industry Update, we are proud to announce that we have selected SoundCam UK as the recipient of our Outstanding Achievement Award.

SoundCam UK is a trading name of Acoustic Camera UK Ltd. and is the UK distributor for the world market leading manufacturer CAE Systems GmbH who are based in Germany. CAE Systems GmbH specialises in developing acoustic and vibration measuring systems, new measurement methods and special tests with a particular focus on the Acoustic Camera. SoundCam UK is proud to distribute such products from a company who have been making these SoundCams for over 15 years.

Based in Coventry, SoundCam UK was established in 2019 by Richard O’Sullivan, where it has remained market leaders for innovative acoustic cameras as well as offering rental, acoustic consulting services and CPD approved training.

“The technology we provide has uses in virtually every industry. If we were to mention product development for example, our technology can be used to make your product quiet. We have seen our tech used extensively in the aerospace and automotive sectors by global brands such as Bentley and Rolls Royce. Other sectors and uses include manufacturing for customers who want to monitor wear on critical plant, or for energy and C02 savings by finding air, gas and vacuum leaks, used by Red Bull and

Mercedes F1 teams. Our tech is also used in construction to improve soundproofing and eliminate acoustic leaks, as well as by councils for environmental noise control. The possibilities are endless,” stated Richard, “in fact I’m off to Nairobi in a couple of weeks to study how baby elephants learn to communicate!”

Anyone wanting to make something quiet will benefit from these products. One example of a previous usage was when a London housewife hired a SoundCam to find the noise paths from her noisy neighbours into her flat. This example clearly shows how easy the SoundCam is to use and how multifaceted its uses are. “Even nontech people can soon master it!” said Richard.

SoundCam UK distributes three SoundCams; SoundCam Ultra, SoundCam 2.0, and Bionic Modular. The SoundCam Ultra is currently being upgraded and from July 2022, it will also be available with optional integrated thermal imaging. The SoundCam Ultra is the brand-new high frequency specialist under the SoundCam family and is the smallest handheld camera that creates acoustic images from audible and ultrasound. The SoundCam Ultra consists of 72 microphones with a sampling rate of 200 kHz, an optical camera, an integrated data acquisition and analysis system, and a display and control unit with touch screen and hardware buttons. Boasting an intuitive and easy to use system, the device can locate sound sources in

real time and display the results instantly on the screen.

“The upgraded model will have thermal imaging capacity making it a sound and heat camera for the same price as the original and still under £10,000. The new SoundCam Ultra will be revolutionary in so many ways, for example it can even be used to rescue victims trapped under

rubble as the super sensitive camera will locate them by sound and by thermal imaging. If you’re involved in this line of work, please get in touch as we’d love to help you,” added Richard.

For more information, see below.

T 02476 98 2424 office@soundcam.uk www.soundcam.uk

Interface Force Measurements has been supporting UK industry with the highest quality force, torque and pressure sensors for more than 25 years.

You can benefit from our experience whenever you contact us about your next measurement application, experience gained helping designers and engineers across multiple industrial sectors.

We’ll use our experience and product knowledge to help you select the best sensors for your application from our wide range of sensors from some of the world’s best sensor manufactures, including:

t Interface Inc – single, dual, 3 and 6 axis load cells and torque transducers

t AMTI – six-axis load cells and force plates

t GP50 – pressure and temperature sensors for oil/gas, aerospace, automotive food/ beverage and general industry

t DDM – miniature pressure sensors for automotive R&D

t XSensor – pressure mapping systems for bed/ mattress, seating, automotive R&D, tire testing applications and impact testing for seats, airbags, helmet and protective equipment

We can also help with your data collection needs with our range of amplifiers, displays and software what will work with our and other manufacturers’ sensors. So, if you have a force, torque or pressure measurement challenge that you’d like our help with, please contact us:

T 01344 776666 info@interface.uk.com www.interfaceforce.co.uk

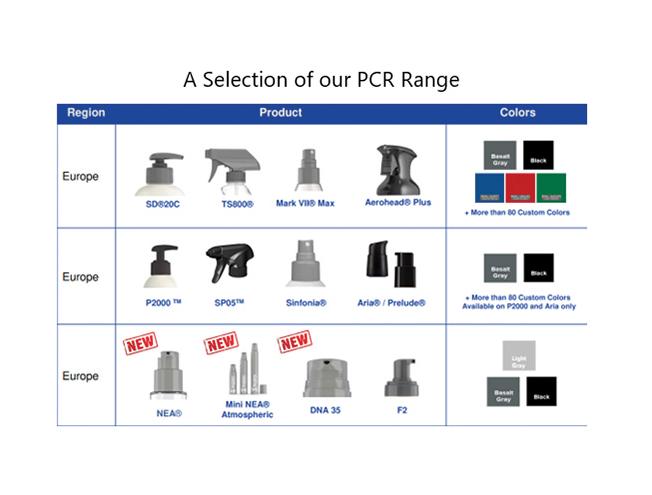

In this issue of Industry Update, we are proud to announce Micro Delta Packaging Ltd as our Packaging Specialist Company of the Month.

Since its establishment in 2019, the company has quickly expanded its market presence and brand awareness through attending well-known industry events such as Packaging Innovations at the Olympia London in December

2021. Micro Delta Packaging is the brain child of Julie Gromoff, Managing Director, who has over 20 years’ experience and knowledge that she has gained from working in the beauty and personal care industry.

Julie’s exceptional skillset and level of knowledge is backed by a small team of four other employees: Andrew Gromoff, Technical Director, Emma Greeno Office Administrator, Kayleigh Russell, Sales Manager, and Vikki Garner, Assistant, who all contribute greatly towards the high level of customer service and the growing success of the company.

“We are a small business but what we can offer is a personal one-to-one service where each client has one dedicated sales person who they work with from

the beginning to the end. This gives our customers a recognisable contact who they can build a rapport with and see the whole project through. We work closely with our customers to ensure at all points their business will grow,” stated Julie.

Micro Delta Packaging Ltd has a large range of products available including airless dispensing systems, pearl airless, bottle tops, garden spray bottles, jars, lotions, PCR solutions, sprays, serums, triggers, tubes, and more. Further in its range of products, the company also offers a printing service on containers and closures which are ideal for creating unique branding. Some examples include round containers printed by silk screen, colour printing, or pad printing for bottles of unusual shapes.

In this issue of Industry Update, we are pleased to announce Worldwide Logistics Group as our Logistics Service Provider Company of the Month.

Established in 1998, Worldwide Logistics Group (WWL) was founded in New York as a joint venture between a freight forwarding veteran and a local trucking company. Over the years the company has expanded exponentially and today provides sophisticated integrated logistics solutions for more than 7,000 companies in more than 100 countries and is wellrespected as a global leader in transport and logistics.

Providing end-to-end logistics, WWL Group offers a complete range of services to support its customers’ needs using its vast network of global offices and trusted partners. Its comprehensive list of solutions includes Air Freight Logistics, Sea Freight Logistics, Land and Road Services, Customs House Brokerage, E-Commerce Logistics, and Warehousing and Fulfilment.

In 2018, Glenn Hayes joined together with WWL Group to head up its UK offices as the Managing Director. Headquartered in Dagenham, its other UK offices are based in Birmingham, Billingborough, London/ Heathrow, and Scunthorpe. WWL Group UK started off with a bigger mission in mind which was to service customers who were active in doing reworks and remedial. “It was about adding value to the supply

chain, and making sure waste wasn’t ending up in landfill. There is a huge amount of waste in the logistics industry, and intrinsically because of the growth of ecommerce, its only getting worse. So effectively, we set up WWL Group UK in 2018 to service this need and since then we have grown dramatically. We now do huge amounts of 3PL and freight forwarding, so our mission statement has slightly changed from where we started to where we are now, but it still formulates a large part of what we do,” said Glenn.

As specialists in logistics and 3PL, the biggest competitive advantage WWL Group UK offer is its ability to be able to integrate with many different sales platforms. “We can seamlessly integrate various services and features into our customers websites and still be big enough to be able to scale their business. We have found ourselves in a small niche where we can help many clients on the fact that we buffer a return to remedial service and offer a full scope of services across UK and Europe,” explained Glenn.

“We also hold stock for customers in our warehouse, where we also have a rework room, here we can rework diptubes to suit our customers bottles. The company we represent have factories in China, Milan, Barcelona, France and Germany,” said Julie.

Acting as the go-to agent and distributor for the cosmetic market, Micro Delta Packaging Ltd has just added two new products to its portfolio, one of which is spout pouches.

As the company continues to expand, it is looking for customers from both small start-ups as well as large brands. “Any customer who is looking to repackage or redesign their products, or even boost their marketing, we can help,” stated Julie.

Moving forward, the company is in the process of applying for Sedex approval for trade ordering in the UK. This will be a step closer to becoming carbon neutral as it gives them accreditation and customers the reliability that their products are from sustainable factories and sustainable brands. This accreditation will offer a full transparency for their claim to ethical sourcing.

For more information, see below.

T 01553 310020 sales@microdeltapackaging.co.uk www.microdeltapackaging.co.uk

warehousing activities include Amazon fulfilment and drip feeding, and its pick pack and dispatch services include seller fulfilled prime, fulfilment by merchant, double scan verification on every order, and integration with eCommerce platform.

Serving a range of vertical markets that include fashion, renewable energy, events, hospitality and retail infrastructure, chemical, pharma, and food, WWL Group UK has recently set up a new office in Poland.

Boasting 105,000 sq.ft, it includes 10 dock doors, a large yard, 6T floor loading, and a 24/7 365 operation. The warehouse will be used for rework and remedial services such as refurbishment, relabelling, repacking, reprocessing, spare parts management and more. Its

In the future, WWL Group UK is keen to expand taking on new sites in India and Africa whilst increasing its customer base. The company has received incredible growth since restrictions loosened from COVID-19 and is set for an even brighter and more successful future.

T 020 3900 2474 uksales@wwllmail.com

www.worldwidelogistics.com

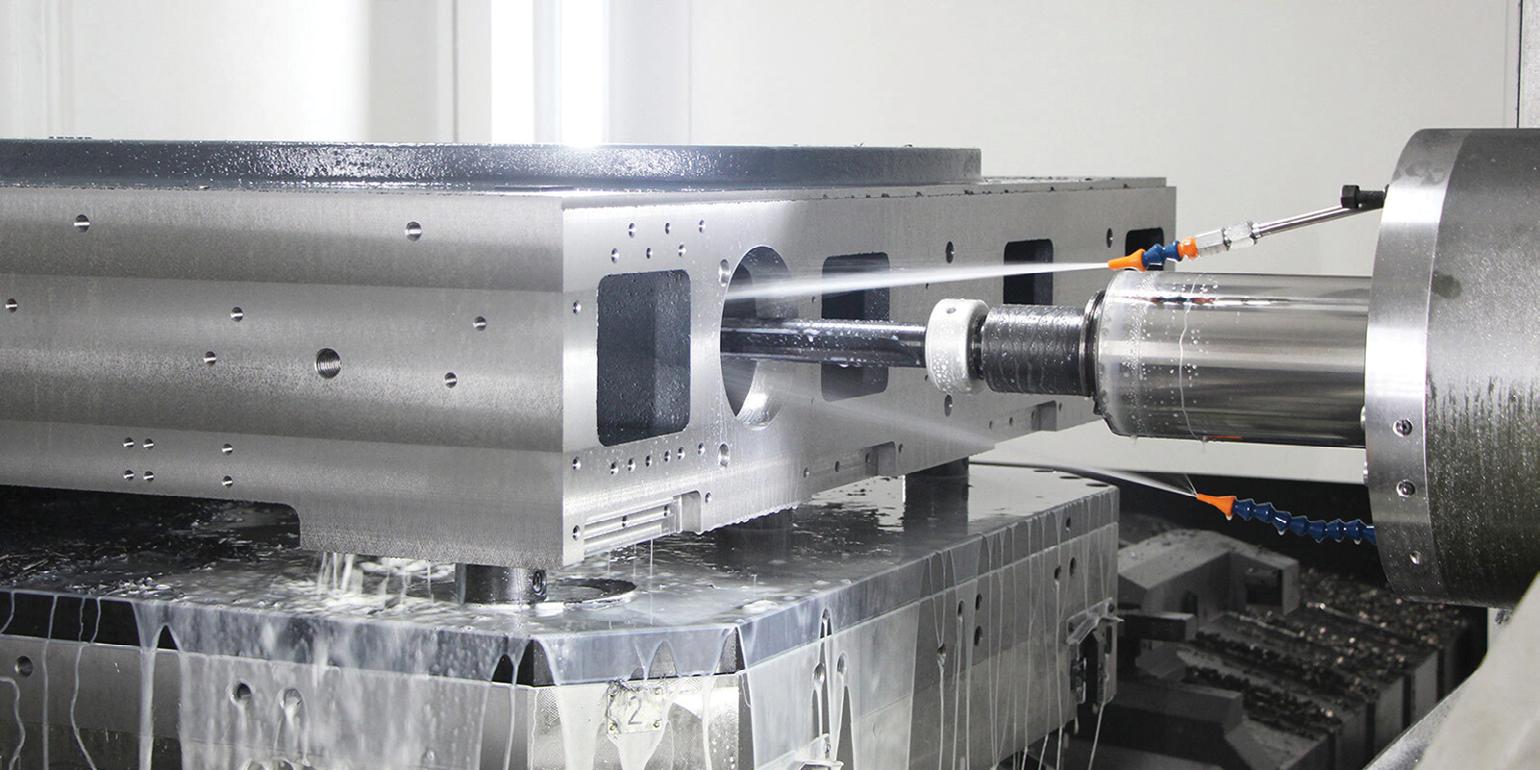

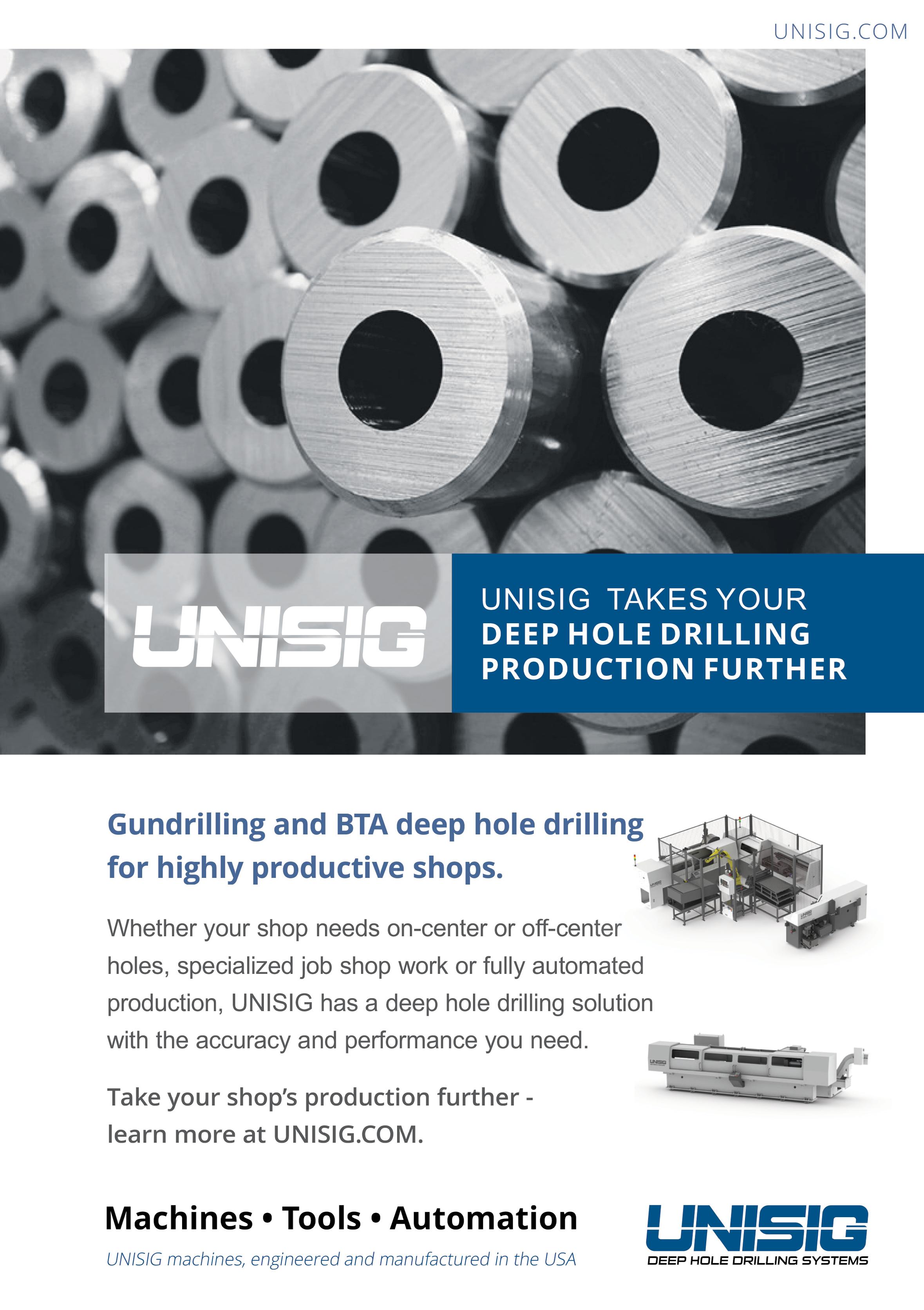

UNISIG produces deep hole drilling machines that are used around the world by nearly every industry imaginable – and at UNISIG, striving for perfection has never been an accident. To secure long-term success, the company decided to further invest in machining its own precision parts rather than subcontracting components, as some of the most critical parts they produced have tolerances and complexity that cannot be made by most machine shops.

To machine their own parts while continuing to grow and develop new products, UNISIG embarked on a new approach to machining which would allow for industry-leading CNC machine tool accuracy and performance to be

which required a change in thinking by the team’s engineers, programmers, and machinists. To harness this new direction, UNISIG put in the time and energy to secure the best manufacturing resources

coupled with new technology that would ultimately eliminate manual intervention in machining that prevails in many shops.

“The deliberate connection between engineering, design, and machining improves our product. Our ability to rely on very high accuracy and productivity from our internal machining capacity allows UNISIG to provide more advanced solutions and value to its customers,” quoted Anthony Fettig, CEO of UNISIG.

Automated machining was the goal,

available, including several Okuma machine tools.

To begin, UNISIG devised a plan to combine modular fixturing, offline tool setup, and full simulation of the machine, workpiece, and tools to provide a platform of innovation within their machine shop. The team’s intent was to radically improve spindle uptime and exploit the full potential of automated CNC machining, even when the batch size would be only one part.

The first step of the UNISIG strategy

was to move away from classic CNC boring mills and adopt the higher productivity potential of CNC horizontal machining centres with twin pallets. After consulting with credible industry sources and leveraging their internal team’s knowledge, the MB-10000H horizontal machining centre from Okuma was selected for medium-sized, high-accuracy part machining.

One of the most important factors in this capital investment was the need to trust the machine accuracy enough to program from its centre of rotation and let the machine run without stopping and manually verifying the machining process many times during the cycle. The Okuma MB-10000H installation was a success and reinforced UNISIG’s wisdom to focus on automated machining – and the benefits were so extraordinary that UNISIG continued to look to additional Okuma solutions to bring its strategic vision to life.

UNISIG’s next target was large-part machining. Previously, to hold the finished machine tolerances, extensive hand scraping was necessary which added a lot of time and expense to produce these machines. UNISIG established a set of machining accuracy parameters that would eliminate much of this handwork to achieve tolerances.

Working directly with the local distributor,

Morris Midwest, UNISIG was able to engage with Okuma America and Okuma Corporation’s technical leadership to tailor the specification of an Okuma MCR-A5CII 35x10 double column machine for the exacting geometry and overall volumetric accuracy needed.

The collective Okuma team ensured the MCR-A5CII machine tool specifications were defined and perfect for UNISIG’s application. A quick-change fixture system was developed by UNISIG to allow two parts up to 3m (10ft) long to be machined simultaneously and removed for setup offline. The results after installation were very impressive, allowing lights-out automatic machining of parts previously not possible for UNISIG to manufacture.

With two machines from Okuma running and performing to expectations, one more opportunity identified for upgrade resulted in the new MA-12500 machine.

The OSP Control common to these three Okuma machines was a big value to the programming and simulation group at UNISIG. “This baseline trust in Okuma is what allows UNISIG to excel at advanced manufacturing,” said Mr. Fetting.

In addition to offline tool presetting and modular workholding on all machines, UNISIG uses a variety of Okuma’s Partners in THINC suppliers including: Mastercam, Vericut® and Renishaw. Using a layered approach to technology and understanding the benefits of eliminating the gaps between engineering, design, and manufacturing, UNISIG has differentiated itself as a machine tool builder. The company’s long history of achievement is one Okuma and Morris Midwest are proud to be a part of –especially in helping UNISIG achieve their goal of capitalising on the full potential of automated machining.

For more information, see below.

T +49 7125 9687590

www.unisig.com

Smart, robust and sophisticated with digital connectivity – EWM continues the XQ series success story, introducing TIG welding machines in the power range from 230 A to 600 A. Whether modular or demodular, the configurable machines from the Tetrix XQ series can be adapted to any task for a welding experience that’s more digital, more universal, and more personal.

The machines are also user-friendly and boast increased efficiency with lots of clever little

The DHS-150 door handle system is especially suited to heavy swing doors

With the new practical DHS-150 door handle system, the slimline AZM150 solenoid interlock from Schmersal is now even easier to use. The ergonomic DHS-150 avoids the need for a separate door handle and is suitable for machine enclosures or fencing and for all standard aluminium profiles with a width of 40 mm. The robust door bolt is particularly useful on heavy swing doors and in for use in harsh environments.

One benefit of the new accessory is that the actuator is pre-positioned by the bolt in the DHS system, thus ensuring its optimal insertion into the device. This gives the system stability against lateral forces. In the event of lateral forces on interlocks that cannot be overcome, the safety door will not be opened –thus causing delays in the production process. In this regard, the DHS-150 door handle system, in conjunction with the AZM150 solenoid interlock, contributes to improved system availability.

In addition, the DHS-150 door handle system is also equipped with an integrated locking device (LOTO). This locking tag function protects operating staff from mistakenly being locked inside larger, walk-in systems and machines while they are performing servicing and repair work. The locking device ensures that the door of the protective device cannot be closed and unintentional machine start-up is prevented.

The AZM150 solenoid interlock has an interlocking force of 1500 Newtons and is characterised by a slimline, space-saving design. In addition, it can be combined with three different actuators for different attachment situations. A positive of the interlock is the rotating actuator head which can be locked with ease by simple placement on the cover, rather than being bolted into place. The rotating actuator head with its two insertion slots enables various installation positions and actuating options and makes the interlock particularly versatile in use.

The AZM150 solenoid interlock is electromechanical in design and can be combined with a high safety standard: the interlock is supplied with a low coding level as standard, or optionally with a high coding level in accordance with ISO 14119. The DHS-150 door handle system can be used with the B1 straight actuator for the standard version as well as for the individually coded version. The B1 actuator is supplied with the high coding level version of the device, but must be ordered separately for use with the standard version.

www.schmersal.co.uk

details. The result: a new TIG welding experience that ensures optimum, reproducible results.

What makes the new Tetrix XQ machines from EWM so special? The new machines are extremely energy efficient and offer high process reliability alongside improved operating comfort, allowing users to adapt to the relevant welding task.

Users can also choose between various rated outputs from 230 A to 600 A for DC or AC/ DC welding processes and take advantage

of an above-average duty cycle. The Tetrix XQ machines come with many different smart TIG and MMA functions to make the welder’s everyday work across a wide range of applications even easier. They are also compatible with gas or water-cooled welding torches and extensive selections of accessories to ensure perfect configuration.

T +44 (0)1670 505875 info@ewm-morpeth.co.uk www.ewm-group.com/uk

After postponing over concerns of the new Omicron variant, Dairy-Tech was finally once again able to welcome exhibitors back on Thursday 7th April 2022.

Showcasing ground-breaking technology, Dairy-tech is the perfect platform for new product launches, introducing the latest innovations and services for the industry, alongside a whole host of speaker sessions dedicated to tackling key topics affecting the industry.

The event hosts the very latest concepts in science and technology and provides networking opportunities

with forward thinking dairy professionals and decision makers.

Dairy-Tech is dedicated to the future success for dairy businesses and the industry, by providing the resources, connecting the industry and showcasing innovation to help the industry keep informed, resilient, proactive and efficient.

Dairy-Tech provides visitors with the ability to gain maximum exposure to new and exciting industry innovations relevant to their business.

This is our pick of the best exhibitors from the show, listed here in alphabetical order: Abbi-Aerotech

B.V., Agri-King, Daisy Vending, Peacock Technology, Pollution Control (UK) Ltd, The Milk Station Company, Wolfenden Concrete Ltd and Wroot Water. Further details can be found on this page and the next page.

If you would like any more information, vist:

https://dairy-tech.uk/

Wolfenden Concrete offer a complete dairy housing and livestock package, making for healthier, happier, more comfortable cows - the key to good yields.

Wolfenden’s SUPA range includes:

t SupaStrong diagonal slats for efficient slurry management combined with a 12-tonne classleading axle load

t SupaDeep channels with 50% extra capacity for superior slurry collection

t SupaWide slurry channels which save as much as 75% of labour time

Wolfenden’s knowledge of the dairy sector means they bring real innovation to farms across the UK. As official distributors of EASYFIX animal comfort products, Wolfenden offer the most advanced cow cubicles, mattresses, feed rails and the latest slurry technology -

whether as part of a refurbishment or within a new-build.

Wolfenden’s latest product is a hybrid concrete / rubber slat system, for durability, longevity and better hoof health and grip. As the only mainland UK manufacturer of hybrid slats, Wolfenden’s new product is wider than the standard hybrid offering, at 4800mm. This makes them perfect for larger dairy farms with wider passage requirements while providing improved animal welfare for cows, whatever the herd or farm size.

Continual innovation is key to Wolfenden’s approach and their solutions for herd welfare and cow comfort have been benefitting UK farmers for over 45 years.

T 01282 844213

info@wolfendenconcreteltd.co.uk www.wolfendenconcreteltd.co.uk

We had a brilliant day at Dairy Tech 2022. At only our second show, it allowed us to create new relationships with visitors and exhibitors. Be sure to visit us again in 2023, with our new product range!

Peacock Technology, based in the heart of Scotland, provides engineering solutions for the Agri-tech and energy sectors.

Our world leading engineers were the first to discover and apply time-of-flight sensing for 3D tracking in robot systems. Alongside the application of new vision technologies in the dairy industry. We offer tremendous new possibilities for advanced automation.

Our first product is the IDS Teat, a compact robot system for disinfecting cow teats on rotary parlour’s post milking. Built around a proven, robust, industrial robot arm and a 3D vision system, IDS Teat can reliably and consistently locate and apply a spray disinfectant to cow teats. This helps to fight mastitis and most importantly improve cow welfare with accurate results every time.

The IDS Teat post milk system is competitive, simple and affordable. We work with our clients to provide a tailored leasing offer, while supplying regular machine servicing and support.

The IDS Teat System – improving your world with robotics and artificial intelligence.

info@peacocktechnology.com

www.peacocktechnology.com

Daisy vending are UK manufacturers of milk and milkshake vending machines.

From our workshops in the heart of Somerset, Daisy’s team of experienced engineers build the most technologically advanced milk and milkshake vending machines on the market, combining industry knowledge with technical expertise to deliver bespoke machines to suit your project.

We can supply everything you would need to set up your milk vending business, including bottles, dairy equipment, bottle vending machines and much more!

Shops and cafes can benefit from our small countertop pergals or

The Groundhog Standard and Super-Dry mechanical slurry Separators have been manufactured in Lancashire for over 45 years. The Groundhog Separator is a well proven robust machine with satisfied customers still using the same separator after 30 years.

In addition to our slurry Separator we can now offer an alternative to building sand lanes. We have adapted our Industrial Lamella Plate Clarifiers specifically to remove sand from the separated liquor after mechanical separation.

t Suitable for all types of Agricultural slurry including sand laden slurry.

t Proven roller/Brush technology that is both low in maintenance time and cost.

t Low power consumption.

t Complete system design including support steelwork, pumps and mixers and automated controls.

t Up to 30% dry solids content in Super-Dry setup.

t Minimal wearing parts, Ideal for Farms separating sand laden slurry.

t Lamella Clarifier technology reducing cost and footprint required for sand lanes.

t Lamella Clarifiers Capturing over 95% of sand in separated liquor.

For more information or a site visit please contact

Tony Dawson

T 01772 620066

M 07793973840

tony@pollution-control.co.uk

www.pollution-control.co.uk

Groundhog Separators are manufactured by Pollution Control (UK) Ltd

Agri-King was founded in 1968 in the states and its European division was set up in 1997 in the UK. Its services spread to farmers across Ireland, England, Scotland, Wales and Northern Ireland, and several European countries with an aim to help farmers achieve their production goals and maintain excellent health and fertility.

The company has its own nutritional team that reviews the latest research and feed technologies to produce the most advanced fortification products on the market. Each diet is balanced using sophisticated lab results to enhance rumen performance, forage utilisation and therefore, health and performance with their key Enzyme program. These are the ‘Key to Profit’ on livestock units. This service is complimented by its high-quality, unrivalled customer care service that carries out regular farm visits, as this is seen as an essential part of working with the farmer to avoid management issues that can later affect herd performance.

Agri-King feed and forage programmes are individual to each specific farmer and their needs. Agri-King Ltd.’s team of area managers collect information about your operation during each visit so that diets can be fine-

undercounter dispensers, and if that isn’t enough, why not add one of our milkshake dispenser bars – adding another 6+ flavours to your range. Syrups are available online in various sizes to fit our machines – look out for seasonal specials.

For even more options, why not include an ice cream vending machine or a fresh milk coffee machine – perfectly made barista style coffee every time.

To place an order or for more information, please feel free to give us a call on 01460 455 555 or email lucy@daisyvending.com

Visit: www.daisyvending.com

tuned to the feeds, conditions and performance targets of the farm. The company offers nutrition programmes for dairy, beef, poultry, and swine, and all Agri-King rations start from accurate analysis, carried out in its state-of-the-art laboratory in the United States.

T 01243 558884 sales@agriking.co.uk

However,

T +44 (0)1749 681381 info@themilkstationcompany.co.uk www.themilkstationcompany.co.uk

With environmental pressure increasing in agriculture, we at Wroot Water have developed the dirty water filter that allows the parlour washing from the dairy unit to be filtered and then distributed on grass land through the K-Line irrigation system.

How this is different to other dirt water disposal systems it that there is a line of 100mt with 8 sprinkler pods, so when in operation the whole area is been irrigated, so that is and area of 2400m2 and applying 4-5mm per hour. At this low application rate of the soil infiltration rate is not exceeded so the protentional for run-off and soil erosion is significantly reduced.

This also avoids the soil becoming water logged destroying soil biology or killing the grass.

This Wroot Water Dirty Water System is simple, easy to set up and runs automatically on a timer. The unit comes as a stand-alone unit, ready to connect the pipes to, plug the electric in and away you go.

The K-line pods are easily moved using a small utility vehicle, quad bike or similar.

Depending on the chamber or tank the dirty water is been pumped from the submersible pump requires checking weekly.

For more information contact Wroot Water tel 01302 771 881 or e-mail info@wrootwater.com

Abbi-Aerotech B.V. developed a directdrive dairy cattle fan with the most modern engine technology: the Abbifan 140-XXP-2. Now available its successor the Abbifan 140-XXP-21. Besides its extremely low power consumption there are also no longer maintenance costs.

In this category of dairy cattle fans, the Abbifan 140XXP-21 is top of its class. No more pulleys, drive belts, bearings or shafts. This means energy savings as high as 70-80% compared with similar existing models. It consumes only 530W/h at max operation.

Dairy farm Rombouts van Wezel in Brecht, Belgium, was one of the first farms to purchase the XXP-2 model 3 years ago. The farm has 130 dairy cows and despite the reasonably new barn, the cows suffered from hot weather. “Now that we are getting more frequent and longer heatwaves, we bought these fans. For its efficiency and practically zero maintenance costs, we chose the Abbifan 140-XXP-2.”

“We installed the fans closer together than recommended and can then leave them to operate more quietly to achieve optimal energy savings.”

Through these fans, we could maintain the level of milk production and minimise energy consumption. The demand for these fans is growing day by day and we continue to develop the best fan for a better future.

T 0031 184 711 344

www.abbi-aerotech.com

Since its formation in 1993, The Safety Knife Company has become a leading manufacturer of safer cutting tools and has helped to prevent countless workplace injuries.

The company’s original product, The Fish 200 Safety Knife, was the result of a chance conversation between the inventor, Bill Ireland MBE, and a farmer who had lost the sight in one eye after an accident cutting string on a hay bale. Once in production, the ‘Fish Knife’ soon found an industrial market as a safer alternative to an open blade knife for removing packaging materials.

Over time the range of products has gradually grown to include other

AudioLINK+ is now faster, quieter, and more reliable than ever before. The second iteration of Aico’s award-winning AudioLINK technology makes it easy to access real-time data from alarms via the free AudioLINK+ app.

AudioLINK+ extracts the same data as AudioLINK, but does this quicker and quieter than before to reduce disturbance and does not affect any other functionality of alarms. With the average time to take a report taking between 4-7 seconds, AudioLINK+ technology makes getting real-time data from Smoke and Carbon Monoxide alarms more efficient –saving time, money and lives.

The AudioLINK+ app is backwards compatible, meaning AudioLINK alarms currently installed do not need to be replaced to utilise the new technology and will work with the new version of the app. However, users will need to update to the latest version of the app to download reports from any AudioLINK+ alarms installed within their properties.

The App generates a simple to read colourcoded report giving information on a range of alarm data including; alarm activations, sensor status, alarm testing information, battery and back up cell status, recorded Carbon Monoxide (CO) levels within CO alarms, and advice on dust contamination levels within the 3000 series alarms.

All of this information can be emailed directly from the phone or tablet to one or multiple addresses, being sent as a PDF report for the property or exported as a .csv file for simple integration with housing management and maintenance systems. Additional information can be added to the report to help link it to a specific alarm and to communicate important and helpful information.

There is no change in the pricing of alarms sold by Aico, just an improvement in the technology offered within the alarms. AudioLINK+ data extraction technology is built-in to all Aico’s Carbon Monoxide alarms such as the Ei208, and the entire 3000 series alarm range.

Find out more about this exciting new iteration of Aico’s home life safety technology:https://www.aico.co.uk/ about-us/why-aico/technology/audiolink/

‘enclosed blade’ safety knives and a variety of retractable blade knives. We are also a stockist for the innovative Slice ceramic blade cutters.

Most of our products are available in ‘metal detectable’ plastics making them suitable for use in food production areas.

We are regularly asked to solve specific problems by customers. Recent project examples include mounting a safety knife on a telescopic pole to enable operators to cut strapping from building materials on lorry trailers. This does away with the need to climb on to the trailer and therefore be ‘working at height’.

NOVA Safety Knives. We are delighted to have been appointed as exclusive distributor for the UK and Ireland for the NOVA Safety Knife range in early 2021.

Our products are available from our web shop, through 100’s of distributors or directly from our sales office. We also have experienced staff on hand to help you through the evaluation process if you are looking to introduce safety knives to your workplace.

T +44 (0)1452 887900 enquiries@safetyknife.net www.safetyknife.net

Sinking concrete floors are commonplace within industrial and commercial units. The cause can be a failure in the floor construction caused by liquid washout of the fill, subsidence of the original construction or settlement of the floor slabs caused by the excessive weight of machinery or loaded racks.

Unstable or sinking slabs can lead to machine vibration which affects the output, quality and longevity of machines. Another problem is misaligned racking and the associated safety concerns in the affected area.

These issues can be solved using simple injections of a geopolymer resin directly beneath the floor slab. The super hard resins expand in the ground minimising any vibration

and can lift sinking slabs.

Using Geobear’s method of floor lifting is 70% faster than any alternative, has 30% lower carbon emissions and comes at a lower overall cost. Any work is completed using minimal plant and we only require small operating areas to complete the work, meaning no operational lost time for you.

Contact Geobear and we can visit your site to assess problem floor areas and provide a proposal for a fast geopolymer solution.

T 0800 084 3503

www.geobear.co.uk/commercial-building-ground-work/

New modular

barrier system launched by seton

Anew retractable barrier system, named EasyExtend, has been launched into the market, offering unique features and benefits for use in industrial and outdoor spaces.

Developed by the health and safety solutions provider Seton, the new and rugged unit is designed to cordon off areas in warehouses, factories, distribution centres and construction sites.

It can span 10 metres — further than most other retractable barriers on the market — meaning a more efficient use of resources. It can be used with standard traffic cones, with its dedicated post and base system, or can be fixed directly onto walls or other surfaces.

The EasyExtend also uniquely stores all the components of the barrier inside the base, making it ideal for rapid and easy setup in the event of a hazard, as well as being possible to store in stacks with little space.

The barrier can be used in three different ways. The modular post and base system gives the choice of using single or dual-level tapes, allowing the user to create a more imposing boundary if they choose to.

Once erected, the base portion features an integrated weight for stability. For extra sturdiness in harsh weather or on uneven surfaces, the user can then fill the base with an extra 12 litres of water or sand.

An adapter can also fix the tape cassette, or clip tape ends, to the top of any standard traffic cone. This lets cones be used in place of posts, if needed, such as around large vehicles.

The same barrier can cordon between fixed objects or walls, rather than needing the posts. Special EasyExtend brackets hold the tape cassette, while a separate receiver clip holds the tape end. Both can be fixed permanently or magnetically to walls, racking, store checkouts or even vans.

The design means a single barrier set can create cordons in different locations, without businesses needing to buy several versions of the same product. The EasyExtend is available with tapes in two colour sets — red and white or black and yellow.

Alex Hinton, product innovation manager at Seton, said: “We’ve created a strong and durable barrier that gets around the problem of many facilities needing to buy several versions of the same product.

“The market-leading 10-metre length and unique modular design of EasyExtend means that, as well as being quick and easy to transport and store, it can be used in a wide variety of settings. From tape combinations to traffic cones and walls, its versatility will be extremely useful for businesses.

“The fact that the barrier posts dismantle and fit easily into the base units, which isn’t possible with any other product on the market, means that they can be stacked and stored on shelves or neatly in the back of a van.

“It also means that they are much faster and safer to take to a location to cordon off a particular area, which could make all the difference when dealing with a sudden or temporary hazard.

“Retractable barriers must be as easy to use as possible, to make sure that staff are happy to use them whenever they may be needed. This is an ethos that we continue to develop our barriers around.”

For more details about the Seton EasyExtend retractable barrier, visit www.seton.co.uk/easyextend.

The Building Safety Bill has recently received Royal Assent and is now The Building Safety Act bringing about the largest change in building regulations in over 40 years.

In order to comply companies will now need to use digitalized proof of materials used and processes followed. SightCall is the perfect digital tool for this as it offers construction site friendly operation and tools to enable remote digital sign off and now through The Farm Visual Support powered by SightCall, we can offer ANY business, no matter it’s size, an affordable solution.

To find out more about our Visual Support powered by SightCall please contact us visualsupport@thefarmltd.co.uk or call 01892

617804

Digital is becoming part of everything we do in the public sector. Significant work has already been undertaken to progress the digital transformation of the UK’s built environment, which is no exception to this.

The Golden Thread has laid out recommendations for the Duty Holder, to find out more read the full article at: https://lnkd.in/d_7WSMcq

SightCall is the perfect digital tool to help your

company follow protocol digitally and now through The Farm Visual Support powered by SightCall, we can offer ANY business, no matter it’s size, an affordable solution.

To find out more about our Visual Support powered by SightCall please contact us visualsupport@thefarmltd.co.uk or call 01892

617804

www.sightcall.com

www.grantthornton.co.uk

Natural & Organic Products Europe is Europe’s leading trade show dedicated to natural products, health food and organic industries. The event is a hub of resources for serious buyers to meet and connect with leading suppliers for two days of business, networking, education and a lot of fun.

Hemsley Organics is an award-winning, organic, and vegan skincare range. The range has been developed by practicing Reiki Masters who set out to launch a skincare portfolio that focuses on a holistic approach to nourishing skin and spirit alike. High vibrational skincare is a new concept, which is rapidly gaining kudos as an advanced twin solution, marrying beauty with enhanced wellbeing.

Hemsley Organics is currently the only British company creating effective and luxury skincare ranges which are uniquely infused with Reiki energy and innovative blends of organic and natural essential oils to enhance your skin.

The Anahata Collection is Hemsley Organic’s first range, and it provides a comprehensive selection of luxury skincare products for women of all ages for their daily skin care routine. The range includes 6 award winning products including a cleanser, hydration mist, eye serum, face serum, day, and night cream for a full healthy skincare routine.

Sustainability is at the core of the brand with its outer packaging created via wind farm electricity. Hemsley

Natural & Organic Products Europe took place at ExCeL, London on the 3rd -4th of April 2022. The event attracted an outstanding attendance of 7,456, with 800 exhibiting companies, consisting of the fastest growing sectors in retail, including: organic, vegan, and free-from food, drink, supplements, personal care, and natural beauty.

The show is split into four dedicated areas, comprised of the Natural Food Show, Natural Health & Living, Natural Beauty & Spa and Vegan World. The show combines brands, products from all corners of the market, and over 1000 suppliers showcasing the latest industry innovations.

This is our pick of the best exhibitors from the show, listed here in alphabetical order: Hemsley Organics, HERBOWSKI and milly&sissy. Further details can be found below.

For more information, please see the details below. www.naturalproducts.co.uk

Organics are proud of a fully transparent ingredients list which are highly organic and ethically sourced, with no synthetic pesticides and fertilisers used to grow any of its ingredients. Aqua is not used as its base, as it’s an inactive ingredient and doesn’t provide any benefit to skin, instead they use the best Organic Bulgarian Rose Water as the base ingredient.

T +44 (0)7402745989 enquiries@debbietrumperconsultancy.com www.hemsleyorganics.com

milly&sissy offer a vast range of zero waste, plastic free, vegan and cruelty free products that are developed in the most sustainable, eco-friendly way.

The company was developed by Milly and Sissy, who both encompass a huge passion for the environment as well as animals and are always looking for ways to improve their way of living to have less impact on the planet.

All its products are made from 99.7% natural ingredients with the base of the formulations deriving from olive oil located from Provence in France, as well as coconut oil and argile also from France. Its synthetic fragrance represents only 0.2% of the entire product with 50% of that being biodegradable which allows the formulations to remain allergen free.

Each formulation is also free from Sodium Laurel Sulphate, parabens, allergens and palm oil, and are suitable for those with sensitive skin.

Every product in the range is and always will be vegan and cruelty free and are approved by The Leaping Bunny programme and certified by The Vegan Society. Every bottle is made either from British made glass or aluminium, and all refill sachets are compostable leaving zero waste.

milly&sissy products include hair and body wash sets, face wash sets, hand wash sets, reusable pump & bottles, shower cremes, deodorants, cleansing pads, and travel sets. Shake up your beauty regime and enter

HERBOWSKI is a botanical plastic-free bath and body brand inspired by Slavic bath house rituals, launched in October 2021. Our story is innately biographical, directed by our founder’s sensations and memories; prompting a sense of nostalgia, recollection of past feelings and a connection to nature. It recalls tales from the Banya (sauna), a life deeply rooted with Slavic nature, and the family, community and connection that comes with it.

We are focused on delivering high quality botanical skincare that contains hundreds of antioxidants, vitamins, and nutrients, bringing outstanding results for skin and hair.

HERBOWSKI full collection includes a selection of soap bars, botanical oils and bath accessories. Our products do not contain palm oils, synthetic detergents, artificial colorants or fragrance, parabens, sulfates, silicones and mineral oils.

At HERBOWSKI we are fully committed to be a plastic-free and carbon neutral brand. Our product packaging is made

the world of vegan, cruelty free, zero waste, 99% natural and reduced carbon emissions products.

enquiries@millyandsissy.co.uk

www.millyandsissy.co.uk

out of 100% post-consumer fibres, we use soy ink, glass and aluminium recyclable bottles, Kraft shipping boxes and biodegradable filling. We also offset carbon footprint by investing in strategic forest preservation projects. All our products are made by hand in Kent.

Contact

M 07801476216

hello@herbowski.co.uk

www.herbowski.co.uk

IG https://www.instagram.com/herbowski_skincare/

In this issue of Industry Update, we have selected Propack Automation Machinery Ltd as our Packaging Technology Company of the Month.

Propack Automation Machinery Ltd has more than 35 years’ experience in designing and presenting solutions to handling and packaging projects. The company maintains an impressive range of machinery, and holds vast experience in filling machinery and in supplying complete filling lines, including downstream automation and packaging. Propack Automation Machinery Ltd’s impressive range and expertise, enables them with the flexibility to work in many different areas and the company places a strong interest in special projects.

Offering a full comprehensive service consisting of consulting, careful project planning, installation and commissioning, qualification, remote maintenance, decentralised service, complete documentation, training and maintenance planning, has positioned Propack Automation Machinery Ltd as a highly flexible futureoriented partner in the field of packaging technology.

Shelf-ready Packaging (SRP), where the manufacturer’s unit of distribution goes straight onto the retailer’s shelf,

plays an important role in the attractive presentation of consumer goods, whether for food or non-food products. For the retailer, shelf-ready packaging increases convenience and reduces the labour needed to keep the shelves well stocked. SRP is environmentally friendly, eliminating plastics by using a single substrate of carton board or corrugated material, while making the packaging fully recyclable.

Propack Automation Machinery Ltd has maintained a long-standing interest in SRP applications and, with over 35 years experience in designing and presenting solutions, is well placed to help both the machinery manufacturer and the end-user. Different collating infeeds will be needed, depending on whether the packs are rigid, such as cartons, cans or bottles, or soft, as when handling sachets, pouches, FFS or block-bottom bags. For soft packs, and working with its supplier J&P

Maschinenbau, based in Dresden, Propack was able to automate a very important new production line for Flahavans, the major Irish supplier of premium porridge oats, while re-designing their full shipper range for SRP. Rigid packs, on the other hand, can also have great variety, whether they are shaped bottles, cans or cartons, and will require different grouping and packing methods.

Christ Packing Systems, based in South Germany, has years of experience in supplying almost every end-of-line machine combination possible and has co-operated with Propack Automation on many projects, across the food, household and pharmaceutical healthcare sectors.

Across the projects described and many others, the range of SRP machinery installed by Propack Automation has covered multi-lane dividing for glass, grouping of pouches and sachets, tray erecting, loading in vertical and horizontal planes, wraparound Shipper Cases in SRP, tray-and-lid combinations, as well as side-loading of carton stacks into solid-board outers, perforated and decorated to a full SRP specification, followed by automatic palletising.

Photos illustrate some of the work which was done and reflect the good and enjoyable cooperation between a like-minded customers, suppliers and machinery manufacturers, to achieve a perfect SRP outcome.

Contact: Patrick Fleming

Propack Automation Machinery Ltd

M 07860 381360

patrick.fleming@propack.co.uk

www.Propack.co.uk

Recycling UK is one of the largest independent recycling companies/traders in the United Kingdom.

From its head office at Tarporley, Cheshire, and associate processing plants throughout the UK & Ireland, it can cover most recycling needs. It also has office/joint ventures in Mumbai, India, and Waterford, Ireland.

It is a trader of all grades of waste paper & plastic in the form of bulk loose, baled, or palletised

material, surplus or damaged reels & redundant stock of paper and plastic packaging and supply material to customers in the UK, Europe, India and throughout Asia.

Its wholly owned subsidiary OWP Ltd processes over 1,500 tonnes per week at a dedicated plant at Oswestry situated on the England/Welsh border with material collected by various means within a 150 mile radius.

It also collects material throughout the UK and

Ireland using trailers for delivery to Oswestry or to one of our associate processing plants.

Please contact our commercial team on +44 (0)1829 732471 or email: commercial@ rukgroup.com or visit: www.rukgroup.com

TANA Recycling Machinery UK has a mission to provide customers with simply more money on the bottom-line with cutting-edge technology in solid waste management. All TANA products aim to provide maximum efficiency and profit to make waste management businesses thrive. TANA machines are designed with skill and experience using the best components available. All products are manufactured from the TANA headquarters in Finland.

When using the right machine, waste can be transformed into valuable raw materials. Reducing, re-using and recovering waste to manage waste sustainably can be done profitably. Efficiently recycling waste by conventional means is notoriously difficult, and in most cases only a certain percentage of the waste ends up recycled. But what if there was an easier way that recycled waste from a variety of materials?

We are lucky enough to have the most versatile machine on the market, the TANA Shark Shredder. General waste, mattresses, tyres, wood, plastic, C&I, C&D the Shark can handle them all and more. Pair that with excellence in service and you have a winning formula.