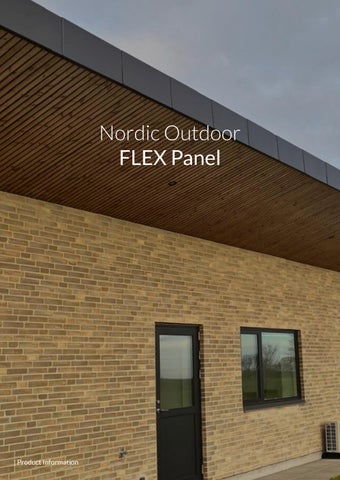

Nordic Outdoor FLEX Panel

Nordic Outdoor FLEX Panel

The Nordic Outdoor FLEX Panel has been developed to offer a durable and high-quality cladding solution that ensures easy and efficient installation. The panel combines aesthetics, functionality, and longevity in one solution, making it ideal for both private and professional construction projects. The thermally treated wood used in the panels is especially suitable for Nordic climates, where it withstands moisture and temperature fluctuations. The manufacturing process ensures a dimensionally stable and resilient product that retains its structure and appearance over time.

With the Nordic Outdoor FLEX Panel, customers save significant time compared to traditional slat mounting, while ensuring correct installation from the very first try. The smart construction and carefully selected materials contribute to a consistent and elegant look that fits perfectly with modern architecture and building styles.

With our FLEX Panel, you get:

Time-saving

Quick and simple installation compared to traditional slat mounting.

Easy installation

FLEX panels can be combined regardless of length.

Danish craftsmanship

Produced in Denmark – ensuring high quality standards through Danish design and manufacturing.

Durability

Chemical-free and naturally resistant to fungi.

Features:

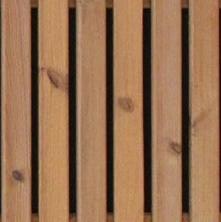

• Thermally treated wood

Increased durability and dimensional stability through a natural heat treatment process.

• Eco-friendly and chemical-free

A sustainable alternative to pressure-treated wood, without harmful substances.

• High dimensional stability and durability

Resistant to weather conditions and retains its structure over time.

• Natural resistance to fungi

The thermal treatment reduces biological degradation of the wood.

• Suitable for façade cladding

Ideal for both modern and classic buildings where aesthetics and functionality are key.

• Minimal maintenance

Only requires light cleaning and possible surface treatment as needed.

• Biological durability class 2

Classified as a durable material with a long lifespan.

The wooden panels are made from FSC®-certified wood and other controlled materials.

FSC® C165957

Dispose of as clean wood for recycling, upcycling, or incineration.

ThermoWood Pine

Tolerances

Tolerances:

ThermoWood Slat

Loose ThermoWood slats can be purchased as accessories and used for custom adjustments and aesthetic details when installing the Nordic Outdoor Panel.

AWAITING APPROVAL

Installation Guide

Proper installation of the Nordic Outdoor FLEX Panel ensures a stable and long-lasting façade.

Requirements for substrate and structure

• Before starting the installation, ensure that adjacent building components are properly executed and provide the necessary protection and support for the cladding. Consider water drainage, ventilation, and potential movements in the structure. The cladding must not be in direct contact with the ground, and appropriate clearance must be maintained from roofs, windows, and doors.

• The batten structure and support battens must be correctly dimensioned and installed.

• The wind barrier must be clean and free of cutting dust.

Fastening

• The FLEX Panel is fastened with ringed nails or Nordic Outdoor FLEX façade screws. (Pre-drilling at the ends of the profiles is recommended to prevent splitting.)

Step-by-step installation

1. Preparation: Ensure the substrate is properly installed.

2. Fastening: Secure the boards with nails or Nordic Outdoor FLEX façade screws.

3. Distance to ground: Minimum 200 mm (7 7/8”) from ground level. Can be reduced to 100 mm (3 15/16”) if using a drainage trench with pebbles.

Panel

adjustment

If the panels need to be adjusted in width or length, we recommend using a jigsaw or circular saw for cutting.

Maintenance Guide

To ensure that the Nordic Outdoor FLEX Panel retains its attractive appearance and long lifespan, regular maintenance is recommended. Thermally treated wood generally requires less maintenance than untreated wood, but external factors such as weather, sun, and moisture exposure can affect the wood surface over time.

Regular inspection of outdoor wood surfaces

A routine inspection of the wood is good practice, especially near ground level, at joints, and in areas with limited airflow.

Replacement of boards showing signs of decay

If signs of degradation or damage occur, affected wood components should be replaced promptly to prevent further deterioration.

Regular cleaning with wood cleaner

Naturally occurring mold spores can settle on wood surfaces, particularly in shaded areas. This can be effectively removed with a mild wood cleaner applied with a brush or sponge. Use of a high-pressure washer is not recommended, as it may damage the wood structure and force moisture into the material.

Surface treatment

Over time, the wood will naturally develop a silvergrey patina – this is a natural process. If you wish to maintain the original color tone, the wood can be treated with an outdoor pigmented wood oil or wood preservative that protects against UV radiation and reduces discoloration. Before application, the wood’s moisture content should be checked to ensure optimal absorption.

Depending on exposure to sunlight and rain, the wood may need to be retreated every one to two years. In especially exposed areas, more frequent maintenance can prolong the product’s life and preserve its aesthetic appeal.

Over time, the wood will naturally develop a silver-grey patina – a completely natural process. If the original colour expression is to be preserved, the wood can be treated with a pigmented exterior wood oil or wood preservative.

Fog & Venø is a leading Danish manufacturer of acoustic and decorative panels with and without acoustic properties. These products are designed and manufactured with a focus on Danish craftsmanship and a constant pursuit of high quality. The panels are suitable for installation on both walls and ceilings.

Fog & Venø has a strategic partnership with world-leading suppliers of materials such as wood veneer, linoleum, foil, and laminate, ensuring that all Fog & Venø products maintain a high standard and a wide range of options. This means that there is constantly reverberation in the room, and this is where our acoustic panels make a big difference.

Our Danish-produced acoustic panels break the sound and absorb the sound wave, so it dies out when it hits the panels. This means that the sound wave is eliminated and the reverberation time is shortened, which will improve the indoor climate and the feeling of well-being in the room, whether it is private, commercial, or public buildings we are talking about.

Contact information

Fog & Venø A/S

Buntmagervej 5, DK-7490 Aulum

Tel: (+45) 88 77 83 70

hello@fog-veno.com www.fog-veno.com