TABLE OF CONTENT

Understanding Humidity and Its Impact

Key Impacts of Humidity on Cold Storage:

Principles of Humidity Control

Principles of Effective Humidity Control:

Technologies for Humidity Control

Benefits of Proper Humidity Control

Best Practices for Humidity Control

Conclusion

INTRODUCTION

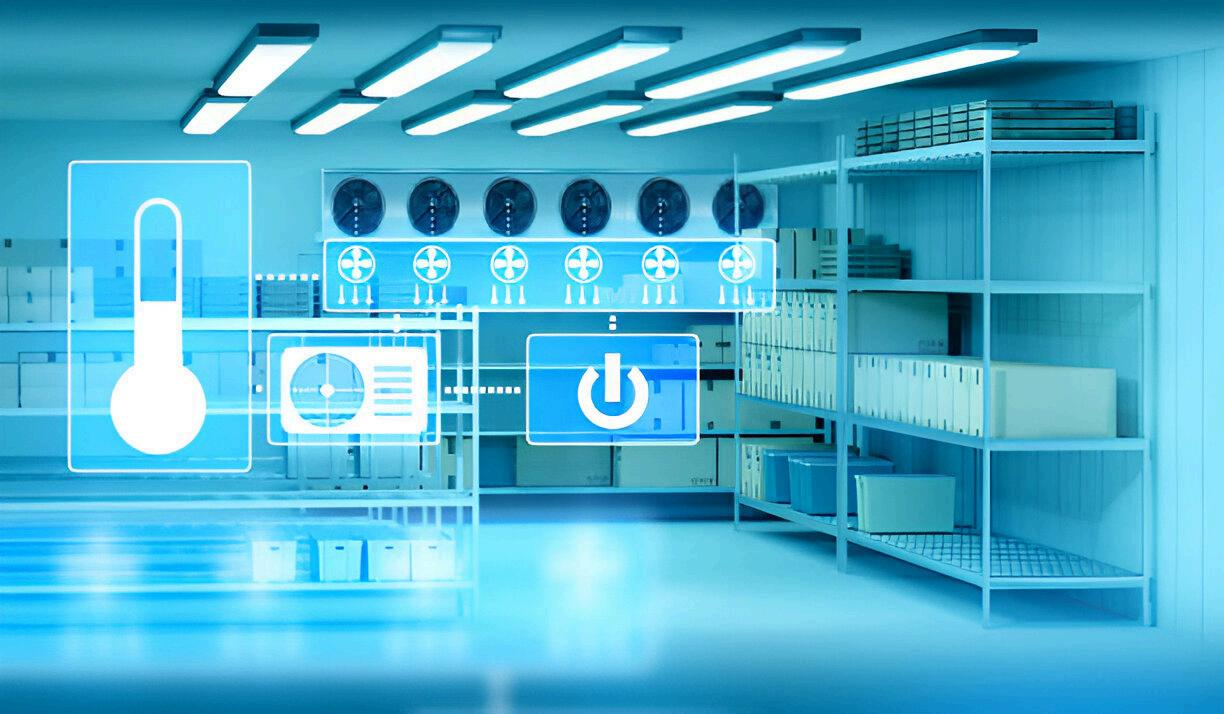

Cold storage facilities play a crucial role in preserving the quality and safety of perishable goods, such as food, pharmaceuticals, and other sensitive materials. A key aspect of effective cold storage is the control of humidity. Proper humidity management is essential to prevent spoilage, maintain product quality, and ensure the longevity of stored items. In this blog, we will delve into the science of humidity control in modern cold storage, exploring the principles, technologies, and benefits that come with maintaining optimal humidity levels.

Understanding Humidity and Its Impact

Humidity refers to the amount of water vapor present in the air. In cold storage environments, humidity levels can significantly affect the preservation of stored goods. Cold storage Humidity solutions High humidity can lead to condensation, mold growth, and spoilage, while low humidity can cause desiccation and deterioration.

Therefore, maintaining a balanced humidity level is critical for the effective operation of cold storage facilities.

Key Impacts of Humidity on Cold Storage

Condensation: Excessive moisture can form on surfaces, leading to the growth of mold and bacteria, which can contaminate stored products.

Desiccation: Insufficient humidity can cause products to dry out, negatively impacting their texture, appearance, and overall quality.

Temperature Stability: Humidity levels can affect temperature regulation, as water vapor in the air influences heat absorption and release.

Principles of Humidity Control

Humidity control in cold storage involves maintaining an optimal balance of moisture in the air. The ideal humidity level depends on the specific requirements of the stored products. For instance, fruits and vegetables may require higher humidity levels to prevent drying, while pharmaceuticals might need lower humidity to avoid moisture-induced degradation.

Principles of Effective Humidity Control

Monitoring: Continuous measurement of humidity levels is essential to ensure that the environment remains within desired parameters.

Adjustment: Employing technologies and systems that can adjust humidity levels to maintain consistency.

Insulation: Proper insulation of the storage facility to prevent external factors, such as ambient humidity and temperature, from affecting the internal environment.

Technologies for Humidity Control

Modern cold storage facilities utilize advanced technologies to maintain optimal humidity levels. These technologies include sensors, humidifiers, dehumidifiers, and integrated control systems.

Key Technologies

Humidity Sensors: These sensors continuously monitor the humidity levels within the storage facility, providing real-time data that can be used to make adjustments.

Humidifiers: Humidifiers add moisture to the air when humidity levels drop below the desired threshold, ensuring that the environment remains sufficiently moist.

Dehumidifiers: Dehumidifiers remove excess moisture from the air when humidity levels exceed the desired level, preventing condensation and associated issues.

Integrated Control Systems: These systems automate the regulation of humidity levels by integrating sensors, humidifiers, and dehumidifiers, ensuring consistent and accurate humidity management.

Benefits of Proper Humidity Control

Maintaining optimal humidity levels in cold storage offers numerous benefits, including enhanced product preservation, improved safety, and reduced operational costs.

Key Benefits

Product Preservation: Proper humidity control helps maintain the quality and freshness of stored products, preventing spoilage and extending shelf life.

Safety: By preventing mold and bacterial growth, humidity control ensures that stored products remain safe for consumption or use.

Cost Efficiency: Effective humidity management reduces the risk of product loss due to spoilage, which can save significant costs for cold storage operators.

Energy Efficiency: Optimizing humidity levels can enhance the efficiency of cooling systems, reducing energy consumption and operational costs.

Best Practices for Humidity Control

To achieve effective humidity control, cold storage operators should follow best practices that ensure consistent maintenance and monitoring.

Best Practices

Regular Calibration: Regularly calibrate humidity sensors and control systems to ensure accuracy and reliability.

Preventive Maintenance: Perform routine maintenance on humidifiers and dehumidifiers to prevent malfunctions and ensure optimal performance.

Data Analysis: Analyze humidity data trends to identify potential issues and make proactive adjustments.

Training: Train staff on the importance of humidity control and the operation of control systems to promote consistent management.

Conclusion

The science of humidity control in modern cold storage is essential for preserving the quality and safety of perishable goods. By understanding the impacts of humidity, implementing advanced technologies, and following best practices, cold storage operators can ensure that their facilities provide optimal conditions for stored products. Proper humidity management not only enhances product preservation and safety but also contributes to cost efficiency and energy savings. As the demand for effective cold storage solutions continues to grow, embracing innovative and reliable humidity control strategies will remain a crucial aspect of modern storage practices.