The fifth wheel coupling market plays a critical role in the transportation and logistics industry, providing essential components for connecting trailers to heavy-duty trucks. In recent years, there has been a notable shift towards the adoption of lightweight materials in the manufacturing of fifth wheel couplings. This blog explores the trends, drivers, and implications of this shift, highlighting key aspects shaping the market dynamics.

Understanding Fifth Wheel Couplings

Fifth wheel couplings are mechanical devices mounted on the chassis of heavyduty trucks, enabling the connection and articulation between tractor units and trailers. These couplings facilitate safe and efficient towing operations, crucial for transporting goods over long distances across various industries such as logistics, construction, and agriculture.

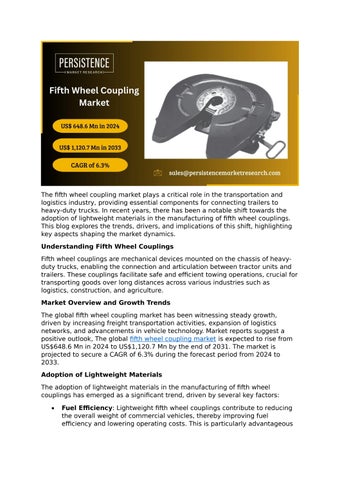

Market Overview and Growth Trends

The global fifth wheel coupling market has been witnessing steady growth, driven by increasing freight transportation activities, expansion of logistics networks, and advancements in vehicle technology. Market reports suggest a positive outlook, The global fifth wheel coupling market is expected to rise from US$648.6 Mn in 2024 to US$1,120.7 Mn by the end of 2031. The market is projected to secure a CAGR of 6.3% during the forecast period from 2024 to 2033.

Adoption of Lightweight Materials

The adoption of lightweight materials in the manufacturing of fifth wheel couplings has emerged as a significant trend, driven by several key factors:

Fuel Efficiency: Lightweight fifth wheel couplings contribute to reducing the overall weight of commercial vehicles, thereby improving fuel efficiency and lowering operating costs. This is particularly advantageous

in the transportation sector, where fuel expenses constitute a significant portion of operational expenses.

Payload Capacity: By incorporating lightweight materials such as aluminum alloys and high-strength steels, manufacturers can enhance the payload capacity of trucks and trailers without compromising on structural integrity and safety standards. This allows for the transport of heavier loads while complying with regulatory weight limits.

Environmental Regulations: Stringent emissions regulations worldwide are encouraging the adoption of lightweight materials to reduce vehicle emissions and improve environmental sustainability. Lighter vehicles consume less fuel, resulting in lower greenhouse gas emissions per mile traveled.

Technological Advancements: Advances in material science and manufacturing processes have enabled the development of lightweight fifth wheel couplings that offer superior durability, corrosion resistance, and longevity compared to traditional steel counterparts.

Market Implications and Innovations

The shift towards lightweight materials in fifth wheel coupling manufacturing is driving innovation across the industry:

Material Selection: Manufacturers are increasingly opting for advanced composites, aluminum alloys, and high-strength steels that strike a balance between weight reduction and mechanical performance.

Design Optimization: Emphasis on optimizing the design of fifth wheel couplings to maximize strength-to-weight ratios, improve aerodynamics, and enhance overall vehicle efficiency.

Integration with Telematics: Integration of lightweight couplings with telematics systems and IoT-enabled sensors to monitor performance metrics such as load distribution, wear and tear, and operational efficiency in real-time.

Future Outlook and Opportunities

Looking ahead, the fifth wheel coupling market is poised for further growth and innovation:

Electric and Autonomous Vehicles: With the rise of electric trucks and autonomous vehicle technologies, there is a growing demand for lightweight fifth wheel couplings that can support the unique requirements of these emerging vehicle types.

Global Market Expansion: Expansion into emerging markets in AsiaPacific, Latin America, and Africa presents new opportunities for manufacturers to capitalize on growing infrastructure development and increasing demand for commercial transportation solutions.

Sustainability Initiatives: Continued focus on sustainability-driven initiatives, including lightweighting strategies and eco-friendly

manufacturing practices, to align with global sustainability goals and regulatory mandates.

Conclusion

The adoption of lightweight materials in the manufacturing of fifth wheel couplings marks a pivotal shift towards enhancing vehicle efficiency, reducing environmental impact, and optimizing operational performance in the transportation sector. As manufacturers innovate and integrate advanced materials and technologies into their product offerings, stakeholders can expect to see continued advancements that redefine the capabilities and functionalities of fifth wheel couplings in modern commercial vehicles. By embracing these trends and leveraging technological innovations, industry players are wellpositioned to meet the evolving needs of a dynamic global market while driving sustainable growth and innovation in the fifth wheel coupling industry.

Follow Us: LinkedIn | Medium | Twitter