Biodegradable Polymer Market Innovations: BioBased 3D

Printing Applications

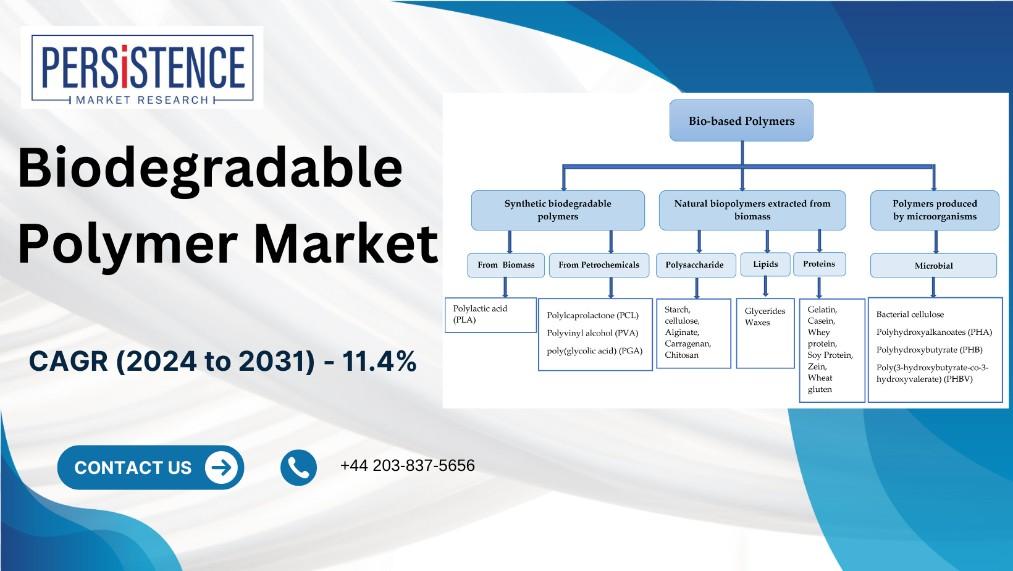

The global biodegradable polymer market, valued at USD 8.34 billion in 2024, is projected to reach USD 20.04 billion by 2031, with a CAGR of 11.34%. This growth is driven by rising environmental awareness, regulatory pressures, and advancements in biodegradable materials derived from renewable sources like starch and lactic acid. These polymers, designed to decompose naturally and minimize environmental impact, are increasingly used in packaging, agriculture, textiles, and medical devices. Key trends include the development of compostable packaging, bio-based and marinedegradable polymers, and integration in 3D printing. Enhanced biodegradability and corporate sustainability initiatives are expected to further propel market expansion.

The biodegradable polymer market is undergoing a significant transformation with the advent of innovative applications in bio-based 3D printing. This technological advancement is reshaping how we approach sustainability, manufacturing, and material use. By leveraging biodegradable polymers in 3D printing, industries can produce environmentally friendly products with enhanced functionality and reduced ecological impact. This article explores the cutting-edge innovations in bio-based 3D printing applications, the benefits they offer, and their potential to drive growth in the biodegradable polymer market.

The Rise of Bio-Based 3D Printing

Bio-based 3D printing represents a fusion of sustainable materials and advanced manufacturing technologies. This innovative approach utilizes biodegradable polymers derived from renewable resources to create 3D-printed objects. Key factors contributing to the rise of bio-based 3D printing include:

1. Sustainability Goals: As industries and consumers increasingly prioritize sustainability, there is a growing demand for eco-friendly materials and processes. Bio-based 3D printing aligns with these goals by using biodegradable polymers that minimize environmental impact.

2. Advancements in 3D Printing Technology: Rapid advancements in 3D printing technology have made it possible to use a variety of materials, including biodegradable polymers. This has expanded the scope of 3D printing applications and allowed for the creation of complex, customized products.

3. Innovation in Material Science: Continuous research and development in material science have led to the creation of bio-based polymers that are suitable for 3D printing. These materials offer properties such as strength, flexibility, and biodegradability, making them ideal for various applications.

Benefits of Bio-Based 3D Printing Applications

Bio-based 3D printing offers several benefits, particularly when using biodegradable polymers. These advantages contribute to the growth of the biodegradable polymer market and enhance the appeal of bio-based 3D printing technologies:

1. Environmental Impact: One of the primary benefits of bio-based 3D printing is its reduced environmental impact. Biodegradable polymers decompose naturally over time, reducing the amount of plastic waste that ends up in landfills and oceans.

2. Customization and Precision: 3D printing allows for the production of highly customized and precise objects. This capability is particularly valuable in industries such as healthcare, where personalized medical devices and prosthetics can be created with bio-based polymers.

3. Resource Efficiency: Bio-based 3D printing often uses less material compared to traditional manufacturing processes. The additive nature of 3D printing means that material is deposited only where needed, reducing waste and improving resource efficiency.

4. Reduced Carbon Footprint: Utilizing bio-based polymers derived from renewable resources can help lower the carbon footprint associated with production. These materials often have a lower environmental impact compared to petroleum-based plastics.

5. Enhanced Properties: Innovations in biodegradable polymers are improving their performance characteristics, such as strength, flexibility, and thermal stability. These enhanced properties make them suitable for a wider range of applications in 3D printing.

Key Innovations in Bio-Based 3D Printing

Several key innovations are driving the use of biodegradable polymers in 3D printing, each contributing to the advancement of the technology and the expansion of its applications:

1. Advanced Bio-Based Materials: Researchers are developing new bio-based polymers that are specifically designed for 3D printing. These materials include polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based polymers, which offer various properties such as high strength, flexibility, and ease of processing.

2. Improved Print Quality: Technological advancements are enhancing the print quality of biobased 3D-printed objects. Innovations in printer design, extrusion technologies, and material formulations are leading to better resolution, surface finish, and overall performance of 3Dprinted items.

3. Multi-Material Printing: Advances in multi-material 3D printing enable the use of different bio-based polymers in a single print job. This capability allows for the creation of complex objects with varying properties, such as rigid and flexible components, using biodegradable materials.

4. Enhanced Degradation Control: Researchers are developing techniques to control the degradation rate of bio-based polymers in 3D printing. This innovation allows for the

customization of degradation times, making it possible to create products that break down at specific rates depending on their application.

5. Integration with Smart Technologies: Bio-based 3D printing is being integrated with smart technologies, such as sensors and electronic components. This integration enables the creation of intelligent and interactive products that combine biodegradable materials with advanced functionalities.

Applications of Bio-Based 3D Printing

The application of bio-based 3D printing is vast and varied, with several industries benefiting from the use of biodegradable polymers. Notable applications include:

1. Healthcare: In the medical field, bio-based 3D printing is used to create customized prosthetics, implants, and surgical models. The use of biodegradable polymers ensures that these medical devices are not only tailored to individual needs but also environmentally friendly.

2. Consumer Goods: Bio-based 3D printing is being employed to produce sustainable consumer goods such as packaging, utensils, and home decor items. These products offer an ecofriendly alternative to traditional plastic items and contribute to reducing plastic waste.

3. Automotive and Aerospace: In the automotive and aerospace industries, bio-based 3D printing is used to create lightweight, high-strength components. The use of biodegradable polymers in these applications can help reduce the environmental impact of manufacturing and end-of-life disposal.

4. Education and Research: Educational institutions and research organizations are utilizing bio-based 3D printing to create prototypes, models, and experimental tools. The flexibility and customization offered by 3D printing, combined with the sustainability of biodegradable polymers, support innovative research and learning.

5. Fashion and Textiles: The fashion and textile industries are exploring the use of bio-based 3D printing for creating sustainable clothing and accessories. Bio-based polymers offer the potential to produce unique, customizable designs with a lower environmental footprint.

Regional Insights and Market Trends

The adoption of bio-based 3D printing varies by region, influenced by factors such as technological infrastructure, regulatory support, and market demand:

1. North America: In North America, the use of bio-based 3D printing is driven by strong research and development capabilities and a focus on sustainability. Companies and institutions are investing in bio-based polymers and advanced 3D printing technologies to support environmental goals.

2. Europe: Europe is at the forefront of adopting bio-based 3D printing technologies, supported by stringent environmental regulations and a strong commitment to sustainability. The region's focus on reducing plastic waste and promoting circular economies is driving market growth.

3. Asia-Pacific: The Asia-Pacific region is experiencing rapid growth in bio-based 3D printing, with increasing interest from industries such as healthcare and consumer goods.

Technological advancements and government initiatives are contributing to the expansion of the market.

4. Latin America: In Latin America, the market for bio-based 3D printing is emerging, with growing awareness of sustainability and environmental issues. Regional efforts to promote eco-friendly technologies are supporting the adoption of biodegradable polymers in 3D printing.

5. Middle East and Africa: The market for bio-based 3D printing in the Middle East and Africa is in its early stages, with increasing interest from various sectors. Government initiatives and industry developments are fostering the growth of bio-based 3D printing technologies in the region.

Challenges and Opportunities

While bio-based 3D printing offers numerous benefits, there are challenges to address:

1. Material Cost and Availability: The cost and availability of bio-based polymers can be higher compared to traditional plastics. Continued research and development are needed to reduce costs and increase the availability of these materials.

2. Performance and Scalability: Ensuring consistent performance and scalability of bio-based 3D printing materials can be challenging. Ongoing advancements in material science and printing technologies are required to address these issues.

3. Consumer Acceptance: Educating consumers about the benefits of bio-based 3D printing and biodegradable polymers is essential for market growth. Addressing misconceptions and highlighting the environmental advantages can enhance acceptance and demand.

Despite these challenges, there are significant opportunities:

1. Innovation and R&D: Continued investment in research and development offers opportunities to advance bio-based 3D printing technologies and expand their applications. Innovation in materials and processes can drive market growth and address environmental challenges.

2. Market Expansion: The growing demand for sustainable solutions presents opportunities for market expansion in emerging regions and new applications. The adoption of bio-based 3D printing technologies can contribute to a more sustainable and eco-friendly future.

3. Collaborative Efforts: Collaboration between industry stakeholders, research institutions, and governments can accelerate the development and commercialization of bio-based 3D printing technologies. Partnerships can drive innovation and support market growth.

Conclusion

The bio-based 3D printing market is thriving with technological innovations in biodegradable polymers, offering a promising path towards more sustainable manufacturing and product development. Advances in material science, printing technologies, and application versatility are enhancing the performance and affordability of bio-based 3D printing. As industries continue to prioritize environmental sustainability, bio-based 3D printing is poised to play a crucial role in reducing plastic waste and promoting eco-friendly practices. The future of bio-based 3D printing looks bright, with opportunities for continued innovation and market expansion driving the growth of the biodegradable polymer market.