Solutions

Catalog

ABOUT FLEXQUBE.

FlexQube is a technology company that deliver state of the art material handling equipment through a patented modular concept. The company develops and designs customized solutions for both automated and manually operated intralogistics. Through the company’s automation concept, self-driving robotic carts are offered. The main operations are in North America and Europe. FlexQube was founded in 2010 and has its headquarter in Gothenburg.

We exist to provide an ecosystem of modular material handling Carts, AGVs and AMRs that helps the worlds’ leading manufacturers to future-proof their factories.

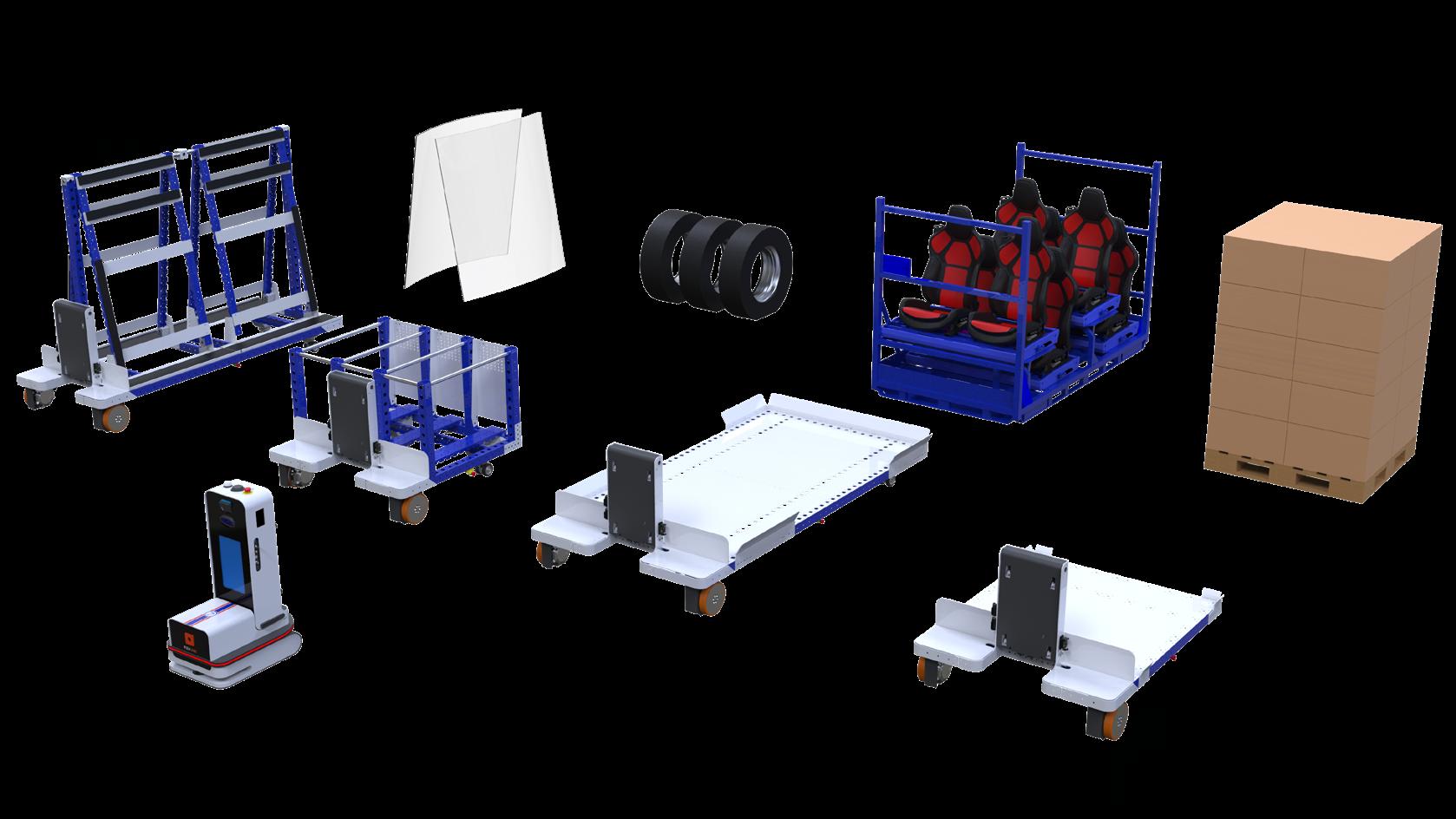

AMR System.

Safe, Smart, Scalable and Successful Material Handling.

DESIGNED FOR THE FUTURE OF MATERIAL HANDLING – we created a unique AMR based on the same flexibility as in all of our FlexQube carts to provide an autonomous solution that adapts to your operational needs.

This is a “one robot/multi-carrier” concept which means that one single Navigator AMR can couple to an ecosystem of different motorized Load Carriers. With the innovative and patented Navigator AMR System, FlexQube can offer customers an automated transport solution to move materials of different size, shape and weight based on the design of the Load Carrier.

T he FlexQube AMR System is a smart choice for streamlining internal logistics, improving workflows and ergonomics.

T he FlexQube AMR System is a safe investment and a people friendly concept that will future-proof your factory for years to come.

The FlexQube AMR System has a standardized interface and can easily be adapted to your factory’s varying needs.

The FlexQube AMR System is easy to implement, offers a hassle-free environment and has great ROI compared to other options.

Automating Transport of Seats and Doors to Cab Assembly Line with an ROI Below 2 Years! Page. 60

INTELLIGENT NAVIGATION ROBOT.

By developing the principle of “one robot for multiple carriers”, we’ve created the flexibility to move anything anywhere, which is critical in today’s complex manufacturing environment.

INOVATIVE SAFETY

The AMR is is detecting the footprint of the Load Carrier in a PLd rated way, and automatically adapts the safety field around the Load Carrier.

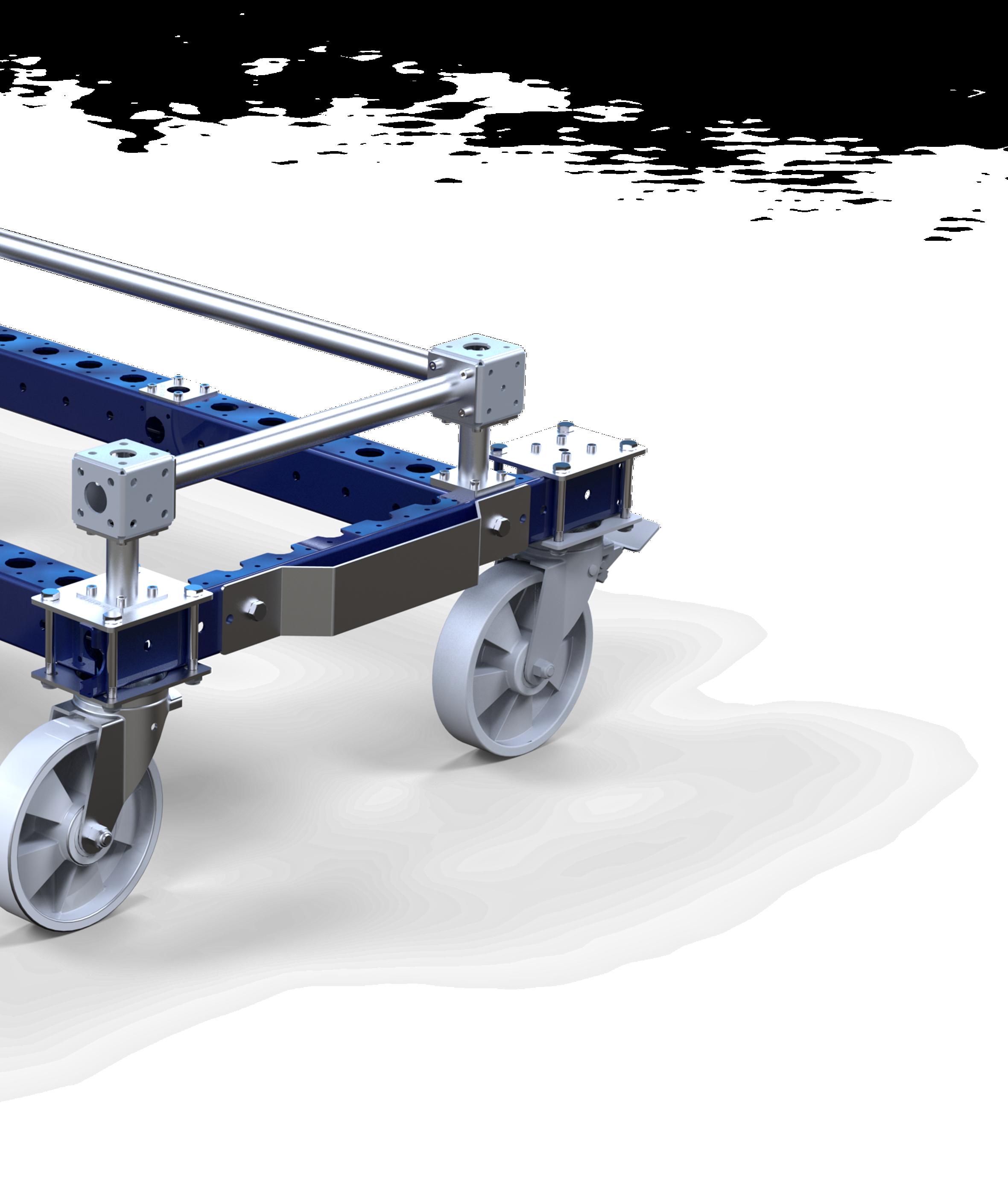

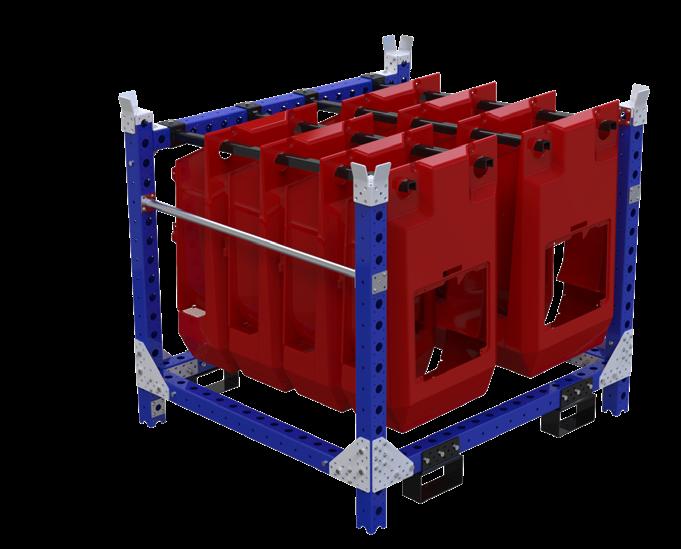

ROLLER LOAD CARRIER

This heavy-duty system is designed to autonomously move pallets and connect to a roller rack at the drop-off and pickup area. This system can move materials weighing up to 3300 lbs / 1500kg kg.

Q-100-8194

TOWING LOAD CARRIER

This heavy-duty system is designed to autonomously move carts that are equipped with a tow bar in manufacturing and warehouse environments. This system can move materials up to 5500 lbs / 2500 kg.

Q-100-8145

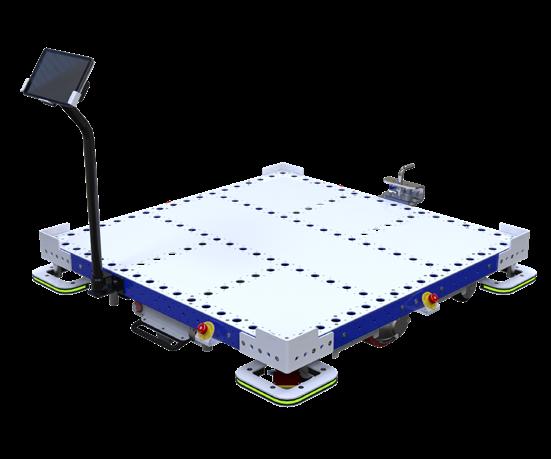

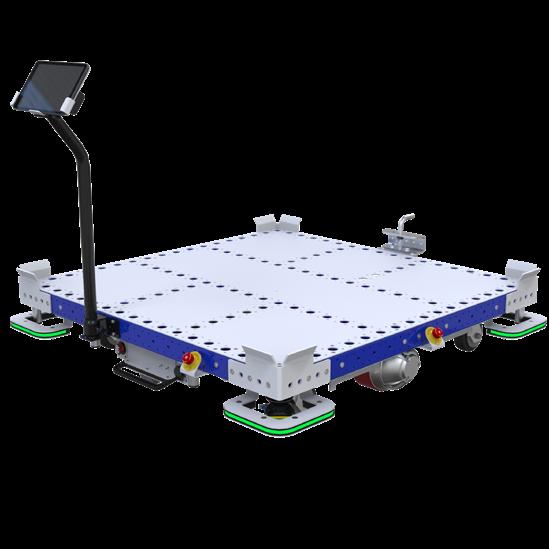

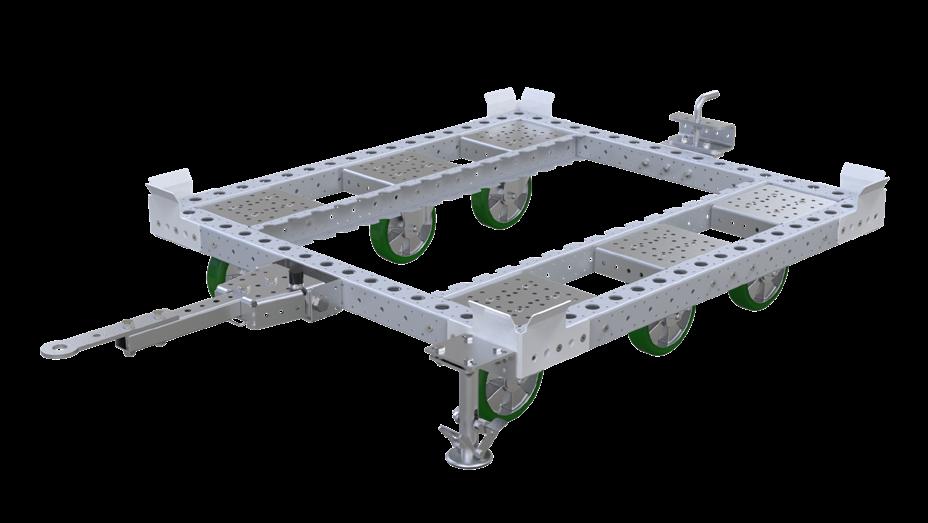

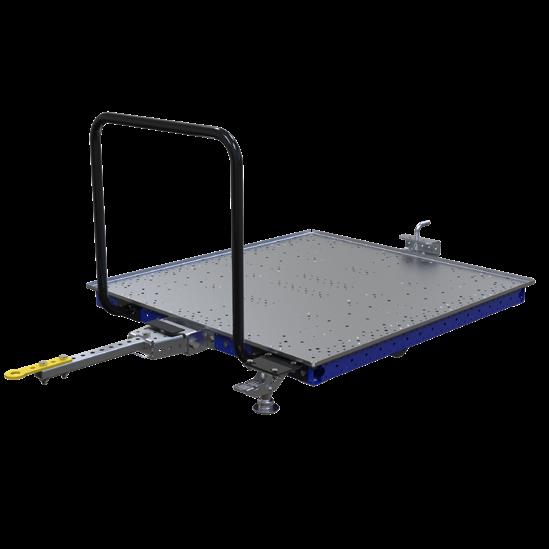

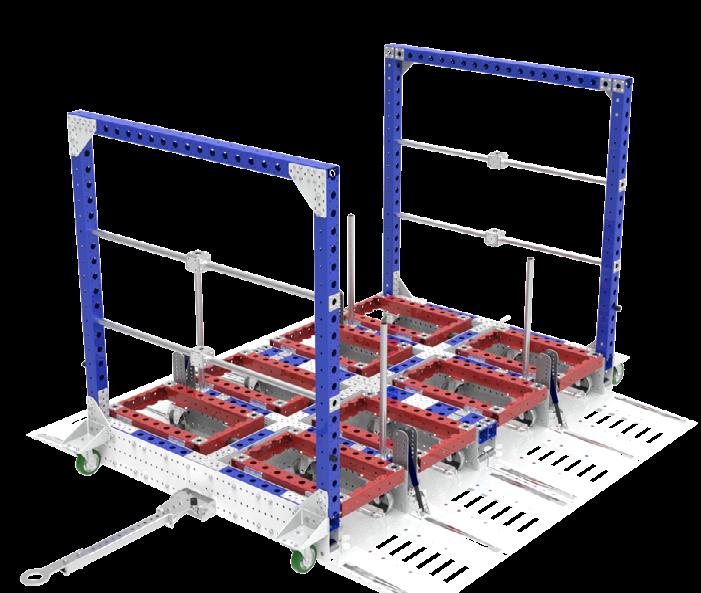

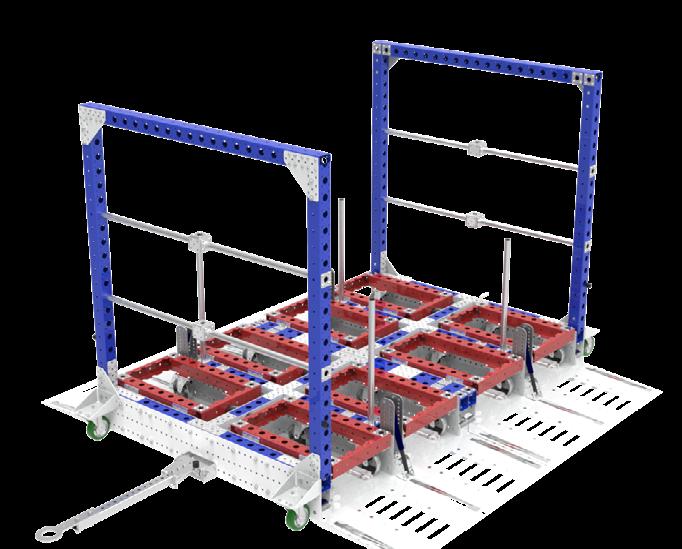

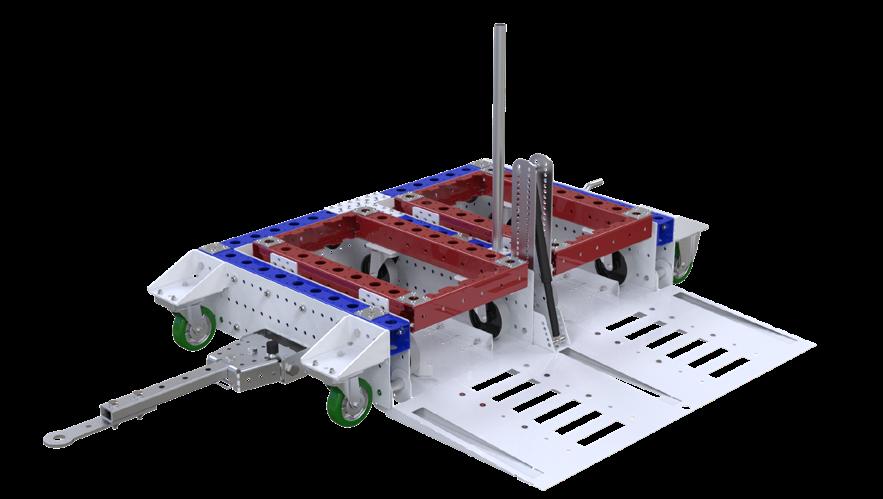

FLATBED LOAD CARRIER

This heavy-duty system autonomously moves pallets, racks, and material kits in warehouses and factories, with load carriers ranging from 910 × 840 mm to 2520 × 2520 mm.

Q-100-6673

1. Navigator AMR

2. Load Carriers 3. Materials

A standardized coupling interface lets you start small and expand as your operations grow, without needing to invest in multiple Navigator AMRs. Modular Load Carriers offer flexibility, making it easy and cost-effective to reconfigure as your needs change.

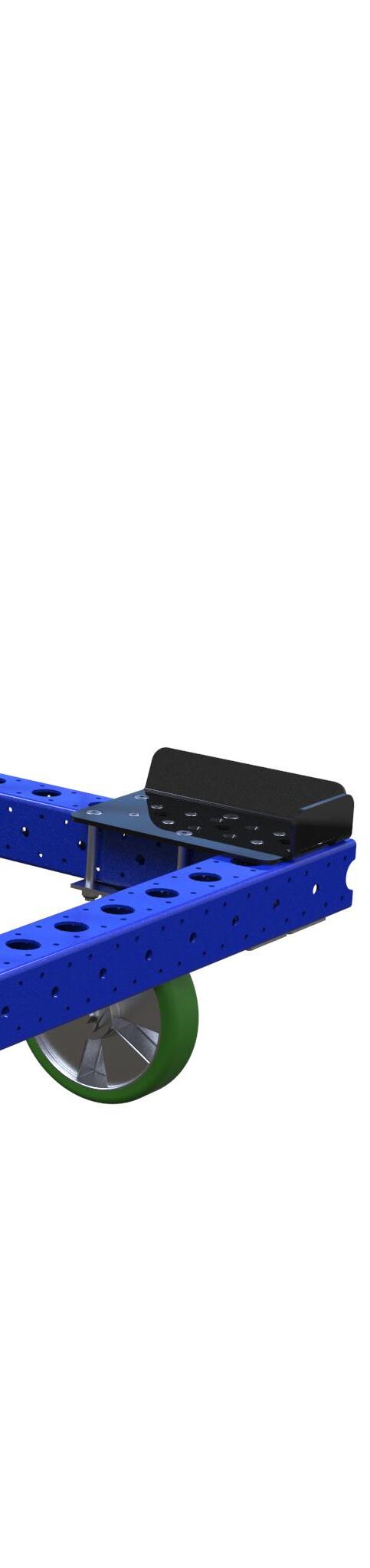

STANDARDIZED COUPLING INTERFACE

- FLEXQUBE PLAY

Through established partnerships with the leading technology providers in the industry, we have developed a safe and quick coupling interface, called FlexQubePLAY. When coupled, the AMR Navigator is raised from the ground. Power and data is transferred from the Navigator AMR to the motorized Load Carriers, which transports the materials while being navigated by the AMR.

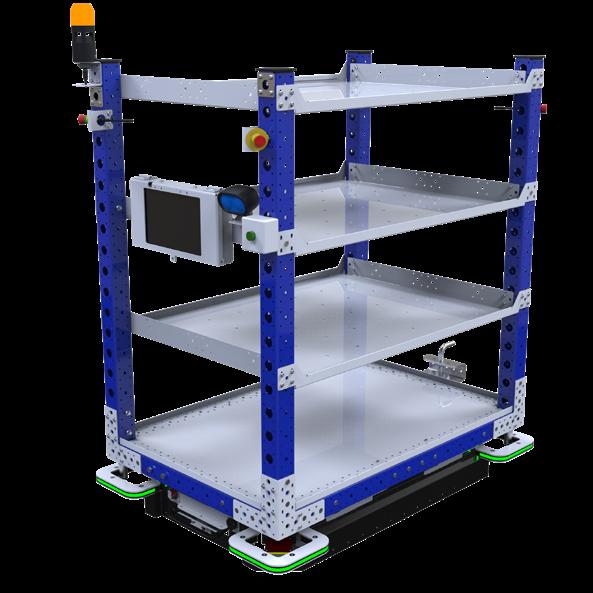

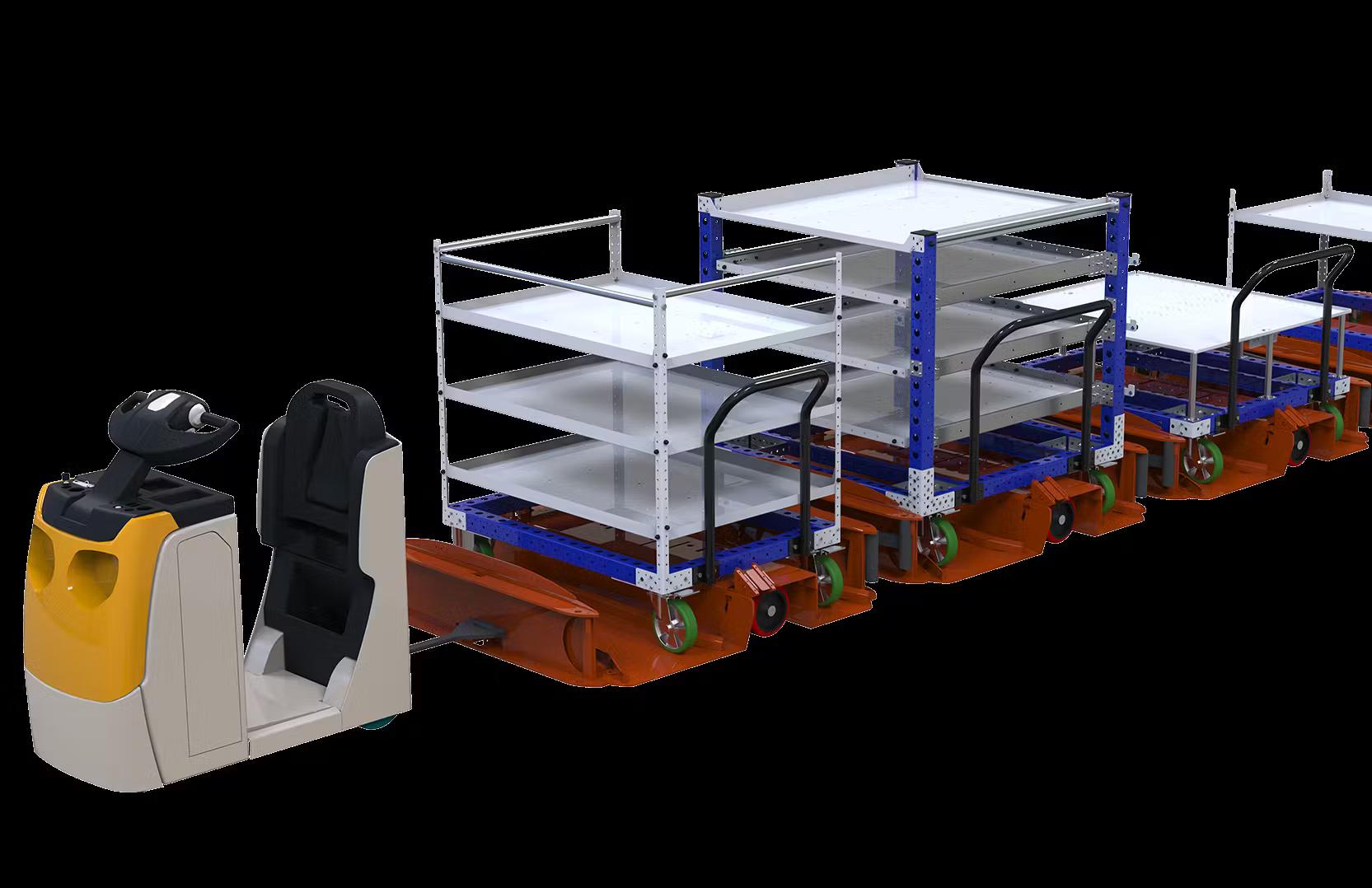

AGV System.

The World’s Most User-Friendly Automation.

OUR GOAL WITH THE AGV IS CLEAR – to provide manufacturers with the most user-friendly automation solution for internal logistics. With our flexible and modular concept, you’ll never have to compromise on your requirements.

Flexibility is key to modern factories and warehouses. FlexQube AGV System is an internal logistics automation solution that makes it simple. FlexQube AGV is a standalone system that offers unlimited customizable cart variations, and that can be up and running within 60 minutes. Designed to accommodate you, your processes and operators, with no need to change your existing infrastructure or material handling fleet, FlexQube AGV is automation you’re ready for.

Simple Effective Flexible

NO COST FOR INFRASTRUCTURE

A low threshold to start with an AGV and scale it depending on needs.

FROM BOX TO USE IN UNDER 30 MIN

Automated recordings of routes help make a quick and easy implementation possible.

MINIMAL TRAINING REQUIRED

A self-instructing digital interface with the ability to make local language adaptations.

WORKS WITHOUT WIFI

All data is stored locally in the AGV and is updated via a 4G connection.

REDUCES MANUAL OPERATING

AGV can replace trucks and trolleys, trains and manual driving, and can work multiple shifts.

ATTRACTIVE COST LEVELS

Focus on the development of the AGV has been to find the optimal balance between cost and transportation gain.

AN EASY PURCHASE MODEL

Leasing with fixed monthly costs and free software updates, but also multiple other purchasing solutions will be offered.

A UNIQUE SIZE RANGE

The AGV can be designed with a length of up to 2.5 metres.

CASE STUDIES

FLEXIBLE TO SELECT A TOP STRUCTURE

The AGV can be adapted to various applications by complementing it with a top structure built using the FlexQube concept.

CAN BE REBUILT AS

NEEDED

The AGV can be updated or rebuilt to a different size should the need occur.

A SECURE FUTURE

The AGV is designed based on a modular architecture, which makes it possible to upgrade functionality and performance.

Eliminating

“We got started with a future factory.”

- Kim Howe, Logistics Manager, Siemens Mobility, Georgia, USA.

Mitchell Plastics prioritizes safety with FlexQube AGV

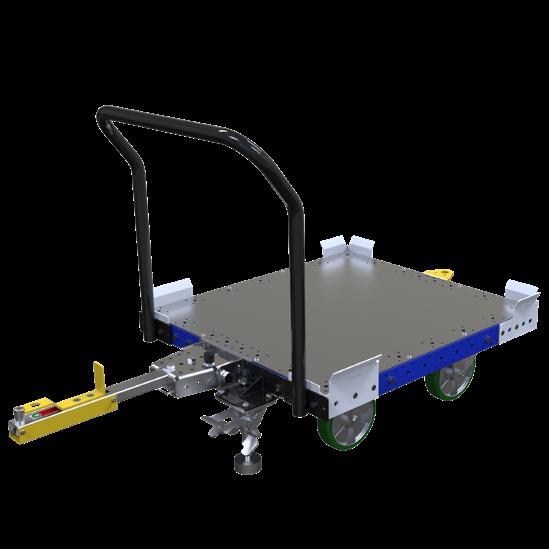

AGV SYSTEM.

The FlexQube AGV is a smart and motorised FlexQube cart. They are designed to make automating your facility a simple and stress-free process. Motors, a battery and cameras are added to a regular FlexQube cart. The AGV is available in any size and shape.

PALLET AGV

50 x 50 inch / 1260 x 1260 mm

Q-100-6510

2,200 lbs / 1000 kg

Laser Scanners Creates a 360º view with no blind spots LOAD CAPACITY

CAPACITY 4,400 lbs / 2000 kg

Hokuyo

4x Emergency Stops

Optical Camera for Line-follow Navigation (Located under the AGV) Tablet Battery

THE AGV CONCEPT - offers a fully customizable AGV with Vision-Based Navigation and 360° Safety.

Navigation: Vision Based Line

Follow

Charge Time: 2 h

Safety: 360º

Customization: You decide the size and top structure of the AGV.

AGV SYSTEM

TOWING PALLET AGV

50 x 50 inch / 1260 x 1260 mm

Q-100-4694

A customer favourite due to it’s user-friendliness and high tow capacity of 2,200 lbs / 1000 kg.

FLAT SHELF AGV

50 x 33 inch / 1260 x 840 mm

Q-100-8109

Flat-shelf AGV designed to tugg flexQube mechanical carts in a tugger train solution.

AGV CARTS

TOWING PALLET AGV

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Transportation: Flatbed, Tugger

• Payload: Pallets, Containers

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Transportation: Flatbed, Tugger

• Payload: Pallets, Containers

• Size: 50 x 41 inch / 1260 x 1050 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Transportation: Conveyor

• Payload: Pallets, Containers

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 2,200 lbs /1000 kg

• Transportation: Flatbed, Tugger

• Payload: Pallets, Containers

Product Information:

A customer favourite due to it’s user-friendliness and high tow capacity of 2,2200 lbs / 1000 kg.

Product Information:

Additional safety feature with a lamp that flashes while the AGV is in motion.

Product Information:

Easy material transfer from and to roller rack. The AGV transport materials to drop-off station where operator retreive the pallet. Automatic rollers are also available.

Product Information:

Base structure implemented at Signify facility to transport bins and cartboards as well as tow mechanical carts in a tugger train. To see case study, go to page 62.

Product Information:

Flat-shelf AGV designed to transport lose materials and to be integrated in a tugger train solution together with FlexQubes mechanical carts.

• Size: 50 x 33 inch / 1260 x 840 mm

• Load Capacity: 1,000 lbs / 450 kg

• Transportation: Shelf, Tugger

• Payload: Boxes, Totes, Misc Parts

Product Information:

Three-level roller shelf AGV designed for transporting loose components in a FIFO setup. Each shelf is angled to accommodate specific drop-off and pickup points.

• Size: 50 x 33 inch / 1260 x 840 mm

• Load Capacity: 1,000 lbs / 450 kg

• Transportation: Flow, Tugger

• Payload: Boxes, Totes, Misc Parts

Product Information:

Mother-daughter cart designed to transport two daughter carts loaded with material. Designed for Q-100-4123 but can be customized for other carts.

• Size: 36 x 33 inch / 2550 x 1470 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Transportation: Mother-Daughter

• Payload: Daughter Carts

Product Information:

AGV with a raised top structure designed for the safe transport of fully loaded pallets. Equipped with a drop pin, it can also tow mechanical carts in a tugger train configuration.

• Size: 36 x 33 inch / 910 x 840 mm

• Load Capacity: 1,000 lbs / 450 kg

• Transportation: Flatbed, Tugger

• Payload: Pallets

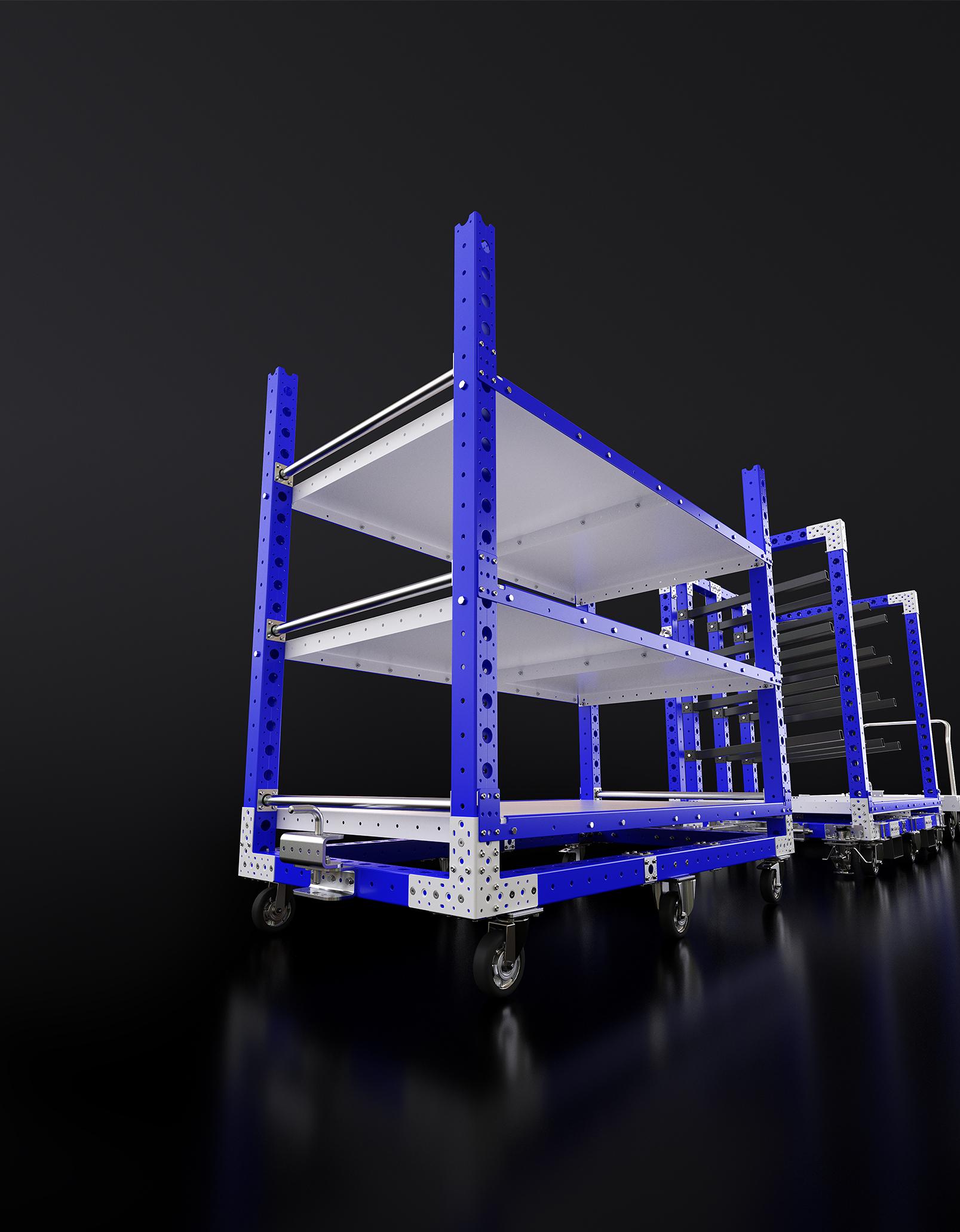

CART System.

The game-changer in flexible material handling.

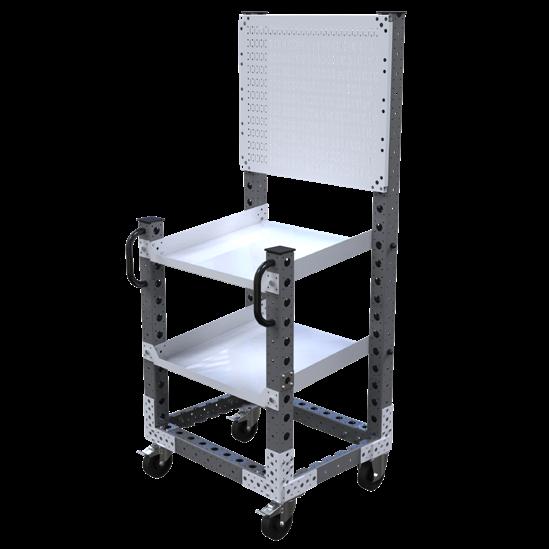

THE WORLD’S FIRST MODULAR MECHANICAL CART SYSTEM – is based on standardized components, the carts can be customized for both transportation and presentation of material, improving work-flows, ergonomics and productivity at any assembly or picking station.

The carts can be taken apart, re-assembled and adjusted as needs change, offering a unique level of flexibility that boosts efficiency and saves time and money. Meet FlexQube Cart System, the game-changer in material handling.

LOOK FOR THIS MARK TO FIND OUR CUSTOMERS FAVOURITE SOLUTIONS

Durable Customizable Flexible

BUILT TO LAST

Engineered with premium, industrialgrade steel, FlexQube carts stand up to heavy loads and daily wear — no compromises, just long-lasting performance.

PROVEN PERFORMANCE

From busy assembly lines to demanding warehouses across manufacturing, automotive, and logistics industries, FlexQube carts consistently deliver consistent, maintenance-free performance you can count on — day after day.

MODULAR DESIGN

Based on standardized components, the carts can be customized for both transportation and presentation of material, improving work-flows, ergonomics and productivity at any assembly or picking station.

TAILORED FOR YOUR NEEDS

From heavy-duty tugger carts to kitting solutions, we create the perfect design for your material flow to solve your operational challenges.

EASY TO ADAPT AND RECONFIGURE

The carts can be taken apart, re-assembled and adjusted as needs change, offering a unique level of flexibility that boosts efficiency and saves time and money.

GROW WITH AUTOMATION

Designed for the future of automation — FlexQube carts evolve with your technology, adapting seamlessly as your automated systems and intralogistics grow.

CASE STUDIES

PROTERRA

Proterra built two new plants with a focus on flexible material handling.

EBERSPÄCHER

“The carts have been a huge improvement when it comes to ergonomics”

- Maritza Zegovia, Eberspächer.

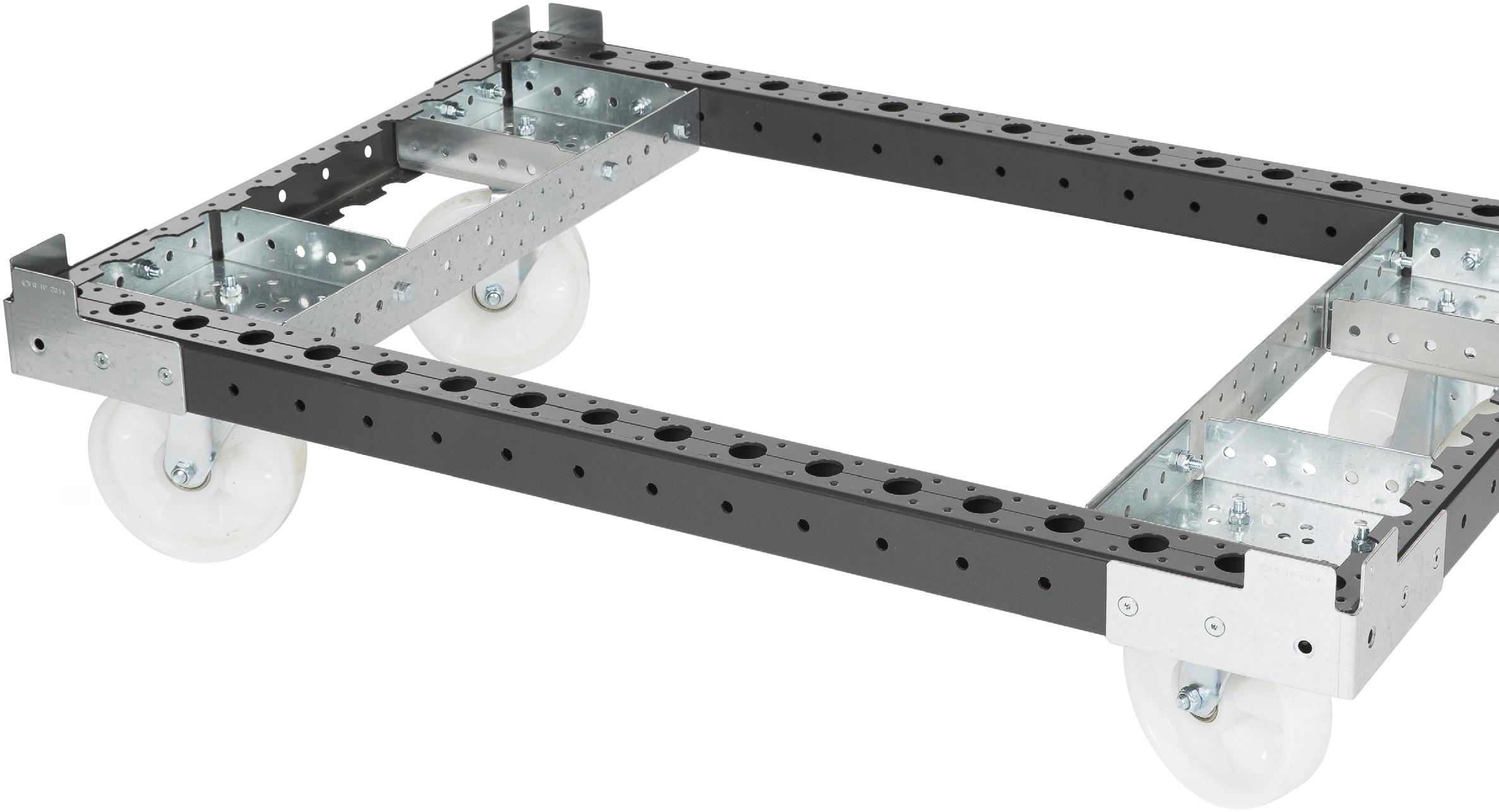

The Basics of FlexQube Carts.

FlexQube carts can easily be optimized for the transportation of material and components, or for both the transportation and presentation of the material to the operator at the assembly station.

BASIC DESIGN

The basic design of a FlexQube cart is a bottom frame with a top structure attached to it. The bottom frame is usually equipped with a set of casters and swivels, handlebars and tow bars, and a brake.

Each of these attachments are specified and located optimally to suit the actual application and the ergonomic requirements. The dimensions of the bottom frame are adapted to your actual needs.

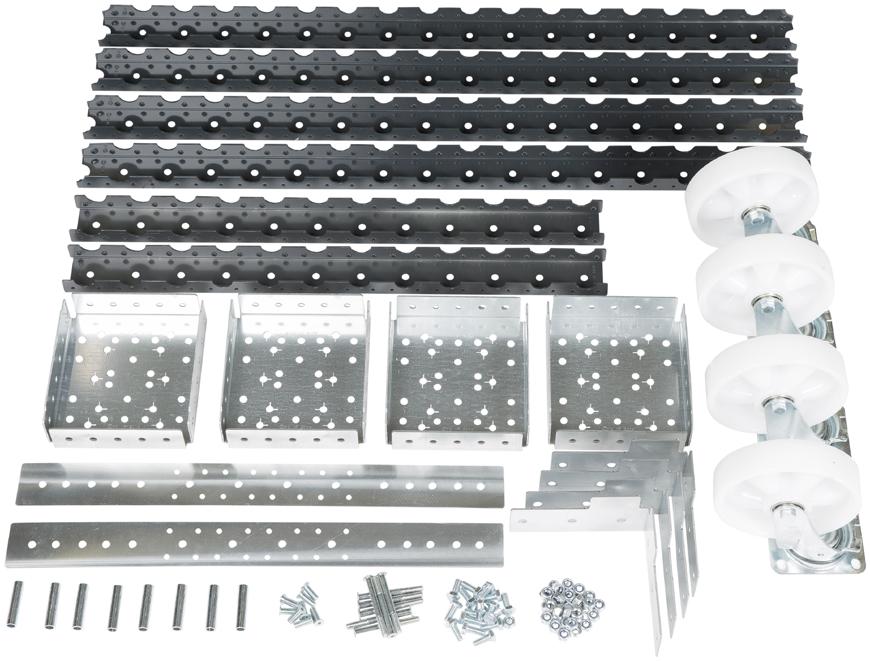

This is a standard collection of basic FlexQube components. This includes the FlexBeam, casters, attachments, fasteners and bolts.

carts with built-in

CUSTOMIZATION

The top structure is optimized for the type of cargo to be carried. It can be anything from a solid steel flatbed for heavy pallets, to an advanced rack for a modelspecific assembly kit.

Check out our Solutions Library™ for inspiration! www.flexqube.com

Ted Tackeberry, Carcoustics

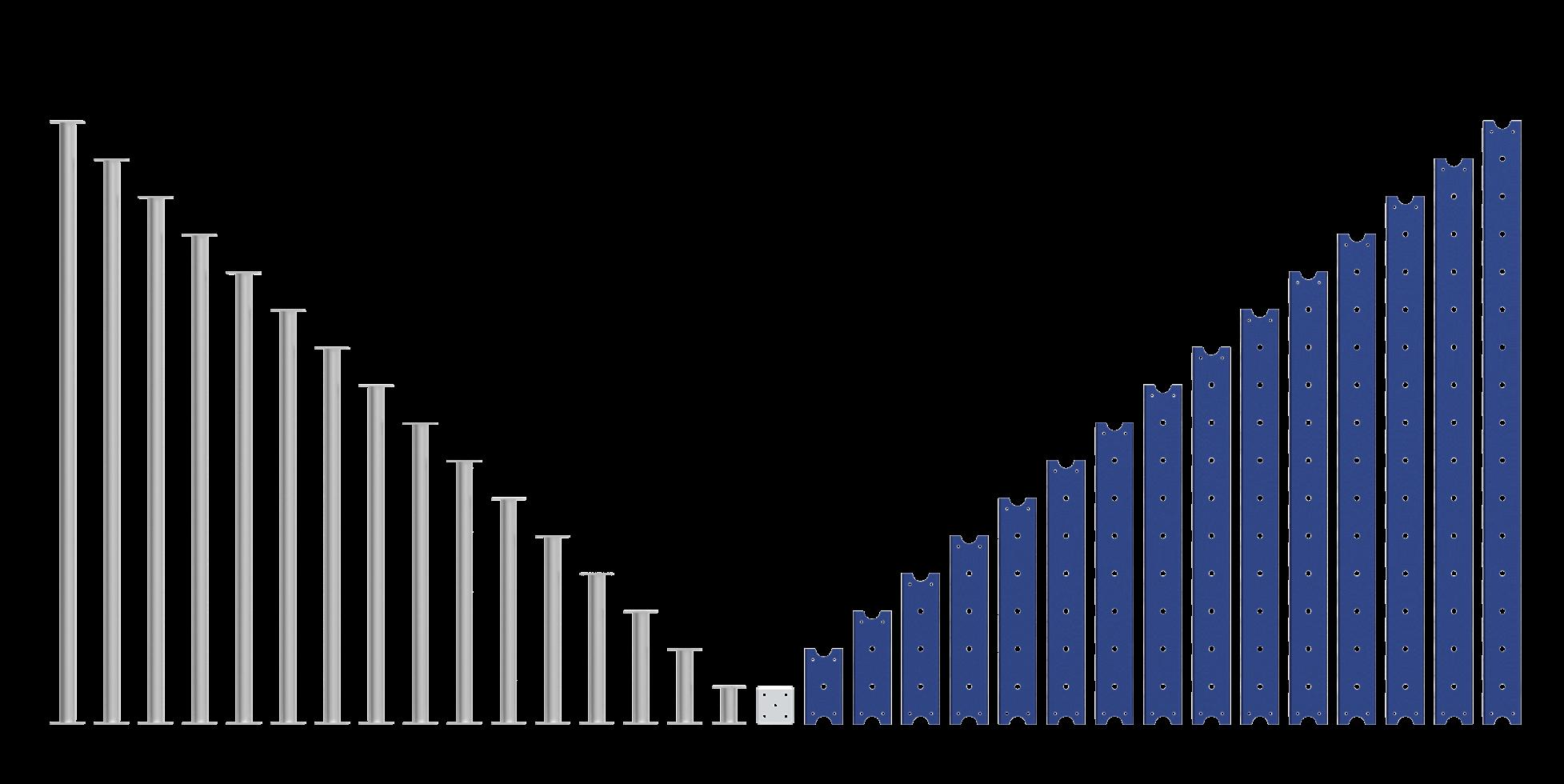

The FlexQube standard module. Seven

says it all.

7CM DESIGN BASE

The FlexQube system is based on the number 7. All FlexTubes and FlexBeams come in length intervals of 7cm and the distance between interfaces is 7cm. Two FlexBeams create a 7×7cm square cross-section and two FlexQubes form a 7×7×7cm cube. FlexPlates and FlexQubes have the same interface and are therefore easily placed anywhere on FlexBeams and FlexTubes to connect them.

FLEXBEAM ™

The standard interface and intervals enable FlexQube to have a very efficient and quick design process, where the lead time from customer requirements to design draft can be cut down significantly.

STANDARD FASTENERS

– NO SPECIAL TOOLS NEEDED

Due to the homogeneous interface, virtually all connections are made using M6 bolts. The FlexBeam also has an M10-hole for heavy-duty connections and thus M10-bolts and nuts can also be used. This means that all connections can be done with a small number of tools.

M6

FLEXQUBE ®

FLEXPLATE ™

FLEXTUBE ™

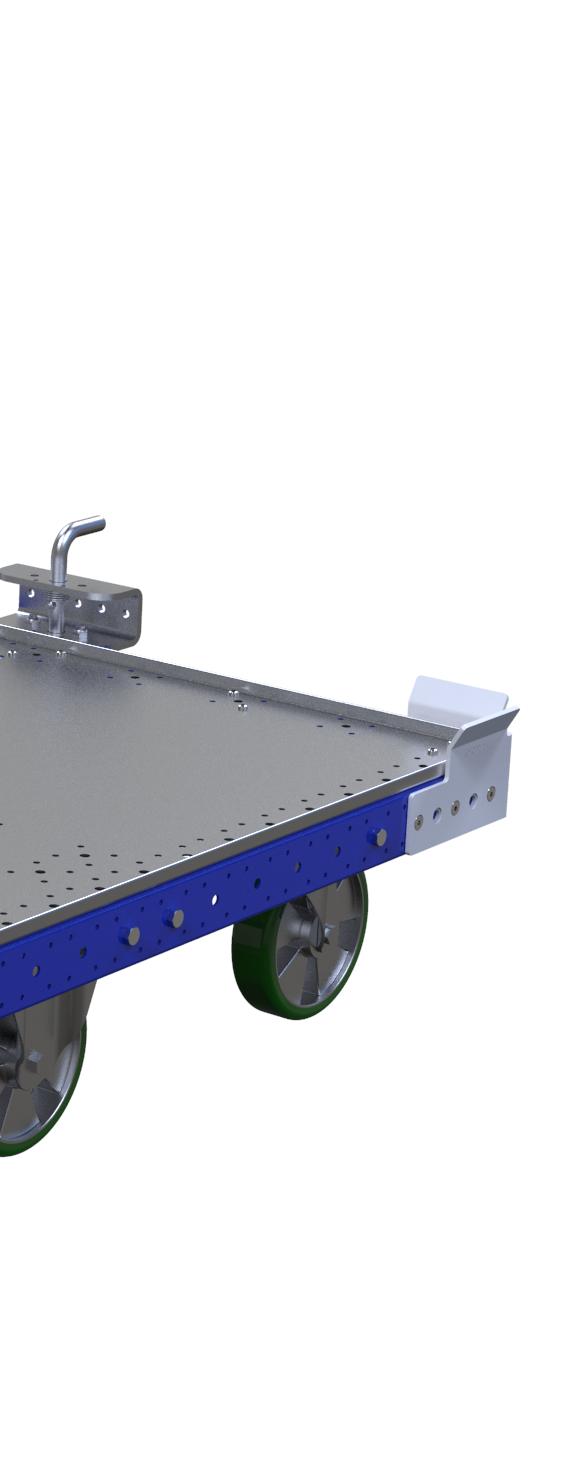

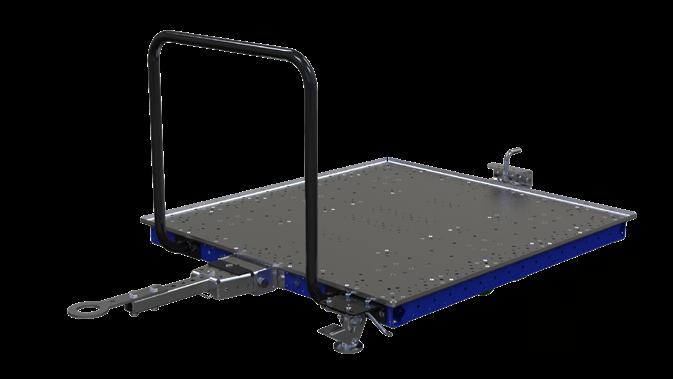

PALLET TUGGER CARTS.

These industrial pallet carts for containers or pallets, are equipped with heavy-duty casters and can move up to 4,500 lbs / 2000 kg. They can be easily fitted into a tugger train system. The userfriendliness is further increased by the removable handle bar with floor lock brake. All standard pallet carts can be adapted to a tugger cart simply adding a tow bar. Each solution can be customized to suit your needs.

LOAD CAPACITY

2,200 lbs / 1000 kg

Safe sorage with floor lock brake

Heavy-duty polyurethane casters for optimal tracking

PALLET TUGGER CARTS

TUGGER CART

47 x 50 ‘‘ / 1190 x 1260 mm

Q-100-1444

This cart can move five carts in a train, with a max load capacity of 2,200 lbs / 1000 kg per cart.

LOW RIDER TUGGER CART

47 x 44 ‘‘ / 1190 x 1120 mm

Q-100-0595

This cart is built for minimal loading clearance. It can move four carts in a tugger train, with a max load capacity of 1,000 lbs / 450 kg per cart.

PALLET TUGGER CARTS

PALLET TUGGER CART

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Tugger Capacity: 4 in train

• Tow Bar: Tongue and Hitch

• Payload: Pallets, Containers

TUGGER CART

• Size: 47 x 50 inch / 1190 x 1260 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Tugger Capacity: 5 in train

• Tow Bar: Tongue and Hitch

• Payload: Pallets, Containers

LOW RIDER TUGGER CART

• Size: 47 x 44 inch / 1190 x 1120 mm

• Load Capacity: 1,000 lbs / 450 kg

• Tugger Capacity: 4 in train

• Tow Bar: Tongue and Hitch

• Payload: Pallets, Containers

LOW RIDER PALLET CART

• Size: 46 x 49 inch / 1168 x 1245mm

• Load Capacity: 1,000 lbs / 450 kg

• Tugger Capacity: 4 in train

• Tow Bar: Tongue and Hitch

• Payload: Pallets, Containers

Product Information:

Our most popular cart in the North American market, valued for its durability, simplicity, and easy manual or tugger-train transport.

Product Information:

Pallet tugger cart designed to transport one or more pallets simultaneously. Equipped with raised corner plates to secure the pallet when being transported.

Product Information:

Low rider cart designed to streamline the order picking process from warehouse to assembly or production area. The low deck height makes it easier to load and unload materials.

Product Information:

Low rider cart designed to streamline the order picking process from warehouse to assembly or production area. The low deck height makes it easier to load and unload materials.

Product Information:

This picking cart is designed to streamline the order picking process from warehouse to assembly or production area. The low deck height makes it easier to load and unload materials.

PICKING CART

PALLET TUGGER CARTS

• Size: 47 x 77 inch / 1190 x 1960 mm

• Load Capacity: 1,500 lbs / 700 kg

• Tugger Capacity: 5 in train

• Tow Bar: Tongue and Hitch

• Payload: Pallets, Misc Parts

TUGGER CART

Product Information:

Standard pallet tugger cart designed with to be transported in a tugger train with excellent tracking properties and silent movement. Equipped with raised corner plates to secure the pallet when being transported.

• Size: 33 x 50 inch / 840 x 1260 mm

• Load Capacity: 1,110 lbs / 500 kg

• Tugger Capacity: 5 in train

• Tow Bar: Tongue and Hitch

• Payload: Pallets

PALLET TUGGER CART

Product Information:

Pallet tugger cart designed with to be transported in a tugger train with excellent tracking properties and silent movement. Equipped with raised corner plates to secure the pallet when being transported.

• Size: 36 x 33 inch / 910 x 840 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Tugger Capacity: 4 in train

• Tow Bar: Foot Release

• Payload: Pallets

PALLET TUGGER CART

Product Information:

Pallet tugger cart designed with to be transported in a tugger train with excellent tracking properties and silent movement.

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Tugger Capacity: 3 in train

• Tow Bar: Foot Release

• Payload: Pallets, Containers

PALLET CARTS.

Industrial pallet carts are built for heavy-duty transport of US pallets (48x45 or 48x48 ) and EU standard pallets or containers and can move materials up to 3000 lbs / 1360 kg. Available with or without a steel deck, they can include ergonomic handlebars, floor brakes, and fixed or swivel casters. The FlexQube system lets you customize carts to your exact needs, and many models are compatible with the STILL LiftRunner Tugger Train System.

Any shape and design with e.g. steel decks, corner guides and colors

Compatible with B-frame in the STILL LiftRunner Tugger Train System

By adding a towbar attachments, all carts can be fitted in a tugger train

Heavy-duty polyurethane casters for optimal tracking

PALLET CARTS

PALLET CART

50 x 50 ‘‘ / 1260 x 1260 mm

Q-100-1079

This extra heavy-duty cart comes without a steel deck, and has a max load capacity of 3,000 lbs / 1360 kg.

FLAT DECK CART

50 x 50 ‘’ / 1260 x 1260 mm

Q-100-2339

This cart is built to be integrated with a LiftRunner B-frame, with a max load capacity of 2,500 lbs / 1137 kg.

PALLET CARTS

• Size: 50 x 33 inch / 1260 x 840 mm

• Load Capacity: 1,100 lbs / 500 kg

• Transportation: Manual, LiftRunner

• Payload: Pallets

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Transportation: Manual, LiftRunner

• Payload: Pallets, Containers

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 2,500 lbs / 1137 kg

• Transportation: Manual, LiftRunner

• Payload: Pallets, Containers

• Size: 50 x 50 inch / 1260 x 1260mm

• Load Capacity: 2,200 lbs / 1000 kg

• Transportation: Manual, LiftRunner

• Payload: Pallets, Containers

Product Information:

Standard pallet cart without steel flat deck designed to transport pallets in a STILL LiftRunner B-Frame or manually. Designed with raised corner plates to secure the pallet when being transported.

Product Information:

Pallet cart without steel flat deck designed to transport pallets in a STILL LiftRunner B-Frame or manually. Designed with raised corner plates to secure the pallet when being transported.

Product Information:

Pallet cart with steel flat deck designed to transport pallets in a STILL LiftRunner B-Frame or manually. Designed with raised corner plates to secure the pallet when being transported.

Product Information:

Sturdy pallet cart designed to transport heavy pallets in a STILL LiftRunner Frame or manually. Designed with raised corner plates to secure the pallet when being transported.

PALLET CARTS

PALLET CART

Product Information:

Sturdy pallet cart designed to transport heavy pallets in a STILL LiftRunner Frame or manually. Designed with raised corner plates to secure the pallet when being transported, and rubber bumbers preventing damage when parked.

Product Information:

Sturdy pallet cart designed to transport heavy pallets in a STILL LiftRunner Frame or manually. Designed with a steel flatbed, and removable handlebar.

• Size:

50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 3,000 lbs / 1360 kg

• Transportation: Manual, LiftRunner

• Payload: Pallets, Containers

PALLET CART

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 2,500 lbs / 1135 kg

• Transportation: Manual, LIftRunner

• Payload: Pallets, Containers

Product Information:

Standard pallet cart designed to transport pallets in a STILL LiftRunner Frame or manually. Designed with raised corner plates to secure the pallet when being transported.

Product Information:

Pallet cart designed to transport pallets in a STILL LiftRunner Frame or manually. Designed with raised corner plates to secure the pallet when being transported.

• Size: 50 x 41 inch / 1260 x 1050 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Transportation: Manual, LiftRunner

• Payload: Pallets, Containers

PALLET CART PALLET CART

• Size: 50 x 50 inch / 840 x 770 mm

• Load Capacity: 1,000 lbs / 450 kg

• Transportation: Manual, LiftRunner

• Payload: Pallets, Containers

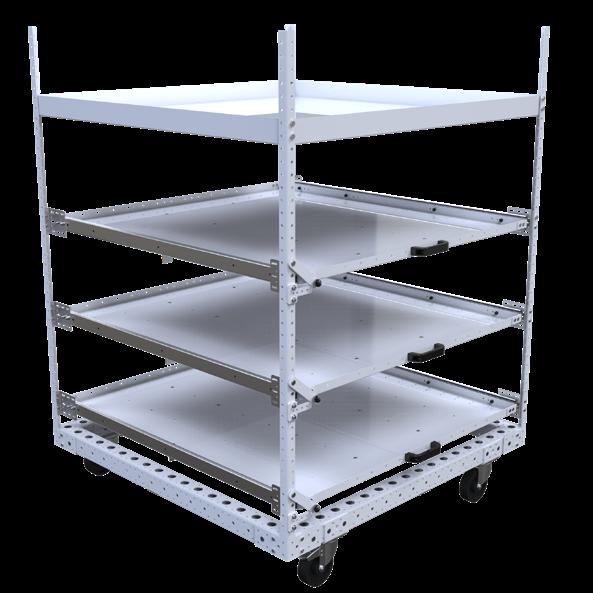

FLAT SHELF CARTS.

The shelf cart is a versatile solution for transporting and presenting different materials. Thanks to its modular design, shelves can be added, removed or adjusted in position directly on-site without hassle. Choose between flat, flow, or roller shelves depending on your need, and adjust the height for maximum operator comfort. The cart can also be equipped with wire mesh sides to keep parts secure, ergonomic handle bars, different towbar options and a floor brake are also available to make handling safe and efficient.

SHELF CART

25 x 50 inch / 630 x 1260 mm

LOAD CAPACITY

600 lbs / 300 kg

Adjust position of shelves

Q-100-2214 polyurethane casters for optimal tracking

All standard shelf carts can be integrated into a tugger train system by adding a tow bar

Shelves can be added, removed or adjusted in position directly on-site without hassle

Several standard size shelf carts available with short lead time

FLAT SHELF CARTS

FLAT SHELF CART

63 x 33 inch / 1600 x 840 mm

Q-100-1424

This sturdy three-level flat shelf cart is designed to move heavy materials up to 220 lbs / 100 kg per shelf.

“KLT” SHELF CART

55 x 25 inch / 1400 x 630 mm

Q-100-8306

This cart is designed to move manually or in a tugger train, with a max load capacity of 1,102 lbs / 500 kg.

FLAT SHELF CARTS

• Size:

25 x 50 inch / 630 x 1260 mm

• Load Capacity:

600 lbs / 300 kg

• Load Capacity per Shelf: 220 lbs / 100 kg

• Payload: Bins, Boxes, Misc parts, Totes

Product Information:

Tall shelf cart for material presentation, featuring three flat shelves and an angled top shelf - all with rubber protection. Transported manually or in a tugger train.

• Size: 63 x 28 inch / 1610 x 700 mm

• Load Capacity:

375 lbs / 170 kg

• Load Capacity per Shelf:

220 lbs / 100 kg

• Payload: Bins, Boxes, Totes

• Size: 63 x 28 inch / 1610 x 700 mm

• Load Capacity: 375 lbs / 170 kg

• Load Capacity per Shelf: 220 lbs / 100 kg

• Payload: Bins, Boxes, Totes

• Size: 69 x 36 inch / 1750 x 910 mm

• Load Capacity: 1,000 lbs / 452 kg

• Load Capacity per Shelf: 220 lbs / 100 kg

• Payload: Bins, Boxes, Misc parts, Totes

Product Information:

Three-level shelf cart with raised edges to ensure materials do not fall during transportaion.

Product Information:

Three-level shelf cart designed with forklift pockets and wire mesh for material protection.

Product Information:

Four-level shelf cart designed with forklift pockets in the middle of the cart.

Product Information:

Three-level shelf cart designed to be transported in a tugger train solution.

FLAT SHELF CART

• Size:

63 x 33 inch / 1600 x 840 mm

• Load Capacity: 660 lbs / 300 kg

• Load Capacity per Shelf: 220 lbs / 100 kg

• Payload: Bins, Boxes, Totes

SHELF CART

Product Info:

Product Information:

Sturdy three-level shelf cart designed to be transported in a tugger train solution.

• Size:

55 x 41 inch / 1400 x 1040 mm

• Load Capacity: 992 lbs / 450 kg

• Load Capacity per Shelf: 331 lbs / 150 kg

• Payload: Bins, Boxes, Misc parts, Totes

FLAT SHELF CARTS

Product Information:

Sturdy four-level shelf cart designed for heavy materials to be transported in a tugger train solution. The shelves can be adjusted in position and features raised edges to ensure materials do not fall during transportaion.

• Size: 55 x 33 inch / 1400 x 840 mm

• Load Capacity: 1,102 lbs / 500 kg

• Load Capacity per Shelf: 220 lbs / 100 kg

• Payload: Bins, Boxes, Totes

Product Information:

Sturdy four-level shelf cart designed for heavy materials to be transported in a tugger train solution. The shelves can be adjusted in position and features raised edges to ensure materials do not fall during transportaion.

• Size: 55 x 25 inch / 1400 x 630 mm

• Load Capacity: 1,102 lbs / 500 kg

• Load Capacity per Shelf: 220 lbs / 100 kg

• Payload: Bins, Boxes, Totes

EXTENDABLE SHELF CARTS.

For increased convenience and accessibility, extendable shelves can be added to almost any FlexQube cart configuration. The robust metal shelves can be extended 100 % from the base and feature a handle bar and a lock mechanism for increased safety during transportation. A telescopic shelf cart is used when you want to store lots of parts tightly packed and yet want an ergonomic and easy reach.

EXTENDABLE SHELF CART

33 x 40 inch / 840 x 980 mm

Q-100-3101

Steel or composite material shelves

All carts can easily be integrated into a tugger train system by adding a tow bar

LOAD CAPACITY

750 lbs / 340 kg

Adjust position of shelves

Extendable shelves for ergonomic and efficient access to parts

EXTENDABLE SHELF CARTS

EXTENDABLE SHELF CART

36 x 55 inch / 910 x 1400 mm

Q-100-2005

This five-level flat shelf cart with extendable shelves and dividers is designed to move materials up to 100 lbs / 45 kg per shelf.

EXTENDABLE SHELF CART

50 x 50 inch / 1260 x 1260 mm

Q-100-5929

This cart designed with one fixed and three extendable shelves can move materials up to 200 lbs / 90 kg per shelf.

Shelves locked in place by easy lock function.

EXTENDABLE SHELF CARTS

• Size:

33 x 40 inch / 840 x 980 mm

• Load Capacity: 750 lbs / 340 kg

• Load Capacity per Shelf: 150 lbs / 68 kg

• Payload: Bins, Boxes, Misc parts, Totes

• Size: 22 x 36 inch / 560 x 910 mm

• Load Capacity: 450 lbs / 200 kg

• Load Capacity per Shelf: 45 lbs / 20 kg

• Payload: Bins, Boxes, Misc Parts, Totes

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 795 lbs / 360 kg

• Load Capacity per Shelf: 200 lbs / 90 kg

• Payload: Bins, Boxes

• Size: 64 x 52 inch / 1610 x 1330 mm

• Load Capacity: 265 lbs / 120 kg

• Load Capacity per Shelf: 66 lbs / 30 kg

• Payload: Misc parts

Product Information:

Extendable shelf cart with one fixed and four extendable shelves with additional lock pins.

Product Information:

Extendable shelf cart with ten extendable shelves with lock pins.

Product Information:

Extendable shelf cart with one fixed and three extendable shelves with lock pins.

Product Information:

Extendable shelf cart with with three extendable shelves and forklift pockets.

Product Information:

Shelf cart designed with one fixed top shelf and two extendable shelves with lock pin.

EXTENDABLE SHELF CARTS

• Size: 91 x 28 inch / 2310 x 700 mm

• Load Capacity: 750 lbs / 340 kg

• Load Capacity per Shelf: 250 lbs / 113 kg

• Payload: Misc Parts

Product Information:

Designed with five extendable shelves with dividers. The shelves are equipped with foam on top of the shelves to ensure they don’t damage any of the parts.

• Size: 36 x 55 inch / 910 x 1400 mm

• Load Capacity: 500 lbs / 227 kg

• Load Capacity per Shelf: 100 lbs / 45 kg

• Payload: Bins, Boxes, Misc parts, Totes

Product Information:

Designed with one fixed and two extendable shelves with lock pins.

• Size: 55 x 33 inch / 1260 x 630 mm

• Load Capacity: 1,000 lbs / 450 kg

• Load Capacity per Shelf: 300 lbs / 135 kg

• Payload: Bins, Boxes, Misc Parts, Totes

Product Information:

Designed with three extendable shelves with lock pins.

• Size: 55 x 33 inch / 1400 x 840 mm

• Load Capacity: 600 lbs / 272 kg

• Load Capacity per Shelf: 200 lbs / 91 kg

• Payload: Bins, Boxes, Misc Parts, Totes

FLOW SHELF CARTS.

A flow shelf cart or rack uses gravity to aid in the flow of materials, components, and tools stored within totes, bins, and boxes. The height of the shelves is easily adjusted and you can add a side and/or back fence to prevent parts from falling out.

FLOW SHELF CART

47 x 30 inch / 1190 x 770 mm

Q-100-4441

LOAD CAPACITY

331 lbs / 150 kg

polyurethane casters for optimal tracking

Flow racks that handle heaviser loads

All standard shelf carts can be integrated into a tugger train system by adding a tow bar

Create your unique design for work stations or tugger carts

Shelves can be added, removed or adjusted in position directly on-site without hassle.

FLOW SHELF CARTS

FLOW SHELF CART

63 x 28 inch / 44 x 39 mm

Q-100-6263

This four-level flow shelf cart is designed to move heavy materials up to 250 lbs / 113 kg per shelf.

FLOW RACK TUGGER CART

28 x 50 inch / 700 x 1260 mm

Q-100-0768

This cart is equippes with three roller shelves, designed to move materials manually or in a tugger train, up to 185 lbs / 84 kg per shelf.

FLOW SHELF CARTS

• Size:

47 x 30 inch / 1190 x 770 mm

• Load Capacity: 331 lbs / 150 kg

• Load Capacity per Shelf: 110 lbs / 50 kg

• Payload: Bins, Boxes, Misc parts, Totes

• Size: 63 x 28 inch / 44 x 39 mm

• Load Capacity: 1,000 lbs / 454 kg

• Load Capacity per Shelf: 250 lbs / 113 kg

• Payload: Misc Parts

• Size: 30 x 47 inch / 770 x 1190 mm

• Load Capacity: 551 lbs / 250 kg

• Load Capacity per Shelf: 110 lbs / 50 kg

• Payload: Bins, Boxes, Misc parts, Totes

• Size: 28 x 50 inch / 700 x 1260 mm

• Load Capacity: 550 lbs / 250 kg

• Load Capacity per Shelf: 185 lbs / 84 kg

• Payload: Bins, Boxes, Misc parts, Totes

Product Information:

Three-level flow shelf cart with spacers on each shelf for efficient line-side presentation.

Product Information:

Four-level flow shelf cart for transporting and presenting loose materials safely.

Product Information:

Five-level flow shelf cart with spacers on each shelf for efficient line-side presentation.

Product Information:

This flow rack features three roller shelves, presenting materials on the bottom two and returning items on the top. Perfect to improve material presentation to the operators.

Product Information:

Sturdy rack with three flow shelves. The position and angle of the flow shelves can be adjusted to match presentation to the operators.

FLOW SHELF RACK

• Size: 28 x 50 inch / 700 x 1260 mm

• Load Capacity: 330 lbs / 150 kg

• Load Capacity per Shelf: 110 lbs / 50 kg

• Payload: Bins, Boxes, Misc parts, Totes

FLOW SHELF CART

FLOW SHELF CARTS

Product Information:

Five-level flow shelves with easily adjustable shelves on both side of the cart. Perfect for material presentation.

• Size: 36 x 30 inch / 910 x 770 mm

• Load Capacity: 400 lbs / 180 kg

• Load Capacity per Shelf: 80 lbs / 36 kg

• Payload: Misc parts

Product Information:

This flow rack features five roller shelves, presenting materials on the bottom four and returning items on the top. Perfect to improve material presentation to the operators.

FLOW RACK

• Size: 63 x 47 inch / 1610 x 1190 mm

• Load Capacity: 1,650 lbs / 750 kg

• Load Capacity per Shelf: 330 lbs / 150 kg

• Payload: Bins, Boxes, Misc parts, Totes

FLOW SHELF WITH TUGGER

Product Information:

Four-level shelf cart perfect optimal to be transported in a tugger train, with excellent tracking properties and silent movement.

• Size: 55 x 33 inch / 1400 x 840 mm

• Load Capacity: 705 lbs / 320 kg

• Load Capacity per Shelf: 176 lbs / 80 kg

• Payload: Bins, Boxes, Misc parts, Totes

HANGING CARTS.

The hanging cart is designed for transporting and displaying materials that need to be hung up such as ropes, cables, wires, cylinders etc. The adjustable hangers allows for quick and easy repositioning to best suit the operator’s needs.

RACK FOR HANGING

52 x 47 inch / 1330 x 1190 mm

Forklift pockets

All hanging carts can be integrated into a tugger train system by adding a tow bar

Casters can be added on hanging rack for easy transportation

Hangers can easily be adjusted in position directly on-site without hassle.

Each cart is designed with hangers optimized for the type of payload.

HANGING CARTS

CART FOR HANGING

36 x 99 inch / 910 x 2030 mm

Q-100-2504

This cart is designed with end-cap protected tubes to safely move materials up to 22 lbs / 10 kg per hanger.

HANGING CART

55 x 25 inch / 1400 x 630 mm

Q-100-8517

This cart is designed to move manually or in a tugger train, with a max load capacity of 1,102 lbs / 500 kg.

HANGING CARTS

RACK FOR HANGING

• Size: 52 x 47 inch / 1330 x 1190 mm

• Load Capacity: 265 lbs / 120 kg

• Load Capacity per Hanger: 66 lbs / 30 kg

• Payload: Roofs, Hoses, Tubes, Wires

Product Information:

Rack designed for forklift transport of heavy panels, with angled hangers to prevent falling and vertical guides allowing up to three racks to be stacked.

• Size: 85 x 41 inch / 2170 x 1050 mm

• Load Capacity: 1,855 lbs / 840 kg

• Load Capacity per Hanger: 155 lbs / 70 kg

• Payload: Hoses, Tubes, Wires, Misc Parts

• Size: 77 x 41 inch / 1960 x 1050 mm

• Load Capacity: 2,600 lbs / 1180 kg

• Load Capacity per Hanger: 150 lbs / 68 kg

• Payload: Hoses, Tubes, Wires, Misc Parts

Product Information:

Simple hanging cart featuring twelve hanging tubes. Transported manually or in a tugger train.

Product Information:

Ideal hanging cart for heavier materials due to the reinforced hangers. It also comes equipped with forklift pockets. Transported manually or in a tugger train.

Product Info:

• Size: 102 x 41 inch / 2590 x 1050 mm

• Load Capacity: 150 lbs / 70 kg

• Payload: Misc parts, Cylinders

Product Information:

Specially designed for cylinders with five wheeld to support the load and two flooe brakes to secure the cart when no in use.

Product Information:

Three-level hanging cart featuring horizontal tubes with end caps to prevent materials from falling. Transported manually or in a tugger train.

• Size: 36 x 99 inch / 910 x 2030 mm

• Load Capacity: 661 lbs / 300 kg

• Load Capacity per Hanger: 22 lbs / 10 kg

• Payload: Hoses, Tubes, Wires, Misc Parts

HANGING CARTS

Product Information:

Large hanging cart featuring horizontal hangers, with end locks to prevent materials from falling as well as forklift pockets. Transported manually or in a tugger train.

• Size: 196 x 33 inch / 4970 x 840 mm

• Load Capacity: 770 lbs / 350 kg

• Payload: Misc parts

HANGING CART

Product Information:

Robust hanging cart perfect for heavy materials, featuring eleven robust hangers and tubes along with forklift pockets.

• Size: 74 x 30 inch / 1890 x 770 mm

• Load Capacity: 2,000 lbs / 997 kg

• Load Capacity per Hanger: 150 lbs / 68 kg

• Payload: Misc parts

Product Information:

Light-weight hanging cart with five tubes featuring end locks to prevent materials from falling.

KIT HANGING CART

Product Info:

• Size: 63 x 22 inch / 1610 x 560 mm

• Load Capacity: 200 lbs / 91 kg

• Payload: Wire coil, Misc Parts

MOTHER DAUGHTER CARTS.

With the FlexQube intuitive mother-daughter cart solutions, smaller carts are transported to relevant work stations in the easiest and most practical way through the use of the mother unit. The size of both carts is customizable to fit the requirements at the assembly line. The mother cart is equipped with a drop pin, wire- or foot release tow bar and is easily connected to tugger trains.

MOTHER CART 2 in 1

66 x 63 inch / 1680 x 1610 mm

Q-100-4043

One or dual side loading

Create your own custommade design

Heavy-duty polyurethane casters for optimal tracking

Perfect for kit-carts and shelf carts

MOTHER DAUGHTER CARTS

Quick and easy locking of daughter carts in mother unit.

MOTHER CART 4 in 1

39 x 74 inch / 980 x 1890 mm

Q-100-3020

Tuggable mother cart designed to transport four daughter carts

Q-100-0132.

THE MOTHER DAUGHTER CONCEPT - is commonly used in a milk run system meaning you use the mother cart to carry daughter carts filled with material from warehouse to assembly line and picking up empty daughter carts on the way back.

MOTHER CART 8 in 1

88 x 58 inch / 2240 x 1470 mm

Q-100-0986

Tuggable mother cart designed to transport eight dollies with electric ramp.

MOTHER DAUGHTER CARTS

MOTHER CART 2 in 1

• Size: 66 x 63 inch / 1680 x 1610 mm

• Load Capacity: 2 Daughter Carts

• Daughter Cart: Q-100-1042

• Payload: Daughter Carts

• Size: 39 x 74 inch / 980 x 1890 mm

• Load Capacity: 4 Daughter Carts

• Daughter Cart: Q-100-0132

• Payload: Daughter Carts

Product Information:

Designed to carry two daughter carts which are locked in frame during transportation. Transported manually or in a tugger train.

Product Information:

Designed to carry four daughter carts which are locked in frame during transportation. Transported manually or in a tugger train.

MOTHER CART 8 in 1 for Dollies

• Size: 88 x 58 inch / 2240 x 1470 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Load Capacity per Hatch: 220 lbs / 100 kg

• Payload: Dollies

Product Information:

Large mother frame designed to carry eight daughter carts in frame to be transported to different work stations. Transported in a tugger train.

• Size: 80 x 50 inch / 2030 x 1260 mm

• Load Capacity: 4 Daughter Carts

• Daughter Carts: Q-100-1000

• Payload: Daughter Carts

Product Information:

Designed to carry four small daughter carts in frame. The carts are locked in during transportation to different work stations. Transported manually or in a tugger train.

Product Information:

Perfect for high-capacity material transport. Mother frame designed to be loaded with six daughter carts on each side of the frame. Transported in a tugger train.

MOTHER DAUGHTER CARTS

MOTHER CART 6 in 1

• Size: 39 x 105 inch / 980 x 2660 mm

• Load Capacity: 6 Daughter Carts

• Daughter Cart: Q-100-2617

• Payload: Daughter Carts

Product Information:

Designed to carry four daughter carts to different work stations throughout the facility. Transported in a tugger train.

MOTHER CART 4 in 1

• Size: 44 x 58 inch / 1120 x 1470 mm

• Load Capacity: 1,000 lbs / 450 kg

• Load Capacity per Hatch: 220 lbs / 100 kg

• Payload: Dollies

Product Information:

Designed to carry two daughter carts. Features lock bars for hatch doors, enabling efficient transport between assembly stations. Transported in a tugger train.

MOTHER CART 2 in 1

• Size: 80 x 41 inch / 2030 x 1050 mm

• Load Capacity: 1,500 lbs / 680 kg

• Load Capacity per Hatch: 750 lbs / 340 kg

• Payload: Daughter Carts

MOTHER CART 2 in 1

Product Information:

This 2-in-1 mother-daughter cart comes with an electric ramp and remote for easy loading and unloading of daughter carts. Tansported in a tugger train.

• Size: 44 x 30 inch / 1120 x 770 mm

• Load Capacity: 440 lbs / 200 kg

• Load Capacity per Hatch: 220 lbs / 100 kg

• Payload: Dollies

KIT CARTS.

Kit carts are specialized solutions designed customized to your special material handling needs. They are most commonly used for material presentation along assembly lines, workstations and service areas. FlexQube carts can be modified for the presentation of any components. They can, for example, be prepared for tires, with a flip ramp where the tires can easily roll up and be placed in the rack. They’re also easily equipped with a floor brake and handlebar.

KIT CART FOR TIRES

44 x 53 inch / 1118 x 1346 mm

Q-100-0520

Ramp to easily load and unload tires

We’ll create the right cart for you based on your operational needs

Present the parts in an ergonomic and efficient way to the operators

KIT TUGGER CART

70 x 47 inch / 1750 x 1050 mm

Q-100-0650

Tuggable kit cart designed to transport different types of materials.

WINDSHIELD CART

91 x 50 inch / 2310 x 1260 mm

Q-100-0446

Kit cart designed specifically to transport windshields for trucks.

KIT CARTS

• Size: 44 x 53 inch / 1118 x 1346 mm

• Load Capacity: 500 lbs / 226 kg

• Transportation: Manual

• Payload: Tires

Product Information:

Designed to load and transport tires. This cart can hold three tires. Equipped with flip ramp to easily load and unload tires.

CART FOR PLATES

• Size: 41 x 47 inch / 1050 x 1190 mm

• Load Capacity: 800 lbs / 363 kg

• Transportation: Manual

• Payload: Plates, Panels, Long Parts

KIT CART FOR TIRES KIT TUGGER CART

• Size: 70 x 47 inch / 1750 x 1050 mm

• Load Capacity: 1,000 lbs / 453 kg

• Load Capacity per Shelf: 249 lbs / 113 kg

• Payload: Bins, Boxes, Misc parts, Totes and parts to be hung

Product Information:

Designed with 17 slots for storage area, with rubber protection at the bottom.

Product Information:

Large kit-cart designed to hang large tubes as well as other items that can be stored on the shelves. Transported manually or in a tugger train.

• Size: 91 x 50 inch / 2310 x 1260 mm

• Load Capacity: 1,100 lbs / 500 kg

• Transportation: Manual

• Payload: Windshields for trucks

Product Information:

Push cart designed for windshields to rest on the rubber deck, leaning against a foam-padded top.

Product Information:

Designed to improve the presentation of materials at the assembly line. The backside is designed to hold longer parts, secured with a safety lock. Transported manually or in a tugger train.

KIT CART

• Size: 47 x 47 inch / 1050 x 1050 mm

• Load Capacity: 1,000 lbs / 453 kg

• Load Capacity per Shelf: 220 lbs / 100 kg

• Payload: Bins, Boxes, Misc parts, Totes

TOOL KIT CART

Product Information:

Cart to store materials on shelves and hang tools on peg board.

Product Information:

Vertical guide tubes holding cardboards in place, with wire mesh around cart for extra material protection.

• Size: 25 x 30 inch / 630 x 770 mm

• Load Capacity: 250 lbs / 110 kg

• Load Capacity per Shelf: 125 lbs / 55 kg

• Payload: Misc parts

CARDBOARD KIT CART

• Size: 49 x 32 inch / 1240 x 820 mm

• Load Capacity: 440 lbs / 200 kg

• Transportation: Manual

• Payload: Cardboards

Product Information:

Custom designed cart to store smaller materials in 25 compartment pockets. This makes it easy for operators to access materials along the assembly line.

• Size: 50 x 33 inch / 1260 x 840 mm

• Load Capacity: 370 lbs / 168 kg

• Load Capacity per Shelf: 26 lbs / 12 kg

• Payload: Bins, Boxes, Misc parts, Totes

STILL LIFTRUNNER FRAMES.

Together with STILL Liftrunner ® tugger train system, FlexQube has developed mother-daughter cart solutions that vastly help your industrial material handling needs. The heavy-duty carts and trolleys are customized for containers and can be made to fit any kind of frame and can also be fitted with a removable handlebar for increased convenience and ergonomic handling.

US SIZE FRAMES

LIFTRUNNER B-FRAME (US)

This frame is highly flexible, with loading and unloading from both sides of the frame.

Q-050-1046

LIFTRUNNER E-FRAME (US)

This frame is a perfect match for our cart solutions, and can be designed with different lengths, widths and loads.

Q-050-1062

BUILT TO MOVE HEAVY MATERIALS SMOOTHLY AND EFFICIENTLY.

Load and unload materials on both sides of the frame.

LIFTRUNNER C-FRAME (US)

This frame is designed to effectively transport heavy loads, and large material handling carts. Mostly used outdoors.

Q-050-1038

LIFTRUNNER FRAMES

Frames compatible with more or less any FlexQube cart thanks to the flexible design.

EUR SIZE FRAMES

LIFTRUNNER B-FRAME (EUR)

This frame is highly flexible, with loading and unloading from both sides of the frame.

Q-050-1089

LIFTRUNNER E-FRAME (EUR)

This frame is a perfect match for our cart solutions, and can be designed with different lengths, widths and loads.

Q-050-1053

FlexQube carts in perfect match with STILL Liftrunner® system.

Since 2019, FlexQube has been the exclusive distributor of the Liftrunner products in North America and South Africa. The Liftrunner tugger train solution from STILL is a market leading solution for transportation of industrial carts at production plants. In cooperation with STILL, FlexQube has created a unique, modular and flexible cart concept that together with the Liftrunner® system forms an industryleading combination and a state-of-the-art material handling solution.

LIFTRUNNER FRAMES

Autonomous Tugger Train Solution.

The Still LiftRunner is compatible with the FlexQube Navigator AMR, meaning that you don’t need to rely on operators to transport the materials. Instead, replace your manual tuggers with the autonomous FlexQube Navigator AMR and towing Load Carrier for an automated tugger solution.

CARTS FOR LIFTRUNNER

EUR PALLET CART FOR E-FRAME

• Size: 50 x 33 inch / 1260 x 840 mm

• Load Capacity: 1,102 lbs / 500 kg

• Transportation: Manual, LiftRunner E-frame

• Payload: Pallets

Product Information:

Standard palllet cart designed to transport pallets manually or with a STILL LiftRunner E-frame.

• Size: 50 x 33 inch / 1260 x 840 mm

• Load Capacity: 1,102 lbs / 500 kg

• Transportation: Manual, LiftRunner B-frame

• Payload: Pallets

Product Information:

Standard push-cart with a bent-top handlebar. The cart is also designed to be transported with a STILL LiftRunner B-frame.

PALLET CART

• Size: 50 x 33 inch / 1260 x 840 mm

• Load Capacity: 990 lbs / 450 kg

• Transportation: Manual, LiftRunner Frames

• Payload: Pallets

Product Information:

Tilt cart designed to improve access to materials for the operators, ensuring high ergonomic standards. The cart is also designed to be transported with a STILL LiftRunner Mother Frame.

• Size: 66 x 50 inch / 1680 x 1260 mm

• Load Capacity: 2,000 lbs / 907 kg

• Transportation: Manual, LiftRunner B-frame

• Payload: Pallets

Product Information:

Pallet cart with a larger raised top to carry larger pallets and still fit the STILL LiftRunner Frame. Designed to be transported with a STILL LiftRunner B-frame.

Product Information:

Perfect to carry heavy pallets and containers. The cart is also designed to be transported with a STILL LiftRunner B-frame.

PALLET CART

CARTS FOR LIFTRUNNER

• Size: 50 x 50 inch / 1060 x 1060 mm

• Load Capacity: 2,500 lbs / 1135 kg

• Transportation: Manual, LiftRunner B-frame

• Payload: Pallets, Containers

SHELF CART

Product Information:

Four-level shelf cart with dividers to keep materials from falling off. The cart is also designed to be transported with a STILL LiftRunner E-frame.

• Size: 28 x 33 inch / 700 x 840 mm

• Load Capacity: 1,240 lbs / 560 kg

• Load Capacity per Shelf: 310 lbs / 140 kg

• Transportation: Manual, LiftRunner E-frame

• Payload: Misc parts

SHELF CART

Product Information:

Five-level shelf cart with shelves in ergonomic position. The cart is also designed to be transported with a STILL LiftRunner E-frame.

• Size: 30 x 65 inch / 770 x 1643 mm

• Load Capacity: 500 lbs / 227 kg

• Load Capacity per Shelf: 100 lbs / 45 kg

• Transportation: Manual, LiftRunner E-frame

• Payload: Totes, Misc parts

PALLET CART

Product Information:

One of the most popular solutions for the LiftRunner system due to its capacity to carry heavy-duty pallets. The cart is also designed to be transported with a STILL LiftRunner B-frame.

• Size: 50 x 50 inch / 1260 x 1260 mm

• Load Capacity: 2,200 lbs / 1000 kg

• Transportation: Manual, Tugger, LiftRunner B-Frame

• Payload: Pallets, Containers

CASE STUDIES. Proven Solutions in Action.

Discover how companies across industries have improved safety, efficiency, and flexibility with FlexQube. Each case highlights a unique challenge and the modular solution that made a measurable impact.

FlexQube Solutions Across Industires.

FlexQube delivers modular solutions that fit every operational need. From robust mechanical carts to fully automated AGVs and AMRs, our systems help companies: WHY CHOOSE FLEXQUBE?

STREAMLINE WORKFLOWS across production and logistics

IMPROVE SAFETY for operators and goods

INCREASE FLEXIBILITY for changing operational needs

FROM CHALLENGE TO SUCCESS

Each case begins by highlighting the challenge our customers faced, whether it was manual material handling inefficiencies, complex production flows, or adapting to new product lines.

Each case demonstrates the tangible achievements — improved efficiency, enhanced safety, and increased operational flexibility — showing the real-world impact of our modular solutions.

Challenge Achievement Solution

Highlighting the FlexQube solution in action, whether it’s mechanical carts, AGVs, or AMRs, designed to perfectly fit the customer’s unique requirements.

CASE: Heavy Truck Manufacturer, Sweden

AUTOMATING TRANSPORT OF SEATS AND DOORS TO CAB ASSEMBLY LINE

RAPID ROI, OPERATIONAL SAVINGS, OUTSTANDING SAFETY WITH AUTOMATIC SAFETY FIELDS AND A MODULAR LOAD CARRIER DESIGN.

To improve safety and efficiency, the company partnered with FlexQube to replace forklifts, one of the leading causes of workplace accidents, with the innovative and patented Navigator AMR System.

An automated system with a non-loadcarrying robot which couples with an

ecosystem of modular and motorized Load Carriers through a standardized coupling. This “one robot, multi-carrier” concept allows the AMR to move racks of various sizes and weights, replacing forklifts in the assembly line with a flexible, safe, and fully automated transport solution.

THE CHALLENGE

The customer needed to reduce forklift traffic and efficiently move materials of varying sizes. High product variation and limited line-side storage required prekitting and precise delivery, while forklifts replenished seat and door racks every 10 minutes, creating complexity and safety risks.

ACHIEVEMENT

FlexQube’s patented AMR System replaced forklifts, transporting modular seat and door racks of varying sizes and weights directly to the assembly line. This improved safety, reduced forklift traffic in high-density areas, ensured 99% uptime, and enhanced picking ergonomics for assemblers.

THE SOLUTION

Two Load Carriers were designed for seats (1610×1610 mm) and doors (1880×2450 mm) using the FlexQube building block system. The standalone Navigator AMR can transport both rack types via a standardized coupling interface, despite their size differences.

An autonomous system developed for smart, safe, scalable and successful material handling

CASE: SIGNIFY, USA

ELIMINATING

FOOT TRAFFIC

WITH ACCESSIBLE & USER-FRIENDLY AUTOMATION

“SO ON AVERAGE, WE ARE LOOKING AT ABOUT A 10-15 MINUTE SAVINGS FOR EACH LINE, HAVING 10 LINES OUT THERE THAT CAN MEAN UP TO 150 MINS OR 2.5 HOURS.”

- Sturgis Kyle, Engineering Manager, Pennsylvania, USA

Signify aimed to give employees more time for core tasks by eliminating singlepart transportation. Implementing the AGV automated material movement across the facility, saving 10–15 minutes per line per day - a significant cumulative time gain across 10 lines.

An unexpected benefit was the AGV’s quick and easy deployment. From unboxing to operation, setup was seamless, and its Android-based interface allowed operators to quickly adapt, making the system both efficient and user-friendly.

THE CHALLENGE

Signify sought to reduce unnecessary foot traffic on the manufacturing floor. Operators often left their stations to move single parts or materials between warehouses. The goal was to eliminate these inefficient, one-off transport tasks.

ACHIEVEMENT

Signify deployed FlexQube carts and an AGV to automate material movement between production areas and warehouses. The setup reduced manual handling, and by adding rubbish and recycling units to the AGV, waste removal was also automated.

THE SOLUTION

Signify began by leasing 2 AGVs and 4 tugger carts. The AGVs automated material transport, reducing foot traffic, while the tugger carts enabled movement of larger volumes. An added benefit was reclaiming employees’ time previously spent on these transport tasks.

Over the course of a week when you begin adding all of that up, you start to see how an operator’s expertise isn’t being leveraged how it should be.

- Sturgis Kyle, SIGNIFY

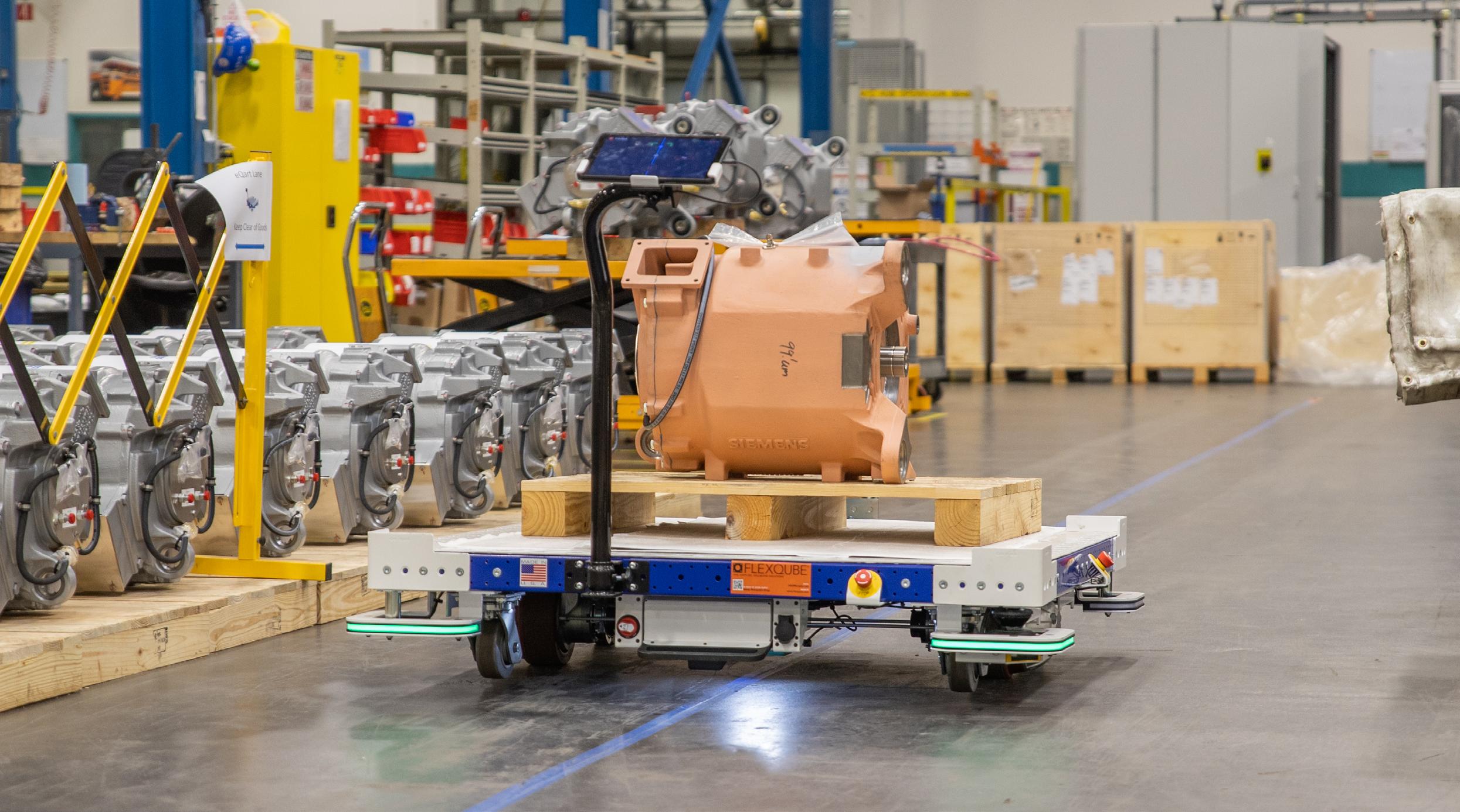

CASE: SIEMENS, USA

SIEMENS GETS STARTED WITH AUTOMATION!

“WE HAVE

AUTOMATION

NOW IN OUR FACTORY, AND WE CAN BUILD ON IT; BRING IN MORE ROBOTS AND BE INNOVATIVE WITH HOW WE USE THIS TECHNOLOGY IN OUR FACTORY ”

-

Kim

Howe,

Logistics Manager, Georgia, USA

Siemens successfully launched their first fully automated AGV project, taking the crucial first step in their automation journey. The implementation allowed them to map out their needs and deploy a solution that is both robust and reliable, providing consistent transport for every

task. With minimal setup time and no additional IT infrastructure required, the AGVs simplified what can often be a complex and daunting process, giving Siemens a strong foundation to build on for future automation initiatives.

THE CHALLENGE

Siemens, recently added new lines requiring updated processes and material transport. Previously, operators moved materials between stations using pallet jacks, forklifts, or push carts. Siemens aimed to keep gearbox technicians at their workstations by eliminating these manual transport tasks.

ACHIEVEMENT

Siemens deployed two AGVs, fully automating multiple material transport tasks across the facility. This eliminated human handling, streamlined processes, and delivered a rapid return on investment while achieving 100% automated transports.

THE SOLUTION

Siemens implemented two AGV designs and a roller transfer station: a flat-deck AGV for forklift-loaded parts and a rollertopped AGV that used gravity and a shooter mechanism to automatically transfer pallets to the station.

We got started with a future factory.

- Kim Howe, SIEMENS

CASE: Mitchell Plastics, USA

MITCHELL PLASTICS PRIORITIZES SAFETY WITH FLEXQUBE AGV

“IT’S ALLOWED THE MATERIAL HANDLERS TO NOT HAVE TO TOUCH THE MATERIAL - SO THERE ARE LABOUR SAVINGS THERE.”

- Dwayne Maust,

Materials Manager, Alabama, USA

Mitchell Plastics improved both safety and efficiency by automating their material flow with the FlexQube AGV system. The AGV’s defined paths have encouraged a cleaner, more organized workspace, eliminating blocked routes and reducing risks linked to manual tugger driving. Initially, Mitchell Plastics had not planned

for automation, but after adopting FlexQube tugger carts, they discovered the potential of combining them with the AGV solution. With FlexQube’s flexible financing options, including short-term leasing programs, automation became an achievable and valuable step forward for the company.

THE CHALLENGE

Mitchell Plastics relied on tugger carts and a driver to move totes throughout their facility. They sought to reduce the labor required for this process while ensuring that safety and ergonomic standards for employees were maintained.

ACHIEVEMENT

FlexQube provided an AGV capable of towing multiple fully-loaded tugger carts, replacing the need for a driver and allowing staff to focus on higher-value tasks. The AGV follows its route safely and consistently, enhancing workplace safety while marking Mitchell Plastics’ first step into their automation journey.

THE SOLUTION

Mitchell Plastics took their first step into automation by leasing a 50 x 50-inch AGV with a tow bar, combined with existing FlexQube tugger carts, creating an efficient automated tugging solution with flexible financing.

This allows for a much safer environment.

- Dwayne Maust, Mitchell Plastics

CASE: PROTERRA, USA

PROTERRA BUILT TWO NEW PLANTS WITH A FOCUS ON FLEXIBLE MATERIAL HANDLING

“SEAMLESS

AND TRANSPARENT PROCESS FROM DESIGN TO IMPLEMENTATION”

–

Lalit Savalia, Proterra, South Carolina, USA

FlexQube developed 25 customized carts tailored to Proterra’s needs, ensuring the design aligned with their brand. Using FlexQube’s web-based DesignOnDemand™, Proterra actively collaborated in the creation of carts for tires, batteries, windshields, tools, hoses, and cables.

The shift from forklifts to cart-based handling streamlined assembly and boosted efficiency. Soon after delivery, Proterra needed modifications, which were quickly implemented thanks to FlexQube’s modular concept and DesignOnDemand™, allowing on-site adjustments with ease.

THE CHALLENGE

Proterra is the largest manufacturer of electric buses in the U.S. When developing and planning for two new plants, they wanted to create both a sustainable yet effective material handling flow.

ACHIEVEMENT

In order to create a more efficient and sustainable manufacturing process in the new facilities, Proterra saw the benefits of leaving welded and unflexible carts behind. The FlexQube concept made it possible for Proterra to achieve this.

THE SOLUTION

Through FlexQube’s unique web-based DesignOnDemand™, over 25 different applications were designed for Proterra! This included applications to improve the presentation and transportation of components throughout the two facilities. The ability to harmonize these more efficient and more ergonomic designs to match their branding created a winning formula.

Reducing the number of forklifts paved the way for a more efficient assembly process.

CASE: PROTERRA

PEG BOARD CART

These carts allow the Proterra operators to actually assemble the bus from the inside, without having to leave the bus. This is a huge improvement in assembly efficiency for Proterra.

ANGLED WORK TABLES

These work tables are custom designed alongside the engineers at Proterra to aid in the development of material transportation.

WINDSHIELD CART

This cart is specifically designed with ergonomics in mind, to make it easier for the operator to move large and odd-sized items such as windshields.

TIRE KIT-CART

These carts are custom-built to enable pushing the cart up to the assembly station and roll the tyre straight off the cart and into the assembly area.

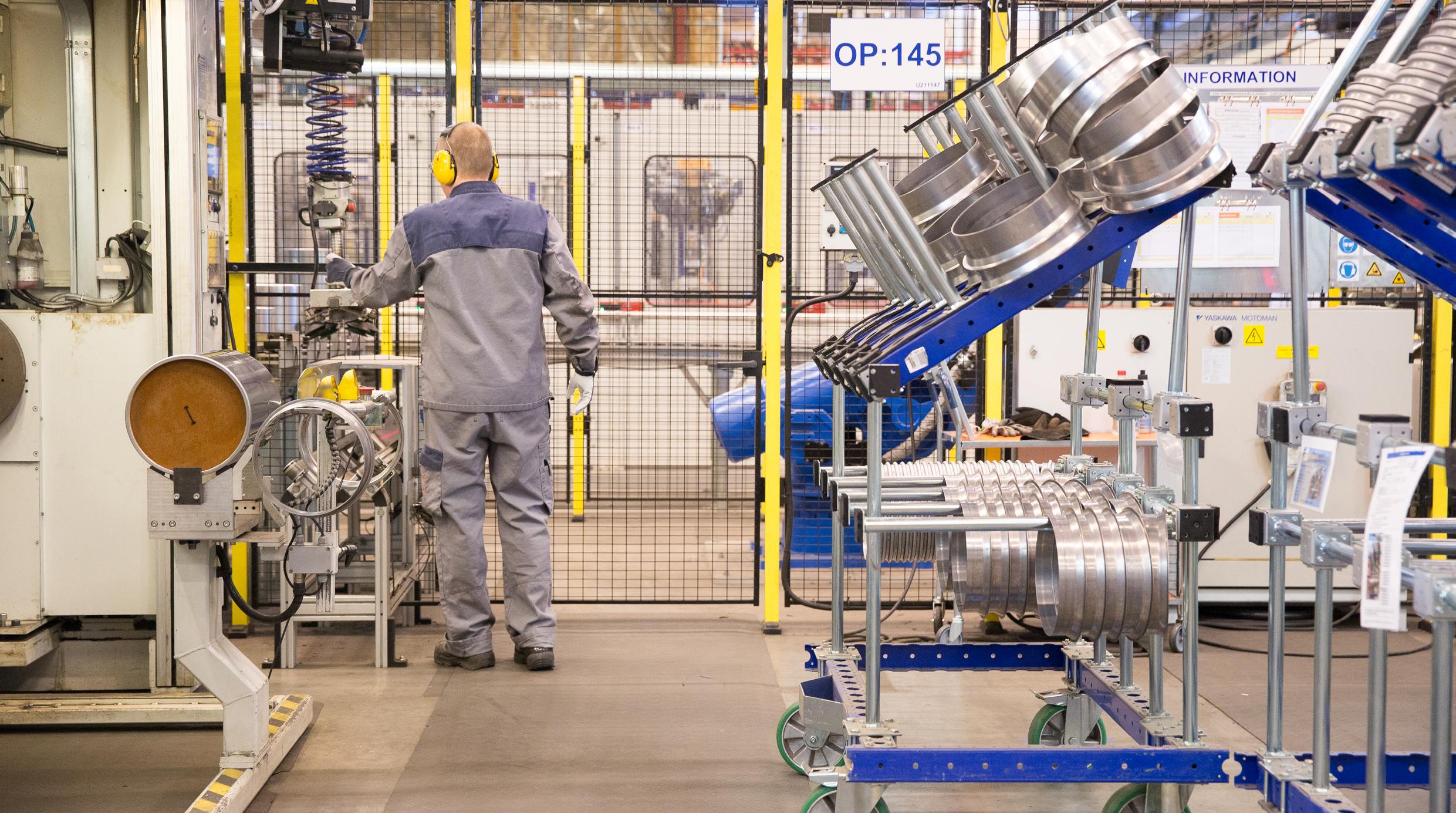

CASE: Eberspächer, Sweden

FORKLIFT REDUCTION AND ERGONOMIC IMPROVEMENT

“THE CARTS HAVE BEEN A HUGE IMPROVEMENT WHEN IT COMES TO ERGONOMICS.”

– Maritza Zegovia, Eberspächer, Trollhättan, Sweden

Eberspächer set out to eliminate forklifts and improve material flow in production, partnering with FlexQube in 2012. Since then, the company has continuously adapted and refined its carts based on operator feedback and evolving needs. By introducing a mother-daughter tugger train system, Eberspächer now transports up to four carts at a time, boosting efficiency and reducing forklift traffic.

The modular FlexQube concept allows upgrades without waste, making it a sustainable long-term solution. Designed in close collaboration with operators, the carts have greatly improved ergonomics and usability. Today, Eberspächer operates over 300 robust FlexQube carts in 15 different versions—reflecting a decade of continuous improvement and satisfied engineers.

THE CHALLENGE

The challenge was to cut forklift traffic, which created safety risks and disrupted flow, while managing parts of varying size and weight in narrow aisles that limited efficient transport.

ACHIEVEMENT

FlexQube’s solutions cut material travel distance by 60%, improved ergonomics, and reduced forklift use, streamlining production.

THE SOLUTION

Customized kit carts were built using FlexQube’s standard components and integrated with the LiftRunner tugger train from STILL, creating a common, flexible platform that serves as the base for all kit carts.

I am extremely satisfied with the carts. I feel proud when I see them at the production lines.

- Mariza Zegovia, Eberspächer

CASE: Autoliv, Mexico

USING HIGH-QUALITY CARTS TO REDUCE DOWNTIME

Since 2015 FlexQube has delivered almost 250 carts to the different Autoliv plants in Mexico with more to come.

Autoliv purchased a variety of FlexQube applications, including shelf carts, mother-daughter (4-in-1) systems for small boxes and totes, and container carts for sizes ranging from 32×30 inches to 1600×1200 mm. Their previous quad-steer system tracked well behind tuggers but

was difficult to move by hand and had poor casters, causing downtime and noisy rides. FlexQube’s modular system offered flexibility for building a long-term cart fleet, extending investment lifetime while improving material flow, productivity, and quality.

THE CHALLENGE

The carts that Autoliv had prior to the FlexQube carts were of low quality & caused a lot of downtime for the manufacturing plant and needed a lot of maintenance. The facility was also experiencing changes in their container sizes due to new demands from OEMs.

ACHIEVEMENT

Using FlexQube carts led to us increasing productivity by reducing the downtime and drastically reducing the need for maintenance. Our FlexQube carts also led to the reduced noise levels in the facility and using only one concept reduced the complexity when needed to change the container sizes.

THE SOLUTION

Autoliv went with a six caster setup which improved the tracking and maneuverability of the material handling carts. The carts were also more user-friendly due to a fixed caster set up in the center. We helped the facility implement a 4 in 1 tugger train system which improved productivity.

FlexQube carts boosted productivity, cut downtime and reducing maintenance needs.

to the world of FlexQube!

FlexQube is building a global footprint in order to follow and support all our customers around the world. To provide the best and most cost efficient, material handling and robotics equipment.

Birmingham, England

FlexQube UK Ltd, Sales Office

Gothenburg, Sweden Head office FlexQube AB, Distribution Center and Manufacturing

Munich, Germany FlexQube GmbH, Sales Office

www.flexqube.com