CARD CLIPPER SERIES

■ ■ ■ ■

Quick assembly (Time-saving)

One press to complete automatic locking (Effort-saving) Vertical blockage structure, full reliability

Instinctive design, user-friendly

Card Clipper-SSD M.2 Card Patented.

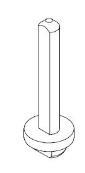

Material and Finish

BASE: PLASTIC

TOGGLE KEY: PLASTIC

SPRING: 300 SERIES STAINLESS STEEL, NATURAL FINISH

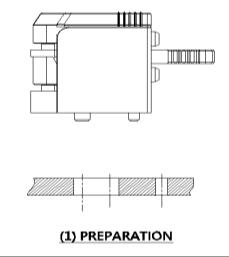

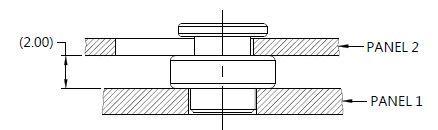

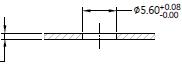

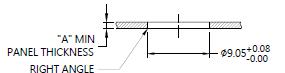

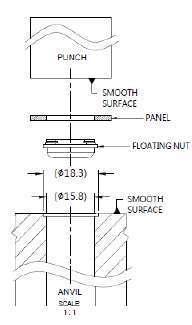

■ Panel Preparation

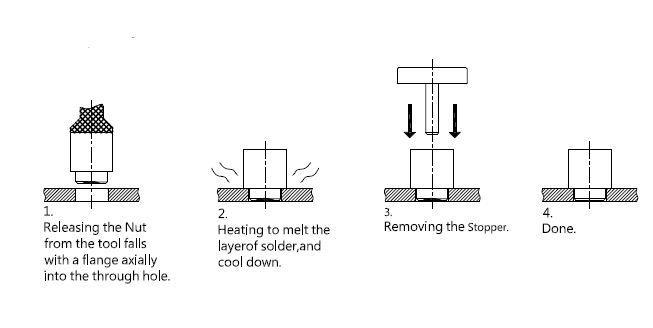

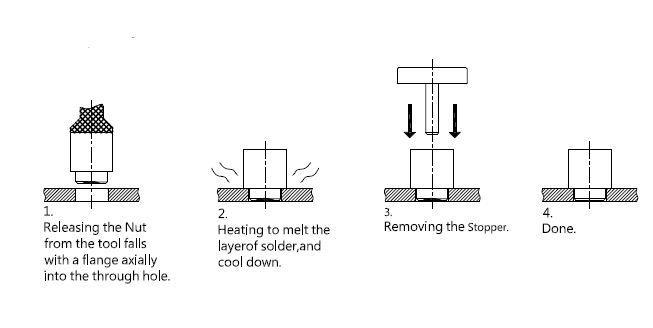

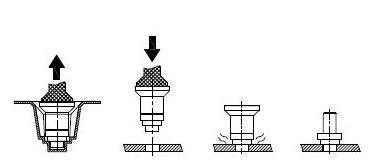

■ Installation

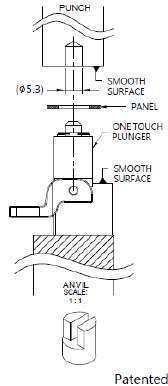

Assembly

Disassembly

Copyright © Since 2007-2016 Fivetech Technology Inc. All Right Reserved.

M.2 BOARD LATCH

Quick assembly (Time-saving).

Simply push to lock/unlock the M.2 card (Effort-saving).

Vertical blockage structure, full reliability.

Intuitive design, user-friendly.

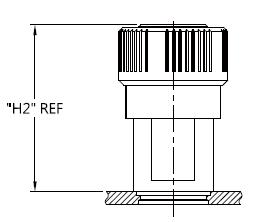

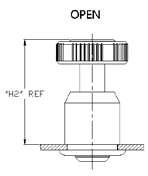

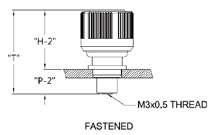

M.2 BOARD LATCH (Screw-in Type)

Material and Finish

Patented.

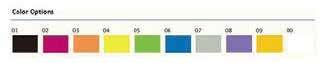

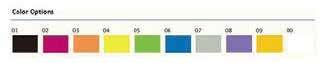

Color Options

M.2 BOARD LATCH

Quick assembly (Time-saving).

Simply push to lock/unlock the M.2 card (Effort-saving).

Vertical blockage structure, full reliability.

Intuitive design, user-friendly.

M.2 BOARD LATCH (Snap-in Type) Patented.

Material and Finish

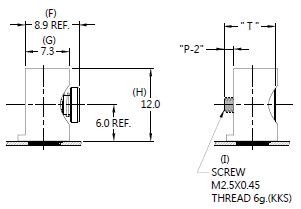

Installation Panel Preparation

Color Options

M.2 BOARD LATCH

Quick assembly (Time-saving).

Simply push to lock/unlock the M.2 card (Effort-saving).

Vertical blockage structure, full reliability.

Intuitive design, user-friendly.

M.2 BOARD LATCH (Snap-in Turn Type)

Material and Finish

M.2 Installation Panel Preparation

Color Options

Patented.

Patented.

Quick assembly (Time-saving).

Simply push to lock/unlock the M.2 card (Effort-saving).

Vertical blockage structure, full reliability.

Intuitive design, user-friendly.

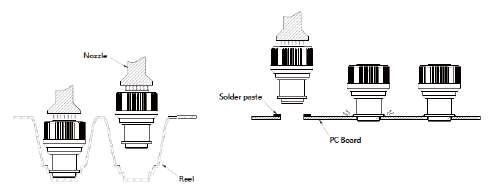

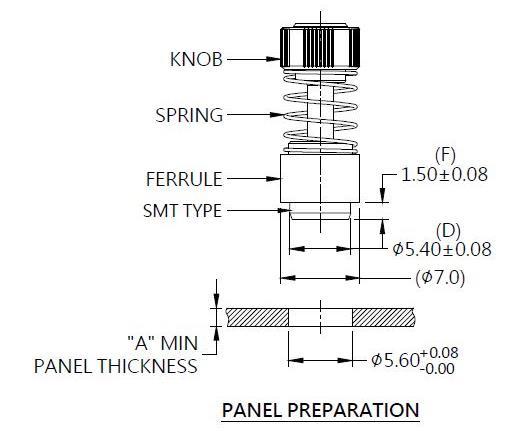

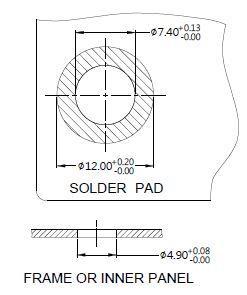

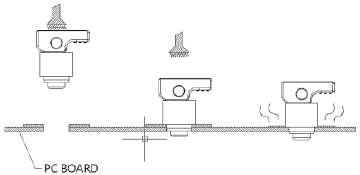

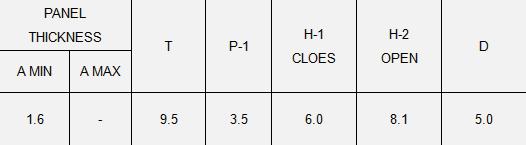

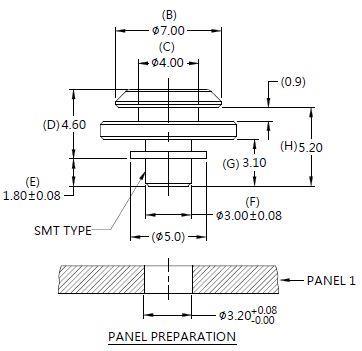

SMT fully automated manufacturing process can increase production stability and production efficiency.

M.2 BOARD LATCH (SMT Type)

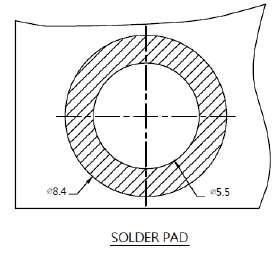

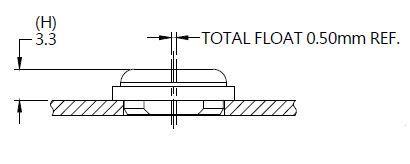

M.2 Installation Panel Preparation

Color Options

Copyright © Since 2007-2016 Fivetech Technology Inc. All Right Reserved.

Two layers each for one SSD, meets special SSD requirement

Two-in-one design with tool-less operation

Quick assembly for time-saving

Suitable for M.2 cards of different lengths

Double M.2 Board Latch

Patented.

Material and Finish

Cover/Layer Cover :

Installation Style Panel Preparation

Color Options

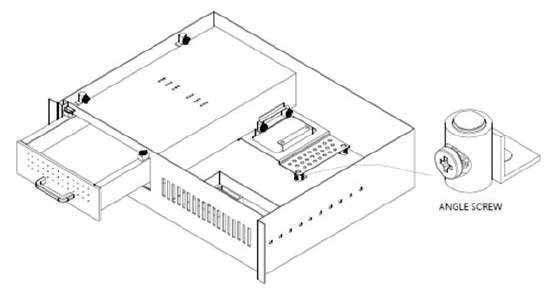

Angle Series

Automatic hold the top cover for smoother operation

Cushion the downward force of top cover pressing down

Laterally installed on both sides of the chassis to save space

Automatic equipment assembly, with high reliability

Customization available, the color can be adjusted according to the corporate identity color

Auto Angle Strut Patented.

Material and Finish

Installation Panel Preparation

Dimensions (mm)

QUARTER TURN

QUARTER LOCK

Patented.

Convenient for 2 U or a higher server module.

Simply press down and turn 1/4 turn to complete assembly/disassembly.

Bat hole design helps easier to align during operation, speeding up disassembly and assembly.

The T-shaped handle makes it more effort-saving, meets the humanized operation.

T-shaped handle 0°/90° positioning function helps save chassis space.

Material and Finish

Push Switch: Plastic: Pantone Black.

Lever / Ejector Rivet / Spring : 300 Series Stainless Steel, Natural Finish.

Washer / Ferrule / Torsion Spring : 300 Series Stainless Steel, Natural Finish.

Stop Base: Carbon Steel, Natural Finish.

Nut : Carbon Steel, Nickel Finish

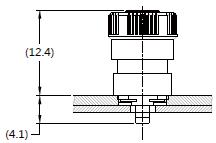

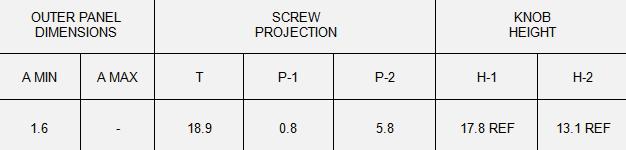

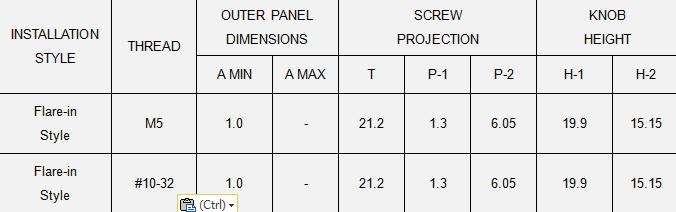

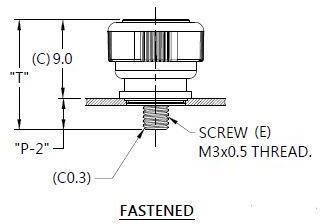

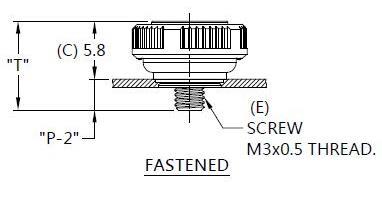

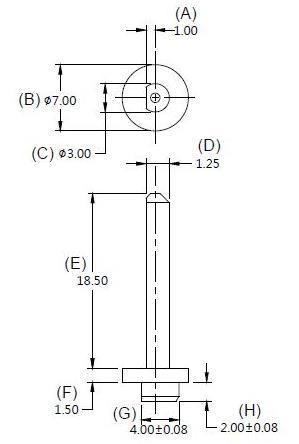

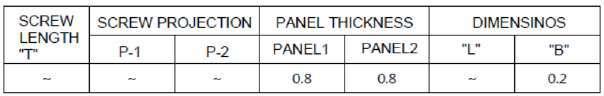

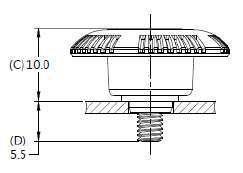

Knob High and Screw Projection Installation Style

Knob Color Options

Auto Lock Patented.

Water drop head type design makes the operation intuitive and friendly

Turn 1/4 to unlock, and simply press to lock, saving time and effort

Special spring force structure strengthens the force between two boards

Material and Finish

Switch :

Finish Pin

:

300 Series Stainless Steel, Natural Finish

Installation

Dimensions (mm)

Installation

Water drop head type design makes the operation intuitive and friendly

Turn 1/4 to unlock, and simply press to lock, saving time and effort

High stability and high strength mechanism design

Special spring force structure strengthens the force between two boards

Dimensions (mm)

Panel Preparation

Installation

Water drop head type design makes the operation intuitive and friendly

Turn 1/4 to unlock, and simply press to lock, saving time and effort

High stability and high strength mechanism design

Special spring force structure strengthens the force between two boards

Panel Preparation

Dimensions (mm)

Dimensions (mm)

Water drop head type design makes the operation intuitive and friendly

Turn 1/4 to unlock, and simply press to lock, saving time and effort

High stability and high strength mechanism design

Special spring force structure strengthens the force between two boards

Panel Preparation

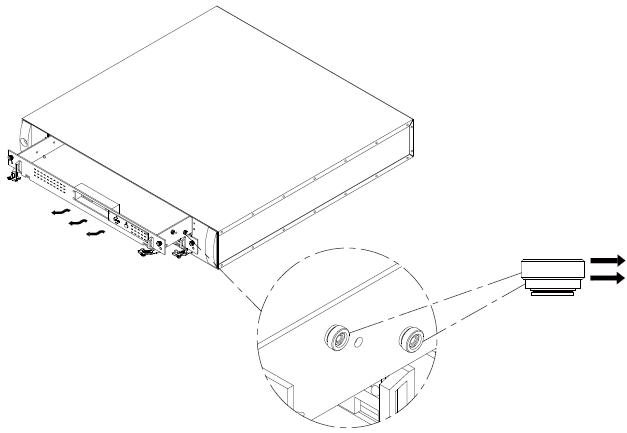

SLIDE ROLLER

Applicable to all kinds of drawing hardware devices. Reduce friction and partially replace slide rails.

Small size, reducing space.

A good and affordable choice.

The size of the rollers can be customized according to our customer needs.

SLIDE ROLLER Patented.

Material and Finish

SLIDE ROLLER

Applicable to all kinds of drawing hardware devices. Reduce friction and partially replace slide rails.

Small size, reducing space.

A good and affordable choice.

The size of the rollers can be customized according to our customer needs.

SLIDE ROLLER Patented.

Material and Finish

Applicable to all kinds of drawing hardware devices. Reduce friction and partially replace slide rails.

Small size, reducing space. A good and affordable choice.

The size of the rollers can be customized according to our customer needs.

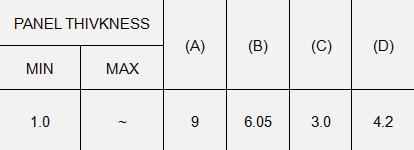

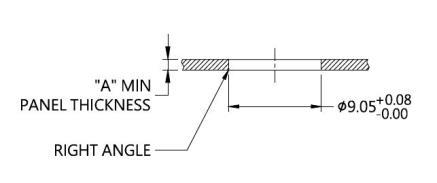

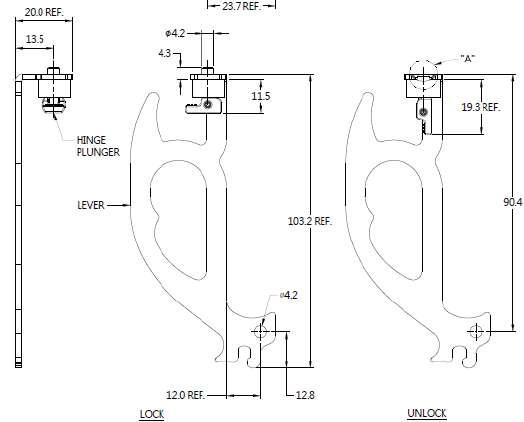

Panel Preparation Installation Style

ROLLER

Roller Bar Patented.

Modular design, easy to install

Effort saving device to reduce friction

A space-saving slide rail solution

Can be applied to all kinds of drawing hardware equipment

The size of the rollers can be customized according to customer’s needs

Material and Finish

Panel Preparation

Installation Style

Dimensions (mm)

EJECTOR

3-Bar Linkages Ejector

The principle of leverage achieves effort-saving eject and hook back function for chassis operation

The linkage design can lengthen the torque to achieve a more effort-saving effect

The front torsion spring buckle design attains lock/unlock in one second

One-piece modular design for easy assembling

Patented.

Material and Finish

Panel Preparation

Color Options

Dimensions (mm)

Lever

Energy

The

EJECTOR

Ejector (Slide Lock Type)

Lever structure, easy to operate, effort saving.

Lever structure easily boost to lift and eject heavy chassis.

Size and length can be customized.

Slide Lock is an optional locking function.

Dimensions (mm)

Patented.

Color Options

Dimensions (mm)

Installation Style

Effort-saving eject and hook back function for chassis operation

Anti-loose function combines the positioning of two boards, and provides clamping force

Modular design, one-piece-item

The metal part can be customized according to the chassis

The plastic part can be designed in different colors to meet your corporate identity

Spring Lock Ejector

Installation

Panel Preparation

Color Options

Dimensions (mm)

Copyright © Fivetech All Right Reserved.

EJECTOR

Lever structure, easy to operate, energy saving.

Energy saving, time efficient, production cost down.

The spec of Ejector could be customized.

Plastic handle color management is available.

504 AUTO OPEN EJECTOR Patented.

Material and Finish

Push Switch:

Plastic: Pantone Black.

Lever / Ejector Rivet / Spring : 300 Series Stainless Steel, Natural Finish.

Washer / Ferrule / Torsion Spring : 300 Series Stainless Steel, Natural Finish.

Stop Base: Carbon Steel, Natural Finish.

Nut : Carbon Steel, Nickel Finish

Recess Style

Knob High and Screw Projection Installation Style

Knob Color Options

CAPTIVE SCREW

Designed for hand operation

Fast positioning device that does not require extra tools

Plastic knob can isolate ambient heat source and static

Captive Screw- Square Type

Installation

Color Options

Dimensions (mm)

Patented.

Material and Finish

Panel Preparation

Color management for plastic material is available Copyright

Designed for hand operation

Fast positioning device that does not require extra tools

Color management for plastic material is available

Plastic knob can isolate ambient heat source and static

Captive Screw- Cloud Type Patented.

Installation

Panel Preparation

Color Options

Dimensions (mm)

Designed

Fast

Color

Plastic

Captive Screw- Square Type

Material

Installation

Panel Preparation

Color Options

Dimensions (mm)

Low profile design for hand operation

Will be fastened on the board and not loosen

Color management is available as required by customers

Plastic can prevent scalding and electricity, and have a better operational feeling

Captive Screw- Low Profile

Installation

Panel Preparation

Color Options

Dimensions (mm)

Low profile design for hand operation

Will be fastened on the board and not loosen

Color management is available as required by customers

Plastic can prevent scalding and electricity, and have a better operational feeling

Captive Screw- Low Profile

Patented.

Material and Finish

Knob: Plastic

Installation

Panel Preparation

Color Options

Dimensions (mm) Copyright © Fivetech All Right Reserved.

Low profile design for hand operation

Will be fastened on the board and not loosen

Color management is available as required by customers

Plastic can prevent scalding and electricity, and have a better operational feeling

Captive Screw- Low Profile

Patented.

Material and Finish

Knob: Plastic

Installation

Panel Preparation

Color Options

Dimensions (mm) Copyright © Fivetech All Right Reserved.

CAPTIVE SCREW

The length can be extended as required

Can be replaced with various threads and head types

Safe and reliable, high yield rate

Color, size, and other specifications can be customized

Infinity Thumb Screw Patented. Material and Finish

Recess Style

Knob High and Screw Projection

Panel Preparation

Color Options

Dimensions (mm)

LATCH LOCK

Position / non-position in one second

Intuitive operation, just flip it with your finger

Forms one piece with the main structure

Color can be customized according to needs

LATCH LOCK Patented.

Material and Finish

Installation

Panel Preparation

Color Options

Dimensions (mm)

MINI HEAD LOCK

Tool-less, quick assembling, efficient in performance.

Forms one-piece with main structure.

Hand pull could achieve the position and unleash could rebound.

MINI HEAD LOCK (Press-in Type) Patented.

Material and Finish

Knob: Plastic

Pin : 300 Series Stainless Steel, Natural Finish.

Spring : 300 Series Stainless Steel, Natural Finish.

Rivet: 300 Series Stainless Steel, Natural Finish.

Ferrule : Carbon Steel, Zinc Finish

Knob High and Screw Projection Installation Style

Knob Color Options

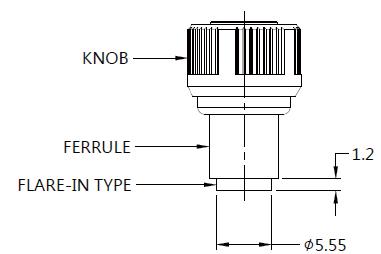

Tool less, quick assembling, efficient in performance.

Forms one-piece with main structure.

Hand pull could achieve the position and unleash could rebound

Mini head Lock (Flare-in Type) Patented.

Material and Finish

Knob: Plastic

Pin : 300 Series Stainless Steel, Natural Finish.

Spring : 300 Series Stainless Steel, Natural Finish.

Rivet: 300 Series Stainless Steel, Natural Finish.

Ferrule : 6000 Series Aluminum, Natural Finish

Knob High and Screw Projection Installation Style

Knob Color Options

The horn shape provides an outstanding operation experience

Designs with spring and will automatically rebound to the lock position when released

The effort-saving structure makes you one-second unlock easily

Side direction operation, suitable for special space restrictions

Horn Looking Slide Lock

Installation

Panel Preparation

Dimensions (mm)

Copyright © Since 2007-2016 Fivetech Technology Inc. All Right Reserved.

LATCH LOCK

Slightly push 90 degrees to unlock, and it will automatically rebound Water drop single-wing shape design, which is convenient for one-finger operation

Can be designed as a bar to prevent objects from popping up

Can be designed to organize the wires neatly

Auto Block Patented.

Material and Finish

Switch: Plastic

Rivet : 300 Series Stainless Steel, Natural Finish.

Pin : 300 Series Stainless Steel, Natural Finish.

Spring: 300 Series Stainless Steel, Natural Finish.

Ferrule : 300 Series Stainless Steel, Natural Finish.

Panel Preparation

Installation Style

Knob Color Options

Dimensions (mm)

SMT soldering process improves product reliability

Automated manufacturing production provides stability and maximizes productivity

Material of plastic knob can sustain high temperature on SMT process

Color management is available as required by customers

SMT Captive Screw- Cloud Type Patented.

Material and Finish

Knob:

Installation

Color Options

Dimensions (mm)

SMT CAPTIVE SCREW

SMT Lift Screw Patented.

Good helper for lifting the motherboard.

Both fastening and lifting functions.

Anti-scalding and anti-electricity plastic layer.

Color and riveting form can be customized.

SMT fully automated manufacturing process can increase production stability and production efficiency.

Material and Finish

Recess Style

Knob High and Screw Projection

Panel Preparation

Color Options

Material of plastic knob can sustain high temperature on SMT process

Production follows standard SMT process

Color management is available as required by customers

Functional device which prevents thread damage caused by inflow of tin in SMT process

SMT Fastener Screw

Installation

Color Options

Dimensions (mm)

Reel

Panel Preparation

Position / non-position in one second

Intuitive operation, just flip it with your finger

Color management for plastic is available

SMT fully automated manufacturing process can increase production stability and production efficiency

SMT LATCH LOCK

Patented.

Material and Finish

Installation

Panel Preparation

Color Options

Dimensions (mm)

SMT full automatic reflux welding process can increase production stability and production efficiency

Efficient performance in assembly, decomposition, and repair

Lateral movement to save space

Fast installation and removal for sliding module

SMT Slide Lock Patented.

Material and Finish

Installation

Panel Preparation

Color Options

Dimensions (mm)

MINI HEAD LOCK

Tool less, quick assembling, efficient in performance.

Forms one-piece with main structure.

Hand pull could achieve the position and unleash could rebound.

SMT fully automated manufacturing process can increase production stability and production efficiency.

Mini head Lock (SMT Type)

Patented.

Material and Finish

Knob: Plastic

Pin : 300 Series Stainless Steel, Natural Finish.

Spring : 300 Series Stainless Steel, Natural Finish.

Rivet: 300 Series Stainless Steel, Natural Finish.

Ferrule : Carbon Steel, Tin Finish

Knob

Knob Color Options

High and Screw Projection Installation Style

High and Screw Projection Installation Style

SMT full automatic reflux process can increase production stability and production efficiency

Welding for reinstallation can increase product reliability

Small size, reducing space.

A good and affordable choice.

Panel Preparation Installation Style

Dimensions (mm) Copyright © Fivetech All Right Reserved.

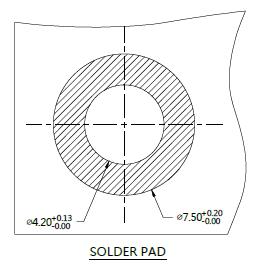

SMT Floating Nut

Provide the nut a floating mechanism in its space, fitting counterparts to absorb tolerances

The bottom square anti-rotation design provides locking torque

Locking in both directions, provides a unlimited application mode

Automated manufacturing fully helps save labor costs enhances efficiency

Installation

Patented.

Material and Finish

Dimensions (mm)

Copyright © Fivetech All Right Reserved.

Panel Preparation

Provides different axial locking direction, reducing the number of parts and saving more space

Leading end is chamfered to prevent rotation, enhancing the reliability

Two-sides locking to provide applications with less limit

Automated production improves stability and reduce labor cost

SMT

Angle Nut Patented.

Material and Finish

Nut : Carbon Steel, Tin Finish

Installation

Panel Preparation

Dimensions (mm)

STANDOFF

SMT STANDOFF

Patented.

SMT fully automated manufacturing process can increase production stability and production efficiency.

Production stability and production efficiency.

Welding for reinstallation can increase product reliability.

Reduce the PCB damage risk caused during assembling.

Material and Finish Standoff : 3000 Series Brass, Tin Finish Plug : Rubber.

Panel Preparation Installation Style

SMT SPOOL

SMT fully automated manufacturing process can increase production stability and production efficiency.

Welding for reinstallation can increase product reliability.

Spool designed for easy assembly, quick release purposes.

Lateral fastening contributes to direction limited panels.

SMT SPOOL

Patented.

Material and Finish

Spool : Carbon steel, Tin Finish.

Panel Preparation

SMT SPOOL

SMT fully automated manufacturing process can increase production stability and production efficiency.

Welding for reinstallation can increase product reliability.

Spool designed for easy assembly, quick release purposes.

Lateral fastening contributes to direction limited panels.

SMT SPOOL

Patented.

Material and Finish

Spool : Carbon steel, Tin Finish.

Panel Preparation

SMT SPOOL

SMT fully automated manufacturing process can increase production stability and production efficiency.

Welding for reinstallation can increase product reliability.

Spool designed for easy assembly, quick release purposes.

Lateral fastening contributes to direction limited panels.

SMT SPOOL

Patented.

Material and Finish

Spool : Carbon steel, Tin Finish.

Panel Preparation

SMT SPOOL

SMT fully automated manufacturing process can increase production stability and production efficiency.

Welding for reinstallation can increase product reliability.

Spool designed for easy assembly, quick release purposes.

Lateral fastening contributes to direction limited panels.

SMT SPOOL

Patented.

Material and Finish

Spool : Carbon steel, Tin Finish.

Panel Preparation

Special two-step design provides quick assembly and disassembly performance of double-layer

Double SMT Spool

Patented.

Installation

Dimensions (mm)

Replace the traditional screw-locking way, effectively saving time and cost

SMT fully automated manufacturing process increase production stability and production efficiency

Material and Finish

The intuitive operation provides the horizontal positioning function Reel

Spool : Carbon Steel, Tin Finish

Panel Preparation

SMT Angle Guide Pin

SMT full automatic reflux welding process can increase production stability and production efficiency.

Welding for reinstallation can increase product reliability. Automated production improves stability and reduce labor cost

Provides different axial locking direction, reducing the number of parts and saving more space

Patented.

Material and Finish Pin : Carbon Steel, Tin Finish

Installation

Panel Preparation

Dimensions (mm)

Automated manufacturing fully helps save labor costs and maximize productivity

The square bottom design of Fivetech SMT STUD can prevent the material from rotating and increase the torque, providing 100% reliability

The SMT soldering process improves product reliability

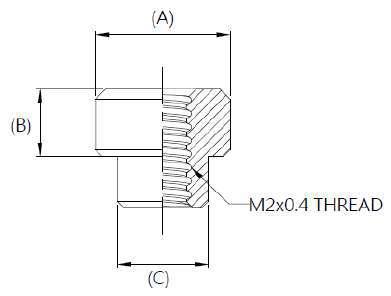

SMT STUD Patented.

Material and Finish

Panel Preparation Installation Style

Dimensions (mm)

Anti-loose function to combine two plates, and provide clamping force

Spring design absorbs tolerances, offering a perfect hand feeling

Automatic production improves stability and production efficiency, reduces labor costs

Fully automated installation process improves product reliability

SMT Spring Lock

Panel Preparation Installation Style

Dimensions (mm)

The guiding direction function can quickly align and correct

Special cutting-edge design can achieve the anti-rotation function when fastening

SMT soldering process improves product reliability

Automated manufacturing production provides stability and maximizes

Customization available

SMT Guide Lock Patented.

Material and Finish

Spool : Carbon Steel, Tin Finish.

Reel

Panel Preparation Installation Style

Dimensions (mm)

Copyright © Fivetech All Right Reserved.

Automatic rebound function provides clamping force and achieves anti-loosening

The spring can absorb tolerances of the upper and lower panels, providing a perfect operating feeling

The angle design fulfills quick-release in different axial directions

SMT fully automated manufacturing process can increase production stability and production efficiency

SMT Angle Spring Lock

Panel Preparation Installation Style

Dimensions (mm)

SMT fully automated manufacturing process can increase production stability and production efficiency.

The unique spring-loaded mechanism designed is to fixed and steady its rebound position, to solve the disturbing noise emitted by vibration.

90-degree positioning, lightweight, user-friendly.

Plastic can be customized for identity color, and the degree of pull can be customized according to the needs.

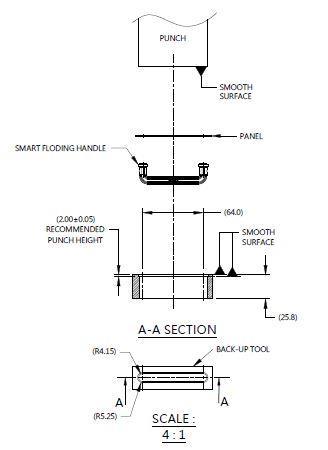

SMART FOLDING HANDLE – SMT TYPE Patented.

Material and Finish

Handle: Plastic

Pin / Rivet: 300 Series Stainless Steel, Natural Finish.

Spring : 300 Series Stainless Steel, Natural Finish.

Ferrule : Carbon Steel, Tin.

Panel preparation Installation Style

Knob Color Options

SMART FOLDING HANDLE

The unique spring-loaded mechanism designed is to fixed and steady its rebound position, to solve the disturbing noise emitted by vibration. 90-degree positioning, lightweight, user-friendly.

Plastic can be customized for identity color, and the degree of pull can be customized according to the needs.

SMART FOLDING HANDLE – PRESS IN Patented.

Material and Finish

Handle: Plastic

Pin / Rivet: 300 Series Stainless Steel, Natural Finish.

Spring : 300 Series Stainless Steel, Natural Finish.

Ferrule : Carbon Steel, Zinc Finish.

Panel preparation Installation Style

Knob Color Options

A fully automated production line saves labor costs and improves production efficiency

Plastic-made handle can improve heat resistance and electrical resistance

Color, pitch, length, size, and other specifications can be customized

Plastic Handle- Press-in Patented.

Material and Finish

Panel Preparation

Installation

Color Options

Dimensions (mm) Copyright © Fivetech All Right Reserved.

A fully automated production line saves labor costs and improves production efficiency

90-degree positioning, prevent shaking and noise

Folded when stored, saves space

Plastic-made handle can improve heat resistance and electrical resistance

Color, pitch, length, size, and other specifications can be customized

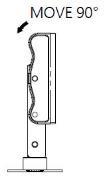

Smart Folding Handle- Flare-in Patented.

Material and Finish

Panel Preparation

Color Options

Dimensions (mm) Copyright

A good helper to draw various modules and PCBs

The T-shaped structure design is ergonomic and only needs two fingers to lift

The foldable fixed storage function helps save mechanical space

It can combine with the function of Latch Lock for easy positioning

Customized available

Low Profile Folding Handle

Patented.

Material and Finish

Latch/ Link : Plastic

Installation Panel Preparation

Dimensions (mm)

Copyright © Fivetech All Right Reserved.

A fully automated production line saves labor costs and improves production efficiency

Folded when stored, saves space

Plastic-made handle can improve heat resistance and electrical resistance

Color, pitch, length, size, and other specifications can be customized

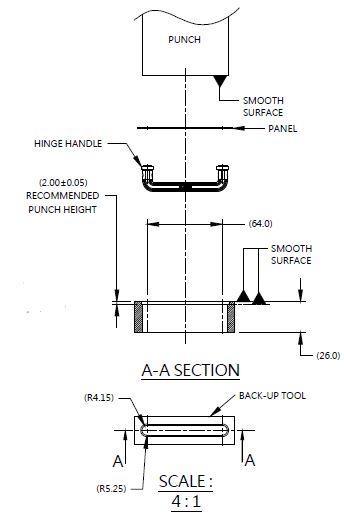

Plastic Hinge Handle- Press-in

Material and Finish

Rivet:

Panel Preparation

Patented.

Color Options

Dimensions (mm) Copyright © Fivetech All Right Reserved.

Installation

A fully automated production line saves labor costs and improves production efficiency

Folded when stored, saves space

Plastic-made handle can improve heat resistance and electrical resistance

Color, pitch, length, size, and other specifications can be customized

Plastic Hinge Handle- Flare-in

Material and Finish

Rivet:

Panel Preparation

Patented.

Color Options

Dimensions (mm) Copyright © Fivetech All Right Reserved.

Installation

A

Folded when stored, saves space

Plastic-made

Color, pitch, length, size, and other specifications can be customized

Plastic Hinge Handle- Floating Patented.

Material

Panel Preparation

Installation

Color Options

Dimensions (mm)

Spring force increases spool securing tightness.

Decreases loosening possibility caused by vibration.

Spool designed for easy assembly, quick release purposes.

Lateral fastening contributes to direction limited panels.

SPRING LOCK

Patented.

Material and Finish

Ferrule : Carbon steel, Zinc Finish.

Cap : 300 Series Stainless Steel, Natural Finish.

Rivet : 300 Series Stainless Steel, Natural Finish.

Spring : 300 Series Stainless Steel, Natural Finish.

Projection Installation Style

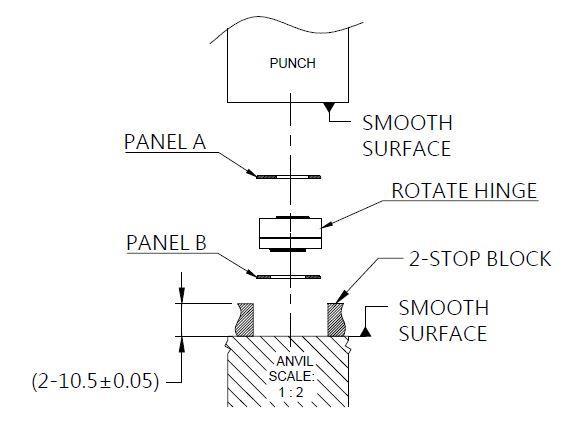

Multi-stage positioning function, increase the design diversity

Smooth rotation with excellent operating feeling

Humanized operation and high reliability

Rotate Hinge Patented.

Installation Panel Preparation

Dimensions (mm)

Efficient performance in assembly, decomposition, and repair.

Forms one-piece with main structure

Hand push could achieve the position and unleash could rebound.

PUSH LOCK Patented.

Material and Finish

Wrench : Plastic

Rivet : 300 Series Stainless Steel, Natural Finish.

Pin : Carbon Steel, Zinc Finish.

Spring : 300 Series Stainless Steel, Natural Finish.

Ferrule : Carbon Steel, Zinc Finish.

Knob Color Options

Special designed knob offers ergonomic hand grip when pulling.

Anti-scalding and anti-electricity plastic layer.

Both fastening and lifting functions.

Plastic color and product specification can be customized.

PULL HANDLE (T TYPE) Patented.

Material and Finish

Installation

Panel Preparation

Color