Characteristics & Advantages of Sugar Centrifugal Screen

Characteristics/Advantages of Sugar Centrifugal Screen

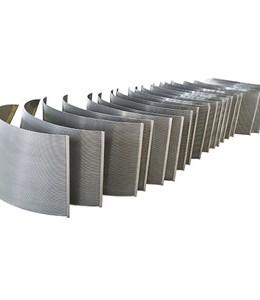

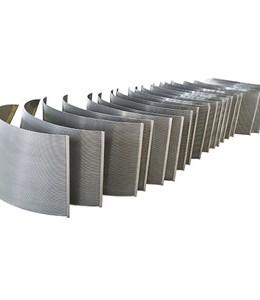

A sugar centrifugal screen plays a vital role in producing commercially clean forms of sugar. These screens are used to get rid of the molasses from the sugar crystals under centrifugal force. They are manufactured to attain the finest possiblemolassesseparationandoverflow.

The efficiency of centrifugal machines and sugar productionisinfluencedbytheperformanceofthis screen. Available in different sizes and made up of copper or brass, or stainless steel, they have a round hole and slotted screens that make them suitableforvarioustypesofapplications.

Someadvantagesinclude:

Better Productivity

Purchasing a sugar centrifugal screen from the best sugar screen manufacturer or exporter helps in better separation and, thereby,betterproductivityofsugar.

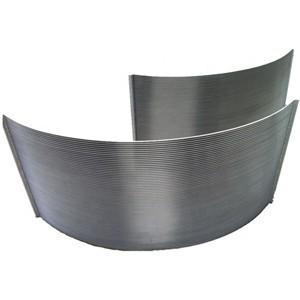

Durable

The best sugar screen exporter and manufacturer will ensure that the product has minimum broken black holes and punches. A great screen is uniformly thick along and throughout the joints. This allows the screen toworkeffectivelyforalongduration.

Efficient residue removal

When sugar screens are used in the separation process, they offer better performance. This allows effective but minimalresidueremoval.Sugarscreensboost the capability of the overall procedure in the productionofsugar.

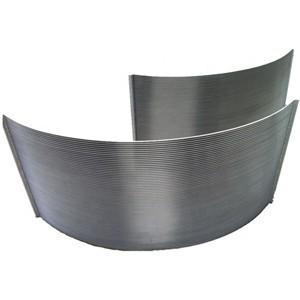

Easy to install and clean

If customers follow the proper instructions of a sugar screen manufacturer, it will be easy to install, use, and operate. The straight and parallel side margins keep the residue minimal, thus making the cleaning process simple andeasy.

To ensure your sugar centrifugal screen last for a long time and is of high quality, purchase from a reputed and reliable sugar screen manufacturers like Fine Perforators.

14, Rani Jhansi Road, New Delhi110055, India Tel: 0091-11-23551444 / 0091-1123679444 Mob: +91 97114 70084 Fax: 0091-11-23613075 Email: fineperforators@gmail.com, info@finehole.com Website: https://www.finehole.com