Gantry Plasma Cutting Machine Manufacturers: Fine Cutting Solution

FineCuttingSolutionisaleadingtop-qualitygantryplasmacutting machinemanufacturersinIndia,deliveringprecisionandefficiencyfor diverseindustrialapplications.Formore,contactus!

FineCuttingSolutionisaleadingtop-qualitygantryplasmacutting machinemanufacturersinIndia,deliveringprecisionandefficiencyfor diverseindustrialapplications.Formore,contactus!

Overview

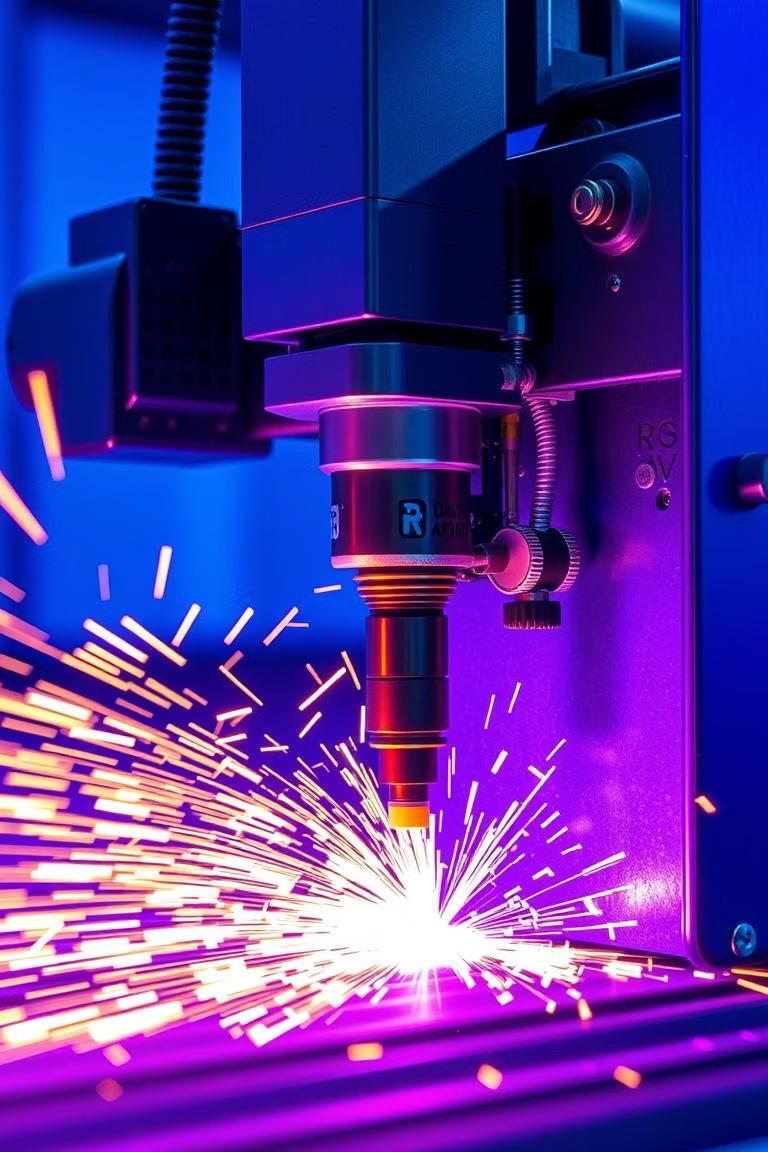

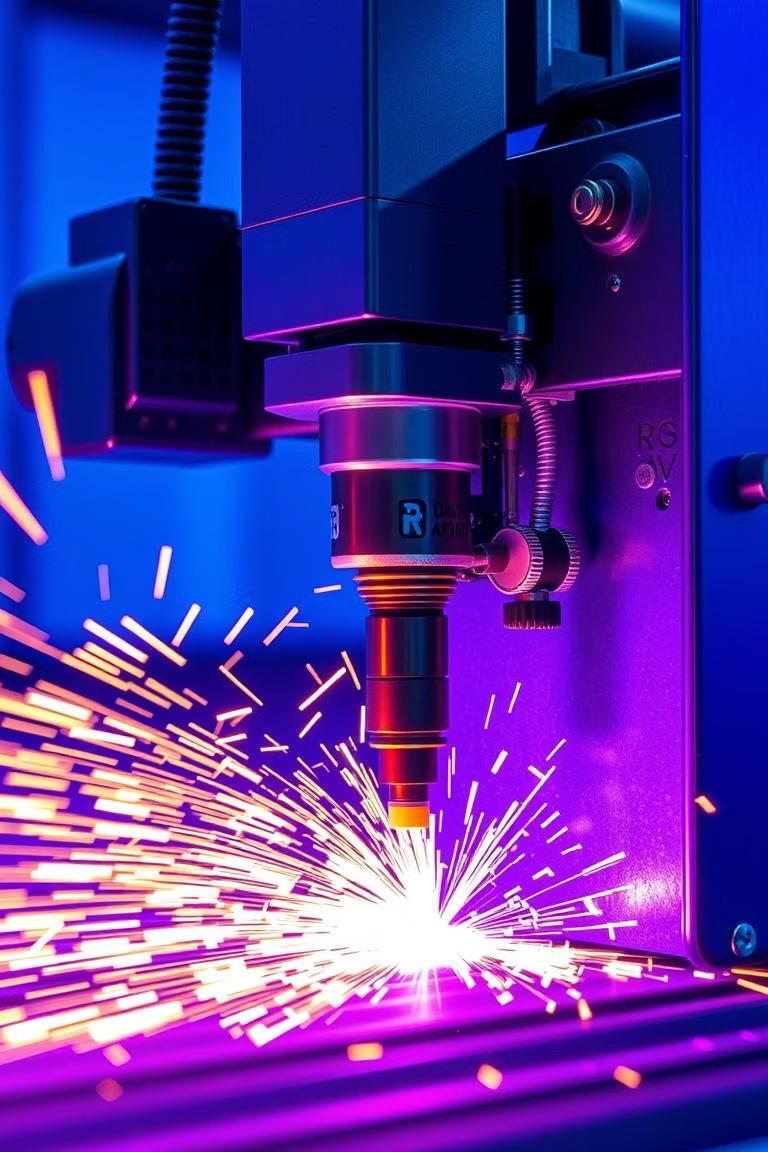

GantryplasmacuttingmachinesareCNC-controlledsystems thatutilizeahigh-temperatureplasmatorchtopreciselycut variousmetalmaterials.

Working Principle Theyworkbydirectingahigh-velocitystreamofplasmagas ontothemetalsurface,effectivelymeltingandseparatingthe material.

1 High Cutting Speed

Gantryplasmacuttersoffer significantlyfastercuttingspeeds comparedtotraditionalmethods.

2 Excellent Cutting Quality

CNCcontrolensurespreciseand consistentcuts,resultinginhighqualityfinishedproducts.

3 Versatile Material Compatibility

Thesemachinescanhandlea widerangeofmetalmaterials, includingsteel,aluminum,and stainlesssteel.

CNCcontrolensuresprecisemovementsandeliminateshumanerror.

Themachinefollowspre-programmedpaths,resultinginhighlyaccurateand repeatablecuts.

Precisecuttingminimizesmaterialwaste,leadingtocost savingsandefficientresourceutilization.

1Diverse Cutting Patterns

2Different Thicknesses

3Customizable Cutting Settings

Gantryplasmacuttingmachinescanhandleawiderangeofcuttingtasks,fromsimplestraightlinestocomplexshapesand intricatedesigns.

Automatedcuttingprocesses significantlyincreaseproduction speeds,allowingforgreateroutput inashortertimeframe.

Automationreducestheneedfor manuallabor,leadingtosignificant costsavingsandincreased efficiency.

1

2

Thecuttingareacanbetailoredtomeetspecificproduction requirements.

Optionslikeautomatictorchheightcontrolandbevel cuttingenhanceversatilityandperformance.

Gantryplasmacuttingmachines findwidespreaduseinvarious industries.

25%

Increased Efficiency

Casestudiesdemonstrate significantincreasesinproduction efficiencyandcostsavings.