Fiberpartner, booth at INDEX™

Fiberpartner, booth at INDEX™

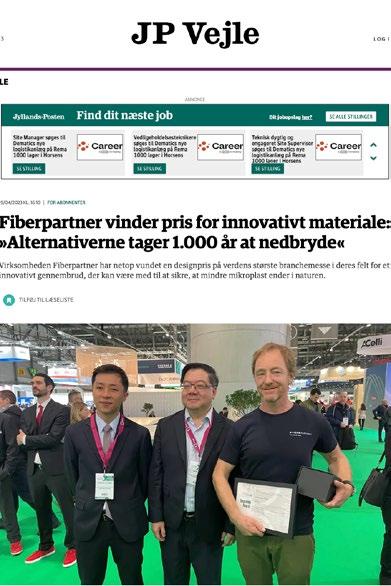

Team Fiberpartner, PrimaLoft®, Far Eastern, and Edana

Team Fiberpartner, PrimaLoft®, Far Eastern, and Edana

Fiberpartner, booth at INDEX™

Fiberpartner, booth at INDEX™

Team Fiberpartner, PrimaLoft®, Far Eastern, and Edana

Team Fiberpartner, PrimaLoft®, Far Eastern, and Edana

edana: INDEX™ Awards: 2023 Winning Entries - click here

A future proof bicomponent fibre core sheath construction, developed from materials with a low carbon footprint, this component was designed to biodegrade in the environments where most plastics eventually find themselves: landfills and ocean water.

• The BioBased PE is produced from sugar cane and has a negative carbon footprint.

• The Recycled PET is GRS certified.

• PrimaLoft® Bio™ an additive technology that enables polyester and fabric fibres to biodegrade in the environment.

Fibres can be processed in a variety of nonwovens technologies and used for different applications. The jury recognized that the hydrolytic biodegradation of fibres in landfill is beneficial for some nonwovens applications.

The fibers are available from 1,5 – 3 deniers and is available in short cut for airlaid as well as longer cutting lengths for carded applications such as air through for hygiene applications, e.g. top sheet as well as industrial applications for insulation. It is engineered to bond to both synthetic and natural fibers.

The performance and durability of the fibers are virtually the same as regular virgin based materials: little or no adjustments needed in the process.

The new innovative fiber is a joint development of FENC in Taiwan & Fiberpartner in Denmark.

PrimaLoft® Bio™ is an additive technology that enables polyester and nonwoven fibers to biodegrade* in the environment. A revolutionary breakthrough that offers a previously unattainable level of performance and climate footprint, reducing microplastics in our landfills and oceans, PrimaLoft® Bio™ is a first-of-itskind technology and represents a critical component to a product’s lifecycle – a safety net should the product shed during laundering or end up in a landfill. It is simply designed to return to materials found in nature.

PrimaLoft® Bio™ has been specifically designed to biodegrade* in the environments where the vast majority of plastics eventually find themselves: landfills and ocean water. According to independent testing, PrimaLoft® Bio™ reached 93.8% biodegradation* in 646 days when exposed to an accelerated landfill environment. At the conclusion of this test, the remaining material was found to contain no trace of plastic, leaving behind only natural, carbon based elements! And what is even better, additional independent testing concluded that the soil left behind remains perfectly suitable for plant growth.

PrimaLoft® Bio™ biodegrades* only by hydrolytic-degradation, the destruction of plastics by hydrolysis exposure to moisture under certain conditions, which results in the scission of molecular bonds, and PrimaLoft® Bio™ will eventually leave no traces of microplastic behind.

*Biodegradable: 93.8% biodegradation in 646 days under ASTM D5511 conditions (landfill environment); 87.9% biodegradation in 1953 days under ASTM D6691 conditions (marine/ocean environment). 47.4% biodegradation in 481 days under ASTM D5210 conditions (wastewater environment); 29.9% biodegradation in 196 days under ASTM D5988 conditions (Soil environment). The stated rate and extent of degradation does not mean that the product will continue to degrade.

18 to 21 April 2023

PALEXPO, Geneva