A BRAND IS A GUARANTEE OF VALUE AND TRUST IS THE MOST IMPORTANT INGREDIENT TO IT

MR JOB PHI - CEO

A BRAND IS A GUARANTEE OF VALUE AND TRUST IS THE MOST IMPORTANT INGREDIENT TO IT

MR JOB PHI - CEO

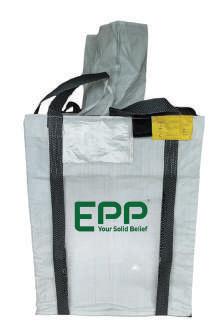

With our 20-year experience in manufacturing and exporting, EPP Vietnam Co., Ltd. was established to bridge the gap between manufacturers and customers and become a leading supplier in Vietnam's plastic packaging industry. Our mission is to provide a comprehensive range of plastic packaging products, including FIBCs (Types A, B, C, D, FRAS bulk bags, Food Grade bags, UN bags, Ventilated bags, and Mesh bags), PP woven bags, Kraft paper laminated PP woven bags, BOPP bags, agricultural films, and PE liners.

We have successfully exported high-quality products to markets in Australia, New Zealand, the United States, Canada, Germany, Norway, Portugal, Africa, UAE, Chile, and other countries with stable quality, competitive prices, and professional services.

EPP Vietnam can currently supply 6 million products annually, underscoring our commitment to meeting customer needs.

With a quality management system aligned with international standards such as ISO 9001:2015, ISO 14001:2015, ISO 22000:2005, HACCP, FSSC 22000, and BRC,… as well as test reports for each product and our professional quality control team we assure our customers of products with "Stable Quality."

Leveraging a comprehensive product control norm system and fostering strong relationships with manufacturers, we identify and utilize each factory's advantageous products. This approach allows us to meet customers' diverse product needs while maintaining a "Competitive Price."

We are committed to providing customers with "Professional Service," which includes consulting on precise product specifications, providing quotes within one working day, ensuring a maximum lead time of four weeks per order, shipping directly to the customer’s port, offering diverse payment methods (TTR, L/C, etc.), resolving complaints within one working week, and consistently listening to customer feedback.

Unity is strength. When there is teamwork and cooperation, great things can be achieved. We cannot go back to the past, but we can create a bright future together. Let's maintain the team spirit and look towards the future, towards the community.

Become a leading supplier in Vietnam specializing in distribution and production. We support manufacturers quickly and closely connect with customers.

Provide a comprehensive range of plastic packaging products, including FIBCs (Types A, B, C, D, FRAS bulk bags, Food Grade bags, UN bags, Ventilated bags, Mesh bags), PP woven bags, Kraft paper laminated PP woven Bags, BOPP bags, agricultural films, and PE liners,…

Our production process has met regional and international standards. Our products are always strictly guaranteed in terms of production processes to create the highest quality products for customers.

The materials are PP & HDPE resin; color, UV, and antistatic masterbatch; non-flammable masterbatch and yarn; conductive carbon yarn; and other additives selected and imported from reliable suppliers according to each product's specifications.

Extruder machines (450-650kg/h) imported from famous international brands such as Starlinger, Lohia, Hana, Hengli, and Yong Ming, … help to create the best yarn with good tensile strength, and stable elongation according to high-quality standards.

Monofilament - making machine (200kg/h) produces high-quality mono yarn with diverse Denier.

Plastic film blowing machine (capacity 160kg/h) can create PE film from 1500mm to 4500mm which will be used to produce FIBC liner.

Circular loom machines (60-100 rpm, 900-2200mm in width) can produce woven fabric rolls with high density and diverse sizes. The fabric surface is also tight and stable.

Belt ribbon Loom (80-150m/h) can create loops from 20mm to 110mm in width with high strength and good loading.

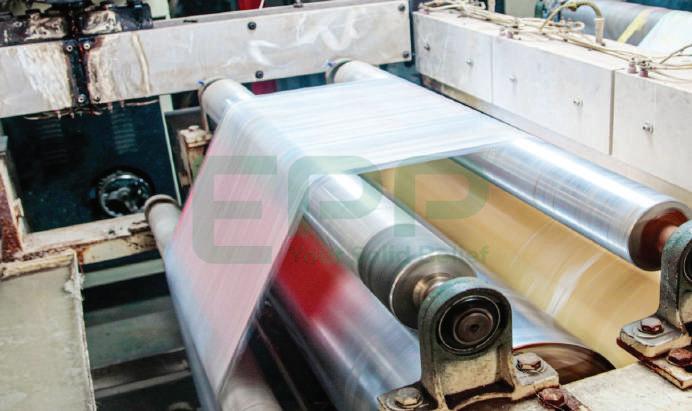

High-speed lamination machines (1 side, 60 -120 meter per minute) are imported directly from Taiwan, China, and India… Lamination density between 15-30 grams per square ensures adhesion and waterproof ability.

Fabric cutting machine systems (15-20pcs/m) can make semi-finished products with various dimensions and high accuracy according to customer's request.

Belt cutting machines (30-60pcs/m) can cut 1- 6 belts at a time.

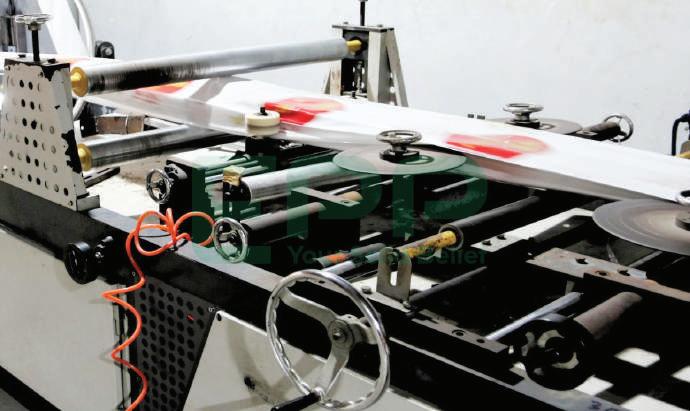

3-5 color Flexo printing machine (200-1200pcs/h) and our high-quality printing colors create sharp, accurate prints with good adhesion.

Our modern sewing machine systems (800-1200 rpm) can meet all technological requirements for FIBC bags such as single or double-needle sewing, over-lock sewing, and chain stitch sewing, …

Moreover, our skilled sewing workers meticulously stitch the essential components and accessories to the bags, producing the finished FIBC bags.

With professional international shipping services, we commit to delivering the products to customers safely flexibly, and on schedule.

With leading technologies, we hope to bring customers the best quality products.

FABRIC TENSILE TESTING MACHINE

YARN TENSILE TESTING MACHINE

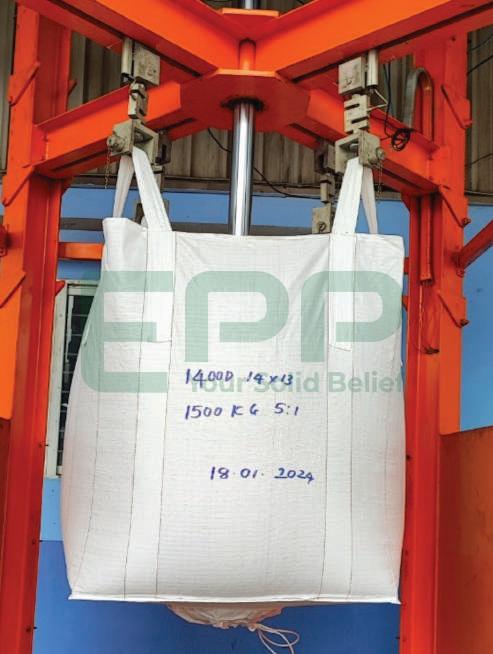

FIBC TESTING RIG

Safe to produce, production must be safe

Safe to produce, production must be safe

WATER JET LOOM

5-LAYER FILM BLOWING MACHINE

BOPP FILM LAMINATING MACHINE

https://eppvietnam.trustpass.alibaba.com