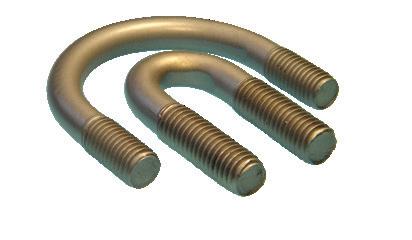

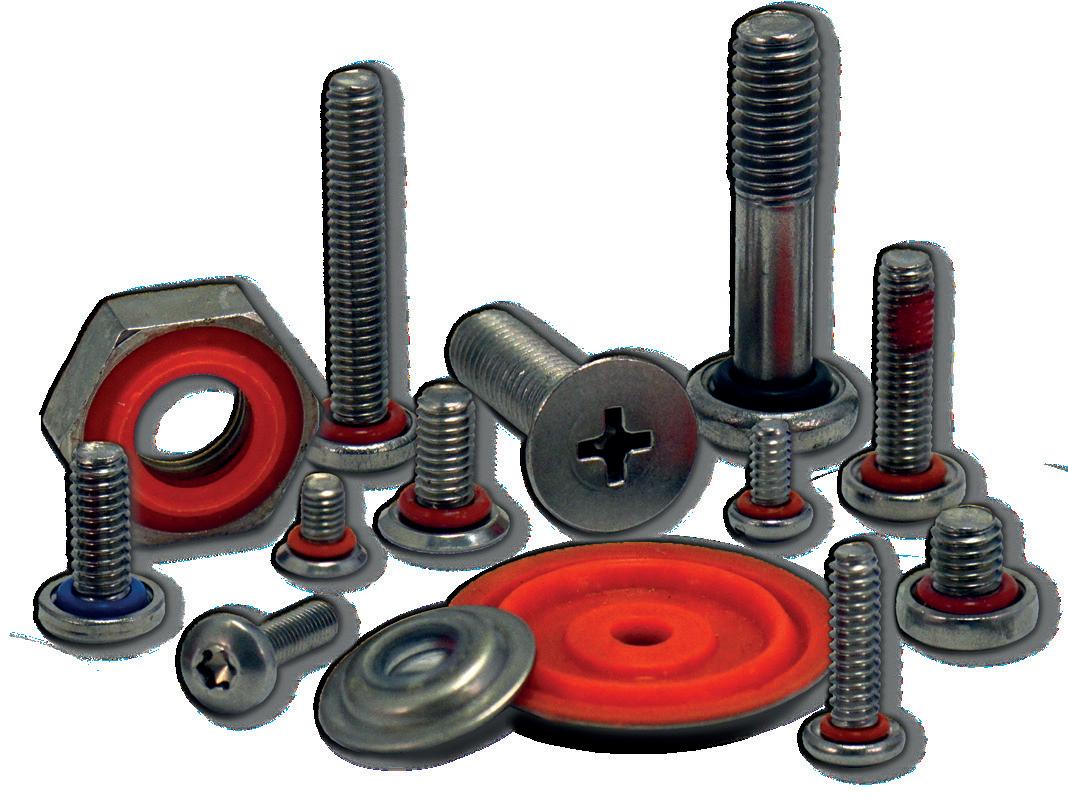

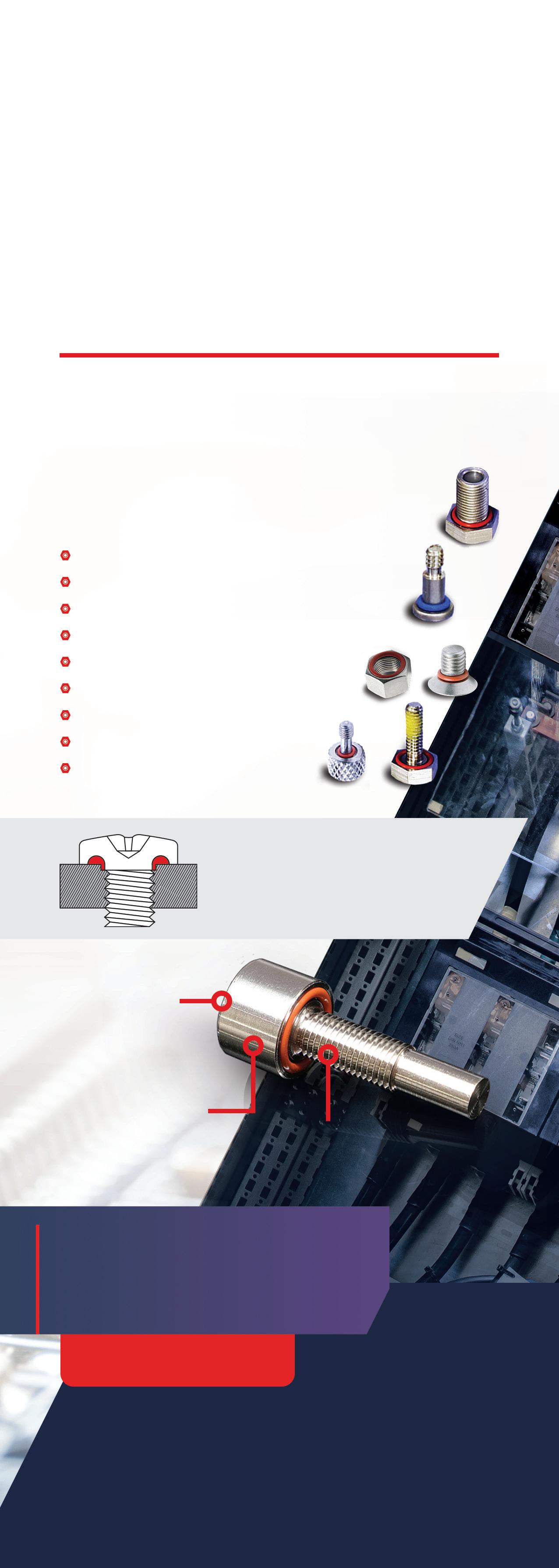

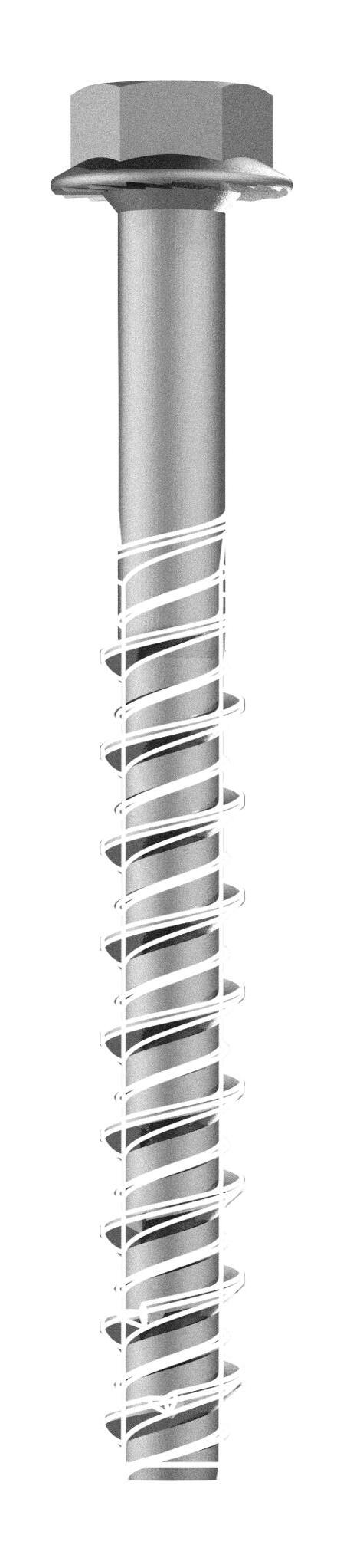

Are you facing challenges developing your application? We offer a tailored solution with lightweight design, more clamping force and smaller fasteners.

KAMAX experts challenge your drawing, analyze your problem and review your application. Our dedicated Application Engineering team is always at your side.

What you need is what we have: bolt design, lab validation, simulation of assembly conditions, supply of test parts as well as high-quality production and shipping of your fastener solution – anywhere in the world.

www.kamax.com

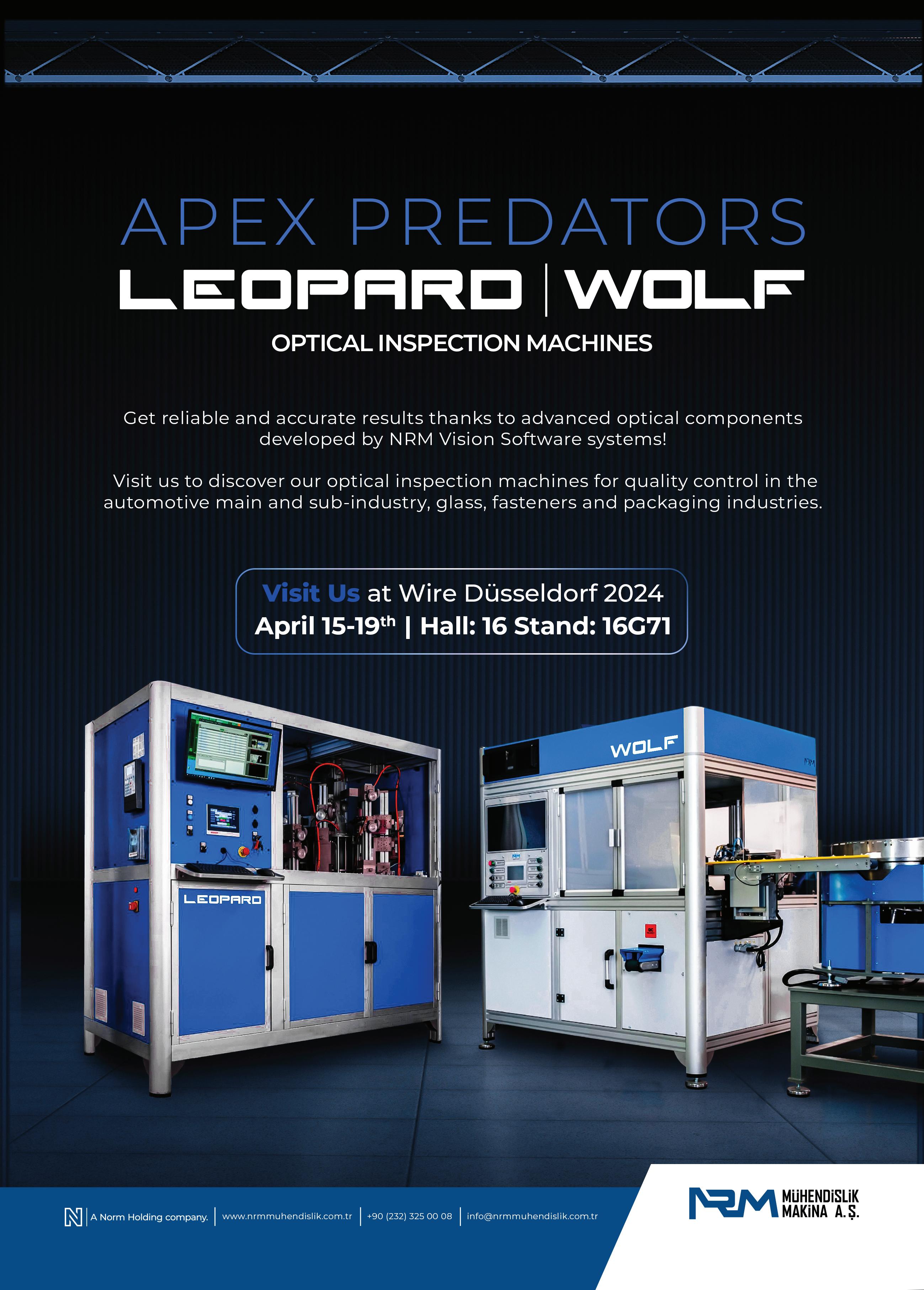

Purchasing additional machinery is always a big investment, but can often be an essential part of a business taking the next step in its development. With automation, digitisation, sustainability and Artificial Intelligence key topics within the market, plus the upcoming wire® Düsseldorf show, we felt it was a perfect time to put a spotlight on the latest developments within fastener machinery.

In our special Fastener Machinery Spotlight feature, we look to provide a unique insight into key areas within the fastener machinery sector, as well as give visitors to the wire® Düsseldorf show, due to take place from 15 th – 19th April, the opportunity to see what they can expect from exhibitors at the show.

The feature includes articles on every aspect of the fastener production process – heading and forging, tooling and dies, threading and secondary operations, turning and milling, heat treatment, as well as inspection and packaging – ensuring that readers will find the latest news on whatever machinery they are looking to update.

Our Cover Story also concentrates on a fastener machinery expert – the world-renowned manufacturer of multi-station cold forming machines for high-precision metal components and fasteners – SACMA Group. The article focuses on how the Italian manufacturer has used a commitment to quality, modularity, excellence, reliability, customer centricity, continuous improvement, innovation, team working, and employee engagement, as its core values to make it the business it is today.

Part of the Mack Brooks Group

www.fastenerandfixing.com

Published by

Managing Director Jamie Mitchell jamie.mitchell@verulammedia.com

Content Director

Will Lowry

will.lowry@verulammedia.com

Deputy Editor Claire Aldridge claire.aldridge@verulammedia.com

Within the Manufacturing Technology section, we also have a great article from Peter Standring, technical secretary, Industrial Metalforming Technologies, who asks the question ‘why heading and forging’ and looks at how even today heading and forging holds secrets that can be easily overlooked.

In addition to sourcing new machinery, a key factor for a lot of readers currently is looking at new suppliers, especially with the global tensions currently around the world. With that in mind, we have an exclusive Made In India feature that not only looks at the current economic situation within India and the Indian fastener market, but also showcases some of the key Indian fastener manufacturers and the steps they have been taking to ensure they can support both existing and new customers going forward in order to take advantage of the opportunity within the market.

To add to this, we have articles from our usual contributing authors – Barbara Sorgato in Construction Fixings and Jason Bader in Management + Systems. We also have special insight articles on Fabory UK, PennEngineering®, Apex Stainless, Remaches Tudela and International Hi-Tech Consulting Srl, as well as features on structural steel and cladding fasteners, rivets and rivet nuts, plus so much more.

Assistant Editor Rebecca England rebecca.england@verulammedia.com

Sales Director Mac Rahman mac.rahman@verulammedia.com

Business Development Manager –Italy

Emiliano Pagliaroli emiliano.pagliaroli@verulammedia.com

Business Development Manager –DACH & Europe Chantal Ridings chantal.ridings@verulammedia.com

Production & Design Manager Lee Duskwick lee.duskwick@verulammedia.com

Bulten AB has reported net sales amounting to SEK 5.757 billion (€510.7 million) for the financial year 2023, an increase of 28.7% on the same period the previous year (2022: SEK 4.474 billion). Operating earnings (EBIT) totalled SEK 230 million (2022: SEK 180 million), equating to an operating margin of 4%.

Adjusted operating earnings

totalled SEK 243 million (2022: SEK 284 million), equating to an adjusted operating margin of 4.2%. Operating earnings were charged with the transaction costs of SEK 13 million – attributable to the acquisition of Exim, an Asian distributor of fasteners and other components.The corresponding period of the previous year was adjusted by approximately SEK 104 million –where SEK 93 million was related to ‘winding up’ costs for Bulten’s operation in Russia.

Based in Singapore, Exim has annual sales in the region of SG$40 million (SEK 320 million). The acquisition affords Bulten a good platform to grow in new sectors, where the distribution stage is a pivotal sales channel.

“2023 was the year when Bulten laid the foundation for future expansion

opportunities in the distribution stage, as well as micro screw sales, through acquisitions and establishing new operations. It was also a year of very high sales, which unfortunately resulted in capacity challenges and also had a negative impact on operating profit, both in Q4 and for the year as a whole,” explains Bulten.

After five years as Bulten’s CEO and president, Anders Nyström departed the company in early February, to pursue “other challenges”. A process to recruit a new CEO and president is underway, having been initiated by the board of directors.

Departing, Anders said: “It has been a privilege to lead and develop Bulten together with the board of directors and all professional employees. My decision to leave has not been

easy, but I feel that the time is right for me to take on new challenges after these five years as CEO of the Group.”

Chairman of the Board Ulf Liljedahl added: “Through his leadership and commitment, Anders has played an important role in successfully developing Bulten AB and taking the company to its current position. During Anders’ time as CEO, the company has experienced strong growth at the same time as the market has been in a period of change. On behalf of the board of directors, I would like to express my thanks to Anders for his valuable contribution during these years and wish him all the best in the future.”

Current Board Member Christina Hallin has been appointed interim CEO and president and will act as such until a replacement has been found for the position.

Despite the tense global economic and political situation, Würth Group was able to grow again, even though the difficult conditions had an impact on its operating result.

Würth Group reported annual sales of more than €20 billion for the first time in its corporate history, according to its preliminary financial statements on the 2023 fiscal year. Adjusted for currencies, sales growth came out at 3.5%. The operating result is expected to remain below last year’s result at €1.4 billion (2022: €1.6 billion), the second best result in the history of the Group.

“Given the cooling global economy, we are satisfied with the past fiscal year. The sales mark of €20 billion is a special milestone for us, as it shows we were able to double our sales volume over the past nine years,” says Robert Friedmann, chairman of the central management board of Würth Group. “Last year, the Group’s heterogeneous structure across different industries and regions, and our business model, were once again the basis of our success. The construction sector, an important industry for Würth Group, showed a slow sales development, which could be compensated for by other strategic business units, such as the Electrical Wholesale unit.”

The ongoing conflict between China, Taiwan, and the USA; the wars in Ukraine, and the Middle East; inflation driven cost increases –especially for energy and raw materials; and high lending rates; all hampered demand in the construction industry, which also had a negative impact on the result.

“Achieving these results in such an environment shows that our more than four million customers greatly appreciate our products and services. They trust us and that is our most important objective. The Würth Group has proven in the past that it can overcome major challenges successfully. The solidarity of our employees and the support of the family, especially by Prof Reinhold Würth and Bettina Würth, give us the necessary stability,” emphasises Robert Friedmann.

In an economically challenging market environment, marked by a strong Swiss franc, Bossard Group achieved sales of CHF 1.069 billion (€1.113 billion) in the financial year 2023 (2022: CHF 1.153 billion) – representing a decrease of 7.4% (in local currency: -2.6%).

Bossard explains that the positive business momentum that continued into the first quarter of 2023 normalised over the course of the year. Normalisation of incoming orders in the course of customer inventory reductions seamlessly transitioned to weaker customer demand. Economic indicators also deteriorated as the year progressed. However, thanks to stable demand in parts of the growth industries, and the gratifying performance of Smart Factory services, Bossard was still able to strengthen its market position in all three market regions.

In Europe, Bossard posted a drop in sales of 6.1% to CHF 586.4 million (in local currency: -3.5%). This result was a consequence of the economic slowdown and normalisation of demand, as well as the stronger Swiss franc. Despite tough economic conditions, the electromobility and railway sectors showed positive accents. In an environment marked by inflation and a shortage of skilled labour, Bossard’s Smart Factory services drew even more attention from customers.

After a phase of double-digit growth rates, demand in America also began to normalise over the course of the year. While sales increased by 3.6% in local currency, sales in Swiss francs declined by 2.6% to CHF 301.5 million. The successful expansion of the customer base over recent years was particularly evident in the positive development of the focus industry of

electromobility. Bossard Ontario Inc, in Canada, which was consolidated since 1 st December 2022, contributed to the sales performance.

Sales in Asia declined by 17.8% to CHF 181.1 million (in local currency: -9%). Particularly in this market region the appreciation of the Swiss franc was significant. Apart from the gratifying development in India, the overall demand momentum in Asia was restrained. Especially in China, where only slight growth momentum was felt after Covid-19 restrictions were lifted. In India, Bossard benefited from nearshoring trends, a dynamic start-up landscape, as well as infrastructure projects in the focus industry of railway.

“At this point in time, it is difficult to forecast how the challenging economic environment will evolve over the coming quarters,” reports Bossard. “Based on current market observations, we expect restrained development in demand in the first half of 2024, along with a continued rise in wage levels. However, even this market environment holds opportunities for growth. The stronger trend toward nearshoring and the digitalisation of processes to increase efficiency, and productivity, should further strengthen demand for our Smart Factory services – in a current environment marked by cost and wage inflation. We continue to stand by our medium term financial goals previously communicated and the consistent implementation of Strategy 200.”

NORMA Group has presented its preliminary figures for the financial year 2023 and the fourth quarter of 2023. With slightly lower sales, the company achieved stable profitability and strong cash flow.

CEO Guido Grandi comments: “We achieved a sound result in 2023 in a challenging environment. We enhanced the efficiency of our operating business more; mitigated the effects of inflation related cost increases; and attracted new customers for our innovative joining technology. In the second half of the year, our improvement measures took effect, so that we achieved a significant increase in earnings in the fourth quarter compared to the previous year. Overall, we achieved a stable margin and considerably increased cash flow.”

Preliminary, unaudited figures put NORMA Group sales in the financial year 2023 at €1.223 billion. Compared to the previous year, the company achieved organic growth of 0.7%. Negative currency effects, however, slowed sales growth by 2.4%. Overall, Group sales were down slightly, declining 1.6% compared to the previous year (2022: €1.243 billion).

Net operating cash flow improved significantly compared to the previous year, reaching €87.3 million (2022: €65.3 million). The primary driver of the strong cash inflow was the lower (trade) working capital, as a result of consistent liquidity management and optimised inventory management.

According to preliminary figures, sales in the period from October to December 2023 fell organically by 1.7% compared to the same quarter of the previous year. This is partly due to a temporary reduction in order ‘call offs’ in the USA following widespread strikes at US vehicle manufacturers in the fall of 2023. Negative currency effects also reduced growth in the fourth quarter by 3.4%. Overall, Group sales dipped 5.1% compared to the same quarter of the previous year to €286.7 million (Q4 2022: €302.1 million).

Guido adds: “Our development expertise combined with our global presence makes us a strong partner for our customers in different markets and countries. I am confident that we will be able to generate further profitable growth in our three strategic business units of Water Management, Industry Applications and Mobility & New Energy. With our ‘Step Up’ improvement programme, we have laid an important foundation in this regard and have already seen initial successes.”

Thanks to Böllhoff Group’s broad product range and international orientation, it was able to achieve an annual turnover of €809 million in 2023 – representing an increase of around 3.3% over the previous year (2022: €783 million).

Michael W Böllhoff, co-CEO at Böllhoff Group, comments: “Despite difficult market conditions worldwide, we were able to achieve moderate growth for our group of companies. This is essentially due to our broad product and service portfolio, as well as our international company network – with our own locations in 26 countries on 5 continents.”

Co-CEO Wilhelm A Böllhoff adds: “It is especially noteworthy that Germany did not contribute to this growth. There is a pressing need for improvements of the much discussed framework conditions in our country, as well a need for more courage, confidence and trust in our own and overall economic strength, also when it comes to creating innovations.”

In 2023, the most important drivers of growth for Böllhoff Group’s sales were India, Mexico and Turkey. For the first time in many years, China did not contribute to growth, largely due to currency impacts.

Looking at Böllhoff’s individual customer groups, past investments in the expansion of the aviation business had a particularly positive effect. Since 2021, the Group has acquired two French manufacturers of special fasteners for aerospace – SNEP SA based in Montbrison, in June 2021, and Gillis Aerospace from Dieupentale, in June 2022.

Demand from the automotive industry, however, remained subdued, characterised by uncertainty in view of the ongoing structural changes in the industry.

Böllhoff Group underlines that the outlook for 2024 is difficult and uncertainty remains high. Many markets are in transition and companies in Böllhoff Group’s customer segments are reducing capacity in some cases or relocating them to other countries.

“We are therefore continuing to work on improving our productivity and processes, in order to remain an all round competent partner for joining technology for our customers,” says Michael W Böllhoff.

“We are also continuing to invest in the company, despite the difficult overall economic conditions – in 2024 this means topics related to digitalisation, as well as in the training and further education of our employees,” adds Wilhelm A Böllhoff.

SFS Group achieved its defined growth targets despite a difficult economic environment in the financial year 2023. Third-party sales of CHF 3.090 billion (€3.217 billion) were generated – a strong increase of 12.6% against the prior year period that was underpinned by robust organic growth of 2.1%. Consolidation effects stemming from the inclusion of Hoffmann as 1st May 2022, accounted for 14.6% of the sales growth.

Geopolitical and macroeconomic developments had a major impact on SFS Group’s activities in 2023. Key leading economic indicators deteriorated considerably over the course of the year. Many customers reduced their inventories as a result of the normalisation of supply chains, after Covid-19 related disruptions, aggravating the situation further.

The Engineered Components segment deftly used the seasonal ‘ramp up’ of components for use in mobile devices in the second half of 2023 to boost the results of the first half year. Demand in the segment’s other end markets remained unchanged overall during the course of the year, whereat Automotive and Medical saw very dynamic organic growth. The segment generated sales of CHF 987.7 million (2022: CHF 1.028 billion).

The Fastening Systems segment achieved a solid result in a weakened market environment with partially high-levels of inventory along the entire value chain – generating sales of CHF 615.3 million (2022: CHF 644.9 million).

After a strong first half of the year, the Distribution & Logistics segment experienced deteriorating market demand during the course of the year. This resulted in a decline in order intake, which was partially offset by the high order backlog. The segment generated sales of CHF 1.487 billion (2022: CHF 1.073 billion). Consolidation effects stemming from the inclusion of Hoffmann accounted for CHF 400.6 million of sales.

With sales growth of 9% in local currencies, Hilti Group reports that it outperformed the market with a total 2023 turnover of CHF 6.5 billion (€6.767 billion). In Swiss francs, growth reached 2.7%, reflecting a significantly negative currency impact.

At a regional level, Europe managed to close the year with sales growth of 8.7% in local currencies, primarily driven by the strong contribution from southern Europe. The Americas region grew by 9.1%, while Asia/Pacific was at 13.8%. China recovered slowly from Covid-19 lockdowns, while the rest of the region achieved solid growth rates. The ongoing war in Ukraine had an impact on the entire EEMEA region (eastern Europe, Middle East and Africa), resulting in growth of 3.1%. The continuous appreciation of the Swiss franc against all major currencies resulted in a negative impact of 6.3% on sales.

“Despite the ongoing economic and geopolitical uncertainties, we grew at a high single digit rate in local currencies and, with that, outperformed our industry. We expect a further softening of the environment in 2024 but are well equipped to face this challenge and confident to continue our growth,” reports Jahangir Doongaji, CEO at Hilti Group.

For 2024, Hilti Group expects a mid-single digit sales growth in local currencies with a significantly negative currency impact in Swiss francs.

Spanish-based Smartfix has announced Carlos Jiménez as its new CEO, as well as a host of modernisation initiatives that include incorporating a new logo, an updated catalogue and an enhanced website.

Smartfix Tecnologia & Innovacion S.L has a customer centric philosophy as the core of its business model and says it takes pride in ensuring a seamless customer experience. From an intuitive ordering process to responsive customer support, every interaction reflects the company’s commitment to provide excellent service.

New CEO Carlos Jiménez, who has taken over from company founder Jose Juan, explains: “We are committed to preserving the values that have defined Smartfix over the years. Quality manufacturing and distribution of blind rivets and self-clinching fasteners are not just a product line, but a legacy we are dedicated to preserving under new leadership.”

In 2023, Smartfix experienced significant domestic growth, solidifying its position in the Spanish market. Looking forward, the company intends to build on this success and establish its global presence in order to meet the needs of customers worldwide. “The goal is to complement established domestic growth by expanding Smartfix’s presence and influence in the international market, fostering new partnerships,” underlines Carlos. “The modernisation initiatives we have introduced – new logo, updated catalogue and enhanced website –have been carefully selected in order to deliver a contemporary and user-friendly experience for the customers, all while preserving the essential quality of our business.”

US-headquartered Simpson Strong-Tie has acquired Swiss roofing and façade fastener manufacturer, PMJ-tec AG, which specialises in A2, A4 and other high grade, corrosion resistant, stainless steel products.

Founded in 1975, PMJ-tec has its main office and factory in Switzerland, as well as warehouses and sales offices in Germany and the Netherlands. Its products, including bi-metal fasteners, carbon steel fasteners, and drainpipe couplers, are engineered with over 45 years of expertise in the construction fixing industry. They’re also manufactured in compliance with rigorous internal and external standards.

Fabio Di Clemente, director EU strategy at Simpson Strong-Tie, said: “PMJ-tec is known not only for its superior quality products, but also for its commitment to clients and service, as well as its innovation oriented culture – all of which makes it a perfect match for Simpson Strong-Tie. This acquisition introduces bi-metal fasteners to our product portfolio, which is of great strategic importance to us.”

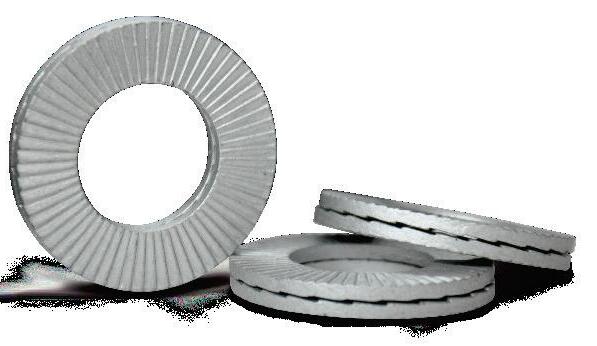

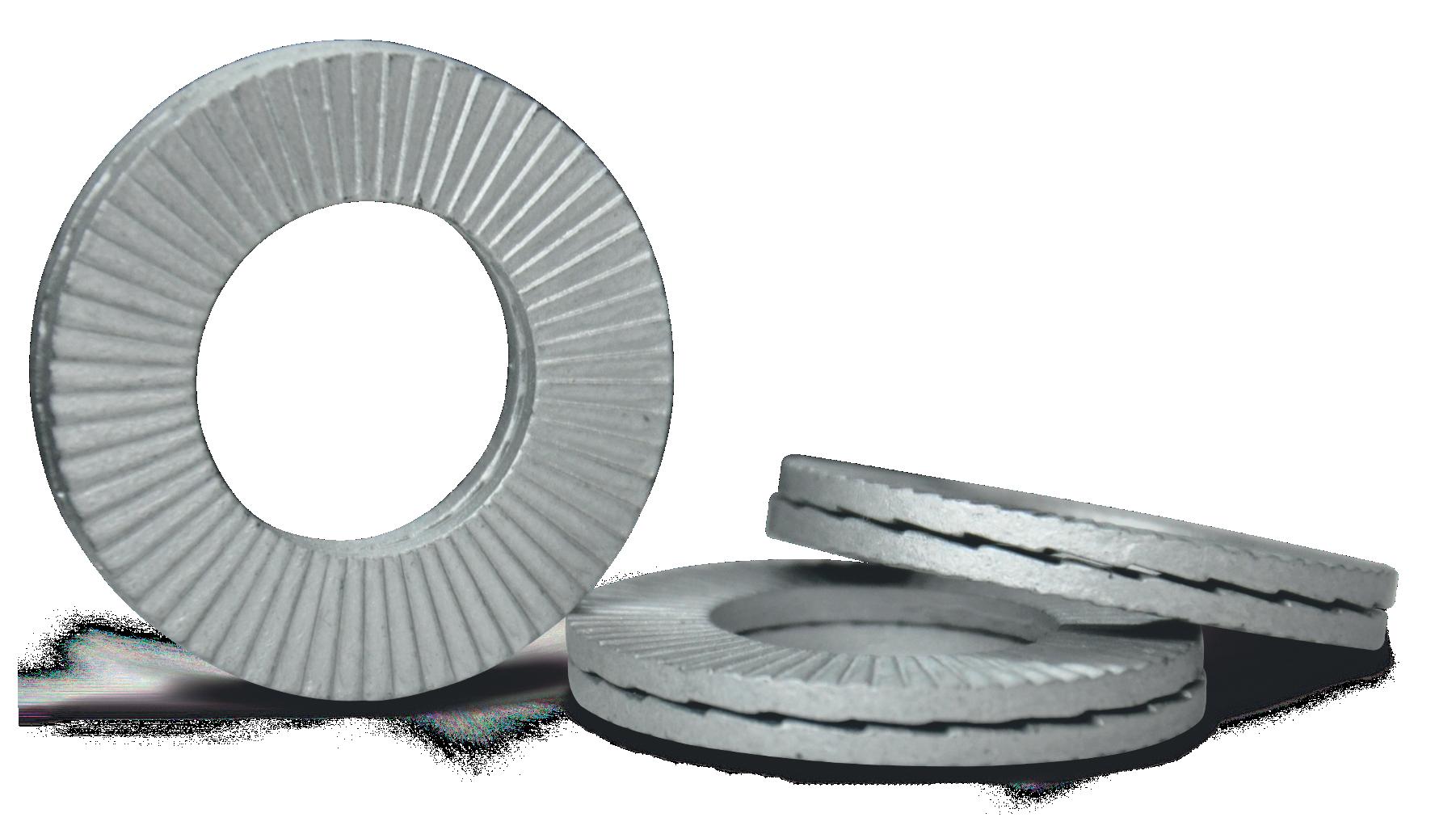

Investment AB Latour has, through its wholly owned subsidiary Nord-Lock Group, acquired Precision Bolting Ltd (PBL) and Condor Machinery Ltd – both based in Edmonton, Canada, with a combined total revenue of around CA$7 million (€4.77 million).

Precision Bolting is a Nord-Lock Group distributor in northwestern Canada and Condor is a niche manufacturer of specialised metal components – a combination that adds great value for customers served. The companies will strengthen Nord-Lock Group’s position in Canada and contribute to the Group’s global offer within the mining segment in particular.

Nord-Lock Group comments: “We want to give our warmest welcome to all PBL and Condor employees. We have been able to get to know the companies well over the years and are impressed with

what they have achieved. We are convinced that the companies’ strengths will contribute greatly to the overall Nord-Lock Group offering and that in turn we will continue to support the companies’ ongoing growth going forward.”

Ken Gamroth and Brent Morgensen, CEOs at PBL and Condor, added: ”We have worked closely with Nord-Lock Group for many years and see this as a natural next step for the development of PBL and Condor. Together with Nord-Lock Group, and its strong market position, we are looking forward to continuing this growth journey together.”

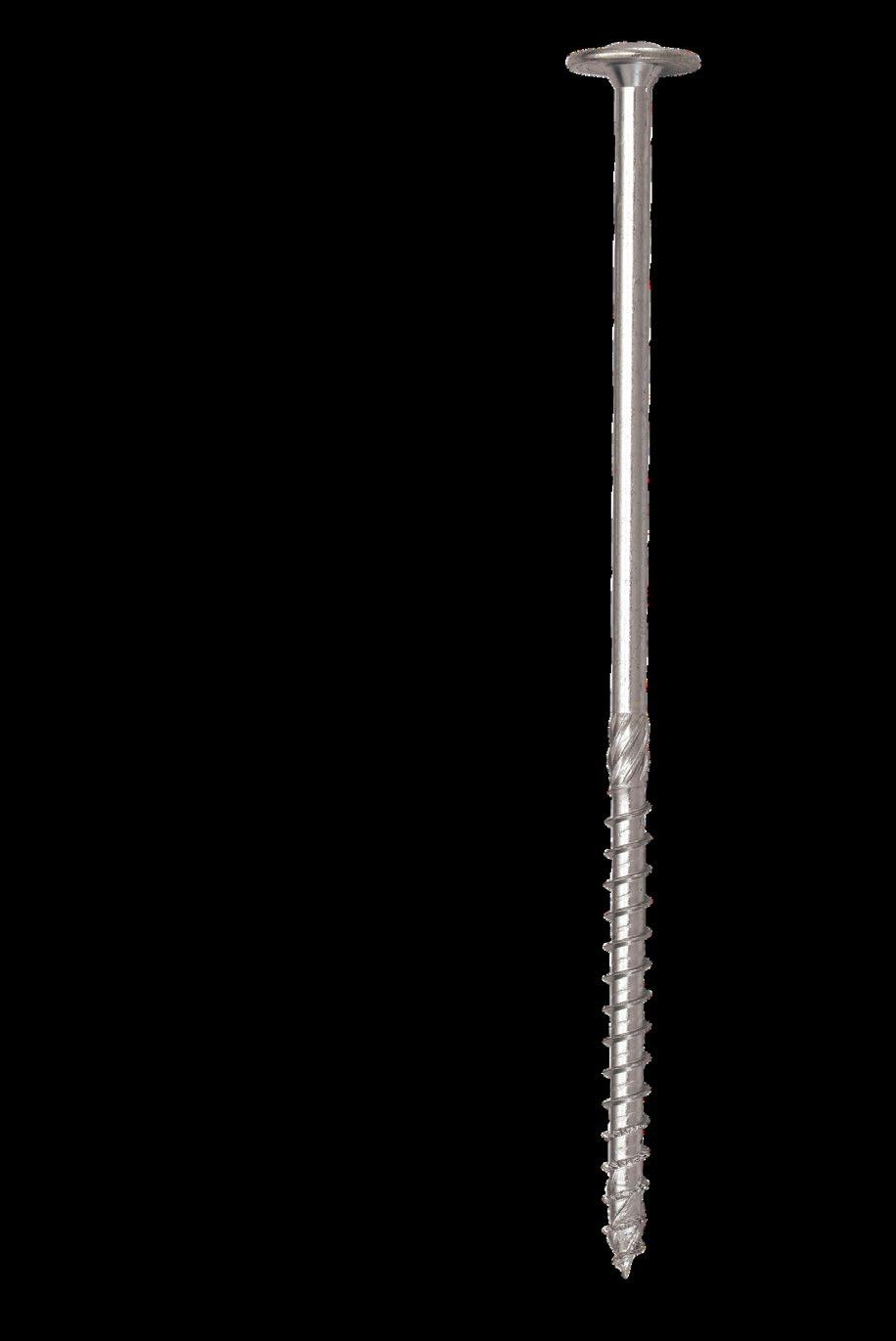

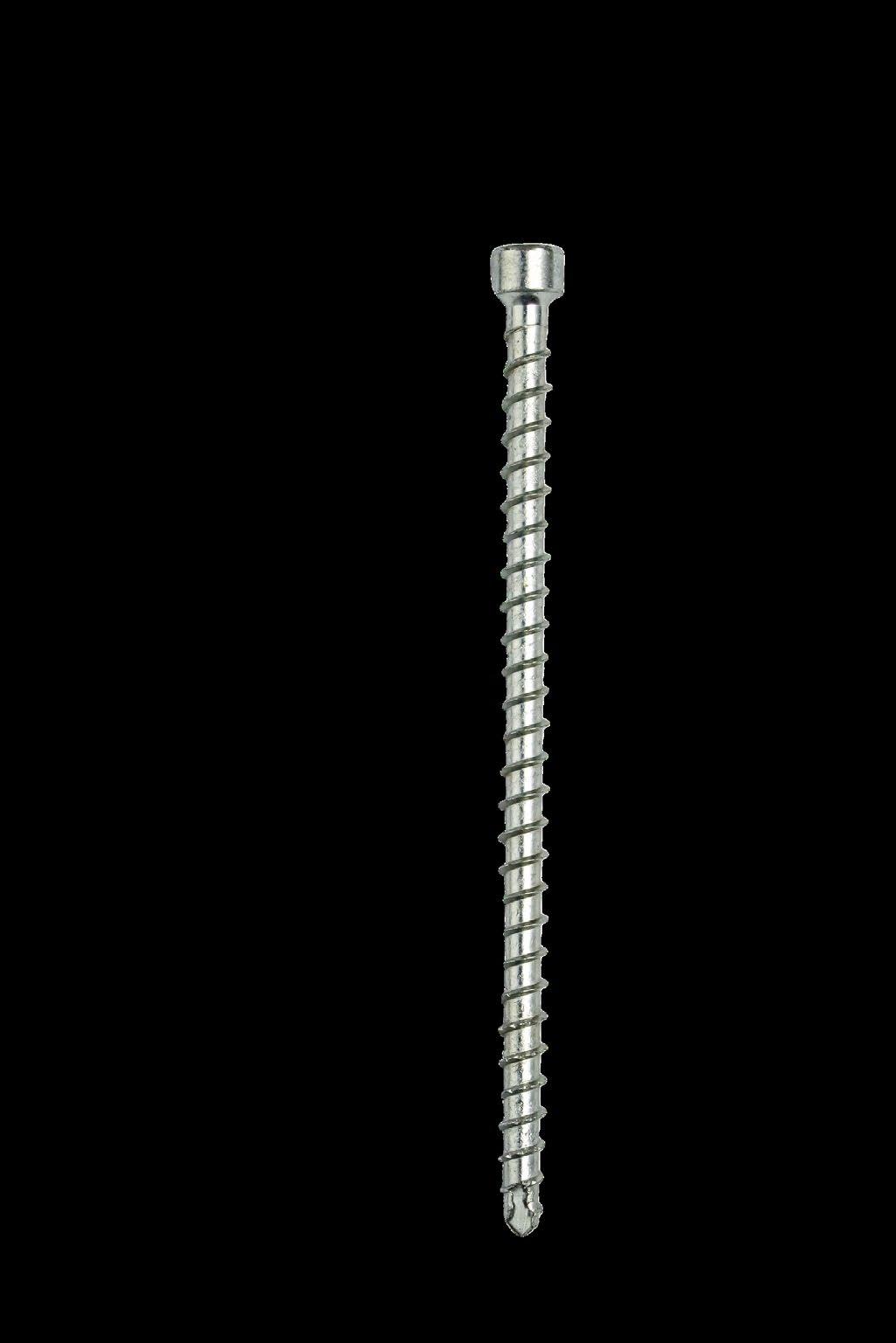

DRIVER BTI

DUAL THREAD

FLOORBOARD

DESIGNED FOR FAST AND SECURE INSTALLATION OF FLOORING AND TO ELIMINATE SQUEAKY BOARDS.

DRIVER B

DUAL THREAD

TONGUE AND GROOVE SCREWS

A SPECIALISED SCREW FOR A SECURE AND HIDDEN FIXING IN TONGUE AND GROOVE INSTALLATIONS.

MULTIPURPOSE EXTERIOR FLOORBOARD TONGUE & GROOVE

TWO LONGER LENGTHS NOW ALSO AVAILABLE IN THE RANGE 220MM AND 240MM

PROFIL®, a leading innovator in automotive fastening solutions, has announced it has moved to new, larger offices in Italy – signalling a significant step in the company’s growth strategy. The expansive facility, strategically located on the outskirts of Milan, not only serves as a testament to PROFIL®’s commitment to excellence but also introduces a suite of capabilities aimed at providing comprehensive solutions to its customers.

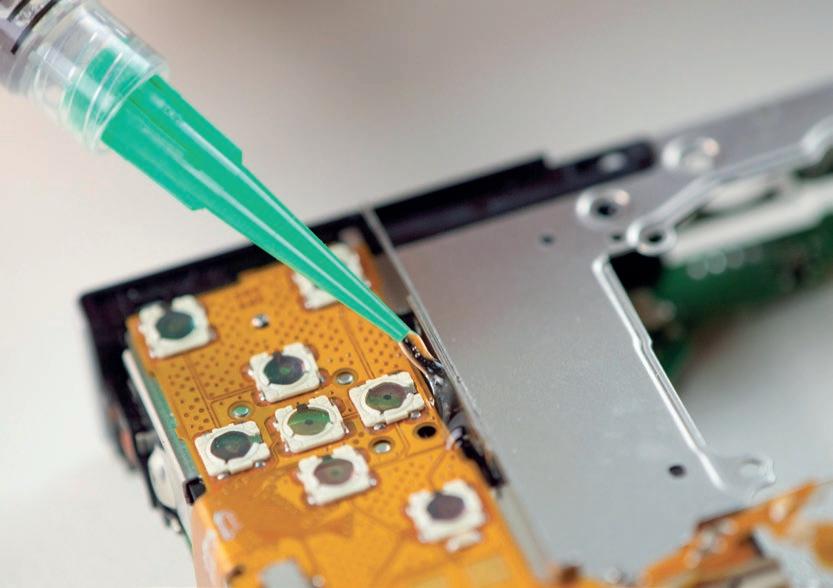

The new offices feature cutting edge amenities, showcasing PROFIL®’s dedication to advancing its services – including on-site testing and prototyping capabilities, allowing for ‘real time’ evaluation and refinement of Mechanically Attached Fastening (MAF) solutions. With pre-installation services, clients can also experience a seamless integration of PROFIL® products into their systems, ensuring optimal performance.

In addition to these capabilities, PROFIL® has established a dedicated research and development centre within the new facility, poised to drive innovation and allow PROFIL® to stay at the forefront of fastening technology and meet the evolving needs of industries across the board.

Founded in 1994, MEKR´S offers a diverse range of fasteners and anchor equipment from its warehouse located in the Czech Republic. As the company continues to prioritise its focus on the export market, it remains committed to delivering innovative solutions and exceptional service not only to international clientele but also to the Czech market.

MEKR’S dual commitment underscores the company’s dedication to providing top quality products and unparalleled customer satisfaction across all regions it serves.

“In the ever evolving realm of fastener solutions, we have distinguished ourselves through our unwavering dedication to excellence, strong export orientation and exceptional customer service,” states MEKR’S s.r.o.

As a prominent wholesaler in the industry, MEKR´S has made significant advancements, driven by its innovative strategies, efficient operations and expansion of storage capabilities. For instance, its current warehouse expansion project, scheduled for completion in 2024, will add an additional 7,500 pallet spaces to the existing capacity of 15,000 pallets.

“With a steadfast focus on quality, dependability, and customer satisfaction, we have established a prominent presence in both local and international markets,” underlines MEKR’S. “Looking forward, our company remains committed to fostering innovation, cultivating strategic partnerships and exploring new avenues for growth.”

One area of particular interest for MEKR´S is the digitisation of internal systems, including the integration of AI and the automation of logistical processes. “This forwardthinking approach reflects our ongoing commitment to staying at the forefront of industry trends and delivering unparalleled value to our customers,” concludes the company.

One of the key highlights of PROFIL®’s new location is the state of the art warehousing infrastructure that houses a comprehensive stock of fasteners. This strategic move ensures customers have immediate access to an extensive inventory, streamlining logistics and reducing lead times.

Christian Pozzi, head of PROFIL® Italy, comments on the expansion:

“Our move to these larger offices represents a pivotal moment for PROFIL®. This facility empowers us to offer an unparalleled suite of capabilities, from on-site testing and prototyping to pre-installation services. The addition of our dedicated R&D centre reflects our commitment to continuous innovation, and the expansive warehousing underscores our dedication to providing swift and efficient solutions for our customers.”

In response to an increased demand for its large diameter springs, Lesjöfors Group has invested over €1 million to purchase an additional hot coiling line. This investment not only doubles its hot coiling production, but also sees the return of the hot coiling manufacturing process in the town of Lesjöfors, Sweden.

In the last three years, Lesjöfors Group has grown from a €250 million company to a €365 million company – with Lesjöfors springs used in applications across a variety of sectors such as energy, rail, mining and power generation. As heavy springs are a key component within these major global industries, it’s fitting that this investment has involved parties from all over the world.

The line was purchased from South Africa, bespoke refining elements have been added with specialist additions from China, and personnel have skill shared across these countries, as well as the UK, Finland and Sweden.

Ola Tengroth, CEO at Lesjöfors Group, reports: “Our heavy springs product range –the larger, wire size market – has been rapidly expanding across our portfolio. This latest investment is in direct response to customer demand, enhancing our hot coiling capacity and capabilities in-line with market growth – ensuring we continue to deliver the quality turnaround times and customer service we excel at.”

NEVIB, the trade association representing Dutch fastener importers, has celebrated its 10 th anniversary with the announcement of a new president – Arnoud Booij, director and owner of ASF Fischer B.V.

The NEVIB association was created 10 years ago by a group of visionary Dutch fastener importers, with the intention of setting up a body to jointly address the many challenges facing the industry. One founding member was former president Robert Klaassen, who was a driving force behind the association’s rise to become the strong organisation it is today. Thanks to his efforts, NEVIB is now the official trade association for the Dutch import trade in fasteners, recognised by governments, the European industry association, EFDA, and all other stakeholders.

Board changes at NEVIB, also announced at the anniversary meeting, include Bart Veldhuizen (from Hoenderdaal) joining the board of directors as a new member, with Vincent van Dijk remaining NEVIB’s secretary general.

Fastenal Europe has presented the ‘Best OEM Wholesaler’ award to F.REYHER Nchfg GmbH & Co KG in recognition of its achievements as a top supplier.

This award is presented in a Europe wide vote to honour top suppliers of fastener and fixing technology. The US company Fastenal is a renowned manufacturer and distributor of fasteners in the field of standard and special parts and is one of the world’s largest industrial suppliers. Its European subsidiary, Fastenal Europe, is also growing with two distribution centres, two production facilities and 75 locations throughout Europe.

Michael Martsch, vice-president of REYHER export sales (pictured on the right of the picture), comments: “We are incredibly proud of the work that everyone here has done. The award as a top supplier and the associated recognition are the result of our joint efforts. REYHER and Fastenal Europe are looking forward to continuing their good collaboration in 2024.”

With over 130 years of experience, REYHER supplies customers from industry and trade worldwide. More than 960 employees at the central location in Hamburg, Germany, ensure a reliable supply of fasteners and C-parts – with individual, flexible solutions, as well as a daily delivery availability of over 99%.

The Fastener Sector of the Confederation of British Metalforming (CBM) has announced the much aniticpated return of the CBM ‘Mini-Expo’ – unleashing an opportunity for UK fastener manufacturers to showcase their capabilities.

Set to take place on 4 th September 2024, at the esteemed National Metalforming Centre in West Bromwich, UK, this one day extravaganza is geared towards providing a comprehensive platform for UK fastener and precision component manufacturers to explore the latest advancements in fastener manufacturing equipment, technologies and services.

The CBM ‘Mini-Expo’ promises an immersive experience, featuring approximately twenty leading UK-based suppliers showcasing an array of manufacturing equipment and technologies. Attendees can explore offerings in cold heading and thread rolling machinery, process

monitoring systems, tooling and dies, coating systems, inspection and test equipment, lubricants, as well as wire and rod materials. Additionally, exhibitors specialising in heat treatment, coating and threadlocking applicators, testing and inspection, and simulation software, will be present – creating a diverse landscape for industry professionals.

“For companies interested in showcasing their products and services at the CBM ‘Mini-Expo’ please contact us for further information and to secure your exhibition space,” highlights the CBM. “You don’t want to miss this great opportunity to immerse yourself in the future of fastener manufacturing.”

Continuous growth and investments saw Spanish lathe maker CMZ deliver 549 lathes during the 2023 financial year, achieving an unprecedented turnover of €110 million – exceeding its strategic plan and beating its previous turnover record.

With a clear target of achieving a €100 million turnover by end of 2024, the company invested in technology and facilities to meet high market demand. However, at the end of the financial year 2023 CMZ had not only exceeded forecasts by 10% but had done so a year early.

CMZ Machine Tool Manufacturer S.L is responsible for product lifecycle from beginning to end, with the company owning the technical support service for all its lathes and aftersales service. In the financial year 2023, the technical support service achieved a €10 million turnover from over 3,600 interventions and delivering 6,747 spare parts. The company’s technical customer hotline, manned by CMZ engineers, also handled a total of 15,000 calls.

Sales of CNC lathes accounted for around €100 million. Of those sales, 75% were exports, the company’s six European subsidiaries and its own wide network of distributors enabled supply to both the domestic market and the ‘old continent’. Almost 10% of sales were to demanding international markets such as the USA and Turkey, which the company believes has great potential for future business.

In addition, in early 2023, CMZ launched the renewed online tool holder shop, CMZ Store, which had processed around 700 orders by the end of last year – with an average ticket

price of €1,645. Thereby enabling the company to provide support and streamline the entire purchase process for its lathes.

2023 also saw the opening of CMZ’s sixth European subsidiary, CMZ Denmark, strengthening its international expansion plan. The Danish market’s potential enables CMZ to increase its market share and offer a more customer friendly, direct service.

To handle last year’s investments in production equipment, over 40,000m 2 of usable space was made available for manufacturing and marketing CNC lathes,

including the opening of CMZ Denmark, and the new Precitorm– cylindrical parts machining plant in Elorrio – which triples the old plant’s surface area. The company points out that by investing in facilities with the latest technology and centres, high market demand can be met with a product in which more than 80% of components are made at its own facilities.

CMZ is now planning to focus on increasing production capacity to 800 CNC lathes a year and aims to open a US subsidiary in late 2024.

While the National Transportation Safety Board (NTSB) works to establish whether the door plug that blew out in mid-air, on a 5 th January Alaska Airlines flight, was outfitted with the four bolts that prevent it from vertical movement, it’s becoming clear where the responsibility lies.

Dominic Gates from the Seattle Times reported: “The door plug that blew off the Max 9 was removed for repair, then reinstalled improperly by Boeing mechanics at the Renton assembly plant. That leaves Boeing primarily at fault for the accident, rather than its supplier, Spirit AeroSystems.”

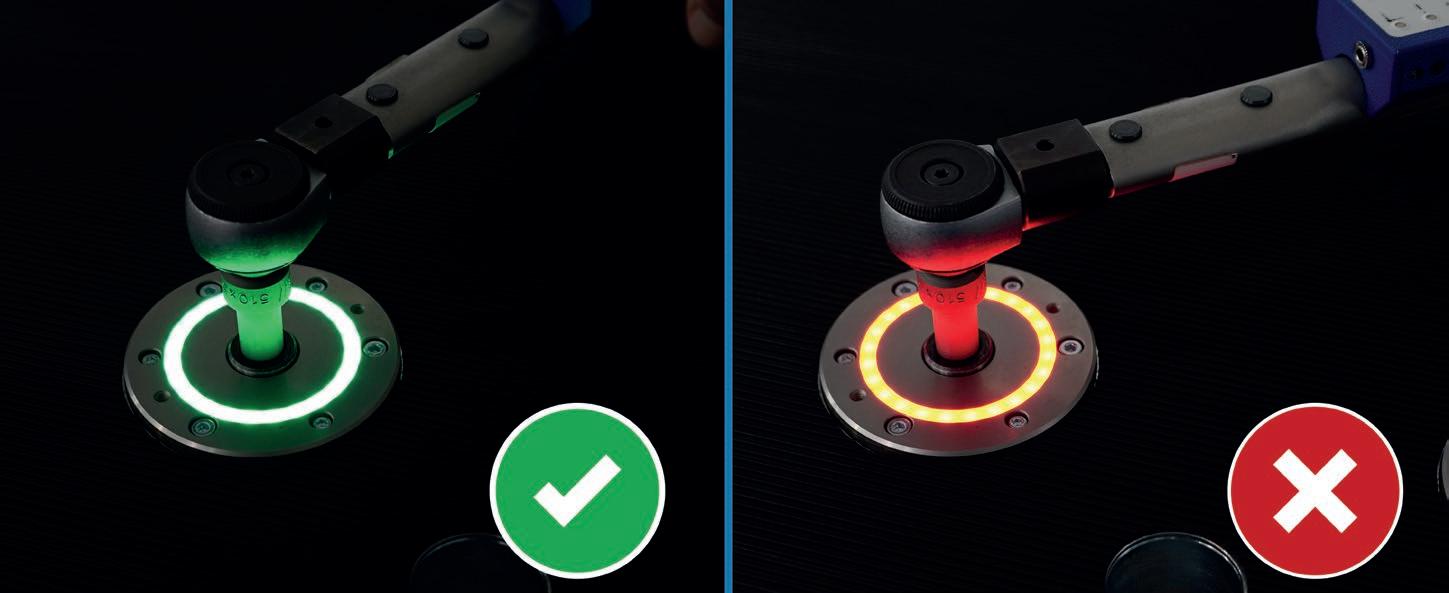

Boeing issued a bulletin to its suppliers to ensure bolts are properly torqued, after multiple airlines reported loose fasteners during inspections of the grounded 737 Max 9, according to a 17 th January memo.

The aerospace manufacturer said that it is “imperative” that suppliers meet quality requirements, according to the memo, which was issued weeks after an accident when a panel ripped off a 737 Max 9 jet in mid-air.

The Federal Aviation Administration (FAA) grounded 171 Max 9 planes with the same door panel configuration.

“Ensure that work instructions are mistake-proof and quality is continuously monitored – particularly torqueing requirements,” the memo stated. The bulletin suggested that suppliers document torque requirements on work instructions, require mechanics to record how much torque is applied when fastening components, and ensure tools are calibrated, so bolts are properly tightened.

Ben Minicucci, CEO at Alaska Airlines, said the airline found “some loose bolts on many” Max 9s during inspections. Other airlines reported

similar findings, and the NTSB is currently conducting destructive testing of the door plug. While investigators have yet been unable to establish whether the plug was outfitted with the four bolts that prevent it from vertical movement, it is too early to say whether the root cause was missing or wrongly installed bolts, according to NTSB chair, Jennifer Homendy, who said: “We’re also looking at the seal. We’re looking at whether there was any sort of structural flexing of the aircraft? It may not be bolts.”

Homendy’s comments come days after the FAA announced that it will increase oversight of Boeing and audit production of the 737 Max 9 jet liner. It will determine whether Boeing, and its suppliers, followed approved, quality procedures. The FAA also said it’s reconsidering its long-standing practice of relying on aircraft manufacturer employees to perform some safety analysis of planes.

The catastrophic failure occurred when a door plug blew off a new Alaska Airlines Boeing 737 Max 9 at 16,000 feet, imperilling 171 passengers and six crew members. Four ‘stop’ bolts should have prevented the door plug from moving upward and coming off the plane. But the bolts were not on the recovered door plug, and investigators are trying to determine whether they were even installed. “We don’t know if they were there, or if, again, they came out during the violent explosive decompression event,” Homendy stated.

A fastener company’s adoption of Artificial Intelligence can be important in hiring younger employees who want a “forward thinking company,” Panellist Lonni Kieffer, of SmartCert, pointed out during a National Fastener Distributors Association panel on ‘Using the Power of AI and automation to make your business more efficient’.

Panellist Rosa Hearn, of Brighton-Best International, declared: “It’s here, AI is knowledge feed and we have been feeding it for years.” Any postings to Facebook or Google are now somewhere in AI, Hearn explained – advising checking what AI knows about your company already. “Be careful what you put into ChatGPT,” she cautioned. She cited the incident of a Samsung engineer posting new proprietary information and “now those company secrets are in the public domain”.

Can AI make you a better salesperson? AI can learn about Rosa’s style from Facebook, LinkedIn and emails and be told to write a ‘personal’ email to a customer.

“Is it good enough to give the customer the ‘fuzzy wuzzies’? Hearn asked. “Time will tell.”

AI “doesn’t know how to say ‘I don’t know,’” Hearn pointed out.

Lonni Kieffer, co-founder of SmartCert, said AI isn’t really new if you think of consumer use of thermostats, GPS, online shopping and social media. Those have been moved from paper to digital and “these tools are all meant to provide efficiencies”. It is also part of “continuous learning” needed in “upscaling workers”.

Kieffer sees SmartCert’s job as a “technology partner” helping to “make life easier”. AI can read documents on your behalf, eliminate human error that you have with manual entry and create searchable data. Older emails are “fraught with peril”, Kieffer said.

“AI is going to get smarter yet,” Kieffer predicted.

The global market for industrial fasteners, which totalled US$89.7 billion in 2022, is projected to reach US$124.9 billion (€115.3 billion) by 2030, growing at a CAGR of 4.2% over the analysis period 2022 – 2030, according to a new report by Global Industry Analysts Inc.

Metal, one of the segments analysed in the report, is projected to record 4.1% CAGR and reach US$110.4 billion by the end of the decade, while growth in the plastic segment is estimated at 5.5% CAGR.

China is forecast to reach a projected market size of US$24.9 billion by 2030, trailing a CAGR of 5.6% over the 8 year period. Other noteworthy geographic markets, include Japan and Canada, each forecast to grow at 2.9% and 3.5%, respectively. Within Europe, Germany is forecast to grow at approximately 3.1% CAGR.

According to the report: “The global economic outlook is improving and growth recovery, albeit on the lower side, is expected for this year and the next. The US, although witnessing slowing GDP growth in response to tight monetary and financial conditions, has nevertheless overcome the recession threat.

Easing of headline inflation in the Euro area is helping boost real incomes and is contributing to pick up in economic activity. China is expected to see strong increases in GDP in the coming year as the pandemic threat recedes and the government sheds its zero-Covid policy. With optimistic GDP projections, India remains on course to emerge into a US$ trillion economy by 2030, surpassing Japan and Germany.”

“The upturn, however, remains fragile,” the report stated, “and a number of interlocking challenges continue to run in parallel, such as continued uncertainty around the war in Ukraine; slower than expected decline in global headline inflation; continuation of food and fuel inflation as a persistent economic problem for most developing countries; and still high retail inflation and its impact on consumer confidence and spending”.

The report continued: “Countries and their governments are showing signs of weathering these challenges, which helps lift market sentiments. As governments continue to combat inflation to get it down to more economically conformable levels, by raising interest rates, new job creation will slow down, and impact economic activity. A

stricter regulatory environment and pressure to mainstream climate change into economic decisions will compound the complexity of challenges faced.”

“Although corporate investments can likely be held back by inflation worries and weaker demand, rise of new technologies will partially reverse this prevailing investment sentiment. The rise of generative AI; applied AI; industrialising machine learning; next generation software development; Web3; Cloud and edge computing; quantum technologies; electrification and renewables; as well as climate technologies beyond electrification and renewables; will open up the global investment landscape. These technologies hold the potential to drive sizable growth and value to global GDP in the coming years.”

The FIN Fastener Stock Index roared back in 2023, growing 44.3% in value, compared to an 18.3% gain by an index of related industrial stocks, and this in a rocky economic year that eventually produced a ‘recovery’ in US industrial fastener demand.

Three of the thirteen companies tracked by GlobalFastenerNews.com’s FINdex achieved significant growth during the year: Simpson Manufacturing, for example, soared 123%, defying broader market adversity with continued earnings growth; Park-Ohio, for its part, also finished strong, gaining 120% in stock value during the year; and Carpenter Technology saw its shares rise 91%.

Over the year, the FINdex achieved strong growth in three of the four quarters, including a 17.2% increase in the final three months of 2023. During the first nine months, the FINdex gained 23%, compared to a 5.6% increase by an index of related industrial stocks.

In 2022, the FINdex lost 11.5%, besting a 15.5% decline by an index of related industrial stocks.

In order to assist domestic Taiwanese enterprises to reduce carbon emissions and create a fair, safe and transparent carbon credit trading system, Taiwan Carbon Solution Exchange, (TCX), jointly invested in by the Taiwan Stock Exchange and the National Development Fund of the Executive Yuan of Taiwan, officially launched its International Carbon Credit Trading Platform at the end of 2023.

Unlike other countries with carbon credit trading platforms that operate on a for profit business model, and in order to avoid market speculation, the buyers on Taiwan’s new platform are limited to domestic legal entities and only allowed to hold, cancel and transfer carbon credits. Sellers must be foreign, or domestic legal entities, with the carbon credits’ trading and payments processed in the form of advance receipts, with credits sold according to quotations; the unit of transaction is 1 tonne of CO 2 equivalent, traded in US dollars. The platform is not open to the general public.

For the sellers’ part, they are specifically required to meet the relevant standards for carbon credits (e.g the carbon credit issuer should be accredited by TCX), the vintage of the carbon credits should be within five years and the carbon credit projects should satisfy at least three of the UN’s Sustainable Development Goals, amongst other things.

TCX hopes that through the establishment of this platform, it can effectively match supply and demand, create incentives for enterprises to reduce carbon emissions, as well as further promote the development of low carbon production technologies and innovative industries.

Source: Fastener World

Wire rod prices are on the move and, according to Taiwan China Steel Corporation’s (CSC) latest reports, the global steel industry has hovered low for a year and a half and stockpile in the downstream is at a relative low, reports Fastener World.

This suggests that steel price and supply is bound to go higher in the first quarter of 2024. Taiwan CSC says that by taking the rise in steel refining material cost and international steel prices into account, led to it raising the wire rod price in January to cope with increased material costs.

It said the first quarter price for 2024 has, therefore, been reflected in accordance with the status of downstream industries.

For wire rod, encompassing low/mid/high carbon, cold headed, and low alloy steel, a price adjustment, (NT$ per tonne), of plus NT$800 has been necessary, while for automotive materials, a price adjustment of plus NT$500 has been made for the quarter.

The Directorate General of Trade Remedies (DGTR), a division of the Commerce Ministry in India, has launched an anti-dumping investigation into the import of fasteners from China. This action was prompted by both sectors’ associations, which reported substantial harm to their respective industries due to a significant influx of these goods from China at dumped prices.

Indian producers have made representations before the authority claiming that prima facie evidence exists, indicating the injury suffered by the domestic industry because of the dumped imports. The associations have highlighted a significant rise in both the absolute and relative volume of these imports from China. The DGTR has expressed its contentment with the accuracy and sufficiency of the information presented in the representations.

The DGTR said that in light of the well-substantiated representations submitted by Indian producers of the specified goods, and after a thorough assessment of the prima facie evidence provided therein regarding the dumping of these goods from the subject country, as well as the resulting harm to the domestic industry, the authority has initiated an anti-dumping investigation.

Source: Chinafastener.com

At the end of last year, the Taiwan Industrial Fasteners Institute (TIFI) held the 19th (4th round) member representatives meeting and the 10th (9th round) joint meeting of the board of directors and supervisors at HI-LAI Arena in Kaohsiung, Taiwan.

During the meeting Tu-Chin Tsai, chairman at TIFI, commented:

“I’d like to thank all fastener industry professionals and seniors for their support to TIFI and thank Taiwan CSC for its great assistance to the Taiwan fastener industry. Thanks to the efforts of all of you, the output value of the Taiwan fastener industry reached NT$200 billion in 2022. However, we would like to remind our friends – who are mainly engaged in the European and American markets –to pay more attention to the current ESG, energy saving and carbon reduction, CBAM, and changes in the international regional situations, and to think carefully before making any major investments. This will mean we can continue to maintain a leading edge in the future in the competition from the same industries in Vietnam, China, Indonesia, and Thailand, etc.”

At the meeting Min-Hsiung Liu, vice-president (commercial division) at Taiwan CSC, also spoke: “At present, the global market has shown an improvement. According to the recent statistics of TIFI, the export volume of Taiwanese fasteners from January to November in

2023 reached more than 1.1 million tonnes. Although the export volume declined by 16.3% in a single month, compared with the average 25% decline in January to November, it has been converged. The internal survey of Taiwan CSC also shows that the orders from small screws customers have shown an increase of about 20%, and those from wire drawing customers have shown an increase of about 20% – 30%. We’re confident that the fastener industry will gradually improve. With regard to carbon neutrality, Taiwan CSC will also assist in conducting carbon inventories and will work together towards low carbon/digital/supply chain transformation, and work towards high value added products.”

As part of the meeting Chairman Tsai also announced that after the Taiwan International Fastener Show, which is scheduled to take place on 5 th – 7 th June 2024, TIFI will hold a member representatives meeting again to re-elect the board of directors, supervisors, permanent directors and supervisors, supervisors convener and the new chairman.

Source: Fastener WorldBocast has announced at a technical exchange meeting for new product releases that zirconia ceramic fasteners would soon enter mass production after eight months of technical research, reports Chinafastener.com.

It is understood that the R&D team of Bocast, under the guidance and collaboration of Professor Xiong Yan from the school of materials at Hubei University of Technology, overcame multiple technical difficulties – such as cracking and sintering deformation in the development of zirconia ceramic fasteners –and achieved ‘one time’ moulding of the final product form through mould design.

Zirconia ceramic fasteners solve the non-conductive, non-resistant to high temperature and strong acid and alkali problems of non-metallic fasteners. They can be widely used in electronics, shipbuilding, medical, aerospace and other fields, with an annual total market demand of over 400 million pieces.

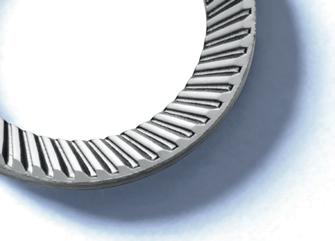

The railway industrial product ‘variable-tooth-type anti-loosening nut’, developed and produced by Qifeng Precision Industry, has passed the trial detection of relevant units in the railway system and has been recognised to the technical standard of Q/CR 484-2015.

The successful research and development of this product will promote the application in the railway transportation field and meet the safety requirements of railway construction and maintenance.

The anti-loosening nut developed and produced by Qifeng Precision Industry has excellent resistance to transverse vibration; can effectively solve the problem of thread loosening; and can be applied to a number of industries such as aerospace, shipbuilding, railway transportation, agricultural machinery and others.

Source: Chinafastener.com

Chinafastener.com reports that the plate and strip plant of Northeast Light Alloy has successfully rolled a certain high magnesium aluminum alloy fastener, laying a solid foundation for rolling more high magnesium content alloys in the future.

During the production debugging stage, after multiple rounds of debugging and production failures, the manufacturer’s debugging personnel confirmed that this machine did not have the ability to produce such high magnesium rods. However, the plate and strip plant, with an unyielding spirit, established a special group composed of equipment technical experts and pooled their efforts to tackle the production work of this fastener, even when the equipment manufacturer’s personnel had all left.

Sérgio Milatias, editor, Revista do Parafuso, www.revistadoparafuso.com.br

Sérgio Milatias, editor, Revista do Parafuso, www.revistadoparafuso.com.br

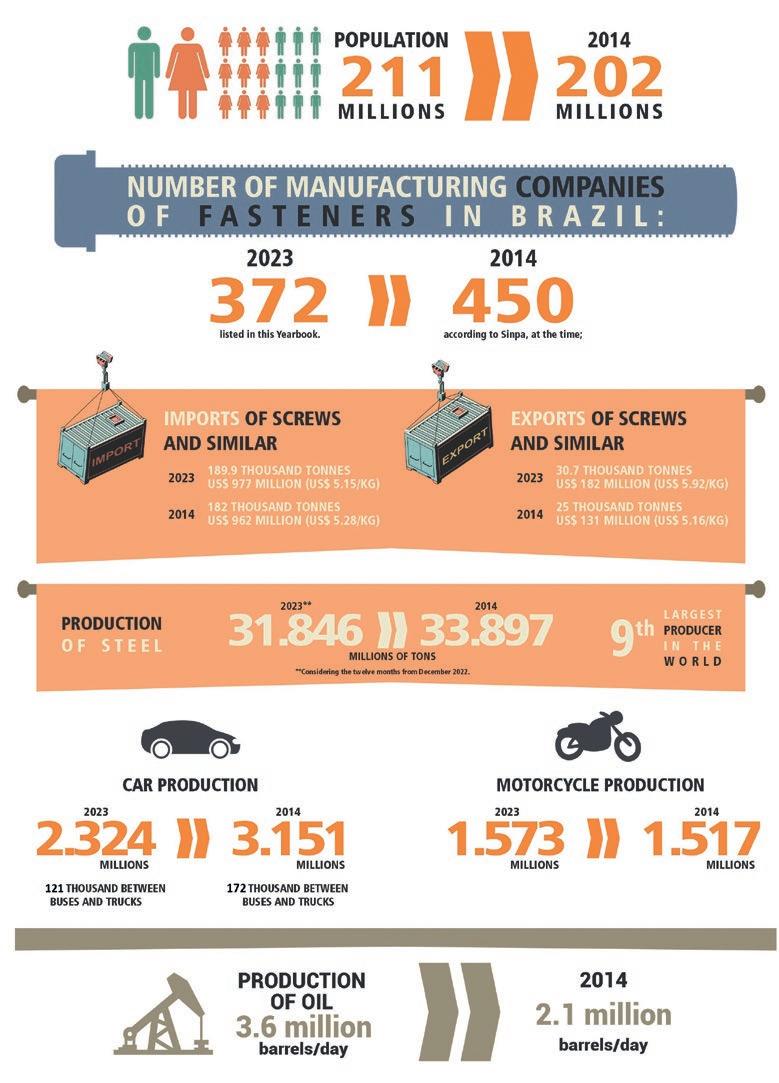

Once again, the Anuário do Parafuso – an annual fastener Brazilian buyer’s guide, distributed to the same readers of Revista do Parafuso –was published, with this year being the 10 th edition. To mark the occasion a comparison was published comparing the fastener sector in 2014 and the fastener sector in 2023.

Firstly, it is important to clarify that Brazil has more than 211 million habitants, 4.5% above the 202 million in 2014. Ten years ago, there were around 450 local fastener manufacturers, with 18% less in 2023 at just 372.

From December 2022 to November 2023, the local steel production was 31.15 million tonnes, around 8% below the 33.89 million tonnes produced in 2014. On the other side, the local petroleum production jumped more than 71%, from 2.1 million per day in 2014 to 3.6 million last year.

During January to December 2023 Brazil imported 189,900 tonnes of fasteners at a total value of US$977 million (FOB price of US$ 5.15 per kg) This is 4.34% above the 182,000 tonnes imported in 2014, and 1.5% up on the total value of US$962 million (FOB price US$5.28 per kg).

Brazilian fastener exports reached 30,700 tonnes for 2023, at a total value of US$182 million (FOB price at US$5.92 per kg), which is 18.5% above the 2014 export volume of 25,000 tonnes and 28% up on the US$131 million total value in 2014 (FOR price was US$ 5.16 per kg).

An interesting comparison is between automotive vehicles, in which the motorcycle sector produced 1.573 million units in 2023, the best historic result, superior to the 1.517 million units in 2014. If passenger cars, buses, and trucks, had experienced a similar increase then Brazil, maybe, could be back on the front cover of The Economist Magazine, as happened in November 2009. However, 2023 closed with 2.324 million units produced (121,133 buses and trucks), more than a 35% decrease compared to the 3.151 million (172,902 buses and trucks) in 2014.

Belenus celebrates its 20th anniversary in 2024, having established itself as the biggest Brazilian fastener manufacturer of nuts, bolts, and special parts.

The history of the business started at 1960, when João Lucas, an ex-taxi driver, became a fastener resale manager. In 1978 he opened his own resale company, having at his side João Marcos Lucas, his son. Under João Marcos, the company experienced a meteoric trajectory and prosperity. In 2004, Sergio Lucas the son of João Marcos Lucas, was already at his side and he created a new company named Belenus – starting a new era as a fastener manufacturer.

During the last two decades the rise and growth of Belenus has changed the landscape of the Brazilian fastener market. Beyond fastener production, the company continued to grow and became a group with operations in other sectors, such as distribution of hardware, tools, and various types of equipment, as well as parts for solar energy installations.

Today, Belenus has around 1,700 employees across the different divisions of the group and has a production capacity to process 10,000 tonnes per month at its fastener manufacturing unit.

In the recent Janus Perspective within Fastener + Fixing Magazine (Issue 145, page 86), it was stated that 2.359 million cars (among passengers and commercials cars, buses and trucks) were produced, but this was just an estimate from ANFAVEA –the local Brazilian automotive manufacturing association. The actual figure produced in 2023 was 2.324 million.

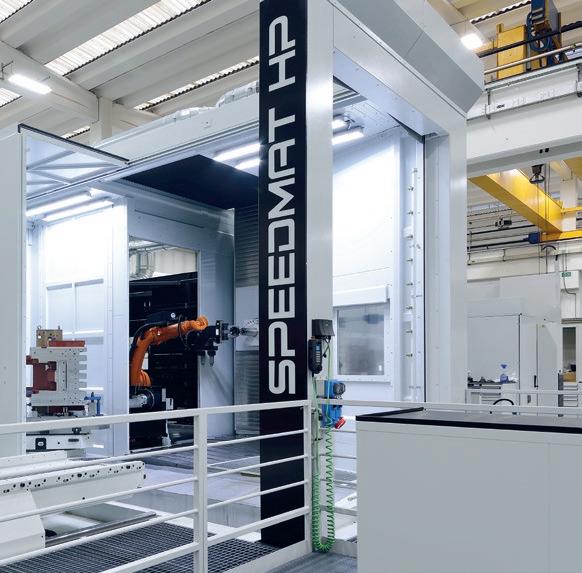

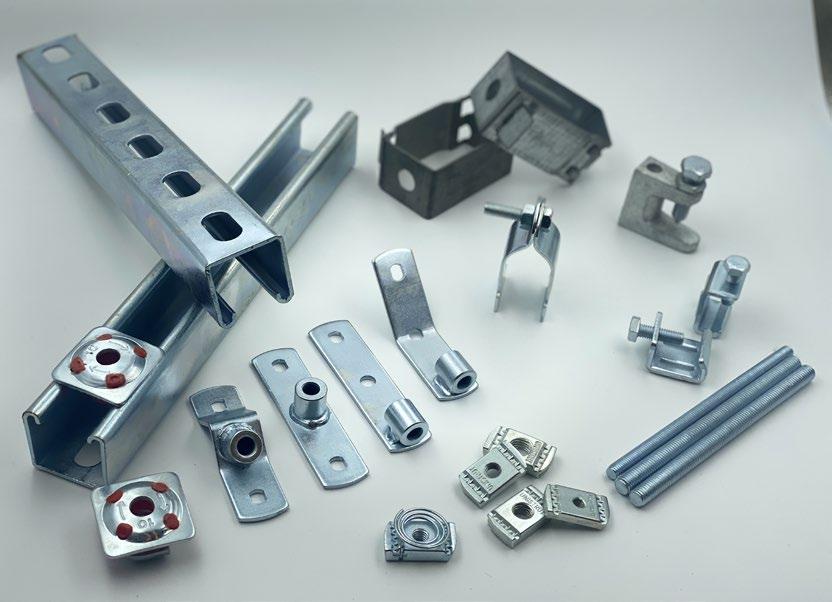

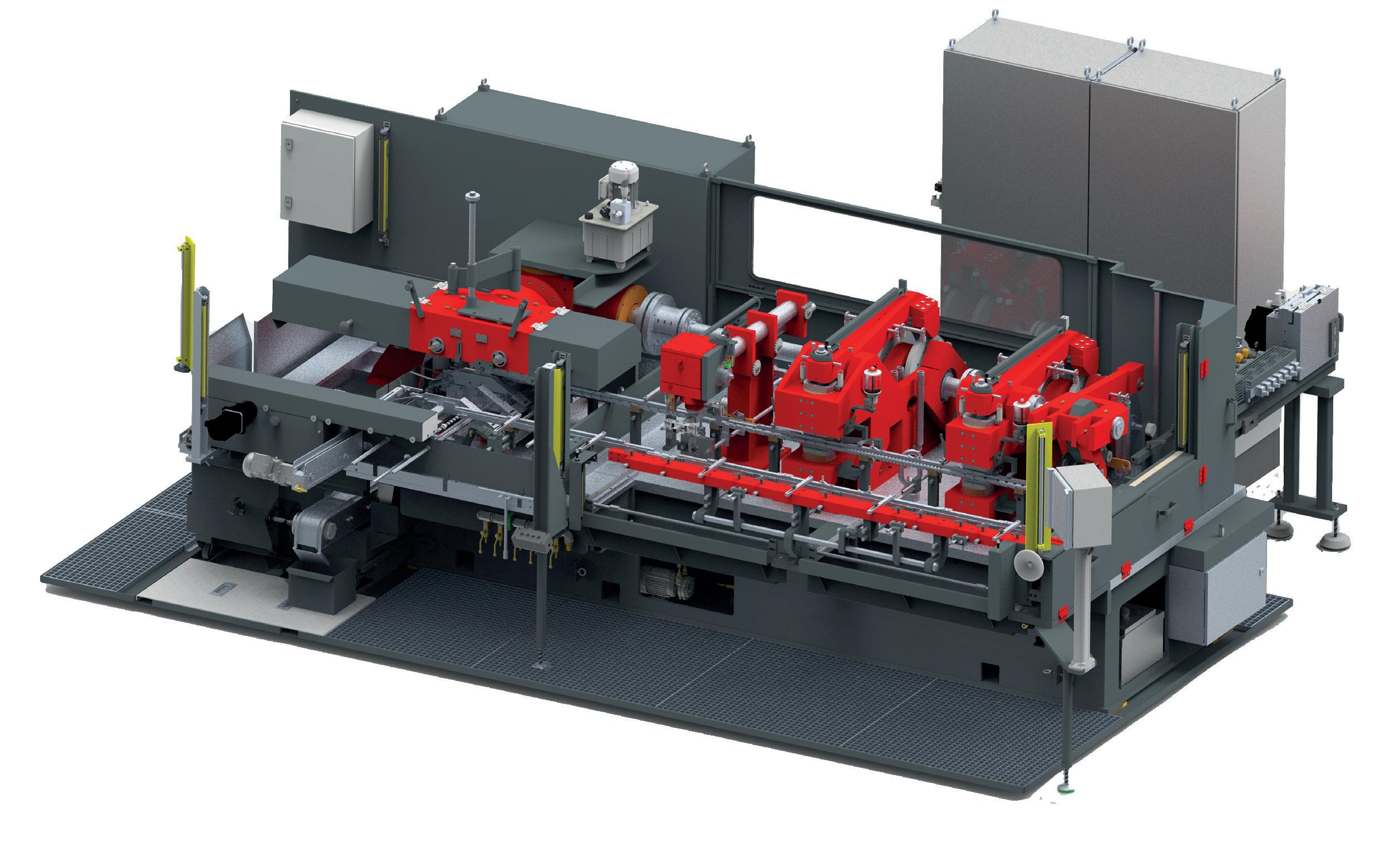

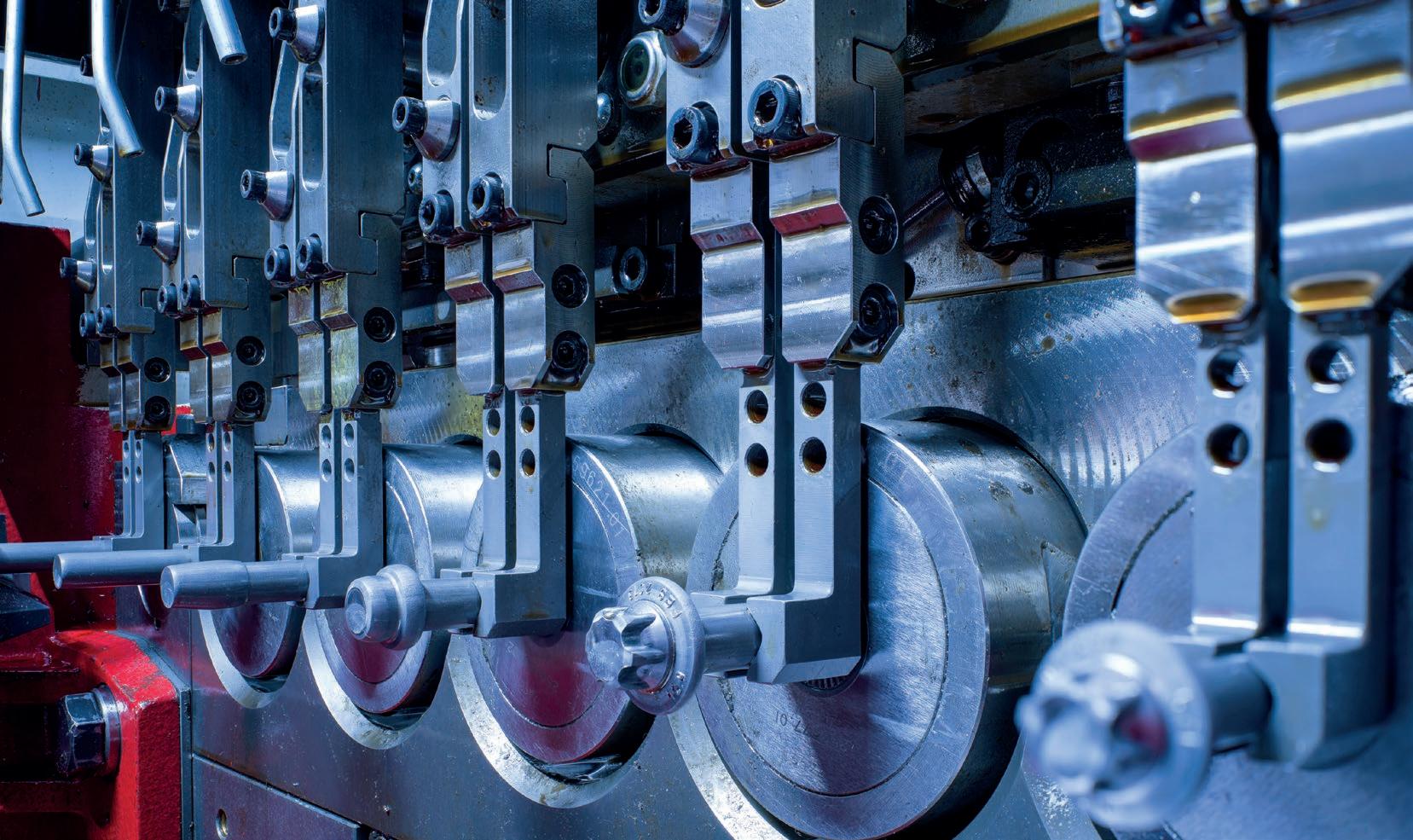

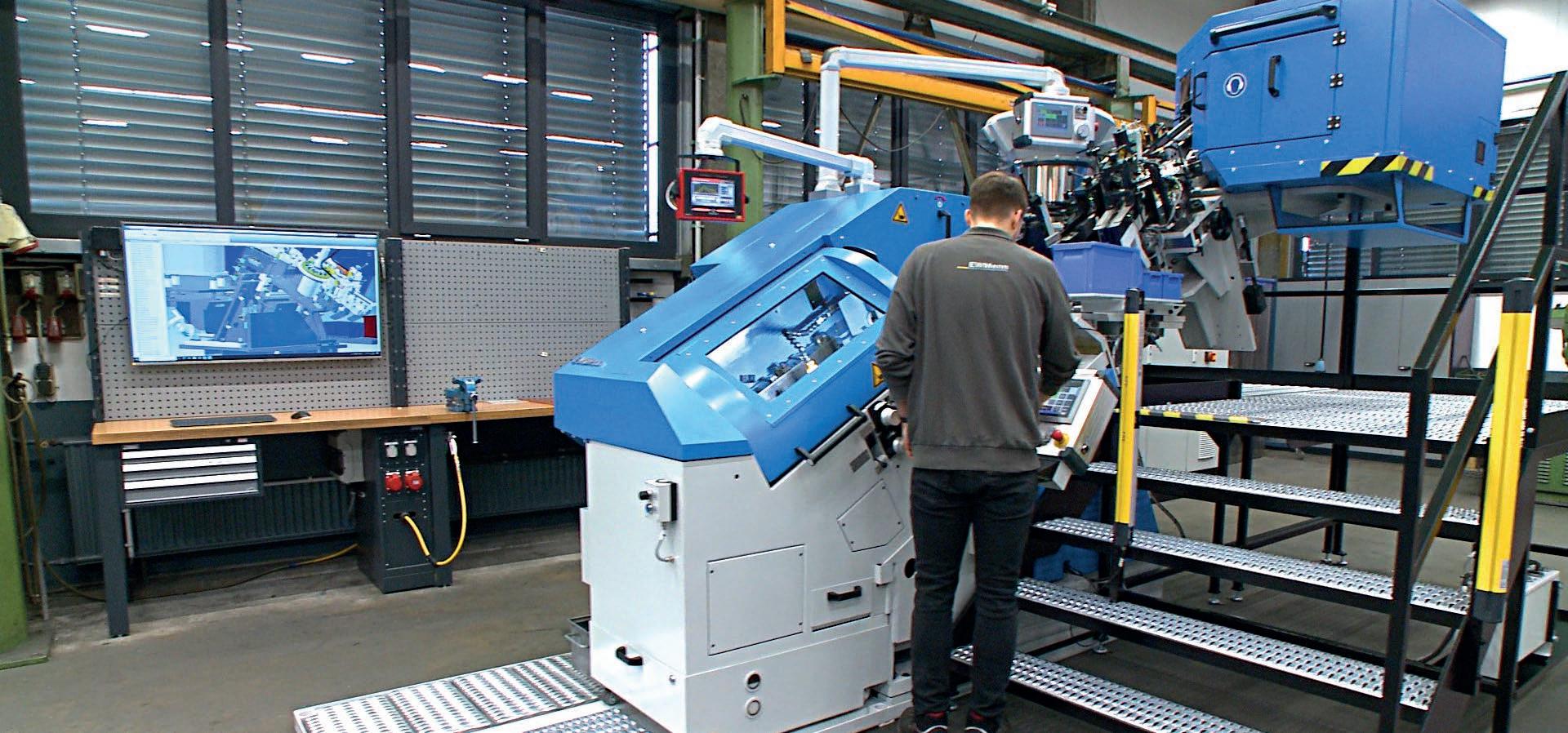

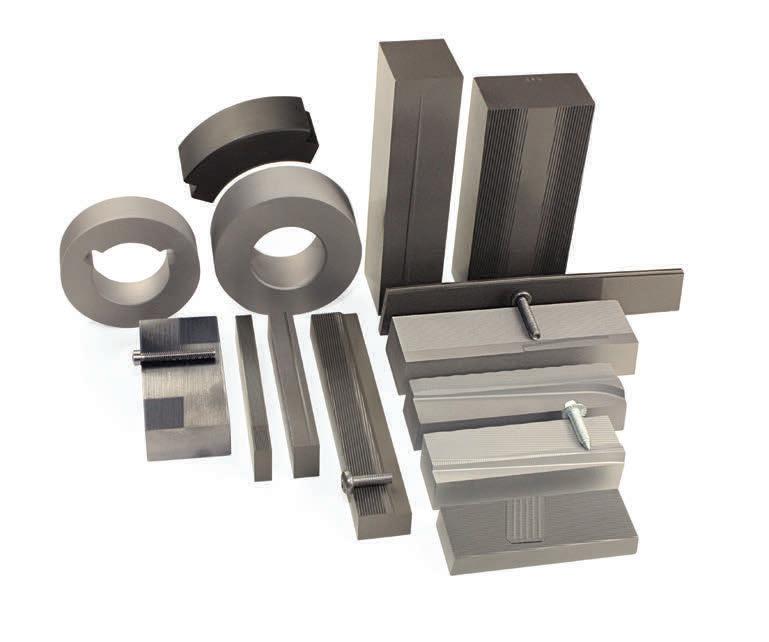

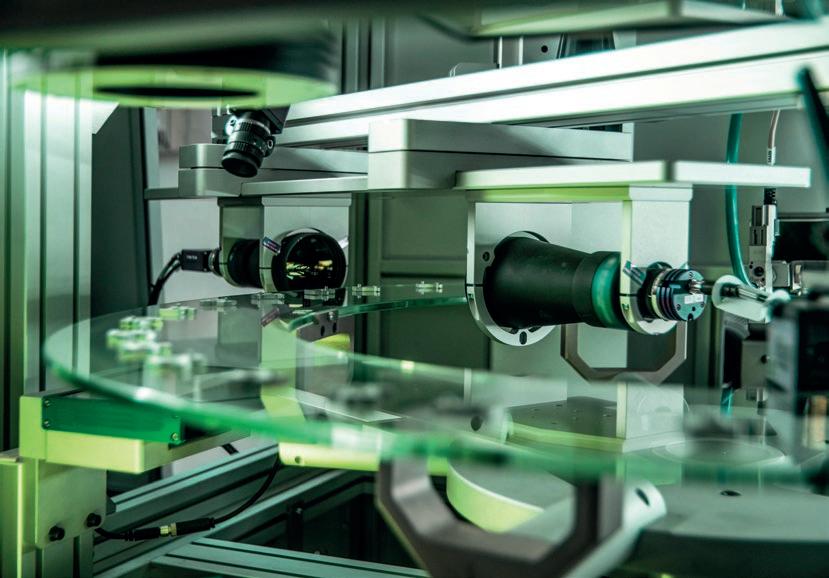

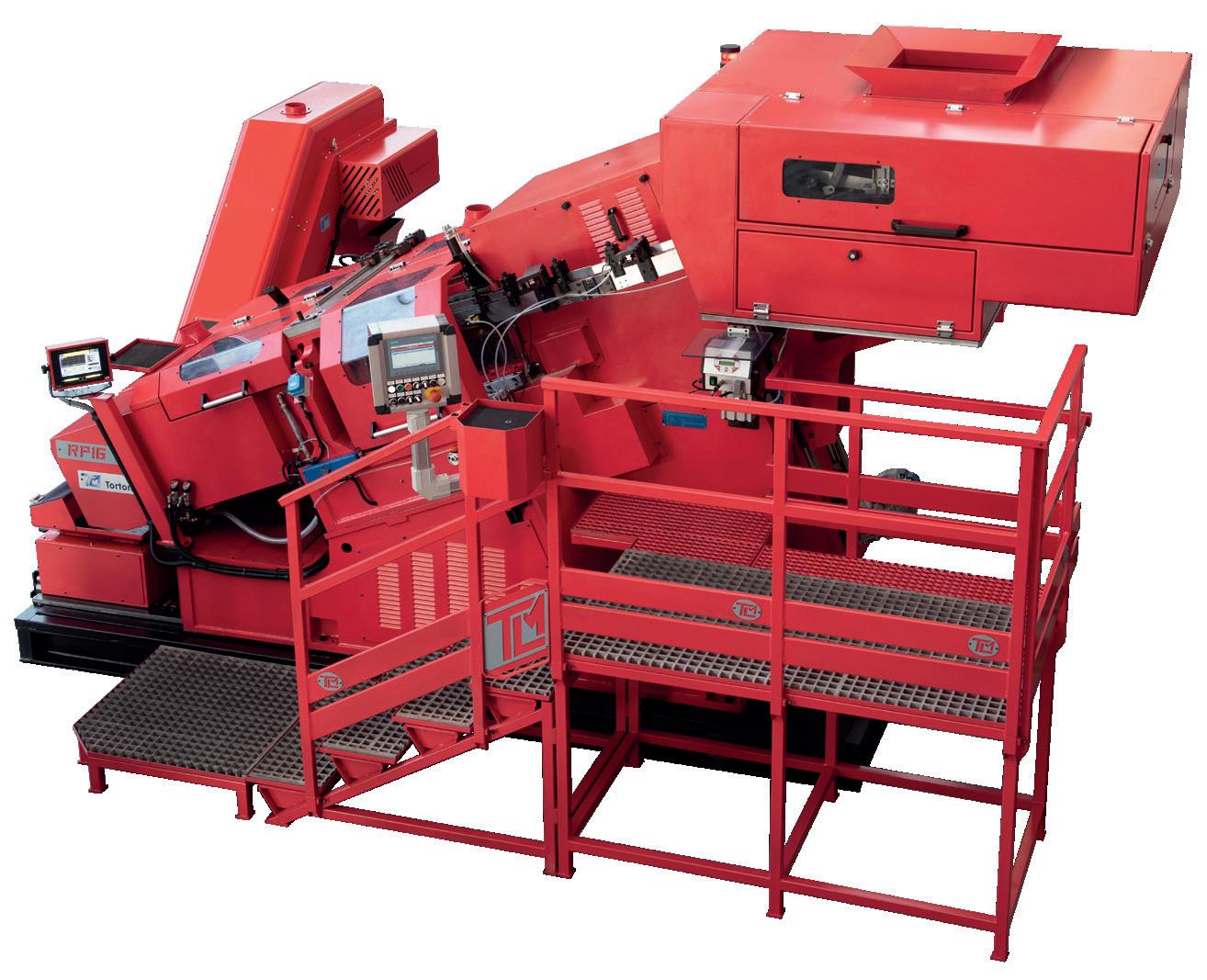

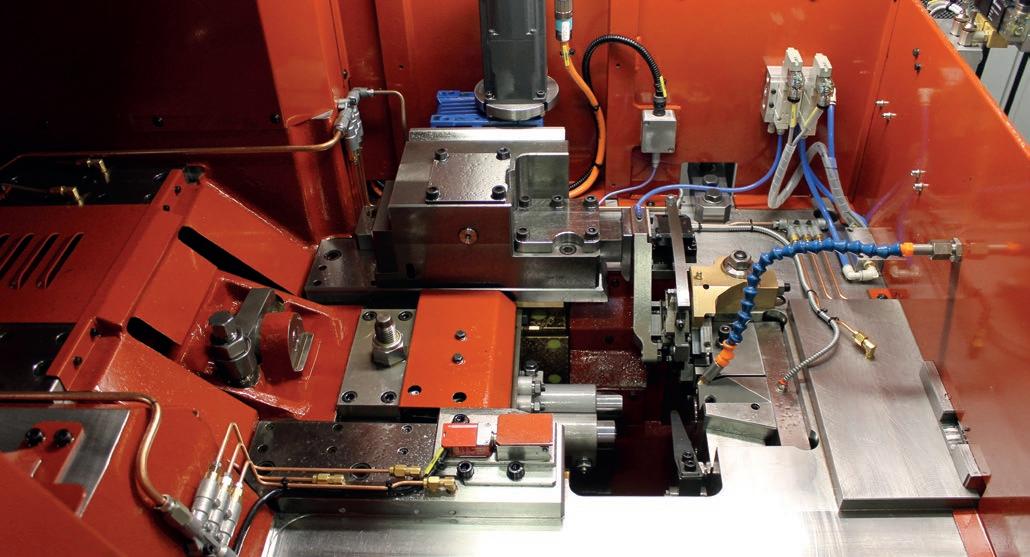

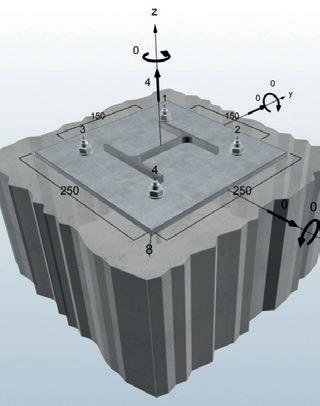

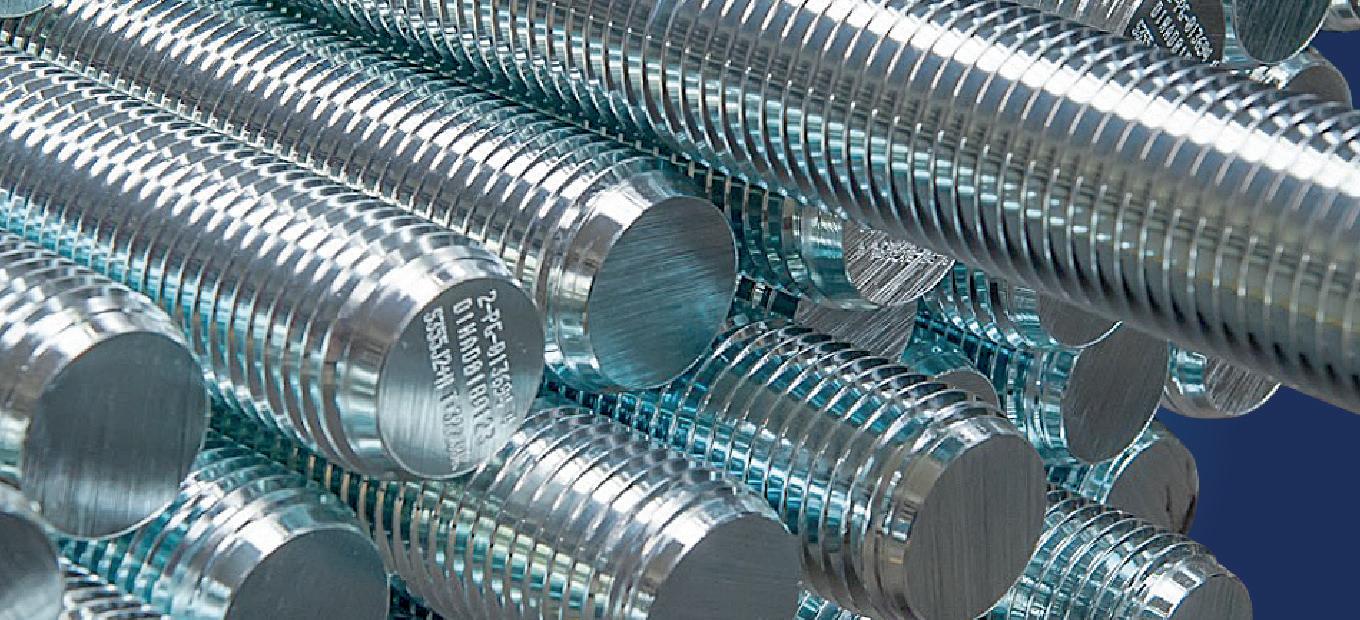

A commitment to quality, modularity, excellence, reliability, customer centricity, continuous improvement, innovation, team working, and employee engagement, are the core values that have been defining SACMA Group since 1939 –making it the world leading manufacturer of multi-station cold forming machines for high-precision metal components and fasteners.

At its headquarters in Limbiate, north of Milan, Italy, the 60,000m 2 plant is the beating heart of SACMA Group.

Here, through an insourced, fully vertically integrated and modular production system, the company machines mechanical parts with the highest standards for precision and raw material quality. Each workpiece is then assembled in-house and becomes part of either a SACMA multi-station cold forming machine or an Ingramatic flat die thread roller.

“These machines then share the same destiny – accompanying customers for the next half century in their workshops, rewarding them with the highest output possible – three shifts per day,” states SACMA Group.

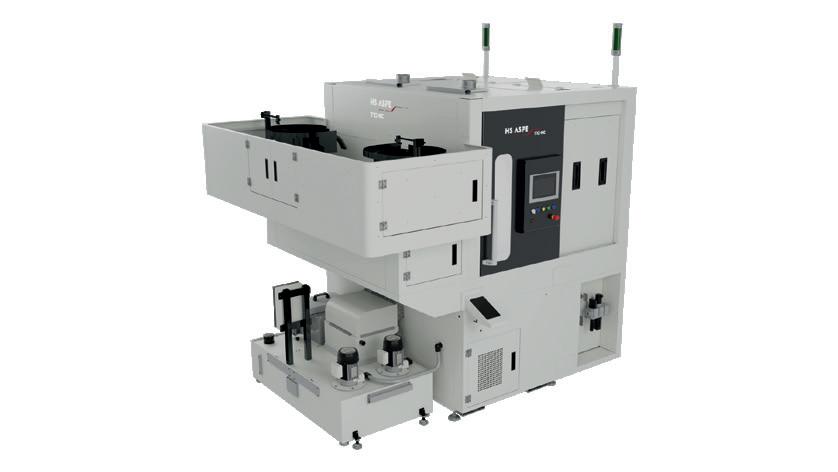

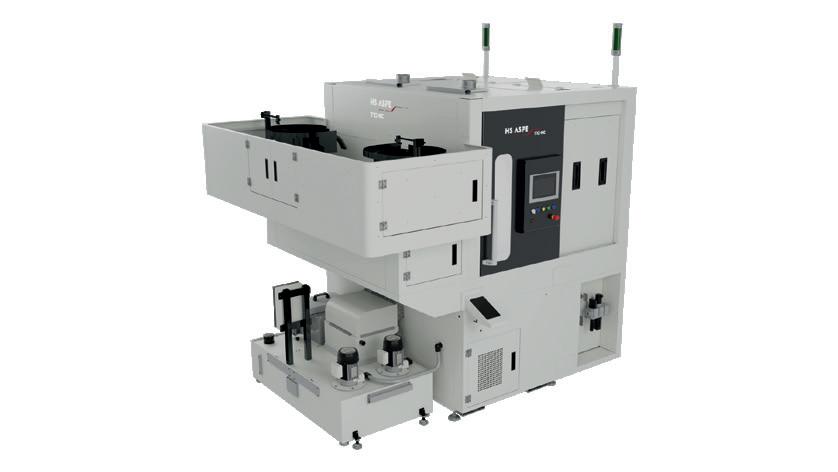

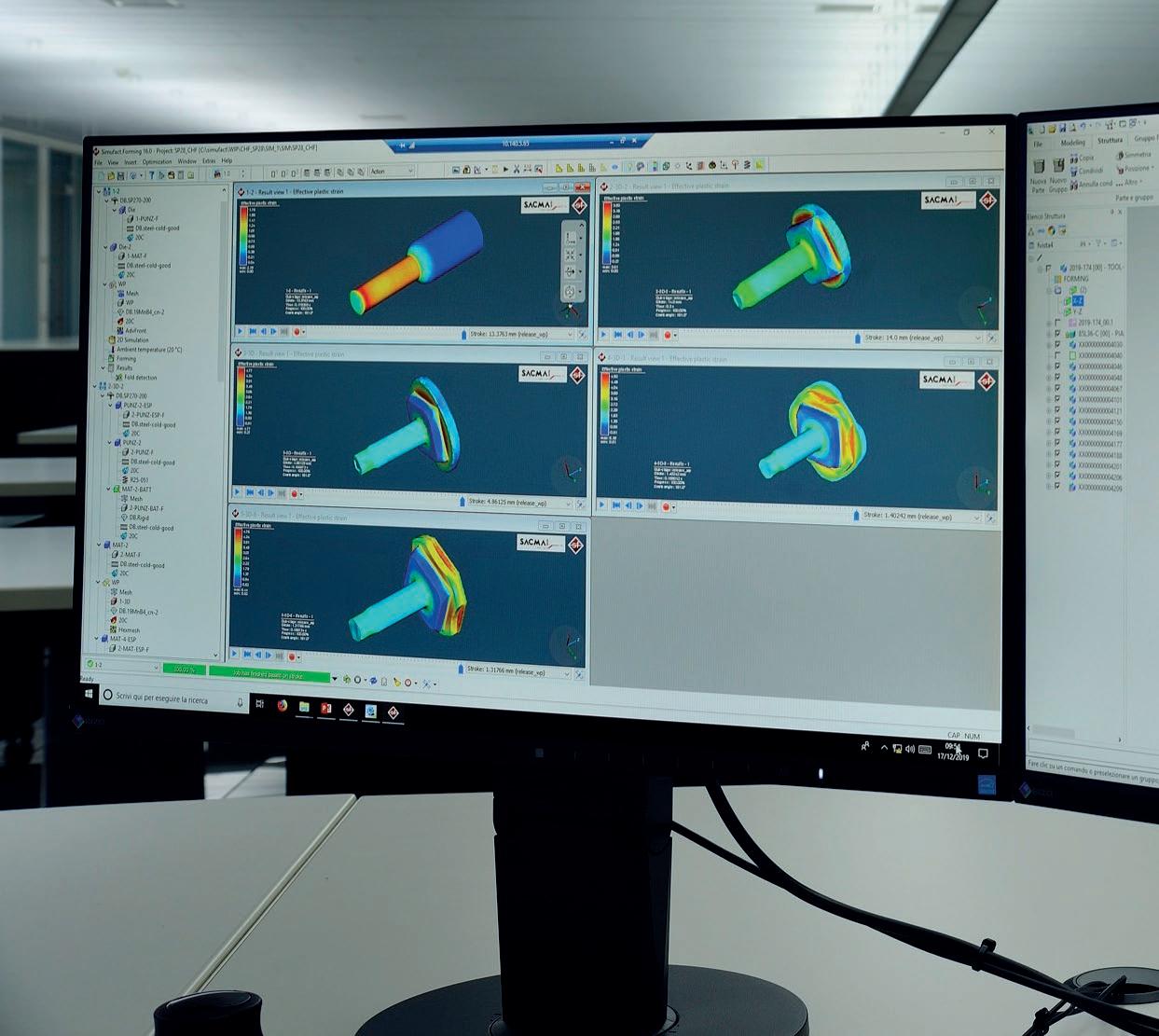

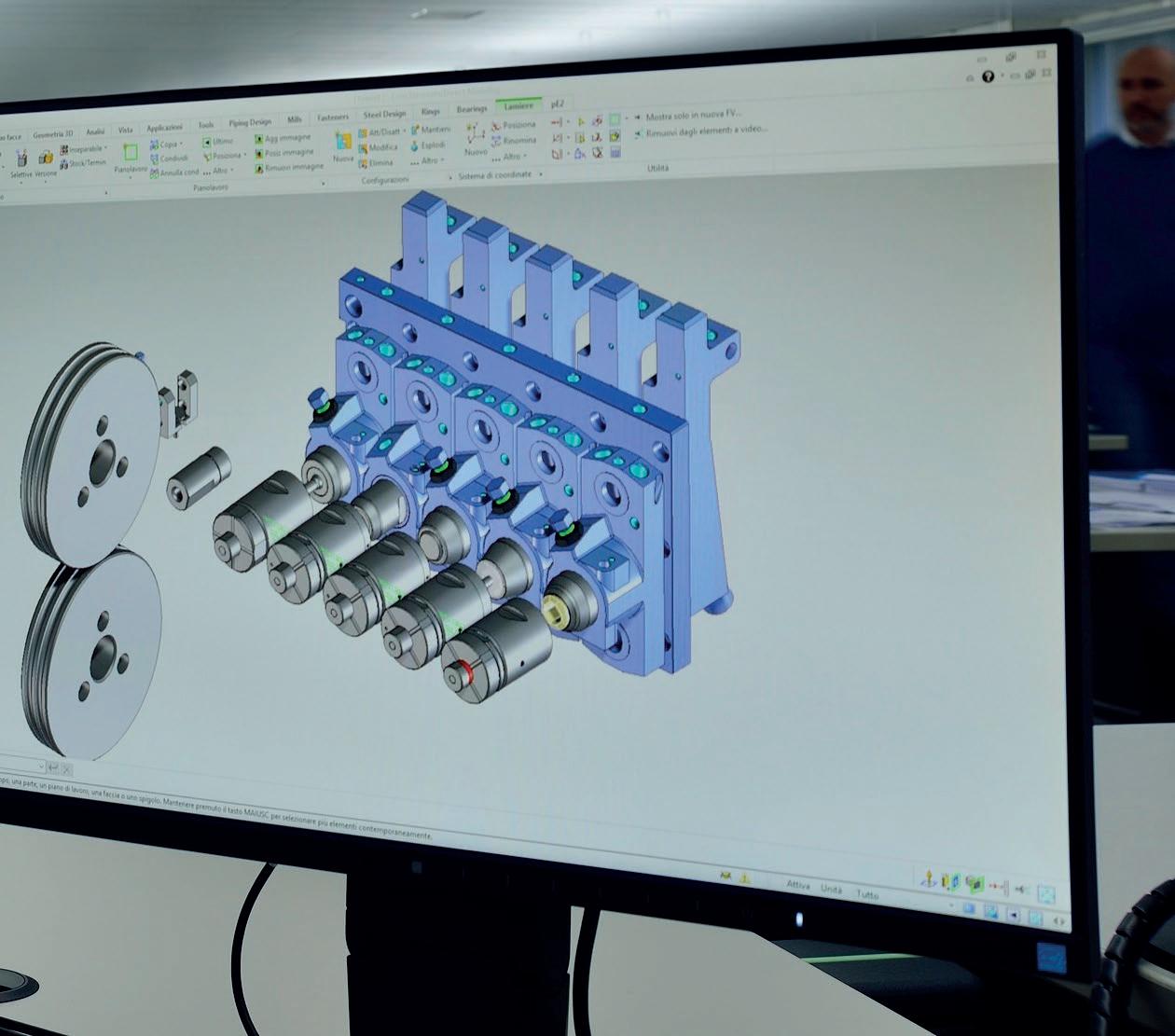

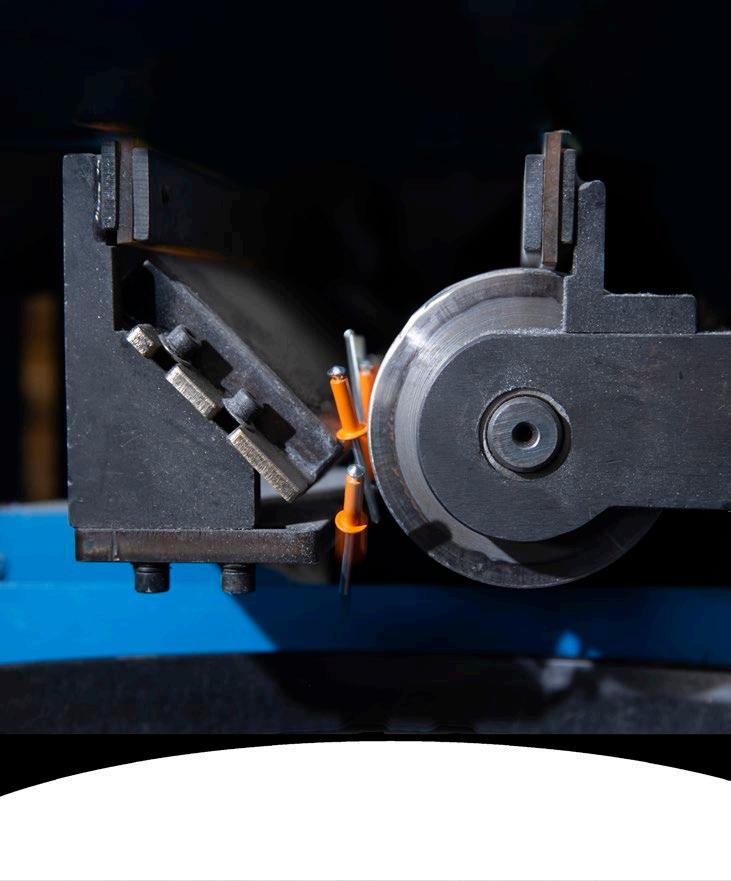

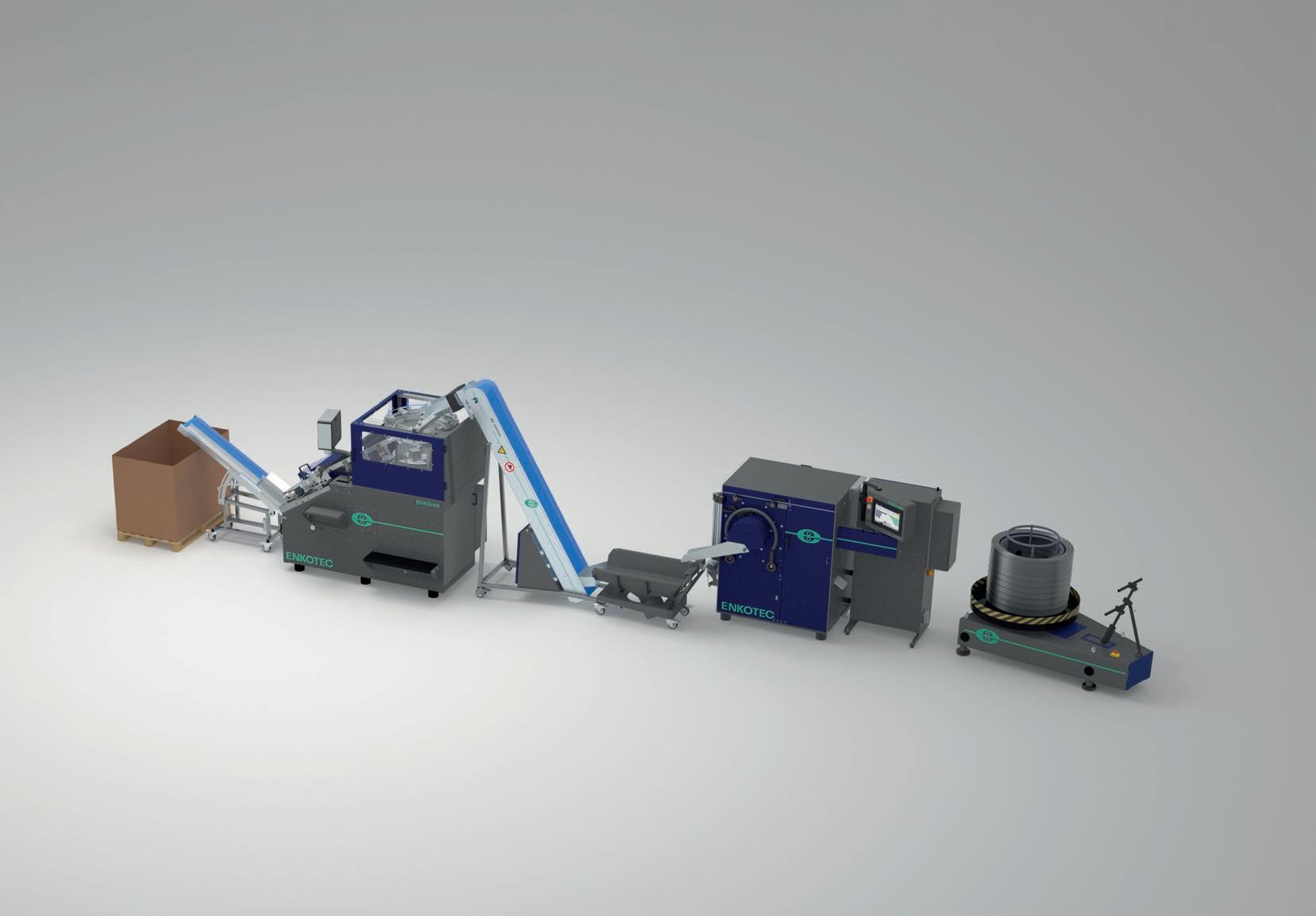

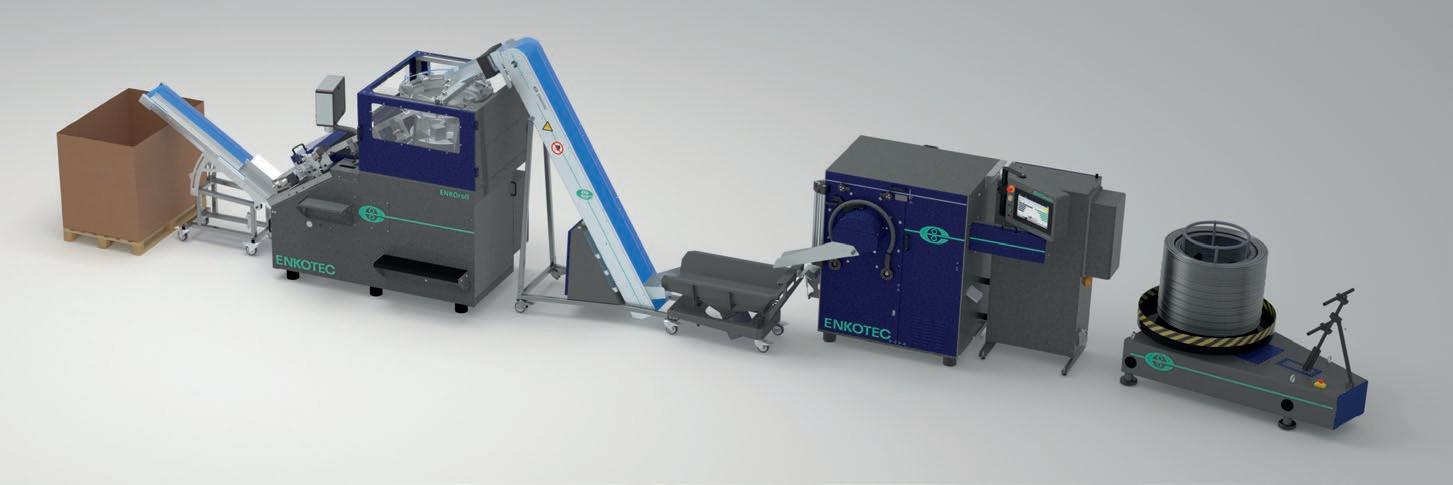

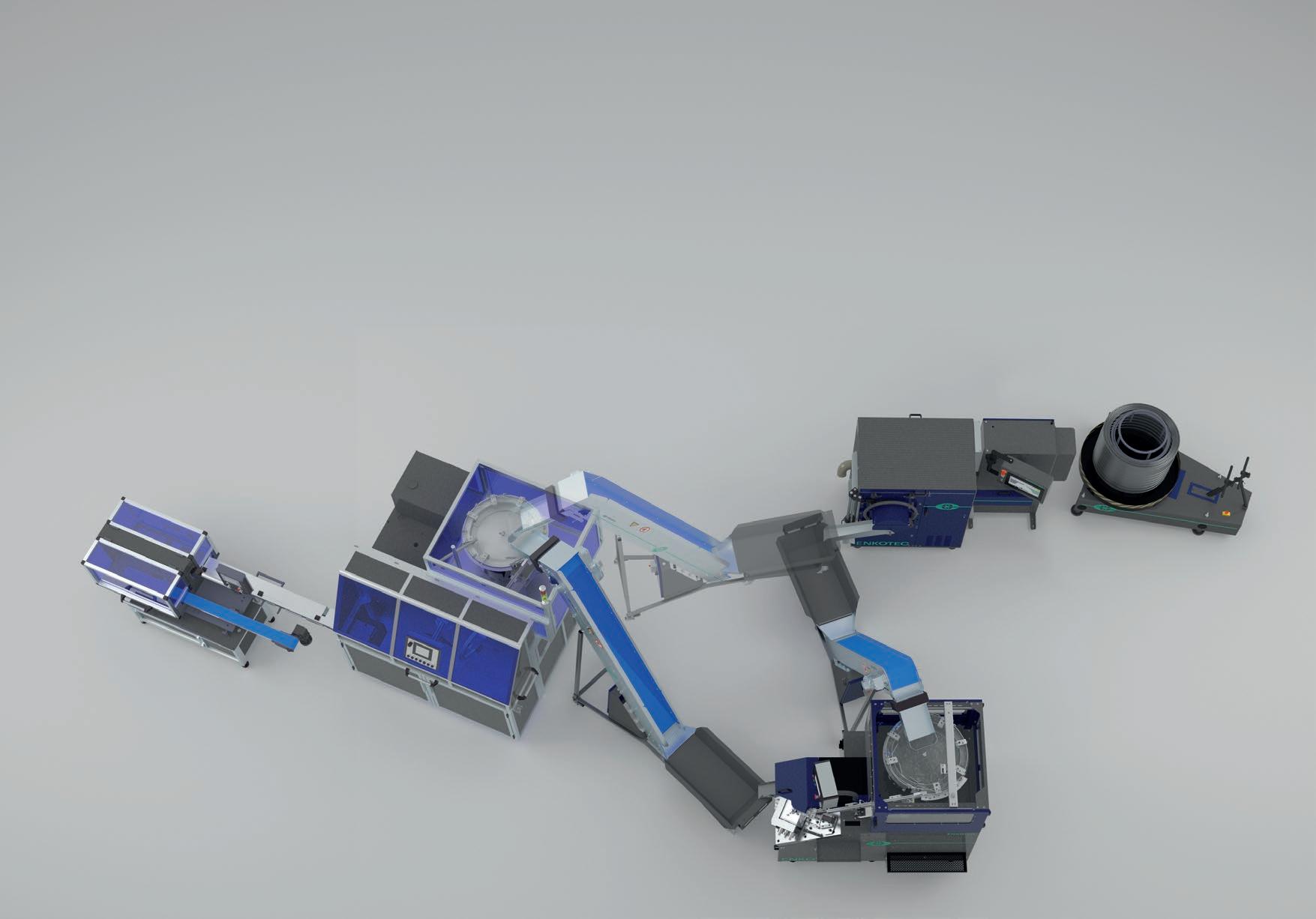

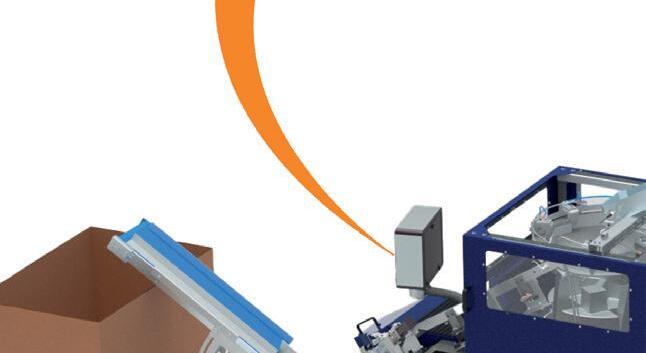

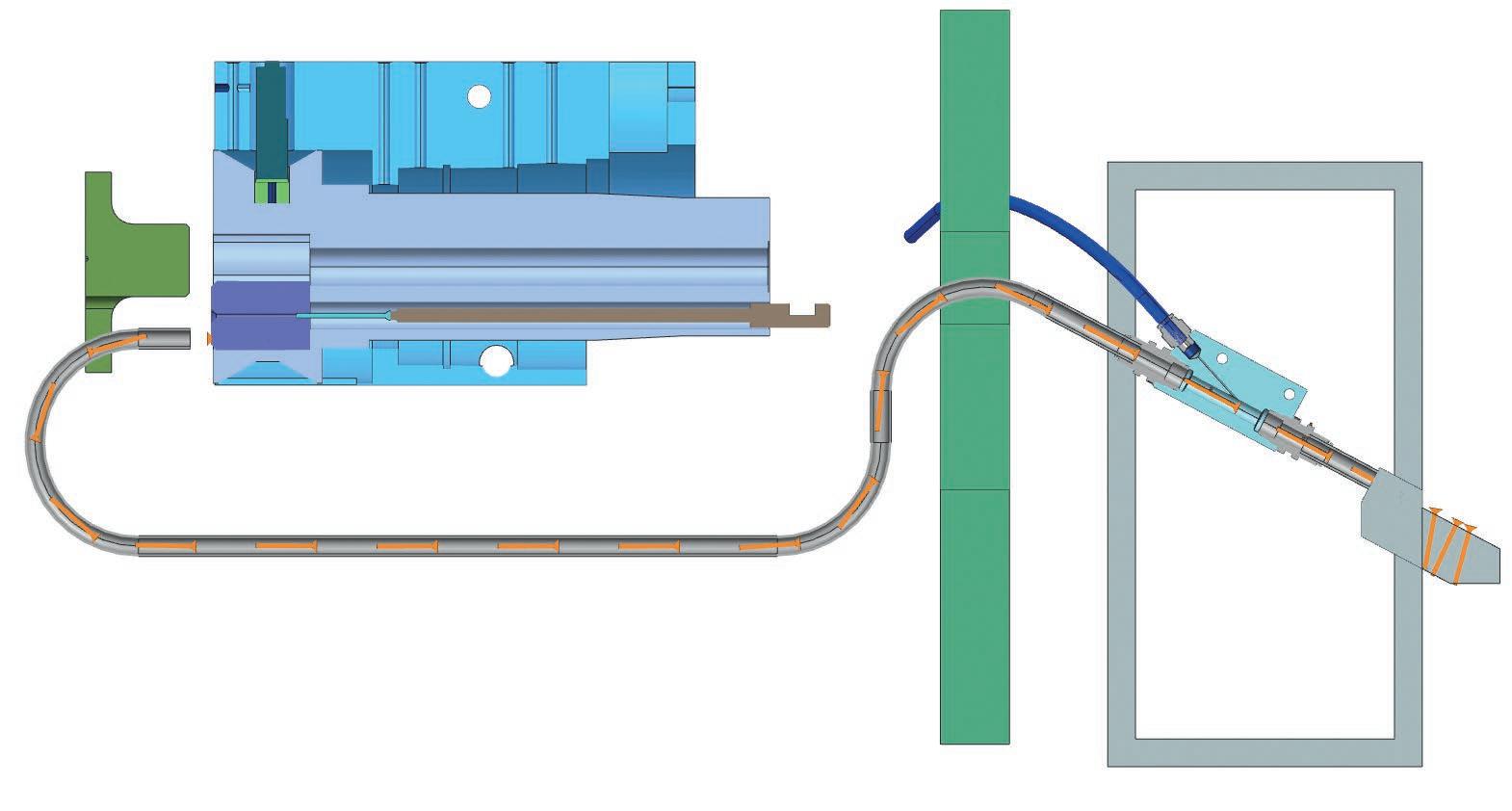

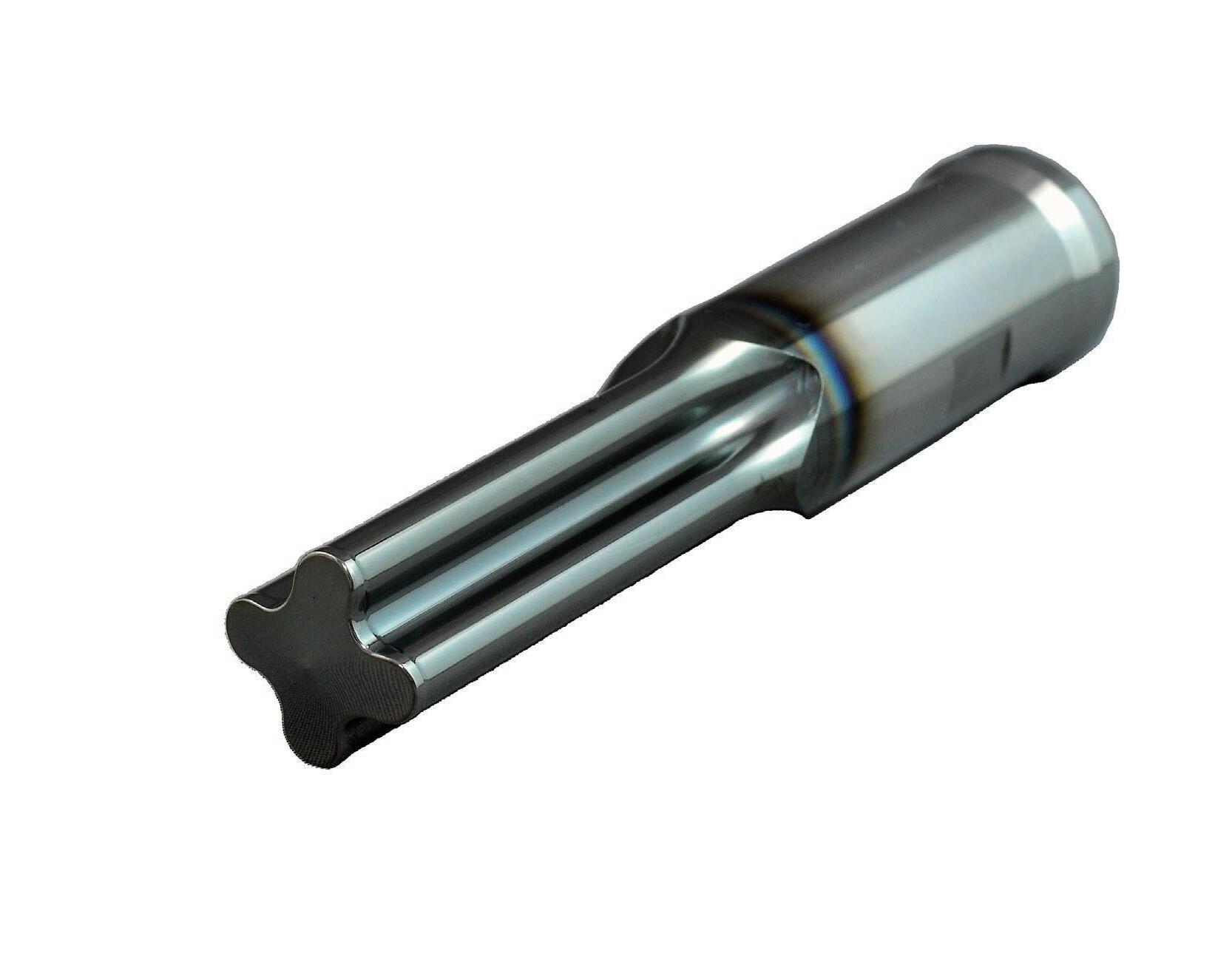

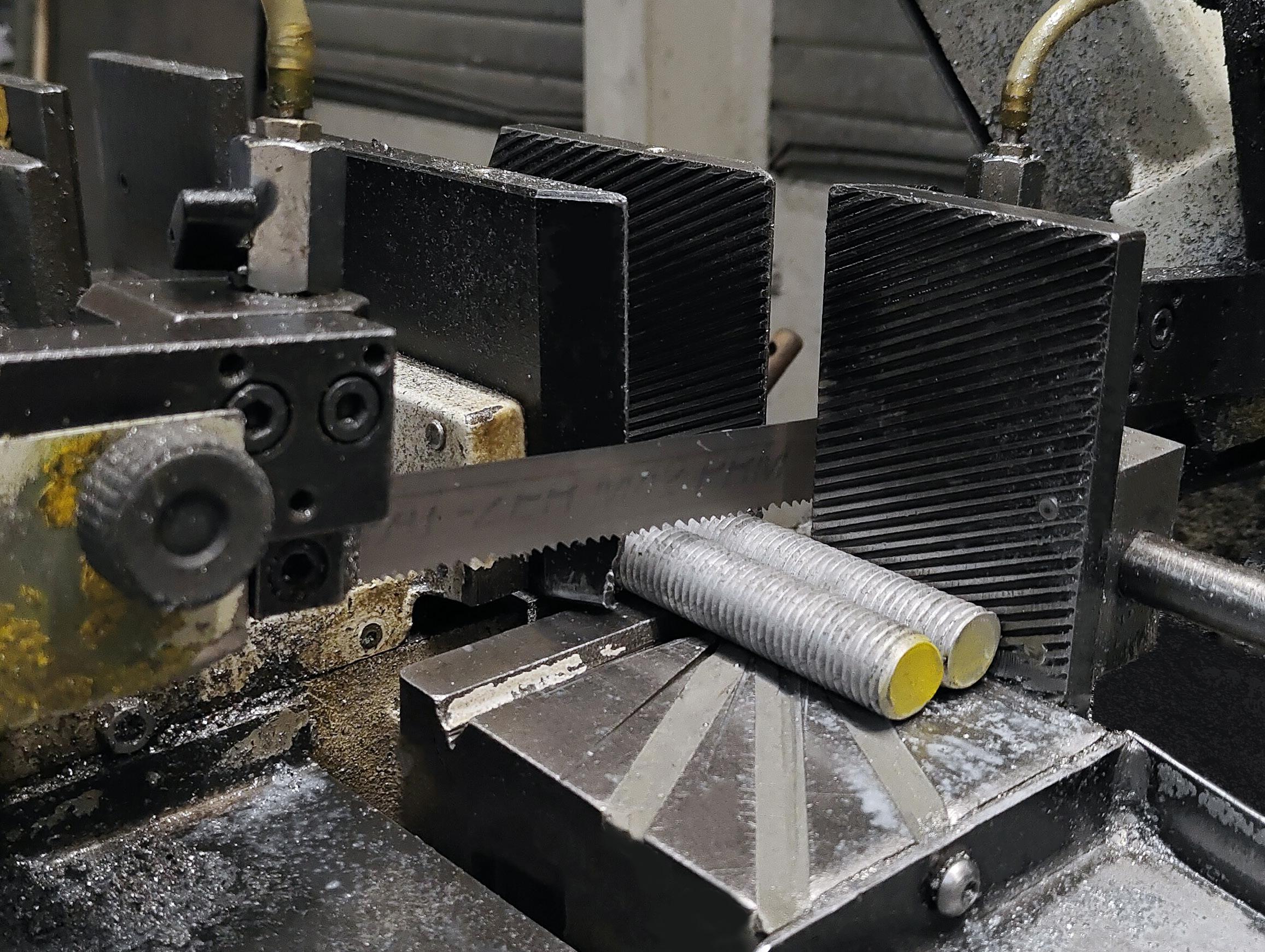

In the last 15 years, SACMA has also been dedicating its efforts in extending its product portfolio through strategic acquisitions and product innovation. The result is what SACMA Group is today – an industrial ecosystem for the fastener and cold forming industry that is able to offer cutting edge technologies from process design through to 3D simulation, such as multi-station cold forming equipment (SACMA), flat die thread rollers (Ingramatic) all the way to dedicated CNC machines for secondary operations after forming and threading (HS ASPE). In addition, anything that goes in between these steps requires stable, high efficiency loading and moving systems and for this SACMA Group supplies reliable solutions through Tecno Lift.

Our business model is focusing on proposing everything possible to support our customers to manufacture fasteners at the lowest cost possible, with the best quality…”

“Our business model is focusing on proposing everything possible to support our customers to manufacture fasteners at the lowest cost possible, with the best quality, thanks to our machineries and ancillaries,” underlines SACMA Group. “Our target is to provide premium machineries to manufacture parts and help the new generation of technicians to work safely, whilst respecting conditions regarding sustainable, which are today’s mandatory key factors. We also invest more than 10% of our sales turnover every year in machineries and buildings to further improve our productivity and to be more efficient.”

SACMA Group adds: “Each entity of the group also has its own R&D, manufacturing department and assembly lines. We strongly believe that it is better to grow in supplying more kinds of machineries, with different entities such as our four brands, than to make more machinery. By proceeding like that we have perfect control of the quality of our products to please the worldwide market.”

SACMA Group is focused on different key markets everywhere in the world and will be busy supplying machines to the worldwide fastener market for both 2024 and 2025. “This is mainly due to the reshoring strategy companies are operating since the Covid-19 period, as well as the increasing demand for machines to supply more fasteners to the automotive market –supported by the EV sector’s growing production,” reports SACMA Group. “We have also seen a lower demand for machines from the construction market, due to the decrease in this sector – impacted by the higher interest rates. However, heavy construction is still demanding bigger sized machines for structural bolt production in order to support the large-scale public works confirmed by different countries around the world.”

The aerospace market has also demonstrated a dynamic trend allowing SACMA Group to supply more Ingramatic and SACMA warm forming machines, and also HS ASPE drilling/tapping machines, to run parts with special materials such as titanium, waspaloy, A286 and inconel. The electrics and general industry fields have also been very active with a lot of requests for smaller machine sizes.

“End users have a high appreciation of SACMA machines, considering them to be well designed, well manufactured, powerful, adaptable

for making special parts, flexible for making long or short parts, as well as being fast and reliable whilst providing low cost production,” underlines SACMA Group. “Our modular system is the best warranty for customers to standardise their process, tooling design and friendly user experience. We have more than 20 million spare parts in stock –making our Group the most trustworthy supplier of machineries. This last advantage allows our customers to have our machine always in condition to manufacture parts without any interruption.”

Another aspect that has enabled SACMA to stand out within the market is the tendency of customers to invest in combined machines that have multi-operation all in one machine. “This provides the best solution for high productivity requirements, consolidation of production methods, floor space usage and workflow in a fastener manufacturing environment. It also makes the production of our customers much more sustainable, which is today a strategical necessity,” underlines SACMA Group. “We are a unique manufacturer able to provide all these solutions, SACMA can provide combined headers with heading, pointing and threading stations; Ingramatic provides the combined threaders with washer assembly, rotative threading and flat dies threading stations; and HS ASPE provides combined secondary operation machines with drilling, chamfering and tapping stations ‘all in One’.”

In total, SACMA Group boasts more than 80 machine models including presses, rolling machines, chamfering machines, tapping machines, drilling machines, lathes, transfer and multi-spindle machines, as well as workpiece handling systems – with a worldwide installed base of around 10,000 machines. “For this reason, we are finalising the construction of a building at our headquarters in Limbiate, Italy, that will be dedicated to the service and assistance activities in order to perform additional support to customers,” highlights SACMA Group. “In addition, we have just finalised the new extension at Tecno Lift to increase its capacity – as the company has been increasing its sales turnover by 15% – 20% every year.”

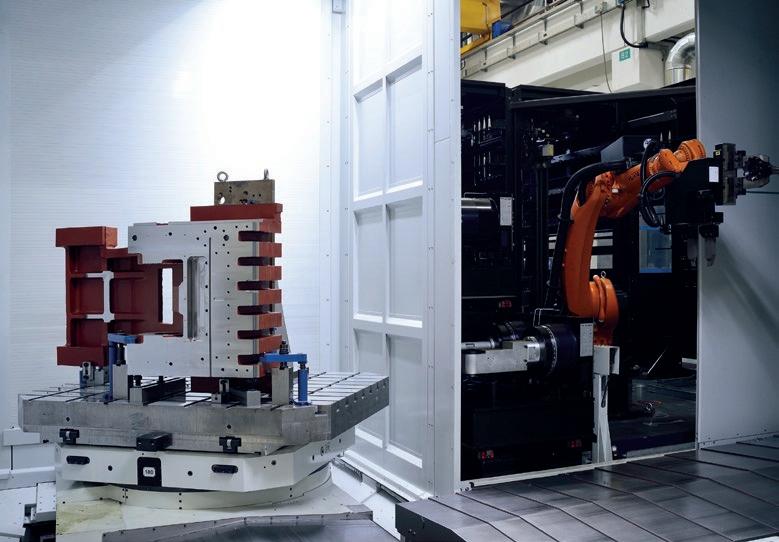

Other investments within the group include the SACMA Vimercate division completing the installation of an FMS line with four horizontal CNC machines – completely equipped with fully automatic loading systems to run parts 24 hours. “This line includes the most advanced features to run our components with a higher quality in a shorter time –helping us to significantly increase productivity,” points out SACMA Group. “In order to facilitate the management of the supply chain, we have also made large investments into vertical storage system in all of our factories – to have a better control of our stock and suppliers.”

With technology continuously advancing at an unprecedented rate, SACMA Group believes it is crucial that it stays at the forefront of the

At SACMA Group we are able to provide a full service to integrate more machines, with different technologies, in order to make a fully integrated cell…”

sector when it comes to implementing new solutions. “As a business we cannot allow ourselves to fall behind, which is why our skilled R&D engineers are committed to hunting down the industry’s most valuable technological innovations,” mentions SACMA Group. “However, it’s not just about discovering them. It’s also about envisioning how they can be integrated into our production processes, machinery, and activities as a whole, as we strive for continuous improvement.”

After selecting and designing an innovative solution, SACMA Group also has a laboratory that is dedicated to testing a solution for at

least two years. “This is the only way to guarantee perfect functioning before looking to apply the solution to our machines and according to our serial production strategy,” explains SACMA Group. “We also have an innovative service to develop new activities or new products through our S-Tooling department, which is where we co-engineer with our customers from the drawing of the part to the industrialised project.”

In addition to staying at the forefront of innovation, SACMA Group also looks to stay ahead when it comes to some of the key topics impacting global markets, for instance sustainability. “For sure sustainability is a topic that we are focusing on and we will need to continue to work on it going forward,” reports SACMA Group. “We believe that we are only at the beginning of what will be a long process when it comes to sustainability. This is because many machines will need to be replaced by new ones that consume less and can make netshape parts in one step – such as with our combined headers, combined threaders and combined machining machines. This series of machinery is also developed with mechatronic solutions to make them energy efficient.”

Internally SACMA Group has also taken steps and made investments when it comes to sustainability. “We have already invested in photovoltaic solar panels and this year all of our companies will be self-sufficient using green energy for the heating, air conditioning and electricity for all of our offices,” mentions SACMA Group. “We will also publish our first sustainability report by June 2024. We believe sustainability is a crucial topic and we want to have the best conditions to be the most sustainable manufacturer of machineries – having a perfect vertical integration of our process, made 100% internally in our factories, as well as using only raw material sourced in Italy.”

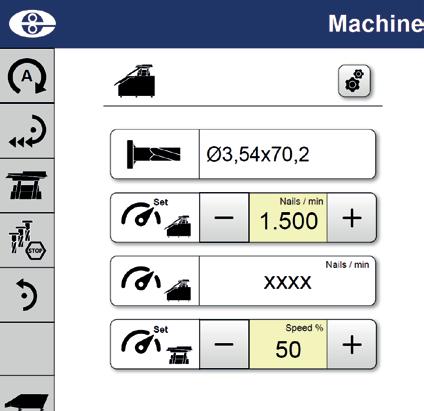

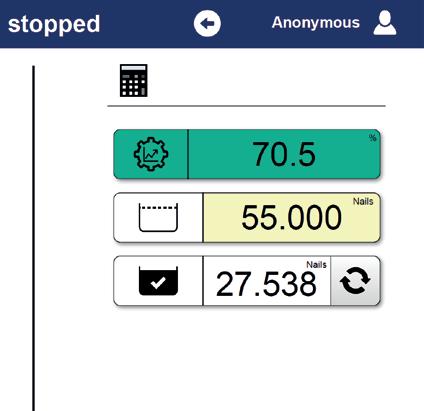

Another area in which SACMA Group has taken significant steps is in regard to Industry 4.0 and digitisation, with the Group already offering different options to customers. “We have created new options for all of our machines to integrate with Industry 4.0, which can be customised based on the customer’s level of digitalisation,” highlights SACMA Group. “From a ‘simple’ option to the ‘full advanced’ option, customers can access a range of data, such as machine alarm statistics, energy consumption in kWh, as well as compressed air consumption in cubic metres, for each order. We also have the SACMA 4.0 web App, which can be viewed on a PC. In addition to the information described above, customers can access the electrical, hydraulic and pneumatic diagrams, which can also be consulted from a tablet or smartphone via QR code on the machine.”

To add to Industry 4.0, and digitisation, SACMA Group is also working on how automation can help provide benefits to both the Group and its customers. “Automation has an important role in helping the technicians to work on the forming machines in order to facilitate their work and we believe automation is an opportunity to make the machines user-friendly,” explains SACMA Group. “That is why we have developed a new HMI program to manage the automation of the machine set-up. From the touchscreen panel, according to the machine model, it is now possible to set-up the entire machine. For example, for bigger SACMA formers, the S-Transfer is available to have the machine fully automatic. Speaking about secondary operation machines, HS ASPE can implement robots to load and unload tools and/or parts. Tecno Lift can also supply automatic devices to create fully integrated cells with more machines connected with loaders and conveyors.”

SACMA Group concludes: “It is clear that the fastener industry is looking to simplify processes with new machines that can help to reduce the overall number involved in making more parts, whilst also requiring less operators and using more automation to help improve the flow of the parts, with attention also given to sustainability. At SACMA Group we are able to provide a full service to integrate more machines, with different technologies, in order to make a fully integrated cell that truly meets and exceeds the needs of every customer.”

www.sacmagroup.com

For over 35 years, Marco Pizzi has developed expertise and knowledge in the mechanical sector, specifically in the field of fasteners. Now he has finally embarked on the path of translating his managerial experience into entrepreneurship through International Hi-Tech Consulting.

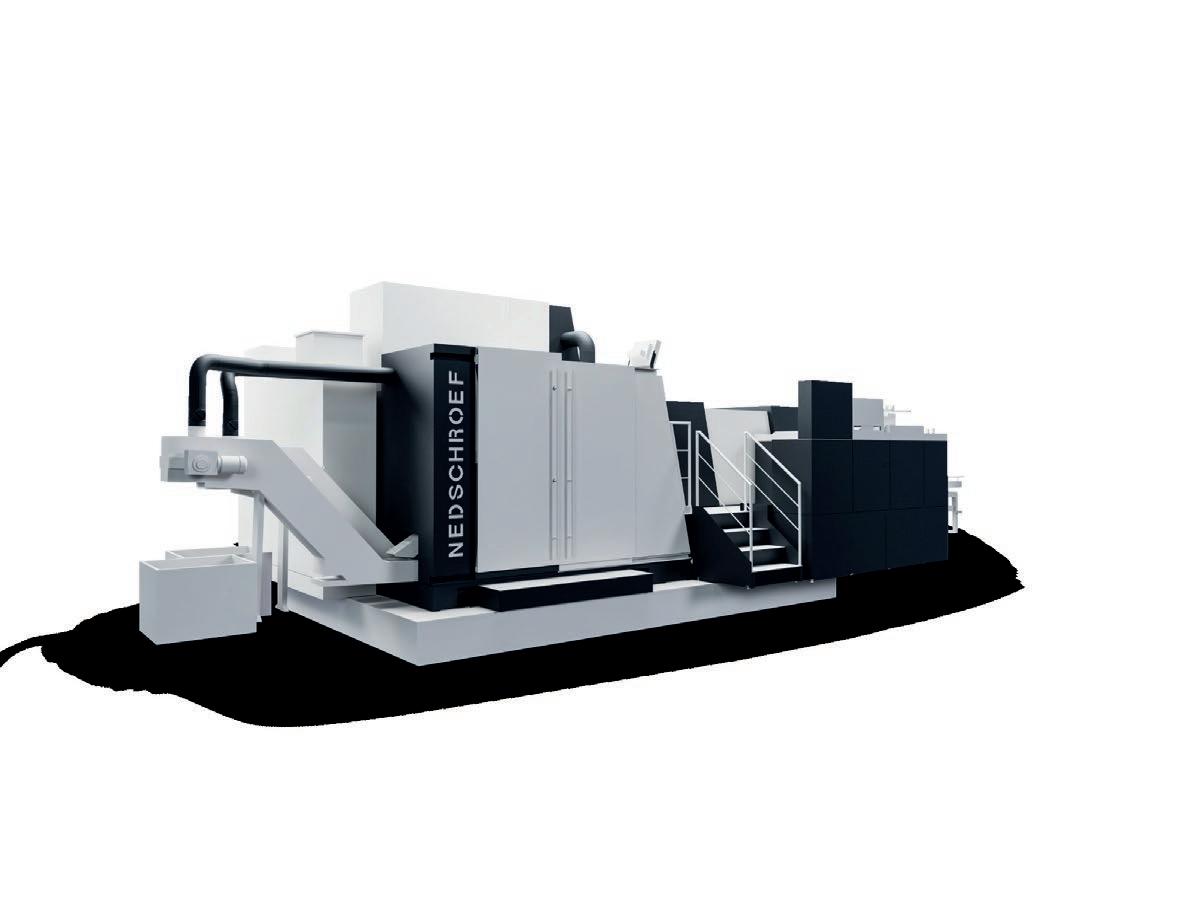

Founded as a communication and technical/commercial consulting agency, International Hi-Tech Consulting Srl (IHTC) designs and provides turnkey equipment, as well as a support service in Italy for their set-up. “We represent the best brands of fastener machinery on the market, including Nedschroef Machinery, Doss Visual Solution Srl, Tramev Srl, Tecnopress Srl, CMS Costruzione Macchine Speciali, Allways Precision Inc, Omig Srl, as well as many others,” explains Marco Pizzi. “We work alongside our clients, offering the best services and guidance, as well as ensuring that they are not just purchasing specific machines or products but are being well guided and supported so that the entire process and investment can become operational within the expected timeframe and with the promised performance.”

Marco adds: “We position ourselves proactively in the market, listening to the needs and desires of our customers and presenting them with a range of proposals and solutions. We don’t operate as traditional agents or representatives; instead, we prioritise offering technical solutions. We sit alongside our clients, helping them evaluate not just a brochure but thoroughly studying, assessing and advising on the best

project and solution for their needs. This is what we do, and it’s what our clients expect from us.”

Within the organisation, IHTC also has designers, process engineers, industrial experts, and capable managers, all dedicated to delivering the best results. “We leverage the expertise of the world’s best industrial partners. The combination of these forces, extensive global experience, and, most importantly, a spirit of innovation and result oriented research, leads us to position ourselves as the best partners in service of the customer,” underlines Marco.

With the current market subject to multiple challenges, including significant fluctuations in costs; immediate and drastic increases and decreases in demand; as well as uncertainties and confusion in supply and demand; Marco believes that innovation is the only want to stay ahead. “This doesn’t just mean purchasing new machinery; it entails studying innovative strategies, reorganising structures, as well as enhancing skills, and response times, to not only maintain relevant positions in the market but also effectively manage external factors and, consequently, costs. At IHTC we offer this kind of service, supporting technological proposals without imposing or limiting the project. This may even involve guiding companies through change with our consultancy, and then the client choosing to entrust the purchase of machinery to third parties. Our objective is broad ranging, aligning with our mission to provide the best solution for achieving the goal.”

We position ourselves proactively in the market, listening to the needs and desires of our customers and presenting them with a range of proposals and solutions.”

With IHTC already securing several significant projects, Marco is looking forward to meeting both existing and new customers at wire® Düssledorf to further consolidate IHTC’s strategy and position. “We plan to participate at the wire® show (hall 16, stand G62) with a stand filled with innovations, information, proposals, and above all, a spirit of collaboration and joy. Because work should be a joy, not a pain. We look forward to welcoming customers in Düsseldorf to meet our team.”

In addition to IHTC, Marco has also established two other companies –BELOWTHELINE Srl and SMARP Advisor Srl – with each division working closely with one another to provide support and services based on the project.

Marco explains: “ BELOWTHELINE is a communication and marketing agency that – leveraging a team of communication, marketing, and 3D video creation graduates – utilises cutting edge techniques and technologies to assist clients in promoting their products and services. Currently heading this division is my son, Alessandro Pizzi, who holds a BA in creative technologies from one of the most renowned and prestigious Italian universities, La Nuova Accademia delle Belle Arti (NABA) in Milan.”

SMARP Advisor serves as the Group’s holding company, exclusively dedicated to overseeing and executing extraordinary operations in the financial and industrial sectors. “We have already successfully executed several mandates for the sale and, in some cases, the identification of Italian and foreign companies, including three European fastener manufacturing companies,” points out Marco. “Our team, with decades of experience, specialises in management, analysis and organisation – complemented by an international legal office operating in Europe and the USA. We can support entrepreneurs and groups in one of the most critical phases of a company’s life and development – from analysis and search to negotiation – identifying the best partner, project, and valuation, whilst guiding them through every stage of due diligence to closing.”

Marco adds: “Our knowledge of the global market, excellent reputation, and understanding of industrial processes, position us at the forefront of this sector – providing support and satisfaction to both financial stakeholders (such as private equity and investment funds) and purely industrial entities.”

UK-based Apex Stainless is looking forward to 2024 as it plans to increase the use of data within the business, thanks to a new ERP system that will help unlock more efficiency gains, as well as deliver a better customer experience.

Over recent years Apex Stainless has taken several steps in various functions within the company in order to use data to help deliver business benefits and gains. The new ERP system is the next step in this process and the company hopes it will act as a catalyst for the business going forward.

“After 32 years, we decided in 2023 that it was the right time to change our ERP system,” explains David Vahter, managing director at Apex Stainless Fasteners Ltd. “From the very first day of setting up the system we were able to sell, distribute and invoice. Whilst, as one might expect, it took a while to settle into the new system, after only a few weeks we were already back at the service levels we expect.”

David continues: “We are convinced that we can use data to help further streamline the business and we achieve this through a combination of improved performance within our operations and through the delivery of new digitised services. For example, orders are now completely paperless, which is also an important step forward in our drive to achieve a sustainable future.”

Finding those wins for the company, and its customers, is going to be a key focus in 2024 for Apex Stainless, especially after the challenges of the previous year. “I think it is fair to say that the market leading up to 2023 was quite turbulent and while we saw supply stabilising during the year, due to a lower underlying demand, there were still several other macroeconomic challenges we needed to manage,” reports David. “Inflation, low unemployment and high interest rates were on top of the agenda in most countries. The cost of running a business today is far from pre-pandemic levels, which I think will continue to be a defining factor over the coming years for many businesses.”

David points out that 2023 was also the year to prepare for the introduction of new compliance directives, such as Russian Sanctions and CBAM, and in both cases BREXIT was a complicating factor. “In some aspects, we are pushing paper like never before and the importance of data is proving more and more crucial when it comes to these new regulations and directives. Compliance is certainly an area that is requiring more attention by businesses. For some of our customers the burden of compliance will open up a few questions in terms of their own supplier base, which is why it is important we are able to show that we are at the forefront of managing this topic.”

Looking forward, David also believes there is an opportunity for the business through nearshoring, with the various challenges within the world leading to uncertainty within markets. “Russia’s illegal invasion of Ukraine does not seem like it will be resolved anytime soon, with the consequences of the war having now reached the Far East supply side with the introduction of UK notice NTI2953 and EU regulation 833/2014

In this aspect, businesses like Apex, can add real significant value to our customers…”

(11th package). In 2024 there will also be the presidential elections in the USA, which have the potential to create more uncertainty. US politics under Biden have been characterised with a move away from China as one of its main trading allies. It is clear from the outside that when China’s ambition changed to producing more sophisticated products, they became more of a threat for the US than just a trading partner of low cost goods. With China being a more prominent figure in the East, and South China Sea, as well as the controversy around Taiwan, one can perhaps foresee more upcoming political tensions.”

David continues: “These topics matter because cash flow, lead times and compliance will all be big considerations for businesses in 2024 and beyond, with companies looking at their suppliers. In this aspect, businesses like Apex can add real significant value to our customers by offering them stock on a short lead time, with sound payment terms and without the need to reassure a certain compliance across a large number of parts and suppliers. Through the foundations that are already in place, as well as the ongoing investments into our operations, we are very excited to see where it takes the business in the next few years, because it has the potential to be highly transformative for us.”

www.apexstainless.com

Empowering