growsmart

Scion Nursery

We revisit a landmark project to revitalise Scion Nursery in Rotorua.

What’s the deal with Coir?

Introducing Coir (coco peat) as an exciting sustainable addition to traditional peat and bark, with a free Coir Trial for readers.

www.primehort.co.nz

ISSUE ONE

DaRos Italy is the global authority in Nursery Automation and well-respected in more than 40 countries. PrimeHor t’s partnership with DaRos began in 2011.

“A relationship of trust and respect - we are proud to have PrimeHort exclusively represent our brand in New Zealand. We appreciate the excellent work done over the years, your contribution has added-value to the growth of DaRos. I look forward to the next business trip to catch up with the extraordinary work of Kiwi growers.”

Fabio Camisa - Senior Sales Manager DaRos, Italy.

The team at DaRos are committed to PrimeHort’s promise of “Growing Smarter Together” for its valued customers. Scan the code to check out why DaRos are leaders in manufacturing machinery and systems for automation in the horticultural industry.

| 2 www.primehort.co.nz

View DaRos Nursery Automation at www.primehort.co.nz or call the PrimeHort team to find out more: 0800 12 77 46.

growsmart

Grow Smart Publication Team

Chantelle Crisp

Molly Lewis

Contact

PrimeHort Distributors

2168 State Highway 1

Kaiwaka

Email: sales@primehort.co.nz

Phone: 0800 12 77 46

Editor

Kirsty Millar

Design

Philippa White

Photography

Tegan Hoyle

This publication is printed on paper made from pulp that is environmentally certified, and from renewable and sustainable sources using vegetable-based inks. It is Elemental Chlorine Free (ECF) and manufactured under strict ISO 14001 Environmental Management Systems (EMS).

This publication has been printed by Webstar, a Toitū enviromark diamond certified company and a winner of a Green Ribbon Award “Minimising our Waste”.

The information contained in this publication is given in good faith and has been derived from sources perceived to be reliable and accurate. Whilst every effort is made to ensure the accuracy and correctness of the information, PrimeHort gives no warranties, express or implied, regarding the information nor does it accept any liability for any opinion or information (including the accuracy or completeness thereof) or for any consequences flowing from its use. The information and views expressed in this publication are not necessarily the views or opinion of PrimeHort’s, its editorial contributors, freelancers, associates or information providers. Independent advice is recommended before acting on information or suggestions contained herein. Readers who rely on this information do so at their own risk. Reference to any specific commercial product, process, or service whether by trade name, trademark, manufacture, or otherwise does not constitute an endorsement or recommendation by PrimeHort.

No part of this publication may be reproduced in any form without the prior written permission of the publisher.

GROWING SMARTER

Welcome to Grow Smart

brought to you by the team at Primehort.

We are excited to launch a magazine tailored to horticultural professionals.

As New Zealand’s leading distributor of nursery supplies and automation, our magazine is based on the idea that to grow smart every page should explore ways to maximise crop yields and streamline operations through nursery automation and innovative horticultural products.

“We’ll throw the spotlight on the industry and its hardworking people, and we’ll provide an honest scorecard on the products and machinery helping you succeed.”

At a time when efficiency and sustainability are paramount in the industry, our team is committed to delivering content that is informative and actionable for the seasoned nursery owner or budding entrepreneur.

We recognise the invaluable role that automation plays in nurseries to stay competitive, improve productivity and ultimately drive profitability, so we’ll pay special attention to this topic.

As Grow Smart takes flight, we invite you to join the conversation. Your feedback will help us shape the future direction of this magazine and ensure it can be a trusted resource for the horticultural community.

Sincerely,

Ernie Wearmouth GENERAL MANAGER | PRIMEHORT

| 3 www.primehort.co.nz

is life.

Water

DAROS WATERING

BOOM

Inside our launch issue

03 Welcome

PrimeHort General Manager Ernie Wearmouth reveals why Grow Smart was created and how it plans to support the horticultural industry.

06 Scion Nursery

We revisit a landmark project to revitalise Scion Nursery in Rotorua.

13

What’s new

Check out the latest products to maximise productivity and crop yields.

14

What’s the deal with Coir?

Introducing Coir (coco peat) as an exciting sustainable addition to traditional peat and bark, with a free Coir Trial for readers.

19

Helping nurture a Kiwi colony

Collaboration, mahi and sponsorship helps plant trees for Taranaki and enables a Kiwi colony to thrive.

20 Leithfield Nursery automate

A bold transition from bare-root growing to a containerised system calls for innovative nursery automation.

25 Meet Joel

We profile PrimeHort’s automation expert and find out what he’s doing to help customers succeed.

26

Cultivating community

Learn more about PrimeHort’s voluntary planting days to help a vulnerable Sandspit.

| 5 www.primehort.co.nz CONTENTS

Right tree, right place, right purpose.

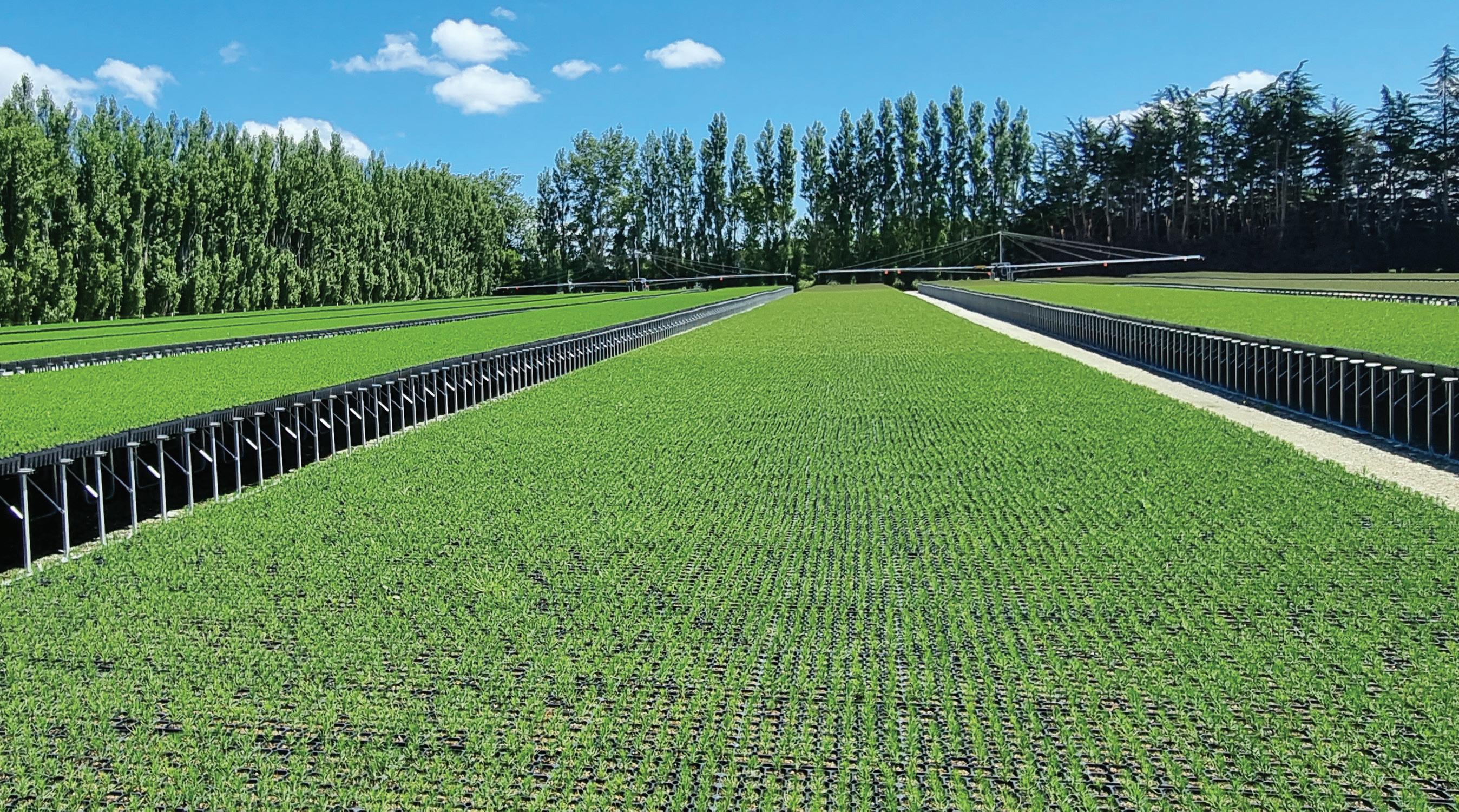

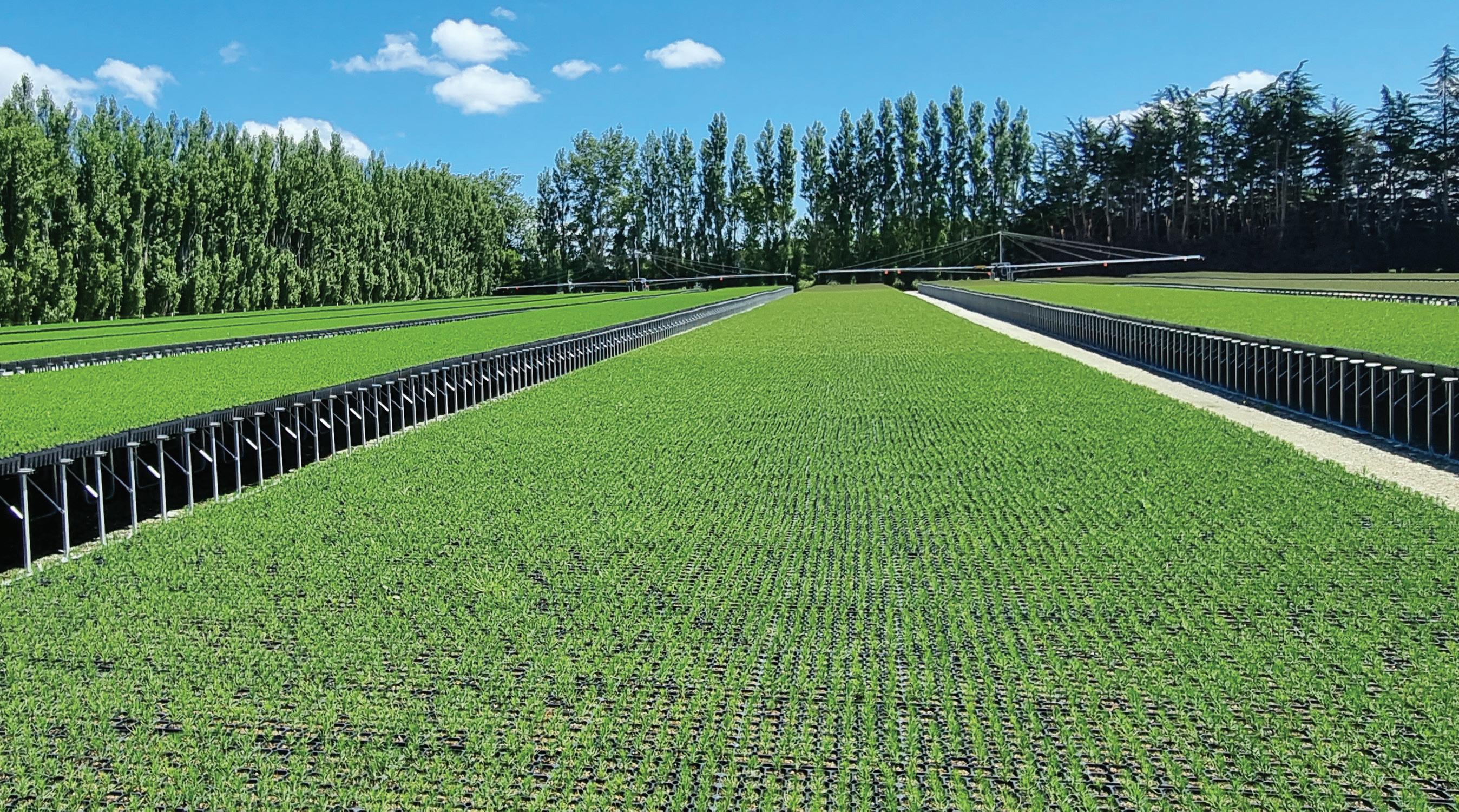

Craig Ford was formerly the Research Group Leader: Plant Development and Physiology for Scion. Together, we reflected on this landmark project to revitalise the 10-hectare Scion Nursery in Rotorua.

| 6 www.primehort.co.nz

LANDMARK PROJECT

Craig Ford

Former Research Group Leader: Plant Development and Physiology for Scion.

Craig Ford

Former Research Group Leader: Plant Development and Physiology for Scion.

Scion Nursery is focused on forestry propagation research and technology development for the industry, along with supporting Scion’s other forestry research requirements around silviculture and disease management. The nursery can produce more than one million seedlings per annum, with shade houses, controlled climate propagation facilities, a large purpose-built container-growing operation and a paper-pot growing system.

What was the vision for Scion Nursery back in 2019?

The overarching theme was to help the forestry industry get to the “right tree, right place, right purpose” objective. The goal was to improve the ability for the nursery to focus more on research, as that is where the nursey started. The aim was in part, to demonstrate and deploy cutting-edge technologies on behalf of producers so they could embrace new propagation techniques for forestry quickly while fully understanding the risks and rewards. We wanted to demonstrate ways to grow genetically improved treesfaster, more sustainably and without compromising health, survival and growth in field.

To do this, we had to review current and future critical issues for our industry, survey what alternatives were in use elsewhere, and explore how to implement those in New Zealand as and when required. We drew on previous experience from South Africa and research on South

| 7 www.primehort.co.nz

American operations – both have advanced their propagation technologies ahead of what most of us do in New Zealand and produce significantly higher numbers of trees per year. The goal was to refine these approaches to something suitable for us here, with our unique growing conditions and markets.

What was the state of the forestry industry back then, and the challenges you had to consider in your vision for the nursery?

When we started this refresh program in 2017, forestry nursery production was about 51 million trees annually. At that time, the government was rolling out their ‘One Billion Trees’ programme, which required one hundred million trees to be established annually, ideally with 30% natives. We realised that scaling up operations, particularly of native trees, would require new approaches, especially where seed availability would be a limiting factor. We also needed to consider future pressures on tree propagation and how we might be able to mitigate them.

Over the past few years, particularly during COVID, our industry has faced significant labour shortages and labour cost increases (bare-root is very labour-intensive). There are environmental and potential social licence-to-operate issues around dealing with large amounts of chemicals and the potential for legislation reducing or even stopping current activities around irrigation, fertigation, and disease control. There is also the looming risk and impact of climate change on bare-root systems, which rely on partial dormancy

combined with cold, wet planting conditions over winter for successful establishment.

Fortunately, the rapid scalability afforded to us through our primarily bare-root P. radiata production (as well as the inclusion of the booming Mānuka plantings) enabled us to quickly meet the increased planting demand of the past few years. With bare-root radiata seedling propagation methods well developed, understood, and executed in New Zealand, we felt that our research should focus on less developed technologies, like containerisation and vegetative propagation (particularly for native trees that were not being deployed at a forestry equivalent scale or cost at the time).

| 8 www.primehort.co.nz

After considering these challenges, what was the final plan for this new nursery research facility?

We saw it as Scion’s job to acknowledge the challenges and let them guide us to find new approaches and technologies for better germination, improved rooting, reduced losses, and deployment of more trees with the same limited germplasm.

So, we set out to create a world-class Propagation Sci-business where we could do our own research, funded by industry and government, to examine containerised, bare-root, and paper pot growing systems and their relevance in a New Zealand context. We designed an appropriate facility (based on other nurseries worldwide) and went to market with a tender document with our key concepts and requirements. Many systems in this wellautomated, lean flow facility were new to New Zealand.

Scion pitched the vision and drawings to PrimeHort on the desired facility. In a nutshell, all of the motherstock was to be contained in a controlled environment, with yearround production and processed in an undercover Header House, then rooted in Rooting Tunnels (with heated rolling benches), then out into a Growing Tunnel for hardening, and a final open growing-out phase to acclimatise for planting.

The facility’s rooted cutting production capacity was 690,000 per annum. This represented a reasonable compromise between research and production-scale activities, which often aren’t transferrable due to scale. This facility allowed Scion to test technologies at scale and

produce plants for field testing at scale, too. Some of the South American nurseries on which the design concept was based produce 50 million per nursery per annum!

What were some of the technologies you deployed?

Some of the technologies we implemented included complete environmental control in our motherstock, rooting and grow-out areas (day length, humidity and temperature). All environmental controls, irrigation and fertigation are controlled by a central system, which can be remotely monitored and controlled. We also installed better ergonomic alternatives to what we currently see, such as motherstock in beds at hip height for weeding and harvesting (all under cover and sheltered from the elements), fully automated containerised production lines, hip height rolling tables in the rooting area (also maximising rooting area under cover), with the longer-term vision of switching all growing tables to rolling benches for easy movement.

Two of the ‘new to NZ forestry’ technologies we initiated were a sandbed containerised system for motherstock (as pioneered in South America) and the paper pot containerised production system.

Government funding, through the ‘One Billion Trees’ programme, also allowed us to test the vegetative propagation of several native species using motherstock in sandbeds too. The results were outstanding. We achieved excellent root strike and growth in several key species, such as

| 9 www.primehort.co.nz

Tōtara for potential forestry purposes and Pōhutukawa for conservation purposes (in response to the Myrtle Rust threat to this iconic species). It was exciting to think we could bulk up and deploy Myrtle Rust-resistant strains if that issue had really taken hold. That was a huge win and proved we could support breeding programs in both cases, with good results.

We were also very fortunate that Ellepot of Denmark supplied us with a paper pot machine to test this technology in radiata and our native trees trials. We tested more than 20 native species, as seedlings, with various paper pot sizes against industry standards (like the PB2 plastic bags) and found that many species can successfully be deployed in a forestry grade (125-150cc) paper pot and that we could significantly reduce the propagation time. Most notably, we could successfully grow and establish twelve-month-old Tōtara seedlings in field.

Other work demonstrated that using paper pots allowed us to reduce the vegetative propagation time for clonal radiata cuttings from 12-14 months to 9-12 months without issue, which was a huge win and successfully showcased a new way of doing forestry in New Zealand.

What was the industry uptake like?

We generated plenty of interest during the early phase and held many open days and private visits. Our work has driven change, especially in producing native trees. We have seen significant uptake of the paper pot technology, in smaller volumes, in the native tree market. The uptake for radiata has been slower because it is a big capital investment, and there is a limited number of companies

pursuing high genetic value through family and clonal cuttings production. Those companies with containerised growing systems have either started producing cuttings in paper pots or are actively investigating them. There has also been a strong move towards paper pots for mechanised planting in our industry.

Generally, the uptake of containerised growing in highly controlled environments could be faster. This is due to the high capital costs of this kind of growing versus the very cost-effective bare-root seedling model. Until legislation (or climate) makes bare-root too difficult, many producers will stick with what they know (and do very well). Ultimately, when the value is in high genetic material and you want to maximise propagation, the answer is a containerised system—so I do see a changeover becoming inevitable, albeit gradual.

The Scion Nursery demonstrated compelling success with containerised growing. Has interest remained strong with forestry growers? At present, there is a strong demand for containerised trees at the fringes of the traditional, winter-based bare-root planting window. This is because containerised plants are more resilient under unpredictable climates, particularly hot and dry planting conditions. As our climate becomes harsher, we may well find an increasing need for this stock type in New Zealand.

The advantage of Scion is the freedom to take risks and test different processes because you have the backing of industry and government. We were able to test and prove results to a level where producers can now invest with confidence – and that is where we got to with paper pot growing.

| 10 www.primehort.co.nz

Based on the work completed at Scion, where we demonstrated examples like 6-month-old radiata cuttings in paper pots being successfully established in the driest March for many years, we have confidence in containerised system suitability, particularly with paper pots. While results like this may take some time to commercialise, demonstrating that containerised stock can be produced in less than 12 months and will survive well in field, makes it far more appealing to the industry.

So what technologies do you think might revolutionise the forestry industry?

Forest Growers Research Ltd would be great to interview. They are researching fantastic automation and remote sensing technology to mechanise the bare-root lifting process. There is exciting stuff happening.

For me, the big shift for forestry propagation would be year-round propagation of radiata cuttings in fully controlled growing environments, setting high genetic gain cuttings into paper pots (like we see in South America and South Africa).

In the face of labour supply issues, social licence-tooperate and climate change, it’s becoming increasingly important to consider moving towards this method. However, I recognise there is still a strong bare-root resource, supplying large volumes of trees to the industry and a niche for those trees, so it will be a slow ship to turn.

Rolling benches like those we planned with PrimeHort are a no-brainer for those investing in a containerised nursery. The industry would benefit hugely from more uptake of rolling benches to optimise productivity and work more comfortably.

Is there a resource or mechanisation you wish existed that would streamline productivity (and profitability) in growing pines?

Yes, an automated lifting, sorting, and grading apparatus to remove the manual tasks of our work. The tech is there for lifting asparagus, carrots, and potatoes, but all of our lifting in the forestry industry for bare-root (circa 90 million+ trees per annum) is pulled out of the ground by hand and manually sorted, graded and boxed. I eagerly watch the work of Forest Growers Research Ltd in this space!

Monitoring our crops remotely using new near-infrared tech, where we can pick up diseases and deficiencies before they are visible to the human eye, would be a huge win. Using cameras on irrigation booms that tell us when a plant gets to a certain nutrient status, we automatically flag macro and micronutrient issues and up the dosing to compensate – now that would be a first prize!

Finally, how would you characterise the current state of the forestry industry?

The golden period of the past few years was driven by a strong timber market and the global Emissions Trading Scheme. This has slowed down recently. In the last year or so, the Chinese market (New Zealand’s primary export market) has slowed dramatically – the housing boom has come to a grinding halt. So, those NZ companies that rely on export will likely need to slow down their harvesting and replanting plans. We might, therefore, see production soften a bit over the next couple of years. A regroup and recovery is what I see on the horizon for nurseries, not ‘boom to bust’ for most operators, but likely a return to where we were at five or so years ago.

| 11 www.primehort.co.nz

FERTILPOT®

Manufactured from 100% renewable raw materials without glues or binders. Fertilpot is extremely popular for the propagation of a wide variety of crops.

• Dense, active root hair development

• No transplant shock

• No root deformation

TOGETHER, LET’S INNOVATE SUSTAINABLY, FOR THE ROOT ENVIRONMENT

• Faster repotting or planting (no need to remove pot)

• No recycling costs

• Accelerated plant growth

• 100% wood fibre (no peat)

• Transforms into humus which improves soil fertility For a greener future, find out more today: 0800 12

for a Greener Future.

sales@primehort.co.nz SCAN TO FIND OUT MORE

77 46 |

What’s new?

Monorail Irrigation Boom

The Monorail Irrigation Boom is the most cost-effective option for greenhouse irrigation booms and should pay for itself within the first year of installation.

For advice on water conservation and smarter work output, call our Automation Expert today. 0800 12 77 46.

28 Cell Forestry Tray

Our best-seller propagation tray has had a makeover!

• Enhanced cell design (side slots on each cell) prevents root spiralling and promotes robust root development.

• Superior drainage for healthy plant growth. Fully automation-friendly to work with existing systems. e.g. trayfiller, dibbling machine and nursery trolleys.

Durable No. 5 polypropylene plastic, expect 9+ years of service life! In-built lugs for quick & easy handling and de-nesting.

Call our Nursery Expert for more information: 0800 12 77 46

Coir Crush Blend

60:40 Coir Pith and Coir Chip

This grade is ideal for larger container sizes such as the 0.5L, 1L, 2L, 5L and for raised garden beds.

• 100% natural product

• Readily absorbs water

and 16L Open Top Bags.

Compressed slabs of coir wrapped in UV-treated plastic and tailor-made by PrimeHort. Consistent, quality growing substrate for hydroponic growing with excellent results. Perfect for strawberries, tomatoes and capsicums.

Enquire about pre-cut plant holes and drainage slits to suit your specifications.

• Excellent growing medium

• Good air-filled porosity

• pH 6-7

• RHP Certified

| 13 www.primehort.co.nz PRODUCT UPDATES

SCAN TO FIND OUT MORE SCAN TO FIND OUT MORE SCAN TO FIND OUT MORE SCAN TO FIND OUT MORE

What’s the deal with Coir?

The hype around Coir (coco peat) as an addition to traditional peat and bark is on the rise.

Growers are striving for more sustainable and cost-effective growing media solutions.

| 14 www.primehort.co.nz COIR BENEFITS & TRIALS

The hype around Coir (coco peat) as an addition to traditional peat and bark is on the rise. This natural and renewable resource is derived from coconut husks and is gaining momentum as growers strive for more sustainable and cost-effective growing media solutions.

PrimeHort is spearheading the conversation on Coir and hopes to build awareness in the nursery sector of using Coir to save money without compromising on quality.

In terms of an artificial substrate, Coir has very good properties. But awareness is relatively low among growers. Traditional potting mix suppliers use pine bark as the base product due to its availability. Of course it’s ‘tried and true’ too – bark, pumice and a bit of perlite, that’s what growers have always known.

Coir is a relatively new substrate, despite being around since the mid 1990s and for about 15 years in New Zealand.

As a readily available substrate, it is a smart alternative to peat, particularly as peat continues to be over mined and cannot be renewed quickly (if ever). The over harvesting of peat has led to mining of younger peat which is more acidic

and less ‘broken-down’ than older peat. Supply threat is also driving up the cost of peat. Unlike peat, which is not as easily decomposed, Coir is fully biodegradable.

Coir is sustainable and readily available. As a byproduct of the coconut industry, it does not contribute to deforestation. The abundance of Coir makes it an ecoconscious choice for nurseries looking to reduce their environmental impact. A coconut husk’s natural resilience also means Coir can be reused for multiple growing cycles, further enhancing its eco-friendly profile.

Some of the benefits of incorporating Coir for healthier plant development include its unique fibrous structure which promotes excellent aeration within the growing medium, preventing compaction and allowing for strong root development. The optimal water retention of Coir ensures consistent moisture levels, reducing the risk of over or under-watering.

Key features of Coir include:

• pH between 5.5-6.5

• EC below 0.5mS/cm

• High air filled porosity

• Excellent water retention without waterlogging

• Minimal media slumping in the pots

• Sustainable raw product

• Relatively low cost raw product

• Lighter than other media

| 15 www.primehort.co.nz

PrimeHort are a leading NZ supplier of this cost-effective growing media. It wishes to empower growers to create their own customised potting mixes as well as work with suppliers who are incorporating Coir into their potting mixes. Stock levels of Coir and fertilisers are firmly secured, along with machines to automate the process and reduce labour costs. But what matters most to growers? The merits must stack up for an industry fraught with rising costs. Quality must also swing in its favour. On canvassing its customers, PrimeHort hears the following, “we understand bark and pumice – but if a product is just as good and no more expensive – we’re keen to try”. So Coir trials are now underway.

TAKE ACTION with a FREE Trial.

Coir Trials are led by PrimeHort and are free of charge for growers.

An indication of how plants are likely to perform in Coir should start to show within 8 weeks. Trials are currently underway in a range of native and amenity species. While managed by PrimeHort, all trials are compared directly against a grower’s existing potting mix, so it’s a very direct exercise where the results can’t lie! But it also means if something needs tweaking, then PrimeHort will coordinate the tailoring of blends, including fertilisers.

By comparing the results of Coir against existing growing media and fertilisers, growers can gauge the tangible benefits of making changes. This risk-free approach allows growers to see firsthand the positive impact on plant health, growth rates, and overall crop yield.

| 16 www.primehort.co.nz

Trials are currently underway in a range of native and amenity species.

Trial options include:

A) 100L of 100% Coir pith with fertilisers added.

B) 100L of 100% Coir 60:40 with fertilisers added.

C) 100L of 50% Coir 60:40 and 50% CAN bark fines with fertilisers added.

Andrew Wearmouth is running the trials from PrimeHort—a familiar name to many. During the last 13 years, Andrew worked for Kauri Park (New Zealand’s most prominent native tree nursery) where he pursued a passion for plant breeding, including developing and managing the Mānuka breeding program of high UMF Mānuka plant genetics. Beginning in 2014, this valuable program continues to run today.

PrimeHort nursery automation specialist, Joel Wearmouth is also setting up nurseries for the blending of Coir with a DaRos Soil Mixer machine and the hydration of compressed blocks using a Coir Processing machine, again with a goal of helping growers save time and reduce labour costs.

| 17 www.primehort.co.nz

1. Cost-Effective 2. Readily Available 3. Excellent Water Retention & Aeration 4. Easy Handling 5. FREE Trials Available 6. Automation-Friendly 7. Sustainable 8. pH Neutral 9. Customised

COIR Fact check:

NZ Grower’s favourite Berry Pot!

DonKwiat is proud to supply PrimeHort with a range of high quality nursery pots.

The 35L Berry Pot is popular with NZ Growers for its clever design.

• Maximum oxygenation to the berry plant roots.

• UV stabilised plastic.

• Perfect elevation for healthy growth & protection from cold weather.

• Dome shape for durability.

• Heavy-duty, injection-molded plastic.

• Side openings drain water instead of collecting at bottom.

• Wide rim for convenient carrying.

Find out more today: 0800 12 77 46 | sales@primehort.co.nz SCAN TO FIND OUT MORE

LANDSCAPE NEWS

Helping Nurture a Kiwi Colony

For PrimeHort, helping customers so they can pay it forward in their businesses is a privilege.

A recent collaboration between Mitre 10 MEGA New Plymouth and PrimeHort saw 2,000 SmartGro Fertiliser Tablets put to good use. Mitre 10 are locally owned and very much part of the fabric in their communities. They like to lend a helping hand to those in need – building decks, making over gardens, painting walls, voluntary planting projects and more. These fertiliser tablets enabled Mitre 10 to support the work of 800 Trust.

Who is 800 Trust?

800 Trust is the brainchild of a small family group who purchased a steep 888-acre bush block on a remote Taranaki property. Originally bought for weekend hunting, this visionary family soon became caretakers of a Kiwi colony.

At the discovery of wild Kiwi, they turned their hobby into a full-time conservation effort, with predators being targeted via AI tech which they have developed themselves. Taranaki Kiwi Trust helped them set up their first trap line, and have been a wonderful support ever since.

Neighbouring farmland and former forestry land has since been purchased and the 800 Charitable Trust was formed, which now spans 3700 acres.

A significant part of their mission for protecting Kiwi and other bird life is to plant more native trees. However, funding this conservation work is an ongoing challenge, which is why partnering with groups like Mitre 10 is so important.

Planting events in September by Mitre 10 and the general public have enabled the planting of 1,000 natives which will help transform the property into a native bird sanctuary.

This is stage one of an ambitious effort to get 7,000 trees into the ground to provide a reliable food source for the birds.

“A big thank you for your mahi and sponsorship with help planting the trees for Taranaki. Thank you to PrimeHort for the sponsorship of the Smartgro Fertiliser Tablets. It was a massive help. We were able to put two tablets under native trees that really need excellent fertilised soil.”

- Miranda Wells, 800 Trust.

Listening surveys now estimate there are 25 pairs living in the project area. In May 2023, 11 Kiwi were released into the land to build on the existing population and enable a larger gene pool, with the longer term vision of Kiwi being able to leave this area and build populations in surrounding areas.

800 Trust Win an Environmental Award.

In November, 800 Trust won the Taranaki Regional Council Environmental Action in Biodiversity Award. A well-deserved recognition for a team who throw absolutely everything into this project. What they are achieving for the Taranaki region is outstanding.

Well done Mitre 10 MEGA New Plymouth for supporting this project – PrimeHort look forward to helping again in the near future.

| 19 www.primehort.co.nz

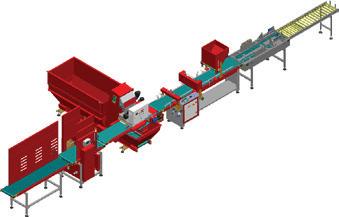

Automate to Boost Productivity

Leithfield Nursery is a well-established business in Southland producing forestry seedlings on a large scale.

| 20 www.primehort.co.nz

LEITHFIELD NURSERY

An

operation of this scale also requires an innovative production system.

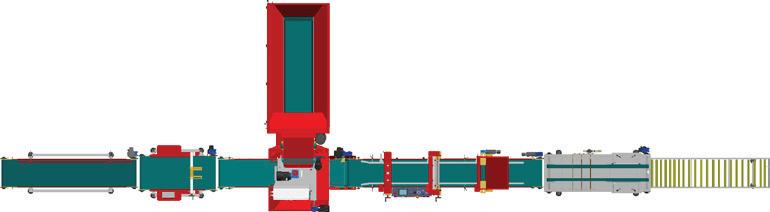

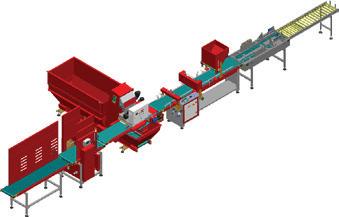

In 2022, Leithfield Nursery approached PrimeHort with an open brief to transition some of their operations from inground planting (selling bare-root pine trees) to a containerised system in the 64 Cell Forestry Trays. The motivation to automate for Leithfield was compelling – they had a presold contract for “as many plants as possible”. So the goal was set at 2.5 million pine seedlings ready for sowing by September, which gave PrimeHort a tight deadline of nine months from initial discussion.

The first site visit revealed a large flat paddock with old established trees. Stage one saw Leithfield clear the paddock and prep it with metal drainage and electrical and water supply lines. From here the first equipment to be installed was a customised DaRos Seeding Line so the team could start sowing while PrimeHort pressed on with getting the Outdoor Benches and Irrigation Booms installed.

For the completion of the growing season, PrimeHort specified a suitable Tray Washer so all of the Forestry Trays can be effortlessly cleaned and sterilised ready for next season. An operation of this scale also requires an innovative production system. An Automated Plug Popper machine has been installed and de-pops seedlings from their trays in a quick, hassle-free manner – up to 400 trays per hour. The end customer receives the pine seedlings in a ready-to-plant manner.

| 21 www.primehort.co.nz

The end result is an impressive nursery where the sky’s the limit.

Fact Check:

What benefits does containerised growing have over bare-root?

Greater control than inground planting, better survival rate, faster/uniform growth, space saving at the nursery, extended seasons, less vulnerable to disease.

What are the staff levels at Leithfield?

Just 4-6 staff have the capacity to produce 2.5m+ seedlings along with other roles.

When is it viable for a nursery to automate?

Nursery automation can be done in stages meaning the initial outlay can be modest. For increased productivity it all begins with the right piece of automation and PrimeHort can support the decision-making process with expert advice.

This time-pressured project went very smoothly. For PrimeHort, it was an exciting undertaking with Leithfield investing circa $1.5m for a custom-designed set up. The PrimeHort nursery automation and projects team enjoyed the challenge of a looming deadline and recognising the importance of strong communication and well-researched technical advice, including details around expected power usage, water volumes and fertiliser requirements. Accurate cost estimates were also vital to ensure no ‘hidden costs’ or stress to the client.

The end result is an impressive nursery where the sky’s the limit. PrimeHort were delighted to assist Leithfield and look forward to growing with the team.

“The team at PrimeHort have been fantastic to work with, right from the planning stage to the final result, the project ran on time and to our requirements. Communication was great with Joel keeping us informed along the way. We’re very happy with the completed installation. We are enjoying working with the equipment and would highly recommend contacting PrimeHort for your nursery needs.”

- Darren Cripps – Production Manager

| 22 www.primehort.co.nz

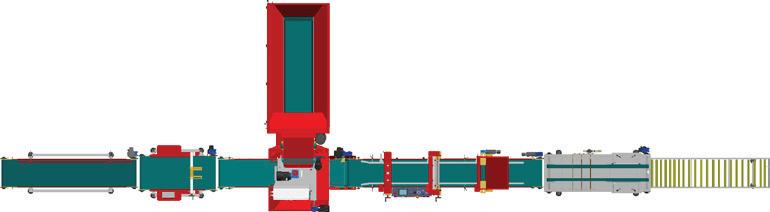

Seeding Line

A DaRos Seeder can significantly enhance the productivity of nursery operations and lead to improved crop yields and potentially higher profits.

DaRos Seeders are designed to accurately and uniformly plant seeds, row by row. Also known as a Precision Seeder, these machines enable the use of small quantities of seeds (naked or pelleted).

Suitable for a wide range of seeds, the machine pre-dibbles the tray, sows the seed, covers the tray with Vermiculite/Agriperlite, waters and stacks the sown trays.

• Independent dibbling unit lets you set the number of seeds per hole, seeding speed and number of trays to seed.

• All adjustments, as well as belt speed, can be programmed via a touch screen control panel.

• Easily substitute the seeding bars and nozzles to allow for different types of seeds.

PrimeHort can install your DaRos Seeder, provide staff training & strong after sales care.

Talk to our Automation expert for more information: 0800 12 77 46

| 23 www.primehort.co.nz PRODUCT FOCUS

LS7-3 SOWING LINE LAYOUT LE IMMAGINI SONO FORNITE SOLO SCOPO ILLUSTRASTIVO NON COSTITUISCONO ELEMENTO CONTRATTUALE. PRIMEHORT DISTRIBUTORS L.NZ.2021.003 01 Mauro D. 01/02/2022 N° rev. 3330 1800 2000 3480 RC7-TR5N-M (1200 lt) LS7-3 (GRR) LBI RI2 2165 1330 2330 DP5-1 NP4-2 P1 INSTALLED POWER 1,2 kW 3Ph+N+E 50Hz 400V P2 INSTALLED POWER 2,7 kW 3Ph+N+E 50Hz 400V P3 INSTALLED POWER 0,7 kW 3Ph+N+E 50Hz 400V A1 AIR CONSUPTION 50/100L/min A2 AIR CONSUPTION 100/150L/min W WATER SUPPLY 2bar P2 A2 P1 W P3 A1 SCAN TO FIND OUT MORE

OVER 75 YEARS OF PROJECTS WORLDWIDE

We build greenhouses and horticultural facilities, with high technological equipment.

PRODUCT FOCUS

Paper Pot Machine

BCC FiberCell Machine

✓�Sustainable paper-based growing – reduce plastic.

✓�Production capacity: Between 18,000 – 36,000 cells per hour.

✓�Two machines in one! Produce 2 rows simultaneously, 15 – 120mm diameter.

✓�Flexible e.g. 1 row can be switched off.

✓�Compatible with all quality/fine potting media.

✓�Easy length adjustment of the paper pots (no tool needed).

✓�Easy adjustment of the paper pot media density.

✓�Multiple paper options available.

To reduce propagation time and maximise productivity, contact PrimeHort for details. Call 0800 12 77 46 | sales@primehort.co.nz

Your

Best Choice

SCAN TO FIND OUT MORE

Meet Joel.

PrimeHort’s Nursery Automation expert, Joel Wearmouth spoke to Grow Smart about smarter productivity for the industry he serves.

How long have you been at PrimeHort and what is your role?

I joined the team in 2011 and went straight into nursery automation sales. I recall my first order was a fairly simple Potting Machine to a grower in Christchurch. The role has evolved to meet new customer challenges, including customised greenhouse structures and fit outs, to hightech robotic machinery like Fully Automatic Transplanters, smartphone-controlled Irrigation Booms, and even climate control systems.

Why do you enjoy doing what you do?

Every project is unique when it comes to machinery and the customers behind them. The industry is vast - from forestry nurseries to producers of microgreens or mass lettuce, NZ native growers, to vertical farmers pioneering ways to grow crops indoors. Our original customer base of native tree growers has diversified tenfold, and it keeps things interesting. Everyone I meet has real Kiwi ingenuity to try new things or let us find a solution to match their ideas.

Nursery Automation is rapidly evolving, how do you keep up?

Keeping up to date with industry trends is a constant focus. We’re fortunate to have global suppliers who lead the stage in their respective fields. Between us, we’re in touch weekly, and as a company we visit our supply partners annually. My next European visit is in June where I’ll spend time in UK, Holland, Germany, Belgium, and Italy. Our suppliers also put in an enormous effort to keep us knowledgeable and competitive – they respect the NZ industry and see us as strong contenders in everything we do. On a personal level, I enjoy following industry influencers on social media, and checking in with customers helps me stay up to date with new ideas or challenges.

What’s your number one tip for growers right now?

At the risk of sounding salesy, my number one tip is to trial nursery automation for a competitive edge! The industry is rapidly embracing the mechanisation of all costly and laborious tasks – it’s like an investment in reducing costs and scaling up profitability. Don’t risk falling behind. If unsure, we can discuss your current operational chokepoints and provide a workable solution. And we are open to discuss options based around cashflow and budgets.

What has been your most memorable work project to-date and why?

Our work with Crown Researcher, Scion is a standout. This comprehensive nursery redevelopment project led us into many industry ‘firsts’ for NZ, including an environmentally sustainable, year-round propagation facility and a sophisticated irrigation and greenhouse climate control hub. Nursery Manager, Matt Dunn reports they are growing pine from tissue culture seriously well and have halved their turnaround on cuttings set in trays for the next stage e.g. from 9-12 months to 4-6 months. SCION are wonderful hosts, so if you are curious about their work, I highly recommend visiting.

When you’re not at the desk, what are you up to?

Spending time with my family and friends, enjoying a craft beer, staying fit with a game of squash, or heading to Gizzy for summer holidays.

Joel looks forward to helping you drive sucess with Nursery Automation, give him a call today.

| 25 www.primehort.co.nz

AUTOMATION EXPERT

Cultivating community, one little plant at a time!

The PrimeHort team love rolling up their sleeves to help with planting days for the Mangawhai Harbour Restoration Society (MHRS) - a cause that deeply resonates.

| 26 www.primehort.co.nz VOLUNTARY PLANTING DAYS

A fun day out swapping the desk for the dunes.

The PrimeHort team love rolling up their sleeves to help with planting days for the Mangawhai Harbour Restoration Society (MHRS) - a cause that deeply resonates.

To date, PrimeHort has donated 640 native plants to help the vulnerable landscape that hugs the Mangawhai Sandspit in Mangawhai Heads, Northland.

As a horticultural and landscape supplier, PrimeHort’s dedication doesn’t stop there. Generosity is a core value, and supporting community initiatives is a great way for PrimeHort to ‘walk the talk’ and actively give back. MHRS is a well-respected local organisation that works tirelessly towards revitalising and preserving its precious local harbour. Their enormous efforts are ongoing and cover everything from well-designed planting and fencing programs to stabilising shifting sands and helping with bird nesting. What a wild place! The sand dunes are a powerful landform to see from afar, but when on the spit their true scale is staggering.

Product Watch

Getting on the tools is great for team building!

The hands-on task of planting is an excellent reminder of the importance of community involvement to help the local environment. It’s also a fun day out swapping the desk for the dunes. The future of this precious landmark requires a community of caretakers and PrimeHort look forward to providing ongoing support.

Planting the seeds for future collaboration.

Find out if the PrimeHort team can help your community horticultural efforts by contacting sales@primehort.co.nz

Recognising the pivotal role that planting plays in the protection of the spit, here’s a few of the resources PrimeHort supplied to help: Smartgro Fertiliser Tablets, Bamboo Stakes, Plant Guards, Contractor Gloves and The Gardener Spades. View online for details: www.primehort.co.nz

In 2022, PrimeHort moved into brand new 4,000sqm facilities. Steady growth meant additional warehousing was required. The most cost-effective solution was the design and installation of a 1000sqm Polyhouse. This modern structure has two purposes: cost-effective storage, and a well-presented showroom. Call in for a closer look! Let’s partner together on a customised Growing Facility or Warehouse and bring your vision to life.

• Tailored designs to maximise productivity.

• Controlled environment to increase crop yields & profitability.

• Multi-purpose e.g. growing facility, warehousing, or showroom.

• Full turnkey offering: design, drawings, installation and after-sales care.

• Extended growing seasons.

www.primehort.co.nz We’ve got you

Enquire Now. 0800 12 77 46 | sales@primehort.co.nz

Covered.

Craig Ford

Former Research Group Leader: Plant Development and Physiology for Scion.

Craig Ford

Former Research Group Leader: Plant Development and Physiology for Scion.