RURAL INFRASTRUCTURE NUTRITION FORAGE AND ARABLE HORTICULTURE ANIMAL MANAGEMENT DAIRY MANAGEMENT

Plan 365 is a technical guide aimed at helping shareholders learn about best practice and the latest advancements in rural technology.

RURAL INFRASTRUCTURE NUTRITION FORAGE AND ARABLE HORTICULTURE ANIMAL MANAGEMENT DAIRY MANAGEMENT

Plan 365 is a technical guide aimed at helping shareholders learn about best practice and the latest advancements in rural technology.

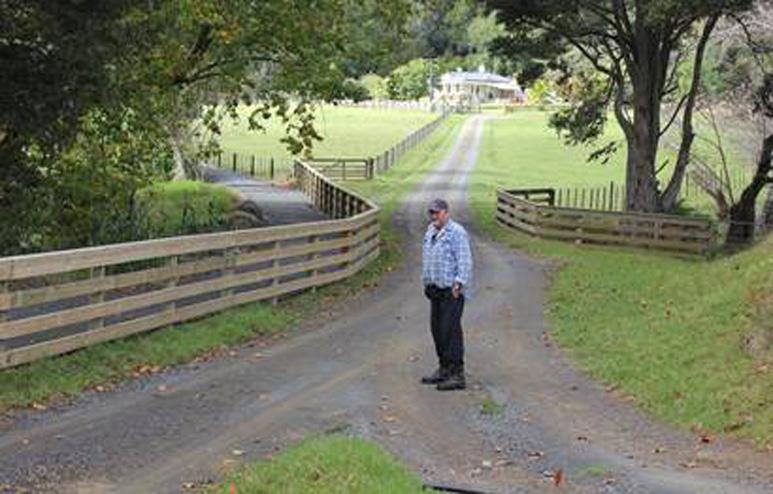

“We’re all struggling. The cycle trail will bring business into the community. It’s a no-brainer.” So says Snow Harrison, referring to the Twin Coast Cycle Trail, which will eventually run for 84 kilometres between Opua in the Bay of Islands to Horeke on the Hokianga Harbour, on Northland’s west coast.

The New Zealand Cycle Trail project arose out of the Government’s 2009 Employment Summit, brought about by the Global Financial Crisis. Vote Tourism appropriated $50 million across 3 years to fund the construction of “Great Rides” across the country. The aim is to create employment in the construction and maintenance of these trails, enhance New Zealand’s competitiveness as a tourism destination and to deliver the benefits of these cycle trails to the wider community.

Last year saw the development of the section of this trail from Okaihau to Horeke, 3.5km of which ran through Snow and his wife Robin’s 260 hectare hill country farm, supporting 250 head

of shorthorn and crossbreed cattle.

“There’s a lot of natural beauty along the trail, which follows the Utakura River, including places to picnic and swim,” Snow says. “Unfortunately, fencing off the river for the trail meant that stock access to natural waterways was no longer possible.”

A reticulated stock water scheme would be now be required. The difficulty and variability of the landscape, with its valleys and steep hilly terrain, would make the design and installation of such a scheme challenging. Snow sought advice from the local Farmlands Waipapa store. Farmlands Technical Field Officer, Doug Morgan, involved Pete Carswell from Iplex Pipelines.

“Due to the terrain, precise surveying from the water source along the pipeline's route was extremely important,” Pete says. A collection tank was installed under the spring at 218m above sea level (ASL), supplying through the system's mainline a 25,000L tank situated at 169m ASL. From this tank the farm's troughs would be gravity fed, as well as provide drinking water on the cycle trail and service the newly installed toilet block.

“The need to maintain enough head in the system to fill this tank required the use of a mixture 16 bar Blackline through to 6.3 bar Greenline PE pipe,” Pete says. “The survey information determined where these different pressure rated pipes would be installed, ensuring the most economic outcome for Snow and Robin.”

A follow up by local Iplex Territory Manager Craig Leith, found Snow very pleased with the new scheme. “Snow is now enjoying the benefits of a reticulated stock water system, offering better water quality and continuity of supply, with less environmental impact on riparian zones,” Craig says. “It’s a win-win situation for Snow, the local economy and the many cyclists that will enjoy the trail over years to come.”

For further information, contact your Farmlands Technical Field Officer or the friendly team at your local Farmlands store. Visit www.twincoastcycletrail.kiwi.nz for details on the ride.

Article supplied by Iplex.

Here’s some handy hints and tips to ensure the installation of your new water tank goes smoothly!

Firstly – preparation is key:

1. Ensure that the tank site is flat and level, free from rocks or stones and any foreign matter that may damage the tank’s base.

2. Ensure the tank site is well compacted if fill is used to prepare or level the site.

3. Ensure that the tank site is at least 300mm larger in diameter than the tank.

4. If a sand base is used, a retaining cover should be used to prevent sand from washing away after installation.

Remember that a full tank will weigh up to 30 tonnes – so it is important that the surface it sits on is stable and firm.

You may also need to ensure you secure the tank once it has been delivered – if it’s windy or stormy, your tank can easily be blown away if not secured down. Adding 200mm of water to the bottom of the tank is usually enough to weigh it down.

An important part of the preparation is to think about the number and types of inlets, outlets and valves you require. Planning how you will install and plumb the tank is important – it is highly recommended you run your project past a drainlayer or plumber to ensure your plans will work!

To take advantage of the maximum catchment of water, it is ideal to place tanks at the end of a building. This way downpipes can be fed from both gutters into the one tank. Please note that the overflow capacity must match the downpipe capacity. For example, two 90mm inlet downpipes would require equal capacity overflows. Note also that tank overflows can go below the ground and come up again, to meet stormwater run off.

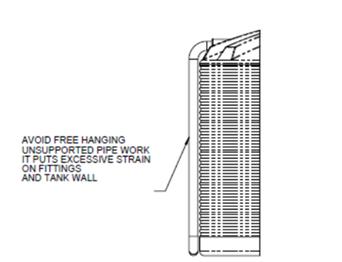

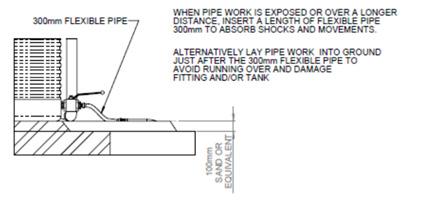

Important considerations when plumbing the tank are:

1. Ensure a flexible hose is installed after the gate or ball valve with a

minimum 300mm length.

2. The tank outlet must NOT be subjected to extra force, e.g. over-tightening of fittings.

3. Overflow must be piped clear of base to avoid erosion.

4. The number of inlet pipes, their sizes and capacities must equal the number of overflow pipes, their sizes and capacities.

5. Do not allow the tank site to deteriorate after installation due to any form of erosion or site destruction caused by vermin such as rabbits.

Promax corrugated tanks can be buried and fully back-filled up to 1 metre in the ground – and still retain their 20 year warranty. Burying your Promax tank is a great way to avoid height restriction issues – also a buried tank with shrubs planted around it is more attractive in your backyard!

When you are planning to bury a Promax corrugated tank, you should prepare the base with 100mm minimum of compacted sand, just as you would if installing the tank above ground.

For more information, please talk to the friendly team at your local Farmlands store.

Article supplied by Promax Plastics.

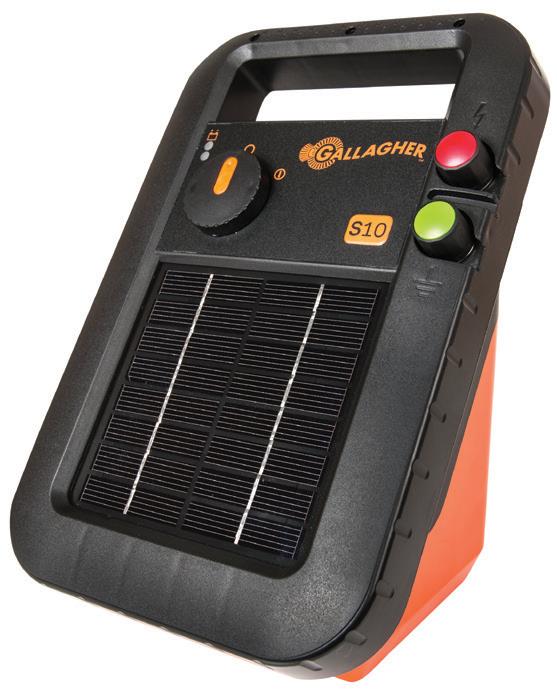

Gallagher’s new S10 Solar Energizer is a game-changer for farmers large and small wanting to capitalise on the benefits of portable solar power for temporary electric fencing.

Compact, robust and fully integrated with a rechargeable battery and solar panel, the S10 is a convenient and costeffective alternative to battery-powered fence systems.

The S10 is capable of powering electric fences up to 3 km on a single wire fence and is both drop resistant and waterproof so is ideal for strip grazing.

Because it uses solar power, it doesn’t require a constant supply of batteries to keep it functioning and is incredibly easy

to set up and operate. Simply hook it up to the fence and earth stake, turn it on and walk away.

Once activated, the S10 can continue to operate for up to three weeks without sun. An easily visible LED Pulse Indicator shows the energizer is working and has enough charge. A red light flashes if the battery is low.

In use the S10 can sit on the ground, be mounted to a wooden post, sit on top of a steel post or be fixed to a pigtail or ring top post using an attachment.

The Gallagher S10 Energizer will be available throughout Farmlands stores from mid-June.

Article supplied by Gallagher.

• Easy to set up and use, a fully integrated solar energizer.

The Gallagher M10,000i Fence Energizer – the most powerful energizer ever produced – is now available in Farmlands stores.

Gallagher’s National Sales Manager, Peter Nation, says the M10,000i packs a whopping 100 joules of stored energy and will outperform any other energizer on the market.

“Land use in New Zealand has changed considerably in recent years, and farms are getting bigger. The M10,000i has been designed specifically to meet the demands of larger properties that need plenty of power over longer distances.”

Robustly built to handle the toughest of farm conditions the M10,000i will power electric fencing systems spanning up to 400ha and its high-efficiency circuitry

delivers outstanding performance and stock control.

Like other i Series Energizers, the M10,000i comes with an energizer Controller to monitor energizer performance and highlight any faults in the fencing system. Fully waterproof, the Energizer Controller displays the energizer’s voltage and current readings and can be used to turn the energizer on or off, set alarm levels and adjust the energizer’s output voltage.

The M10,000i is also compatible with i Series fence monitors and remotes which enables the user to quickly locate faults within a monitored zone, turn the energizer on or off remotely, and test a fence once a repair is completed.

Article supplied by Gallagher.

• World's most powerful energizer —100 stored joules delivering 10,000 volts.

• Powers up to 400 hectares/1,000 acres.

• Includes separate Energizer Controller to view fence performance at a glance at a convenient location.

Alpaca are interesting animals that are popular on New Zealand lifestyle blocks and farms. Alpaca are domesticated animals from South America and belong to the group ‘Camelids’ along with camels and llamas. They have been bred historically for their high quality fibre, which is used to make knitted and woollen items. They also make great pets with friendly personalities.

Alpaca are social herd animals and prefer to live in family groups. Interestingly enough, they are used as herd protectors for grazing animals in some countries around lambing or kidding time, as they protect the newly born animals from predators such as foxes, eagles and canines, attacking them with their front feet. In New Zealand, alpacas have even been used to protect chickens on free range farms from hawks.

Alpacas are known as ‘pseudoruminants’, as they have a similar digestive system to traditional ruminants – however they have three stomach compartments rather than four, lacking the omasum. Transit time of consumed feed through the gastrointestinal tract is slower in alpaca compared with other ruminants, which allows for a greater degree of fermentation of lower quality cell wall materials. This means that alpaca are good rough paddock feeders and can do well on poorer quality pasture compared to cows and sheep.

Alpaca have some unique nutritional requirements that need to be taken

into consideration when keeping them. Vitamin D (the ‘sunshine vitamin’) deficiency is common in alpaca, possibly due to their evolution in sunny South America. This deficiency is exasperated in the winter months due to decreased sunshine hours. Vitamin D plays an important role in bone development and deficiency during pregnancy and lactation can cause rickets in young cria, due to low vitamin D in colostrum and milk. Symptoms of rickets include bowed legs, shifting leg lameness, joint enlargement, a humpback appearance and a slowed growth rate. Supplementing pregnant and lactating alpaca with vitamin D is a necessity – non-pregnant and male alpaca will also benefit from vitamin D supplementation.

Camelid nutrition experts have recorded that alpaca and llama do not show strong licking feeding behaviours. This means that using feed/salt blocks may not be particularly effective. Alpaca may still take interest in the blocks and attempt to bite pieces off but they may not be able to

consume sufficient amounts to meet their needs. For this reason loose minerals or mineralised pelleted feeds are better options for supplementing alpaca.

Polioencephalomalacia (PEM), inflammation of the brain due to a thiamine (vitamin B1) deficiency, is a condition more commonly seen in alpaca compared to other animals. The gut flora of ruminants and pseudo-ruminants usually produce enough thiamine to satisfy animal requirements, however thiamine production can be reduced in certain circumstances, for example when there is too much sulphur in the diet, or if the rumen is not functioning optimally. Some weeds are also suspected to play a role in thiamine deficiency, due to the presence of an enzyme that breaks down thiamine. Symptoms of PEM include lethargy, low appetite or neurological impairment (head and ear twitching, drooling and staggering). Once an animal is showing signs of neurological impairment, injected thiamine is required quickly to avoid death. Regular supplementation of thiamine is the best way to prevent PEM cases arising. Pelleted feed is a great way to ensure alpacas get all of the vitamins and minerals they require daily. Farmlands has two alpaca options – Alpaca Pellets and Alpaca Conditioning Mix, which both contain vitamin D and thiamine, along with a vast profile of other nutrients essential for optimum alpaca health. Article supplied by Stacey Cosnett, Nutritionist, Farmlands Nutrition.

Continuous improvement of the genetic merit is an important consideration in most dairy herds. However, this improvement in genetic gain can only be realised if the resulting heifers are sufficiently well grown to get in-calf, calve at around 22 months of age and compete with older cows as soon as they enter the herd.

The digestive tract of the neonatal calf is dramatically different to that of the adult ruminant. Consequently, the young calf requires a low fibre, highly digestible feed in the first few weeks of life. Liquid feeds such as colostrum, milk or milk replacer are important sources of energy (from fat and lactose), as well as essential amino acids necessary for lean tissue growth. However, these feeds are relatively expensive and transitioning the young calf from liquid feeds to hard feed and home-grown forages is important for economical calf rearing. Feeding strategies that encourage early and healthy rumen development are particularly useful in ensuring that the calf transitions easily from liquid feeds

to forages and that calves can make effective use of these forages.

Establishing a rumen microbial population is the first step in developing the rumen. While the rumen of the young calf is sterile at birth, bacteria with the potential to colonise the rumen are rapidly acquired from the environment, other animals the calf comes into contact with and feed. For these bacteria to grow and multiply they require a source of nutrients and liquid in the rumen. Hard feed such as NRM Moozlee or GrowUp 20% pellets provide a substrate, which support the proliferation of those bacteria that are typically found in the rumen of mature cows. This typically occurs about 2 weeks after dry feed intake starts.

The end products of the fermentation of starch found in feeds such as Moozlee and GrowUp 20 percent plays an important role in the development of the epithelial tissue lining the rumen. It is this epithelial tissue that will play a vital role in absorbing the volatile fatty acids released by the fermentation of feed (either grain or forage) by rumen microbes as the calf matures and thus affects the efficiency that the calf can use feed.

Lean tissue growth in the early stages of the calf’s life is driven by the supply of essential amino acids present in the feed or milk consumed. While the supply of amino acids from milk or milk replacer is relatively constant, there can be considerable variation in the quantity, quality and digestibility of amino acids found in different grains, oilseed meals

and other hard feeds. NRM Moozlee and GrowUp 20% are formulated to contain high quality protein sources such as soyabean meal, which the young calf can easily digest.

At the same time, it is important to ensure that the macro (calcium, phosphorus and sodium) and trace (copper, zinc, cobalt, selenium and iodine) mineral requirements of the young, rapidly growing calf are met. All NRM calf feeds are formulated to provide a balanced supply of both macro and trace minerals, as well as vitamins (such as vitamin A, D and E), which help support the development of a healthy immune system. The inclusion of Bovatec® aids in the prevention of coccidiosis, a parasitic disease of calves, which if not controlled results in the destruction of the lining of the small intestine, dramatically affects weight gain and can result in death.

Dairy heifers are an investment in the future of the herd. Selecting a calf feed that helps to ensure good early growth rates, builds a strong skeleton and sets heifers up for a productive lifetime is one way of ensuring a good return on investment.

Contact your local NRM Feed Specialist or Farmlands store to help choose the right calf feed for your future cows.

Article supplied by Natalie Chrystal, Nutritionist, NRM.

Storage of animal feed in vertical silos, or bins, is the most common form of dry feed storage on New Zealand farms. Silos can be a great way to store feed, as they reduce wastage and protect feed from climatic events and from pests such as birds and vermin.

Silos also allow farmers to reap the financial benefits of purchasing feed in bulk and feed it easily through inshed feeding systems or into troughs and feed-out bins. Silos do however need to be cleaned thoroughly at least once a year, to ensure that the feed stored inside them is kept as fresh as possible. A great time to do this is just before the start of a new season.

The storage of feed in silos is subject to large fluctuations in both temperature and humidity within the silo, which can lead to condensation forming on the inside of the silo from time to time. Both feed and feed dust will stick to the side of the bin, absorb the moisture and build up over time. This feed will deteriorate with mould developing and subsequent mycotoxin production. When this spoiled feed falls off into good feed, consequences for the animal range from decreased feed intake and feed refusal due to the presence of mould, which animals can be very sensitive to the smell and taste

of, right through to mycotoxicosis. This can occur when poisonous toxins produced by moulds are consumed at high enough levels to cause animal health issues. To avoid these problems occurring, silos need to be cleaned at least once a year and preferably every 6 months, to ensure that excessive mould does not build up on the inside of the silo and that feed delivered to the animal is as fresh and palatable as possible.

Farmlands has developed a new silo cleaning procedure that describes the best practices for cleaning animal feed silos. There are two methods to use, either a wet method or a dry method. The wet method is the most effective and preferable method for cleaning a silo, however dry cleaning is a better option when the silo boot cannot be removed easily or it is too dangerous to attempt wet cleaning. When using the wet method, using a suitable disinfectant such as Virkon® during the clean is worthwhile. Both methods benefit from dusting the inside of the silo with a liquid or powder mould inhibitor after cleaning, to hamper future mould growth.

Safety is the most important consideration and any attempt to climb up any silo requires suitable safety

equipment. Suitable protective clothing including gloves, eye protection and masks should be worn at all times. A safety harness with suitable anchor points is also essential equipment.

Wet cleaning

1. Ensure the weather is suitable to allow the silo to air dry after washing.

2. A high pressure water blaster with a long enough hose is required – do not attempt to carry heavy equipment up the silo.

3. The boot at the base of the silo needs to be removed prior to a wet clean. If this cannot be achieved then a dry clean would be the alternative option.

4. Once the boot has been removed, cover any electrical fittings that may be exposed and ensure that there is sufficient drainage below the silo to allow feed waste to freely be rinsed out of the silo.

5. For large lumps of feed on the side of the silo, a long lightweight pole can be used to dislodge these prior to washing. An aluminium pole usually used for swimming pool brushes works very well for this. Attach a safety cord to the pole and fix this to a suitable point at the top opening of

the silo. This will allow you to easily retrieve the pole if it accidentally falls into the silo.

6. Using the water blaster working from top to bottom of the silo, rinse off as much of the feed stuck to the sides as possible.

7. Once feed has been removed from the sides, use a suitable commercial grade detergent to wash the inside of the silo.

8. Rinse the inside of the silo thoroughly once washed.

9. Use a suitable disinfectant (such as Virkon®) once the silo has been washed and rinsed and allow this to dry. A foaming disinfectant with suitable surfactants would be most suitable.

10. Once the silo is dry, a light spray with a mould inhibitor is useful. Alternatively, dust the inside of the silo with a dry mould inhibitor product.

11. Ensure that the boot is also washed, cleaned and disinfected prior to re-fitting it to the silo.

12. Once the silo and boot are both thoroughly dry, replace the boot onto the base of the silo, ensuring that all seals are in place and are in good working order.

13. Ensure that any feed residue washed out of the bin is collected and safely disposed of. Do not allow feed residue to be washed into storm water systems.

14. Test that all is in working order before filling the silo with feed.

Dry cleaning

1. A dry clean will produce dust that is potentially harmful, so care should be taken to avoid breathing in dust. A safety harness with suitable anchor points is also essential equipment.

2. Dry cleaning is typically used when the silo boot cannot be removed easily or it is too dangerous to attempt wet cleaning.

3. A high pressure air blaster with a long enough hose is required – do not attempt to carry heavy equipment up the silo.

4. Disconnect the cross auger from the feed hopper in the shed and direct this into a suitable waste container, so any waste residue can be removed efficiently from the base of the silo.

5. For large lumps of feed on the side of the silo, a long lightweight pole can be used to dislodge these prior to air cleaning. An aluminium pole usually used for swimming pool

brushes works very well for this. Attach a safety cord to the pole and fix this to a suitable point at the top opening of the silo. This will allow you to easily retrieve the pole if it accidentally falls into the silo.

6. Using the air blaster working from top to bottom of the silo, blast off as much of the feed stuck to the sides as possible.

7. Once the silo is clean, a light spray with a liquid mould inhibitor is useful. Alternatively, dust the inside of the silo with a dry mould inhibitor product.

8. Ensure that any old feed is removed from the base of the silo and disposed of.

9. Replace the cross auger outlet to empty back into the shed hopper.

10. Ensure that any feed residue blown out of the bin is collected and safely disposed of.

11. Test that all is in working order before filling the silo with feed. For further information, talk to one of the friendly staff at your local Farmlands store.

Article supplied by Natalie Chrystal, Nutritionist, NRM.

A drop in the milksolids price has left many farmers wondering how they can generate a profit (or at least minimise their loss) in a financially challenging season.

Put simply, profit is the difference between income and costs. There are essentially three ways to increase profit –increase income, decrease costs, or do a combination of both.

Cutting costs that do not affect production (e.g. deferring the purchase of a new ute) will automatically improve profitability, however the reality is that many farm costs (e.g. depreciation and labour) are semi-fixed. Reducing inputs such as feed, fertiliser, or animal health is likely to have some impact on production, either now or in future seasons. This is where budget slashing gets a whole lot trickier.

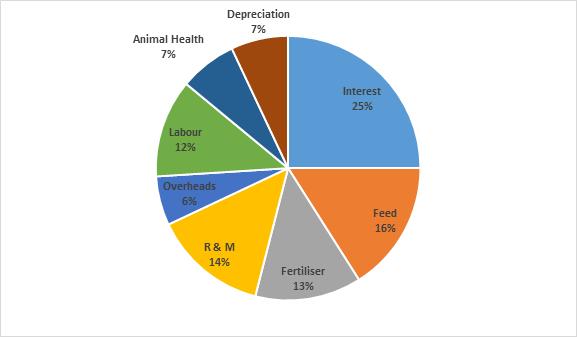

In a paper titled “Smarter spending for a low pay-out” presented at a recent Southland Demo Farm Field Day, Howard de Klerk (Dairy Nutrition and Management Solutions) shows that the biggest cost to the average New Zealand farmer is interest (Table 1).

Table 1: Total production costs of an average NZ dairy farmer.

Howard points out that while it is not included in Farm Working Expenses and therefore the net profit per hectare, interest has a major impact on the amount of cash the farm generates. Changing production per cow will not alter interest (assuming no extra shares are required or sold off) – but as production rises, interest per kgMS drops. Diluting interest costs by keeping production up is important, especially for farms with higher debt loadings.

The key, according to Howard, is to find the level of production where operating costs are controlled but the farm is producing enough milk to dilute interest and other semi-fixed costs. At this “sweet spot” profit is maximised — production below this level is not optimum and production above this level is simply buying production.

So what are the keys to farming profitably in a low pay-out year?

Good farm management practices should apply whether the pay-out is low or at record levels. The key difference is that in a high pay-out year you can make more mistakes and still be profitable. Conversely, profit is less forgiving of mistakes in a low pay-out year. Three things to consider are:

1. Reduce costs carefully.

Before cutting any input ask yourself, “what will be the impact on production and will the saving outweigh any potential loss in income”? Reducing feed input usually reduces milk output. Be realistic about how much supplementary feed you need. Don’t assume you can make

it through with a lot less than previous seasons unless you can see realistic opportunities to increase pasture and/or supplement utilisation, or are happy to accept a drop in production.

2. Make sure your comparative stocking rate (CSR) is in the correct range.

DairyNZ recommends a CSR around 80 to maximise profit. This means that for every tonne of feed offered there should be around 80kg of cow liveweight to eat it. See www.dairynz.co.nz/feed/ feed-management-tools/comparativestocking-rate/ to calculate your CSR.

3. Purchase supplements wisely and use them strategically.

The main aim of feeding supplements is to fill feed gaps and therefore produce more milk. It will always be uneconomic to feed supplements and waste pasture, or to waste supplements. Think about what you are trying to achieve with your feed and compare bought-in supplements on a c/MJME basis. Look for opportunities to reduce your supplementary feed spend by switching to a higher proportion of lower cost, home-grown supplements such as maize silage.

As Howard points out, profit will already be down this season due to the lower milk price. Reducing production could reduce profit even further, so think carefully before you make any decision to cut costs, which will drastically affect your production.

Article supplied by Pioneer® brand products.

If your established pastures are looking the worse for wear this season, with broadleaf weeds taking the place of productive, high value grazing, it’s time to turn to a unique new herbicide from New Zealand’s leading crop protection supplier, Nufarm.

Sprinter ® 700DS is a new-generation liquid phenoxy herbicide, which combines the latest advances in formulation technology with proven performance in the field.

It’s the only product of its kind in the world and is patent pending in New Zealand. Key benefits for Sprinter 700DS include ease of use, strong compatibility with companion products, excellent translocation of active ingredient through plant tissue and good weed control.

It is recommended for use in the period from autumn to spring, to rid established pastures of nuisance weeds like storksbill, dandelion, docks, thistles and ragwort.

It is ideal for getting rid of seedling thistles prior to the coldest part of winter and it also has a good fit with farmers who need to tidy up established pastures after a difficult summer and autumn.

“Months of dry weather have led to many established pastures becoming thin and open. This makes them highly susceptible to broadleaf weed ingression and this in turn has a negative impact on spring pasture production and quality,” Nufarm Technical Specialist Cynthia Christie says.

“We’ve learned from experience that the sooner drought-damaged paddocks can be restored to productivity, the faster farmers recover from adverse seasons like the one we’ve just had. Timely, effective broadleaf weed control is a significant part of this process.”

Another big advantage is that unlike some other phenoxy herbicides, Sprinter 700DS will not crystallise under cold conditions and thus potentially block spray equipment. Because it is a 2,4-D amine, Sprinter 700DS is non-volatile, providing pastoral farmers an alternative phenoxy herbicide in regions where use of older, 2,4-D ester formulations are subject to local body regulations,

like Northland and Gisborne, or where sensitive crops have become more widespread.

Christie says tools like Sprinter 700DS are helping farmers become more flexible and productive in their use of phenoxy herbicides to maintain high value, weed-free grazing.

Farmers now have the right tool for phenoxy herbicide application when weeds are actively growing, without the negative of the clover injury incurred by 2,4-D ester formulations. For further information, talk to one of the friendly staff at your local Farmlands store.

Article supplied by Nufarm.

Calves need access to water from day one and it is a good idea to get your water troughs fitted and operational before calving hits.

Water is not only essential for development but calves who have access to water will eat more grain, leading to better rumen development and higher average daily weight gains.

There are many types of water troughs available, choose one that has a float valve with an enclosed float, so there is less chance of a calf playing with it and flooding the pen. Using a waterer with a relatively small bowl ensures constant refilling with clean water. For maximum time saving in your sheds, a waterer that protects the water supply from contaminants will eliminate time spent cleaning out mucky water troughs.

• Stops dust, bird and calf faeces from contaminating the water supply.

• Drain for easy cleaning.

• Riser with 20mm thread.

• Fully protected float valve.

• Reduces labour in the calf shed.

Most importantly, never feed calves water from teats. When calves drink water from a trough, the oesophageal groove directs it to the rumen where it is utilised in rumen development. If calves drink water from a teat, the oesophageal groove can direct it to the abomasum.

• Stops dust, bird and calf faeces from contaminating the water supply.

• Drain for easy cleaning.

• Riser with 20mm thread.

• Fully protected float valve.

• Reduces labour in the calf shed.

• Ideal for larger pens of calves.

For more information, talk to the friendly team at your local Farmlands store today.

Article supplied by McInnes.

• Drain for easy cleaning.

• Fully protected float valve.

• To cut costs, use one Snack Water Trough between two pens.

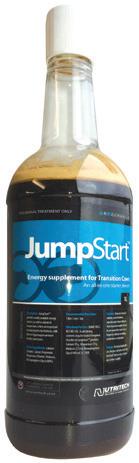

The “transition period” for dairy cows is commonly known as the period from 4 weeks before to 4 weeks after calving, during which time the cow is subject to extreme metabolic changes. This is arguably the most important time to strategically feed the cow properly to ensure the prevention of metabolic issues including milk fever, grass staggers, rapid weight loss and ketosis. These metabolic issues all have consequential effects on milk performance, health and fertility.

Milk fever is a common consequence of metabolic changes during the transition period. The DCAD (dietary cation anion difference) of the diet pre-calving has a significant influence on switching on calcium mobilisation around calving. The higher the DCAD, the higher the risk of milk fever. In New Zealand, a high DCAD is often a result of high potassium levels in pasture or from grazing on effluent pasture paddocks. Farmers can lower the DCAD by supplementing with lower DCAD feeds including maize silage, grain based feeds and anionic minerals.

• Easy to use, highly palatable, flowable formulation.

• 70g calcium/1L dose –highest on the market.

• 440ml MPG/1L dose –highest on the market.

• 16 MJ of energy per litre.

A combination of anionic minerals together with important vitamins (e.g. vitamin D), macro minerals (e.g. magnesium) and trace minerals should be included in a premium transition premix such as NutriMin® Springer Cow Balancer.

In the 4 weeks after calving, feed intake in a dairy cow does not increase sufficiently to meet the energy requirements for milk production over this period. The cow compensates by mobilising body fat to meet this energy requirement for milk production. Fat mobilisation becomes an issue when the cow’s liver fails to cope with the breakdown products of fat mobilisation, resulting in fatty liver, ketosis and in very serious cases death.

An effective strategy to deal with clinical or sub-clinical ketosis is to provide glucose pre-cursors, which increase glucose production in the liver, thereby reducing fat mobilisation. An available source of glucose pre-cursors is monopropylene glycol (MPG). This can be obtained from a product like Jumpstart®, which also includes molasses (as a readily available source of energy) and calcium and magnesium (to help prevent milk fever and grass staggers).

A further consequence of clinical and sub-clinical ketosis and increased body fat mobilisation, is that it can lead to poorer conception rates. This is due to the relationship between negative energy balance and hormones

responsible for oestrus and fertility. A strategy to minimise negative energy balance is to supply the cow with rumen protected bypass fats, such as Golden Flake®, which can be added via the supplementary feed (e.g. adding to maize silage). As their name suggests, rumen bypass fats bypass the rumen and supply a concentrated energy source to the dairy cow after absorption through the small intestine.

To summarise, the “transition period” is a critical period in dairy cows’ productive cycles, which significantly impacts on subsequent lactation performance, health and fertility. The most cost effective approach is to feed and manage cows well during this period, to maximise performance and minimise issues. This can be achieved by good management, advice, feeding and use of the best products.

For more information, talk to the friendly team at your local Farmlands store today.

The start of July is just around the corner – and for OSPRI’s NAIT programme this means by law you are required to tag and register all your cattle and record their movements. So now’s the time to get up to speed with what you need to do and make sure your NAIT account is up to date.

By making sure your NAIT account is up to date, you’re doing more than just playing by the rules. In the event of a disease outbreak, NAIT will help New Zealand swiftly contain the disease, protecting your livelihood and our country’s reputation in the international markets.

The lowdown on the rules

1. Register yourself

If you’re in charge of cattle or deer, whether it’s one or 1,000, you need to be registered with NAIT. You can do this online at nait.co.nz or by calling 0800 624 843

2. Tag your cattle and deer

By 1st July 2015, all your cattle need to be tagged – this includes all cattle born before the NAIT programme became mandatory on 1st July 2012 – even if they’re not leaving your property.

Exception: Calves only need to be tagged before they are 6 months old or before they leave your property –whichever comes first.

3. Register your animals

Registering your animals is the next step after they’ve been tagged. It’s an easy to forget but crucial step, as it activates the animal’s tag in the NAIT system and distinguishes tags sitting in the shed from tags that are actually in animals. This is important for disease control. Registering your animals involves logging on to the NAIT system and telling NAIT what tags were put in animals and then entering some details about those animals.

4. Record animal movements

Stock movements must be recorded by both the sending and receiving parties. This includes private sales and Gypsy Day, as well as short-term movements like grazing, mating and events.

Exception: If you send animals to a NAIT accredited sale yard or meat processor, they will record the movement on your behalf.

So what’s changing on 1st July?

The main NAIT requirements will not change. The main difference is that stock born before the NAIT programme became mandatory on 1st July 2012 need to be tagged and registered – prior to 1st July 2015 these had a 3 year exemption if they stayed on the same property.

The rules are also toughening up, so OSPRI will be ensuring people are complying with these requirements. The priority is on educating and helping farmers to get it right, through the contact centre and NAIT workshops held throughout the country.

Need help?

OSPRI manages the NAIT programme and their staff are available to help with any of your NAIT questions on 0800 624 843. You can also visit nait.co.nz for more information.

Article supplied by OSPRI.

Attention, dairy farmers – in preparation for the dairy beef calves you are rearing, it is advisable to order enough NAIT tags through Farmlands in advance. Beef calves reared only require a single NAIT tag.

The best advice is to apply an FDX Birth Tag. This will provide the lowest cost compliance and the convenience of an animal number on the tag, to make identification and transfers easier. Allflex NAIT Birth Tags can be paired to a management tag, which allows clear visual identification during rearing. A new feature on Allflex FDX Tags is they now have a yellow centre, to provide easy technology identification

May and June is the most common time of the year to apply management tags to your R2 heifers that are about to calve and join the milking herd.

Tag application

It is important to apply your management tags correctly. Correct placement will ensure the tags stand the best chance of providing clear paddock identification, less snagging and tag deformation for the milking life of the animal. The female tag must

always be applied to the front or inside of the ear, between the two cartilage ribs and half way between the head and tip of the ear. Where possible, we advise using a head bale and working from the front of the animal. This is safer and will help you get correct application.

Using the correct applicators will make application far easier and safe. By using old or incorrect applicators, you risk damaging the tags and reducing their service life.

Tag combinations

There are three common tag combinations used – ranked in market preference, these are:

LaserPlus marking:

LaserPlus was proudly developed in New Zealand to provide permanent, clear paddock identification, even in the most adverse situations. LaserPlus rapidly became the most proven and trusted marking system preferred by dairy farmers.

Dairy culls require a NAIT device before they move to slaughter. The FDX lowcost TRAKA tag is the best and most commonly chosen tag for this job. TRAKA tags come in bulk packs for convenience and ordering a few extra is no problem, as they do not expire.

Lice infestations are becoming a serious problem for many farmers. Optimum wool length and environmental conditions during autumn and winter favour lice survival and development.

It sounds easy to control lice, right? We know they spend their entire life on the sheep, so why can’t we just treat and forget about the problem? Lice control and eradication can be unsuccessful, as it only needs a small, surviving population of eggs, nymphs or adults to multiply and the problem continues. Heavy lice infestations cause loss of wool value and animals look unhealthy and under-perform.

There are multiple products available with various claims and time recommendations for lice treatment. Many products contain harsh chemicals, and must be used with care to avoid human and environmental exposure. Care and informed product selection is recommended.

Stock should be checked for lice every

• Active: 25g/L Diflubenzuron (IGR).

• Magnum provides long-term protection (up to 12 weeks).

• Rainfast, can be applied to wet sheep.

• Provides dual fly and lice control.

• Easy on equipment – won’t damage or clog gun.

Registered pursuant of the ACVM Act 1997, No. A7704.

time you yard them. Lice are easier to identify in animals with greater than 6 months of wool. Part the wool in at least 10 areas on both sides of the sheep and look for lice at skin level and lower fleece. Multiple sites need to be inspected, as the parasite often has uneven distribution over the sheep. The most effective time to treat animals for lice is when their wool is short. Coopers MAGNUM® is best used within 24 hours off-shears when increased grease production (stimulated by shearing) aids the product’s binding and new grease encourages lice feeding and uptake of the ingredient. MAGNUM contains an ‘insect growth regulator’ in an aqueous formulation, which makes it safer for operators. MAGNUM used correctly as part of strategic lice control plan will provide at least 20 weeks’ lice control — guaranteed.

Using MAGNUM at pre-winter or pre-lamb shearing provides extended cover during the harder

months of winter and into spring. Used pre-lamb, MAGNUM prevents the transfer of lice from the ewe to the lamb during suckling.

The Coopers lice range also contains Coopers ZENITH®, which has the same active as MAGNUM but is formulated for saturation dipping (shower or plunge). When saturation dipping is used, it is important that full saturation of the fleece to skin level is achieved — a difficult task once a fleece has 2—3 months of growth on it.

Heavy lice-infestation on sheep with 3 months or more wool growth can be devastating for your season’s wool production. Emergency lice treatment is required to reduce fleece damage and animal irritation. Coopers VANQUISH® is a powerful synthetic pyrethroid (SP) pour-on for use in these situations with up to 10 months wool growth.

Coopers recommends effective, sustainable and responsible lice treatment that becomes part of your animal health plan.

For further information, talk to one of the friendly staff at your local Farmlands store.

Article supplied by Coopers.

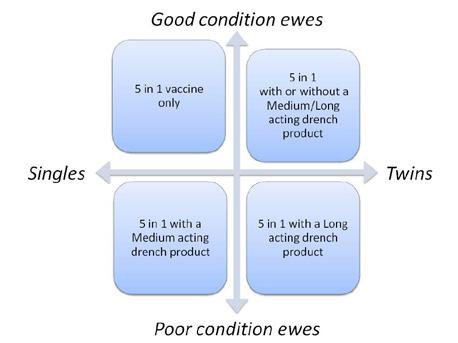

There are a lot of different products on the market for pre-lamb treatment, so how do you go about choosing the right product for your operation?

Not one particular product is going to suit all your needs. By scanning your ewes, you can divide them up into groups with different needs.

Normally you would have two groups, singles or multiple bearing ewes. These can be divided further based on condition score, into good condition ewes and poor condition ewes. So you will have single bearing ewes that are in good condition. These ewes don’t need any treatment at all really. They can get away with a 5in1 vaccine only. It is good not to treat some ewes on your farm, as this will give the opportunity to slow down the development of resistance to anthelmintics.

The second group of ewes will be your single ewes that are in poor condition, which could be set stocked heavier. These ewes will need some help to get them over that feed pinch, so you could either use a very short acting treatment at docking or give them a persistent acting product such as Eweguard ®, a 6in1 vaccine and persistent acting wormer, to help get them through the lambing period. With the multiple ewes, you will have poor conditioned twin ewes. They are going to be the group on the farm that will get the maximum benefit from

treating pre-lamb. These ewes have twins in them so by using a long acting product like Cydectin® Long Acting Injection for Sheep, to give maximum parasite protection, you’ll get also the most cost effective return.

The final group of ewes is your twin ewes that are in good condition. They are a difficult mob to decide what to treat with and that decision will probably depend on other factors, for example withholding time. If you have a terminal mob of ewes, which you’re going to have to wean and get straight to the works, you don’t want a long withholding time on those ewes, so you may choose a shorter acting product. The other factors to consider would be how much time you’ve got, how much labour you’ve got and what your facilities are like. If time and labour are limited then you’re probably better going with an injectable product like

Cydectin® Long Acting Injection for Sheep rather than a capsule. In summary, one particular product is not ideal for all your ewes. We need to break the ewes down into groups — ideally if you’re scanning into singles and twins — and then break them down again by condition score into poor and good conditioned ewes. From there, use the most effective treatment that will meet the requirements for those particular groups.

Medium acting drenches include: Cydectin® Oral Drench for Sheep, Eweguard ®, or Cydectin® Injection for Cattle and Sheep.

Long acting drenches include: Cydectin® Long Acting Injection for Sheep.

For further information, talk to one of the friendly staff at your local Farmlands store.

Article supplied by Zoetis.

It’s now time to consider pre-lamb ewe drenching vaccination. Mature animals generally have strong immunity against parasites for most of the year. However, at lambing this immunity can wane, leaving the animals more susceptible to the harmful effects of parasites.

We know that there are several factors to consider one of the most important considerations is weighing up the benefits against the cost. So we’ve made it easy, comparing some of the top quality pre-lamb ewe products that we have to offer: their cost per ewe, application method, targeted parasites and length of persistent activity — and a simple summary of each product to help make

• Protects ewes and their suckling lambs against Pulpy Kidney, tetanus, blackleg, black disease and malignant oedema.

• Can be used 2-6 weeks prior to lambing.

• Provides up to 16 weeks protection for suckling lambs.

• Contains levamisole to enhance the ewe’s immune response to vaccination and to control gastrointestinal roundworms and lungworm.

• Easy to use, a simple quick injection vs. capsules, means less time spent drenching and handling sheep.

• Delivers 112 days protection against Ostertagia, 91 days against Barber’s Pole and 42 days against Trichostrongylus

• Longer protection from worms means better productivity and cleaner pastures.

your decision easier. Whether you’re treating 150 ewes or 1,050, Farmlands has a great range of pre-lamb products for every budget. If you need any advice on what product will work best for your stock, call in to your local Farmlands store and have a chat with one of our knowledgeable staff members. Between our in-store team and our expert suppliers, we’ve got it covered.

• The trusted 5-in-1 clostridial vaccine.

• Protects against Pulpy Kidney, tetanus, blackleg, black disease and malignant oedema.

• For use in sheep, cattle and goats.

• Nil meat withholding period.

• Available in selenised.

pursuant of the ACVM Act 1997, No. A0934 and A0935

• Ultimate protection from a 6-in-1 vaccine and wormer, in one single shot.

• The vaccine protects the ewe and the lamb from five serious clostridial diseases and cheesy gland.

• Broad spectrum worm control with persistent activity against Barber’s Pole and Ostertagia for 35 days and against Trichostrongylus for 7 days.

• Helps keep pastures cleaner for the newborn lamb.

• Available in selenised.

• Broad spectrum worm control with persistent activity for sheep against Barber’s Pole and Ostertagia for 35 days, and against Trichostrongylus for 7 days.

• Used pre-lambing, helps keep pastures cleaner for the newborn lamb.

• Easy to use, non-sting injection with a wide safety margin.

Just because Destruct has been around for some time doesn’t mean it is down and out — quite the opposite. In the past 25 years the Macrocyclic Lactones (ML) have been the big boys on the block, with a broad spectrum of activity that has made them dominant in both the internal and external parasite market. However their broad spectrum of activity can have some downsides, especially when nontargeted parasite species are exposed, as tolerance will inevitably develop, with no production benefit.

Propetamphos, the active ingredient in Destruct, specialises in external parasites

and has a specific spectrum of activity for controlling all sucking and biting lice in cattle, with no impact on internal parasites. The pour-on formulation is easy to apply to larger dry adult cattle, with only a 3 day meat withholding to worry about. Lice are still difficult to kill, so care on application and handling is still required to achieve the best result as well as treating all in contact cattle.

As lice numbers start to build this winter, treating external parasites with broad spectrum ML is unnecessary or possibly ill-advised. Instead choose Destruct.

Article supplied by Bayer.

• Powerful and proven.

• No recorded resistance by lice on NZ cattle.

• Only 3 day meat withholding period.

• Only 5 day milk withholding period.

Eon is tailor made for value at a time when it is needed most!

Over the past decade, eprinomectin has been the subject of several studies worldwide. In all but one of these, cows were treated at, or soon after, calving. Two of the larger-scale studies were conducted in New Zealand and Australia.

Increased milk production: Milk production benefits of the global studies overall averaged 0.7 litres/cow/ day for eprinomectin-treated cows.1

Improved reproductive efficiency: Two of the studies using eprinomectin have also shown positive reproduction responses, particularly in first calvers. These have been manifest in significantly shorter calving to conception intervals, as well as a reduction in the number of breedings required.2

Selective treatment of younger and lower condition cows, while milking may not only maximise returns but also reduce selective pressure for drench resistance. The tried and tested pour-on formulation is not only convenient but it also gives control of sucking lice as an additional feature. If lice are a main issue then nondrenched cattle should be treated with a specific lice only treatment like Destruct, at drying off.

References

1. Sanchez et al., 2004. 2. McPherson et al., 2000.

Article supplied by Bayer.

Registered pursuant of the ACVM Act 1997, No. A5740.

• Eprinomectin pour-on for cattle.

• Nil milk withholding.

• Rounds, lungworms and sucking lice.

• Controls inhibited Ostertagia

• Ideal for beef and dairy cattle.

Registered pursuant of the ACVM Act 1997, No. A10357.