Farmers Guide sales executive Will Taylor travelled to the Business Innovation Show in Birmingham this month. The show aims to help farmers and landowners to make more money from their land, via diversi cation and innovation. Pictured on the Wigwam Holidays stand are (l-r): Site owner Wigwam Holidays Charnwood Forest, Steve Small; copywriter and content creator, Helen Burt; site owner Wigwam Holidays Charnwood Forest, Clare Small; marketing manager, Morgan Gulland; managing director, Charles Gulland; B2B sales and marketing executive, Rory Watt; and Will Taylor.

The latest New Holland T7.300 tractor was launched publicly at the French Sima Show in November, but David Williams got to see it perform in the eld beforehand. Find his write-up on page 51.

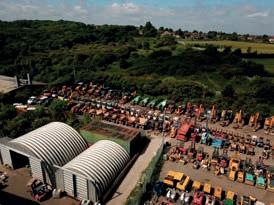

Pictured with

Northants-based dealer Attle eld Farm Machinery. See our January edition for a full report.

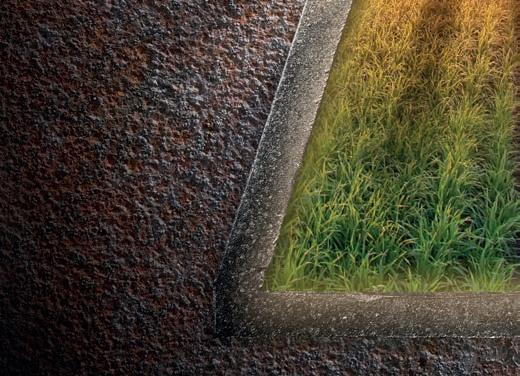

Rachel Hicks chatted with north Essex farmer James Nott to discuss how he’s making a grain maize break crop so pro table, despite the extreme weather this summer – read the article on page 26. David Williams also attended to report on the grain maize being harvested – you’ll nd his part of the story on page 58.

An elderly farmer received a letter from the Department for Work and Pensions, stating that they suspected he was not paying his employees the statutory minimum wage and that they were sending an inspector to investigate.

On the appointed day, the inspector turned up. “Tell me about your sta ,” he asked the farmer.

“Well, there’s the farm hand; I pay him £240 a week and he has a free cottage,” he replied. “Then there’s the housekeeper; she gets £190 per week along with free board and lodging.

“And then there’s the half-wit. He works a 16-hour day, does 90% of the work, earns about £25 a week and, as a special treat, occasionally gets to sleep with my wife.”

“That’s disgraceful!” said the inspector. “I need to interview him immediately!”

“That’ll be me then,” replied the farmer.

David Williams attended an exclusive press launch of new Deutz-Fahr 6.4-series models at the Deutz-Fahr factory at Lauingen, Germany in late October. He is pictured on the production line with SDF chief operating o cer Alessandro Sapio (centre) and SDF UK country manager Graham Barnwell. Farmers Guide’s sister publication, Fruit & Vine Magazine, was o cially launched at the National Fruit Show in Detling at the beginning of November. The team spent two successful days at the event, nding out the latest innovations and news in the fruit industry. Deputy editor Sarah Kidby is pictured on a tour of Su olkbased Braiseworth Orchards with owner Jeremy Linsell, who she interviewed this month for the second issue of Fruit & Vine magazine which lands in December. Spearhead director of sales and marketing Antony Prince, David Williams attended a working demonstration of new side-arm hedge cutters and heavy-duty stubble and grass mowers from Spearhead at David also reported on the opening of the new Ben Burgess Oakham depot. Pictured (l-r): Ben Burgess company director Ben Turner, David Williams, Ben Burgess Oakham branch manager Robert Burdock, John Deere division sales manager Joedy Ibbotson and Ben Burgess John Deere dealer principal Ben B Turner. Read the full report next month.Performance on a new scale. Packed full of technology, such as a newly developed engine with Fendt iD low-speed concept, the intelligent VarioDrive driveline with variable all-wheel drive, combined with high-performance hydraulics with a delivery rate of up to 220 l/min, make the Fendt 700 Vario Gen7 a pioneer in the 200-300 hp class. Learn more: fendt.com/nextgen700

Noventum Power Limited is one of the leading large-scale renewable energy companies in the UK

We will work with you, helping you towards developing your land into an income generating asset that can provide additional income streams for your business.

The benefits include:

• Diversifying revenue streams away from farming or other land uses

• Deploying solar power or wind turbines on your available land

• Maintaining agricultural use through sheep grazing when possible

We are looking for sites between 50 acres and 200 acres, ideally close to a nearby grid connection

Land should be relatively flat and Grade 3 or lower

Well screened by hedges and a good distance from residential property Not in a valued landscape or near historic buildings

We have a team of experienced, highly proficient renewable energy experts. They have an extensive record which encompasses the following:

Land Acquisition Investment Construction Energy Storage Planning and Permitting Grid Solutions Power Engineering & Grid Connections

Operation and Maintenance

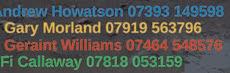

If you would like to discuss how to potentially earn a secure and long-term predictable income stream from your land, please get in touch and contact us on:

As the world gets used to extreme market volatility, created by the ongoing logistical issues surrounding the war in Ukraine, I wonder how many of you are considering your next move – be that in selling your remaining 2022 crop or even your 2023 and 2024 options? So asks Open eld’s head of compliance, shipping and research, Cecilia Pryce (right).

However and whenever you decide to sell your grain is a very personal thing but, with the current daily price volatility are you really con dent you are getting the best price? Historically, market price movement was limited to a few pounds a week, with a forward price which was usually larger than the spot value; but this year we have seen a real mix of prices. How many of you realised that the November 2022 London wheat futures contract moved in a £17 trading range in just one day in early March? In fact, the average daily move since the invasion on 24th February, i.e. the average daily price move, from high to low, has been £6.80, but prior to that date it was just £1. It’s a sobering thought; not just for farmers selling grain, but for buyers who need grain to feed livestock or make bread. Getting the day and time wrong is no small issue when you have to then price the goods through to nal consumer, be that through feeding livestock and selling meat or buying grain for ethanol. Everyone is in the same boat.

In early November, the lifetime average price of the November 2022 London wheat futures contract was £211.65, with a high of £351.50 on 17th May. The uncertainty of supply of any commodity which is taken for granted, and has an element of inelastic demand, is always going to result in price escalation; but what happens next is the question everyone is asking.

The answer is, unfortunately, relatively impossible to predict and comes down to politics and Mother Nature. As the Southern Hemisphere crops approach maturity, the world will start looking south to see if the various Brazilian, Argentinian, and Australian crops reach expectation. Can they and will they ll any of the Northern Hemisphere’s shortfalls? More importantly, will they also have the logistics and political desire to export their crops and, if they don’t, what price impact will that have closer to home?

The questions keep coming but even on our own back doorstep we

must face our own domestic issues. The uncertainty over bird u, the state of the pig industry, the price of feed and the lack of silage – not to mention the ability of the UK consumer to pay for higher priced goods – is a constant worry for all in agriculture. The country will need to consume, but just how much can be pared back or will be forced back? If we believe the UK cereal crop numbers, then we should have enough to help feed others globally. That’s the beauty of relatively free trade, but what happens if we get to the spring and nd the cupboards are empty?

The need for timely and accurate UK statistics is vital. Over the years, Westminster gave up worrying as we always had enough. What surprises me more than anything is that if we have all digital tools in the world, are we ready to believe other countries’ crop numbers yet have very little con dence in our own? Furthermore, the UK can’t publish an o cial crop number until 15th December, halfway through the trading year. Is this really acceptable, and does it send out the right message to anyone or does it just add to the price volatility? Never has it been more important to have a farm marketing plan and make sure

you are speaking to and dealing with the right people.

Recent softening in PK pricing has created a buying opportunity at signi cantly reduced levels compared to late summer, comments Open eld’s fertiliser manager, Lucy Hassall. Due to the current costs of inputs, soil pH should be considered as a starting point to ensure crops are receiving optimal nutrition. pH is key to maximising the value of fertiliser applications with a target of 6.0 for grassland and 6.5 for arable. Lime applications should be used as the primary input where soils are below optimum levels. This will allow nutrient uptake where it could otherwise be ‘locked up’ in the soil when not at target and will help to ensure there is no nancial waste from applying the product.

When carrying out a basic soil test for phosphorous, potassium and magnesium, a pH value will also be included. PK holidays can be more costly in the long run when building back up to target levels, and can have an impact on the overall value returned with potential yield losses. FG

A new collaboration with Taylored-Agri has opened up a range of further development opportunities for Yara’s wellestablished precision agri-tool, the N-Sensor.

Taylored-Agri will now be the customer-facing party for all UK and Ireland N-Sensor users, and will look after sales, training and servicing.

In practical terms this is hugely positive for farmers, as the two companies have a strong shared vision for the ongoing – and

extensive – use of smart tools in agriculture. Around 1.25M hectares are currently scanned by the N-sensor each year, so it is hoped this development will provide a tangible boost to UK farming.

Alan Rix, sales manager at Yara, commented: “Satellite imagery is undoubtedly the entrée to precision farming. The N-sensor however takes this to another level allowing farmers to measure a crop’s nitrogen requirement in real-time and variably adjust

the fertiliser rate to suit the crop’s development. With partnerships like the one with Taylored-Agri, we are con dent that the data collected by the N-sensor will prove to be of even greater bene t to farm e ciency and productivity."

Five machinery dealers from across the UK have been honoured with this year’s Krone Dealer Awards. Taking the title of overall Dealer of the Year was Scottish business, George Marshall Tractors. Krone UK managing director, Marcus Oliver, explains that the award was judged on the dealer’s overall commitment to the brand, product representation across the range, aftersales care, parts stocking and business development.

Among the winners, Carr’s Billington was awarded for Sales Dealer of the Year.

On 14th October, the new production facility for Fendt loader wagons was o cially opened at the Wolfenbuttel site in Germany. The inauguration of the development and production site was attended by representatives from politics and business, employees of the site, as well as customers and sales partners. On Saturday, 15th October, an Open Day was held at the plant, where the citizens of Wolfenbuttel and interested people from the

region could visit the new production lines.

Roundbalers have been manufactured on the factory premises in Lower Saxony, Germany, since 1899. In 2017, Agco/Fendt acquired the traditional baler site in Wolfenbuttel (formerly Welger Werke). Since then, more than €20M has been invested to build a modern and sustainable development and production site.

Since September 2022, all models of Fendt loader

wagons have also been assembled in Wolfenbuttel in a 4,200m2 production hall. A further 10,000m2 of logistics space has been added for the loader wagon assembly.

The highlight of the opening was the handover of the rst Fendt Tigo manufactured in Wolfenbuttel to a Dutch farmer. During the subsequent factory tours, the invited guests were able to see the loader wagons and round baler assembly for themselves.

group after-sales manager, commented: “Myself and all of the team at B&B Tractors would like to congratulate Brad in his achievement of runner up in the LE-TEC Technician of the Year Award and we would also like to say well done to all the other candidates who entered.

“This award helps to con rm Brad’s passion and commitment to the job, and proves that the AGCO

apprenticeship programme along with hard work, dedication and the support of an employer is a great route to becoming a master technician.

“We would like to say a huge thank you to Brad for delivering rst-class customer support, with the assistance of our after-sales teams, and I’m sure there will be more awards to come for him.”

Krone also recognised Lincolnshire-based JPM Agricultural Ltd with the New Dealer of the Year Award, for its success in making it into the top 10 dealers for turnover in its rst full year of supplying Krone products. The award for Service Dealer of the Year was presented to Compass Tractors Ltd in the South West.

Finally, the Ambassador of the Year Award was presented in memory of Krone employees, Rodney Benson and Darren Metcalf, who both sadly lost their battles with cancer earlier this year.

“This year’s award was presented to Tim Adcock from Chelmsford’s Adcock Agri Ltd, who has displayed an infectious ‘can do’ attitude, which cascades and manifests itself throughout his team and truly works in partnership with Krone, in a exible but driven manner,” said Marcus.

JCB has unveiled a world rst for the industry – a mobile hydrogen refueller, providing a quick, easy way for customers to refuel machines on site. Around 97% of construction machines have fuel delivered to them while working on site. This means customers are already used to a transportable fuel, allowing refuelling to take place in minutes.

The rst hydrogen-powered machine to be unveiled was a JCB backhoe loader followed, a year ago, by a Loadall telescopic handler.

The technology went on to be shown in the Green Zone at COP26 in Glasgow as world leaders debated measures to drastically reduce greenhouse emissions.

The choice of training for farmers and trainee pest controllers to become recognised competent users and authorised purchasers of professional grade rodenticides has been updated in conjunction with the Campaign for Responsible Rodenticide Use UK (CRRU).

For farmers and pest control trainees, there are now seven courses in total. In each case, passing the end of course exam yields a formal quali cation/certi cation accepted at point-of-sale for

professional use rodenticides under the UK Rodenticide Stewardship Regime, operated by CRRU.

The seven courses are:

• RSPH/BPCA Level 2 Award in Pest Management

• RSPH/BPCA Level 2 Certi cate in Pest Management

• City & Guilds NPTC Level

2 Award in the Safe Use of Pesticides for Vertebrate Pest Control for Rats and Mice

• Lantra Awards Level

2 Award in Rodent Management

• Killgerm Principles of Rodent Control (Exam through BASIS)

• RSPH Level 2 Award in the safe use of rodenticides

• BPCA Using Rodenticides Safely (Exam through BASIS).

The BASIS Rat Control For Gamekeepers course also remains available.

View the list online here www.thinkwildlife.org/ training-certi cation/

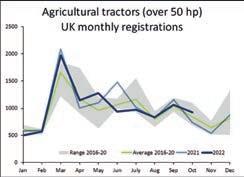

The number of agricultural tractors registered in the UK in October was up by more than a quarter, compared with the same month last year, at 926 machines. That is the fastest year-on-year rise since August 2021 and the monthly total is the largest for the time of year since 2016. October was the third month in a row when registrations were above the seasonal average over the previous ve years, with

10% more tractors registered this year than in a typical October. It remains to be seen whether the upturn is just a short-term one or if it indicates that supply chain disruptions are beginning to ease. These have meant 3% fewer tractors have been registered so far this year than in January to October 2021, despite demand remaining strong.

Month: 926 units +25.3% change (compared with October 2021).

Year to date: 10,223 units -3.5% change (compared with January-October 2021.

Agricultural machinery manufacturer Claydon recently welcomed 50 agricultural students from the University of Helsinki. The visitors came to learn how direct strip seeding could enable Finland’s farmers to operate more e ciently and better utilise the limited time available to establish autumn and spring-sown crops. The visit took place at the Claydon factory in Su olk in the East of England. After seeing the company’s Evolution mounted and Hybrid-T trailed drills, Straw Harrows, TerraBlade inter-row hoes and TerraStar light rotary cultivators being manufactured, the group toured the Claydon family’s 325ha arable farm which produces a range of combinable crops.

Hosted by company founder and chief executive Je Claydon, the students’ nine-day tour took them to six cities in England, Scotland, and Wales, including London and Edinburgh. They also visited numerous farms, an agricultural museum, the JCB factory, a distillery, Rothamsted Research in Hertfordshire, and Syngenta’s Jealott’s Hill International Research Centre in Berkshire.

The supply of winter bean seed in Britain has been secured following a successful derogation bid led by the Agricultural Industries Confederation (AIC).

Biox-M manufacturer, Juno (Plant Protection) Ltd, says it is delighted to report that Xeda International SA has received approval for a minor but entirely sensible change to the label for Biox-M in the UK. Biox-M is 100% spearmint oil applied to stored potatoes as a hot fog.

The change con rms permission to use variable rates of Biox-M to suit the condition of the crop and of

the store.

The revised wording on the label will be:

Dose rate: 30–90ml/ tonne depending on sprout size and application interval. Repeat applications may be made at a minimum of 21-day intervals. A maximum total dose of 360ml/tonne of potatoes must not be exceeded.

There are some other minor changes to wording

on the label, which will be shared with users of Biox-M as soon as the new label has been approved.

This note is not intended to replace the Product Label or Safety Data Sheet supplied with the product and must be read in conjunction with both those documents to ensure the safe use of Biox-M at all times. Every store is di erent and should be managed accordingly.

The exceptionally hot and dry conditions throughout this summer have taken a toll on germination rates, risking a depleted quantity of winter bean seed available for the 2023 drilling campaign.

Working on behalf Britain’s certi ed seed sector, the AIC liaised with the industry, gathered evidence and applied to Defra and devolved partners for a temporary derogation covering England, Scotland and Wales.

The derogation, which was approved on 17th October, allows for a limited quantity of winter bean seed to be sold with a germination rate of no less than 70%.

“This is good news for the certi ed seed industry and gives some much-needed certainty for British growers,” says Rose Riby, AIC arable and seed sector head, who spearheaded the derogation request.

With lower yield variability and decreased input costs, not to mention being an important weed control tool for farms with a signi cant black-grass burden, spring cropping options o er some impressive bene ts – despite the reduction in overall yield versus their winter counterparts.

Given the extreme weather conditions seen over the last few years, along with signi cant increases in the cost of inputs, spring crops are increasing in popularity – particularly among farmers who rely on them for weed control, adding diversity to rotations and spreading the workload. What’s more, margins have also begun creeping up; going some way to reduce the pro tability gap between the spring and winter varieties.

New spring-sown portfolio bene ts all types of grower New high-yielding wheats for both milling and feed use combined with a malting barley featuring “outstanding” alcohol yields are underlining KWS’ commitment to developing strong spring-sown options with valuable marketing opportunities, says the company’s Dr Kirsty Richards.

She comments: “Modern spring varieties are robust, exible and pro table, with yields and physical grain qualities matching many of their late sown winter rivals and KWS is committed to investing in long-term breeding programmes to support this sector.

“Spring wheat, in particular, has seen a real resurgence in interest over recent years thanks to its rotational bene ts helping growers buy time to get soils back in shape,

tackle weeds more e ectively and simplify their overall crop management.”

One of the most important developments in spring wheat for some years is the inclusion of the Group 1 variety KWS Ladum to the current RL, Dr Richards says.

“KWS Ladum is a KWS Sywell x KWS Talland cross which combines high yield with an excellent disease package, including a 7 for septoria.

“It’s the rst of a new generation of spring wheat varieties for the UK market, capable of delivering top milling and baking quality for growers with exceptional productivity.

“With fantastic grain quality, including a protein level of 13.2%, a Hagberg of 324 and a speci c weight of 78.0kg/hl, it’s a variety that is fully approved by UK our millers, having the highest Group 1 quality.

“Its disease package is also strong, featuring an [8] for mildew, a 6 for yellow rust and 7s for brown rust and septoria. It’s a short and sti -strawed variety that is early to harvest, too.”

KWS Fixum is another new spring wheat option on the RL for the rst time this year, Dr Richards explains.

“KWS Fixum is the highest yielding spring wheat on the 2022/23 Recommended List, with a wellrounded disease package supported by good physical grain quality and agronomic characteristics.

“At 108% of controls when spring sown, it is 3% ahead of the next highest yielding variety on the RL and this is combined with super grain quality featuring a speci c weight of 77.8kg/hl.

“Furthermore, during testing over the last few very di erent spring seasons, KWS Fixum has delivered consistently high yields – no matter what the weather conditions under which it has been grown.”

For spring barley, candidate-listed KWS Curtis provides good potential for both the brewing and distilling sectors in a true farmer-friendly package that could help growers meet rising demands for increasingly sustainable production, she believes.

“KWS Curtis could well be a strong dual-purpose variety for the malting industry and is currently

under test by the MBC with potential for both the brewing and distilling markets thanks to its high levels of hot water extract, good spirit yield and top grain credentials.

“In the eld, KWS Curtis has good yields across the country. In the north it achieves 104% of controls, while in the east this rises to 108% –which coupled with its earliness and sti straw, will make it a rst-choice variety for many growers.

“KWS Curtis has strong sustainability credentials too. Its combination of high yields, good alcohol yields and strong straw make it a step ahead of current commercial varieties in terms of CO2 emissions, helping ensure more sustainable production for the entire supply chain.”

With increasing pressures on growers, we recognise that break crops play a fundamental part of crop rotation, providing welcome improvement to your cereal crop.

Elsoms’ expanded spring crop portfolio includes beans, peas and linseed, helping you to improve your soil’s nitrogen, control problem weeds and with healthy margins, they make a welcome contribution to your bottom line too.

Speak to your seed merchant today about availability or discover more at www.elsoms.com/spring-crops

The third year of growing LG Diablo was certainly one to remember for Yorkshire farmer Paul Rogers (right), after the variety revealed its true yield potential on his 182ha farm near Ripon.

Some 25ha averaged 10t/ha sold weight at 15.5% moisture, with one eld hitting an impressive 10.6t/ha. Furthermore, all crops achieved the full malting speci cation required by grain buyer Saxon Agriculture, coming in at 1.51% nitrogen and an average speci c weight of 68kg/hl.

“I’ve never seen anything like it. The barley was rolling o the combine like a crop of rst wheat. It was phenomenal.”

Mr Rogers acknowledges the highest yields did come from the farm’s best “good bodied” land, that did not drought o in the dry season, but even so, he would have still only expected yields of nearer 7.5t/ha.

“I don’t know exactly where the big yield came from, because we didn’t do a lot di erent to the year before, apart from getting crops in earlier, around mid-March instead of early April. It was just an earlier spring; the soil conditions were correct for drilling.”

The LG Diablo established quickly, resulting in a dense plant stand that “looked like a carpet,” he notes. “The key was to keep it standing, which meant we did put on an extra growth regulator, in addition to Terpal (ethephon + mepiquat).”

Mr Rogers admits that while he may not be able to guarantee hitting such impressive yields every year, LG Diablo’s performance in 2022 at least demonstrates what the variety is capable of on his farm and soil types.

A key reason for growing spring

barley on the farm is for its role in controlling black-grass and ryegrass, Mr Rogers says. “Both are becoming more of a problem, but I’ve found that if I can get thick coverage of spring barley, it does a tremendous job of smothering the black-grass, which we did see last season.”

He adopts a very traditional approach to establishing spring barley. Preceding stubbles are left to green-up after harvest, before land is ploughed in November, allowing bare soil to weather and breakdown naturally over winter. He then goes in with a power-harrow/box drill combination, once ground is dry and warm enough in the spring, usually around early April.

“It normally doesn’t worry me drilling spring barley towards the middle of April, if that’s when conditions are right, so long as I can make sure it goes into moisture, and I can conserve that moisture in the seedbed.

“The important thing is to drill when conditions are right, not on a particular date.”

Ploughing in November allows time to achieve a good ush of weeds in the autumn, which means no pre-emergence spray is needed in spring. “I don’t want anything knocking the crop, and pre-ems can sometimes hold barley back a bit. I prefer to wait until weeds have emerged after drilling, and then tackle what’s there. The spring barley itself is our grassweed control, so we only really need broad leaf chemistry.”

“LG Diablo has performed well for us in all the three years we’ve grown it, so I’ve no plans to grow anything else next year,” he concludes.

A spring barley variety that combines

consistent yields across all UK regions on the 2022 AHDB Recommended List with high grain quality in terms of speci c weight, is being launched to growers of feed barley.

SY Splendor, from Syngenta, was originally bred for the malting market where it was evaluated for brewing use. But, despite having been withdrawn from malting tests, it continues to o er useful features that could appeal to feed barley growers, Syngenta seeds portfolio marketing manager, Kathryn Hamlen, points out.

Topmost among these are its consistent treated yields of 102% of control varieties across all regions on the 2022 AHDB spring barley Recommended List, says Mrs Hamlen, plus its high speci c weight of over of 68kg/hl. But SY Splendor also o ers other characteristics that could be useful if growing spring barley in certain grass weed situations, she adds.

“Spring cropping is a well-known method of reducing grass weed populations,” says Mrs Hamlen, “as it gives growers more time to remove an extra ush of weeds before planting. On top of this, spring barley is a competitive crop and therefore has more e ect in suppressing grass weeds. However, the other desirable traits of SY Splendor are its vigorous growth habit and sti straw with good brackling resistance.

“Early vigorous growth helps a variety to better compete against grass weeds from the beginning of the season – allowing good plant establishment before the grass weeds get a chance to compete. Sti straw helps later in the season if grass weed populations are higher – as it can help the crop to better withstand grass weeds pulling it down.

“Meanwhile, speci c weight is a stable characteristic, which means if you choose a variety that starts with a high speci c weight, it will help to mitigate against the competitive e ects that grass weeds have for

reducing crop grain- lling.

“It is precisely because SY Splendor was originally developed as a malting variety that it has such a good speci c weight,” Mrs Hamlen adds.

Currently, the feed sector accounts for about 20% of the UK spring barley market.

barley variety a “ rm farmer’s favourite”

RGT Planet spring barley has earned a reputation for exceptional consistency among growers and maltsters since it appeared on the Recommended List in 2015 and the variety is set for another successful season in 2023, the breeder reckons.

Farmers know how to grow the variety, which has become a favourite for many thanks to its dependable yields, strong agronomics and excellent grain quality, says RAGT’s arable crops manager Tom Dummett.

“RGT Planet is very vigorous, putting down strong roots and tillering profusely. It has good resistance to rhynchosporium and is excellent on ramularia.

“The variety produces an excellent sample, helped by its reluctance to deteriorate in the eld, protecting speci c weight and germination.”

As well as making a big impact in the brewing supply chain, RGT Planet has also taken a signi cant share of the feed barley market, adds Mr Dummett.

Cambridgeshire farmer Sam Morris grows combinable crops across 750ha of heavy clay from Top Farm, Croydon, and has sown RGT Planet for the past three springs.

“We went into barley purely to help keep black-grass in check, but it seems to perform really well on this farm. We use it as the rst crop in a double spring break, following it with beans.

“Planet itself is pretty competitive.

We drill early to get it up and away, and we combine it as early as we can, which helps spread the harvest.”

Mr Morris grew 55ha of the variety last season, and was impressed despite the dry season. “We drilled the crop in February and cut it on 25th July. It yielded over 9t/ ha – it’s now done that over three very di erent years, and it’s been fairly easy to get a brewing premium.”

Gavin Bowser, who looks after 1,000ha of mainly arable cropping at Croft Marsh, Skegness, Lincolnshire, grew around 120ha of RGT Planet last season on silty clay loams to help control black-grass.

“The variety does the job well. We aim for a good thick crop to smother the black-grass and to get good yields.

“We’ve been growing Planet for six years and we were pleased with it again this year. A 44ha block which was ploughed and cultivated after maize and drilled on 23th March, looked exceptionally well.”

The crop averaged 8.5t/ha and met malting speci cation. “That was pretty good in a year like this, especially as it doesn’t require the chemicals and fertiliser that winter wheat does.”

Ken Goodger’s 10ha crop of RGT Planet averaged 8.75t/ha at Pates Farm, Welney, Norfolk. “That was an excellent yield for a spring crop this season, although we did drill it in early March on very good silty land.”

Mr Goodger, like the other growers, will be sowing RGT Planet again next spring. “It suits our fertile soils; it doesn’t brackle over or go at, so it combines well,” he explains.

In a year of uncertainty and volatility in all areas of our lives, it is a good moment to take stock and look at how we can be more in control of our gross margins, comments Fairking Ltd.

Fairking Ltd has been growing niche market crops since the 1970s, and believes that by far the most consistent and successful of these has been borage; the seed oil of which is used in both pharmaceuticals and cosmetics.

Although it is a crop which requires special attention at harvest, Fairking says it has more than 100 growers throughout the country bene tting both in their arable rotation and also nancially when compared to other spring sown crops.

As both farmer and merchant, the company explains it can see the bene ts a later sown spring crop brings to its own farm’s black-grass control by both allowing a late application of glyphosate in April before sowing, and the ability to direct drill the following wheat into a low-residue, slug-free borage stubble. Financially, being able to grow a crop where the price is xed means growers know their costs and gross margin before starting the season, meaning they can make a decision rather than take a gamble.

One of the reasons for the crop’s huge success is that the English climate produces the best quality oil in the world, making it very di cult for other countries to compete.

Dutch trader De Wit Speciality Oils owns a speciality extraction plant

continued over…

...from

on Humberside. It o ers safe backto-back grower contracts through Fairking as its sole agent, based in Essex.

With increasing demand, the future looks bright and prices for next year’s crop are now set at £3.85/kg with possible additional bonuses. Yields are normally around 400kg/ha but can be as high as 650kg/ha. Low fertiliser and chemical requirements mean that the main growing costs are for seed and swathing.

Borage is an attractive, environmentally- and bee-friendly crop which provides bee keepers with huge quantities of exceptional honey.

Harvesting does require a bit more attention than some of the other crop alternatives, but Fairking explains the rewards are worthwhile and says it is there to help with contracts and specialist advice.

Interested farmers wanting further details should contact Fairking directly.

Despite the UK’s driest summer since 1976, this season’s spring bean crop yields have generally held up well con rms Danny Richardson (pictured), combinable seed product specialist for Wynnstay Group PLC.

Based in Shrewsbury and

Based in Shrewsbury and serving growers across the western half of Britain, from Chester down to Cornwall, Mr Richardson believes a combination of higher rainfall in early spring, low disease pressure, and the opportunity to utilise earlier drilling windows following a mild winter helped many farmers during an agronomically challenging year dominated by extreme heat and summer drought conditions.

“Had this also been a highpressure year for disease, then that would have certainly compounded the issues already facing growers leading to much greater yield losses. That aside, it’s been a good year, particularly for those who drilled spring beans early. There’s a squeeze on soya right now which has helped increase demand for pulses, and the market for home grown protein is buoyant with good ex farm prices being paid.

“Of the newer varieties on the 2022 PGRO Descriptive List, Capri catches the eye as a high yielding, early maturing bean. With a solid rust score, respectable thousand seed weight (TSW) and excellent standing ability it ticks the right boxes for both domestic and export markets and is de nitely a variety that growers need to keep on-side,” he concludes.

drilling window of 23rd

raced away during April, less moisture than he’d

For Boston-based rst-time Capri grower Danny Anderson, of P & N Anderson and Son, an early drilling window of 23rd to 24th March proved to be the right strategy, as his 14ha crop of Capri raced away during April, despite a dry spring and less moisture than he’d have preferred.

“We direct drilled this time to get the seed a little deeper into the soil, allowing it to nd more moisture, then rolled immediately afterwards to lock in the moisture. The Capri established very evenly and there were no bare batches. By 10th May, when we sprayed a combination of Laser plus Toil to clear up some wild

page continued over…

lgseeds.co.uk/lg-diablo

There’s no hiding the fact that it’s a great yielder. David, Fife

oats and post-emergence weeds, the crop has successfully grown away from any smaller emerging weeds, so it was a cautionary spray if anything.

“Only one fungicide was applied post- owering, primarily for rust and downy mildew control and we added some foliar feed to give the Capri a boost during the prolonged dry spell. Overall, the crop coped very well with the high summer temperatures, reaching a height of six feet in places, with the taller canopy helping to give the soil around the base of the plants a decent level of shade.

“We grew Lynx in 2021, a shorter crop in height, and subsequently lost some beans in the harvest that the combine header couldn’t reach; but there were no problems this time. When we cut Capri on 29th August, the nal overall yield of 5t/ha was impressive, given the substantial dry spell. With more moisture I’ve no doubt we’d have been looking at an even higher yield.

“We’ll de nitely grow Capri again. It’s a tall early-maturing variety, looks agronomically strong, coped

well with the hot dry weather and owered well producing a lot of pods. The potential is there for an even higher yield with slightly better weather,” con rms Mr Anderson.

LS Plant Breeding Ltd’s Carrington is the highest yielding green pea on the PGRO Descriptive List of combining peas, with a high downy mildew resistance and good standing power. It is also resistant to pea wilt.

Michael Shuldham, pulses product manager for LSPB, details Carrington’s set of bene ts for growers: “The variety was added to the PGRO Descriptive List 2022 for combining peas (DL) as the highest yielding pea of all with a yield gure seven points clear of the next green pea variety on the list.

“Added to its yield bene t, Carrington has high resistance to downy mildew (8) – especially important in light of the challenge of downy mildew control with the loss of Wakil XL.

“The variety’s high standing ability at harvest (7) updates the old perception of peas being prone to going down in poor weather. Modern varieties like Carrington are early to mature and stand much better than those of a decade or so ago.

“Colour retention on sample quality is also important for marketability – and Carrington stands out for its colour retention with trials data showing the variety consistently retains its colour.

“In summary, Carrington is one of a newer generation of pea varieties with improved genetic capacity led by traits such as its impressive yield potential, disease resistance and standing power.” FG

Dairy farmers could mitigate the impact of rising feed and fertiliser prices by growing more maize in 2023.

While the last 12 months have seen some substantial milk price gains, these have been o set by rising commodity prices and global factors which continue to cause the cost of purchased feed, fertiliser and fuel to rise. The ongoing challenge for most dairy farmers is therefore to mitigate these price increases so their businesses can capitalise from milk price buoyancy.

“One of the ways farmers can o set rising feed costs is to maximise the amount of home-grown forage they produce,” comments Tim Richmond (pictured), LG maize product manager. “The rst step is to start planning early, with the clear goal being to improve forage productivity to ensure silage clamps are full of high-quality winter feed.

“For many, that could simply mean growing a larger area of maize, with the higher yield that maize produces compared to grass silage putting more feed in the clamp. It could also allow more grass to be used for grazing if the requirements for second and subsequent cuts are reduced.

“This strategy could also enable growers to optimise their use of nitrogen by prioritising valuable fertiliser reserves for use on early season grazing pastures and rst cut silage leys which will deliver the best response to nutrient applications.

“Increasing the proportion of forage maize being grown will also reduce the farm’s overall fertiliser

requirement as maize has a lower nitrogen requirement per hectare compared to a traditional mixed grass grazing and silage system and can make e cient use of readily available FYM and slurry.

“And, because maize harvesting is a one-pass operation, signi cant fuel savings can be made at the end of the growing season compared to taking three or more cuts of grass silage.”

The greatest cost savings will be realised where growers choose a maize variety which is suited to their speci c location and soil type, and which produces a crop with a high starch content and enhanced cell wall digestibility.

maize variety which is suited and soil type, and which produces a crop with feed value of forage maize

“With each new generation of varieties, the feed value of forage maize takes another small step forwards,” Mr Richmond continues, “with high yielding, early maturing varieties such as Saxon and Dignity enabling growers to o set purchased feed costs by lling their clamps with high quality maize forage.”

Saxon and Dignity have been added to the NIAB/BSPB Descriptive List for 2023, with both delivering early maturity (FAO 170 for Dignity and 180 for Saxon) which means they can be harvested early, easing harvest workloads and making the establishment of successor crops more feasible. They also combine exceptional yield (Saxon being the highest yielding variety on the new BSPB/NIAB list) with excellent ME content, high starch yields and superior cell wall digestibility. FG

At an online event hosted by Trinity Global Farm Pioneers, expert speakers discussed how agroforestry and biodiversity can help drive agricultural production and explored the barriers to uptake among farmers. Henrietta Szathmary writes.

The webinar was free to attend, and took place on 11th October as part of Countryside COP 2022. At the end of the event, attendants had the opportunity to share their thoughts and ask questions through a dedicated Q&A session.

The webinar was opened by Emily Pope from Trinity Global Farm Pioneers (Trinity GFP).

Trinity GFP is a free-to-use virtual knowledge exchange platform that provides spaces for sharing ideas and advancing best practice. Through the platform, users can connect with like-minded people, attend and host online events, and expand their knowledge in areas of interest relating to agriculture.

The webinar’s rst speaker was Martin Lukac, professor of ecosystem science at the University of Reading. In his talk, he gave a broad overview of the bene ts and limitations of agroforestry and shared details of a study looking at farmers’ attitudes to adopting farm woodland.

To begin with, Prof Lukac introduced the concept of agroforestry, which he de ned as “the purposeful integration of woodland with an agricultural production system”. Its two main types, he explained, are silvoarable (trees + crops) and silvopasture (trees + grazing livestock) systems.

He then gave a rundown of the various bene ts agroforestry can bring to traditional farming and the wider environment. He emphasised that the greatest bene t comes in the form of

ecosystem services, such as increased pollination, natural pest control, and carbon sequestration.

According to Prof Lukac, the bene ts of agroforestry relate to:

• Diversi cation

• Biodiversity

• Carbon

• Soil protection

• Pest regulation

• Climate regulation

• Resilience

• Stability

• Landscape amenity.

As for its limitations, the three main factors outlined by the professor were establishment cost, management complications, and opportunity cost. Elaborating on the latter, he explained that trees can decrease crop productivity by overshadowing the plants and competing for nutrients, which represents a concern for farmers.

Prof Lukac also shared details of a recent study that surveyed 2,000 farmers in the South East and East of England about their views on adopting an agroforestry system.

The results showed farmers considered a positive contribution to farm income to be the most important factor when it came establishing woodland on elds, followed by the reduction in productivity of adjoining land and improvement to landscape amenity.

The results have also shown that farmers widely believe implementing agroforestry would reduce greenhouse gas emissions and improve landscape appearance. On the ipside, many also believe the system would reduce yields on nearby

land due to competition between the trees and the crops.

These ndings are summarised in Figure 1 below.

Overall, Prof Lukac believes the small and large-scale bene ts of agroforestry outweigh the costs in terms of landscape productivity and ecosystem services. However, he warned that many farmers don’t know how to get started with agroforestry, and providing the necessary support will be critical to uptake.

The next speaker of the event was Dr Alexa Varah, post-doctoral researcher at the National History Museum, who covered how agroforestry systems a ect environmental outcomes like biodiversity and pollination.

In her talk, Dr Varah presented an applied research project she carried out with colleagues to determine the environmental bene ts of agroforestry

systems. The project compared four silvopasture and two silvoarable sites with monoculture controls using six UK farms.

Although the study measured a range of environmental outcomes, Dr Varah highlighted biodiversity and pollination in her talk.

To measure the abundance and diversity of pollinators, the number of bees, butter ies, and other insects were recorded on all sites using pan traps, Dr Varah explained. Pollination was also directly measured by counting the number of seeds produced by potted plants on the elds.

The ndings have revealed that agroforestry systems attract a higher number of pollinators and insect species than monoculture systems. Fields with woodland had twice as many bumblebees, solitary bees and hover ies, with some sites giving home to over 10 times the number

Resolute ticks all the boxes. We are able to achieve the 30% starch we need along with good digestibility

of solitary bee species compared to control elds.

Moreover, plant pots produced more seed in agroforestry systems, indicating higher pollination. This underlines how increased pollinator presence can directly bene t crop yield in silvoarable systems.

Dr Varah also pointed out that the choice of tree species will have an impact on how insects and other wildlife respond. In a silvoarable set-up, she suggested taking advantage of the understory and establishing owers or vegetation to support pollinators or biodiversity.

In her conclusions, Dr Varah echoed Prof Lukac highlighting that agroforestry systems are a more e cient way of using land due to more biomass being produced, which in turn increases the landscape’s carbon storage capacities.

The nal speaker, Dr Ben Woodcock, gave his talk on the sustainable intensi cation of farming systems to support biodiversity and crop yields. Dr Woodcock is an ecologist at the UK Centre for Ecology and Hydrology.

First up, he discussed how intensive agriculture is likely a major contributing factor to the rapid decline of pollinator species in the last few decades. While bringing biodiversity back into agriculture is key to retaining important insect species, farmers will show reluctance unless they see a bene t to yield, Dr Woodcock said.

To expand the existing evidence base that biodiversity can support agriculture, Dr Woodcock and his colleagues conducted an experiment implementing the approach at landscape scale.

The study was carried out at the 1,000-acre Hillsden farm, which previously used an intensive farming

system and was heavily reliant on agrochemical input. The farm was split into 15 farmlets of 50–60ha each, where three di erent treatments were applied:

• Treatment 1: Business as usual

• Treatment 2: 3% land removed to wildlife habitats

• Treatment 3: 8% land removed to wildlife habitats.

Wildlife habitats could include eld margins or eld corners and were created to promote biodiversity not yield, Dr Woodcock stressed. Yield maps were then used to monitor changes to crop production over an extended period of time.

After ve years of running the study, the results were analysed and related to the regional average. While yield from control crops remained just below average, there was a gradual increase in yield from crops that received the second and third treatments.

The ndings are displayed in Figure 2 below.

As shown on the graph, there is a time lag before crops grown in systems integrating biodiversity start producing higher yields. Dr Woodcock said the lack of instant turnaround that can be easily achieved with agrochemicals is the main reason why farmers are reluctant to implement such systems.

To nd out whether the results of the study are generalisable, Dr Woodcock and his colleagues conducted another experiment across 18 farms that use various farming systems. Treatments similar to the previous study were applied over a period of four years, and preliminary results show crop yield responded best to more complex biodiversity treatments.

In summary, Dr Woodcock pointed at the growing scienti c evidence that biodiversity can support agricultural production, but said it will never become a sole solution to increasing yield. FG

lgseeds.co.uk/saxon

“Saxon’s improved vigour meant it was greener at harvest and it out-performed our other varieties.”

Nigel Harper, Cheshire

Mr Nott farms a total of 4,000 acres, the majority of which is on contracted land. Soil type is predominantly clay, with some sandy clay loam pockets, and he generally follows a min-till approach – although this is exible. He reckons that due to climate change, growers should consider doing what the continent is doing, and comments that fortune favours the brave – while those who are risk averse might just

grow winter beans, he believes you need to experiment and try other options – as such, he’s now opting to grow grain maize as an alternative break crop within the rotation.

Mr Nott also grows OSR, but he can nd it to be hit and miss; he’s also grown peas in the past, but became fed up of chasing pigeons away; and following winter oats, he says the ground becomes poisoned by black-grass.

The farm has a black-grass burden, so weed control for the maize is based around mesotrione + nicosulfuron which Mr Nott says provides excellent control. He does dabble with pre-ems such as pendimethalin, but nds them underwhelming due to the spring season in the area being so dry historically, so prefers to use contact herbicides.

“We’re all looking for a break crop, and the economics with grain

maize, to me, look right,” explains Mr Nott. “I understand why people don’t like it, as many don’t want to combine in October/November; but I believe it’s nancially rewarding and not as di cult as people might think.”

Once the grain dries down, it won’t absorb further moisture due to its waxy coating. So, as long as the maize is t to go, the wet weather is far less of a problem than for a eld of wheat. In fact, he says that on a wet day, it would be far easier to combine a eld of maize than it would be to forage it.

Mr Nott explains that with forage, you’re creating bare land, trying to get 20t/acre o the eld with trailers impacting the ground, just as you would if you were lifting sugar beet.

When harvesting the grain only, however, you’re taking closer to 4t/ acre, while the combine is laying down a “magic carpet” of maize stover on the ground which the machinery can then travel on.

This year, he ran a Farmet Triton over the stover, mulching it in slightly, before drilling the following crop with a Vaderstad Rapid – establishing the commodity crop in two passes. He’s looking to experiment with a Claydon drill behind the maize next year.

Mr Nott does admit that with

profitable commodity, not justJames Nott farms in north Essex, and has been growing grain maize as a successful and, importantly, pro table break crop since 2021. Rachel Hicks reports.

maize you have to accept you will need to dry the crop, which has to be factored into the margins. Last year, the crop was dried for £20–£25/t, while energy prices this year meant the drying cost was £30–40/t. The rst year, he used a continuous ow drier, which he says takes 10% moisture out in one go; but this year he hired a Master batch drier from Master Farm Services (GB) Ltd, which he found to be very e ective, and intends to do the same again next year. He says that once you’ve got it down to 15% moisture, it stores very well – although it sells o -farm very quickly so isn’t in store for long.

Mr Nott doesn’t understand why so many growers favour beans as a break crop. “Sure, you don’t have to buy fertiliser, it’s great that they x nitrogen, you can combine them early and they give a good entrance to a rst wheat. But when you look at the raw economics, it just doesn’t work for me,” he comments. “Also, beans are a one in ve-year crop, whereas maize could be grown one in two, or could even be grown continuously if you really wanted to, given its pro tability.”

Mr Nott uses prothioconazole to mitigate any problems with fusarium when drilling a rst wheat after maize,

but suggests concerned growers could just not take this risk and opt for spring barley before wheat –particularly if getting a crop in the ground in October behind the maize is too di cult. He also points out that, even if you’re unable to harvest the maize until November, you can always just grow grain maize again.

This year, Mr Nott drilled DSV Likeit, KWS Anastasio and Pioneer P7034 on a eld-by- eld basis. His critical requirements when choosing grain varieties, compared to forage varieties, are:

• Needs to mature relatively early

• Needs massive standing power, with no susceptibility to lodging

• Fusarium resistance

• Eyespot resistance.

Next year he’ll also be growing a block of RGT Duxxbury as a bit of an experiment. Mr Nott says Duxxbury may or may not be a grain variety, but thinks it should mature two weeks earlier than his other varieties; so as long as he is able to harvest it in September, he’ll be home and dry.

It has the standing power he’s looking for, and although it might be weaker on fusarium resistance, it likely will be combined so early that he doesn’t think that will be a problem.

He drills the grain maize at a seed

rate of around 75% of the forage maize rate, planting 80,000 seeds/ha2 compared to 105,000 seeds/ha2 for forage. This is because a decreased seed rate gives better light penetration and increased cob size and structure of the crop.

In a drought year like 2022, this also means the plants aren’t competing so much for water, which was a massive bene t for Mr Nott this year.

He says marketing has not been an issue whatsoever, with so much maize being imported into the country and the ethanol plants in Lincolnshire

running on it.

It’s currently pricing at around £40/t above the price of wheat. But Mr Nott reckons that even once you factor in the £40/t of drying cost, you’re netting a better margin than for wheat due to the lower input costs with it yielding on average 9t/ha, which is comparable to winter wheat (see Mr Nott’s estimate of his expected gross margins below).

Although this year hasn’t been great for maize, he points out it can often yield 10–12t/ha in a good year.

Turn to page 59 to read Mr Nott’s grain maize harvest story. FG

During this time, the company says it has adapted to many market conditions and trends, and gained experience both in the UK and globally – as far a eld as New

Zealand, Australia, and the Congo.

The Master Driers team now have vast knowledge of, and a product adept at, drying all types of combinable crops as well as other

products that have never been near a eld, such as recycled PVC material, the company says.

While not all of its 4,000 customers are likely aware, the initial concept of Master Driers’ type of batch drier – conceived in Italy in the late 1960s – was intended for drying maize and paddy rice. It was only in the early 1980s, when the rst Pedrotti machines landed on the shores of the UK, that the machines began to develop their capabilities for drying the UK’s more traditional combinable crops.

However, the modern Pedrotti Master Drier is seemingly going back to its roots and increasingly being used in varying areas of the country, from the Southwest to as far north as Aberdeenshire, to dry grain maize.

With capacities currently up to 100m3 (roughly 76t of wet grain maize), with larger capacity machines in the pipeline, there is a Master Drier for all farm scales, the company reckons. There are machines currently at work in many locations, helping farmers get their maize crops from the eld to the store in a cost-e ective and timely way, even when moisture levels are

pushing the 40% zone.

Some machines are taking the maize from eld to nished storage moistures, while others are doing the initial dry, from moistures where a continuous ‘tin box’ drier simply wouldn’t cope with grain maize above the 20% mark, Master Driers reckons. It can then either be fed into the wet tip of the continuous drier to nish the drying or dried down to nish moisture to utilise both machines.

Other machines are also doing their drying cycles, to then dump onto a drying oor where the crop can be cooled to make use of these expensive pieces of capital investment!

The beauty of a Master Batch Drier is that they can be used inside or out, and with a lot of the company’s machines now being fully galvanised, they should maintain even better residual values.

If you want to discuss purchasing or hiring machines for the future, feel free to contact any of the team at Master Farm Services who are always happy to help with all aspects of grain drying, power/ generators, conveyors, bins, and storage solutions. FG

“Obviously, cover crops haven’t answered every question,” Mr CliftonHolt says. “They certainly have a good place, but there are limitations.

“Their main value to us is that they assist in developing a soil structure into which we can drill spring crops sensibly, and for the extra nutrients they can provide to the next crop.”

Parts of the farm, especially on Romney Marsh, are high pressure for black-grass. Back in the mid-2000s, Mr Clifton-Holt recalls that some elds became almost unfarmable, with blackgrass reducing wheat yields to only 5t/ha.

“We haven’t completely conquered this challenge yet, but we are getting on top of it, having taken some big decisions,” he explains. “These included reducing cultivation passes and depth, incorporating grass leys, sprayingoff badly infested crops and spring cropping.

“All the things that everyone now talks about to combat black-grass are definitely the way to tackle it. We’re glad we took those decisions early on.”

Spring cropping remains integral to current control tactics, with a double spring crop break within a six-year rotation that also includes two winter wheats, winter barley and oilseed rape.

Surprisingly perhaps, spring barley is not a favoured option. Spring oats and spring beans have become the mainstays and cover crops grown ahead of all the plantings.

“With spring crops, there are three over-wintering options,” Mr Clifton-Holt says. “Leave the ground as a stubble, cultivate it, or plant something that can be drilled into. We took the view that the latter option had to be the best way, and it’s working well for us.”

Any cultivations the ground requires are carried out immediately after harvesting each autumn, and the cover crop drilled as soon as possible after that. The aim is August, but it can be as late as late September, depending on weather and workloads, he admits.

Fine-tuned mixes

In recent seasons, the species mix and agronomy of the covers has

been ne-tuned with the help of the latest research and on-farm trials overseen by Agrii agronomist, Neil Harper. Drilling large 0.3ha plots of individual species and mixes has been very helpful in providing the best insights here.

“Our best mix to date has been based on rye, phacelia and linseed,” reports Mr Clifton-Holt. “We prefer rye to oats because it’s more prostrate. Oats can be a bit oppy and hold more water, making the eld wetter when you come to drill it.

“Phacelia is a great plant –everyone should be growing it. While linseed does a really good job of soil

structuring and soil improvement if you handle it right.”

Following recent trialling with Agrii, the base mix has been tweaked to include a vetch. And buckwheat is also being explored to see whether its phosphate mining ability will help – especially at current prices.

“I was initially reluctant to include vetch, but Neil showed me good evidence there wasn’t any carryover from nematodes or pests that will a ect our pulse crops. One of the reasons we took him on four years ago was to access to this sort of wellresearched support. So, we’ve chosen to run with it.”

Overwinter management di ers depending on the following spring crop. Covers ahead of spring oats are grazed into January and February with a ying ock of sheep, before being sprayed o with glyphosate pre-drilling.

Mr Clifton-Holt is in two minds about the value of the sheep here. “The head is telling us it’s the right thing to do, but we’re not yet totally convinced,” he admits.

“We’re seeing some surface compaction following the sheep

grazing,” Mr Harper points out. “It’s not that they’re being left on the ground too long, but more a matter of soil type. A high silt content means the surface can cap badly if put under pressure when it’s wet. In which case we’ve found spring cereal yields su er where we direct drill rather than cultivating.

“People might argue that this is because of the cover crop. But we want the cover crop because it’s doing the right thing for our soils and holding nutrients. We are trying to be exible with what we do to make the system work.”

As a result, a light spring tine cultivation now routinely precedes spring oat drilling with a Vaderstad Rapid to remove any shallow compaction. This has improved spring oat performance noticeably.

Without sheep grazing, covers before the spring beans are typically sprayed-o with glyphosate around Christmas to reduce the vegetation. With a surprising amount of regrowth in the base and blackgrass, they are usually sprayed again a week before direct drilling with the farm’s Amazone Cayena.

Yields of the spring beans have

de nitely increased since using the cover crop. “They’re running up to around 5–5.5t/ha and they’re certainly more stable,” Mr Clifton-Holt reports. “We don’t have the variability we used to have. I wouldn’t grow beans without them now.

“As we’ve only ever grown spring oats after covers, we don’t know how much they actually contribute to the crop’s performance. Having said that, we’re happy with the 7–7.5t/ ha the oats deliver. And, as they’re on a contract at a decent price, the numbers add up.” FG

They say size isn’t everything, but the Condor direct tine seeder, in 12 and 15 metres, ticks both the size and the flexibility boxes. The 8,000 litre seed hopper, which is carried on the tractor link arms to ensure plenty of traction, is split into 3 - enabling up to three different seed varieties or a mixture of seed and fertiliser to be drilled simultaneously - and all from vari-rate maps.

With up to 200 kg of coulter pressure, the ConTeC pro chisel opener ensures a residue-free seed groove with the seed being embedded into the furrow by the following press wheel on each coulter. It couldn’t be simpler, it couldn’t be more effective and above all it helps you love your soil.

For the perfect seed placement - let’s get straight to the pointLinseed. Vetch.

In the last 30 years, D S King and Sons, farming in Bourne in Lincolnshire, has adapted its business to keep pace with an increasingly challenging industry, while helping to secure a sustainable farming future.

The business currently runs to 688ha of tenanted and contract farmed land and supports a rotation based on milling, feed and seed quality wheat, winter feed barley, OSR, winter beans, linseed and spring oats. Wheat

is grown on a two-year rotation and yields average 9.5t/ha.

“Liquid rather than granular fertiliser has been used on the farm for decades due to its improved accuracy, better environmental

pro le, convenience and better health and safety implications compared to a granular fertiliser alternative,” says Daniel King (pictured). “It has had a huge impact on our

business performance over the years.”

Omex liquid fertilisers are delivered from Bardney in Lincolnshire and pumped directly into the farm’s two strategicallypositioned 50t bunded tanks.

“A key advantage of liquid fertiliser is that there is no risk to our employees unloading heavy bags or lling the spreader,” he says. “We also don’t have to worry about storing bags under cover, which frees up valuable space for crops and machinery.

“Granular fertiliser can be applied up to 24m but there is always going to be over and under lapping, especially on the headlands,” he explains. “With all farmers now having to be more environmentally aware, liquid fertiliser ts the pro le perfectly and in my opinion is really the only option for farming’s future.”

He adds that with a liquid system being so much more accurate, it presents an excellent opportunity to reduce inputs without compromising yield and quality.

If you’re thinking of moving to a liquid fertiliser system, speak to liquid fertiliser expert Omex. FG

Soil health has been broken down into measurable parts to help farmers optimise productivity. Dr Amanda Bennett, AHDB senior environment manager, explains.

Soils are the foundation of agriculture, providing a range of ‘ecosystem services’, helping to regulate climate and water, sequester carbon, and cycle nutrients. It is important that soils are managed appropriately to deliver these functions. Yet, their inherent properties (soil type and geological history) and site-speci c management mean each eld’s soil has its own unique ngerprint.

Cultivations, drainage, inputs, rotation, and cropping sequence all impact a soil’s physical, chemical, and biological make-up, meaning that what works in one eld may fail to work the same way in another. However, to optimise soil health, you need to measure it rst.

The levy-funded Soil Biology and Soil Health Partnership developed and validated a set of practical indicators for the routine measurement and monitoring of soil health:

• Visual evaluation of soil structure (VESS)

• pH

• Extractable nutrients (P, K, Mg)

• Soil organic matter

• Earthworms

• Measures of microbial activity.

The researchers worked with farmers, industry and scientists, to develop a robust, simple, and

visual framework – the Soil Health Scorecard – to group these soil health indicators.

Although putting the indicators in one place was a great step, it is the inclusion of benchmark values that o ers a potential revelation for soil management. For each indicator, the partnership identi ed ‘typical’ benchmark values (expected ranges for UK soil types and climate regions). The scorecard exploits these values to grade the results of site-speci c soil analyses using a tra c light code:

Green (monitor): Typical or optimum result, with low risk of sub-optimal soil conditions (continue to monitor on a rotational basis)

Amber (review): Moderate risk of sub-optimal soil conditions (further examination, such as more frequent or detailed sampling, may be needed)

Red (investigate): Potential risk of sub-optimal soil conditions (more immediate management intervention may be required).

The Soil Health Scorecard is a simple way to generate soil health data. However, for it to be e ective, it is essential to follow sound soil sampling and analysis approaches.

The AHDB Cereals & Oilseeds YouTube account features a ‘how-to’ eld demonstration video, delivered by NIAB’s Elizabeth Stockdale. The

guidance document also details the benchmark values for the physical, chemical, and biological soil health indicators. Importantly, the guidance highlights management recommendations for the current tra c light soil condition – to help you maintain or improve your soils.

This structured way to evaluate soils is also useful if you want to assess changes to soil management. For example, if you plan to change your cultivation technique, simply complete the Soil Health Scorecard rst. Subsequent analyses will provide valuable insight into how soil condition has been a ected, allowing you to make more informed decisions to bene t your farm business. FG

Unlike other schemes, Agreena’s third-party veri ed and tradeable CO2 certi cate ownership sits directly with the farmer, who can choose to keep them, sell them to institutional or private organisations, bundle the certi cates with their crops, or work with Agreena to achieve the best price. The number of certi cates a farmer can earn is based on the adoption of regenerative farming practices, which reduce greenhouse gases (GHG) and remove CO2 from the atmosphere and store it in the soil. Farmers participating in the AgreenaCarbon programme receive up to three certi cates per hectare, depending on the practices adopted, such as sowing cover crops or no-till farming. Depending on current market conditions, the value of certi cates are selling for £20–40 each.

supporting cleaner water run-o . This bene t has resulted in water agencies focused on a clean and safe water supply, such as Severn Trent, partnering with Agreena.

On a practical level, participation in carbon schemes can support longterm climate resiliency for the eld – in addition to providing co-bene ts such as higher nutrient content of crops and increased biodiversity.

Overall, harvest 2022 was good, despite the heatwave which served to highlight the unpredictability that climate change delivers, with many farmers completing harvest in record time.

In addition to a dry harvest year, the geopolitical challenges of 2022 hit UK farmers in agricultural inputs. Defra’s annual price index reported a 33.1% in ation spike for inputs over the last harvest year, largely attributed to rising fertiliser and energy costs. And with Basic Payment Scheme (BPS) payments declining by 35% in 2023 compared to 2020, and energy prices set to rise this winter and in ation potentially rising to 13% by the end of year, these challenges look set to continue.

Soil carbon schemes, such as AgreenaCarbon, are ramping up to provide UK farmers support in retaining their pro tability in the face of these economic challenges with a second revenue potential.

“Carbon certi cation schemes can play a key role in helping farmers

overcome nancial uncertainty by impacting the bottom line through an additional revenue stream from the sale of carbon certi cates, at the same time as improving the environmental sustainability and resilience of their farming businesses,” said Simon Haldrup, CEO and co-founder of soil carbon certi cation company, Agreena.

Carbon farming initiatives for farmers are on the rise across Europe. Agreena has expanded its operations out of Denmark with more than 20 employees in the UK and is now serving 13 countries across Europe, with more than 500,000ha under management and plans to expand into seven new countries this year.

Haldrup says the key to the company’s success has been ensuring farmer control in decision making.

Not only does carbon farming provide an increasingly important additional revenue stream, the longterm bene ts from regenerative agriculture practices support the farm business by decreasing fuel and labour costs, potentially reducing farm machinery and fertiliser costs.

Soils are one of the greatest life-supporting resources on the planet – but currently are falling into a crisis globally, with one-third of our precious soils degraded. Regenerative and sustainable practices are being looked to by leaders and pioneering farmers across the world to support longterm soil health. A key bene t of regen ag is the ability to increase the water holding capacity of soils and

“Harvest 2023 may well be a di erent story. Much will depend on input costs and the weather,” says Thomas Gent, well-known regenerative farmer from South Lincolnshire and the market lead for the UK at Agreena. “What is certain is that farmers will be looking for ways to remain pro table and achieve return on investment from their crops. Carbon farming delivers that return both in terms of a revenue stream and long-term improvements in business resilience.”

AgreenaCarbon for the 2023 harvest year opened on 12th October 2022. Now, farmers are able to log into the platform for free to quickly determine their baseline and estimated calculation of the value available from carbon certi cates. The company has enhanced its programme o ering to include more cultivation techniques this time around: “And there is more exibility for each farmer’s business needs, supporting the pace of adoption of new practices,” concludes Mr Gent. FG

NAAC seed section chairmain, Richard Jones (pictured), comments: “It has been a good year for farmers to keep their own seed this autumn. Hot dry weather, no wet grain to dry, good quality crops and relatively high seed prices have all come together to create a perfect storm when it comes to home-saved seed.

“And who can blame growers for wanting to save some cash, with so much uncertainty in the market? Mobile seed processors across the country have seen a rise in tonnages processed on farm this year, and it

viable and professional mobile seed processing industry.

“I have been processing seed for over 40 years – both certi ed and home-saved – and I cannot imagine drilling the screenings and the cha along with all the weed seeds! It makes no sense. Independent research by the NAAC has shown that the best graded seed is more vigorous, and produces stronger plants with more tillers, which has shown that good quality seed is the foundation of a successful crop.

“Seed size and quality really do matter, and it is questionable whether drilling ungraded seed is economically viable. The skill, technology, investment, care, hard work, research and development in the seed cleaning industry through 200 years has ensured that farmers have goodquality, viable seed, whether it be home-saved or certi ed, to grow a crop to the best potential possible.

Seaweed extracts: Snake oil or sea magic?

Seaweed extracts have risen in popularity, driven by environmental pressures, the soaring cost of fertilisers, improved knowledge of their functions in plants and soil health, and their natural ability to support metabolism in plants through the provision of amino acids, hormones, sugars, nutrients, and phytohormones.

extracts should be included in any IPM programme; not simply as ‘ re ghters’ when plants are under stress, but also as a soil conditioner. Used either on their own, or in combination with other products, they will enhance the e ectiveness of any programme, the company explains.

SeaPhyte apply as soon as the crop has sufficient leaf cover to absorb the product, dramatically increasing root development and exudates into the soil

CropTek Bio Ltd says seaweed

Croptek Bio Ltd o ers a range of products made by specialist manufacturers to work in all types of crops. Most popular is SeaPhyte, which is applied immediately the crop has su cient leaf cover to absorb the product, “dramatically” increasing root development and exudates into the soil, CropTek Bio says. SeaPhyte is followed by further applications of SeaFol which maintains the plant and soil health by feeding soil microbes and boosting crop tolerance to abiotic and biotic stress. These treatments give the best returns when applied as part of a programme. FG

Follow with SeaFol which maintains the plant and soil health by feeding soil microbes and boosting crop tolerance to abiotic and biotic stress

emphasises the importance of having a These treatments give the best returns when applied as part of a programme

Sandy can boost business resilience with smart, independently accredited, easy-to-use software for measuring, managing and monetising farm carbon and natural capital.

To request a demo visit www.trinityagtech.com

Trusted by leading farms of all sizes, including:

“To have baseline data that you know has sufficient rigor gives you the confidence to explore options you otherwise couldn’t. Once you do, the continued revelation of amending management practice makes you realise just what’s possible.”

Craig Livingstone, Lockerley Estateacross the enterprise. He also wanted to test his theory that a slight reduction in total nitrogen is possible, and varied rates to match crop biomass based on varying crop biomass captured using FieldView satellite imagery (see Figure 2 below).

Feed wheats typically get 220kg N/ha and milling wheats a 20kg N/ha top-up. For the trial, the standard dose was reduced to 200kg/N/ha with a further variation of +/-20 based on low or high biomass.

Nutrient use e ciency (NUE) was the driver for these trials but they have proved useful in giving a steer on just how low nitrogen rates could go.

The farmers are using Bayer’s FieldView platform to scrutinise the results and last season’s data does pose a question over how much exibility growers have.