UK DAIRY DAY

What

John Deere’s 5130M put through its paces

DAIRY SHOW

A seven-page sneak peek at this year’s show

What

John Deere’s 5130M put through its paces

A seven-page sneak peek at this year’s show

To find out how we can protect what matters most to you, search ‘NFU Mutual Farming’ or contact your local agency

Covering small farms, large farms and everything in between.

Provided by NFU Mutual Agents, located in rural towns and villages throughout the UK.

Expert advice to identify the health and safety dangers facing your farm and provide personalised solutions for everyone’s safety.

From pensions to investments, life cover to business protection, we’ve been helping customers with their financial planning needs for 95 years.

Editor Katie Jones 07786 856 439 katie.jones@agriconnect.com

Creative Services

Mike Begley

mike.begley@agriconnect.com

Katie Haydock katie.haydock@agriconnect.com

Picture Editor

Marcello Garbagnoli 07815 003 236 marcello.garbagnoli@agriconnect.com

Sales Gemma Thorpe 01772 799 500 gemma.thorpe@agriconnect.com

Account Manager

Mark Jackson 01322 449 624, mark.jackson@agriconnect.com

Classified Advertisements 01772 799 400 fgclassified@agriconnect.com

Advertising Production

Justine Sumner 01772 799 437 Fax: 01772 796 747 justine.sumner@agriconnect.com

Circulation and subscriptions 0330 333 0056 help@subscribe.farmers-guardian.com

Subscription rates: UK £65 a year Europe: £85 World: £95

ISSN 1475-6994

© Farmers Guardian 2024 All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system without the express prior written consent of the publisher. The contents of Dairy Farmer are subject to reproduction in information storage and retrieval systems.

Dairy Farmer, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ

Origination by Farmers Guardian, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ. Printed by Warners Midlands, The Maltings, Manor Lane, Bourne, Lincolnshire, PE10 9PH. No responsibility can be accepted by Dairy Farmer for the opinions expressed by contributors.

Welcome to this bumper 104-page edition, which is packed with farm features from around the country, topical advice from industry experts and an analysis of the latest news and milk prices.

This month also sees us look forward to two important dairy industry events – UK Dairy Day, taking place on September 11; followed by the Dairy Show on October 2.

Both events look set to be great days out, with trade stands galore, interesting seminars and panels to learn from, and some great show cows to look at.

For those of you who plan to go, it will be a welcome break from the farm I’m sure.

It is more important than ever to make sure you get a break. Even if it is only for a few hours in between milkings, speak to fellow farmers and hopefully learn something which can be implemented back at home.

And while news of the current trajectory of dairy producer numbers in Great Britain is extremely concerning, it is also heartening to hear of young farmers still wanting to get into the industry (see pages 30-31), and also see family farms who are committed to the future of dairy farming (p50-52).

With all the negative news currently circulating, it is important we also try look for positives when we can.

There has been a sharp decline of 440 dairy producers in the year to April 2024, with most producers leaving the industry over winter.

What

Managing

Sneak

John Deere’s 5130M put through its paces

92 MILK ANALYSIS

EU butter soars again after slow July

94 NEW PRODUCTS Round-up of products and updates hitting the market 98 GOOD EVANS

‘A bit of continuity is nice isn’t it? There’s something reassuring about it’

Fewer

According to AHDB’s latest survey of major milk buyers, it was estimated there were 7,130 dairy producers in Great Britain as of April 2024.

Freya Shuttleworth, AHDB senior analyst, said although milk prices were higher, they had dropped off ‘substantially’ from the 2022 peaks.

“This, alongside robust cull cow prices, continued inflationary pressure on key inputs and increased interest rates driving up the cost of borrowing, might have incentivised producers to shut up shop as farm margins tighten,” she said, adding increased regulatory pressure could also have been a driver.

NFU dairy board chair Paul Tompkins said the industry could not continue on the trajectory it was on.

For some, a continued low milk price has squeezed the potential of making any profit

BRUCE MACKIE

He said: “Those high input costs are now embedded into the business. The inflationary pressure is still there.”

He added potential environmental regulations were weighing ‘heavily on farmers’ minds’.

While he said it was important farmers ensured they farmed alongside the environment, he also said there was a lot of investment

JTackling the challenges of bovine TB, water quality and the Sustainable Farming Scheme (SFS) must be priorities for new Welsh First Minister Eluned Morgan.

Farming unions have welcomed Ms Morgan, after she officially became First Minister following a vote in the Senedd on Tuesday, August 6.

Huw Irranca-Davies has been appointed as Deputy First Minister, alongside his role as Cabinet Secretary for Climate Change and Rural Affairs.

NFU Cymru president Aled Jones said he was looking forward to working with Ms Morgan on ‘a

range of priority issues for Welsh agriculture’.

He said: “There can be no doubt that the sector is facing some very considerable challenges at the moment, including the requirements of complying with the regulations around water quality, the stress caused by bTB, as well as of course concerns around the SFS.”

Farmers’ Union of Wales president Ian Rickman said he was looking forward to looking with Ms Morgan to achieve the ‘best policy outcomes for Welsh agriculture and our rural communities’.

needed, which margins were not going to cover.

Despite falling producer numbers, milk production in the 2023/24 milk season was only back 0.2% year on year.

In Scotland, the Sco ish Dairy Ca le Association recently released its six-monthly gures for dairy herds and dairy cows in Scotland in 2024, which revealed a net decrease of 21 dairy herds (2.6%) within Scotland to 773.

ere had also been a decrease

JTesco Sustainable Dairy Group (TSDG) has announced it is to reduce its pool of contracted farmers.

The group consists of 400 farmers who supply the supermarket directly with fresh milk for its own label.

It is believed the move has been taken following a reduction in demand.

According to reports, a period of 12 months’ notice will be served on those concerned and applies to all volume bands.

It is not yet known how many farmers will be impacted, but it is thought Tesco has consulted with group members and will initially seek farmers to leave the pool voluntarily.

in the total number of dairy cows to 180,250 – a drop of 0.25% over the same period.

NFU Scotland milk commi ee chair Bruce Mackie said the union was not surprised.

He said: “Increased regulatory pressures, continued in ationary pressure on key inputs, a lack of labour and interest rates still driving up the cost of borrowing remain the

• Ideal for any tractor from 40 to 270hp

• Attach/detach in under 2 minutes

• Unrivalled

main reasons why many have decided to call it a day.

Formed in 2007, the TSDG was the first supermarket aligned contract and consists of the largest group of dairy farmers working directly with a retailer in the UK.

Although milk prices are starting to increase, it is too late for some who have su ered from the gap which has grown between the top and bo om of the price league table, where, for some, a continued low milk price has squeezed the potential of making any pro t.”

NFU dairy board chair Paul Tompkins said: “We want to see more farmers working closely with supply chains rather than fewer, so to hear the opposite happening is not a great thing. We want to encourage more collaboration not less.”

Tesco was contacted for the purposes of the article.

The Royal Veterinary College (RVC) has been awarded a £1.2 million grant from the Bezos Earth Fund to explore how methaneproducing micro-organisms colonise the gastro-intestinal (GI) tract of calves in the first six weeks of life and how they impact the developing immune system.

Scientists says the research will provide vital information on the optimal way to administer any potential vaccine to reduce methane production from livestock.

This project is the first of its kind, and the scientists involved say it could significantly contribute to the fight against climate change.

Methane emissions are released mainly from enteric fermentation, the digestive process which breaks down grass and hay fibres for the generation and absorption of nutrients.

Recent analysis has identified that the main intervention to reduce this type of methane production is to directly target the micro-organism which produces it – methanogenic archaea.

There has already been considerable research looking at how to control the production and formation of methane in the largest stomach of domestic livestock.

Previous studies have indicated the potential of vaccines as a sustainable approach to reducing this methane production by impacting on methane-producing archaea – in part because this approach does not require daily access to the animals.

However, little is currently known about if and how methanogens are

detected and controlled by the immune system.

This RVC study aims to fill this knowledge gap and determine when methanogenic archaea colonise in the GI tract, how they spread through the GI tract in the first weeks of a calf’s life and how they potentially interact with the animal’s immune system.

The study team, led by Dirk Werling, professor of molecular immunology at the RVC, will establish the pattern of methanogenic archaea’s colonisation.

To do this, they will collect blood, saliva, ingesta and colostrum samples from Holstein Friesian calves and their dams.

They will then analyse the samples to identify microbes and create cultures which can be shared for further analysis, as well as modifying and testing the methanogen.

The data collected throughout this process will provide substantial new information to inform the development of a methanogen vaccine.

Prof Werling said: “I believe that the funding will enable us to perform research on a topic which affects us all, global warming, but in a way that both animals and humans benefit from it.”

Dr Andy Jarvis, director of the Future of Food at the Bezos Earth Fund, said this project represented a ‘moonshot’ in efforts to reduce livestock methane emissions.

He said: “The potential to apply the proven success of vaccines in global health to cattle and significantly cut emissions is both ambitious and exciting.”

JResults from the latest badger vaccination trial have proved ‘encouraging’, yet questions remain about costs and scale, say farming leaders.

More than 260 badgers were vaccinated as part of the four-year study, which was carried out across 12 farms in Cornwall.

The results, published by People and Nature, found the percentage of badgers testing positive for bTB fell from 16% to zero during the period which began in 2018.

The study concluded that the case study ‘does not demonstrate a causal link between badger vaccination and

declining bTB’, yet it did suggest that a ‘larger-scale evaluation of badger vaccination’ was warranted.

Researchers also said the study showed that badger vaccination ‘was practically achievable’.

The findings were met with caution by the farming industry, which questioned the size, location and efficacy of the trial.

Dairy farmer Phil Latham said: “If you look at where this trial has taken place, it has happened not in isolation but in the heart of a

cull area. Without geographic separation, I think it is impossible to come up with any meaningful conclusions.

“What they have done is really laudable and it is all useful stuff, but it would have been more useful and meaningful if it had been in an area outside the cull. To me, the information is spurious.”

NFU Cymru vice-president and dairy farmer Abi Reader said any work to try and eradicate the disease was ‘encouraging’.

“Firstly, it is quite a small area and we need to understand the costs – who is going to be respon-

sible for them, as over a wider scale it could be a considerable amount of money?

“We have similar things going on in Wales and farmers can opt to go into badger vaccination areas, but there is a lot of paperwork and administration which goes with it.

“So if the Government would like to see this rolled out further, we do need something to address the costs and any policy barriers.

“It is just a bit soon for everyone to start celebrating this just yet.”

Dan and his family own and run the 300-hectare (741-acre) Cockhaise Farm, near Haywards Heath, West Sussex. The farm is home to an organic autumn-calving herd of 240 Holstein and Friesian crosses. He also contract farms another organic autumn-calving herd of 220 cows at Bore Place, near Edenbridge, Kent.

“ There is no doubt the last year has been a challenging time for organic dairy farmers

It is the time of year again to switch off the vacuum pumps, stop making ice and shut the farm gate as we hit the peak three to four weeks of our summer dry period.

After what has been a reasonably good growing season, the cows are in great condition heading towards calving later in August, with it bringing the hope and budgeted improvement on the last 12 months.

There is no doubt the last year has been a challenging time for organic dairy farmers across the country, with many deciding they have had enough, either leaving the milk pool altogether or taking their farm out of organic.

We have been through similar thought processes, but are keeping faith with the production system we believe in and confidence that Arla will be able to back up its positive words with a milk price that follows the same trajectory.

There is no doubt that financial stress can have a great impact on the people in and around the farm, with belts being tightened and manpower reduced at times to help ride through the stormy waters.

The last four months has also seen half of my team head to pastures new, something I have been lucky enough not to experience in the last 10 years. Entering the recruitment market can feel like rolling the dice sometimes and this year has certainly had plenty of ups and downs.

At home I now have a settled team with a great blend of experience and youth, all brimming with energy and excitement for the season to come.

On our farm in Kent, our new farm manager decided to pull out at the 11th hour for personal reasons, leaving a sizeable hole to fill.

In these situations, people either fade away or step up to the mark and I have been hugely impressed with the way the team down there have responded to the ever-changing situation, giving me the confidence to be able to hand over more day-to-day responsibility, thus giving me a little breathing space while we work out plans for the coming season.

One of my key goals this calving season is to maintain our excellent work in rearing calves, both for ourselves and to sell to others. We have used a similar system for many years now, based on feeding six litres per day whole milk to calves, but a recent talk at an Arla meeting has me questioning this.

Much of the research now points to feeding eight litres/day and feeding 4kg of hard feed once weaned, double our current level, leading to improvements in lifetime production traits. With the price of organic milk and hard feed, this would impose a huge increase in the cost of rearing our heifers, so I need to see if there is a middle ground where we are looking to make improvements, but not at the expense of the profitability of our business.

Becky Fenton and husband Paul milk 200 pedigree Holsteins under the Springlebee prefix at Centenary Farm, a Cheshire county council farm. In 2021, they bought a farm in Staffordshire and they plan to farm there once the new dairy set-up has been built.

“ I’m very honoured and privileged to have been asked to judge Dairy Farmer of the Year for the British Farming Awards

In my last column, I wrote about how we were embracing a zero-grazing system, which initially increased our milk yield but significantly added to our workload. Forget that.

A few weeks later, yields dipped, grass quality was poor and we were fed up with the extra tractor work and scraping copious amounts of muck. Also, it eventually stopped raining.

So, we decided to turn the cows out and feed them a buffer of grass and maize silage, alongside mash pro and a 21% dairy nut. This change substantially increased the yield by about 5.7 litres per cow and it has sustained.

I have just got in from milking and feeding calves. Currently we have 90 calves on milk, which is a bit of a tedious task after night milking.

We started weekly fertility visits about 12 months ago and, at the time, it felt fantastic getting everything in-calf to sexed semen. Now several months later, we are flooded with heifer calves.

The new calf shed is full, the new stable/log store has calves in it and God knows where the next calves born are going to live.

Calves in the new calf shed are doing exceptionally well and we are really pleased with the design and the functionality of the shed.

We applied for the automatic calf feeders through a Farming Equipment and Technology Fund grant and it was accepted. We plan to install one mixing station with four feed stations, hopefully this will improve growth rates. Next, we need to build the weanling shed.

We went to Nantwich Show recently and, considering I only entered five days prior, we did alright. We took

one milking heifer straight from the field in her working clothes to the show and were thrilled to achieve reserve junior champion.

This family line is my favourite, one of our original families from when we started farming in 2008, tracing back to a herd favourite, Shottle Peta EX96 (8)e 6 stars.

This year I have stewarded two Cheshire Farms Competition classes. Firstly, the black and white class, where we had a great day visiting five different herds. What stood out to me was that all five operated different systems, each doing a fantastic job.

I often think that perhaps we should push more for yield, but in reality, I believe we should farm in a way which suits our system, land, infrastructure, finances, family, etc. One size does not fit all.

The second class I stewarded was buildings. We visited a first-class potato farmer, among some other great farms, but the farm which impressed me most was a single gentleman finishing 500 beef cattle on his own. His shed design was simple but effective. Credit to him, and thank you to all who entered.

I’m very honoured and privileged to have been asked to judge Dairy Farmer of the Year for the British Farming Awards.

I still can’t believe I have been asked, and I look forward to the judging day at Farmers Guardian head office, where I hope to be wowed by the finalists.

Investing in milking technology is not always about chart-topping cow numbers or yields. For one dairy farmer it is about steady growth, efficiency and keeping it simple. Natalie Noble reports.

The 64-point rotary parlour at Appledore Farm near Crediton, Devon, milks around 320 cows per hour at peak production.

That £1 million investment has reduced Chris Blake’s morning milking time from four hours to less than two – a valuable return, he says. But when it comes to technology, he likes to keep things simple.

He says: “There are too many people trying to sell you things and make it complicated. It should not be complicated; get as much milk from grazed grass or forage into your bulk tank as cheaply and efficiently as possible.

“Invest in technology where it makes sense for your business –where it will improve your efficiencies and have definite cow, people and business benefits.”

Farming in partnership with his parents, Bill and Jan, and with his own young family, future-proofing the business is a priority.

So when ground was broken

last year to install the GEA T8500 rotary parlour, complete with parlour building, collecting yard and comprehensive handling and foot care facilities, it felt like a milestone for the farm’s future.

Appledore is home to 600 autumn-calving Irish Holstein Friesians, producing an average milk yield of 8,000 litres and 640kg of milk solids per cow on a 305-day lactation.

From the farm’s 158-hectare (390-acre) grazing platform and home-grown forage, his cows produce some 4,400 litres of milk, representing around 56% of total yield, with a 16% or 18% cake fed through the parlour.

Supplying Arla on a manufacturing contract, composition currently sits at 3.61% protein and 4.42% butterfat.

Chris wants his cows to be happy, healthy and fertile – efficiently converting the farm’s forage into milk, while producing the next generation of heifers. His philosophy is simple; making the most out of grass during the grazing season (mid-February/

March to November), along with silage and home-grown feeds during the winter housed period (November to turnout).

The Blakes’ dairy operation also incorporates a 300-cow unit in Winkleigh. The former beef and sheep farm, purchased in 2020, has undergone a dairy conversion and now boasts a 24:48 swing-over parlour with collection yard, handling facilities and sand-bedded cubicles for winter housing.

It also comprises a 78ha (193-acre) grazing platform and was self-stocked from the home farm.

The Winkleigh farm replicates much of the Appledore home farm, says Chris.

“The principles are the same; to get as much in the bulk tank from the forage we grow as efficiently as possible.”

As well as happy cows, he wants

The farm has a 158-hectare (390-acre) grazing platform.

happy sta . And, as the business has grown over the years and cow numbers have increased, milking through the 54:54 herringbone parlour at Appledore twice daily became di cult and time-consuming.

Peak production, morning milkings were taking up to four hours, resulting in cows spending more time standing in a collecting yard and less time grazing, lying down, drinking or at the feed trough.

And it was not just the cows Chris was concerned about, the

long milkings were also hard on his sta . He worried about the impact on them and future labour, too.

Turning back the clock, the Blakes’ herringbone parlour was originally installed in 2001 as a 40:40 before it was expanded to a 54:54 in 2015, to accommodate more cows.

is previous upgrade gave them insight into how investment and technology needed to keep up with their business’ pace of growth and

ambitions, while also addressing labour concerns.

“We could have spent more than £150,000 on upgrading the parlour again,” explains Chris.

“But we knew that we would not be able to further increase cow numbers and we would still have long milking hours and concerns about sta ng.

“Finding and retaining reliable, competent people is, I think, one of the hardest challenges in the dairy sector.”

Robots did not make sense for the Blakes’ system, with the furthest elds up to 2km away from the parlour.

A rotary parlour, however, o ered the throughput with minimum labour as well as improved cow comfort and ow.

He says: “It is how we have grown our business; maximising milk from where we can walk cows and stocking the platform relatively high.”

Robustness and reliability were

rCarrying 238 R1 heifers and 250 R2 heifers to mitigate TB risk/stocking

rAverage total concentrate use: 1.8t/cow

rUp to 8kg cake fed in parlour, average 3kg/cow

rAutumn-calving: 12-week block (Mid-August to November)

rTop 50% of milking cows and heifers artificially inseminated (AI) to Irish Holstein Friesian,

important qualities when choosing the new parlour, as was integrating data from the system into the cow management so ware without hassle. And Chris was not looking for all the bells and whistles of optional features, either.

“I wanted something that had been proven to work well in a similar system to mine,” he says.

“It is essentially New Zealand Milfos working equipment and GEA technology. It uses the same GEA milk meters that we had used previously, which I like, and it is robust and simple.”

e 64-point rotary has adjustable rotation speed, automatic cup removers, milk meters, cluster drop system and automatic teat sprayers, which Chris says make milking more e cient, puts less strain on sta and provides consistency.

e set-up also features an automatic wash and an under-pass

everything else AI’d to Aberdeen-Angus beef

rHeifers synchronised

rCows and heifers averaging 77% six-week in-calf rate

rTypical replacement rate at 18-20%

rAnnual herd health review – all stock vaccinated against BVD, IBR and leptospirosis

rMastitis: 22 cases per 100 cows

system, which allows sta to quickly and safely access the wash room and control stations.

A main control screen displays cow data, including average daily milk and what she is being fed.

It allows the operator to instruct how the cow will exit the parlour, for example to segregate her for treatment if required.

Cows are ed with CowScout collars which work with the parlour’s automatic identi cation and sorting system.

ey also o er a more accurate means of monitoring individual and whole herd health, productivity and fertility – proving particularly useful for heat detection – and health indicators such as rumination.

“Rumination data helps us spot ‘o ’ cows, which in a rotary – where cows are in and out so quickly – acts

as a technical pair of eyes,” says Chris.

Cow ow and handling are common stressors, so Chris wanted to get it right.

“I probably spent more time trying to work out my exit area and handling, than the rest of planning.”

His handling system is comprehensive: a main exit race passes cows through a footbath, but he can also sort cows to the le or right using auto-segregation gates.

Segregated to the le , cows can be ltered down a herringbone race for arti cial insemination, with a separate walkway for sta for safety.

Cows can be segregated and guided to the foot trimming crush, which also has manoeuvrability around it for a telehandler.

Down the righthand race, he can hold 40-50 cows for actions such as pregnancy diagnosis.

“ e exit area is as important as the parlour set up and technology you buy into. Managing big numbers of cows e ciently is not just about buying big equipment. You need to think about the logistics,” says Chris.

With the rst cows moving through the new rotary on November 20, 2023, Chris says it is still too early to tell what the true productivity value of the parlour is –but milk is up and cows and people are spending a lot less time in the parlour.

He says: “We did not invest just to increase yields, the value is in how it has changed the working environment and use of time.

Mr Blake’s philosophy is to make the most out of grazing, home-grown feeds and silage. The £1 million investment includes the GEA T8500 rotary parlour, parlour building, collecting yard

“With 600 cows milked twice daily, in our old parlour that was seven to eight hours plus wash down for two people. We would also have to get rid of cull cows pre y quickly

rMaize silage: 35kg

rGrass silage: 20kg

rRape: 2kg

rMaize distillers: 2kg

rRolled wheat: 1.5kg

r18% dairy cake: 3-4 kg

in the spring because milking would become really hard work.

“With the rotary we have not had that pressure, so we have milked more cows this spring and into the summer, in a be er working environment, in less time and with less labour.

“Morning and a ernoon milkings are now both under two hours and we can milk with just one person if need be; just slow the rotary down a li le and be about 15-20 minutes slower.”

Chris is also due his annual herd health review and expects to see a reduction in mastitis cases.

“Our somatic cell counts have been be er since moving to the rotary. During the winter, our cell count averaged 40,000-50,000 lower than the past couple of winters, which were around 120,000.

He has also noticed a positive change in cow behaviour, with cows quieter and more relaxed through the whole milking process.

Chris says it is important to weigh up what you need and what are just expensive additions. For example, he opted out of control panels on every point, which would have cost up to £200,000 more.

“It was not going to make any di erence – and certainly not put £200,000 more milk in the bulk tank. I am really happy with what we have got here now; the technology and infrastructure serves us well and I am con dent about it as part of our investment for the future.”

Do you make maximum use of your robot

Using ForFarmers OptiRobot our Dairy and Robot Specialists are able to assess whether the interaction between robot settings, nutrition and health is optimal. It often turns out that small changes can make a big difference; Our Robot Specialists can help highlight areas where you can improve with the unique ForFarmers OptiRobot which provides:

9 Greater insight

9 More opportunities

9 Increased returns

For more information speak to your local ForFarmers Robotic Specialist or visit >

0330 678 0982

info.uk@forfarmers.eu www.forfarmers.co.uk @ForFarmersUK

‘Should there be so much emphasis

Charlie Taverner is the farming futures policy lead at the Food, Farming and Countryside Commission. He has a dairy farming background and previously worked as an agricultural journalist. He also has a PhD in the history of food.

quick quiz: What is the most popular action in the Sustainable Farming Incentive (SFI)?

In April this year, farmers across England were receiving £74.2 million for establishing and maintaining herbal leys – the action known as SAM3. Not only was this by far the most funded of the 23 available, it accounted for a quarter of all the money paid out. Based on a rate of £382 per hectare, just under 200,000 hectares were being managed with a mix of grasses, herbs and legumes. While the breakdown of that land hasn’t been published, this interest makes sense, particularly among livestock farmers. By integrating more diverse swards into their grazing platforms, they can potentially increase soil health, build resilience against drought and reduce fertiliser use, while receiving a reasonable payment, even after their costs. For many, it’s a no-brainer.

The question is whether it’s the right thing to do. For individuals, it comes down to whether they can make the leys work on their land and for their business. That money isn’t free cash: among the challenges are getting establishment right, working out which herbs work best in your soil, and maintaining that

diversity over at least three years. But plenty of grazers report that eventually the liveweight gains and milk yields stand up.

The bigger issue is whether the Government should put so much emphasis on herbal leys. These latest statistics come from a report published in July by the National Audit Office (NAO), reviewing Defra’s Farming and Countryside Programme. Only the wonks whose job it is to study policy will likely read the entire, wordy document.

But that’s a shame because the report gives a precious insider view on schemes now critical to farming finances, the environment and the shape of the countryside.

A central aim for SFI is to encourage at least 65% of land managers to adopt nature-friendly farming on at least 10% of their land by 2030. Herbal leys are a classic example. The varied and deeper rooting plant species help regenerate life in the soil as well as providing habitats for creatures above ground. By letting plants go to flower, a field becomes more attractive for pollinators.

Of course, there are other ways of providing these benefits. There has been chatter, especially online, about some land managers hastily converting established grassland to get the payment, without necessarily committing for the long run. Permanent pasture could be carefully managed to allow native species to return, though that obviously takes years. For the moment, the Government has landed on herbal leys as one of its tools of choice.

This reflects the report’s main critique of the whole scheme: its ‘iterative’ nature. This is the way SFI is being rolled out gradually and tweaked over time. It also allows farmers and landowners, wherever they are, to pick and mix options on pockets of land, without being tied into a suite of changes. This approach ensures feedback can be rapidly reflected, and has probably contributed to the SFI’s rising uptake. But, as the NAO points out, it has big drawbacks. First, by leaving the scheme open-ended, the overall

“ It’s vital all farmers feel they can trust that the Government is taking big, strategic decisions on their behalf

costs can balloon, as can the amounts poured into certain actions. at is money that might have gone towards more ambitious nature recovery projects, which might nd their budgets squeezed.

Second, it’s unclear if this piecemeal programme is achieving its overarching aims. It’s great that farmers everywhere are being incentivised to boost biodiversity, but Defra has itself admi ed the funding will need to become more targeted. If this happens, practices that are becoming standard, such as the herbal leys, might receive less money or lose it altogether.

It’s li le wonder that farmers are sceptical about the Government’s direction. Earlier this year, there was uproar about SFI’s possible impact on food security. In the latest round of Defra’s own opinion tracker,

just 40% of respondents said they were positive about their farming future.

ere are some low-cost ways that Ministers could rebuild dwindling con dence. ey could be upfront about their long-term plan for how they want Britain’s farmers to farm. ey could publish a transparent and accountable land use framework that balances the need for food, nature, housing, energy and all the other demands. And they could produce a regular impact report on how the various schemes are a ecting food production and hi ing environmental targets.

As we are realising, the new payment regime is reshaping how our land is used. But farming is complicated enough without these wider worries.

at’s why it’s vital all farmers feel they can trust that the Government is taking big, strategic decisions on their behalf.

High concentrate diets and acidic clamp silage are some of the main causes of sub-acute ruminal acidosis in dairy cows. Katie Fallon reports.

Arelatively common nutritional condition seen among the UK’s dairy herds, subacute ruminal acidosis (SA ) is a result of the rumen pH dropping below six for a prolonged period of time.

Resulting in the burning of rumen papillae, ca le with SA are unable to absorb volatile fa y acids, and therefore unable to absorb energy e ciently.

Generally caused by the overfeeding of concentrates, a lack of bre in the diet, wet and acidic silages, or turnout onto lush grass,

SA is a reasonably common condition, but is not always easy to identify.

Debby Brown, veterinary technical manager at Dugdale Nutrition, says the condition can o en go under the radar in herds and cause niggling issues that are not always picked up on, or it can be more severe and show clinical signs.

She says: “Whether it is diagnosed or not is very dependant on who is spending time looking at those cows.”

Clinical signs of SA include

variable consistency of faeces, an increased amount of cud balls seen throughout the shed, reduced cudding rate and a reduction in the number of cows lying down and comfortably cudding.

She says: “In some situations, you will see a drop in bu erfat in the milk, and if you are striving for more milk, you will not achieve it. It de nitely holds milk back.”

Mrs Brown says some cows will be more a ected than others, depending on yield and the amount of cake being supplemented in the parlour, but it can also be a whole herd issue.

She adds: “You can walk

through a shed and feel that the cows are not quite right.”

Mrs Brown says diagnosis of the condition is based on walking around the cows and seeing clinical signs as well as in milk production. She says it is also possible for vets to carry out a rumenocentesis and take a sample of rumen content to check for SA , but the results are not always reliable.

“If it is not something that a herd has had historically and something has changed – such as suddenly changing onto a wet, acidic silage, or feeding a lot more concentrate – then you will see

SA develop fairly quickly,” says Mrs Brown.

In this case, she says the condition is relatively easy to treat with dietary adjustments to raise the pH of the rumen, including the use of rumen bu ers.

“It might be that you add a bit more straw into the ration to slow down digestion or balance the silage out, or reduce the amount of concentrate and put a bit of dry forage in the ration,” she adds.

If SA has been present in the herd for a long period of time, Mrs Brown says readjusting the

Debby Brown

diet is the only option in terms of treatment.

“In this situation, a lot of the time cows will have to go through a dry period and come back into lactation, so you are looking at a 12- to 18-month cycle before the rumen recovers,” she says.

She adds: “Some cows will never recover – it depends how long-term the damage is. e longer the SA goes on for, the more damage to the papillae and the longer it takes to recover.”

When looking at prevention, Mrs Brown advises ensuring diets contain enough bre as well as regularly sampling forages to combat acidic silages before they are fed to the herd.

She says: “It is a case of being on the ball more than anything else, so you can stop it before it starts.”

Mrs Brown advises that, as a minimum, silages should be sampled when changing clamps or if changes in the silage are noticed throughout a clamp.

“I would advise testing at least monthly. If you see sudden changes in the cows, even if you have not changed clamps, it is worth resampling to see if something has changed,” she says.

Apart from the sale of youngstock and any additional farm diversification projects, most income on any dairy unit is earned through milk yield and milk quality.

Milk yield is easy to measure, but analysing milk quality is typically dependent on monthly milk recording and/or tests carried out by the milk purchaser.

In both cases, the information obtained will be several days out of date by the time the results have been received.

Assessing milk quality at each milking has previously been prohibitively time-consuming and expensive, but there is now a new way to achieve daily milk analysis which does not require any additional labour capacity.

In addition to measuring rumination frequency and duration to assess the general well-being of dairy cattle and activity patterns to identify the tell-tale signs of heat events, the SenseHub Ecosystem from MSD Animal Health also enables herd managers to gain an improved understanding of their herd’s milk quality at every milking.

Two in-line milk monitors, both of which are compatible with any type or make of milking parlour, assess a range of key parameters as each individual cow is being milked.

The SenseHub Dairy In-Line MilkPlus Sensor monitors critical milk data,

such as yield, fat, protein, lactose, blood and conductivity.

Meanwhile, the SenseHub Dairy In-Line Somatic Cell Count Sensor provides individual somatic cell count (SCC) results within two minutes of the start of milking.

Data from these sensors is automatically displayed as easy-to-understand graphs and reports in the SenseHub app, which makes it simple for herd managers to keep a close eye on milking trends and milk quality of individual cows.

Animals can also be monitored on a group basis to guide longer term herd management decisions.

For farmers who want access to the milk quality insights offered by the MilkPlus and SCC sensors (plus the ability to control a SenseHub automatic sorting gate), but do not want to monitor for heat and health, the SenseHub Dairy system is compatible with Allflex Livestock Intelligence’s Electronic Identification (EID) eartags.

This entry-level EID-based package is available via the new SenseHub Essential application plan and provides farmers with the option to upgrade to the wider SenseHub Ecosystem at any point in the future.

Producer Sally Williams has developed a rigorous calf health and hygiene strategy, providing a

Sally Williams and her parents, Alex and Ruth Wilson, run a herd of 350 Holstein Friesians, housed indoors, with six robotic milkers.

e family also rear all their own beef progeny, including dairy bulls. In total, they manage 1,200 head of ca le.

Since coming back to work fulltime on the farm in 2009, Sally has focused on se ing up a series of calf health and hygiene management protocols that help ensure every calf is as robust as possible.

“We have a top-notch calf-rearer who is really motivated, making sure everything is done right for every calf, every time,” she says. “Mortality is less than 0.5%.”

e family’s calves are housed in hutches, ‘buddied up’ in pairs, with up to 100 calves in total at busy times.

Sally says the hutches are completely mucked out and disinfected between one group of calves and the next, before being li ed o the ground to expose them to UV light for at least three weeks before new calves come in.

e calf rearing area is twice the

J As well as maintaining the overall quality of livestock bedding, results from an on-farm trial have shown that using a natural microbial bedding conditioner can also help deliver an impressive reduction in ammonia emissions.

Lientjie Colahan, environmental product manager at Lallemand Animal Nutrition, says: “The mix of bacteria, enzymes and highly absorbent carrier absorbs excess moisture

challenge and maintain calf health, welfare and performance, says Sally.

“We need all the cogs working together to make sure the calves are bombproof, paying meticulous a ention to detail in everything from feeding to hygiene,” she says.

“If there is ever a blip in one area, calves can usually withstand it because all the other pillars are still in place and we have laid strong groundwork.”

required size, so only half of it has calves at any time, leaving the remaining ground to rest. Strict hygiene protocols are followed for milk buckets and teats.

To prepare hutches for new calves, the calf-rearer spreads a microbial bedding conditioner on the ground before pu ing straw in, and then adds more conditioner on top of the straw.

Once calves are in, Sally says they apply the microbial bedding conditioner, Eazybed Pro, which supports the growth of positive microbes,

in bedding and helps maintain a positive microbial bedding condition.

“This results in reduced ammonia emissions and improved air quality.”

She adds: “The trial showed that the bedding conditioner reduced NH3 emissions by up to 50%. The air quality in the shed was maintained as a result of the maintenance of bedding dryness and microbial quality. The reduction of smell was particularly noticeable.”

three times a week to help maintain overall bedding hygiene and reduce the prevalence of bacterial problems.

“We started using it a couple of years ago when we were having challenges with crypto a ecting calves,” says Sally.

“An outbreak is a re ection on management. I wanted a proactive solution to help avoid future problems, as you are never going to be able to completely get rid of crypto in the calf’s environment.

“ e bedding conditioner is a gentle product for people to handle and it has de nitely helped us keep on top of protozoal and bacterial issues.”

Bedding hygiene is just one of the many management factors that combine to help reduce pathogen

Another crucial element of calf health protection at Clackmae Farm is their plentiful approach to colostrum management.

Sally says: “Newborn calves are given four litres of pasteurised colostrum via a tube, then for the rst ve days they are fed a highfat pasteurised milk containing high-quality colostrum.

“ e next stage is a pasteurised milk and milk powder mix.

“We feed far more than anyone else I have come across – calves are drinking 12 litres per day by three weeks old.”

A home-mixed blend is o ered from birth and calves are usually consistently eating it a er a week to 10 days.

As well as colostrum intake, further preventative health measures include a dose of feed additive each

strong foundation for herd performance at Clackmae Farm in Berwickshire. Dairy Farmer reports.

morning and night. Tannic acid powder is also added to the milk once a day from birth.

e la er helps protect against cryptosporidiosis and coccidiosis, also giving protection against coccidiosis beyond weaning. At 10 days old, calves receive a Rispoval intranasal vaccination.

Sally says: “If any calf begins to look a li le o -colour, our calf-rearer always acts quickly, giving them an immune support gel to help stabilise the gut, along with Rehydion and a Metacam injection, before problems have a chance to develop.”

At six to seven weeks old, calves move from the hutches into the shed in groups of seven, where they remain on milk and are weaned very gradually at nine to 10 weeks old,

moving from twice-daily milk feeds to once a day, then coming o milk completely.

A weigh-band is used regularly from birth to monitor growth, with all dairy and bull calves managed and fed in the same way until they are six months old.

Sally adds: “We are a closed herd and, other than airborne disease spread, so many potential problems are down to gaps in monitoring and management. It is up to us to maintain and evolve our calf-rearing protocols; nothing is xed.

“ ere will be new health challenges appearing and we are always open to trying new things as new research comes up.”

Calves are gradually weaned at nine to 10 weeks old, moving from twice-daily milk feeds to once a day, then coming off milk completely.

Achieving the highest possible outcomes for your livestock starts with the care and attention which goes into youngstock. In this series, Neogen, Trouw Nutrition and Virbac have teamed up to explain best practice when it comes to health, hygiene, genetics and nutrition.

Increasing the volume of milk replacer fed to calves prior to weaning is a proven strategy resulting in long-term benefits to fertility, survivability and lactation performance.

This has been demonstrated by Trouw Nutrition’s Lifestart trials, which compare groups of calves fed different volumes of high quality milk replacer. These results should not come as a surprise, says Dr Aaron Brown, Trouw Nutrition’s technical sales manager, as allowing calves to feed to appetite mimics their natural behaviour when feeding from their dams.

He says: “Young calves are driven to consume milk and allowing them to satisfy this behaviour from birth will support reaching the peak of the feed curve as quickly and efficiently as possible.

“The aim should be to match the natural feed curve so the peak allowance is typically consumed from as young as a few days old.

“When calves are allowed to feed to appetite, signs of hunger stress, such as vocalisation or unrewarded visits to the feeder, are much reduced.

“A survey commissioned by Trouw Nutrition showed 65% of dairy farmers are feeding their calves six litres or less of milk replacer per day. There is a misconception that if calves are fed less milk, starter feed consumption is optimised, but research shows it is not as simple as this.

“Studies show calves fed ad-lib or high volumes of good quality milk replacer grew more rapidly and had greater acceleration of solid feed intake when weaning commenced, compared with groups with more restricted access.”

In the first four weeks of their lives, calves are monogastric and therefore unable to properly digest solids.

Elevated feeding strategies over this period can optimise development and integrity of the gastrointestinal tract which promotes greater intakes throughout the cow’s life, according to Dr Brown.

Trouw Nutrition’s Lifestart trials compared calf groups made up from 86 Holstein heifers fed on two different rates of a high-quality milk replacer.

Dr Brown says: “Calves were split into two groups as calves and were fed twice-daily with one group receiving four litres of milk per calf per day and the other group receiving

eight litres of milk prior to weaning at eight weeks old.

“Those calves fed at the higher rate reached their target weight for first service 16 days ahead of the calves fed at the lower volume. These calves also went to yield an extra 400 litres on average over their first lactation.”

The study monitored the calves from birth and some of the group are now in their sixth lactation.

Results for the cohorts showed that 17% more of the group fed the higher volume of milk replacer finished their second lactation and ongoing survival rates in subsequent lactations were also significantly higher.

Dr Brown says some farmers opt for lower feeding rates because of concerns about cost.

He says these concerns are misplaced as much of this additional investment will be recouped in the short-term due to reductions in the number of days to first calving and lower incidence of disease.

He says: “Using an average cost of milk replacer of 37ppl, feeding an extra two litres of milk from birth to weaning will cost £32.

“However, the daily cost of feeding a heifer while she is not in milk is £2.30/day and so if age at first calving is reduced by eight days, this offers a feed cost saving alone of £20.

“Add in the earlier and higher

● Feed milk replacer at the concentration and volume required to achieve targeted growth rates –typically at least 10 litres per day fed as a minimum of two feeds

● Calves have a higher

energy requirement in cold environmental temperatures, requiring an average of 0.50.6MJ of energy for every 5degC drop in temperature below 15degC; adapt feeding regimes to meet this need

● Maintain a high standard

of cleanliness throughout the preparation and feeding process

● Ad-lib clean water from birth is essential for good rumen development and feed intake

● Drinking from a teat, rather than a bucket or trough, helps the calf satisfy its urge to suckle

milk yield and savings from reduced disease incidence the return on investment really starts to stack up.

“High growth rates in the first few weeks of life have been shown to demonstrate long-term benefits in relation to fertility, health, survivability and lactation performance.

“During the first four weeks of life, feed conversion rates for calves are high, as calves will convert more than half the weight of the feed they consume into growth.

“The first 50 days of a calf’s life are crucial for organ development, specifically the liver, lungs, heart and mammary tissue, so if milk is restricted over this period, animals cannot make up for this shortfall in later life.

“Furthermore, feeding higher volumes of milk over the first three to four weeks will not have any impact on the consumption of starter feed, as it is minimal at this age.

“Concerns that increased feeding rates in very young calves can lead to overspill of milk into the rumen are unproven.

“Calves are typically fed four litres of colostrum in one feed immediately after birth, with a second colostrum feed of two litres shortly afterwards. Most calves will consume this amount, so milk volume can usually be increased to eight litres within the first week.”

Dr Brown says supporting young calves with increased energy intake at a young age can also help prevent the often crippling effects of infections causing scours, such as cryptosporidium.

He says: “Allowing higher intakes helps calves to recover more quickly from cryptosporidium because the energy supplied

supports hydration and helps the calf to mount an immune response. This feeding regime will promote the development of the gastrointestinal tract, thus improving the ability of calves to digest solid feed as they approach weaning age.”

Choosing a milk replacer which can be fed at higher volumes is important, with composition closely resembling cow’s milk with a higher percentage of dairy protein.

Raw whole milk is typically composed of 32% fat, 26% protein and 36% lactose on a dry matter basis.

Milk replacers which are high in digestible dairy protein and the correct fatty acid balance will reduce the likelihood of scours and abomasal bloat, Dr Brown says.

“Calves fed a milk replacer with a higher proportion of dairy protein and a fatty acid content

with a composition which is as close as possible to the equivalent in cow’s milk will achieve higher growth rates and improved organ development.

“Milk replacers containing more short- and medium-chain fatty acids are more easily digestible by the calf. They can, therefore, be fed at the higher rates recommended in the Lifestart trials with minimal risk of gastral upsets.

“Trouw Nutrition milk replacers have optimal vegetable oil content to provide better quality fats with a similar macronutrient content to cow’s milk.”

Dr Brown advises feeding milk replacers as close to appetite as possible in the first four to six weeks.

He advocates careful observation of milk intakes of individual

calves to guide feeding rates, as some calves will increase their consumption more quickly over time than others.

He says: “Higher intakes can be achieved with two feeds of five to six litres each per day, but feeding more frequently is always desirable. The use of automatic feeders can enable ad-lib provision of milk replacer, promoting higher intakes.

“Feeding eight litres or more per day or more of a high-quality milk replacer to pre-weaning calves unlocks their genetic potential.

“Proven benefits include a reduced age at first calving, increased lifetime productivity and improved profitability, resulting in a reduction in the cow’s carbon footprint.”

l The combined expertise of Neogen, Trouw Nutrition and Virbac provides valuable insight into best practices for health, genetics and nutrition. By implementing these strategies, farmers can improve the quality and performance of their herds while promoting better animal welfare. Investing in youngstock through preventative care, genetic evaluation and high-quality nutrition is a key factor in achieving successful livestock production.

Running two dairy farms in a co-operative model is proving costly in the Czech Republic in terms of logistics, labour and equipment costs.

With that in mind, the agricultural co-operative Kozichovice, with a total of 600 milking cows, will merge its two farms on to one location, with the goal of saving 15% in operational costs.

e co-op was founded in 1950, then re-established again in 1989, with 230 small land and property owners, following the Velvet Revolution, which saw the end of communist rule in the country.

Farm manager Jakub Fukal

A Czech co-operative plans to merge its two dairy farms in 2025 to save 15% in operational costs. Chris McCullough reports.

explains the farm is located in the middle of Czechia at an altitude of 465 metres above sea level, with an average annual rainfall of about 450mm.

He says: “We cultivate 2,100 hectares of crops, run two dairy farms and also operate a biogas plant.

“Elections within the co-op are held every ve years and all members elect seven members on to the management board, from which one overall manager is chosen.

“In total, we run 600 cows of the Czech red breed, much like the Fleckvieh or Simmental breed, across the two farms.”

e herd’s average yield per cow is 9,100kg of milk at 3.8% bu erfat and 3.5% protein. Each farm has 300 cows which are milked twice a day.

Cows are arti cially inseminated with genetics from Czech and German bulls.

Mr Fukal says: “Our breeding

strategy is to have strong animals with healthy legs, bones and regular udders. Hand in hand with healthy animals goes longevity, which is also what we aim for.

“One of our goals is to try to improve the cow’s udder shape as we are struggling somewhat with udder irregularity.

“Heifers undergo genomic testing and are paired with suitable sires to achieve our breeding goals.”

e two farms within the co-op are operated independently of each other. Two employees feed the cows and clean the barns, while two sta milk the cows on shi rotations.

In total, there are 16 people on both farms as part of the milking team. e co-op employs a total of 67 people, 24 of which work in livestock production.

Cows are milked using two milking parlours – a DeLaval seven-a-side herringbone and a Westfalia six-a-side auto tandem.

Mr Fukal says: “Cows are milked twice per day. We start milking in the morning at 3am and nish at 8am, then in the a ernoon we start milking at 2pm and nish at 7pm.

“Our milk is sold to Madeta, the largest dairy processor in Czechia, which handles one million litres of milk per day. It is sold to the processor through a marketing co-operative, which delivers 100,000 litres of milk per day to the dairy.

“Our daily milk production is 16,000 litres and we are trading at 0.1095 Czech Koruna per litre [36ppl].”

Kozichovice continues to invest in the farms, upgrading equipment and infrastructure, and has plans to merge the two farms to one location.

Mr Fukal says: “Last year, we bought a new feed wagon, and the

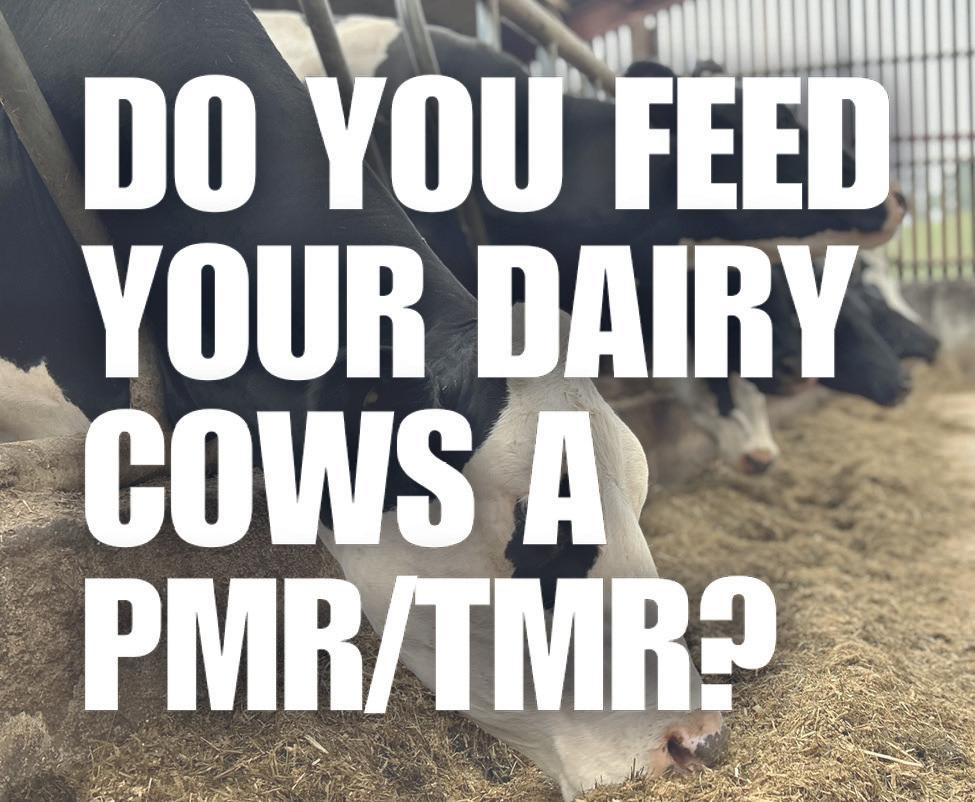

rCows are housed in groups all year round according to their lactation, and fed an appropriate total mixed ration (TMR)

rCows are fed with a Storti horizontal feed wagon on one farm and the other farm uses a vertical feed wagon of the same brand

rThe TMR for one cow per day consists of 24kg of maize silage, 10kg of alfalfa and peas, 7kg of complete feed mix, 2.5kg of rape meal, 0.5kg of straw and two to four litres of water depending on the dry matter of the TMR

ventilation system in the dairy barns was upgraded.

“We have plans later this year to construct a new DeLaval 15-a-side parallel milking parlour on one of the farms with an 18,000-litre milk tank.

“And we plan to construct a new cow barn for 320 dairy cows some time in 2025. We will also be modernising the barns for the dairy calves.” e total investment for these

projects is expected to be about 50 million Czech Koruna (£1.6m).

Mr Fukal says: “ e main reason for this signi cant investment is because in 2025 we aim to merge our two farms together into one location to reduce operating costs.

“We also plan to sell our own beef and milk through self-service vending machines on-farm.”

Free next working day UK mainland & Ireland delivery ORDER BY 3PM when you spend £100 online excluding VAT Make your life easier with our Electric Farmer Crush Do ring us if you’d like more information!

As with most dairy farms around the world, the main problem on this co-op farm is sourcing experienced labour.

Mr Fukal says: “At the moment, this hard labour job is not regarded as lucrative within society, especially because of weekend shi s, night

shi s, etc. However, we try to o er people appropriate salary conditions and employ people mainly from Czechia.

“Other challenges we face are uctuating milk prices and the EU Green Deal will have some major implications.”

From farmer cattle crushes to wooden blocks, we have everything you need to keep your cows' feet healthy!

"Thank you to Steve and his team for an excellent and very quick service and very competitive prices every time, thanks!”

Breeding company Viking Genetics recently held a conference where updates on research and milk price predictions were given. Ellie Layton reports.

Astudy carried out in 2023 has compared the performance of three-way cross-bred cows against pure-bred Holstein cows.

Carried out by Italian professor of animal science Dr Giovanni Bittante, the study looked at a range of body measurements, as well as different metrics of the cows’ productivity and production efficiency.

The study involved 791 cows, 440 cross-breds (comprising a cross of the Viking Red, Montbeliarde and Holstein breeds) and 351 purebreds, managed across two herds.

Within each herd, cross-breds and pure-breds were managed as one group, being reared and milked together and fed the same diets.

The heart girth, height at withers, and body length were measured, and body condition score (BCS) was determined on all cows on a single test day.

Dr Bittante said: “The body weight of 225 cows was used to develop an equation to predict weight from body size traits, parity and days in milk, which was then used to estimate the total body weight

of the group and protein and lipid contents of each animal.”

Dr Bittante said that he found that combining measures of production and efficiency traits related to body composition and the energy cost of production seemed to be more effective criteria for comparing cross-bred and pure-bred Holstein cows than just milk, fat, and protein yields.

“Evidence suggested that maintenance energy requirements may be closely related to body protein mass and we believed Holstein and crossbred cows may be different in body

JAlso speaking at the conference, dairy market analyst Chris Walkland, said he predicted a plateau in prices ahead of autumn.

He said: “We have had a good run of milk prices, which has been echoed globally, although I think it may be ending as we start to see a plateau trend amid steadying prices.”

Despite the spotlight on the

dairy sector not always being positive, Mr Walkland reassured farmers that this was an exciting time to be in the dairy industry, with significant investments from processors and fellow dairy farmers being made.

Mr Walkland said: “Although producer numbers have fallen over the past decade, by up to one third in some counties, businesses are expanding and,

composition, so we measured their net energy for maintenance,” he said.

“On the same day that body measurements were collected, individual test-day milk yield and fat and protein contents were retrieved once from the official Italian milk recording system.”

It was found that cross-breds had similar predicted body weight and net energy for maintenance when compared with the Holsteins. However, net energy for mainten-

as a result, we are still seeing the same production levels.”

However, he added the cost of staying in production was increasing and environmental demands were also stronger.

He said: “European politicians are forgetting about food production, and they are obsessed with emissions and water regulations.

“Of course, there needs to be a handle on nitrates, water

ance of cross-breds was 3.8% lower than that of the Holsteins.

He said: “We also found that in our environment, cross-bred cows yielded 4.8% less milk and wasted 3.4% less energy than the pure-bred Holsteins. When comparing genetic groups with production traits, it suggested that the cross-breds and pure-breds have the same ability and efficiency per unit of body protein mass.”

Looking towards the end of life, Dr Bittante observed cull cow carcase traits in a separate trial. This trial involved data taken from 18,014 cross-bred and Holstein cows slaughtered in four slaughterhouses, with all cows graded using the EUROP grid. Dr Bittante said carcases from culled cross-bred cows graded 13% higher for fat compared with culled pure-bred Holsteins from the same herd. He said: “Despite Holsteins having a higher body weight, cross-bred cows exceeded their carcase weight and their higher fat level translated to their lower maintenance cost. Holsteins displayed a higher protein level, which comes at a higher production cost.”

quality and similar aspects, but one day they will wake up and say we have pushed this too far; food is too expensive and there will be a revolt.”

To help secure the market for dairy products in the future, Mr Walkland said there was a need to ‘prove consumers wrong’. He said: “We need to give them permission to eat our dairy products without guilt.”

B r i t ishfarmingproducts createdbyexpe r t s Bir t i s h farmingproducts createdb y e x p e r st

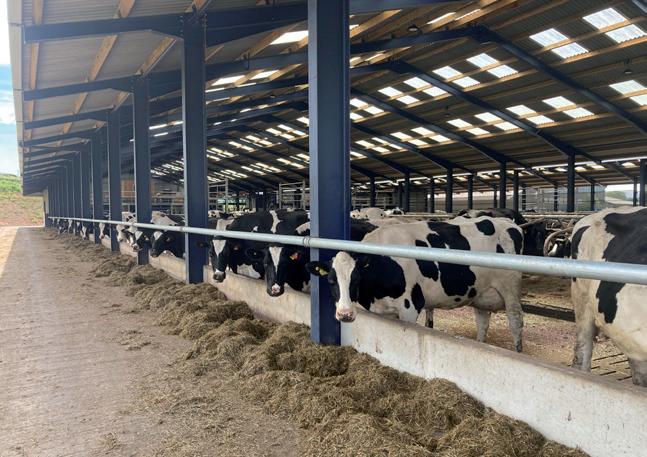

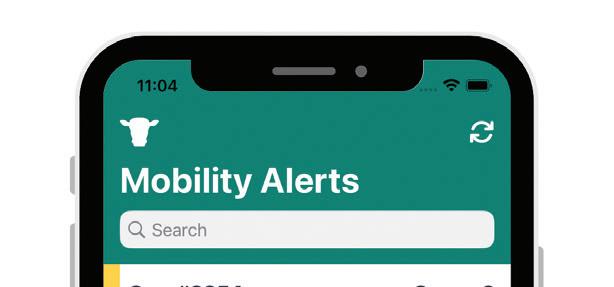

A series of farm events organised by Stride, the UK dairy mobility initiative, highlighted the importance of prevention strategies in reducing the consequences of poor mobility. Dairy Farmer reports.

Mobility remains a major issue on dairy farms, but a greater focus on prevention will help reduce mobility issues across all farm systems, according to Ma Dobbs, chair of the Stride technical board.

Speaking at a farm event, he told delegates that this was one of the conclusions from the recent national mobility survey conducted by Stride, a not-for-pro t industry initiative headed up by Ceva, HerdVision, IVC Farm Vets, Neogen and Zinpro.

He said: “As much of 80% of foot health problems are a ributable to previous lameness in the herd, so farms need to implement comprehensive prevention protocols to help avoid mobility issues becoming a chronic problem.”

Gillian Whitehurst, clinical director at Glenthorne Vets and regional head of IVC Farm Vets, said once a cow becomes lame, in ammation will damage the foot tissue, predisposing cows to repeat problems.

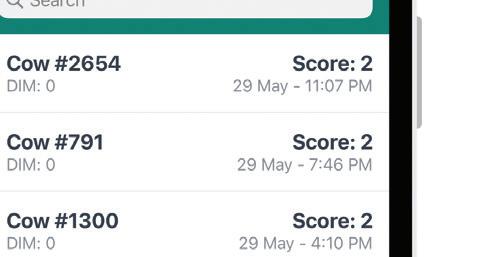

She said the key to prevention was early detection and prompt e ective treatment and added there needed to be a shi in a itude towards mobility scoring. She said it must be seen as an e ective way to pick up changes in mobility quickly and not just as a benchmark or to ful l the requirements of the milk processor. Frequency of mobility scoring needs to be increased too.

She said: “Any cows agged up as score two should have feet checked within a maximum of 48 hours. Cows at score three must be checked

Ms resh said camera technology could also be used to score heifers and dry cows, and Jonathan Huxtable, of Zinpro, said the transition period was crucial in helping reduce the consequences of compromised mobility.

quicker. It is inevitable that if you mobility score more frequently, there will be a peak of score two and three cows to treat initially as you get on top of problems, but this should be a short-term issue.”

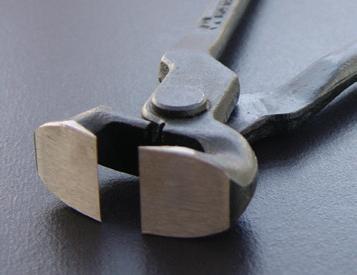

Ms Whitehurst advised that a ected feet should be trimmed and a block applied if required.

“Cows should also receive a non-steroidal painkiller to help red-

uce both pain and in ammation. She said blocks should be checked and replaced every four weeks as necessary, explaining that a poorly positioned block was worse than no block.

e biggest reasons given for not mobility scoring cows more o en are the time taken to both score cows and interpret the results and having suitably trained sta . is means many farms rely on a Register of Mobility

Scorers-trained professional and inevitably less frequent scoring.

Georgia resh, of HerdVision, said: “One option to overcome these issues and to ensure problem cows are spo ed sooner and more consistently is to use automation.

“Camera technologies mean milking cows can be mobility scored every day with the data analysed and problem cows reported sooner and automatically to an app accessible by people across the farm team.”

He said lameness is a transition disease and increased lameness is seen in cows which do not transition well. He added compromised mobility in transition cows would result in lower dry ma er intake (DMI) in both pre- and post-calving cows.

He said: “If DMI is reduced, cows will mobilise body fat, including fat from the foot pad, which will predispose cows to foot problems.

“If we manage transition cows be er, we can ensure be er DMIs and prevent loss of the footpad.”

He said transition cows needed plenty of space and advised no more than 80% occupancy in transition cow housing. Cubicles should be larger to accommodate the increased size of heavily pregnant cows.

He said: “If cubicles are too small, cows will nd it harder to get in and out, increasing the stress on the ankles, hooves, tendons and ligaments, resulting in a greater risk of compromised mobility.

“Set a target of zero lameness in dry cows. Carry out a hoof check two weeks before going dry and rectify any problems at this stage. en putting cows in a good environment with reduced stress will give them the time to rest and recover.”

e n a b l e s m o r e i n f o r m e d b r e e d i n g d e c i s i o n s t o c r ea t e f u t

Accelerate your herd’s potential G E N E a d v a n c e ® i s t h e n e x t s t e p f o r b ui l d i n g p r o g r e s s i v e,

h e r d r e p l a c em e n t s , w i t h c u t t i n g -

g e d i g i t a l t

s a n d t o

- t i e r g e n e t i c s . O ur t ea m b e c o m e p a r t o f y o ur t e a m ; p r o v i d i n g

e x p er t i s e , p er s o n a l i s e d b r e e d i n g p l a n s , a n d o n g o i n g g en et i c

r e v i ew s t o p r o d u c e b e t t e r c o w s f a s t er

W e ’ r e d e d i c a t e d t o a c c el e r a t i n g y o u r h e r d ’ s g e n e t i c p r o g r e s s J o i n u s

C a l l u s t o d a y o n o r s c a n t h e Q R c o d e t o

d i s c o v e r h o w w e ’ r e m a k i n g f a r m i n g B e t t e r T o g e t h e r . 0 1 2 7 0 6 1 6 6 8 1

qr code

There are several positives offering welcome news for the dairy sector following the unprecedented challenges over the past 12 months. Dairy Farmer reports.

According to the latest Kingshay Dairy Costings Focus Report, following a sharp drop in milk prices to an average of 36.49ppl in July 2023, values have steadily risen – but they still do not cover the full cost of production or provide a fair return for family labour for many farmers. e gap between the highest and lowest milk prices has also uctuated, peaking at 13.8ppl in March 2023 before narrowing to 11.6ppl in March 2024.

Kathryn Rowland, Kingshay’s senior farm services manager, says: “It is clear the UK milk market is changing as retailers and consumers demand more. Given the increased focus on climate change, it is essential that the market can deliver premiums to cover the extra e ort and costs on-farm.

“Milk processors like First Milk are already o ering premiums for regenerative farming practices and, going forward, it is likely that the range in pricing within contracts – let alone between them – is going to widen.”

An insight into trends over the past 10 years reveals that while average milk yields have slightly increased and remain in the mid 8,000 litres per cow range, milk solids have hit a new record of 646kg/cow, marking almost an 11% increase over the past 10 years, outpacing the 5.4% rise in milk yield. is is most likely due to producers focusing on feed e ciency and ful lling their milk contract requirements, the report says.

Average herd sizes have increased by two head, year-on-year, and now

stand at 219 cows compared to 185 in 2014. Stocking rates have also seen a rise, reaching 2.39 cows/hectare compared to 2.25 a decade ago.

e atrocious weather means that, unsurprisingly, milk from forage has decreased by 3% on last year to 2,691 litres/cow. Although, Scotland managed to buck the trend with a 16% year-on-year increase.

On the health front, herd health has generally improved in nearly all areas. Mastitis cases have decreased to an average of 26 cases per 100 cows, indicating be er management, facilities, breeding and recording.

However, lameness has seen an increase which, having declined annually since 2020, jumped by four cases per 100 cows to 37. is was

likely due to poor weather conditions in 2023/24 a ecting grazing access and leading to longer housing periods. Mobility scores remain identical to last year, with 5.9% of the herd scoring 2 or 3, suggesting changes in lameness recording practices.

Fertility trends have returned to normal following the hot summer of 2022/23, which negatively impacted oestrus cycles. e calving interval has narrowed back to match 2021/22 levels at 393 days, with days to rst service at 70 – one day longer than in 2021/22.

e 200-day not-in-calf rate was 12%, which was one percentage point below 2021/22, while the infertility culling rate dropped back to match the previous year’s 6.7%.

e cost of an extended calving

interval has dropped from £5.89/day per cow to £4.88/day, mainly due to lower milk prices and feed costs.

E ciency varies widely across production systems, with all-yearround calving herds with a housing focus producing the greatest margin per cow (£2,495/cow) and autumn/split block calving herds with a grazing focus giving the highest margin per litre (29ppl).

Similar trends in milk prices were seen in organic herds, with the margin over purchased feed per cow dropping by 13.9% to £2,048, compared with £2,380 the previous year. Although organic herds are much larger compared to conventional, herd size has also grown by 19% over the past decade to 243 cows.

A former accountant has taken a leap into dairy farming, with milk from his 40-cow herd sold direct to the public on the Isle of Man. Chris McCullough reports.

Starting up a dairy farm on the Isle of Man was a goal Carl Huxham set himself over 10 years ago, and it is one he achieved by keeping things simple.

Back in 2006, just a year a er graduating with a business degree, Carl purchased 34 hectares (85 acres) of land to run a suckler herd on alongside his day job as an accountant.

In 2007, with the help of a £20,000 Young Farmers and New Entrants Start-Up Grant, Carl was able to build the rst shed that the parlour is now located in, and this heralded the foundations of what is now Cronk Aalin Farm in Sulby.

Carl says: “I le accountancy in 2012 with the aim of milking cows and retailing the milk direct to doorsteps. I purchased a secondhand milking set-up comprising a Fullwood 16-point parlour with a 1,600 litre bulk tank and water heaters, all for £8,000.

“ e cubicle sheds were completed that year and I installed the parlour over a six-month period. During that installation, I changed the system to an eight-point

swingover, adding ACRs and milk meters. With the infrastructure in place, I purchased 24 heifers and we started milking, initially feeding the milk to calves.”

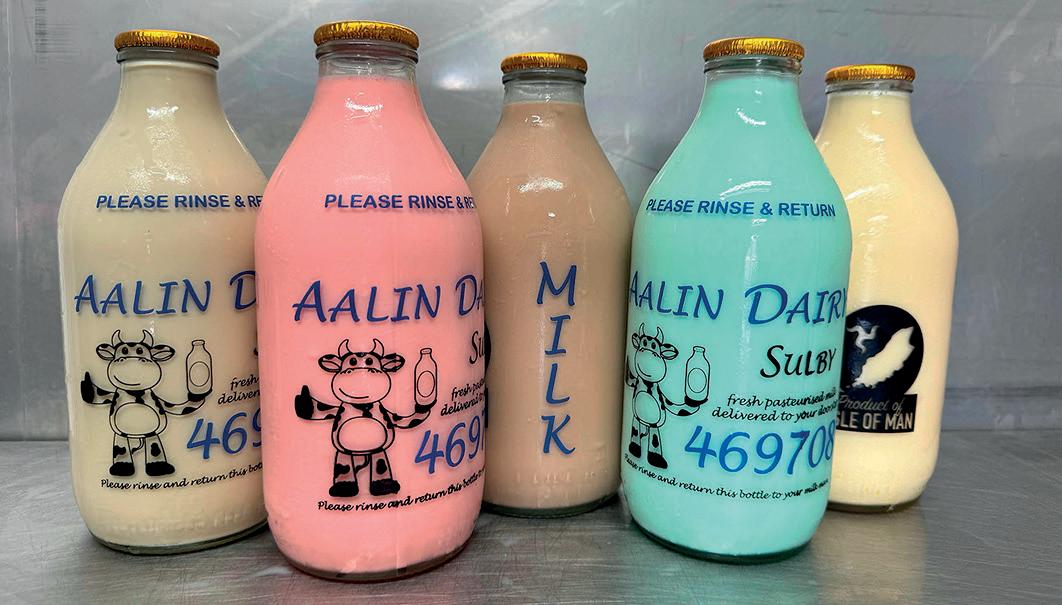

In 2014, together with his wife Sarah, Carl launched the Aalin Dairy business producing milk and delivering it straight to customers.

He says: “In the beginning, I milked the cows, washed the empty glass bo les, then pasteurised, bo led and delivered the milk.

“Over the last 10 years, the milk rounds have increased to nine. We are now using electric vans to make

the deliveries, covering the top half of the Isle of Man.

“Our farm really has been built from scratch over the past 18 years.”

A house on the farm was nished in 2015 and an indoor silage pit was built in 2022.

In 2020, Carl was able to buy 8ha (21 acres) from a neighbour.

Herd

Cronk Aalin Farm is home to a modest-sized herd of 40 cows, which started o dominated by the Holstein Friesian breed. Carl is now adding the Montbeliarde and Ayr-

shire breeds into the mix to suit land conditions more.

e average yield of the herd is 6,000-7,000 litres per cow per year at an average 4.8% bu erfat and 3.4% protein.

Carl says: “Being on a hill farm ranging from 480 feet to 900 above sea level, we need a cow that has strength and good feet, which is why I now favour the Montbeliarde. I personally like red cows, therefore all of our chosen AI bulls must be red.”

Cows are normally grazed from March to November in one group, and are housed in the winter on cubicles bedded with straw.

When at grass, cows are supplemented with 2kg of a 17% concentrate, which is fed in the parlour. is ration changes in the winter to grass silage mixed with pea and barley wholecrop and rolled oats, with a 20% cake fed at 4kg/cow/day.

Carl says he aims to rear ve replacement heifers per year using AI.

He says: “Currently, we are running a Limousin sweeper bull, but there is li le demand for beef cross calves locally.

“ ey are generally reared to about three or four months old and

rSurplus milk is made into yoghurt

rYoghurt and cream from Aailin Dairy has won Great Taste Awards

then sold to other farmers on mainland UK.”

e Huxhams employ one fulltime employee on the farm and another full-time employee to work in the milk processing room. A team of 11 delivery drivers work on a rota system delivering the milk on Mondays, Wednesdays and Fridays.

Carl says: “I milk the cows and oversee the farm operations, while Sarah looks a er all the paperwork and the customer side of the business. All our milk is sold at 85p per pint, delivered direct to the customer base by our drivers. We use pint glass bo les to sell the milk in, which are washed and reused, [therefore] increasing our sustainability.”

rThere are another 27 dairy farms on the Isle of Man and they all supply the island’s central processor, with one also retailing some milk to customers

Even though Carl has invested in the farm since its humble beginnings, he continues to enhance it, but at the same time keeps things simple.