Mike Begley

Picture Editor

Marcello

marcello.garbagnoli@agriconnect.com

Head of Commercial Solutions

Mike Hartley

Account Manager

Mark Jackson

Classified

Advertising Production

Circulation

Subscription

Dairy

Iusually try to steer clear of ‘weather talk’ in these columns. Mainly because more often than not the weather will have changed before the magazine lands on your kitchen table.

But in this case I am hoping the weather does indeed change, with much of the country now desperate for rain.

Over the last few weeks we have seen heatwaves, extreme weather warnings, hosepipe bans and official drought declarations for some parts of the country.

And while England experienced the driest July since 1935, the reason for the current drought situation is also down to the rainfall we have had in previous months. For the UK as a whole, nine of the last 12 months have been drier than average.

Livestock farmers are having to deal with

limited grazing and the prospect of lower conserved forage stocks going into winter, due to lighter silage and maize crops. Many will be looking at the options of buying-in feed, opening up precious winter feed clamps early or reducing stock.

This feels like a double whammy, given the well-documented rise in input costs farmers are also having to factor into their budgets. What is clear from milk production data is that production globally is down on previous years and for the UK in particular that trend looks set to continue, given the current weather and feed situation (for more on global milk shortages, see pages 92-93).

What impact will this have on the price of milk? I’ll ponder this while I join farmers up and down the country in perfecting my rain dance.

DAIRYING

RISK

Farmers are having to make di cult decisions ahead of the winter time, as they turn to feeding winter forage to ca le following the drought.

A lack of grass has meant farm ers are using their winter feed now with concerns already for forage stocks in the winter.

Amy Eggleston, a dairy farmer from Leicestershire, said they had not had any ‘proper rain’ since early June.

“My dad has been farming here his whole life and says this is the driest he has ever seen the

farm. Essentially, we do not have enough grass to feed the cows.

“We are using our winter feed now to feed the cows,” she said.

ForageAid trustee and Som erset farmer James Winslade said while nobody had asked the charity for help yet, there could be a serious forage shortfall this winter.

“Quite a few southern dairy farms are feeding rst cut silage and some have yet to get their second cut as there is no grass around,” he said.

J ieves are looking to make up for lost time a er the Covid19 pandemic, with Land Rover Defenders the s spiking in 2021, NFU Mutual has warned. e insurer has urged farmers to be on their guard, despite new gures revealing that the cost of rural crime fell for the second consecutive year in 2021, down 9.3% to an esti mated £40.5 million.

Rebecca Davidson, rural a airs specialist at NFU Mutual, high lighted security measures, rural crime initiatives, quieter roads and community vigilance had

played their part in suppressing countryside crime in 2021.

But she warned there was no time for complacency, as initial claims gures for the rst quarter of 2022 showed costs were up by more than 40% on the same per iod the previous year.

Her comments followed the pub lication of its latest Rural Crime Report, which found Land Rover Defender the costs were up 87% to £2.6m in 2021, as criminals stole the iconic vehicles and stripped them down.

According to Met Office statistics, England experienced the driest July since 1935.

“While there may be an oppor tunity for another cut, most will not have their usual three cuts.

“Hopefully it will be a short winter or the charity will be needed more and more.”

It comes as processors an nouncing prices spoke of the markets ‘stabilising’.

But NFU dairy board chair Michael Oakes said there were still question marks over where the prices would go next with milk pro duction not picking up and traders he had spoken to trying to gure out if the market had peaked or if it was the ‘normal August lull’.

“ ere is still not a lot of con

dence from farmers to produce more milk.

“ en you have commodity traders who buy forward wonder ing whether they should be buy ing or they risk being le without product,” he said, adding there did not seem to be much news to push the price back down.

Farmers were not pushing for more milk, said Mr Oakes, and were considering their options ahead of the winter period.

He said many were consid ering selling cows ahead of winter with prices good, which would have a knock on e ect on production.

JA group of more than 60 farmers has called on the Government to support a transition to regenerative agriculture in response to soaring fertiliser and fuel costs.

According to the alliance, brought together by the Sustainable Food Trust, the crisis has highlighted the scale of the UK’s dependence on imported inputs. It said a shift to regen methods was ‘essential’ for longterm domestic food security in an increasingly volatile world.

JNinetyfour per cent of respondents to a new Countryside Alliance (CA) poll have rejected the claim that the BBC covers rural issues fairly and impartially.

The survey, which canvassed more than 3,400 CA members, was launched in response to the broadcaster’s recent announcement that it had set up an internal content review for specific programmes.

The poll found 92% believed the BBC’s national news failed to represent rural issues, while 89% felt the same about Countryfile 79% about The Archers.

While there may be an opportunity for another cut, most will not have their usual three cuts

JAMES WINSLADE

Milk prices need to remain at record highs to preserve the Sco ish dairy herd, a er the latest Sco ish Dairy Ca le As sociation (SDCA) gures showed there were 13 fewer dairy herds since the start of the year.

at was the message from NFU Scotland milk commi ee chair Gary Mitchell as the SDCA revealed its latest set of gures.

ere are now 819 herds in Scotland with average cow num bers standing at 231, an increase of two animals per herd since the beginning of January.

Lanarkshire was the county most a ected by the reduction in the number of farms involved in dairying, with a net loss of four herds. Dumfriesshire and Wig townshire each lost three herds. e gures also showed that the percentage of cows being o cially milk recorded had remained static at 72%.

Jane e Mathie, SDCA secre tary, said: “ ere is a continued

There are 13 fewer dairy herds in Scotland since the start of the year.

increase in individual cows regu larly monitored for somatic cell count, pregnancy diagnosis and health testing, especially Johne’s, IBR and BVD, through milk samples.

“ is gives more accurate infor mation to assist be er nutrition, fertility and health management.”

Mr Mitchell said: “Milk prices must continue at record levels and keep running ahead of unpreced ented input costs if the latest dairy herd gures for Scotland are to be maintained in 2023.”

He added it would be fascinat

JFor some years now, farm groups have been asking Govern ment where food production sits in policy terms, writes Abi Kay.

But now, they are starting to ask where it sits in practical terms too.

At the moment, we are hear ing a new story every day about how viable farmland is being lost to housing developments, solar farms or afforestation.

This rush to plant trees to help meet the country’s net zero target is particularly con cerning for the tenanted sector.

Recently, Defra reported a 3% reduction in the area of land let under Farm Business Tenancies (FBTs) between 2019 and 2020 – the first ever drop since FBTs were introduced in 1995.

The Tenant Farmers Association has laid the blame for this contrac tion at the feet of landlords who have been quick to take back land in order to cash in on Government tree planting schemes.

And with a further £44.2m being allocated by Ministers to plant 2,300ha as part of the Nature for Climate Fund, the

ing to see the gures in January 2023 following the in ation agri culture is facing.

“Not only are many dairy farmers receiving the highest milk price they have ever seen, but they also have a long list of costs and invoices to match,” he said.

With processor prices now approaching or surpassing 50ppl, Mr Mitchell said it was vital they remained high.

“ at price momentum must be maintained if the size and scale of Scotland’s dairy herd is to be preserved,” Mr Mitchell said.

problem is set to get worse. We cannot let this situation continue – a way has to be found to balance all the competing demands on our land.

Defra Secretary George Eustice has, belatedly, come to the same conclusion, promising recently to put together a land use strategy, despite his earlier reservations.

But the chances are he is on his way out when the new Con servative leader comes in.

No one wants to see the state in full control of land use, but the market is already being distorted

J

e biggest increase in inter est rates in 27 years will provide a further squeeze on margins for those with borrowing as the Bank of England a empts to slow in ation.

e bank announced the sixth consecutive increase, with rates rising from 1.25% to 1.75% in August.

Martyn Dobinson, partner at Sa ery Champness and a mem ber of the rm’s land and rural practice group, said it would hit farm businesses with borrowing.

“ e climate is looking very di cult now for farm and other rural enterprises operating with the tightest margins and li le, if any, prospect of respite as we move closer to a likely reces sion,” he said.

Interest rates were set to rise from 1.25% to 1.75% in August.

by Government targets. Ministers have a duty to protect farmers, farmland and food production, and that means taking action to mitigate the impacts of their earlier decisions.

They can start by keeping the pledge of a land use strategy alive.

Ketosis has a domino effect on the stability of the health of your herd, allowing damaging and costly disease conditions to topple their performance.

average, 28.5%1 of cows suffer from ketosis with SOFT* cows especially at risk. Identifying and protecting these vulnerable animals

a big step towards

cows

Dan and his family own and run the 300-hectare (741-acre) Cockhaise Farm, near Haywards Heath, West Sussex. The farm is home to an organic autumn-calving herd of 240 Holstein and Friesian crosses. He also contract farms another organic autumn-calving herd of 220 cows at Bore Place, near Edenbridge, Kent.

Although you will be reading this in September, I am currently writing this in mid-July, with temperatures knocking on the door of 40degC and my feet in a cold bucket of water to stave o self-combustion in my tropical o ce.

Although the temperatures are certainly on the high side, we are fortunate it is only really for a couple of days, before normal summer weather resumes later this week.

In recent months, I have spent more and more time looking at the cost of running an autumn calving herd through winter, with ever-escalating feed costs making the production of milk uneconomic.

However, with every dry summer we receive, I feel relieved we are able to dry all of the cows o to far ung corners of the farm onto standing hay, therefore taking the pressure o the grazing platform.

As a simple self-feed farm, we are just not set up for bu er feeding, so the ability to stockpile grass through the good months to feed out now is our saving grace.

I have been fortunate enough to have had several groups of farmers and advisers here over the last month, although by the 10th visit the well-trodden route around the farm was looking a bit worse for wear.

I love the challenge of hearing honest views on what we are doing here. It is important I am able to come out of my comfort zone in order to keep on making progress.

Topics for discussion included the breeding of our cows, with question marks as to whether they really were the same 550kg average as when weighed four years ago.

We have nailed our colours rmly to the Irish Holstein Friesian mast over the last seven years and we have seen the bene ts of improved fertility and constituents, but I can’t a ord to milk bigger cows, particularly on an organic system, so will be weighing cows this winter to make sure we are still on the right track.

One of the other main talking points was slurry handling and the confusion over upcoming legislation and how that a ects what we do on the ground on our individual farms. At Cockhaise we have a lagoon which wraps around our cubicle shed, so completely incompatible with any sort of cover system.

We also use straw for bedding which then needs to be dug out once a year, again, not compatible with a cover.

We also use a Briggs irrigator to apply the watery slurry that comes through the weeping wall, a system which enables us to follow the cows round during the grazing season. But will this be allowable?

One thing for sure is that at some point in the near future we will need to invest signi cant capital in order to continue dairy farming, but for the time being I am happy to watch and wait, both for the clari cation on the rules, but also how other farms tackle these issues.

Before we start calving later in August, I am o for two weeks of yet more heat in Corfu. Having had our last three years of holidays cancelled, this is long overdue and a great opportunity to leave the farm, turn o my phone and have some much needed R and R.

As the challenges become greater in the coming years, it is really important to look a er yourself and those around you.

Becky Fenton and husband Paul milk 200 pedigree Holsteins under the Springlebee prefix at Centenary Farm, a Cheshire county council farm. In 2021, they bought a farm in Staffordshire and they plan to farm there once the new dairy set-up has been built.

Istart this column with achievement. A er several years out of the show circle, we decided it was time to get back out there. So at the end of July we a ended our local agricultural show, Nantwich Show. e show has been cancelled the previous three years and was newly relocated this year. We decided to take just one third calved cow and three calves for our boys to show.

I am pleased to say we came away with overall su preme dairy championship. is is something that we are proud of and the rst time we have achieved this accolade in our showing history.

All three of our boys took calves into the showman ship class and our eldest son took home the award for champion calf handler.

We have always been fond of showing and I can appreciate a good cow, but two things I always remem ber about judging of any kind really is ‘it is only one per son’s opinion’ and ‘is it best to have one amazing cow for everyone to see at a show or a good uniform herd of unrecognised cows at home?’

One thing myself and fellow exhibitors noticed at Nant wich Show was there was a real engagement and interest in the livestock from the general public. We were happy to answer questions they had and let them stroke the ani mals. We sometimes take for granted how lucky our chil dren are to grow up on a farm. A farmer once said to me ‘if you have not lived on a farm you have not lived at all’.

Since our farming journey began, we have always been keen to build our portfolio. is has always proved us well when applying for farms and other opportunities.

We recently entered the Cheshire Farms Competition and were fortunate to win two classes and were awarded rst prize in the ‘combined west and east Cheshire county farms’ class and also the and ‘dairy herd black and white’ class. is led us to be in with a chance in the overall supreme competition. Unfortunately we did not win but I would like to congratulate the Beck family of Sandbach on their success. We a ended their open evening and it demonstrated that they were worthy winners.

Here at Centenary Farm, we graze our cows day and night in the summer months, alongside silage fed twice daily.

In normal circumstances we have enough grass in front of them to rotate elds. However, in June and July we experienced exceptionally dry months with very limited rainfall and therefore limited grass.

We were forced to open rst cut silage and bu er feed 8kg of brewers’ grains and 1kg of blend. Adding moisture and palatability to the diet li ed intake and resulted in an increase of 2.8 litres per cow. at said we have nally had a downpour of rain and now ceased the blend. ird cut silage was minimal and disappointing due to the weather. Fourth cut is looking more prom ising and bulking up well. And we have shut o grazed elds for extra silage.

We recently completed our carbon footprint assessment, it was relatively painless, some might think pointless. Our next inspection is from the Environment Agency, who are carrying out routine visits in Cheshire to see if we are complying with regulations and discuss ways to protect the environment.

Meanwhile, I strive to get through the summer holidays without loosing the plot.

“ There was a real engagement and interest in the livestock from the general public

Holstein UK president John Jamieson made a switch to organic milk production in 1999 and has just completed a five-year plan to modernise the facilities on his farm near Dumfries. Wendy Short reports.

The 240 Holstein cows at the Jamieson family’s Upper Locharwoods Farm produce a 10,000kg yield from a simple organic diet of silage and home-grown grains, supplemented with a protein mix which is fed in the parlour.

e unit is run by John Jamieson and his wife Helen, together with their son Graham.

e Firth herd, which calves all year round and is milked with a 12-hour interval starting at 3.30am, is housed from early October until mid-March.

Milk production totals 2.2 million litres at 4.22% bu erfat and 3.02% protein, with milk sold to Muller.

e ve-year modernisation plan included the 2020 replacement of the 20:20 herringbone with a GEA T8900 rotary parlour, which is one of the rst models to have been installed in the UK.

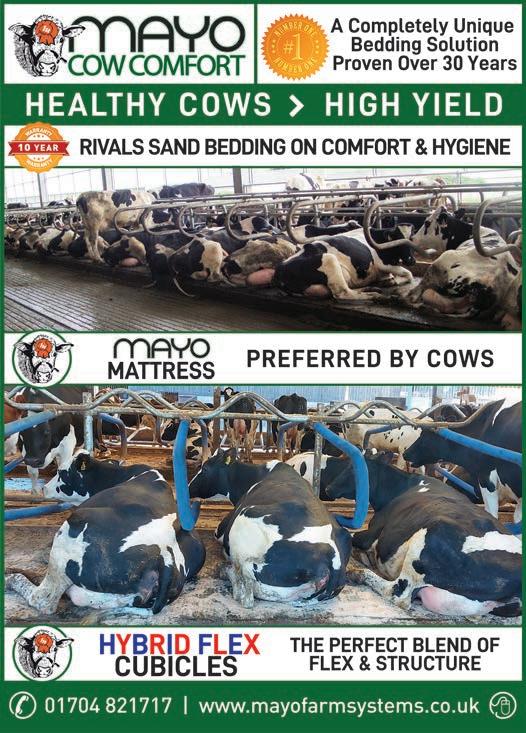

Another new feature is 180place accommodation which has been designed speci cally for sand-bedded cubicles, although the transition group continues to be kept on sawdust-topped ma resses.

John says: “A fully sand-bedded cubicle can require up to six tonnes of sand per cow per year, but we have cut usage to 1t by applying a thin layer over ma resses.

“A sla ed se lement channel

runs through the shed and the sand is removed twice a year and spread on the land.” e sand bedding has addressed the drive to minimise the incidence of mastitis, he adds.

“As an organic farm, we must consider antibiotic usage as a last resort. If antibiotics do have to be administered, we face a double milk withdrawal period compared with a conventional unit.

“Our policy to use a teat sealant as standard across all dry cows works well and the sand bedding has been highly benecial in reducing the number of mastitis cases, with the current average for somatic cell count at 122,000. is reduced reliance

on the use of antibiotics continues to keep us focused.”

e dairy unit also bene ts from a 50kW solar panel system and a 200kW biomass boiler. Another element of the improvement was the installation of one million gallons of additional slurry storage; it has improved utilisation by allowing for more exible application times.

Sexed semen from genomic sires is used exclusively. Type classi cation is part of the Holstein Complete Package from Holstein UK and the unit currently has 34 EX and 115 VG-scored females.

ese come from families including Vale, Rudy, Missy and Roxe e. Lack of time prevents showing, but the herd has enjoyed previous success at AgriScot, as well as the National Holstein, Royal Highland and Great Yorkshire shows.

In the early days, Hanoverhill Starbuck had a signi cant in uence on the herd and subsequently animals and embryos were purchased from some of the top herds in North America and the UK.

e lower end and repeat breeders are put to an Aberdeen-Angus and their cross-bred calves are sold at four weeks to a local nisher. e aim is to calve heifers at 24 months.

All replacement calves are reared in hutches and fed pasteurised whole milk until 12 weeks and it has been found that giving calves warm water twice a day has improved growth rates.

John says: “ ere is no doubt that the biggest step forward within the dairy industry in recent times has been the introduction of sexed

semen. e technique is a great innovation and has li ed the burden of unwanted dairy bull calves on our farms.

“Our goal has always been to breed cows which have strength, good locomotion with high, wide rear udders and a wide rump.

“Another desired trait is low pin se ings, which aid fertility. ere is a great selection of genetics within the

breed and it is a question of picking the one which suits the farming system and the producer’s criteria.”

e herd is not subject to a formal health scheme, but the cows are monitored for a range of diseases through the Ca le Information Service (CIS).

e milk is routinely tested for leptospirosis and IBR, while cows are individually tested for Johne’s

every three months and calves are ear-notched for DNA and bovine viral diarrhoea control.

Some 24 hectares (59 acres) of the 275ha (680-acre) farm total are dedicated to winter cereal crops, with a similar acreage sown with spring cereals.

e grain balances the grass silage

and protein mix by providing starch for the total mixed ration, says John.

He says: “As an organic farm we do not have as many tools in our toolbox as a conventional farm when it comes to formulating diets.

“We have no access to organic by-products, so we tend to stick to a simple system. Our herd is proof that the Holstein can convert forage e ciently and we are always in the

top three organic herds in the country with our costings.”

e average cow weighs about 650kg, but the breeding policy is moving towards a slightly smaller animal.

John says: “If we can keep a smaller cow which requires less maintenance but can match our current yields then it makes sense to go in that direction; research shows it is possible.

“We have a responsibility to continue to look a er the environment and I think we must all do our bit, although we also have the added challenge of feeding a growing population.

“Organic farming has been an interesting journey and we have learned a lot about managing the soil so that the soil in turn looks a er the crops.”

e family has farmed at Upper Locharwoods for 70 years

rDuring summer, the herd is grazed on a paddock system

rFive cuts of ryegrass and clover silage are taken each year

rConcrete cow tracks were installed three years

The farm’s 40-point rotary parlour.

and changed from pedigree Ayrshires to Holsteins when the Firth Herd was rst registered in 1982.

John says: “I worked in Canada

ago and they are considered a very worthwhile investment

rLand is a heavy, droughtresistant loam at close to sea level in a high rainfall area, all of which makes for good grass production

for a spell and came home very impressed with the Holstein. I felt it was the breed for the future and my father was good enough

rThe farm includes 40 hectares (100 acres) of site of special scientific interest peat land which is only lightly grazed; it is believed its value may be more fully appreciated in the future

to support my decision to grade up the Ayrshires.

“Grading up the herd allowed us to retain the strong cow families we had established over the years.”

Having invested in facilities to improve production e ciency, the only potential change in the near future would be to slightly increase cow numbers to 300 cows, he says.

Meanwhile, he is enjoying his term as Holstein UK president.

e role normally lasts for 12 months, but he agreed to stand for an additional year, due to the restrictions imposed by Covid-19. is year’s celebrations included a visit to Upper Locharwoods, where visitors appraised the cow families and took a great interest in the new dairy unit.

John says: “ e organisation is doing well and we have about 6,000 members, which includes a strong Holstein Young Breeders movement.

“ e sta members are eagerly anticipating our imminent move into new headquarters. Our location will remain in Telford, Shropshire, but the new building will also accommodate CIS and the National Bovine Data Centre.

“In my opinion, the Holstein as a breed is in a strong position to face whatever the farming future holds.”

whole herd approach for

Dairy farmer Andy

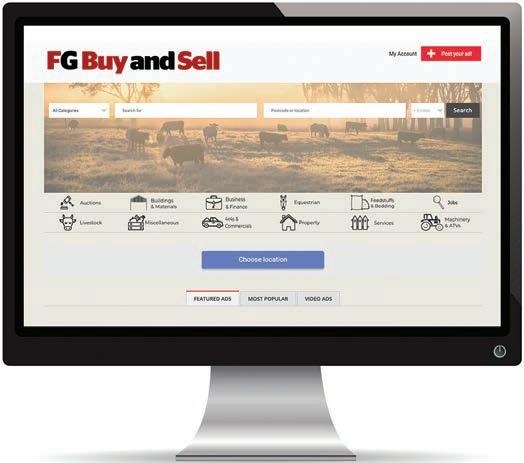

Venables farms in partnership with his family, milking 330 cows in Cheshire, selling milk on a Co-op contract. He is also managing director of Hillsgreen, a marketing agency dedicated to agriculture with many high-profile clients, including NFU and Cereals.

We are well aware of the e ects the current nancial situation is having on our dairy farming businesses and, therefore, the impact it is having on our buying decisions.

In ation in food prices is now hi ing consumer pockets and with the crisis in Ukraine starting to make our Government realise the bene ts of domestic food production, we as an agricultural industry have an opportunity to connect be er with consumers and in uence their buying decisions.

In recent years, we have been doing more to tell our story and get closer to the consumer with initiatives such as Open Farm Sunday growing in popularity and farmers-turned-YouTubers, such as Tom Pemberton, gaining large audiences online. However, collectively, there is so much more to do.

Alternative and plant-based food and drink brands are be er at this than us and it contributes to the cat egory’s ever-increasing popularity.

We can’t just assume that British consumers understand the nutritional bene ts of buying dairy and the bene ts of a lower carbon footprint through buying British; we need to tell them.

ere are many misconceptions around farming too, such as those around its environmental impact, that we must educate the wider world on. If we don’t, it’ll damage the industry’s reputation.

All of this is why it’s so important that we start to share more about what we do. Not only will it educate people, but it will encourage more people into the sector, helping diversify our workforce and it can open up another revenue stream for farmers.

If you’re connecting with consumers, you can also sell to them. Selling direct for some farmers could help to provide the additional revenue stream needed to plug the gap due to the reduction in Basic Payments.

A cultural shi in how consumers shop can be used massively to our advantage. People now want to ‘shop small’ and endeavour to support local and independent businesses.

Vital

Farms should be a vital retailer in local communities. People can buy fresh as well as supporting hyper-local economic growth. Not travelling as far to shops will also result in less CO2 emissions from vehicles as we shorten the supply chain.

e demands of consumers when it comes to online grocery shopping are high too. ey want choice, good quality, good price and good customer service. Whether they’re buying from Amazon, Uber Eats, Tesco or their local milkman or veg box supplier, the expectations are the same, but local, friendly, face-to-face contact is always going to rank more highly when it comes to customer service. While the variety, quality and price of products can be in your full control.

Back in 2019, I looked to utilise online channels and launched the ‘Mission 4 Milk’ campaign, which aimed to dispel the myth of ‘full fat milk’ and raise awareness of the health bene ts of milk.

Andy Venablesis campaign started on social media and soon gained traction o ine too, with many farmers pu ing up roadside banners. is was a small self-funded cam paign, but it showed the opportunity to raise awareness with the consumer. So, while the bene ts of connecting with the consumer are clear, how to go about doing it can be overwhelming.

Whether you are looking to build your own brand and sell direct to consumers, wanting to promote agriculture via social media, or wanting to execute a national campaign which promotes your industry, it can be daunting. ese are the reasons why we have launched Mission.AG for farmers. Mission.AG will o er free marketing education resources developed speci cally for agriculture.

We need to upskill our sector in digital marketing, then the concept of connecting with consumers via digital channels will not be as intimidating. ere are many ways to e ciently and cost-e ectively build a relationship with consumers, particularly by utilising digital methods.

We are building a positive community of likeminded farmers with a forum where you can share marketing best practice, ideas, industry knowledge and experience, as well as ask questions and learn from others.

Over time, we then see the opportunity to work with our community to launch national consumer marketing campaigns.

If you need inspiration or are questioning the importance of direct-to-consumer relations, then think about industries such as insurance, travel, fashion and ultimately, a lot of non-fast moving consumer goods retail.

ey utilise technology and digital platforms very well. For some of these, consumer sales are only a small part of their business, such as insurers or banks, which sell their product through brokers.

However, they have still built a consumer-facing brand and engage with consumers because it builds brand recognition and trust, which means we are more likely to buy from them, even if it is indirectly.

is is our industry and we have a real opportunity to make a di erence to our future, but I strongly believe the biggest di erence will come if the consumer is be er informed and makes buying decisions based on the bene ts to the British farmer.

rFor more information, visit mission.ag

The abomasum is nor mally suspended in the omentum, or adipose tissue layer, on the right side of the abdomen

and in a low position inside the last rib, says Brendan John, of Somer set-based Evolution Farm Vets.

He says: “In most cases, a displaced abomasum will slide to the le of the abdomen and come to rest between the rumen and the body wall as an LDA. is means that food and gas cannot move out of the abomasum and it will subse quently swell with gas, trapping it in the wrong place.”

Cows respond to an LDA with a range of severity of clinical signs and the disorder can be di cult to spot, because the full range may not be present in every case, he says.

“An a ected cow may have decreased appetite and depressed milk yield, with rumination absent or in decline. It may lose body condi tion and the dung can become loose, while a veterinary examination will reveal an increased heart rate.

“One classic nding is for the vet to hear a high-pitched sound through the stethoscope when the abdomen is ‘ icked’. Overall, the

Abomasal disorders are an all too common problem in high-yielding adult dairy cows, with left-displacement of the abomasum (LDA) the most frequently reported. Wendy Short reports.

signs are similar to those associated with acetonaemia/ketosis.”

Abomasal displacement occurs when there is poor muscle tone in the abomasum and above-average gas production. A number of factors can reduce muscle tone, with low blood calcium being one of the most frequently observed. However there are several other causes, he says.

“In a pregnant female, the abom asum can be displaced as the foetus grows. Post-calving, it will generally slide back into place, but if it does not rectify itself, it can lead to an LDA.

“Feeding high levels of rapidly fermentable concentrate feed, which is associated with acidosis, is also believed to have an association with LDA.

“ e abomasal lining can be dam

aged due to the ingestion of sand or gravel, while pregnancy-linked stress or metabolic disease, particularly hypocalcaemia, will reduce alimen tary system motility and increase risk.

“Systemic diseases associated with toxaemia, such as metritis, can also trigger LDA, along with inad equate long- bre dietary roughage.”

Research into genetic links for LDA has focused on predispos ition to low abomasal muscle tone. High-yielders are thought to be at greatest risk, particularly in early lactation, due to the high levels of calcium being diverted to the milk.

Any fresh calver should be monitored, as this is the point when the abdominal space is at its greatest.

JThe graph shows the onset of LDA and recovery post-surgical correction, taken from robot milking data.

The green line plots rumination minutes per day. A target value is about 600 minutes/day, although this varies between individuals.

The line shows post-calving rumination climbing to 600 minutes, followed by three periods of poor rumination over the first fortnight.

The squares indicate times when the robot alerts to this cow; they occur frequently, especially between days 10-15.

At the same time, milk yield (black line) dips, with the robot alerting to insufficient yield four times. The cow was identified by the farmer as having an LDA on the evening of day 14

However, an LDA can occur at any time, especially in late winter and early spring, when ca le are housed.

As with most disorders, early diagnosis will increase the chance of a favourable prognosis, he says. Faced with an LDA case, the vet has recourse to two main treatment options: non-surgical and surgical.

Mr John says: “Non-surgical inter vention has variable success rates.

e cow can be cast on to its right side and rolled, in an a empt to move the abomasum back into the correct position. e animal will need to be re-examined two days later, because the recurrence rate is high, at about 75%. In addition, a chronic LDA case can lead on to problems including ulceration, reduced milk yield and adhesions in the abdominal cavity.

and the cow had an operation on day 15. Rumination and yield recovered rapidly, as expected in uncomplicated LDA cases.

“ e other non-surgical but invasive technique is the use of toggles, which are suture materials with plastic or metal pieces at the end to form an ‘H’ shape.

“One end of each toggle is inserted into the abomasum using a large, needle-type device and the two are tied externally. is provides an anchor point to keep the abomasum in place. e method will reduce the chance of recurrence, but full recovery is by no means guaranteed.”

In his experience, surgical methods of treating LDAs are usually the best option for saving the cow. e standard operation involves making an incision in the abomasal wall and stitching the abomasum to the body wall muscles to prevent further movement.

Mr John says: “ ere are several techniques to choose from if surgical treatment is chosen. e incision can be made on either the right ank, the le and right ank simultaneously or to the right side of the midline with the cow lying on its back.

“ e right ank or paramedian, beside the midline, approaches are most o en favoured by vets, although no one method stands out as being signi cantly more e ective compared

with the others. Some practices have started o ering keyhole surgery for LDA treatment, but in my opinion it is unlikely to become commonplace. e technique has pros and cons, compared with standard surgical correction.

“We all recognise the lower infection risk with the small access holes needed for keyhole surgery. Nevertheless, the paramedian, non-surgical approach is already minimally invasive; the incision is only the width of a hand and the wound is le open for less than 10 minutes. is curtails the chance of the post-operative infection.

“ e equipment required for the keyhole technique is expensive and a practice may choose to buy only one set. is would need to be collected and returned to headquarters for sterilisation before and a er each surgery. In a practice which has multiple vets working on farms up to an hour from the centre, this would waste valuable time.”

e national average for cases of LDA in the dairy herd is estimated at 2%, says Mr John.

“ is gure sounds relatively low, but in terms of the total cow population, it means a fairly high number of individuals will be diagnosed with an LDA. Where we have been working on prevention, we have reduced average incidence to well below 1% of the herd, but this still means large farms are likely to see several cases a year.

“One case is too many and, as an industry, we must work to minimise health disorders in general. In my opinion, good transition management is key and milk producers are recognising that a ention to detail during this period will pay dividends on herd health in the long-term.”

Holstein sire Geno source Captain has held the number one position he regained earlier this year in the young genomic sire ranking, pub lished in August by AHDB Dairy.

He a rms his place by smashing the £1,000 barrier for Pro table Lifetime Index (£PLI), achieving a comfortable lead over two of his sons, which join their sire to take the top three places.

High production Captain im proves his £PLI to £1,014, thanks to small improvements across the board, most notably for Calf Sur vival (CS).

With a CS of 5.8, thanks to the addition of new UK data, he becomes one of the breed leaders for this trait. His index of 4.9 for EnviroCow also tops the breed for green credentials, aided by excellent transmission of feed conversion e ciency (Feed Advantage 257).

e Captain son (out of a Redrock dam) in second place is the new entry, DG Peace (£PLI £962), whose transmi ing pa ern is similar to that of his sire, with high Predicted Transmi ing Abilities for milk (1,025kg) and protein (41kg).

Moving up the ranking to third place is Cogent Koepon Rocky (£PLI £959), a UK-bred Captain

son from a Kenobi dam. Each of the top three sires score well for resist ance to digital dermatitis, helping them achieve above average scores for Lameness Advantage.

e next six places are taken by new entrants since the previously published genetic evaluations in April, and leading the pack is De novo 17835 Lennon-P.

is Mendel son transmits high daughter Lifespan Index (+162 days) and strong daughter Fertility Index (FI 13.6), helping to earn him one of the highest indexes for HealthyCow, at 315.

In h position, Peak AltaSeverus (by Peak AltaPlinko) is another high fertility bull (FI 15.3) with strong lifespan (LS 156) who is also predicted to transmit shorter than average gestation length at -3 days.

Sixth placed CherryPenCol HighCloud (by Peak AltaZazzle) is a high fat transmi er (54.2kg) with a very favourable Lameness Advantage of 3.7, while seventh and eighth position are taken by two full brothers – Pine-Tree Denovo Aleo (£PLI £946) and Pine-Tree Denovo Avon (£PLI £922).

Both are by Aladdin out of the same Legacy dam and o er very high fat transmission for both

weight (56.7kg and 59.6kg fat) and percentage (0.34% and 0.37%, respectively).

is revised ranking gives Holstein producers plenty of scope to add new sires to their breeding strategy, with the usual caution advised to ensure there is a divergence of bloodlines chosen among so many previously unknown names.

Marco Winters, head of animal genetics for AHDB, says: “It is par ticularly important to take steps to ensure genetic diversity as so many previously unknown sires enter the market and it is no longer realistic for most to memorise each of their pedigrees.

“We would strongly recommend

the use of a computer breeding program, such as our own Inbreed ing Checker included in AHDB’s Herd Genetic Report.

“ is will ensure a proposed mat ing does not narrow bloodlines un duly but with this proviso – and the need to spread risk by using a team of young sires rather than focusing heavily on individuals – there is a wealth of genetic improvement to be made from these high £PLI sires.

“All of the leading group and many more have exceptional health, environmental and e ciency credentials, all of which will help breeders improve the welfare, sustainability and pro tability of their herds.”

Anew frontrunner has emerged in the daughter-proven sire ranking. Bomaz Monument-P takes this position for the rst time, as the in uence of his early daughters milk ing outside the UK begins to be felt. ese help earn this polled ABS Medley son a Pro table Lifetime Index (£PLI) of £785, along with high Predicted Transmi ing Abilities (PTAs) for fat (43.9kg and +0.22%), daughter Lifespan (LS +134 days) and Calf Survival (CS +3).

Monument-P also has the best EnviroCow index of any proven sire at 3.8. is means that thanks largely to his ability to transmit high milk solids, with strong lifespan and im proved feed conversion e ciency, his daughters are predicted to create fewer greenhouse gas emissions in their lifetimes for each kilogram of solids-corrected milk they produce. e next three places are all occu pied by sons of the popular mating sire DG Charley, who now has a total of four sons in the top 10. e rst of these is Denovo 14566 Crosby, the former frontrunner from the April run of genetic evaluations. Now in second place with a £PLI of £737, his index features strong udder health (Somatic Cell Count -25 and Mastitis -3), with breed-leading Calf Survival (CS 6.1).

Moving up to third position is Hurt genlea Richard Charl, with a £PLI of £730. This high milk bull (PTA milk, 966kg) also features a very favourable

Maintenance Index of -16. New in fourth place is Neal, the best Feed Advantage bull in the rankings with a score of 197. Neal also features a good genetic index for digital dermatitis, at 0.7, which helps earn him the best Lameness Advantage in the top 20 at 3.5. e familiar name of Westcoast Yamaska appears in equal h position, his 1,183 UK daughters milking in 223 herds helping to earn him a £PLI of £723.

He shares this position with Riethil Summerlake, who features the best udder health data in the top 20 (SCC -30, Mastitis -4) and is the top 10’s fourth son of Charley.

Topstone is a new entry in sev

enth position, with a £PLI of £722. A son of Bomaz AltaTopshot (who incidentally still ranks in the top 20 himself, with 1,757 UK daughters), Topstone transmits long daughter lifespans (LS +165 days) and a short Gestation Length (-4).

Eighth and ninth places are held by bulls which were also high- iers in the previous index run. Both sired by De-Su 13050 Spectre and both o ering outstanding fat transmis sion, the rst is ABS Zebedee (PTA fat 49.6kg), with a £PLI of £706, ahead of ABS Crimson.

With even higher milk solids, Crimson weighs in with PTAs of 50.9kg fat and 33.2kg protein and a £PLI of £703.

e highest daughter fertility bull of the top 20 is UK-bred Stowey Magician. He rounds o the top 10 with a Fertility Index of +16.6 and a £PLI of £700.

Marco Winters, head of ani mal genetics for AHDB Dairy, says: “Sires in the daughter-proven top 10 ranking come with £PLI reliabilities ranging from 70% to 97%, o ering the highest level of predictability in their breeding per formance. is provides reassurance for producers who prefer to use tried and tested bloodlines, which they may choose to mix with a team of high £PLI young genomic sires to make the greatest genetic gains.”

The daughter fertility improver Catlane Caleb maintains his long-held lead in the British Fries ian ranking on Pro t able Lifetime Index (£PLI), with a slight increase in his £PLI.

Now at £PLI £373, he also

o ers high milk components with Predicted Transmi ing Abilities of 0.26% fat and 0.16% protein. His daughter Fertility Index (FI) is 12.1 on the Fries ian breed scale.

Retaining his second place is Inch Persistent (£PLI £352), the highest type transmi er of the breed, with a Type Merit (TM) of 2.32. He combines this with a good index for HealthyCow at 255.

A daughter of Rivervalley Cece Chrome, the leading Jersey sire, ranked on £PLI.

Stability at the top of the Jersey rankings sees the high milk volume River Valley Cece Chrome hold on to the top spot with a £PLI of £478. His 493 UK daughters con rm his

production, while he also has the highest TM of the top ve bulls at 2.1.

In second place is VJ Ravning gaard Huus Hamlet (£PLI £447). High daughter fertility (FI 11.7) and the transmission of good overall health earns him a HealthyCow index of 213. e Ayshire rankings show no change in the top three places, with VR Alatalon Flame Feton retaining the number one position. rFor other breed indexes, visit ahdb.org.uk/knowledge-library/ dairy-breeding-and-genetics

Producers calving in a block this autumn and now turning their attention to sire selection will find the Autumn Calving Index (£ACI) highlights sires most suited to their needs.

At the top of this ranking is Bomaz Monument-P, who makes his debut as a proven sire.

Also leading in the separate Profitable Lifetime Index (£PLI) ranking for year-round calving herds, he shows what a strong contender he is across a range of UK farming systems. In particular, he offers high milk fat, long daughter lifespans

and good calf survival, all of which are requirements of any successful dairy enterprise. Monument-P’s £ACI of £661 is 15 points ahead of second placed Progenesis Wimbledon (£ACI £646) who is also the leader in this month’s Spring Calving Index (£SCI) ranking.

In third place is the UK-bred Holstein, Boghill Glamour Persuade (£ACI £637).

With 10 milking daughters contributing to his index, he just qualifies for these daughterproven rankings on early data.

Following Progenesis Wimbledon in the £SCI rankings is the previous Jersey

frontrunner, VJ Ravninggaard Huus Hamlet (£SCI £548).

Moving up to take third place is another Jersey in the shape

of VJ Groenbjerg Lobo Lobster. His £SCI of £542 reflects his daughters’ high milk solids and good lifespans.

ve way to maximise home-grown feed and ensure ca le have a nutri ous ra on.

There was a clear choice this year, infl uenced by fuel and fer lizer prices. You could take fewer but bulkier cuts or opt for a mul -cut system. Whatever your approach, the hot weather has held back grass growth leaving forage stocks lower than normal years.

As the winter of 2021 was mild, the growing period was prolonged, so 2022 silages are higher in fi brous overwintered material. This promotes rumen health but is less readily diges ble for the cow.

As the energy content is lower than previous years (reported by Trouw Nutri on GB), a balance of rapidly fermentable carbohydrates and proteins is needed to support milk produc on.

The benefi ts of adding Sedagold Syrup to dry forages Hot weather means drier forages, which are less palatable. Adding a liquid feed like Sedagold Syrup to hay or haylage is an easy way to

encourage intake, “A er speaking to Duynie, I realized that I could extend my forage stocks by mixing Seda Syrup with available straw to make a nutri ous feed.” (Duynie Customer)

Not only is the syrup high in protein and energy, but it also reduces dust, binds in smaller mineral-rich par cles, and prevents selec ve feeding by coa ng the ra on. As Sedagold counteracts high lignin values, it improves the diges bility of the feed as a whole and makes nutrients more available.

Jersey breeder Holger Hedelund Poulsen is aiming to build a sustainable and self-sufficient business against a backdrop of a changing dairy industry. Chris McCullough finds out more.

Selling pedigree Jersey heifers overseas has proven to be good business adding extra value to a Danish dairy farmer’s milk income.

Holger Hedelund Poulsen sells about 20 of his replacement Jersey heifers in-calf each year to farmers mostly in the Netherlands and Germany.

Along with his wife Karen, Holger runs 190 pedigree Jersey cows plus followers and calves at their Ejer Mollegard farm situated in Ejer Bavnehoj, the highest point in Denmark at 170 metres above sea level.

Even now at 72 years old and with no dedicated succession plan for the farm, Holger shows

no signs of slowing down his milk production. In fact, he talks about continued investment into the farm and his cows.

Back in 1972 when Holger took over the farm it only had 15 hectares (37 acres) and 17 cows, but today it has expanded to 270ha (667 acres), of which 125ha (309 acres) are leased.

Back then there were about 100 dairy farms in the area, but today, in trends replicated all over the world, those dairy farm numbers have fallen to just two, albeit with increased cow numbers.

For the past 14 years, three DeLaval robots have milked the cows on Holger’s farm, with annual average yields standing at 11,000kg.

With labour availability a constant issue on Danish farms the robots have proved their worth year a er year, milking the cows an average 2.95 times per day.

Meanwhile, Holger and one worker supplies all the labour required on the farm with a parttime assistant dra ed in when necessary during the busier periods.

Holger runs a speci c breeding programme on the farm which also sees him export heifers to other parts of Europe.

“I use sexed semen from Viking Genetics on the Jersey heifers to produce my replacement stock,” says Holger.

“Half of my replacement heifers,

about 20, are exported for breeding each year and I keep the other half.

“We also use sexed male semen from Aberdeen-Angus bulls on some of the older cows.

“ ese calves are sold at about eight to 10 weeks old.”

He says there is ‘strong demand’ from other farmers for his heifers.

He adds: “Normally, I sell them, robot-ready, at 1.5 years old in calf for about €1,500 each to customers in e Netherlands and Germany.”

Over the years Holger has pushed to become more self-sucient in terms of his feed requirements for the herd, saving money on costs which has been a real bene t these past few months.

Since starting to farm more than 60 years ago, Holger says he has aimed to make his business more sustainable and reducing his reliance on feed and protein imports was very much part of his plan.

Today, he grows more than 80% of the feed requirements for his herd on the home farm, greatly reducing the carbon footprint in the process.

Crops such as maize, grass, barley, wheat, rye, rapeseed and fava beans are grown on the farm with around half of it sold to other farmers.

“We make four cuts of silage each year,” says Holger.

“Plus we grow a range of other crops to feed the cows. Right now we are about 80% self-su cient in terms of our feed production.

“We still have to buy in some protein but I grow about 66% of what I need in terms of that as well.

“ e rapeseed and fava beans are vital crops for us.

“Both whole and ground

rapeseed and ground beans are included in the diet roughage while grain is mixed on the farm with protein, which we still need to purchase.

“On average our feed costs alone work out at 15 euro cents per kilogramme of feed.”

Holger is a big believer in utilising technology to make his farm and herd even more e cient.

Every piece of data generated

by the milking robots is analysed and acted upon if anything could be improved.

“Farmers can increase their herd yields per working hour by acquiring knowledge and new technology,” he says.

“And that helps to save on costs and increase pro ts.”

Holger is also an in uential voice when it comes to the dairy industry in Denmark. When Arla

rThe herd’s average lifetime yield is 50 tonnes over 4.5 lactations with 0.8 calvings per year

rMilk is sold to Arla and at DKK5 per litre (56ppl)

rThe herd is split into young cows and older cows and is then fed accordingly in the shed and at the robotic milker

rOnly the dry cows and younger stock graze outdoors

launched Kaergarden (which is basically Lurpak bu er mixed with vegetable oil) Holger acknowledged the initiative but was quick to criticise the co-op for using imported soya oil rather than locally produced quality rapeseed oil.

ree weeks later the dairy had taken on board his concerns and the new products were manufactured solely by locally produced oils.

Dairy farms should eliminate chlorine-based products in nal rinses to reduce the risk of chlorate residues in milk products.

e latest advice from the Milking Equipment Association (MEA) states that cleaning and disinfection of milking equipment should avoid or replace the use of chlorine in the nal rinses.

MEA chair John Baines says: “EU Legislation has set a new maximum residue limit for chlorates in milk products to ensure that levels do not exceed 0.1mg/kg.

“Chlorates are breakdown products from chlorine-based chemicals used in milking equipment cleaning and disinfection. e risk of chlorate residues is highest in heavily processed products, especially milk powders and infant formula. e European Food Safety Authority has advised that exposure to chlorates for long periods of time can lead to iodine de ciencies in infants.”

Red Tractor standards state that milking equipment should be le free of chemical residues by implementing a nal rinse with potable (drinking quality) water.

When water is used directly from mains supply, it may not be necessary to use any disinfectant in nal rinses. It is a requirement

rDo not use hypochloritebased disinfectants in the final rinse of parlours and bulk milk tanks

rFollowing disinfection, make sure all milk-contact surfaces are rinsed with clean potable water, for example, direct from mains supply rWhere private water supplies are used, or there are doubts about water quality, use alternatives to hypochlorite such as peracetic acid, which degrades over time and does not leave residues

to add disinfectant to private supply water or where there are doubts about water quality.

In this case, sodium hypochlorite has been the traditional disinfectant added to nal rinses.

Mr Baines says for farms cleaning milking equipment manually, the absence of careful measurement of chemicals may result in unsafe levels of chlorine in nal rinses.

He adds: “Using more chlorine will not necessarily improve the cleanliness of milking equipment.”

With automatic cleaning control systems, correct installation, calibration and maintenance of equipment is paramount to regulate the use of disinfectants.

“Automated equipment should be installed, calibrated and serviced by trained dairy technicians, ideally with a Milking Systems Technician Accreditation (MSTA) to ensure correct concentrations of chemicals are used,” says Mr Baines.

Where chlorine-based dis-

JA new chlorate maximum residue limit (MRL) for liquid milk came into force in June 2020 under EU legislation and applies to the UK post-Brexit.

The MRL for liquid milk (raw or pasteurised) is 0.1mg/kg.

The MRL for foods intended for infants and young children is still set at 0.01mg/kg.

Compliance with MRLs will be checked by the Health and

infectants are used in nal rinses, Mr Baines advises that chlorine-free alternatives such as peracetic acid should be considered.

He says: “ e MEA accepts that the use of chlorine-based products is not prohibited. However, milk buyers expect that farms reduce the risk of chlorate residues by using a peracetic acid in nal rinses, boiling water cleaning, or disinfection.”

Mr Baines says robotic technology has taken the lead on cleaning without chlorine, choosing to use

Safety Executive and some milk processors have already added questions about best practices to reduce residues into their Red Tractor Assurance audits.

Historical advice to disinfect parlour systems and bulk milk tanks with hypochlorite as a final rinse is no longer in line with Red Tractor Assurance standards and industry recommendations.

a boiling water alternative. Acid or alkali is added to the early stage of the cleaning to prevent fat or mineral deposits. Most importantly, the high temperature disinfects equipment surfaces, meaning that no disinfectant is required. is removes the risk of chlorates in milk products.

“While technology has some of the answers, installation, calibration and maintenance of all milking systems should be carried out according to manufacturer’s guidelines, by MSTA-accredited technicians.”

Using min-till to establish a multi-species sward in permanent pasture has rejuvenated leys at a Montgomeryshire organic dairy farm, increasing perennial ryegrass in the sward by 30% and boosting white clover content, too.

e Lloyd family have been farming organically at Gate Farm, Llandyssil, since 2015, in a system that maximises milk production from grass.

eir herd of 170 Friesian Holsteins produces an annual average yield of 6,600 litres per cow, with 4,100 of those litres coming from forage.

Ploughing has traditionally been used in the farm’s reseeding programme, but, keen to trial methods that minimise soil disturbance, third-generation farmer Glenn Lloyd embarked on a Farming Connect focus farm project to investigate how min-till could be used to increase sward diversity in permanent pasture.

Since the farm is organic, a herbicide cannot be used before seeding and the thick thatch at the base of the 30-year-old sward proved a challenge.

Helen Mathieu, of Germinal, who provided technical input into the project, says old permanent pastures bene t from a herbicide treatment because old grassweeds and grasses need to be killed o to allow room for new perennial ryegrass.

In a system when this cannot be applied, Ms Mathieu says it is important to use the right seed drill for the job.

For the Gate Farm project, a Gu ler Greenmaster 300 Tined Seed was used.

Mr Lloyd says it was a ‘tall order’ to overseed permanent pasture with a thick thatch.

“It was a big ask, but it was impressive watching the machine work; it really did rip through the thatch.’’

e eld was overseeded with a mixture of plantain, chicory, red and white clover and perennial

ryegrass at the end of July, when conditions were very dry.

Performance the following spring was impressive, says Mr Lloyd.

“Growth in the spring and late autumn has been exceptional.’’

It had an opening cover of 3,100kg DM/hectare when it was grazed in late February.

Ryegrass content in the eld, which previously had a high proportion of meadow grass, had been boosted by at least 30%. But there had been poor establishment of herbs and legumes – chicory and plantain content was sparse.

“ e herbs have really struggled with the permanent pasture,’’ says Ms Mathieu.

She says overseeding with herbs would be more successful in fouror ve-year-old pasture. e condition of the pasture, the type of drill used and the prevailing weather conditions are all important factors for overseeding, she adds

“If it is really dry mid-summer

and you get good soil-to-seed contact, it is likely to be more successful; herbs and legumes like to be planted in good time, no later than mid-August.’’

Although the results from mintill at Gate Farm had been mixed, Mr Lloyd says the project has given him the con dence to include this technique in his cultivation toolkit going forward.

He says: “It has proved that it is possible, but perhaps the soil needs to be aerated too, to get a be er result.”

Mr Lloyd is also aiming to reduce the farm’s reliance on bought-in feed and, as another Farming Connect project, he grew 4.5ha (11 acres) of brassicas using both conventional and min-till establishment.

He opted for Redstart, a hybrid brassica that grows quickly and vigorously and o ers grazing options from July to around the end of January, depending on sowing date. e crop was grazed with 28 in-calf heifers, each with a daily dry ma er intake requirement of 12kg.

rLand farmed consists of 97 hectares (240 acres) owned and 57ha (141 acres) rented rSoils average 6.5–7 pH and index 3 for P and K rFarm rises from 550-900ft r50% of milk sold to OMSCo and 50% in direct sales through Daisy Bank Dairy r1.3 tonnes of concentrates fed per cow

e crop provided 7kg and round bale silage of 5kg.

Ms Mathieu calculates the conventional crop grew 3t DM/ha at 15-18% protein and 12ME at a cost 4p/kg, and extended the grazing season by 70 days.

Although the conventionally established crop grew well, performance was poor in the section of the eld where the min-till technique had been used to plant the seed into permanent pasture.

“I think this project has shown that conventional cultivation is be er for growing brassicas, as they bene t from having a ne, rm and clean seedbed,’’ says Ms Mathieu.

With continued high protein prices this winter a new approach based on increased precision could be the way to tackle costs while improving efficiency. Dairy Farmer reports.

More e cient cows and a re duction in costs per litre requires a rethink in how we satisfy the protein and amino acid requirements of dairy cows, says Dr Sion Richards of Adisseo.

He says protein systems used in ration formulation have evolved over the last 40 years to be er re ect what happens in the rumen, moving from crude protein to digestible protein and most recently to metab olisable protein systems.

While each development increases the precision with which cows’ requirements can be de ned and met, there is still a major aw.

Dr Richards says: “Quite simply, cows do not need protein per se in their diet. What they need is a supply of amino acids which they then syn thesise into the speci c proteins such as milk protein or body protein.”

He explains that all proteins are made up of a combination of 20 amino acids. When protein is fed to the cow, a signi cant proportion of the protein is broken down to nitrogen and amino acids. ese are reconstituted in the rumen into microbial protein, a good source of amino acids. is microbial protein then passes into the hindgut to sup ply amino acids for the cow to use.

Dr Richards adds: “ is is the microbial protein which is the cheapest way to provide protein to the cow, so we want to optimise this. is is done by making sure we drive the rumen by supplying a synchronised balance of energy and protein supply to the rumen

to achieve maximum microbial protein production.”

In the hindgut the microbial protein is joined by bypass protein which is protein that avoided fer mentation in the rumen. Together these are used to meet the cow’s metabolisable protein and amino acids requirements.

“To be e ective, a diet must provide the supply of amino acids the cow requires. As soon as an amino acid becomes limiting, the performance of the cow is a ected, usually by sparing amino acids from functions like the immune system, fertility, or milk protein to maintain production.”

Dr Richards says in most UK

dairy diets, methionine is the rst limiting amino acid with an esti mated 95% of diets being de cient, with lysine being the second limiting amino acid.

“ e usual approach when for mulating diets is to formulate to metabolisable protein and usually to over feed metabolisable protein to try and ensure the cow is sup plied with all the amino acids re quired. e problem is that this is a blunderbuss approach, pushing up protein use and costs and increases nitrogen excretion.”

Dr Richards says a more precise way to meet requirements is to for mulate to amino acid requirement and if required, supplement the diet with rumen protected amino acids.

“A typical UK dairy diet is 17-18% crude protein and this oversupplies metabolisable protein by 8-10% while o en still failing to supply su cient essential amino acids. A typical diet formulated to balance amino acids will be 14-16% crude protein, with a metabolisable oversupply of less than 5% while delivering more closely what the cow requires.”

He observes that the average dairy diet in the EU is already 16% crude protein while diets in the US are closer to 15%. e reason is that there is a bigger uptake in these countries of feeding for speci c amino acid balance. Currently fewer than 5% of the UK dairy herds are fed this way.

“Products are available to allow diets to be formulated to lower total crude protein but with speci c amino acid sup plements to meet requirements more precisely. For example, MetaSmart is a rumen-protected source of methionine.

“Adding 35g/cow of this would improve methionine supply and allow a reduction of 1kg/day of soya in the diet.

“With soya predicted to be well over £450/t this winter, saving 1kg would reduce diet costs by 45p/cow/day. Adding 35g of the rumen-protected source of me thionine will typically cost less than 20pp/day, allowing a reduction in feed costs while feeding the cow be er and helping boost milk price through superior milk quality.”

Quite simply, cows do not need protein per se in their diet

JOHN THOMAS Regional Business Manager Lallemand Animal Nutrition

JOHN THOMAS Regional Business Manager Lallemand Animal Nutrition

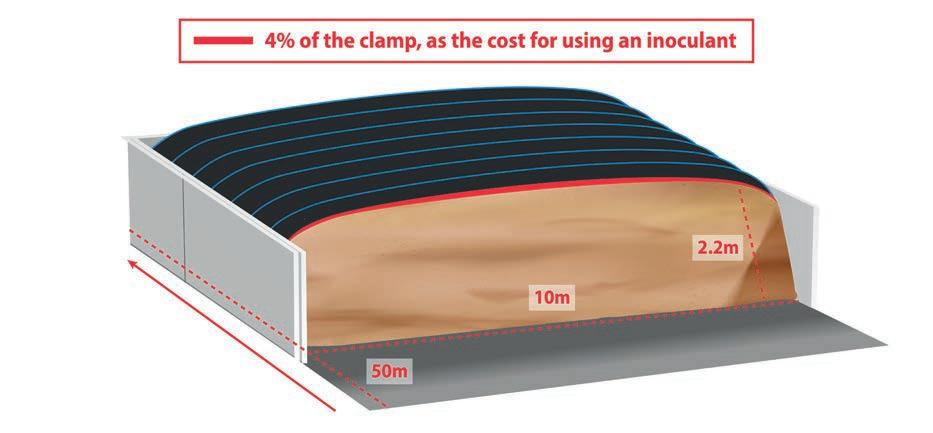

Bought-in feed prices are soaring and this coupled with variable maize yields up and down the country, means that the value of forage in the clamp is going to be higher than ever. That applies to maize just as much as grass silage and it is vital to take steps to preserve its quality and reduce waste, all the way through from harvest to feed-out.

Alongside the use of a silage inoculant, attention to detail at every stage of the process is key to yield the greatest benefits.

Harvest timings will vary hugely across the country depending on time of planting and soil type, and the key is to cut when the crop reaches the correct dry matter –ideally averaging 30-35% for the whole plant.

It’s important to balance the rate of the maize coming in with the weight of the packing tractor to make sure it goes into the clamp in tight, even layers, as the first step for effective fermentation is to remove as much air as possible.

If the clamp is left poorly compacted and spongy, the beneficial microbes cannot start to work as quickly and there is an increased risk of spoilage microbes interfering with fermentation. Good compaction increases the likelihood of a more stable silage during feed-out.

Magniva Platinum Maize, which is formulated specifically for maize, will ensure an optimal fermentation as well as keep the silage stable, reducing dry matter losses and contamination with yeasts and moulds.

An oxygen barrier cling film under the top sheet is really beneficial; the film is drawn down into the undulations left by the tractor wheelings eliminating air pockets and helping to prevent any air moving down into the silage through the winter. Ordinary black plastic sheet is much more porous and allows air in over time. After ensiling, it’s important to keep an eye on the sheet weighting system.

After a few days, the sheet can blow up like a balloon, which is a sign that fermentation is working well, but it can lift up gravel bags so once the sheet has settled you should recheck the gravel bags/tyres. Also remember to keep an eye out for vermin.

If there is brown/orange gas seeping from the silage do not approach the silage until this gas has completely dissipated as it could be nitrogen dioxide which is highly toxic. With the variability in growing conditions seen this year, some maize crops may be particularly susceptible to the formation of silo gas due to drought stress.

All the above factors will combine to help reduce dry matter losses – it is worth comparing the number of tonnes going into the clamp with the tonnes actually fed. The level of ‘shrink’ or wastage will have more of an impact than ever this year.

At feed-out, you should ideally cut to a depth of one metre per week, across the silage face. If that is not possible, then you should still aim to cross the entire face each week, trying to keep up with the oxygen infiltrating the clamp.

If it is taking more than a week, consider taking ½ shear grab depths across the face which will result in a more consistent feed. It is better to have a small, but consistent, amount of loss across the face. Defacers are a good option to help ensure a more consistent feed goes into the mixer wagon.

Feed-out is when the benefits of inoculants really become evident. Magniva Platinum Maize has a unique combination of homofermentative microbes, which produce lactic acid, to drive an efficient fermentation and heterofermentative microbes which produce acetic and propionic acids which are needed for silage stability at feed-out. The microbes change the type of yeast present, and the pH of the silage remains stable even 10 days after exposure to the air, slowing the natural growth of yeasts and making the silage last longer and retain more nutritional value.

Farmers can reduce the fermentation, feed-out and peripheral aerobic losses by 10% by using a combinationof good management principles and a Magniva Platinumforage inoculant designed for maize.

Taking an example where 1,000 tonnes of 30% DM maize silage is required, we can calculate the potential costs.If the farmer did not treat their silage with an inoculant,they would stand to potentially lose 100 tonnes of silagewhich would have cost £39/tonne to grow, making thesilage that is left to feed £3,900 more expensive.

The financial cost of maize silage waste, both in the clamp and in the ration, can easily run into thousandsof pounds. With feed prices so high and less foragelikely to be available this year, there’s no room for thesestaggering losses.

The key message is to not cut corners with clampmanagement at any stage and maintain close attentionto detail as, once maize starts spoiling, it loses a lot of its energy value quite rapidly.

Cumulative dry matter losses from maize silage betweenclamp filling and feeding can be significant, with theMaize Growers Association providing typical figures in October 2020, shown in table 1.

If the 100 tonne shortfall then had to be made up by buying inmaize silage, it would cost the farm a total of £6,500, assuminga maize silage purchase price of £65/tonne fresh, excludingdelivery, for autumn 2022 (our own forecasted price).

Taking the scenario further, if there is no maize silageavailable and the farmer needed to replace the lost energy and protein by purchasing straights, it would cost£7,083 for the 100 tonnes required. This is based on a maize silage with 30% DM, 11 MJ/kg DM metabolisableenergy and 80g/kg crude protein having a relative feedvalue of £70.83/tonne fresh, compared to barley at aprice of £250/tonne and rapeseed meal at £300/tonne.

There is a good return on investment for protecting yourmaize silage crop with an inoculant, especially given thecosts involved in growing and storing maize.

Inoculating maize with the Magniva Platinum forage rangewill give a return on investment of at least two to one if onlythe additional growing costs are considered, and this returngoes up to four to one and higher when considering the replacement costs using either maize silage or straights.

Table 1 Maize silage dry matter losses (MGA, Oct 2020)

In short, it takes a very small reduction in waste to pay forthe inoculant, which can be visualised as a shallow layer ofsilage across the clamp. For a 1000-tonne clamp of silage,the cost of treating the crop with a Magniva Platinumforage inoculant, would equate to growing about 43tonnes, just 4% of the total amount of silage with equates toless than a 10cm strip across the entire face of the clamp.

A salmonella infection can be devastating to a dairy herd, as dairy farmer Derek Semmens found when he experienced an outbreak in his calves and milking herd. Dairy Farmer reports.

Farming on the south west Cornish coast, Derek Semmens milks a 210-cow dairy herd, grazed throughout the summer, alongside an arable operation which includes growing cauliower for a well-known retailer.

e cows at Trendrennen Farm, Penzance, are milked through a 14:28 herringbone swing over parlour, averaging about 9,500 litres annually, with the milk sold to Saputo Dairy UK for cheese.

It is a closed herd, with replacement heifers reared on-farm and beef calves sold as stores.

“ e calves were sick in the morning and dead by the a ernoon.

“We thought it was pneumonia, but the post mortem our vet sent o con rmed it was salmonella Dublin. en the cows started aborting – it was a distressing time.”

Salmonella Dublin is the most prevalent strain found in UK dairy herds and has a range of clinical signs, including abortion, which typically occurs between ve and eight months of pregnancy.

“ e infected cows were aborting

about ve or six days a er drying o ,” says Mr Semmens.

“Several cows died a er aborting and milk yields dropped. e calves that recovered from the infection still stand out now, because they are behind on growth.”

e outbreak in the calves was particularly damaging because it happened when Mr Semmens was breeding heifer replacements, meaning that he has fewer heifers coming through in that age group.

Mr Semmens has a good relationship with his vet Ma hew Berriman, who has worked with the farm business for 20 years.

“We have a routine visit every two weeks, which I used to see as a major farm expense, but Ma ’s advice is invaluable.”

“Up until last year I was not really aware of salmonellosis in dairy herds, as I had not experienced it.

“I turned to Ma for advice. He said we needed to vaccinate, alongside implementing other biosecurity measures, so we did that.”

Mr Berriman suspected the disease had been present in the herd for a while, but some trigger prompted the outbreak of clinical disease.

He says: “Ca le that become infected with salmonella Dublin can go on to become carrier animals, shedding the bacteria intermi ently and contaminating the environment around them.

“ ese carrier animals o en do

JFarmers who are concerned about salmonella should work with their vet to establish the risk of disease.

Alongside quarterly bulk milk testing for salmonella

antibodies, this can be done using MSD Animal Health’s new Salmonella Risk Assessment app.

The checklist tool helps vets and farmers to work

not show any symptoms and can be di cult to detect, which is why routine monitoring and biosecurity measures are so important.”

As a closed herd, Mr Semmens’ farm was not exposed to the risk of buying in ca le infected with salmonella. erefore, to control the disease within his herd, his vet recommended a vaccination programme supported by wider biosecurity protocols.

“We went straight into vaccinating all the cows and heifers,” says Mr Semmens, who also vaccinates against BVD, IBR, and leptospirosis.

“ e cows will get an annual booster and the heifers will be done three to four weeks before they calve, to help ensure antibodies are passed via colostrum to the calves.”

together to analyse six key areas and consider a multitude of factors on-farm, from calving hygiene to the threat of infection from other herds.

We asked a range of children aged between four and eight what question they would most like to ask a farmer, and worked with farmers to provide them with the answers in our Ask a farmer video series.

biggest digital campaign, #Farm24, has taken its profile to new heights this year following unprecedented activity across social media and beyond.

Sponsored by Morrisons, farmers and ancillary organisations embraced the event to educate consumers about where their food comes from and what a typical day across the industry can look like. This year’s messaging also highlighted the affordability of local produce as part of the solution to help tackle the cost-of-living crisis.

It took less than two hours before the hashtag was trending at number one on social media, along with our umbrella campaign #FarmingCAN (see panel, right)

joined by a string of celebrities and leading figures including Miranda Hart, Dan Lydiate, Kelvin Fletcher, Phil Vickery and Alexander Armstrong to name but a few, who all wasted no time in dedicating their support and pride towards the role of British farmers and associated communities.

Radio 1’s Greg James raised the awareness stakes when he dedicated a shout out to the campaign after being alerted by one of his contributors, Young Farmer Tom, about how and why the event was taking place.

Kicking off at 5am on Thursday, August 4, 2022, 24 Hours in Farming exploded across Twitter, Instagram, Facebook and TikTok as farmers proudly shared posts, videos, pictures, vlogs and hosted a diverse mixture of events to mark the much-loved farming event.

Sophie Throup, head of agriculture, fisheries and sustainable sourcing at Morrisons, said: “What a fantastic 24 Hours in Farming it’s been. Such a range of stories and some really creative posts too bringing the story of farming to customers and citizens - worldwide.”

A host of industry organisations welcomed the chance to tell consumers about what they do, producing engaging videos to share with the British public.

Prime Minister Boris Johnson was

Alongside the promotion of farming and its associated organisations, there was a significant drive for consumers to watch, learn and share key information about how farming contributes to key pillar areas such

as the economy, environment, science, technology, careers and mental health and well-being.

For more information on each of our ambassadors and to read more about the campaign, visit FGinsight.com/farm24

WE teamed up with 12 new ambassadors in a new move for the initiative to share with consumers a snapshot into their everyday

farming lives and how they each have entered and progressed their farming careers, dispelling many myths along the way. Taking to Instagram for a

number of lives throughout the day, thousands of users joined to hear more from about their individual farming journeys.