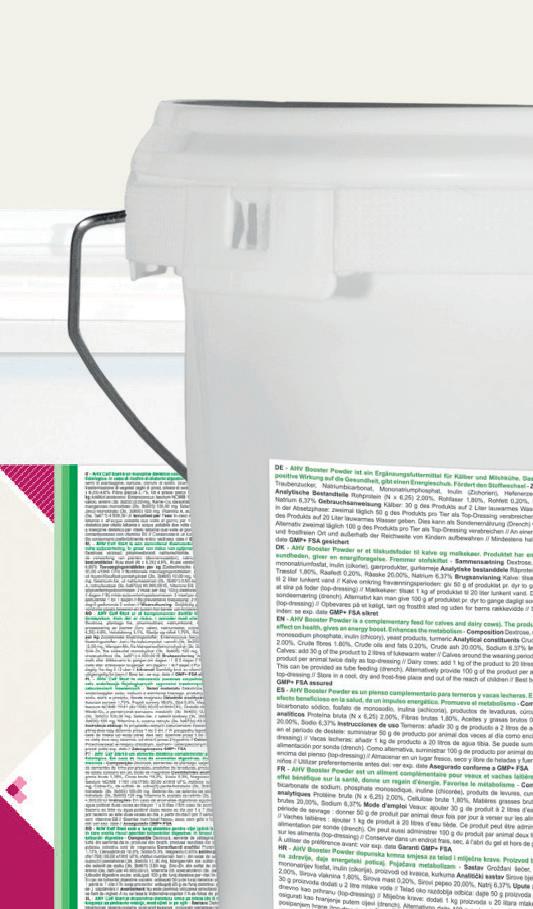

Andrew Biggs BVSc, FRCVS and Vale Veterinary Laboratory Data Primary pathogen identified in all high SCC and clinical mastitis milk samples from 2019-2021. STARTVAC® Inactivated vaccine, Bovine mastitis, in injectable emulsion. COMPOSITION PER DOSE (2 ML): Inactivated Escherichia coli (J5) 50 RED60*; Inactivated Staphylococcus aureus (CP8) SP 140strain expressing SAAC** 50 RED80***. Adjuvant. * RED60: Rabbit effective dose in 60% of the animals (serology). **SAAC: Slime Associated Antigenic Complex. ***RED80: Rabbit effective dose in 80% of the animals (serology). INDICATIONS: Cows and Heifers: To prevent Mastitis For herd immunisation of healthy cows and heifers, in dairy cattle herds with recurring mastitis problems, to reduce the incidence of sub-clinical mastitis and the incidence and the severity of the clinical signs of clinical mastitis caused by Staphylococcus aureus, coliforms and coagulasenegative staphylococci.The full immunisation scheme induces immunity from aproximately day 13 after the first injection until approximately day 78 after the third injection (equivalent to 130 days postparturition). Further information available from the SPC or on www.hipra.com. For more information about side-effects, precautions, warnings and contraindications please refer to the SPC, the packaging or product leaflet. LEGAL CATEGORY: POM-V- Veterinary medicinal product under veterinary prescription.

MARKETING AUTHORISATION HOLDER: Laboratorios Hipra, S.A. la Selva, 135, 17170-AMER (Girona) SPAIN. MARKETING AUTHORISATION NUMBERS: UK(GB): Vm17533/5010, UK(NI): EU/2/08/092/003-6. Use Medicines Responsibly. UBAC®, emulsion for injection for cattle. COMPOSITION PER DOSE: Lipoteichoic acid (LTA) from Biofilm Adhesion Component (BAC) of Streptococcus uberis, strain 5616 ≥ 1 RPU. Montanide ISA 907.1 mg. Monophosphoryl Lipid A (MPLA). INDICATIONS: For active immunisation of healthy cows and heifers to reduce the incidence of clinical intramammary infections caused by Streptococcus uberis, to reduce the somatic cell count in Streptococcus uberis positive quarter milk samples and to reduce milk production losses caused by Streptococcus uberis intramammary infections. Further information available from the SPC or on www.hipra.com. For more information about side-effects, precautions, warnings and contra-indications please refer to the SPC, the packaging or product leaflet. LEGAL CATEGORY: POMV- Veterinary medicinal product under veterinary

HIPRA UK and IRELAND Foxhall Business Centre, Foxhall Lodge, Foxhall Road, Nottingham, NG7 6LH. United Kingdom Tel.: (+44) 0115 845 6486 · ukandireland@hipra.com · www.hipra.com

prescription. MARKETING AUTHORISATION HOLDER: LABORATORIOS HIPRA S.A Avda. la Selva 135. 17170 Amer (Girona) Spain. MARKETING AUTHORISATION NUMBERS: UK(GB): Vm17533/5011, UK(NI): EU/2/18/227/001-004. Use Medicines Responsibly These products are not licensed for concurrent use. A decision to use either of these vaccines before or after any other veterinary medicinal product therefore needs to be made on a case-by-case basis. Take the next step with Mastitis Vaccination Ask your vet about your mastitis prevention plan 28,2% E. coli 11% Staph. aureus 11% Non-aureus Staph 35,9% S. uberis 4,4% Strep. dysgalactiae 2,5% Bacillus 2,7% Coryne. bovis 0,9% Klebsiella spp 3,6% Others Pages 32-50

52-70 HOUSING & SLURRY YOUNGSTOCK Storage solutions and the value of cow space Coronavirus, pneumonia and rearing protocols

72-74 MACHINERY MILK PRICES

76-78 JCB J403E electric loader put through its paces TIP OF THE MONTH: Study the credentials of methane inhibitors – p14 Pages 20-21 Breeding Managing extended lactation production August 2023 Volume 70 Issue 8

Pages

Pages

Pages

TRUSTED INSURANCE FROM THE UK’S LEADING RURAL INSURER

With over 110 years’ farming experience and expertise, we’re here to put your mind at ease. Whatever cover you choose from us, you can be sure of a high level of protection.

To see how our policies and services can benefit your farming business, search ‘NFU Mutual Farming’ or contact your local agency office.

The National Farmers Union Mutual Insurance Society Limited (No. 111982). Registered in England. Registered Office: Tiddington Road, Stratford-upon-Avon, Warwickshire CV37 7BJ. Authorised by the Prudential Regulation Authority and regulated by the Financial Conduct Authority and the Prudential Regulation Authority. A member of the Association of British Insurers.

a word from the editor

After years of waiting, Defra has finally released some details about the dairy contract regulations which are due to come into force later this year.

On the face of it, it might all sound very encouraging, but some within the industry have said more detail is still needed and the latest news has been met with caution.

Power

Farming Minister Mark Spencer says these new regulations will give ‘power’ back to the farmer and the Government will step in as a ‘referee’ when needed as a way of providing certainty and stability. But exactly how this might happen, unfortunately, remains unclear. As dairy analyst Chris Walkland points out,

milk prices are also market-related and the only way to provide certainty and stability is by underwriting a minimum selling price.

The rules around notice periods and the way changes to contracts are made are, of course, welcome, and will go some way to giving farmers more confidence.

However, I am less confident that the regulations will ensure farmers are paid ‘a fair price’ for their produce. Let’s hope this is not an ‘over-promise’ which will be ‘under-delivered’.

Finally, take a look at pages 30-31 to find out more about how you can get involved in this year’s #FARM24 campaign.

Starting at 5am on August 3, farmers and industry organisations throughout the UK will be taking to social media to take farming closer to the masses. We’d love for you all to get involved too.

3

ENGINEERING RAKE, SEED AND ROLL DÜVELSDORF GRASSLAND MAINTENANCE EQUIPMENT FROM LYNX Rake out weeds and mosses with GREEN.RAKE Fully adjustable levelling rail and rake angle Optional seeder with SEED.CON smartphone control interface TERRA.ROLLER with Cambridge or toothed rings Even weight distribution - uniform ground pressure Use rake and roller independently or coupled together MORE WAYS TO ADD MORE PRODUCTIVITY FRONT LOADERS • FRONT LINKAGES & PTOs • PICK-UP HITCHES • WEIGHTS • REVERSING FANS • FRONT PRESSES For further details about any products in the Lynx Engineering range call us today on 01327 843215 or visit www.lynx-engineering.co.uk NEW Dairy Farmer, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ Origination by Farmers Guardian, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ. Printed by Precision Colour Printing, Halesfield 1, Stirchley, Telford TF7 4QQ. No responsibility can be accepted by Dairy Farmer for the opinions expressed by contributors. Editor Katie Jones 07786 856 439 katie.jones@agriconnect.com Content Editor/Designer Mike Begley 01772 799 405 mike.begley@agriconnect.com Picture Editor Marcello Garbagnoli 01772 799 445 marcello.garbagnoli@agriconnect.com Sales Director Stephanie Ryder 07917 271 987 stephanie.ryder@agriconnect.com Account Manager Mark Jackson 01322 449 624, mark.jackson@agriconnect.com Classified Advertisements 01772 799 400 fgclassified@agriconnect.com Advertising Production Justine Sumner 01772 799 437 Fax: 01772 796 747 justine.sumner@agriconnect.com Circulation and subscriptions 0330 333 0056 help@subscribe.farmers-guardian.com Subscription rates: UK £65 a year Europe: £85 World: £95 ISSN 1475-6994 © Farmers Guardian 2023 All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system without the express prior written consent of the publisher. The contents of Dairy Farmer are subject to reproduction in information storage and retrieval systems.

AUGUST 2023

Contacts

What’s inside?

Gov revea dairy cont

Dairy farmers have reacted with caution to a long-awaited announcement on milk contract legislation but the wait continues for clarity on what the changes will mean and whether the Government can really deliver.

Speaking at the Great Yorkshire Show, Farming Minister Mark Spencer said the Government’s plans for supply chain intervention, which he expected to be legislated on before Christmas, would give power back to dairy farmers to challenge prices and stop contract changes being imposed without agreement.

He said: “In the past, there has not been a referee when there are disagreements between farmers and processors, but this

is where the Government will step in if necessary.”

However, he added the Government would not undermine the flexibility processors need, but farmers ‘should always be confident’ in the price they receive.

No guarantee

But dairy analyst Chris Walkland was cynical, stating it was ‘a joke’ that the statutory instrument on which the legislation would be laid was still not ready and that there was no guarantee the legislation would make farmers better off.

He said it was ‘disingenious and misleading’ for Mr Spencer to state these regulations would provide price certainty and stability for farmers as those were ‘entirely market-related’. He suggested this might be achieved if Defra was to underwrite a minimum selling price for milk,

Farm deaths highlight importance of safety

JUrgent steps are needed to readdress the balance of health and safety on farms after 21 work-related fatalities in agriculture, forestry and fishing between April 2022 and March 2023.

Highest rate

This makes it the industry with the highest rate of injury per 100,000 workers across Great Britain, despite a drop of two on last years’ figures, according to the Health and Safety Executive.

Six members of the public were also killed in work-related incidents in the sector. More deaths have

already been reported since March, with two toddlers killed on Devon farms in May and June.

David Exwood, NFU vicepresident, said it was important to come together and bring about a culture change in agriculture.

“We need to look at the figures and ask why these incidents are happening and what factors contributed to the incidents taking place in the first place,” he said, highlighting factors including weather and tiredness.

“And the figures detail that you are three times more likely to have an accident if you are over 65.”

NEWS 4 AUGUST 2023

JULY 2023 VOLUME 70 ISSUE 7 8 DAIRY TALK Updates from Claire Eastham and Matthew Winter 10 ON FARM Could there be a future in blended breeding? 14 DAIRY MATTERS Mandating the use of methane inhibitors 16 VET’S VIEW Antibiotics must be used with extreme care 18 WORLD DAIRYING Breeding cattle for in a African climate 24 DIET FORMULATION 26 SUSTAINABILITY 28 INITIATIVES 30 #FARM24 32 YOUNGSTOCK REARING Coronavirus, pneumonia and rearing protocols 54 HOUSING & SLURRY Storage solutions and the value of cow space 72 MACHINERY JCB J403E electric loader put through its paces 76 MILK PRICES 80 MILK ANALYSIS Milk prices stable for now 82 NEW PRODUCTS Round-up of products and updates hitting the market 86 GOOD EVANS ‘Good job they weren’t here when the rats were on the move’ 88 BUSINESS CLINIC Regenerative dairy on show at Groundswell and Down To Earth 90 RESEARCH Substituting soya with roasted beans 16-17 Vet’s

88-89 Business Clinic

View

ls long-awaited ract detail

but this was not going to happen.

Mr Walkland added prices were already transparent ‘if you know where to look’. But he highlighted there were positives, as the legislation would tighten up rules on notice periods and improve other aspects of the farmer-processor relationship.

Dairy farmer Bre Hall, Bedale, North Yorkshire, said he was concerned about the lack of detail from Mr Spencer about speci c pricing. He added farmers had been

‘held to ransom’ by processors lowering prices and making abrupt changes.

Fair price

“Dairy farmers themselves need to be involved in se ing a fair price without greed coming into play,” he said, questioning whether the reality would be fairness for farmers or processors.

NFU dairy board chair Michael Oakes has described the announcement as a ‘signi cant step forward’

in o ering farmers assurance over the price of milk production.

He said: “For a long time, unfair milk contracts have held British dairy businesses back and these changes will give dairy farmers much needed business security and condence, as well as helping to share risk along the dairy supply chain.”

Dairy UK also said the regulation would bene t dairy farmers in the future, adding the regulation needed to strike the ‘right balance’ between greater transparency and exibility.

FARMING EQUIPMENT & TECHNOLOGY FUND 2023

Eligible items in our ranges:

JAn ambitious target for organic making up 25% of the market has been set by Organic Farmers and Growers (OF&G), but Government backing and security of funding was critical in achieving its goals.

That was the message from OF&G chief executive Roger Kerr at this year’s National Organic Conference on July 4.

Mr Kerr said farming today was about ‘regeneration of resources, responsibility in production, sufficiency in consumption and ethical development of our food systems’. Communication was key, with Mr Kerr recognising organic farmers have in the past struggled to have ‘one unified message and voice’.

Organic farmers target market share M&S milk pool

JAs part of its wider low impact farming programme, Marks & Spencer has announced that the 27 English and Welsh farms in its dedicated milk pool will use an innovative next-generation green fertiliser from spring 2024.

Known as Impact Zero, the fertiliser range is manufactured by Fertiberia using green hydrogen rather than natural gas and has been shown to deliver nitrogen use efficiency 22% higher than conventional fertiliser.

Official Distrib f View our cow comfort range: www.wilsonagri.co.uk Contact us at HQ: 028 7086 8430 Mattress Dairy Grip rubber AgriCow Pendulum Cow Brush Calf De-horning crate Calving Gates Cattle Crushes Slat Rubber

Matthew Evans 07922 422556 Charlie Sutcliffe 07703 679023 Midlands & Wales Scotland & Northern England

Livestock Equipment www agrikit co uk A COMPLETE RANGE OF COW COMFORT PRODUCTS Pasture Mat the premium cow mattress

NEWS 5

AUGUST 2023

Mark Spencer said the Government’s plans for supply chain intervention would give power back to dairy farmers to challenge prices.

Welsh Gov accused of ‘burying heads’ over bTB

Adairy farmer in Pembrokeshire, whose herd has gone down with bovine TB (bTB) after five years of being clear, has criticised the Welsh Government for ‘burying their heads in the sand’ and ‘not caring about farmers’.

Fourth-generation dairy farmer Steve Evans milks 460-480 cows just outside Haverfordwest.

In early July, he had 30 cows declared as reactors which will be culled and 47 inconclusive reactors (IRs). He said after blood tests, he was ‘fully expecting’ all IRs to leave the herd.

Mr Evans said most reactors were in-calf and he estimated that, over the next 12 months, this bTB breakdown could cost his business about £250,000, factoring in all cash losses.

Double figures

He said: “When you are half-way through reading the test and you are already into double figures, you are just thinking ‘how bad is this going to be?’

“I was standing there thinking that the Government has to move on this fast, this is completely out of hand. How can we go from a clear test in March to this?

“The only reason we tested

is because a farmer nearby had gone down,” he said, adding that testing in November as planned could have been ‘absolutely catastrophic’ and ‘could have cleaned’ the farm out.

Mr Evans said he was fearful of the growing threat in Pembrokeshire, with six other farms going down in the ‘last 16 weeks’, suggesting there should have been an opportunity for a ‘targeted trap and test badger cull’.

He said he was ‘extremely frustrated’ by England being able to use ‘all tools in the box’, including targeted badger culling, but said whenever there was any mention

of wildlife in Wales ‘the shutters come down’.

He added they had done everything within their power on biosecurity.

Mr Evans said he will now have to ‘review everything on the farm’ to mitigate the financial losses.

Rearing costs

He said: “You end up spending more and more on rearing costs and straw. Your workload increases, but because your income goes down, you might have to let a staff member go. It just ends up as a total disaster.”

Mr Evans said he was already feeling stressed about his next TB

This is completely out of hand.

How can we go from a clear test in March to this?

STEVE EVANS

test, which will take place in autumn when cows will be ‘flat out calving’.

A Welsh Government spokesperson said it had been clear it would not cull badgers and highlighted ways for farmers to limit bTB through biosecurity.

For example, these measures include tackling badger and cattle contact and reducing the risk of buying infected cattle.

The spokesperson said: “It is important to discuss such measures with your vet. We have also been clear Government cannot do this alone and working with our farmers and vets is crucial to reach our shared goal of a TB-free Wales.”

AHDB survey reveals significant increase in sexed semen use

JAHDB’s latest survey of breeding companies has revealed a substantial increase in the adoption of sexed dairy semen, surpassing previous years’ figures.

The data collected over the 12 months leading up to March 2023 shows that sales of sexed semen increased to 76.5% of

all dairy semen, marking a notable surge from 70% in 2022.

The Holstein breed remains the most popular choice, representing just over 77.9% of dairy sales. The survey also indicates that beef semen sales to the dairy herd have risen to 49%, up from 48% of total sales in 2022.

The preferred breeds for this

purpose continue to be the British Blue and Aberdeen-Angus, followed closely by the Limousin and Hereford breeds.

There has also been a significant rise in the popularity of the Wagyu breed, which is gaining traction in the market.

Marco Winters, head of animal genetics at AHDB, said:

“We expect that the increased confidence among farmers in choosing sexed semen will continue to drive the upward trajectory we are witnessing.

“This is great news, as farmers are becoming more empowered to make targeted breeding decisions by only breeding replacements from their best females.”

NEWS 6

AUGUST 2023

RUMISTART GREEN

An energetic booster to support the milking ruminants

• Improves Feed E ciency

• Limits Ketone Production

• Reduce Risk of Energy Deficiency

• Lower Carbon Footprint

Propylene Glycol (vegetal origin) and Sorbitol

Energy intake

Volatile Fatty Acids and Sodium Propionate

Energy intake

Yeast extracts and Cobalt

Ruminal activity stimulation

To find out more open your camera and hover over the QR code or use your browser www.ruminantad.com

T: 01576 205 480 E: enquiries.uk@kersia-group.com

Claire Eastham

DAIRYTalk

Claire Eastham farms with her husband Martyn in Dorset, where they milk 120 spring calving cows. After gaining knowledge and experience working for other businesses, the couple started their own dairy farming journey in 2015 by taking on a share farming agreement before progressing to their current county council farm.

“ I wonder if these dry spells might lead to innovation; perhaps direct drilling cereals into a ley for added bulk at cutting?

After starting my last article with ‘well the sun is finally shining’, this time I will begin by saying ‘hurrah it has finally rained!’ Farmers and the weather, eh? What a difference three months has made, or to be more precise for us, it is ‘what a difference a couple of days made’.

We tried to plough (yes I know) one Saturday and the ground was too wet to go. We managed to plough it by the Monday and by the Friday we were already starting to get concerned the crop would never grow.

However, our first ever arable crop of barley, oats, peas and vetch, under-sown with a clover ley, was planted towards the end of May. The birds ate lots of peas – £5 kites on temporary fence posts did quite well keeping them at bay, but I would be more prepared next time.

The oats and vetch are both doing well, with recent showers having brought on the grass and clover, so time will tell.

We have also trialled varying rates of gypsum in that field and, visually, I would say that the five-tonne/acre plot does look better now, with a heavier and more consistent crop, compared with the 3t/acre and 1t/acre rates.

This will be harvested for wholecrop as the crop looks fit to do so and will be put into the silage pit with grass on top. The aim is to feed it to the dry and transition cows.

Better quality

Our hay is also safely in, with a lighter, but better quality, cut than last year.

The South West does seem to having continual dry spells and our weather is now more similar to what we have traditionally seen in the South East. So, it is a case of having to adapt.

We need to think which crops will be okay with very wet feet through winter, but then go on to also be able to tolerate a dry time.

Research shows C3 plants, such as cereals, can tolerate these conditions. Maize, a C4, always seems like a risk to me on heavy ground and potentially a poor choice for soils, although practices are improving.

I wonder if these dry spells might lead to innovation; perhaps direct drilling cereals into a ley for added bulk at cutting?

The Government has finally announced the new Sustainable Farming Incentive measures and agreed to cancel existing agreements, which now look poor in comparison.

My first thoughts are the options offer a good selection, with most farmers now being able to access options with little or no system change. For example, NUM2 legumes on improved grassland (a clover ley to you and I) will now be able to net £42/acre per annum.

Other options require a little more work and consideration, but are good practice and a win for the environment too. Here I think NUM2 and all three hedgerow options will be optimised alongside our existing herbals leys in Countryside Stewardship.

Serving seems to have gone well, with the two new Hereford bulls, called Willy and Welly, now in with the herd to sweep up.

Our first use of sexed semen has gone well, with seemingly more repeats on the conventional at the moment.

We are continually short of heifer calves; this year we had 34% heifers to bulls. One bonus would have been the large numbers of male beef calves, but we have only just managed to sell them all after finally going clear of TB on a test of two inconclusive reactors.

The herd test is only a couple of weeks away now, so hopefully another smooth run.

8

AUGUST 2023

Matthew Winter

Matthew Winter returned to the family farm in 2011 and is one of four partners in the mixed dairy/arable family farm in Lincolnshire, where 210 Holsteins are milked under the Corringham prefix. He sits on the Holstein UK board of trustees and started his career at Holstein UK as an animal breeding analyst before training to be a chartered accountant.

“ Will Lincolnshire soon only be responsible for powering the light in the fridge?

The second half of June always seems to be a particularly chaotic time for us, with Lincolnshire Show (our local show), second cut silage and multiple Arla deadlines all seeming to come together.

We usually take a team of six or seven animals of all ages to Lincolnshire Show, which, as everyone always comments, is a really nice friendly show.

Although it struggles a bit for dairy cattle numbers, being in one of the most sparsely populated areas for dairy farms, the quality of cattle is always high.

As well as being an opportunity to advertise our own cows and herd, we also use it as an opportunity to promote what we do and always try to produce an informative display aimed at the many groups of school children guided round by the society stewards or teachers (although many of the adults seem equally interested).

It has been a bit of a mission of ours to try to use this opportunity to educate the public, ever since a few years back when one teacher walked into the Holstein shed and proudly exclaimed to his primary school class ‘and here are the goats’.

We have also had the additional task of moving most of our youngstock, which are mainly on rented summer grazing, back home for a few days to make way for an archaeological survey for a huge solar project.

Power stations

When I was a child, the steam and smoke trails from three coal-fired power stations were clearly visible from our farm, but now there is just one remaining, which has been converted to gas.

These existing grid connections, the low population density and flat land apparently make this area ideal for solar farm development.

There are four projects locally, totalling 13,000 acres, which are in the public consultation and pre-planning stage.

I have mixed feelings about it. As landowners, we have been given the opportunity to contribute some land which has the potential

to be quite lucrative and give certainty to some of our income.

I do agree with the general principle of moving towards more sustainable sources of energy. On the other hand, this will decimate our local farming community and it has been met with hostility from some local residents.

Will Lincolnshire, often described as the breadbasket of England, soon only be responsible for powering the light in the fridge?

The last week in June saw Holstein UK’s celebration and AGM, with this year’s event being planned by the incoming president Andrew Jones, of Rossett Holsteins, and held around Chester.

Although I was disappointed not to be able to attend this year, I heard from those who did that it was hugely enjoyable, with some very interesting visits.

As I write this I am looking forward to a day out at the Great Yorkshire Show, which is always a good show and a nice opportunity to catch up with fellow farmers.

I must try to make the most it, before returning to freeze-branding, foot-trimming and topping it off with our Arlagarden audit later in the week.

9 DAIRY TALK AUGUST 2023

Jim Morrison, who is coowner of the award-winning British Friesian Inch herd from Downpatrick, Co Down, is clear in his views that dairy farmers will need to bring the issues of sustainability and improved e ciency to the fore, given the scale of climate change targets. He says that focusing on traits such as longevity and inherent cow fertility will be crucially important.

“One way of fast-tracking these objectives is by crossing the likes of British Friesian and Holstein bloodlines in a strategic manner in order to produce rst cross females which can milk e ciently over a long number of lactations,” says Jim. “ e principles associated with hybrid vigour have worked well for the pig and poultry industries over many years. Both sectors have moved forward very quickly in terms of genetic improvement and I see no reason why the same levels of improvement cannot be achieved within the dairy industry.”

According to Jim, the Holstein cow will always take the lead where milk production is concerned. But

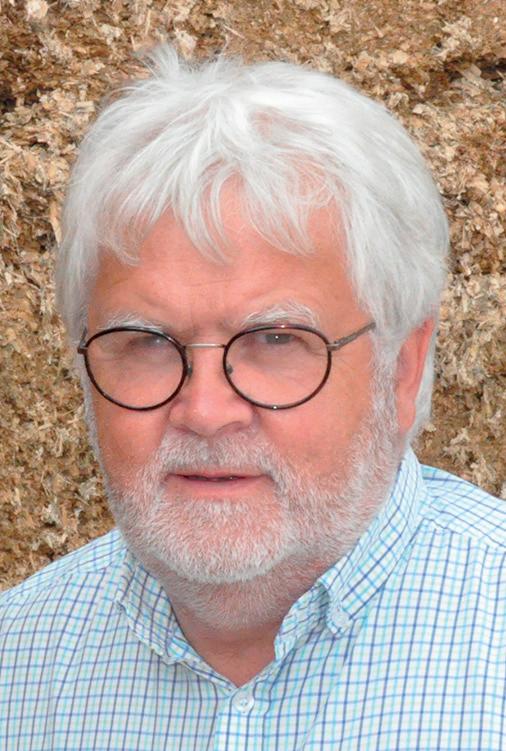

Noted pedigree breeder Jim Morrison believes the milk industry across the UK and Ireland should take a leaf out of the pig sector and embrace the benefits of blended breeding programmes. Richard Halleron reports.

Could blended breeding be the future for British and Irish dairy?

he says the British Friesian can add more, particularly from a fertility, health and longevity perspective.

“We also need to breed cows that can make optimal use of grazed grass and forage. Despite the rise in fertiliser prices over the past year, grass is our cheapest feed,

and utilising it to maximum e ect should be a priority for dairy farmers in this part of the world.”

Driving all of this is the need to maintain pedigree bloodlines of the highest standards, which is evident within the Inch herd. e herd is owned and cared

for by a partnership of the Morrison and Cleland families. e partnership is now in its ninth year and sees James and Sarah Cleland manage the milking herd at the home farm, while Jim and Jeannie Morrison care for the young bulls and heifers at their base ve miles away.

AUGUST 2023 10 ON FARM

Jim Morrison believes focusing on longevity and inherent cow fertility will be crucially important.

Part of this process is ensuring that the bloodlines forming the nucleus of the herd are maintained

JIM MORRISON

e two families’ commitment to maintaining standards has been recognised, as the herd was named British Friesian Herd of the Year for 2023. is award, which was launched by Holstein UK just three years ago, recognises the UK’s top performing British Friesian herds and is based on a combination of classi cation and production.

While the Friesian component

of the Inch herd is only 30-head, the cows within this group contain a selection of the breed’s elite bloodlines. It all adds up to a heritage which stretches back over many generations. In total, there are 100 cows in the Inch herd; all are full pedigree and most are Holsteins, but a small number of Swedish Reds have been added in recent years.

Inch Friesian genetics are held in

high esteem and many bulls have been sold to artificial insemination (AI) centres across the UK and Ireland.

Performance

“We are always striving to improve the performance of the herd and part of this process is ensuring the bloodlines forming the nucleus of the herd are maintained and built on,” says Jim.

“To this end, we have used semen from Inch bulls which have performed well in various AI programmes.”

Jim says British Friesian genetics are the key to building strength in the UK and Irish milk sectors and he is conscious that large numbers of commercial dairy farmers now recognise this reality.

“In many cases, herd owners with predominantly Holstein herds want

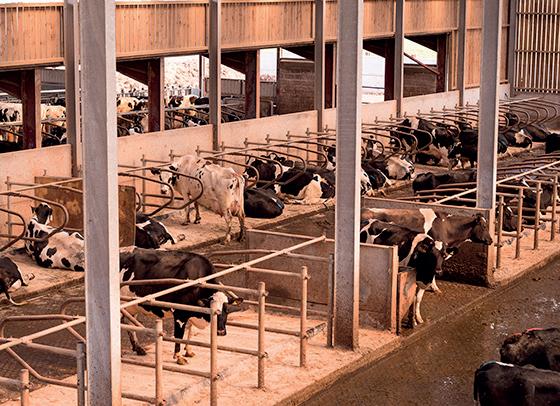

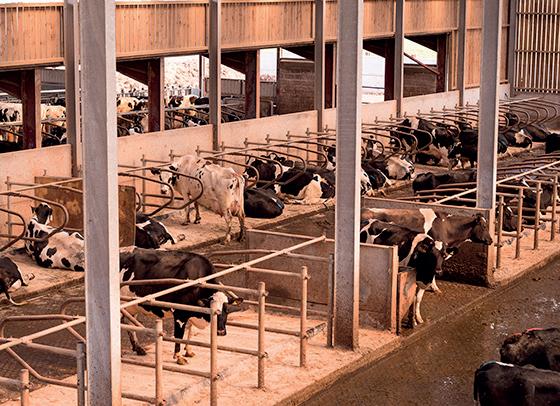

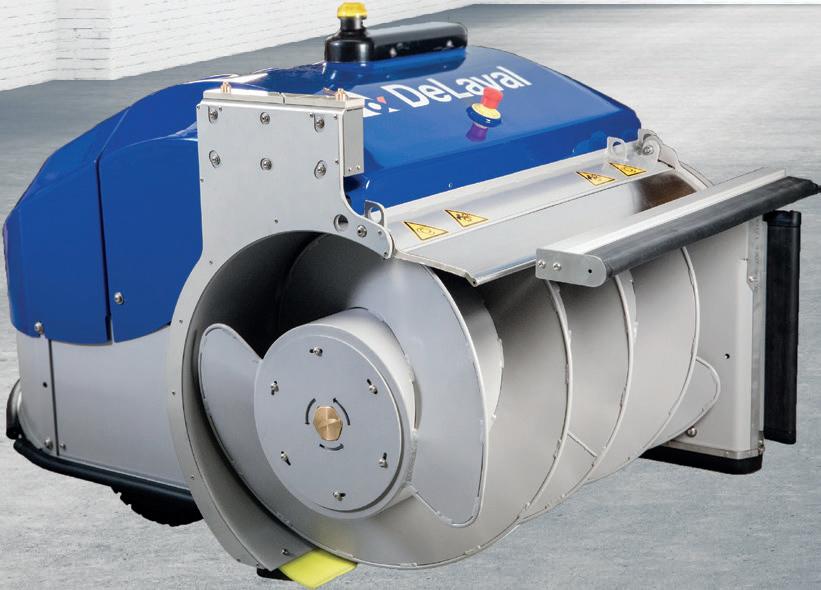

AUGUST 2023 11 Meet your new team members Find out more • DeLaval feed pushing robot OptiDuoTM • DeLaval milking robot VMSTM V300/V310 • DeLaval manure robot series MAKE YOUR TEAM COMPLETE www.delaval.com

James Cleland (left) and Jim Morrison with their award for the British Friesian Herd of the Year 2023. PICTURES : Columba O’Hare

ON FARM

to work with a less angular animal. Improving fertility is a key driver right across the dairy industry at the present time. In our own case, the average calving interval is 368 days.”

All strategic decisions regarding the development of the herd are taken on a partnership basis.

Where the issue of sustainability is concerned, James Cleland focuses on two key factors: longevity and grass utilisation.

James says: “Cows which stay in a milking group for an extended number of lactations reduce the number of herd replacements required on annual basis.

“In turn, this reduces the number of animals needed to maintain the output of the business.

“Breeding cows that can make best use of grazed grass is an obvious plus, but it is also important that the grazing infrastructure is in place to allow this to happen.

“We also believe it is wrong to have cows performing to the absolute limit of their abilities all the time; it comes down to a question of balance.”

e actual performance achieved by the Inch Friesian groups speaks for itself. e cows are averaging 8,343kg of milk at 4.87% bu erfat and 3.62 % protein and about 1.5 tonnes of concentrate is fed per lactation. Currently, 61% of the

Friesian milkers within the Inch herd have achieved ve lactations; the comparable gure for the Holsteins is 36%. In addition, the herd has been ranked top in the UK for PLI for the past three years – 60% of the milking herd is classi ed Excellent, with the rest achieving VG. e one exception is a GP83 classi cation.

Holstein

e Morrison family were one of the rst families to embrace Holstein genetics in the 1970s, and the herd is the current Northern Irish Premier Holstein small herd, as well as a two-time winner of both the national Premier Herd competition and the Master Breeder award.

However, a er almost 50 years of breeding Holsteins, it was decided to revisit the British Friesian as part of an overall herd breeding plan.

e aim of this plan was to produce more strength and longevity from a medium-sized, easily managed cow.

e resultant hybrid animal really impressed and there has been great demand for bulls with this breeding.

One cow, Inch Jed Daphne EX 93, was used as the cow to start a Friesian line within the Inch herd and bred Inch Counselor Daphne EX 94, which is the only cow in the UK herd book to classify EX 12 times.

Another of her daughters, Inch Storm Daphne EX 95, was Irish National Holstein champion and Northern Ireland cow of the year on two occasions.

Daphne had exceptional protein and fat, and Jim believes she may be

Farm facts

rMilking production began at Inch in 1949, when Tom and Marion Morrison bought Dairy Shorthorns, before introducing three British Friesian heifers three years later

rThe Morrison family was one of the first families to embrace Holstein genetics in the 1970s

rUnder the management of Tom’s two sons, Jim and Frank, numerous quality cattle were produced, including Inch Star Nina EX, which was the first

the number one – or at least in the top few cows – for fat and protein percentages in the history of the British Friesian breed.

He says: “ is further con rms the strength of these traits in the family. Today, there are 14 Friesian Daphne cows in the Inch milking group.”

Last year, two new families were introduced when two heifers were purchased from the Whinnow herd of Ian Blamore in Cumbria.

One purchase, Whinnow Centurion Priscilla 2, is a daughter of the elite breeding cow Lismulligan Priscilla 48 EX 94. e other heifer, Whinnow Jingle Wendy, is a daughter of Lakemead Wendy 35 EX 94.

Jim says: “ e aim at Inch is to enjoy providing breeding ca le to meet the ever-changing and varied requirements of dairy farmers.”

Irish National Holstein Show champion, before selling for the record price of 6,500gns; she went on to become Winter Fair champion for her new owners

rA simple grass-based system suits the herd well, with buffer feeding of silage and concentrates fed in the parlour

rThe partnership currently have 15 bulls at leading artificial insemination studs, plus many more bred to Holstein herds providing hybrid vigour

AUGUST 2023 12

Two-year-old Inch Patrol Daphne VG 87.

The Inch herd is based at Downpatrick, Co Down.

BREEDING THE WAY TO LOW METHANE COWS

At last, a genetic solution to methane emissions

For the first time producers around the world can genetically benchmark and monitor their herd’s methane efficiency with Semex Elevate®. The genomic test that analyses what you can’t see or measure on farm returning valuable information to aid your breeding decisions.

Breeding for reduced methane production has a reliability of 70-80%, is low cost, permanent and cumulative and what’s more it’s independent from other traits such as milk, fat and protein.

20-30% reduction in methane by 2050 through genetic selection is now a reality.

From the people who brought you the power to reduce antibiotic usage with

Semex UK: www.semex.co.uk : 0800 86 88 90

DAIRYMatters

‘It will be fascinating

to see how Defra mandates the use of inhibitors’

This month, industry commentator Eric Lister, who has worked in the industry for more than 40 years, discusses methane inhibitors and offers a word of warning that they may not be the silver bullet in the race to reduce emissions.

Somebody looking in on the industry could be forgiven for thinking that all farmers need to do to reduce emissions is to sprinkle a magic methane inhibitor on the diet and all their problems would be solved.

Manufacturers make some impressive claims and Defra have been so enthused that it is considering mandating the use of inhibitors.

But dive a bit deeper and it soon becomes clear that things are far from straightforward.

No-one can deny that the drive to reduce dairy emissions is absolutely vital and methane is undeniably a component of these emissions. The current thinking is that dairy farming is responsible for only about 2.7% of total UK emissions, with enteric methane accounting for just under half of this, so about 1% of UK total emissions. Yet everywhere you look, methane reduction is seen as a major issue.

Methane is part of the dairy emissions problem, but it is most definitely not all of the problem and, from a farm profitability perspective, is probably not a high priority. And methane inhibitors are certainly not a silver bullet.

On most, if not all, dairy farms, methane reduction needs to be incorporated into a more holistic approach to emission reduction. Many existing approaches have the potential to reduce emissions without incurring greater costs, allowing environmental and economic sustainability to increase in tandem. And they are measurable, so you can assess the results.

Reducing replacement rate, lowering age at first calving, removing soya from diets, reducing silage waste, improving nitrogen use efficiency and increasing feed efficiency will all help cut emissions and also contribute demonstrably to a business’ bottom line. The same cannot be said for methane reduction, with most inhibitors increasing costs for no economic return.

But the pressure is building on dairy producers to prepare to use one of the many inhibitors currently

going through the regulatory approvals process, and more are on the way.

They have different modes of action and a range of effectiveness. It will be fascinating so see how Defra mandates their use in practice, especially when it will never be able to practically determine how much its policy actually reduced emissions.

Manufacturers claim to reduce enteric methane anywhere between 6% and 28%. This means they will reduce total dairy farm emissions by 2.4-11%, but at a cost which has to be paid. So there are a number of questions which should be asked before committing to an inhibitor.

Q WHERE IS THE EVIDENCE THE PRODUCT WILL WORK?

A Check the science and challenge the claims, taking independent advice. How many trials have been carried out and what reductions have been achieved?

How have methane reductions been measured in farm trials? In at least one major widely reported farm evaluation in Holland, not a single methane reading was taken, yet a 28% reduction in methane was reported. These claimed reductions were just computer-modelled.

Q HAVE THERE BEEN ANY LONG-TERM STUDIES?

A It is one thing to measure the effect for a short period, but where is the evidence of continued efficacy or indeed of any problems where the product has been fed for an extended period over several lactations?

And what about feeding methane inhibitors to dry cows, as remember cows generate methane every day, not just when in milk?

Most studies to test these inhibitors are carried out over a short period of time – about 12 weeks or so. What about a full lactation? Or two?

There is concern that the rumen microbiome will do what it does best – adapt over time, resulting in an inhibitor which no longer works.

14 AUGUST 2023

“ Methane inhibitors are certainly not a silver bullet. On most, if not all, dairy farms, methane reduction needs to be incorporated into a more holistic approach

Do not forget, evolution has brought us an animal which can convert brous material humans cannot digest into something we can consume –and a natural part of that cycle is to expel waste as methane. As in Jurassic Park, nature will nd a way. It always does.

Q HAS IT BEEN TRIALLED ON SYSTEMS SIMILAR TO MINE?

A ere has been li le if any evaluation of any of the products in grazing systems, for example. Most studies have involved total mixed ration (TMR) systems with housed cows. But what about simple silage and cake systems?

Q HOW CAN AN EXPENSIVE INGREDIENT BE FED?

A Most products are not suited to inclusion in compounds, especially in feed-to-yield systems. How can you include an expensive ingredient which has a set daily requirement in a feed which might be fed anywhere from 2-10kg/day?

Some products need to be introduced gradually, so how does this work on a commercial farm with groups of cows?

If included in TMR systems, you could be feeding very small quantities, which could cause practical issues? What happens if TMR is not fed as a bu er in grazing systems?

Q HOW AM I SUPPOSED TO KNOW IF IT IS WORKING?

A If you are paying to add an ingredient, it is only fair you can measure its e ectiveness. But how can you measure what you cannot see? One hopes the manufacturers are working on this.

Q WHO PAYS AND WHERE IS THE RETURN?

A Perhaps the major issue. Any methane inhibitor will increase feed costs – some by as much as 1ppl – so where is the return? Someone needs to pick up the bill. It is unlikely retailers will allow milk prices to rise to cover the cost, as this would fuel food in ation.

It has been suggested that processors may absorb the cost in their sustainability budgets, but is this realistic? Unless there is a creative scheme to monetise lower methane emissions, the e ect will be to reduce margins.

Methane is part of the dairy emissions issue. In the recent KW survey into dairy farmer a itudes to sustainability, currently only 13% of producers are considering methane reducers.

Hopefully, the remainder will be doing their due diligence and make sure they get some clarity and answers before deciding what to do.

In the meantime, perhaps the focus should be on other ways to reduce emissions which have a positive impact on pro tability?

15 AUGUST 2023 AGRICULTURAL & INDUSTRIAL STEEL FRAMED BUILDINGS Livestock Housing, Crop Storage, Industrial & Commercial, Tip Troughs Schurr Cow Brushes BEDDING MACHINES Telephone: 01524 792247 e-mail: sales@rebuildings.co.uk www.rebuildings.co.uk Scrape, Sweep and Spread in one pass. Bedding Material and Labour saving. Reduce cell count and increase production. Prevent disease and maintain good animal Health. Self-loading models available. Simple to drive and manoeuvre. 1 or 3 wheel drive. ELECTRIC ASK FOR DETAILS NOW AVAILABLE NEW

The practicalities of feeding methane inhibitors need to be addressed.

Research into antimicrobial resistance on dairy farms has uncovered some confirmed cases and while it is not yet a major problem, farmers are warned to stay vigilant. Wendy Short reports.

Antibiotics must be used with extreme care

Antimicrobial resistance is a worldwide issue, with a widespread occurrence, because bacteria can evolve and mutate in a range of environments.

Vet, Rachel Hayton, of Synergy Farm Health, says on dairy farms, resistance has sometimes been uncovered in association with mastitis cases and some youngstock health issues.

She says: “In the dairy industry, bacteriology is o en part of an investigation into a mastitis

problem, but it is not routine practice to identify the bacteria type for some other common diseases. Mastitis can be contracted in two main ways: it is passed from cow to cow or it is picked up from the environment.

“ e number of contagious bacteria types which can be passed from one animal to another is relatively limited. erefore nding a rising level of antimicrobial resistance in these bugs could create a big problem for some dairy farms.

“Resistance has been identi ed in one bacteria type, staphylococ-

Data on antibiotic usage

JWhile meticulous records of antibiotic usage must be kept by law, Rachel Hayton advises producers use this information to track their own progress.

“All dairy farmers should know how much antibiotic they are using annually.

“This will allow them to understand whether the amount has increased or decreased over the past 12 months and to focus on problem areas. The vet will hold this information and it should be brought into the discussion; they can often help with analysis.

“For herds registered at more than one practice, it is vital there is full information sharing between the vets.”

Many vet practices, and other businesses which support farmers, run benchmarking groups where anonymised data can be shared on a confidential basis, she says.

The standard metric for antibiotic usage is mg/kg population correction unit (PCU), with the figure calculated using the number of milligrams of antibiotic administered annually to cows and replacement youngstock and the total number of cows, multiplied by a standardised weight.

“As can be imagined, the result will vary depending on farm type; for example between breeds, or flying herds versus herds breeding their own

cus aureus, but it is not thought to be at a high level and monitoring continues. By contrast, there are thousands of environmental microbial strains that have the potential to cause disease and many resistant strains have been found in one of these in particular: e.coli.

“ It is possible that the levels of resistance vary across geographical areas and from farm to farm, but the a ecting factors are not yet well understood.”

Ms Hayton explains resistance occurs due to natural mutations that crop up when bacteria

replacements. Therefore it is important not to infer too much from comparisons between different units.

“Another recommended practice is to get into the habit of regularly reviewing the farm’s antibiotic policy and try and pick out any weak points.

Challenging

“Preventative strategies can be then put in place to keep the usage level down. All dairy farms will experience a challenging year every now and then; the key is to learn from mistakes and put measures for improvement in place. Vaccination also has an important role to play.”

While vets do not see clinical examples of resistance often, Rachel Hayton says it is important the industry retains access to a full range of effective antibiotic treatment options.

reproduce. It can also be transferred directly from one bacterium to another in the form of plasmids.

“Antibiotic-resistant strains do not usually persist unless they have an advantage over non-resistant strains. is could occur where they are exposed to antibiotics on a regular basis; for instance in an animal’s digestive tract or udder, or in the environment.

Mrs Hayton cites the AHDB’s Medicine Hub as a vital tool for an industry wishing to be proactive in driving responsible antibiotic usage.

“The Medicine Hub is our way of demonstrating where we are nationally. This is vital if we are to compete in global markets, as well as reassuring our domestic consumers.

“Farmers can register online to create a Medicine Hub account and give permission for their vet practice or other third party to access the data or upload on their behalf. It provides a confidential way of recording antibiotic usage and sharing anonymised information with the industry.”

AUGUST 2023 16 VET’S VIEW

“While vets do not see clinical examples of resistance very o en, it is important the industry retains access to a full range of e ective antibiotic treatment options and vigilance be maintained.”

It is possible to con rm antimicrobial resistance in the laboratory and there are a range of techniques available.

“Antibiotic pro ling conducted on any bacterial isolate may highlight resistance, although it is not always standard practice.

Factor

“It should always be considered a factor with any clinical case that is not responding to treatment, but it can sometimes be missed, as animals may be euthanised if they are not ge ing be er.”

All antibiotic treatments should be given in accordance with veterinary instructions, or as detailed in herd health plans; also following data sheet instructions.

Ms Hayton says: “ e rst chance to treat an animal is always the best chance, so a producer must have clear protocols in place for all the common conditions and make sure that they are regularly reviewed with their vet.

“ is includes applying the correct withdrawal periods.

“Some farms have been using on-farm culture systems to identify the mastitis cases which are more likely to self-cure without antibiotic treatment.

“In these cases, a non-steroidal anti-in ammatory drug might be su cient. is system is only suitable for certain farms and situations and I would not recommend selective treatment in most cases.”

By contrast, selective dry cow therapy is now widely accepted and has contributed to a reduction in antibiotic usage on dairy farms.

“It should be applied following a review of cow history, including clinical mastitis history and cell count data. Successful dry cow therapy relies on the teat being surgically clean before treatment and the tube must be inserted using the correct technique.

“ is is particularly important for cows receiving a non-antibiotic internal teat sealant alone.

“Research suggests that at least 85% of cows can be cured of sub-clinical mastitis during the dry period and the target is for fewer than 10% to contract a new infection.”

She adds it is vital to monitor cow health, particularly in the rst few days, keep a clean environment and ensure targets are met.

HIGHLIGHTING HEAT STRESS

In addition to its ability to detect heats accurately and reliably, the SenseHub® dairy cow monitoring system from MSD Animal Health also provides around-the-clock health and welfare monitoring for hard-working dairy cows.

By measuring rumination frequency and duration, SenseHub’s neck collars and eartags can be used to accurately assess each individual cow or heifer’s feed intake and monitor the general well-being of animals on an individual or group basis.

In addition, their ability to monitor how frequently and heavily cows are breathing also enables SenseHub tags and collars to be used to determine when animals are at risk of heat-induced stresses during periods of hot weather.

If elevated rates of respiration are detected, the SenseHub app automatically

sends an alert to herd managers and their staff to warn them that the herd is in danger.

Armed with this knowledge, herd managers can then take action to protect the herd and reduce the impact of heat-related conditions, such as depressed feed intake, lower milk yields and reduced fertility.

Knowing which individual animals or groups of cows require additional attention during hot weather enables resources to be targeted to those animals most in need of help, ensuring productivity is maintained and giving time back to herd managers, their staff and their families.

To find out how more about how SenseHub could protect your herd during periods of hot weather, please call the SenseHub team on 01207 529 000. Alternatively, to send us an email, please contact us at allflexuk@msd.com

SenseHub is not intended to diagnose, treat, cure or prevent any disease in animals. For the diagnosis, treatment, cure or prevention of disease in animals, you should consult your veterinarian. The accuracy of the data collected and presented through this product is not intended to match that of medical devices or scientific measurement devices.

For more information, visit farmersguardian.com/MSDSenseHub

AUGUST 2023 17

CONTENT

SPONSORED

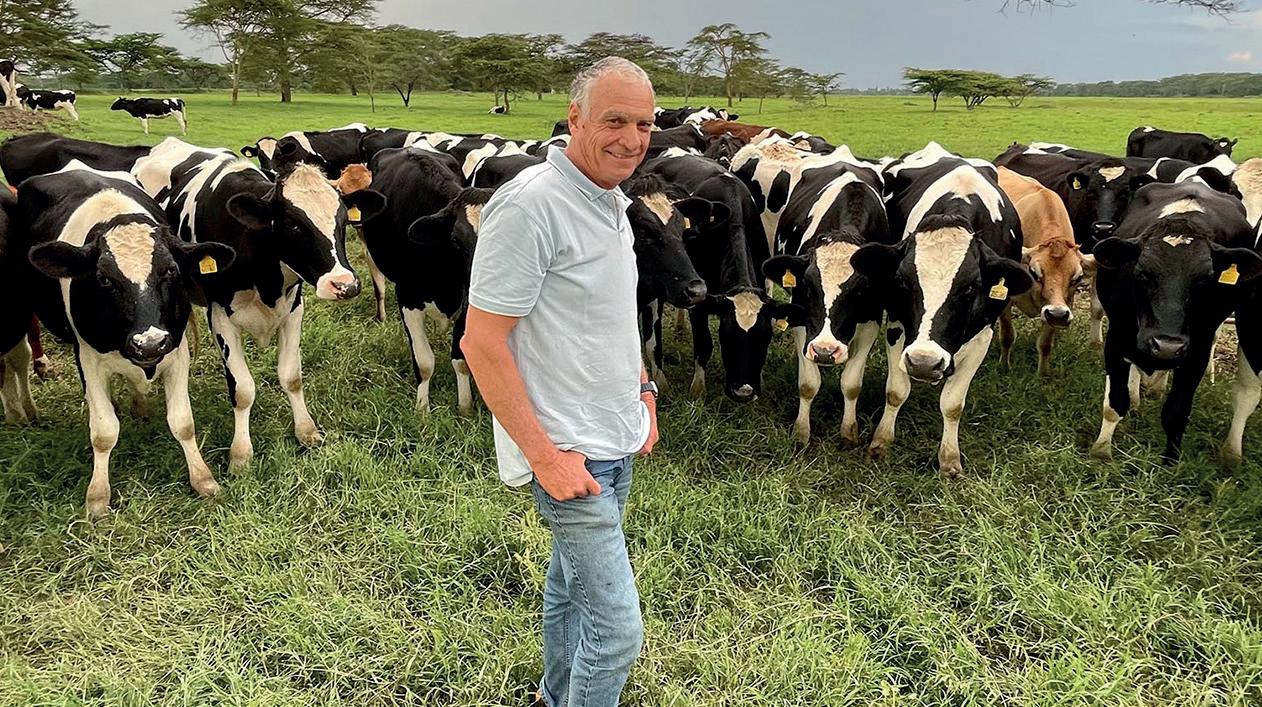

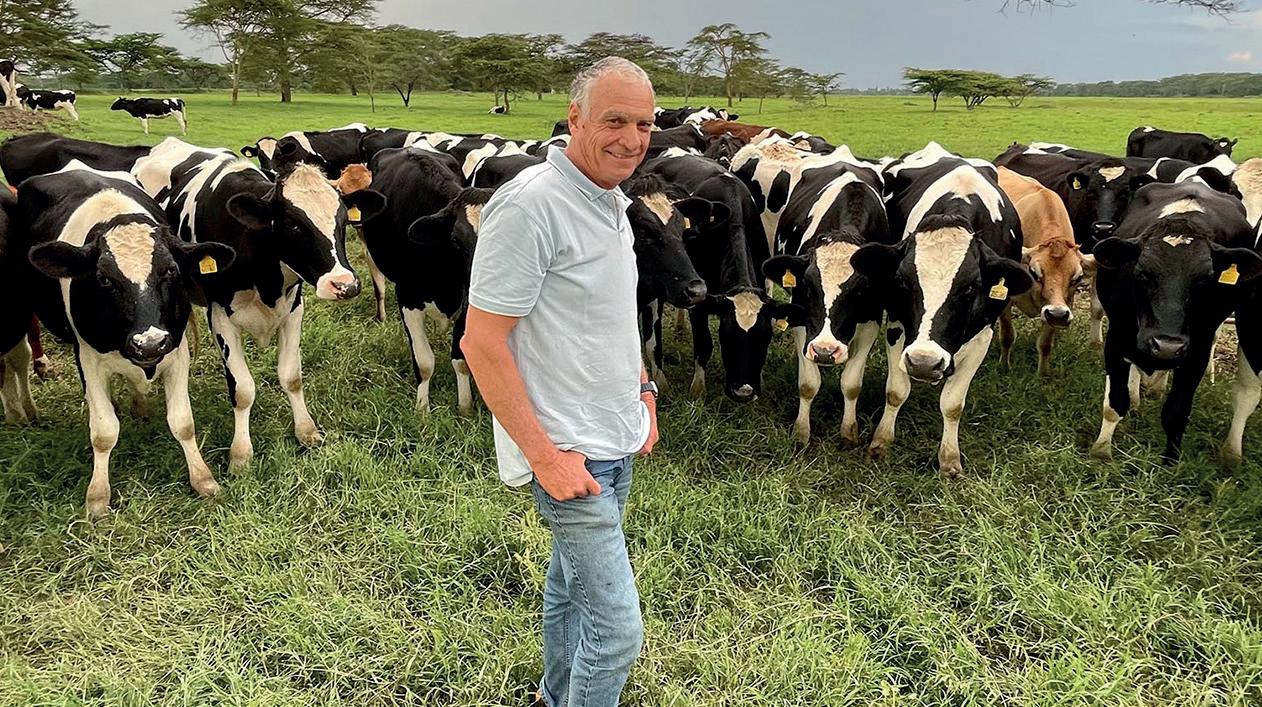

The main focus of Hamish Grant’s dairy business is breeding and selling cattle to other farmers in East Africa. Chris McCullough reports.

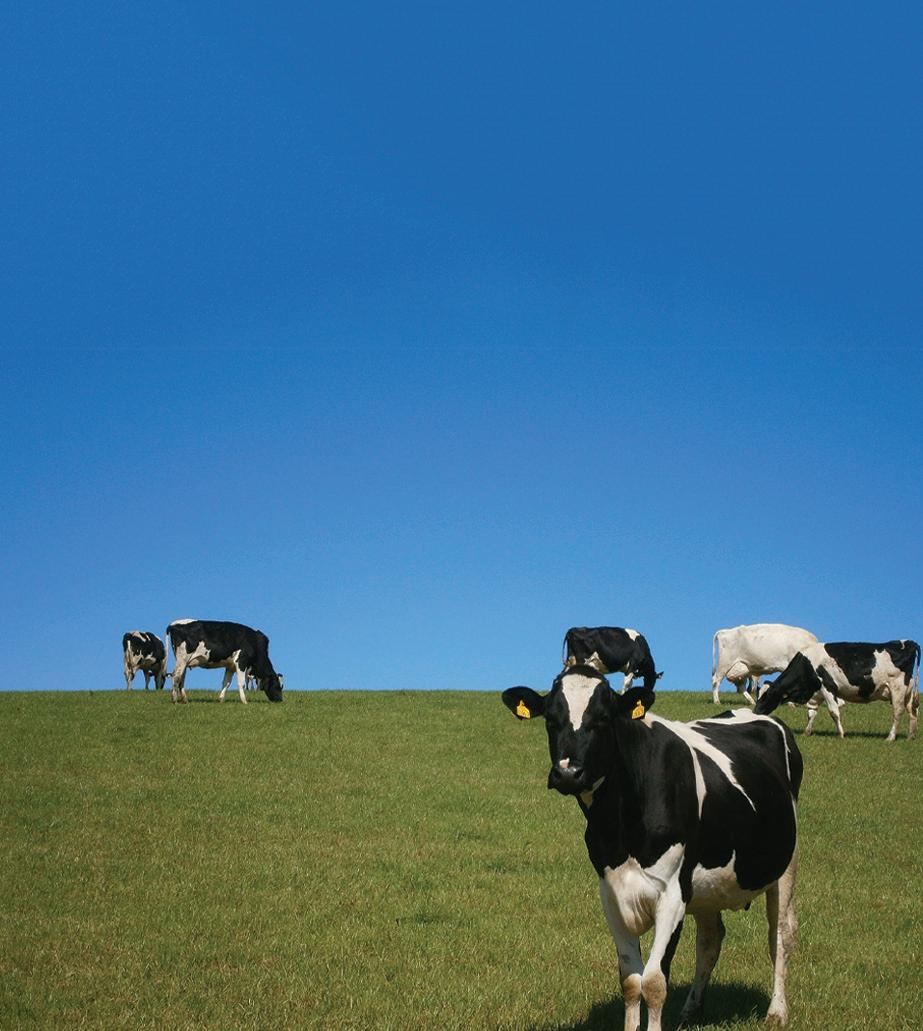

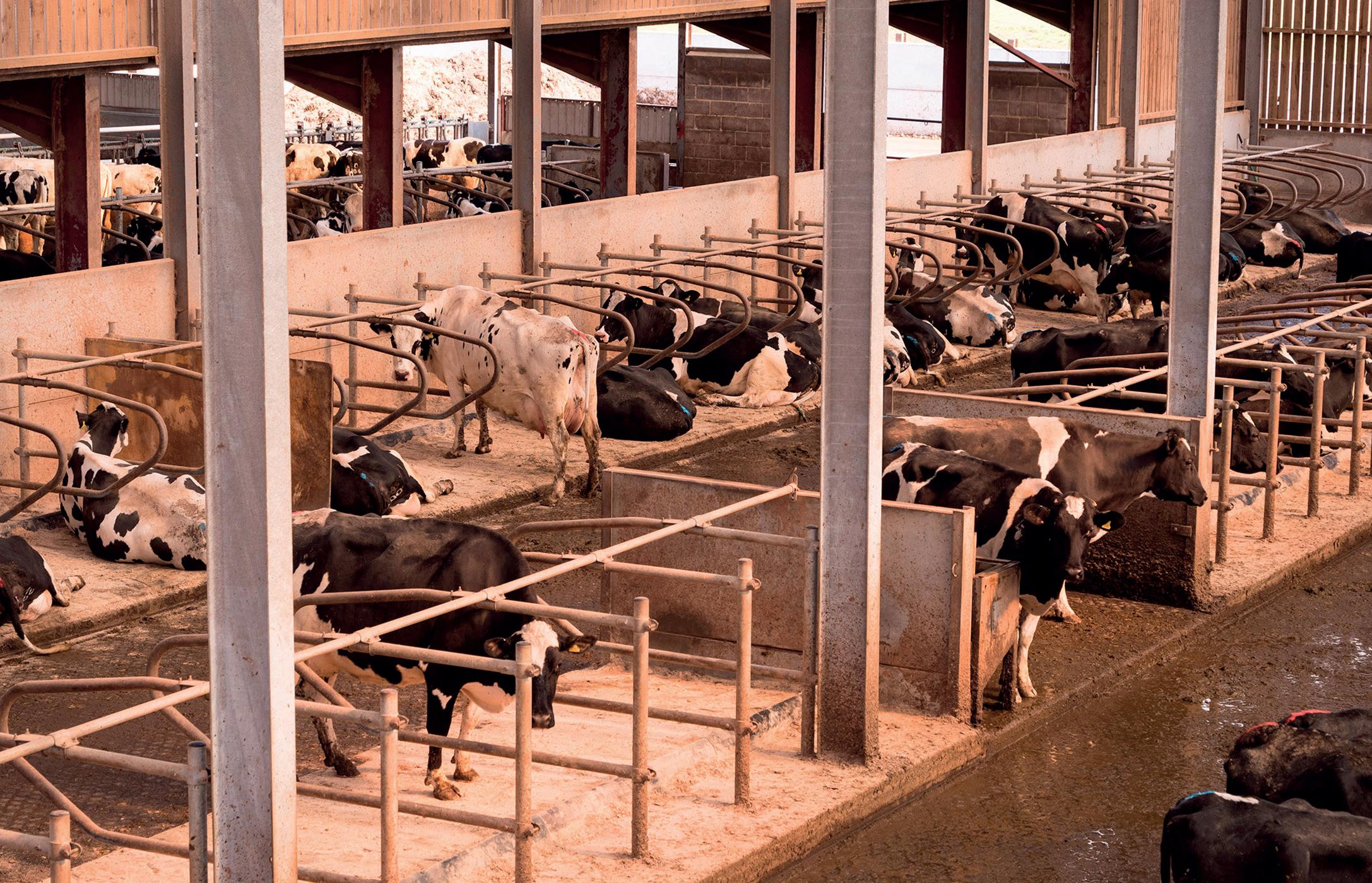

Hamish Grant runs 500 cows on his 1,600-hectare (3,954-acre) farm in Kenya.

Breeding cattle for harsh African climate

While most dairy farmers strive to breed a cow that can produce a lot of high quality milk, it is the animal’s survival traits that are more important to one Kenyan breeder.

Under his own unique business model, Hamish Grant at Gogar Farms, Rongai, in the Ri Valley, breeds dairy ca le for farmers across east Africa, with an emphasis on animals that can survive

the harsh African conditions.

Hamish says: “Initially we ran Ayrshire ca le on the farm, but since the mid-1990s we switched to Holstein Friesian which now make up more than 90% of the herd. Our primary business is breeding heifers to sell to customers across eastern Africa, meaning milk is more of a by-product for us.”

e farm normally runs about 500 cows, but with followers, ca le numbers on the farm are more than 1,400 head.

The cows are milked outdoors twice per day in a mobile unit.

Hamish says: “ e cows are kept outdoors all year round, and are milked outdoors using a mobile system with bucket milking. is unit is moved daily which increases our sustainability as we do not have slurry to worry about.”

e outdoor milking system currently works well for Hamish and his team as there is a river that snakes through the dairy grazing, making it di cult to round cows up to walk to a milking parlour.

Hamish says: “In the past, all our milking equipment was Fullwood, but we are now changing to the Bereket brand made in Turkey.

“ ere are eight stalls on each side of the mobile unit, with two sta milking and one assistant on each side. We run two teams for the morning and evening milkings.

“Each team milks for about seven hours. e rst team milks from 2am to 9am and the second team from 2pm to 9pm.”

Cows are kept in two groups with about half in the rst calvers group and the rest in the mature group of second lactation and older animals.

Under Hamish’s pasture-based system, the cows eat as much grass as possible, but in the dry season he bu er feeds some silage via a 22cu.m mixer which transports the feed to boxes in the elds.

Ticks

Hamish says: “ e main challenges we face here are tickborne diseases.

“We have to spray each cow every week through a spray race otherwise ticks proliferate and are vectors for diseases such as Redwater, Anaplasmosis and eileriosis.”

e herd is also vaccinated against foot-and-mouth disease three times a year.

Cows yield about 18-20 litres a day, but Hamish says the milk is a by-product of his business model

AUGUST 2023 18 WORLD DAIRYING KENYA

Farm facts

rGogra Farms employs more than 100 people

rThe farm has operated for more than 100 years and extends to 1,600 hectares (3,954 acres)

rMilk is sold to processor

BioFoods Kenya for the equivalent of 35-40ppl

rSexed semen is used on all cows and heifers

as he is focused on breeding cows and heifers suitable for other dairy farmers, and his system does not give the ca le opportunity to express their true potential.

He says: “ at is why I want to use genomics that will give a better idea of their potential than our milk yields.

“Farmers who manage the cows intensively commonly get twice as much milk from

these cows when we sell them.”

In terms of stock sales, Hamish sells about 200 in-calf heifers each year to farmers in Tanzania, Uganda and Ethiopia.

He says: “In-calf heifers sell for about $2,800 at 2.5 to three years old as they grow a bit slower under our conditions.

“However, they are tougher than fast grown heifers.”

In addition, he also sells third and fourth calving cows to other dairy farmers, for about half the price of the heifers.

He says: “Breeding cows are also valuable as farmers like cows at the peak of their milking potential.”

In order to breed the right animals for African conditions, Hamish uses AI bulls that rank highly on the Nordic Total Merit Index.

He says: “I use VikingGenetics Holstein Friesian semen as the o spring are not as big and cumbersome as North American or

Dutch stock. ey are also much be er suited to the varied, and o en challenging conditions in Africa. Big animals struggle here in droughts, on uneven terrain and under less than ideal management.

“Also, we nd cows that are more than 50% black in colour are less susceptible to skin cancers and are longer lasting, so we tend to avoid bulls that are mainly

white in colour if possible.”

Hamish says he averages around one in three sexed semen straws resulting in a pregnancy over all his herd, including both young heifers and older stock.

“Interestingly, there is not as much drop o in that percentage in the older cows,” says Hamish. “ e worst pregnancy percentage is always with the rst calver as they are still growing.”

AUGUST 2023 19

WORLD DAIRYING

KENYA

Hamish has to breed heifers to survive the harsh African conditions.

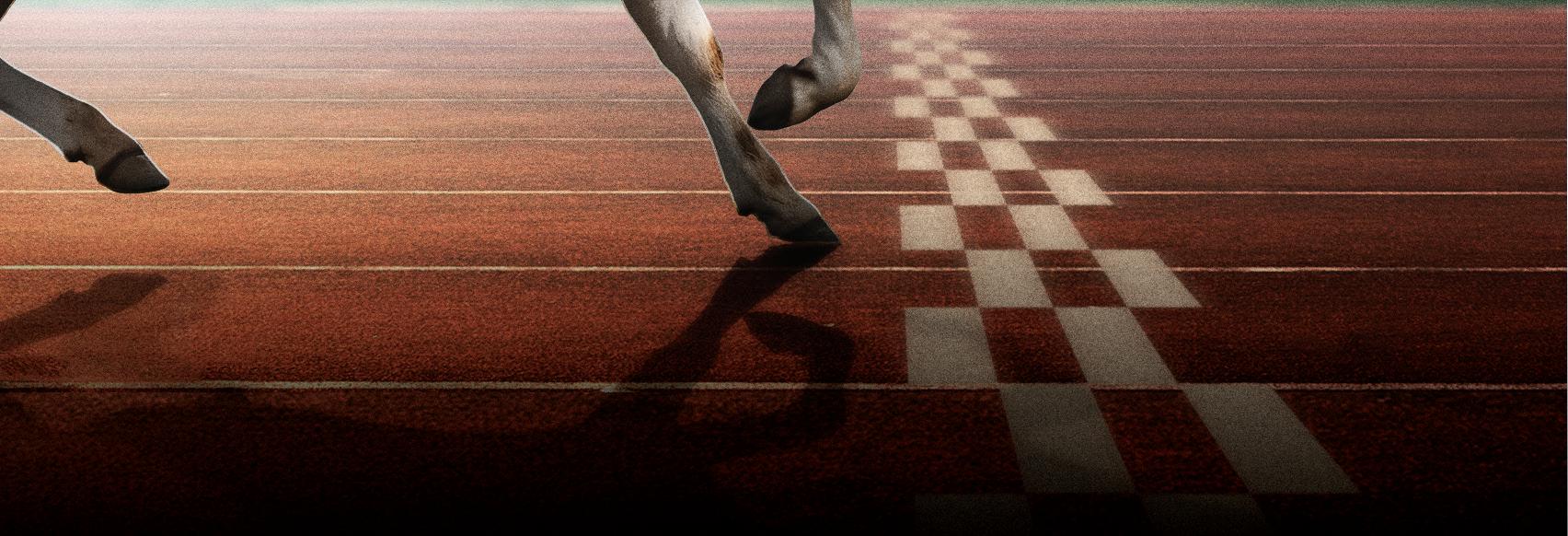

Extended lactation production is attracting interest in the Netherlands and Denmark and while it might look attractive for some UK producers, it should only be introduced with proper planning. Wendy Short reports.

Managing the risks of extended lactation production

To some extent the technique of extended lactation production is already practised on a smallscale on UK farms, when drying off is delayed for a cow that is still producing high milk volumes.

However, extended lactation comes with risks and incorporating the technique will require specialised management, says Duncan Williams of Promar.

The theory behind extended lactations is that keeping high-yielding cows milking for longer can lift average lifetime yields, as well as increasing longevity.

This is largely down to the reduced number of days dry and fewer transition periods.

This is clearly the opposite of standard reproductive advice, which for decades has been to get cows pregnant as soon as possible, says Mr Williams.

He states that the key elements to consider are herd health status and milk production persistency.

He says: “If farmers have problems with the transition stage, the solution should be to tackle any health problems, rather than using extended lactation to calve less frequently.

“Any transition or health issues will decrease a cow’s milk yield, making that animal unsuitable for the practice.”

Extending the lactation is not as straightforward as simply delaying service for a random group of cows, he explains.

“The chosen animals must have the potential for persistent lactation; the technique is inadvisable for cows whose production falls off sharply at the end of the milking period. They should also have high health status, with no historical record of health problems.

“If farmers really want to try the system and they have done

Farmers who wish to experiment with extended lactation must have a good system of data management

DUNCAN WILLIAMS

all they can to maximise transition success and milk persistency, I would recommend selecting a small group of high-yielders for an initial trial.

“I suggest that the group should only include 5-10% of the herd for producers who are testing it for the first time. Heifers are the most obvious choice, because they tend to be healthier and their lactations are often more persistent.”

The voluntary waiting period on the selected animals can be moved back 30-50 days, he says.

Waiting period

The average voluntary waiting period, which is 42 days for cows and 60-72 days for heifers, could be adjusted to 70 and 100 days, respectively.

The practice is only applicable to all-year-round calving herds, as it will have an undesired effect on the calving pattern for seasonal-production herds.

Extending lactations will alter the herd’s overall reproduction statistics, so producers must be able to calculate the reproductive performance of the remaining herd separately.

UK producers have shaved off 30 days from the average calving index over the past 15 years, reflecting a significant improvement in general fertility management, he says. The current average calving index for the UK dairy herd is 394 days, with a general target of 365-380 days.

Correct feeding is an extremely important aspect, he adds.

“If the practice is not carried out correctly, the end result will be a cow which piles on weight in the final period of milking.

“Subsequently, she may be difficult to get in-calf and there is a risk she will not perform to her full potential during the next transition period.

“Rations must be tailored specifically for extended-lactation cows and it may be easier to achieve greater precision on farms with milking robots.

“Adequate energy and protein in the fresh ration will set cows up for long milk production.

“However, consideration must also be given to ensure the right balance between energy and protein in late lactation to avoid the cow laying down fat. Milk yields can fall after turnout, so that must also be kept in mind.

“Lactation persistency is a heritable trait. Cows with high milk yield potential tend to have a flatter lactation curve, but production can be manipulated to a large extent through nutrition.”

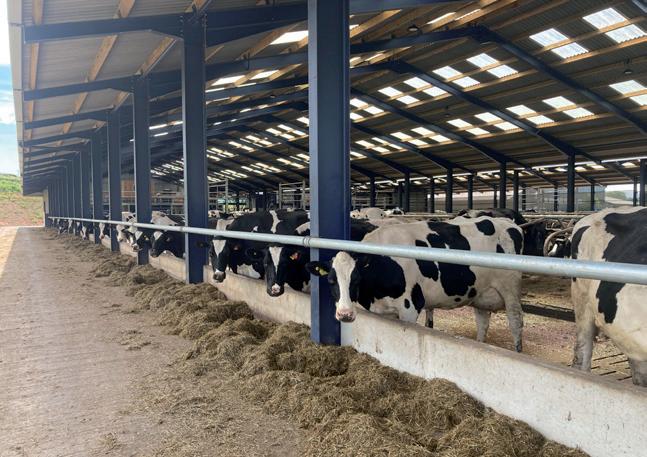

Housing availability is another factor to review when weighing up the potential benefits of experimenting with an extended lactation policy, says Mr Williams.

“Most farms have a limited number of cow spaces over winter. In these cases, it may be better to keep high-yielding

AUGUST 2023 20 BREEDING

cows and aim for an improved daily herd yield, rather than target individual cow lifetime daily milk production.”

Changes to the breeding policy may also a ect the number of heifers which are coming through the system for producers who breed their own replacements, says Mr Williams.

And extended lactation can slow genetic progress, although the impact will be limited, especially on units which use sexed semen.

Plans should be drawn up in conjunction with breeding advisers to mitigate both these issues.

Mr Williams says: “Farmers who wish to experiment with extended lactation must have a good system of data management.

“It is essential to monitor its e ect on the business by analysing the gures, so decisions can be made on whether or not the practice is improving pro tability.”

Complex

Extended lactation is a complex and contentious issue, he says.

He says: “Standard practice is to get the cow back in-calf as soon as possible, because more frequent calving will increase peak production period for the herd overall and will ll the bulk tank more e ectively.

“ ere may be bene ts in extending the lactation of speci c cows, but the practice must not be used in an a empt to justify an underlying fertility problem within the herd.

“At rst glance it may appear to be an a ractive proposition, because drying o a cow which is still giving high yields can be viewed as counter-productive.

“However, it should only be introduced with correct planning. Otherwise there is a risk it will have a negative e ect on overall pro tability.”

AUGUST 2023 21 before 31st July 2023 and receive a FREE heavy duty IMS auger upgrade Step up to a Strautmann Save on labour, wear & fuel Verti-Mix * This promotion is for business purposes in the UK only for new equipment and is subject to credit acceptance and any qualifications in government or company policy. Finance is available on 50% of RRP or the balance to finance whichever is the lower. VAT - Hire Purchase: Full VAT on signing. Lease: VAT payable on each rental as it falls due. VAT charged at the current UK rate at time of acceptance. Administration fees are payable on all transactions including interest free agreements. Written quotations are available on request from Strautmann Finance. Strautmann Finance is a trading style of Peregrine Asset Finance Ltd, 3 Maple House, Wykeham Road, Northminster Business Park, Upper Poppleton, York, North Yorkshire, YO26 6QW. Peregrine Asset Finance is authorised and regulated by the Financial Conduct Authority number FRN649227. Peregrine Finance offers financial facilities to UK businesses only through a number of authorised funders, a list of which is available on request. 0 % FINANCE 4+20 monthly payments @ 0% Flat Rate p.a, based on 50% RRP ENDS 31 st AUGUST 2023 * T&C’s apply, strautmann.co.uk/finance Distributed by Distributed by Visit strautmann.co.uk to see the full range of Verti-Mix feeder wagons or call OPICO now on 01778 421111 OPICO Ltd ask@opico.co.uk strautmann.co.uk Profit from our knowledge strautmann.co.uk

Having good stocks of quality forage helps to improve farm resilience in times of volatile milk prices and unpredictability. Volac silage experts offer guidance.

You only need to look back over the last two years to see the volatile and unpredictable nature of modern dairy farming. We have experienced milk prices hitting exciting highs then heart-sinking declines, variable input costs and a severe drought last season in some areas which left many farms facing a forage crisis.

While only part of the solution, having good silage safely ‘banked’ puts farms in a better position to navigate volatility and unpredictability, says Volac forage expert for southern England Ken Stroud. And with the spotlight on greenhouse gas emissions, good home-grown forage is highly sustainable, he adds.

Mr Stroud says: “A lot of money is invested in growing a maize crop to produce a good source of dry matter (DM) and metabolisable energy.

“At the end of the season, it is crucial to ensure as much of that investment as possible is recouped. This is achieved through harvesting the crop at its nutritional peak, then

ensiling correctly to safeguard against losses in the clamp.”

Maize losses

Typically, Mr Stroud says the equivalent of one in every 10 trailer loads of maize DM ensiled is lost in clamps due to the growth of unwanted bacteria, yeasts and moulds. However, this can easily double, particularly where attention to detail slips during the ensiling process.

He says: “What is also important to realise is that these unwanted microbes feed first on the sugars and starches, rather than fibre. So the silage remaining is also lower in energy. Making consistently better maize silage requires a multi-step plan.”

1

HARVEST AT MAIZE’S PEAK

Mr Stroud says capturing maximum nutrient content in maize starts by harvesting when the whole plant reaches 30-33% DM, but also while leaves are still green.

He says: “Maize is often regarded as only ready to harvest once leaves die back. But by then it is past its best.

“Although harvesting later can

Five steps for better maize

increase starch in the cobs, by harvesting while leaves are still green and lush, the plant is more digestible to the cow.

“In addition, dead foliage harbours unwanted yeasts and moulds and is more difficult to consolidate in the clamp than softer, living tissue, which makes it vulnerable to losses from heating [aerobic spoilage].

“Even last season when a lot of maize in parts of the country died off prematurely because of the drought, crops which were cut earlier tended to produce better silage.

“It is easy to miss the 30-33% DM target if contractors cannot get to the farm in time. So check crop percentage DM regularly to give contractors plenty of notice.”

2 LEAVE ENOUGH STUBBLE

Although it is often tempting to cut maize crops closer to the ground in search of extra yield, Volac silage expert for Wales and the west of England, Peter Smith, urges strongly against this.

He says: “For a start, the stem base is low in nutritional value. But it also contains high numbers of undesirable microbes, for example bacteria from the soil which interfere with the fermentation in the clamp, as well as yeasts and moulds. Therefore, ask your contractor to leave at least 15cm of stubble.”

3

CHOP TO THE CORRECT LENGTH

Chop maize short enough to aid consolidation but long enough for it to perform in the rumen, advises Peter Smith.

He says: “With maize vulnerable to heating, chopping shorter helps you squeeze out air during rolling and is especially important if maize is dry. Consider chopping to 1.5-2cm or down to 1.2cm if needed.”

4 PRESERVE WITH A DUAL-ACTING ADDITIVE

While heating in maize silage causes significant losses, do not think this is the only source of loss, says Volac silage scientist Dr Mark Leggett.

SPONSORED CONTENT

AUGUST 2023 22

Ken Stroud says making consistently better maize silage requires a multistep plan.

CHECK OUT THE CAMPAIGN FOR BETTER SILAGE

● As well as its Cut to Clamp initiative, Volac is proud to be one of the sponsors of Dairy Farmer’s Campaign for Better Silage. See page 29 or visit farmersguardian.com/ bettersilage

As much as half the losses can be invisible due to an inefficient fermentation, he says, making it important to safeguard against both problems.

Dr Leggett says: “An efficient, rapid fermentation is the starting point to good maize preservation. Fermentation is carried out by bacteria.

“However, while some bacteria will ferment maize sugar purely to desirable lactic acid, which is highly effective at preserving maize against the growth of unwanted spoilage bacteria, others ferment sugars to other compounds, including CO2

Yeasts and moulds

“This is not good, because as well as being a greenhouse gas, CO2 is a direct loss of DM.

“You cannot control which types of bacteria are present on the crop. However, by applying an additive, such as Ecosyl, containing the proven strain of efficient lactic acid-producing bacteria, Lactobacillus plantarum MTD/1, you increase the likelihood of a quality fermentation.”

Unfortunately, unwanted yeasts present on maize at harvest can survive in low pH conditions, says Dr Leggett, and even grow on lactic acid when exposed to air.

He says: “This process, which causes maize silage to heat up and is called aerobic spoilage, not only burns away valuable energy, but also releases CO2 and results in losses in the silage’s DM.

“As the lactic acid is used up, the pH also rises, which allows other fungi to grow, further reducing nutritional value and palatability and potentially resulting in mycotoxins.

“The dual-acting additive Ecocool not only contains Lactobacillus plantarum MTD/1, proven to produce a rapid fermentation, but also a second beneficial bacterial strain, Lactobacillus buchneri PJB/1, which generates acetic acid which has anti-yeast properties.

“Ecocool has been shown to reduce yeast levels and keep silage cool and stable for more than 10 days.

“Increasingly, Ecocool is being used as an integral step in making silage. With the growth of many maize crops affected by the drought last season, many farmers reached for Ecocool in order to preserve what maize they had.

“Farmers who have tried Ecocool tend to stick with it as the additive of choice.”

5FILL, SQUEEZE, COVER AND WEIGHT

The attention to detail put into filling, compacting, sheeting and weighting has a massive impact on how well maize silage turns out, says Volac silage expert for northern England, Jason Short.

The aim is to get the air out quickly and keep it out in order to aid the fermentation and limit the growth of yeasts and moulds which cause heating losses, he adds.

Mr Short says: “To minimise air ingress, line the clamp walls with polythene side sheets before filling. In order to get maximum benefit from compaction machinery, fill in layers at most 10-15cm deep and at no more than 20-degrees to the horizontal.

“Maize needs a terrific amount of compaction. A crop at 30% DM requires about 25% of its weight

arriving at the clamp per hour to be rolling it constantly. So 100 tonnes per hour requires 25t. This might be a loading shovel plus a good-sized tractor. Drier crops will need extra compaction. Once filled, place an oxygen barrier film on top. This will be sucked into the surface contours of the maize to help create a seal. Pull side sheets over it, using a minimum one- to two-metre overlap all around.

“Then finish with a polythene top sheet and a protective woven sheet over the top, fully weighted with silage mats, touching tyres or bales. Protect against rodents and use netting to protect against bird damage.”

SPONSORED CONTENT

For more information on Volac’s Cut to Clamp initiative, visit cuttoclamp.com

for silage

Peter Smith advises that maize is chopped short enough to aid consolidation but long enough for it to perform in the rumen.

Peter Smith

Jason Short

Dr Mark Leggett

AUGUST 2023 23

Ken Stroud

Calcium and magnesium are important elements to get right for dairy cows, as the wrong levels can lead to hypocalcaemia and other health problems. Dairy Farmer reports.

Correct calcium levels in the blood are needed to keep the cow mobile, eating well, producing a good milk yield and remaining healthy.

Dr Graham Shepherd, founder of G. Shepherd Animal Health, says: “Calcium is a metal, like iron, but the animal eats it as mineral salts and uses it in small particles, called ions, in the fluids of the body, deep in the nerves and muscles.

“Calcium is stored in the bones, but bones are solid and the system for making solid bone into small ions is complicated and can become sluggish. Magnesium and vitamin D are important for this function.”

One of the main functions of calcium is helping the nerves send signals to the muscles.

Dr Shepherd says: “As calcium is involved in making the muscles do their jobs, low calcium can cause weakness in the cow.”

The most common problem linked with calcium is milk fever.

He says: “The weakness in the muscles will keep the cow on the floor, due to the calcium going to the udder and the calf.”

However, hypocalcaemia is a common problem which often cannot be seen.

“We see its effects in a freshly calved cow not getting off to a good start and achieving her full potential. Effects include a displaced stomach, mastitis, retained cleansings, womb

Lick buckets can help at pasture, but the intake of magnesium is erratic and unreliable DR GRAHAM SHEPHERD

Important elements in dairy cow nutrition

infections, poor appetite, ketosis and low milk yield.”

Sometimes a top-up of calcium is needed and, despite the best management, some cows just cannot mobilise enough calcium from their bones to meet demands.

Dr Shepherd says: “There is about 6kg of calcium stored in the bones; the calf and the udder take 11g of calcium a day from the blood.

“If blood levels drop by a quarter, this means the cow is in sub-clinical hypocalcaemia. If the blood levels drop by half, the cow is on the floor.”

Correct dry cow nutrition is a tool which can help. “Calcium is absorbed from the food in the gut, so a nutritionist should be able to make a programme for the farm, fitting in forages and perhaps calcium binders, dietary cation anion difference or other strategies.”

After calving, the total mixed ration should contain 200g of calcium for a typical cow’s daily intake, so Dr Shepherd says it is important the cow eats her ration.

He says: “A top-up helps to keep the gut muscles and leg muscles functioning so she can eat her

ration. A suitable top-up would be supplements such as boluses and fresh cow drinks.”

Magnesium aids calcium mobilisation from the bones, but is also needed for regulating muscle and nerve function, as well as enzyme function.

Dr Shepherd says: “It is a macro-mineral, so it is a metal element needed in relatively large amounts by the cow to stay healthy, productive and alive.”

Bone magnesium does its structural job and is mostly unavailable to the cow.

“What is important is the magnesium levels in the tissues and cells. Levels there are mainly dependant on absorption of magnesium from the rumen.

“Salt, as sodium, helps this absorption, so I always advise lump rock salt for lactating and growing cows.”

Common problems with low magnesium include staggers, milk fever, mastitis, retained placenta, endometritis and poor appetite –all because magnesium is integral for calcium to do its job.

Antagonists of magnesium include potassium from fertiliser or slurry, aluminium from soil contamination and oils in the diet.

Mr Shepherd says: “High potassium interferes with the sodium system for magnesium absorption. And lush grass, which is high in potassium as well as unsaturated oils and protein, will reduce rumen available magnesium.”

Sources of magnesium include mineralised concentrates, minerals with added magnesium and soluble supplements for water.

Dr Shepherd says: “Lick buckets can help at pasture, but the intake of magnesium is erratic and unreliable, similarly with minerals in water.

“The intakes will be variable, particularly in wet weather, because cows will be getting a lot of water from wet pasture and puddles.”

Magnesium

Magnesium is usually added to concentrates and dry cow minerals as calcined magnesite, a form of magnesium oxide.

Dr Shepherd says: “Some grazing herds will top dress the grass with calcined magnesite before grazing when it is considered to be a staggers risk.

“Another option is that calcined magnesite can be mixed with molasses and fed along a trough to high-risk groups. A typical amount would be 50g of calcined magnesite per day, but always consult with a vet or nutritionist.”

And Dr Shepherd says it is important to be vigilant with magnesium use.

“There have been cases of magnesium poisoning when too much magnesium powder has been added to water troughs and the trough is slow to fill.”

AUGUST 2023 24 DIET FORMULATION

After calving, the total mixed ration should contain 200g of calcium for a typical cow’s daily intake.

ARE YOU A RUMINANT FARMER LOOKING FOR A HIPRO SOYA REPLACEMENT?

Cut down on food miles using a more sustainable product, increased output and all at a reduced cost!

Increase in milk and meat yield

Bypass protein level of 84%!

Meeting the demands for DUP whilst giving the animal maximum efficiency