INTEGRATED SYSTEMS FOR CLADDING

▪ Solutions designed for attaching canopies to cladding

▪ Maintaining insulation without sacrificing safety and durability

▪ Solutions designed for attaching canopies to cladding

▪ Maintaining insulation without sacrificing safety and durability

Thermal insulation has become an increasingly popular building solution for improving the energy efficiency of living spaces. Its main characteristic is in fact to reduce heat loss to the outside, eliminating thermal bridge phenomena. However, the fixing of heavy loads on claddings represents a challenge for many professionals in the sector and requires the use of solutions that have been studied and then tested, capable of guaranteeing maximum performance in terms of durability and

Unsuitable examples:

1. FIXING ON WOODEN SUPPORT

safety, avoiding unpleasant cracking problems that are created by the use of threaded bars fixed without specifically dedicated supports. The use of improvised or uncertified solutions, such as elongated fixings with thermal break extensions with untested materials, presents risks and criticalities that should not be underestimated, which can compromise the effectiveness and tightness of the entire cladding system and structure.

Using wood as an insulating block is not the suitable choice. In the application depicted, the wood undergoes a strong compression, which could deteriorate the fibres irreparably. Moreover, if not properly treated, the wood may absorb water and lose its mechanical strength characteristics.

Some may venture an installation without diversifying the insulation material that the canopy rests on.

The canopy is therefore installed on the cladding itself, resulting in cracking of the area where the aluminium profile compresses the surface of the plaster.

The cladding has no compressive strength

Sometimes, however, the installer installs the canopy by compensating for the depth of the cladding, with metal tubes near the fixing rods. However, this solution is not suitable because all the load, both wind and snow, is concentrated on the small section of the installed pipes

The Faraone technology package for fixing on claddings.

The technology package consisting of the structural block and the canopies of the Linea 3 family, are subjected to strict safety tests at the Faraone Lab.

Overcoming the criticality of heavy fixings without compromising energy efficiency

Only through the use of tested and innovative solutions was it possible to combine energy efficiency, structural safety and durability. Faraone has worked towards these ambitious goals, arriving at a product characterised by the following aspects:

1. Test reports: The fixing rods and the structural system have been load-tested and awarded specific certificates, attesting to their strength.

2. The supporting elements are made of highstrength polymer material with low thermal conductivity to limit the effect of thermal bridges.

3. Punctual thermal bridging to standard: thanks to the insulating material they are made of, structural blocks reduce the effect of thermal bridges, minimising the transmittance effect of the rod.

High-density EPS structural block

Dimensions: - Linea Mini 3: 100x90x145 (3.93”x3.54”x5.70”) (not less than 145 -5.70”-)

- Linea Maxi 3: 100x110x145 (3.93”x4.33”x5.70”) (not less than 145 -5.70”-)

ASSEMBLY STEPS

1) Shape the cladding

2) insert the rods

3) insert the block in the correct direction, following the instructions below.

4) proceed with the normal installation of the canopies following the assembly instructions for Linea Mini 3 and Linea Maxi 3.

CUTTING THE BLOCK AND ROD:

Always cut the block to the desired size.

Rod projection: The rod must protrude 22 mm (0.86”) from the edge of the structural block laid in concrete.

ASSEMBLY STEPS

1) Shape the cladding

2) insert the rods

3) insert the block in the correct direction, following the instructions below.

4) proceed with the normal installation of the canopy following the assembly instructions of Linea Maxi 3.

CUTTING THE BLOCK AND ROD:

Always cut the block to the desired size

Rod projection: The rod must protrude 28 mm (1.10”) from the edge of the structural block laid in concrete.

• Laminated tempered glass with rigid plastic from family 2 (type SG, X-LAB, ABAR)

INDICATED GLASS (Rigid plastic interlayer)

8(T)+8(T) SG 1000X1200 mm

5/16”(T)+5/16”(T) SG

39.37x47.24 in

8(T)+8(T) SG 1000X1200 mm

5/16”(T)+5/16”(T) SG

39.37x47.24 in

FIXING ON REINFORCED CONCRETE

• Laminated tempered glass with rigid plastic from family 2 (type SG, X-LAB, ABAR)

INDICATED GLASS (Rigid plastic interlayer)

LOAD (kg/m2)

10(T)+10(T) SG 1000X1200 mm

10(T)+10(T) SG 1000X1500 mm

3/8”(T)+3/8”(T) SG 39.37x59.05 in

10(T)+10(T) SG 1000X1500 mm

10(T)+10(T) SG 1000X1500 mm

12(T)+12(T) SG 1000X1200 mm

3/8”(T)+3/8”(T) SG 39.37x59.05 in

12(T)+12(T) SG 1000X1500 mm

12(T)+12(T) SG 1000X1600 mm

1/2”(T)+1/2”(T) SG 39.37x62.99 in

12(T)+12(T) SG 1000X1600 mm

1/2”(T)+1/2”(T) SG 39.37x62.99 in

FIXING ON REINFORCED CONCRETE

Our experience is at your service. We guide you in choosing the best solution for your needs.

To follow a project in all its phases is sometimes very difficult. For this reason, we provide you with a total assistance from technical advice to post-purchase.

We carefully select the experts who carry out the installation of our products to ensure our standard of quality. During this phase, tests are carried out on site to ensure that the installation has been performed in a competent manner and that everything is safe.

How you can contact us

email: faraone@faraone.it

Tel: +39 0861 784200

web: faraone.it

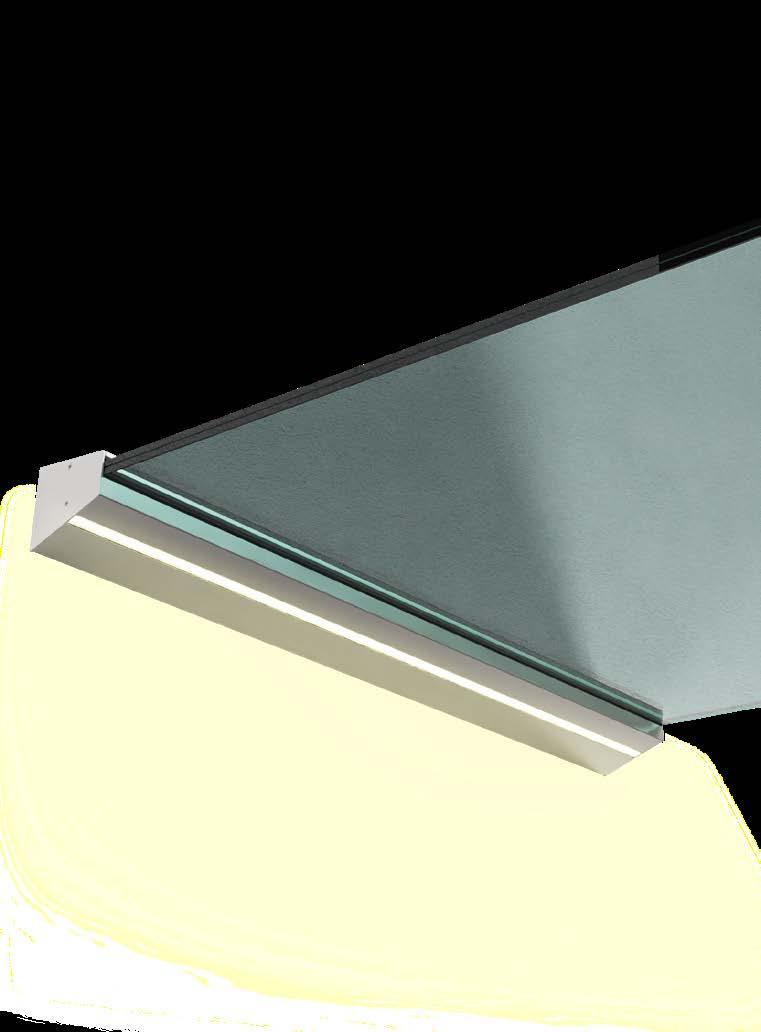

LINEA series canopies:

1) Load-bearing structure fixed to the wall consisting of an extruded aluminium alloy EN AW 6063 profile with T66 treatment. The profile gauge is suitable to withstand the weight of the glass, wind static load test and snow load; all suitable based on the glass projection. The finish of the profiles will be anodised to the colour silver of the 20 micron (0.79 mil) class, or painted with polyester powder to the required colour.

2) Accessories required for containing, clamping and levelling panes, even in side-by-side positions. Glass anti pull out accessories present.

3) Fixing the structure to the wall with threaded rods and certified chemical resin. Ensure fixing on reinforced concrete or load-bearing masonry, stating that you are aware of the weights due to wind load and the load that the fixing must withstand. See weight table from the catalogue.

4) 410 kg/m3 (25.6 lb/ft³) highdensity EPS block, size 145x110x100 (5.70”x4.33”x3.93”) (linea maxi 3) or 145x100x90 (5.70”x3.93”x3.54”) (linea mini 3), suitable as a support and compression shim for fixing heavy loads on claddings.

5) The glass panes of the Linea model canopies shall be tempered and laminated with a rigid interlayer (type SG or similar from "family 2"), with the guarantee that in the event of accidental breakage of the two panes, they will remain horizontal, i.e. they will not fall vertically on any persons. The shim must be as indicated in the supplier's catalogue, 8+8 or 10+10 or 12+12 (5/16”+5/16” or 3/8”+3/8” or 1/2”+1/2”), depending on the model and projection. Laminated glass with normal PVB or EVA, may only be used for projections up to a maximum of 120 cm (47.24”)and in any case by positioning the canopy at a minimum height of 2 metres (6’7”) above the glass projection.

(If the panes break, they must be folded sheet-like above the height of the person).

6) The entire canopy must have a strength test certificate of at least 300 kg/m2, in addition to the weight of the glass.

The strength of 300 kg/m2 (61.44 lb/ft2) may change depending on location/ height above sea level.

TRANSPORT COST - ITALY:

As stated in the order confirmations. It varies according to quantity and location.

Any complaints must be received by Faraone within the strict time limit of 8 days from receipt of the goods, no returns of goods are accepted unless previously authorised by Faraone as carriage paid.

Returned products that by any chance should reach Faraone without prior authorisation shall be unconditionally refused and sent back to the sender carriage paid.

• In Italy:

For new customers, when the amount is less than EUR 5,000.00, payment is only by cash on delivery (i.e. to be paid to the courier upon unloading) or by bank transfer in advance upon signing the order. Cash discount 3%.

For amounts exceeding EUR 5,000.00: 30% down payment at the time of order, 70% with RiBa (cash order) 30/60 days subject to acceptance of our credit insurance; if insurance cover is not accepted, you can opt for the following:

- cash on delivery to be paid to the courier upon delivery, cash discount 3%.

- by bank transfer upon signing the order, cash discount 3%.

- with collateralised securities with a maturity of 30/60 days, to be agreed. For regular customers, who have the overdraft of the insurance cover payment with RiBa (cash order) 30/60 days end of month.

Failure to pay even one due date entitles Faraone to suspend deliveries and revoke the payment terms granted.

• Abroad:

By bank transfer upon signing the order - VAT: all prices in the price lists are exclusive of VAT.

NB. As our products are subject to continuous innovation and improvement, design and construction features may change without prior notice. The images contained in the production catalogue are purely approximate, therefore our company reserves the right to make improvements to the products without prior notice. All models and designs are the exclusive property of Faraone. No reproduction is permitted. Prices are exclusive of VAT, without transport and installation.

All rights reserved

Faraone s.r.l. a socio unico Via Po 12 / 64018 Tortoreto (TE) Italy. T. +39 0861 784200 www.faraone.it