In 2024, FaB solidified itself as Wisconsin’s leading food and beverage network by driving innovation, growth & sustainability.

As we reflect on 2024, it’s clear that FaB Wisconsin has solidified its position as the state’s leading food and beverage network. This past year, we focused on driving innovation, fostering growth, and championing sustainability pillars that will define the future of our industry. Our initiatives embody these values, further cementing our role as a vital resource for our members and the industry.

Throughout the year, FaB Wisconsin provided members with access to invaluable resources, including best practices, industry insights, and networking opportunities. These tools have been instrumental in supporting our members' business success and ensuring they maintain an edge in a dynamic market. 2024 was a year of remarkable growth. We continued to expand our statewide reach, welcoming 27 new members to our network. Our engagement with food and beverage companies throughout Wisconsin has never been stronger. We were also honored to receive the WAT Grant, which will enable us to provide significant training opportunities to FaB member companies, further enhancing their capabilities.

One of our proudest accomplishments this year was conducting our talent and wage survey. FaB remains the only organization in Wisconsin offering this vital resource to food and beverage manufacturers. The survey provides invaluable insights into talent attraction and retention strategies, empowering businesses to stay competitive in today’s labor market.

In 2024, we hosted numerous webinars and events that delivered valuable information, education, and opportunities for collaboration. Over 500 food and beverage industry professionals came together at these events to share knowledge, network, and celebrate Wisconsin’s leadership in the sector. These gatherings continue to elevate our state’s reputation as the ideal location to launch and grow a food and beverage business.

FaB also collaborated with economic development organizations across Wisconsin to attract and support food and beverage manufacturers considering relocation to our state. These efforts further strengthen our network and showcase why Wisconsin is the nation’s premier home for food and beverage companies.

Looking ahead, we’re thrilled to approach FaB’s 15th anniversary. The milestones we’ve achieved over the years reflect the strength of our organization and the resilience of our industry. As we continue to grow and evolve, we remain committed to supporting our members and advancing Wisconsin’s food and beverage sector.

Thank you for being part of FaB Wisconsin. Together, we are driving innovation, growth, and sustainability ensuring that Wisconsin remains the leading state for food and beverage businesses for years to come.

Executive Director, FaB Wisconsin

We’re FaB Wisconsin, and we know this industry well.

From bakers to banks, we’re here to support and advocate for your business. We’re optimizing Wisconsin’s industry ecosystem and its workforce for industry innovation and growth, connecting you with best practices, know-how, and resources to assist with growth plans and goal achievement.

Our state’s industry know-how, expertise, and experience is reflected in our member companies and organizations and in the thousands of those who bring the world Wisconsin’s food and drink.

Local and global. Big and small. Nutrient-dense and decadence. We’re here for the food and beverage makers, manufacturers, distributors, and all of those who support and supply the industry. We’re working to make our state the best place to grow your food and beverage industry business.

We were proud to serve 141 member companies in 2024. Whether you’re manufacturing, distributing, or providing services to the industry, we’re grateful for your participation and the opportunity to serve.

New FaB Members in 2024

We were thrilled to add 27 new members to our crew in 2024, expanding our reach across the state.

2,000+

27 Industry Professionals in Our Reach

Whether you’ve just joined or have been with us for years, thank you! Our industry network is better with you as a member.

$198,593

100%

WAT Grant

Thanks to the Workforce Advancement Training (WAT) Grant awarded to FaB, our members saved significantly on company training costs.

Income From Membership & Programming

Our work is made possible through the support of your annual membership dues and the success of programs like our FaBsafe Certificate®.

BY EMILY ALLEN, ASSISTANT DIRECTOR

Curt Kluth CEO of Saz’s

Welcome to Milwaukee! Enjoy our beer, brats, cheese…and barbeque.

It’s hard to spend a summer in our city without seeing the Saz’s name, and that’s by design.

An institution in the city’s festival circuit, Saz’s can be found operating concession stands at Summerfest, Wisconsin State Fair, Bastille Days and Irish Fest, and in 2024, as vendor for the 2024 RNC.

“As our hospitality scene continues to flourish, we’ve been proud to call Milwaukee home for over 48 years,” says Curt Kluth, chief executive officer. “If it’s your first time in Milwaukee, you have to do a Miller Brewery tour and then head just a few blocks west to Saz’s State House so you can join us for a cocktail and a bite where it all started in 1976.”

In 1979, just three years after Saz’s put its stake in the ground, a State House regular shared the need for a food vendor at Summerfest’s Miller Jazz Oasis. After “a lot of brainstorming and a couple of Miller High Lifes,” Summerfest attendees were introduced to a selection of handheld menu items – meant to be enjoyed while standing and watching live music. Saz’s has been a Summerfest mainstay ever since, where today a dedicated team of over 200 workers serve up thousands of meals daily.

Kluth says the classics, like hand-rolled mozzarella marinara, sour cream and chive fries, and white cheddar cheese curds, still reign supreme.

“We are so proud that when people think of Summerfest food, Saz’s is usually one of the first things out of their mouths,” says Kluth. “We have to be ready with truckloads of food each year from our local partners like Johnsonville, Sciortino’s Bakery, Milwaukee Pretzel Co., and of course, with plenty of Wisconsin cheese!”

Saz’s State House is still operating in the same location today, and in addition to its festival portfolio, Saz’s maintains successful catering and barbeque product retail divisions. They’re also a major employer in the city, especially seasonally.

“For many of our team members, it’s their first taste of the workplace, and as a seven-time Top Workplace award winner, we see many individuals come back to join our team summer after summer,” explains Kluth, who himself has been an employee of Saz’s since 1994. “We’re home to a diverse and motivated workforce.”

Kluth credits the Saz’s pipeline of hospitality talent for providing great food and over-the-top service to Milwaukee residents and visitors alike, cementing their decision to thrive in the city where the company’s story began.

“Saz's heart beats to Milwaukee's rhythm,” he says, “especially now as we raise a toast to the city's vibrant charm and one-of-a-kind flair with a summer to remember just around the corner.”

Our Leadership Council comes together throughout the year to help us develop deeper industry intelligence and build a dynamic industry network for innovation, growth, collaboration, and support. Council members are among the first to offer insights and to take actions to maximize our goals while achieving theirs.

BY ANNA LARDINOIS, MKE STARTUP NEWS

In 1986, Jeri Mesching was a retired elementary school teacher. Her children were grown, and she had no interest in joining her friends on the golf course or tennis court. So, what does one do when you’re an empty nester without time-consuming hobbies?

For Mesching, a talented home cook, the answer was to start a business.

“I had friends who started Christmas in the Country in Cedarburg, which is where we got our start. A dear friend who was one of the original organizers asked me to make something and I said, ‘I can’t do anything.” She said ‘Are you kidding? Going to your house for dinner is like going to grandma’s’, she said this because I made everything from scratch. I baked all of our bread. I thought everybody did that,” Mesching recalled.

To appease her friend, she made a large batch of her signature sweet and tangy mustard and jarred it for the Christmas market. To the surprise of no one but Mesching, the jars were quickly snapped up by holiday shoppers. At the end of the day, she sold every jar and had a long list of names of people who wanted more of her tantalizing mustard.

It was the start of what would become East Shore Specialty Foods.

A lot has changed since the company sold its first jar of mustard. Today the East Shore Specialty Foods owns a manufacturing plant in Hartland with 10 employees and sells its wares nearly everywhere fine foods are sold. As the company approaches its fourth decade in business, the company now produces 10 unique flavors of its mustard and 10 different kinds of dipping pretzels.

“The pretzels came about because when I first started, the specialty food industry was almost nonexistent. Everywhere I sold the mustard, they would ask me to come and do demos. What do you serve the mustard with? I couldn’t give everyone a sandwich so I started doctoring up the pretzels and then people said I can’t buy the mustard if I can’t buy the pretzels. That taught me a lot,” Mesching explained.

“I made a lot of mistakes, and I learned from them. I just worked and worked. At first, I rented a kitchen two days a week. I put everything in my car and hauled it over to the kitchen, carried it in, made my stuff, put it back in the car, brought it home, sat around the fireplace and labeled the jars at night. That’s how I did it,” Mesching said.

The company made the leap from a regional favorite to a global brand through the International Fancy Food Show in New York.

“The first time I attended the show I carried two baskets with pretzels and mustard up the stairs. Now, we ship pallets to the show,” she said.

I made a lot of mistakes, and I learned from them. I just worked and worked.”

Mesching began her business at a time before startup accelerators and incubators existed. She had no friends or family members who owned a business. With no outside support, she relied on her hard work and keen business decisions.

“I have never identified as a woman-owned business…I always thought it shouldn’t matter, and I think I made it not matter. When I went to purchase quantities of whatever, I always could find sources, and no one ever said to me. ‘oh my gosh, you’re a woman.’ It was not an issue. I honestly have never had a problem due to the fact that I was a woman,” she said.

Mesching attributes much of her bootstrapped company’s success to the fiscal discipline she has maintained since its launch.

“I never took any risks because I saved before I spent. I didn’t ask (the bank) for outrageous amounts of money that I couldn’t back in some way. We have always been very fiscally responsible and the only time I ever had a loan was when I built (the factory) and I paid it back quickly. We put an addition on maybe 10 years ago or so and I paid that back within months. It has always been important to me to be fiscally responsible. It’s very difficult to do and it doesn’t get easier,” she said.

Mesching is still involved in the operations of East Shore Specialty Foods, but the company is now led by her daughter, Kristin Graves.

“She’s much more educated than I am and she’s much better at the really difficult things,” Mesching proudly stated. Graves earned her MBA from Marquette University and currently resides in the family home that appears on the label of each jar and bag that bears the East Shore Specialty Foods name.

From its humble beginning to the globally recognized brand it has become, East Shore Specialty Foods stands as a testament to Jeri Mesching’ s hard work, resourcefulness, and fiscal discipline. Under the leadership of Graves, the company continues to maintain its commitment to quality and tradition.

A Goodman's Desserts produces scratch baked desserts. With over 30 years of baking experience, we bake scratch desserts the old fashioned way with natural ingredients. These recipes are family treasures recipes handed down from my Mother, Grandmother, Godmother and Aunts. The desserts include Bread Pudding (Regular, Rum and Bourbon options), Butter Cookies with a sugar glaze, and Lemon Pound Cake.

A better craft spirit experience awaits. Our award-winning products are locally distilled with pride, right in the heart of Downtown Milwaukee. And now, experience our full offering with the Central Standard Crafthouse & Kitchen. Cocktails, apps, and entrees, all inspired by local chefs and our in-house mixologist. We truly are crafted to gather

Nothing beats Crustology®. We specialize in a Midwestern cracker crust a thin pizza crust like you’ve never had before. Available in a variety of different flavors, we’ve got a crust to fit every type of topping, from our classic The OG to the wellseasoned Herb-Infused.

We take pride in constructing facilities where communities work, live, and play. Findorff has a rich history in craftsmanship excellence, from minor renovations to program management of complex facilities. We’re committed to bringing the highest level of service and quality to every project we build. We are especially proud to be celebrating 50 years of building Milwaukee in 2025 with deep gratitude to our community, partnerships, people, and projects that we've been a part of.

Food For Health is a 501c3 public charity and Community Based Organization focused on preventing, managing & reversing disease with a delicious, people-centered medically tailored meal program for our most vulnerable populations. As the only Medically Tailored Meal (MTM) provider in the state of Wisconsin, we’ve joined forces with other like-minded organizations across the nation as part of the Food Is Medicine Coalition (FIMC) to realize our vision of creating equitable access to healthy and happy lives through the power of food.

Sometimes you need more than an ingredient – you need a solution. Formula changes. New product ideation. Production issues. Through it all, we help you get quickly from line to shelf. Across the span of almost 200 years, we have grown from offering the finest in yeast to serving as one of the largest ingredient suppliers in commercial baking. Rise to the top with Lesaffre

Founded in 2013 by Katie and Matt Wessel after they spent a year in Munich, Germany, Milwaukee Pretzel Company handcrafts authentic Bavarian soft pretzel twists, bites and buns using a traditional German recipe and a whole lotta loveand no preservatives! Our mission is simple: To bring the pretzels we fell in love with in Germany to all of you. Find us in bars & restaurants, your local grocer and order online at milwaukeepretzel.com!

For 75 years, the Olesen family has continued to use the traditional methods of Old Denmark to make our Kringle. Each Kringle takes 3 full days to make, resulting in 36 delicate layers for a truly flaky and flavorful pastry. Combine our scratch made fillings from the finest ingredients we can find, you are certain to find a flavor suited just for you.

The Omanhene Cocoa Bean Company is producing world class chocolate entirely in Ghana using the finest cocoa in the world: customers love trying the “chocolatiest” milk chocolate. The word “Omanhene” (oh-mahn-hee-nee) comes from the Twi language and is the title for the traditional king or chief, the repository of ethical and moral authority in Ghana.

Rishi Tea was founded on the commitment to set the standard for quality and expand the awareness of exceptional tea and its rich, inspirational tradition. We offer premium tea and botanicals imported directly from growers across the world and draw inspiration from ancient artisanal practices that use organic cultivation techniques as well as modern culinary innovation.

It starts with great beer and a moment in time, spent among those whose company you love, with nowhere else to be. It’s beer brewed by a world-class brewmaster and his longtime friend. It’s Milwaukee made and Wisconsin proud. But most importantly, it’s permission to pause and enjoy a great beer with great company. You have your home, you have your work, but everyone needs a third space.

Tribe 9 Foods is a specialty food manufacturer headquartered in Madison, Wisconsin that produces specialty pastas, nut butters, cookies, and bars. As a certified B Corp., held to the highest standards of social and environmental performance, Tribe 9 is on a mission to improve lives through food by creating more nutritious foods while having an impact on people and the communities they serve. Founded in 2017, Tribe 9 includes Taste Republic and RP’s Pasta Co.

At this webinar on February 21, members learned what’s on the regulatory horizon and how their companies could be affected. Paul Benson, Joe Olson, and Mickey Foti of Michael Best discussed important changes and trends to be on the lookout for 2024, and dove into Assembly Bill 304, which, among numerous other changes, implements new requirements in liquor licensing and redefines what constitutes a “malt beverage.” Attendees learned what this new law means for the sale, distribution, and production of alcohol in the state of Wisconsin.

We’re the food and beverage makers and manufacturers and all of those who support and supply the industry. Local to global. Big to small. Nutrient-dense to decadence. From farm to factory to fork with operations in Wisconsin.

A Goodman's Desserts*

Acuity Insurance

Actalent

Aerotek

Altura Design

American Pasteurization Co.

Baensch Food Products

Baker Tilly

Bassett Mechanical

BDO USA

Belmark Inc.

Biospringer North America

Boelter + Lincoln

Briess Malt & Ingredients

Burke Candy & Ingredients

Butter Buds Food Ingredients

Catapult Commercialization Services

Celtic Marketing Food Brokers

Central Standard Craft Distillery*

Central Storage & Warehouse Co.

Clock Shadow Creamery

Colliers

Consolidated Construction

C.O.nxt

Craft Beverage Warehouse

Create-a-Pack Foods

Crustology*

Culver Brand Design

Dairy State Foods

Danfoss

Denali Ingredients

Didion Milling

Drink

ZYN

Doral Corp.

East Shore Specialty Foods

Emmanuel's Mix

Employ Milwaukee

Engauge Workforce Solutions

ePac Flexible Packaging

Eurofins

Farm Wisconsin Discovery Center

Feeding America Eastern Wisconsin

Findorff*

First Citizens Bank

Foley & Lardner

Food for Health*

Food Tech, Inc.

Forage Kombucha

Fortune Favors

Frederick Packaging

Fresh Is Best

Fromm Family Foods

Galloway Co.

Garden-Fresh Foods

Gehl Foods

General Mills

Good Foods Group

GOpak

Gott Pet Food

GRAEF

HARIBO of America

Harrigan Solutions

HGA Architects & Engineers

Hollander Chocolate

Jamaican Fair Trade

Jefferson County/ThriveED

JF Ahern Co.

Johnsonville Sausage

JP Cullen

JPMorgan Chase Keller, Inc.

Kewaskum Foods

King Juice Co.

Krier Beverage

Krones

Lakefront Brewery

Lakeland University

Landmark Credit Union

Lauterbach Group

Lesaffre Yeast Corp.*

LMI Packaging

Lotza

LTL Service

M3 Insurance

Manpower Group

Masters Gallery Foods

Masterson Co.

MATC

McMahon Associates

Michael Best

Milwaukee Chip Co.

Milwaukee Pretzel Co.*

MilwaukeeWarehouse

Miron Construction

Molson Coors

Mount Mary University

MRA

Novonesis

O&H Danish Bakery*

Ocean Spray

Olympia Granola

Omanhene Cocoa Bean Co.*

One Source Staffing Opportunities, Inc.

Learn

Orange & Fifth

PAK Technologies

Palermo's Pizza

Parallel Employment Group

Plethora Trading

PPC Reclosable Packaging

Rally Energy

Rapido Talent

Real Food Brands

Rebel Green

Regal Ware

Rely Contract Manufacturing

Reynold's Pasty Shop

Riley Construction

Rishi Tea*

Roehl Corp.

RSM US LLP

Sargento Foods

Saz's Hospitality Group

SITE Staffing

Society Insurance

Source Wurx

Stella & Chewy's

Supper Club Fine Foods

The Great Plate

Third Space Brewing*

Third Wave Bioactives

Tribe 9 Foods*

Tweet/Garot

Valentine Coffee Roasters

Vanguard Renewables

WDS Construction

WI Center for Manufacturing & Productivity

Wisconsin DATCP

Wisconsin Foodie

Wisconsin Economic Development Corp.

WI Women's Business Initiative Corporation

Wixon

WMEP

Thanks to the members who joined us for our "Forecasting Trends in CPGs" webinar on May 22! Marketing experts Rochelle Schnadt and Kelli Calkins from premium member C.O.nxt shared what's on the horizon in food and beverage: branding trends to lean into, where consumer tastes and preferences are leading us, and the importance of using (or at least considering) influencer content as part of your marketing plan.

We aim to make Wisconsin’s food and beverage industry know-how – of the best in the world – better known and more accessible to our members. That’s where our FaBricators come in. This group of experienced and vetted industry professionals are here to help. If you have a question, sticky situation, or need a resource, ask us! We’ll distribute your inquiry to our pool of FaBricators and help you get the answer you need. Totally confidential, we encourage you to ask questions about HR, food safety, operations, sustainability…anything!

Put Your Industry Experience to Work. Become a FaBricator!

If you have industry experience and a willingness to help your peers, consider applying to become a FaBricator! You’ll receive member inquiries in your areas of experience, and if you know the answer or have a resource, simply respond. Or don’t – this is a zeroobligation position.

Do it for business development. Do it to share your knowhow. Do it to help grow the food and beverage industry.

There’s no question too big or too small! Here are some of the categories – or areas of experience –our FaBricators can assist you with: Areas of Experience

• Accounting & finance

• Buildings & facilities

• Business planning

• Distribution & retail

• Entrepreneurship

• Exporting, importing & international

• Food and/or beverage production

• Food & employee safety

• Human resources

• Information & technologies

• Legal

• Insurance

• Marketing

• Mergers & acquisitions

• Operations

• Regulatory, licensing & labeling

• Research & development

• Sales

• Supply chain, logistics & transportation

When we say “ask us anything,” we mean it! We helped our members make connections, solve problems, source items, and much more this past year. Here’s a breakdown of what kind of questions our members asked in 2024 via the FaBricator Program.

FaBbringstogethera communityofcompaniesand individualsinterestedin helpingtogrowthefood ecosystemhereinWisconsin. Practically,theauthentic relationshipsdeveloped throughFaBallow my company toanswerquestionsquickly andrapidlynavigatenew obstacles. We’re happy to then shareourlearningswithothers tocontinuetoadvancethe whole FaB community.”

Brian Durst, CEO of Tribe 9 Foods

Created and developed by FaB Wisconsin, FaBsafe is an industry-recognized annual basic food and beverage safety training certificate of completion for those interested in or already working in a role associated with food, beverage, or ingredients manufacturing to stay compliant with FSMA’s requirement for documented food safety training.

In 2024, FaB took a big step forward by putting the suite of courses in the FaBsafe Certificate® program fully online, making it more accessible and affordable for our members. Now, participants can complete the program at their own pace or as part of larger company training, making it easier than ever to fit learning into their schedules. This move helps us support workforce development and keep raising the bar for industry standards and FSMA compliance.

In addition, thanks to the Workforce Advancement Training (WAT) Grant awarded to FaB, our members are benefitting from significant savings on their FaBsafe certificates and other food and beverage-specific industry training.

We offer the FaBsafe Certificate® to assist in your FSMA-requiredannual training. This course provides a foundation of food safety training, including the importance of a food safety mindset and GMPs, that may be applied to any food or beverage manufacturing environment.

Industry professionals who have already earned their original certificate of completion can take advantage of the Refresher to fulfill their FSMArequired annual training. The Refresher course focuses on the basics of food safety in food manufacturing, including GMPs.

Providing a basis of good manufacturing practices (GMPS), hazard analysis, and regulatory, this course is perfect for high school and college students considering or currently pursuing a career in food, beverage, or ingredients manufacturing.

BY EMILY ALLEN, ASSISTANT DIRECTOR

When it comes to implementing technology and artificial intelligence in your food and beverage-related business, making assumptions can be a good thing.

“Assume your employees are using it on their own time on their own devices,” explains Sarah Alt, Chief Process & AI Officer of law firm Michael Best, “and assume your competitors are using it and could surpass you.”

AI and value-added technology has infiltrated the business world. While there’s space for skepticism, its proliferation in day-to-do life makes it difficult to disregard in a business setting.

“Even if you attempted to block access to OpenAI's ChatGPT or Google's Bard anytime in the last 9-12 months, they have since started offering these capabilities built into their browsers,” Alt says. “It’s common to feel like this is a constant game of ‘keeping up’ with technology companies, which can be daunting for even the mightiest of us.”

Companies like Miron Construction are up to the challenge, leaning into technologies to better serve their clients in the food and beverage manufacturing space.

Brian Athey, Director of Construction Innovation at Miron, explains that “it’s a challenge to keep up, and change management is the most important part of what I do. There’s such a thing as software fatigue, constantly going from one

system to the next. We’ll never get away from that, but my job is to make sure that if we’re picking something, we’re picking the right thing.”

Athey says Miron’s use of AI and technology is mindful –“Without controlled collaboration, you have chaos” – and is implemented with efficiencies in mind.

What started with the use of iPhones to capture individual photos has advanced into 360° video, allowing construction progress to be tracked and keeping clients confident in the accuracy of their projects.

Other technologies implemented by Miron, like laser scanning, can convert data into BIM (building information modeling) without the need for redundant tasks requiring blueprints and a tape measure.

“Now someone can go out, drop a tripod, and easily create a model. The efficiencies of that are astronomical. You’re saving trips to the job site and can be confident the dimensions are correct,” says Athey. “There’s no guessing and no mistakes that can be made there.”

Athey says these types of technology are invaluable in the food and beverage manufacturing industry, where

unique equipment and processing lines can make or break a project, noting that food and beverage is “one of those industries that are ahead of the curve” in terms of AI and technology implementation and innovation.

“We had a food and beverage facility with an existing piece of equipment. We needed to know before the installer arrived…is this really going to fit in the new space? We were able to walk him through scanning the space with his iPhone, and by noon the next day, we confirmed the equipment would fit,” he says.

Alt says data is “the most essential ingredient” for artificial intelligence and technology usage in the food and beverage industry and warns that when proceeding with AI or technology initiatives, there should be absolute certainty that the application fits the business’s ethical responsibilities, as well as legal requirements.

“There are so many innovative ways AI can help predict changes in the food supply…ingredients, substitutes, consumption, growing patterns, and more,” says Alt. “So let's get those ideas out on the table, vet them, and bring them to life.”

It's an interesting time to be in business. Members joined us on April 4 to hear the experts from premium member RSM US LLP share the economic outlook for 2024: trends to watch for, need-to-know tax information, and what your food and beverage company could expect in the coming year. After the presentation, attendees reveled in networking with their industry peers and enjoyed refreshing beer courtesy of member Third Space Brewing and mouth-watering appetizers from member Saz's Catering.

Special thanks to our host, Andy Gehl of Third Space Brewing, and speakers Mike Graft, Karen Galivan, Zach Rieboldt, and Peter Cadigan of RSM US LLP.

Nothing says summer in Wisconsin like sipping beer on the river! Attendees joined us on June 25 at member Lakefront Brewery, where they mixed, mingled, and made connections with their food and beverage industry peers. We kicked off our 2024 Talent & Wage Survey with survey sponsor One Source Staffing, learned about MATC’s Craft Brewing Diploma Needs Analysis, and enjoyed cold brews and tasty appetizers courtesy of Findorff

FaB and MATC are working to develop a Craft Brewing & Distilling diploma program, thanks to an idea from Russ Klisch, president of Lakefront Brewery. We’re conducting a needs analysis to determine preferences in developing the program and its content and gather and economic outlook and relevant wage data.

Q: How would the brewing industry benefit from a craft brewing program?

A: As with any vocation, a quality training program is key to having a quality workforce. And, with a trained quality workforce, a company doesn't have to spend as much time creating its own training programs and training their employees. A company can spend time on other things to build them into a world class operation.

Q: Why did you reach out to FaB to get this program moving?

A: I felt FaB was the only organization that had the best and the most extensive connections to bring together the largest and smallest brewers, the vocational school MATC, and the potential teachers and curriculum needed to provide quality education to the students in the program.

BY EMILY ALLEN, ASSISTANT DIRECTOR

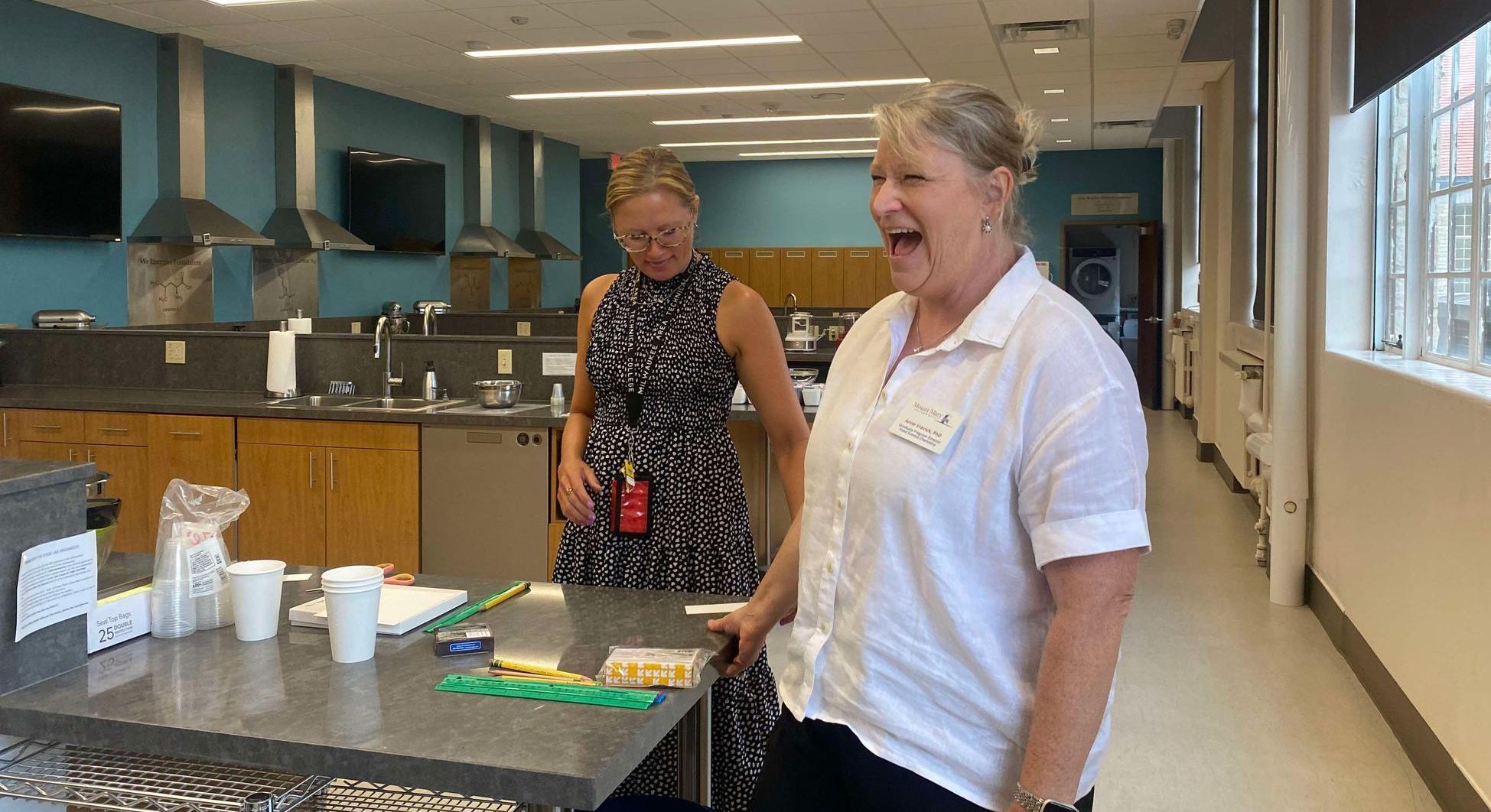

Most students don’t set out to study food science in college, and Dr. Anne Vravick wants to change that.

“Young people don’t know about the excellent careers available in the food industry,” says the food science graduate program director at Mount Mary University. “Most of them fall into our four-year food science program a year or two after they enter college and begin thinking more seriously about their future.”

EMILY ALLEN

With over 141,000 food and beverage manufacturing jobs just in the state of Wisconsin, the career possibilities of the industry expand beyond food science and working on a line, with opportunities in human resources, law, regulatory, marketing and more.

To create a talent pipeline of viable industry talent, Vravick has been working closely with Marie Colmerauer, instructor of chemical technology, nutrition and food science at Milwaukee Area Technical College, which offers a two-year degree in food science technology.

“It's especially important for food-related programs to connect with students ‘early’ since the careers are not as well-known as more traditional paths,” says Colmerauer

Vravick and Colmerauer both see value in representing their respective schools at student-facing events, including FaB Wisconsin’s annual Farm-Factory-Fork Career Discovery event – where they meet face-to-face with hundreds of Wisconsin high schoolers – and have been putting their heads together to develop additional opportunities for students and their instructors.

Recently, the two schools partnered to host their first Teachers Teaching Teachers event to encourage high school science instructors to add food to their classrooms. Attendees dove into hands-on activities – like tracking the temperature of different homemade ice cream recipes – and were sent home with a trove of resources and inspiration.

“Biology and chemistry can come alive for students when they can relate it to the foods they eat every day. I mean, why not study bacteria growing in yogurt or the chemical structure of a flavor molecule?” says Vravick.

Both instructors stress the importance of parents and teachers nurturing curiosity in students – asking questions about how food is made and who’s responsible for making it, for example, or encouraging participation in science-related courses or summer jobs.

“College-ready students are motivated by curiosity and getting tasks done on time,” she explains. “Those same traits lead to a successful career and can be developed in

Biology and chemistry can come alive for students when they can relate it to the foods they eat every day.”

students' younger years by connecting school to reallife scenarios and through jobs or extra-curricular activities.”

While her outreach initiatives have led to increased enrollment, Vravick is convinced the magic happens when you spark the interest of biology, chemistry, consumer science and culinary teachers who have a direct influence on students.

“Most of our food science students had a teacher in their life who told them about how cool it is to study the science behind why food changes when we mix, cook, freeze, or dry it and that they could actually do this for a career,” she says. “There are so many places in the food industry that apply science in ways you’ve never imagined. Go visit a food company and see if they’ll take you on a tour or tell you more about what they make. Never stop exploring!”

FSMA 204 will be implemented in January 2026…will you be ready? Thanks to the members who joined our webinar on September 26 for an in-depth look at the new food traceability law, set to transform industry practices. Leah Ziemba, Partner and Food and Beverage Group Co-Chair at Michael Best and Sara Sarnstrom, Regulatory Compliance Manager at Denali Ingredients delved into its requirements, impact on supply chains, and best practices for compliance.

Take advantage of the exclusive FaB WisconsinEurofins Partnership group discount to receive up to 25% off select testing services from Eurofins.

Eurofins is the world leader in its field, providing a portfolio of over 200,000 reliable analytical methods for characterizing the safety,identity, purity, composition,authenticity, and origin of products and biological substances to the food, pet food, and dietary supplements industry.

New Berlin, WI52151 Micro-MKE@ft.eurofinsus.com 262-727-6006

The dedicated Eurofins team in NewBerlin, WI is readyto help FaBmembers reach their food safety and quality goalseverstep of the way. Eurofins' close proximity and flexiblestaffing mean in-personconsultations on short notice and teleconferencingsessionsat your convenience.Whateverthe need,Eurofins is here for you!

Learn More & Take Advantageofthe FaB-EurofinsPartnership Discount

Our members were ready to up their game in talent management at our members-only luncheon on November 19. We kicked things off with the exciting results of the 2024 Talent & Wage Survey, sponsored by One Source Staffing, showcasing what’s happening in our industry. Attendees heard from HR pros about what’s working for them when it comes to attracting and retaining great talent and left with fresh ideas and practical strategies to implement at your own company. Special thanks to our panelists and speakers: Tammy Flora, VP of Human Resources & Corporate Communications at Masters Gallery Foods; Skyler Pyzynski, HR Manager at General Mills; Wendy Bushell, Chief People Officer at Palermo's Pizza; Matthew Heppert, VP of Operations at One Source Staffing; and Jeff Sachse, Director of Entrepreneurship and Innovation at Lakeland University.

The 2024 FaB Wisconsin Talent and Wage Survey offers an in-depth look at the thriving food and beverage manufacturing sector, one of Wisconsin’s most vital and profitable industries. With over 3,700 food and beverage companies across the state, this industry employs more than 141,000 people, making it a cornerstone of Wisconsin’s economy. Sponsored by One Source Staffing, this year’s survey features insights from 56 participants representing key areas of the industry, including food and beverage product and ingredient manufacturing, distribution, packaging and equipment, and food service.

The story presented in this year’s Talent and Wage survey is dominated by concerns about turnover and retention. Companies responding to the survey expressed confidence in their ability to find talent across many occupational classes but are unsure of their ability to retain their most valuable team members as movement within the industry remains the norm. The cost of this churn is substantial and has led many industry leaders to rethink their culture, onboarding processes, and benefits programs. Combined, they suggest that companies across the food and beverage industry are taking a more holistic approach to talent.

Comprehensive total wage data for the top 59 in-demand industry positions, including:

• Buyer/Purchasing Agent

• Food Production Worker

• Warehouse Worker

• FSQ Technician

• Plant Manager

• Production Manager

Modified Policies, Perks & Practices

Details of what companies are doing to recruit and retain to remain competitive in today’s job seekers’ market, encompassing:

The results of this survey include data from 56 Wisconsin-based food and beverage organizations, fresh insights and more robust intel on recruitment and retention tactics food and beverage employers are actively using, and wage/salary data for 59 jobs common to the food and beverage industry.

All current members receive a free copy of the results. Non-members can purchase a copy for $500.

Email Gina at gbalke@fabwisconsin.com to get yours!

Jefferson County has been a hotbed for food and beverage manufacturing as of late, with Palermo’s Pizza, Kikkoman, Onego Bio, Purina, and a Food and Beverage Innovation Campus among recent projects in the area.

Q: Why is Jefferson County such a great place for food and beverage companies to relocate, grow and expand?

A: Jefferson County is where opportunity and resources come together for food and beverage companies. First, there’s our location perfectly situated between Madison and Milwaukee, with easy access to major transportation networks. That connectivity makes it simple for companies to move products quickly and efficiently, whether they’re distributing regionally, nationally or even globally.

But it’s not just about geography it’s about the resources and support businesses find here. Jefferson County is part of Wisconsin’s thriving food and beverage ecosystem, which includes everything from top-tier agricultural producers to a workforce that understands the industry’s unique needs. And through partnerships with local technical colleges and workforce training programs, companies relocating or expanding here can count on a steady pipeline of talent.

What really sets us apart, though, is our collaborative community. We’ve seen firsthand how businesses thrive when they’re supported by local government, economic development organizations like ThriveED and a network of suppliers and contractors who genuinely want to see them succeed.

FaB was honored to attend multiple industry groundbreakings in 2024, including the completed renovations in Wixon’s R&D and innovation center (36 new jobs) and Kikkoman’s new facility in Jefferson (80 new jobs).

In addition, FaB has been working with WEDC, ThriveED, Milwaukee 7, and other economic development organizations to meet with companies interested in moving to or expanding in Wisconsin.

BY ANNA LARDINOIS, MKE STARTUP NEWS

For most people, messy kids just mean stained carpeting and mountains of laundry. For Rick Kellow and Beth Kuehl, having messy kids sparked the idea for a multi-million-dollar business.

It all began one night in the family’s theater room.

“I went downstairs to check on the kids playing video games. There were spilled cans of soda and chips all over the place. I came upstairs and told my wife that we needed to buy a plate that holds both drinks and food,” Kellow recalled.

She assured him that nothing like what he was describing existed. He was incredulous, but after some research, he discovered that she was right.

Just a week later, Kellow turned his vision of a combination plate and cup into a plastic prototype. The dish was a hit with the family, but the $5,000 price tag for the creation of the prototype wasn’t, so, the idea to develop the prototype on a larger scale was shelved.

Although the plan to develop the prototype on a larger scale was shelved, the prototypes themselves didn’t gather dust. They quickly became the favorite dishes of the household. When their oldest child left for college, he took one of the dishes with him. His dormmates loved the spill-resistant design just as much as the family did.

This newfound popularity reignited the discussion about bringing the dishes to market. After careful consideration, Kuehl and Kellow decided to invest $50,000 in an injection molding tool in 2015, enabling them to produce the dishes on a larger scale. They named their innovative product GreatPlate, and they began promoting it at tradeshows.

At their first show, they got contracts from Menards and CVS.

The sales were an amazing coup. They sold over 100,000 units, and GreatPlate performed well in stores. However, their big break proved to be shortlived as follow-up orders from these retailers did not materialize.

Years later, QVC discovered GreatPlate and the company’s fortunes changed again. After GreatPlate’s first appearance on the network, sales soared.

“I think we’ve done three and a half million plates with QVC alone,” he said. The strong response from QVC viewers led to guest appearances on the Food Network, the Rachael Ray Show, the Today Show and local newscasts across the country. Kuehl makes regular appearances on the network to promote the dishes and Kellow says she has developed a fanbase.

According to the company website, to date, GreatPlates has sold more than $10 million worth of plates.

“It’s been about 9 years for us to become an overnight success,” Kellow jokes.

For every deal that we got, we had 20 rejections. We would go to Walmart every year and they would say, ‘you’re selling this to us for a dollar and I can buy this for a quarter from China,’” he recalled.

“Today, the company continues to grow with the help of its partners Pro Ex Extrusion, Horicon Bank, and investor Tim Algiers.

Oshkosh-based manufacturer Pro Ex Extrusion manufactures GreatPlates. The company makes the classic GreatPlate, as well as a version that allows users to insert a stemmed glass into the dish. Pro Ex also makes the company’s GreatCoasters and is set to begin production on the soon-toto-be-released platter-sized product designed for large meals.

“Right now, we can scale our process. We can double or triple our production in 90 days,” he said.

Another key partner in the growth of the company is the 125-year-old Wisconsin-based financial institution, Horicon Bank.

“We didn’t need money in the beginning because we bootstrapped it on our own,” Kellow said. “Mike Fleischmann from Horicon Bank reached out and said, ‘if you ever need anything, give me a call.’ And sure enough, we started to grow into large programs with QVC, we needed a cash infusion, and you couldn’t have found an easier guy to work with. If you don’t have a good bank behind you, you’re in trouble. That’s the biggest problem with entrepreneurs- how do you finance your receivable? In some cases, these larger buyers take you out 90 to 120 days. That’s pretty hard. Horicon Bank never blinked; they just said ‘okay’. To have that kind of support behind you, that’s one of the most critical pieces. Otherwise, you can’t fulfill the order.”

As their product line expands and their customer base grows, Kuehl and Kellow continue to achieve remarkable success. A recent milestone was adding the Southern-based travel center chain Buc-ee’s to their roster of clients.

“One of our big successes right now is Buc-ee’s They use us, and there are projections that they’re using half a million plates per year,” Kellow said.

I think we’ve done three and a half million plates with QVC alone.”

Between the impressive list of retailers and the new products created to meet a wider customer base, the future looks bright for this Wisconsin-made innovation.

It’s no wonder eight of the 10 largest food companies in the world have chosen Wisconsin as home to their operations. They benefit from the state’s reliable supply chain, central location for efficient distribution, natural resources, and a highly skilled workforce with deep experience in food and beverage manufacturing.

Built on a strong foundation of agricultural traditions, cutting-edge food science, and advanced manufacturing, Wisconsin provides a unique and dynamic environment for food and beverage companies to succeed.

*LightcastQ12024Dataset

† LightcastQ42022Dataset §WEDC

141,000 Industry Jobs & 3,700 Companies in Wisconsin*

#1 in Food Product Machinery Manufacturing in the United States †

Take advantage of our signature benefits to keep you and your business engaged, connected, and growing. A FaB membership is company-wide and covers all your employees, making these benefits available to you and your entire team.

Virtual events & webinars

As important and timely subjects are identified, we respond with events featuring industry experts. Stay current and on top of your game with webinars for talent attraction and retention, food safety, scaling your business, supply chain, and more.

In-person events

Learn from industry experts, get inspired by notable industry professionals, and network with your industry peers at our in-person events.

FaBricator Program

Looking for best practices, resources, and mentoring?

Just ask! Looking to share your industry experience? Apply to become a FaBricator!

Leadership Council

Our Leadership Council works to develop deeper industry intelligence and build a dynamic industry network for innovation, growth, collaboration, and support.

Survey participation

Take part in and get exclusive access to the results of our surveys, providing you with industry insights, wage data, and more.

FaBsafe Certificate®

The FaBsafe Certificate® is a renewable basic food safety training certificate covering the basics of GMPs, HACCP, personal hygiene, and preventive controls.

Farm-Factory-Fork Career Discovery

Inspire the next generation of talent into the careermaking possibilities of our food and beverage industry.

We joined FaB to be part of Wisconsin's Food and Beverage community and gain access to the organization's resources and services. FaB is important to the food and beverage industry in Wisconsin with access to professionals to consult, staffing connections and regulatory compliance assistance as well as an array of events that build networks and open business opportunities.”

Stacy La Point, Owner of Fresh Is Best

Lab testing discounts

Take advantage of the FaB Wisconsin-Eurofins partnership group discount to receive up to 25% off select microbiology and chemistry testing services from Eurofins.

UHC Level Funded Healthcare Plans

For small businesses seeking a more affordable health plan and more options for employees, members get access to the MMAC’s UHC Level Funded healthcare plans, which can include medical, dental, vision, life, disability, and critical illness.

Logo visibility

Display your company logo on our member listing. If you’d like elevated visibility, consider a Select or Premium member upgrade.

Job listing

Find your next hire! Unlimited job postings are included in your membership.

Industry calendar

Advertiseyour food and beverage-related events, webinars, and networking opportunities.

Choice, Select, and Premium-level members get boosted benefits including logo or ad space in our Annual Report, Leadership Council representation (for food and beverage companies), and more!

Q: Can you tell us about your company?

A: MilwaukeeWarehouse provides food-grade warehouse and distribution services to many of the food and beverage organizations in the Midwest. With expertise in warehousing, inventory management and fulfillment, we help businesses optimize their logistics operations. Our commitment to reliability and personalized service makes us a trusted partner for companies in this business segment.

Q: Why did MilwaukeeWarehouse join FaB?

A: We joined FaB to connect with industry leaders and stay ahead of emerging logistics trends. This partnership aligns with our commitment to continuous improvement and delivering innovative solutions to our clients.

Q: Why is being part of the FaB network important to you?

A: Being part of FaB provides great opportunities to network, share insights, and learn from industry experts. It reinforces our dedication to excellence and ensures we remain at the forefront of logistics innovation.

BY EMILY ALLEN, ASSISTANT DIRECTOR

As the cookware industry navigates a landscape marked by supply chain disruptions and growing consumer demand for sustainability, Regal Ware – who has spent 100 years manufacturing cookware and over 75 years selling it globally – stands poised for innovation.

FaB sat down with Milissa Rick, the company’s chief marketing officer, to discuss how the company is addressing these challenges and is navigating its recent move to Milwaukee, which promises to enhance community engagement and marketing strategies.

FaB Wisconsin: What are some of the biggest challenges currently facing the cookware industry and how is Regal Ware positioning itself to address those challenges?

Rick: "The cookware industry faces a range of challenges, from global supply chain disruptions and rising raw material costs to the increasing demand for sustainable, health-focused products. Consumers today are more mindful of where and how products are made, and they expect brands to be transparent and environmentally responsible. At Regal Ware, we view these challenges as opportunities to lead with integrity and innovation.

We’re addressing supply chain complexities by investing in advanced manufacturing processes, which help us maintain efficiency and quality control. On the sustainability front, Regal Ware is deeply committed to environmental stewardship. We’re exploring new materials and sustainable manufacturing practices to minimize our ecological footprint. Our cookware brands (Saladmaster and American Kitchen) are designed to be durable and long-lasting, reducing the need for replacement and, by extension, minimizing waste. By focusing on quality and sustainability, we aim to meet the evolving needs of our customers and ensure our cookware aligns with their values.“

Regal Ware has a long history in the cookware industry. How do you envision the brand evolving in the next five years, especially in terms of consumer trends and sustainability?

"Regal Ware’s rich heritage, spanning almost 80 years, gives us a strong foundation, but we’re always looking to the future. Over the next five years, we plan to deepen our commitment to sustainability and innovation, aligning with key consumer trends like health-conscious cooking, eco-friendly products, and smart technology integration. We’re actively researching ways to incorporate sustainable materials and energy-efficient production methods in our manufacturing processes. Additionally, we recognize that today’s consumers want

cookware that supports a healthy lifestyle, and we are poised to be a leader in the kitchen space; we’re continuing to innovate with products that enhance the cooking experience while preserving nutrients and reducing the need for added fats.

On the technology front, we’re exploring smart cookware options that can provide consumers with real-time feedback on cooking temperatures and methods, helping them achieve the best culinary results. Through these efforts, we’re not only preserving our legacy but evolving to meet the needs of modern consumers who value sustainability, health, and innovation.“

What motivated Regal Ware's decision to relocate its headquarters to Milwaukee, and how do you anticipate this move will impact your marketing strategy and community engagement?

"Relocating our headquarters to Milwaukee was a strategic decision to be closer to an urban center where we can connect more directly with our customers, partners, and the broader business community. Milwaukee’s vibrant culture and strong business environment offer us the opportunity to collaborate with local organizations, attract top talent, and expand our reach. This move also allows us to strengthen our

community engagement efforts. Milwaukee is a city rich in history and innovation, much like Regal Ware, and we’re eager to contribute to its continued growth. For instance, our new office will enable us to host events, collaborate with local culinary schools and food entrepreneurs, and participate more actively in community initiatives.

From a marketing perspective, being in Milwaukee enhances our ability to stay in tune with consumer preferences and trends in the Midwest and beyond, while also being committed to manufacturing in Washington County. It brings us closer to our roots while positioning us for future growth in a way that’s community-centered and responsive to our customers’ needs."

$198,593 grant awarded for discounted training

FaB Wisconsin has been awarded the prestigious Workforce Advancement Training (WAT) Grant in conjunction with Milwaukee Area Technical College. The $198,593 grant will provide FaB members who applied discounted training for their employees.

Members will have access to the FaBsafe Certificate® and MATCprovided courses including Food Quality Management, Food Manufacturing Processes, Manufacturing Maintenance, Emotional Intelligence, Leadership Principles, Effective Communication, Excel, Command Spanish for Supervisors, and more.

This initiative reflects FaB’s ongoing commitment to fostering growth, knowledge, and excellence within our membership and the food and beverage industry of Wisconsin as a whole. We are thrilled that we can offer this benefit to our members, and thank you to Trisha Stehr of MATC, who was instrumental in making this grant a reality!

BY MARK FELDMANN, MILWAUKEE AREA TECHNICAL COLLEGE

You could call Thalia Rivera a foodie.

Something is always baking in the oven or simmering on the stove at her house. She has taken all three cooking courses offered at Nathan Hale High School in West Allis.

“I love those classes,” she said.

It was in her latest cooking class that she heard about and signed up for Farm-Factory-Fork Career Discovery, an annual event sponsored by the Food and Beverage (FaB) Wisconsin to make high school students aware of the abundant educational and career opportunities in the food and beverage industry.

On Wednesday, October 16, Rivera was one of 150 students from nine area high schools who attended the event, which was held at Milwaukee Area Technical College’s Downtown Milwaukee Campus for the first time in the event’s 10-year history.

The students heard from career experts, conducted food science experiments in MATC’s chemistry laboratories, and met representatives from two dozen companies and employers connected to the industry, including General Mills, A Goodman’s Desserts, Palermo’s Pizza and Sargento Foods.

Rivera listened keenly at the Sargento table as a representative described the food science careers available there.

“Doing something with food is definitely an option,” said Rivera, a senior at Nathan Hale. “I definitely want to go to college after high school, and it’s pretty likely I’ll come to MATC.”

MATC offers a whole menu of programs related to the food and beverage industry. Students can earn associate degrees in Food Science Technology, Culinary Arts, Baking and Pastry Arts, and Hospitality Management,

or a technical diploma as a Food Service Assistant.

Food Science Technology applies the principles of chemistry and biology to ensure food products are safe and meet quality standards, and to create innovative ways to produce, package, preserve and distribute foods.

“Some of you might know exactly what you want to do, and maybe you don’t,” MATC President Anthony Cruz, Ed.D., told the students at the start of the event. “Here you might see something new, something you never thought about before that will pique your interest.”

In high school, Marie Colmerauer, an MATC food science instructor, loved chemistry and math. She also worked at a Culver’s restaurant and a Cousins sub shop. After college she worked at Kraft Foods, perfecting the shape of pasta for macaroni and cheese, and at Sargento Foods.

“I loved science and I loved food and wanted to find a way to combine all of it,” she said. “Maybe you hear some of your story in my story.”

Careers in the food and beverage industry are largely recession-proof, and as was recently discovered, pandemic-proof, said Gina Balke, executive director of FaB Wisconsin.

“These jobs were deemed essential,” she said. “Wisconsin is home to thousands of food and beverage companies. There are a vast amount of career opportunities.”

According to FaB, getting skilled professionals into the industry is vital because millions of people are retiring from the workforce and the world’s population is expected to reach 9.7 billion by 2050.

Wisconsin is home to thousands of food and beverage companies. There are a vast amount of career opportunities.”

MATC has great partnerships with employers in the food and beverage industry, Dr. Cruz said. Those companies help shape MATC’s courses to ensure the college teaches exactly what employers need, he said. “We make sure that we’re aligned,” he said. “That’s the great part of being at a technical college.”

Farm-Factory-Fork has been held almost every year since 2014. Mount Mary University, Lakeland University, Concordia University of Wisconsin and at Milwaukee Public Schools’ Vincent High School have served as hosts.

This year at MATC, the event attracted students from Germantown, Greendale, Hartford Union, Kettle Moraine Lutheran, Nathan Hale, Plymouth, Random Lake, Tenor and Vincent high schools.

MATC has been a partner with the FaB Wisconsin since it was formed, said Trisha Stehr, manager of client services for the college’s Workforce Solutions team, which helped organize the event. FaB officials also sit on the college’s Food Science Technology Advisory Committee, she said.

About MATC: As Wisconsin’s largest technical college and one of the most diverse two-year institutions in the Midwest, Milwaukee Area Technical College is a key driver of southeastern Wisconsin’s economy and has provided innovative education in the region since 1912. More than 30,000 students per year attend the college’s four campuses and community-based sites or learn online. MATC offers affordable and accessible education and training opportunities that empower and transform lives in the community. The college offers more than 180 academic programs many that prepare students for jobs immediately upon completion and others that provide transfer options leading to bachelor’s degrees with more than 40 four-year colleges and universities. Overwhelmingly, MATC graduates build careers and businesses in southeastern Wisconsin. The college is accredited by the Higher Learning Commission