Ornamental and Miscellaneous Metal March/April 2004 $6.00 US

Job Profiles

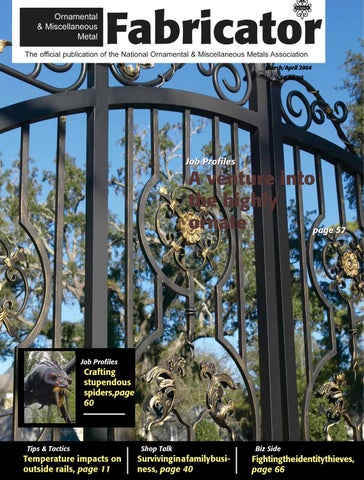

A venture into the highly ornate page 57

Job Profiles

Crafting stupendous spiders,page 60

Tips & Tactics

Temperature impacts on outside rails, page 11

Shop Talk

Surviving in a family business, page 40

Biz Side

Fightingtheidentitythieves, page 66