Precast Concrete Guide

BUILDING SMARTER, FASTER, AND MORE EFFICIENT

Revolutionizing Data Center Construction

In the fast-paced world of data center construction, speed, reliability, and cost-effectiveness aren’t just important—they’re essential. Fabcon brings over 50 years of experience in delivering cutting-edge precast concrete solutions that meet the toughest demands of hyperscalers, co-locators, architects, and general contractors.

Our precast systems offer durability and performance to contribute to sustainability in construction. They help reduce the volatility caused by weather delays, as they are less dependent on clear conditions, making them an ideal choice for year-round construction.

Our reach across the country supports repeatability in design, customer experience, execution, and value engineering, enabling us to efficiently support projects with our capacity and logistics. We specialize in delivering precast concrete solutions that meet rigorous performance standards while ensuring your projects stay on schedule, within budget, and align with environmental goals.

Call (800) 727-4444 if you’re not currently working with a Fabcon Sales Engineer.

We’ve Got You Covered

Eight locations and multiple options

Our eight strategically located manufacturing facilities ensure an effective delivery span that covers most everything east of the Rockies and north of the Gulf Coast. We have delivered and installed our product all over the United States and also in four Canadian provinces.

Dark blue represents the states where Fabcon has produced a data center.

Safe Work, Strong Results

We are committed to safe workplaces. Our safety practices keep plants and jobsites protected, safeguarding our people while ensuring projects run smoothly every year.

Shaping Tomorrow, Responsibly

Sustainability is a foundation responsibility in the concrete industry, achieved through multiple approaches. By committing to smarter practices, we not only build durable structures today but also help preserve resources for future generations.

Proactive to acquire Fabcon specific EPDs which are more environmentally friendly than industry standards

Corporate representation on PCI’s Sustainability Committee

D ue to cement’s impact on emissions, using supplementary materials to replace a portion of cement in mix designs to reduce our Carbon Footprint

Tracking Greenhouse Gas Emissions

(Cement is responsible for 7% of the global man-made greenhouse emissions (2nd largest industrial source of CO2))

Quality At The Core

Quality is our highest priority. Every one of our plants holds industry certifications, and we continually invest in advanced equipment and technologies to ensure unmatched precision and consistent results.

Certified Plants

All plants are Certified to PCI Architectural Category AD

Most plants have the additional PCI Architectural Certification AB and AC

Quality Capital Improvements

Quality Continuous Improvement

Improvements in concrete batching including new mixers

Upgrades to casting machines

Bed heat controls

Bed quality repairs

Partnership with Sika for admixtures and mix designs

Projection lasers

VersaCore Pro upgrade

We Make It Happen, Faster.

When you choose Fabcon, you’re choosing more than just precast panels — you’re choosing a partner who is with you through the entire project from start to finish.

Customized Turnkey Solution s

You get the biggest benefit when we’re a part of your project team from the start. From inception to installation, our solutions are designed to support structural and architectural precast solutions.

Consultation

We partner with our customers from day one, offering customized turnkey solutions that meet project demands.

Project Management

Our skilled in-house team takes full responsibility for every project, guiding it through all phases from engineering through install. This comprehensive approach allows us to maintain strict control over each stage and ensure the best results.

Design

Our engineering and drafting teams partner closely with the structural and architectural teams to ensure our designs align with project specifications.

Manufacture

State-of-the-art manufacturing facilities are climate-controlled and PCI-certified, helping ensure accuracy and quality for every project and application.

Logistics

Detailed yard operations go beyond storage to include quality inspections, finish treatments, and delivery sequencing that help expedite project timelines.

Installation

Our highly trained, expert PCIcertified installers tailor installation methods to each project and site-specific needs.

Rock-Solid Solutions For Your Next Project

Fabcon’s structural precast panels offer endless rock-solid solutions for time and budgetsensitive projects. We build everything from grocery stores to corporate headquarters, manufacturing facilities to ice arenas, and car dealerships to data centers and more.

The Go-To Choice For Data Centers

When you choose Fabcon, you’re choosing more than just precast panels — you’re choosing a trusted partner who is with you every step of the process and is committed to delivering excellence, efficiency, and long-term value.

01 Unmatched Reliability & Experience

With over 50 years of experience collaborating with hyperscalers, co-locators, general contractors, and architects, we’ve built a reputation for delivering data centers that consistently exceed expectations.

02 Faster Construction Timelines

With over 20 million square feet of precast panels produced annually, we have the expertise and capacity to fasttrack your project. Our panels arrive on time, ready to install, minimizing downtime and speeding up operations.

Consistent Quality & Controlled Manufacturing

Our state-of-the-art manufacturing process guarantees high standards with minimal on-site errors and rework. This ensures repeatable results, reduces risk, and minimizes delays and cost overruns.

04 Superior Energy Efficiency & Thermal Performance

Our Thermo Dynamic Insulated Wall Panels ensure regulatory compliance and provide exceptional thermal performance in any climate. This translates to reduced long-term energy costs and a stable environment for sensitive equipment.

05 Versatile & Durable Solutions

Fabcon tailors its precast concrete panels, from lightweight that reduced loads to heavy-duty panels for extreme durability, ensuring secure, long-lasting structures that withstand the rigorous demands of modern operations.

Data Centers Built On Conficence

We build with the same principals as you – speed and performance, creating the structural enclosure that secures what matters most to your business.

Data Center Projects in the Last 10 years

300 General Contractors

Avg number of unique GC’s we work with/year 250 Architecture Avg number architecture

MISSION-CRITICAL OPERATIONS WHERE

DATA

THRIVES Trusted by Data Center

Industry Leaders

With decades of proven performance, Fabcon reassures that the most critical projects will stand the test of time.

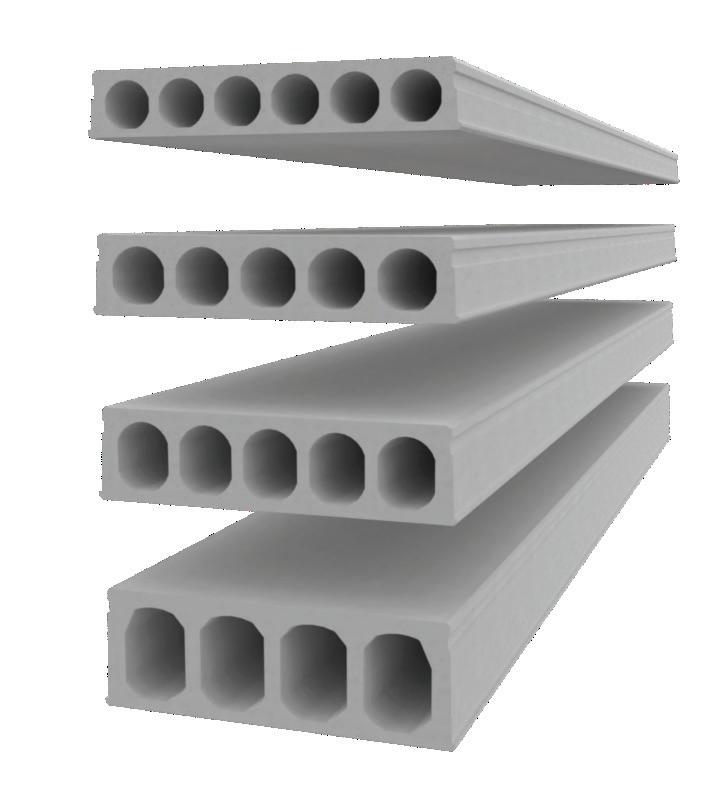

Walls Panel Types

Architectural Structural Insulated Elevator / Stair Shaft

Architectural Precast

Wall Panels are secured into the building ’s super-structure and offer a wide range of decorative finishes.

Structural Precast

Wall Panels are built to resist and stabilize roof, floor, and lateral building loads.

Insulated Precast Wall Panels feature both structural properties and architectural abilities which include a thermal insulation layer between the interior and exterior concrete wythe.

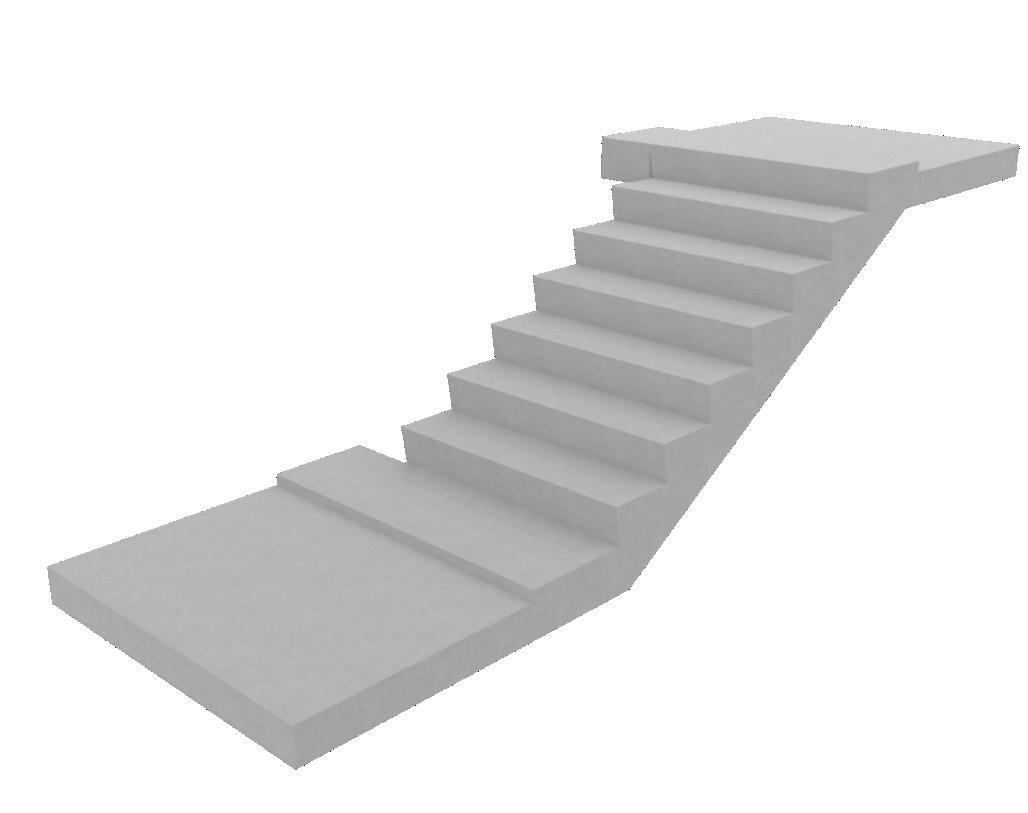

Elevator / Stair Shaft

Precast Wall Panels are used with stairs, landings, and openings for quick and efficient installation, offering a time saving alternative over masonry or wood based products.

Shear Precast Wall Panels provide the structures with lateral load stability.

Total Precast

The elements of the building, including walls, floors, columns, beams, and even façade panels, are manufactured off-site in a controlled environment. Precast elements are then transported to the construction site and assembled. The integration of precast components offers many advantages, such as accelerated construction timelines, enhanced durability, and consistent quality. The modular nature allows for customization in design, enabling you to explore innovative aesthetics while adhering to structural requirements.

Your Finish, Your Way

Our precast panels are available in a multitude of colors and finishes for your exteriors. Your imagination is the only limitation when considering the scope of naturally occurring aggregates, pigments, and custom imprint capabilities.

Painted Exposed Aggregate

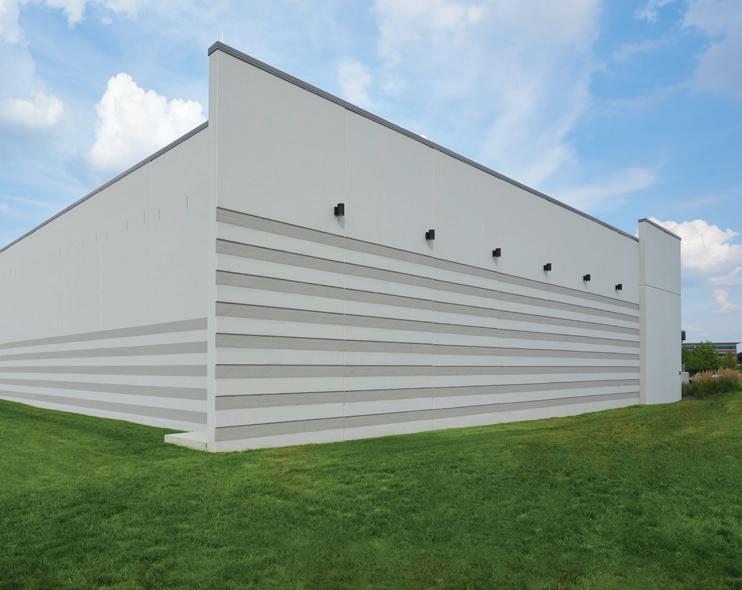

Ohio Data Center

Powering Hyperscale Data with a Full Precast Structure

Located in a rapidly expanding digital hub, this Ohio Data Center is designed for hyperscale data operations with a complete precast concrete structure. The building features structural gray precast insulated and solid wall panels, double tees, stairs, solid slabs, columns and beams — engineered for strength, speed, and efficiency. To meet an aggressive schedule, erection crews utilized a two-crane setup, with precast components sourced from multiple facilities. This allowed for parallel production and streamlined delivery, keeping the project on pace despite its complexity. Precast sped up installation while providing the strength and precision needed for a mission-critical facility.

BUILDING SIZE

PRODUCT

FINISH GENERAL CONTRACTOR ARCHITECT

422,800 SQFT

INSULATED AND SOLID WALL PANELS, DOUBLE TEES, STAIRS, SOLID SLABS, COLUMNS AND BEAMS, STEEL FORM (FLOAT)

STRUCTURAL GRAY FINISH

TURNER CONSTRUCTION COMPANY HKS, INC.

BUILDING SIZE PRODUCT FINISH

GENERAL CONTRACTOR

ARCHITECT

24,423 SQFT

VERSACORE PANEL

STEEL FORM (FLOAT)

QUANDEL CONSTRUCTION

BATIR ARCHITECTURE

Fabcon Projects

General Contractors

Avg number of unique GC’s we work with/year

Architecture Firms

Avg number of unique architecture firms/year

End Markets Served Number of end markets we serve/year

On-Time Delivery

We know deadlines matter. Our streamlined manufacturing process and efficient logistics system ensure that your panels arrive exactly when you need them. This allows for quick installation & eliminating project delays.

Proven Track Record

We’ve worked with leading hyperscalers and co-locators to deliver data centers of all sizes and complexities. Our vast experience means we can handle any challenge & deliver solutions that meet your specific needs.

Certainty and Peace of Mind

When you partner with Fabcon, you’re getting more than just precast panels. You’re getting a team that is committed to delivering on time, within budget and without surprises. We eliminate the guesswork & keep your project on track.