OPHTHALMIC LABS & INDUSTRY

Connect, discover, stay up-to-date

5/2023

▶ Special topic: Sustainable Processes

A broad vision of sustainability

“There is no waste at all‒, only raw materials!”

▶ Technology

Anti-reflex coating and process control

Thickness and weight of ophthalmic lenses

One drop and you regain the vision of a 20-year-old?

▶ Market Survey

AR-Coating machinery

THE NATURAL WAY OF DEBOXING

Environmentally friendly

DBX m dulo

With DBX Modulo ONE, SCHNEIDER debuts a powerful and fully automated new lens deboxer for high throughput, 24/7. The innovative technology unpacks all common kinds of boxes and materials – cardboard, blisters, even sleeves –damage-free with a clean process. It requires a minimum of energy and e ort.

After swiftly identifying the type of box, DBX Modulo ONE opens it “naturally”: It unfolds, takes out and unwraps, entirely without touching the lens surface. SCHNEIDERs eco-friendly process avoids cutting or burning the material using sharp blades or high energy lasers – no cutting particles or dust and no fumes. All waste material is separated and collected individually to simplify recycling and further increase sustainability.

DBX Modulo ONE follows SCHNEIDERs vision to provide the full solution for ophthalmic labs, from warehousing all the way to inline coating and beyond. Ophthalmic lens production fully-automated and entirely hands-free.

ISSN 1614-1598 66527 Volume 19

Eyepress Fachmedien GmbH Saarner Str. 151 45479 Muelheim a. d. Ruhr 66527 Germany

www.schneider-om.com

Unboxing any kind of box

www.optimal-technologies.com t: +44 (0) 1462 491616 e: sales@optimal-technologies.com

Discover the CHC200, a complete cleaning and coating system that effortlessly coats more than 200 lenses per hour utilising the best experience of our 25-year history. When it comes to the ultimate performance cleaning and coating system for your lab, don’t leave it all on the role of a dice! SEE US AT

Why Gamble on the Quality of Your Coatings?

Hanna Diewald Chief editor

Sustainability: everyone round the table, please!

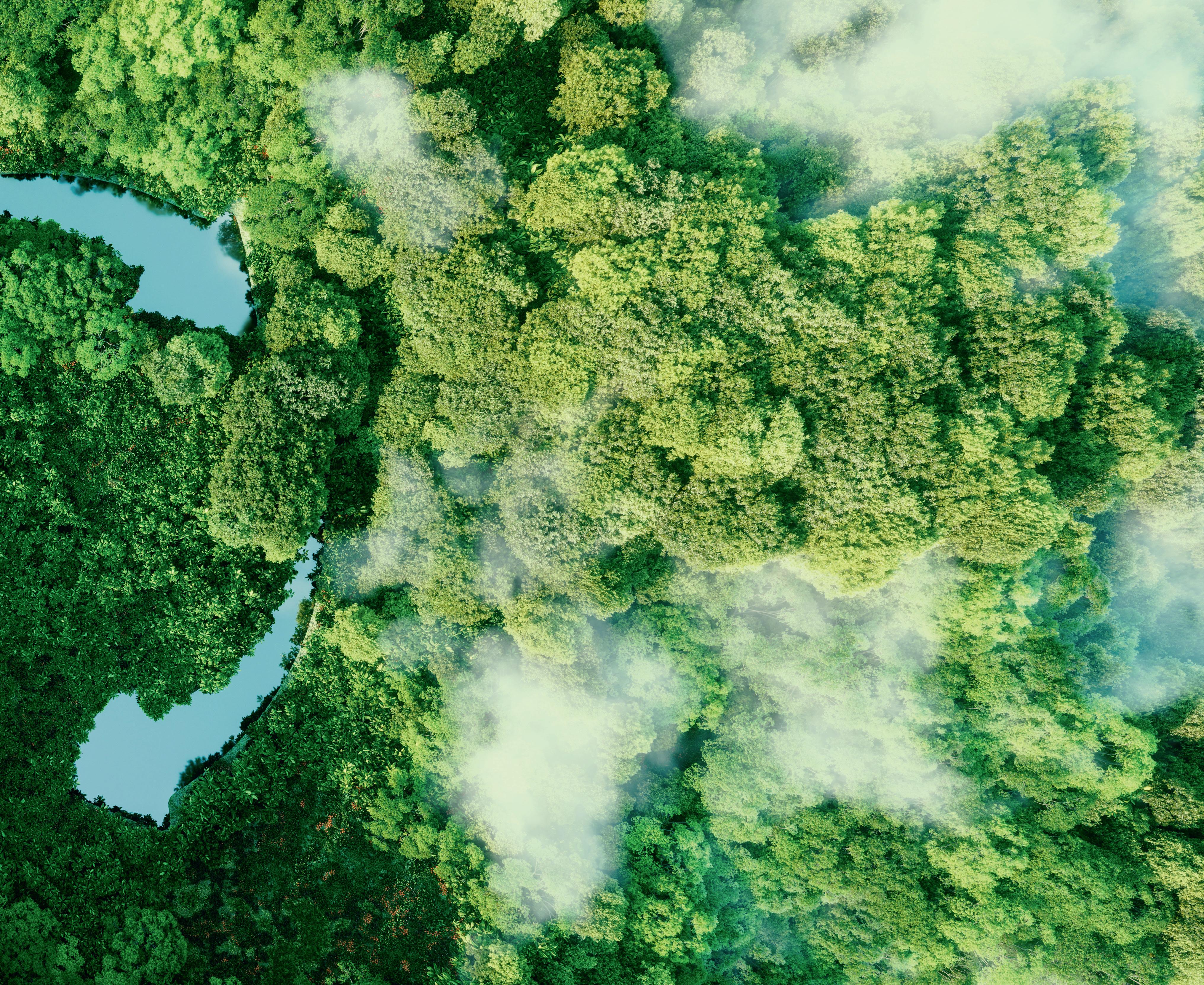

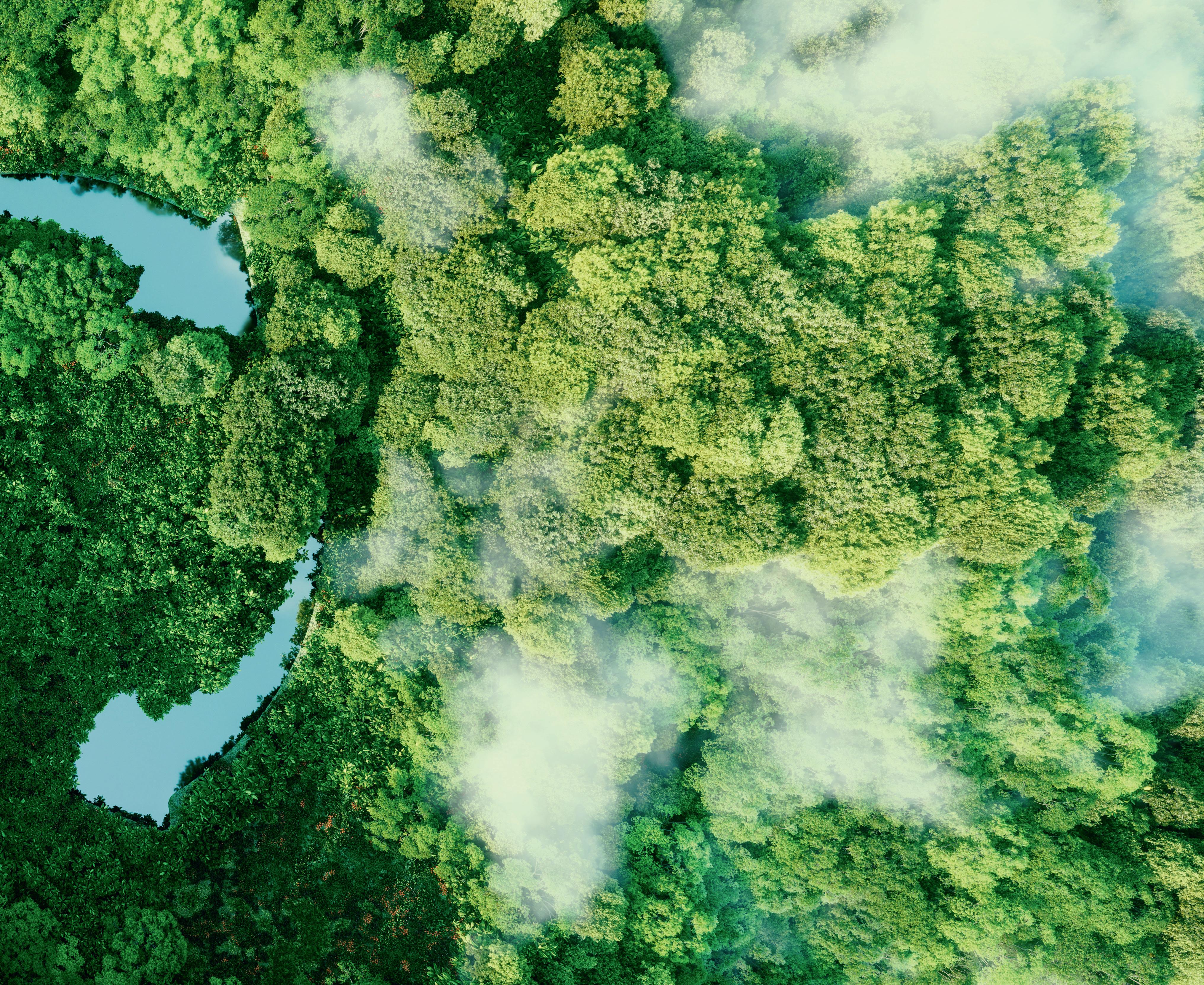

We live in a time when climate change and natural disasters around the world are setting the global agenda. Thus sustainability has a high priority for many companies today – at least in theory.

In practice the definition of sustainability is extremely imprecise, covering ecological aspects as well as economic and social factors. It is sustainable to put solar cells on your roof, to send spectacles to third world countries and to create a diverse work environment.

Where ecological aspects are concerned, it is sustainable to conserve resources, to reduce packaging as well as to promote recycling. Naturally all this is good, it all makes perfect sense!

But who has the final say when it comes to deciding which company or which country is acting truly responsibly? How are consumers supposed to distinguish between greenwashing and genuinely effective measures, when often even the experts can’t immediately tell the difference?

Fairness and comparability but especially the effectiveness could certainly be improved. For example, by companies or entire industries

pulling together: If industry standards are set, if terminology is defined more clearly, if the same international regulations apply to everyone, so that the problems, rubbish and chemicals are not simply transported from one side of the world to the other.

And there needs to be involvement at every level: material suppliers, manufacturers, retail stores and online sellers. For example, recycling procedures can only be established, if everyone sits down at the table to set common goals. The path will not be easy, but in the end it will be worth it. Then sustainability can become truly effective and fair.

In this issue we focus on “sustainable processes”, giving practical examples for the optical industry. These range from how to avoid waste, to filtration via recycling. We also talked to a circular economy expert about how companies can use recycling to benefit themselves and the environment. And last but not least, this issue is also about a “sustainability mindset” – both personally and in companies.

And perhaps it will inspire one or the other to look for partners, to exchange ideas and take a joint approach to some of the topics discussed.

Tell us your opinion, ideas and suggestions: hanna.diewald@mafo-optics.com READ FOR FREE app.mafo-optics.com MAFO 5-23 3 LETTER

GAME CHANGER

Block-less Freeform Lens Production System VISIT US AT SEPTEMBER 29TH - OCTOBER 2ND PARIS, FRANCE BOOTH 6K129

The

By Jamal J. El-Hindi

By Julia Baier

By Julia Baier

By Peter Weber

By Peter Weber

Britta Butz

Britta Butz

MAFO 5-23 5 SEPTEMBER / OCTOBER 2023 MAFO issue September / October 2023 Content Topics in this edition Special Topic Special Topic Special Topic At a glance 6 All about you News from the international ophthalmic industry 7 All about markets Data in graphics 8 All about products Innovations and products for your lab 52 Suppliers Guide 56 Closing Words Lowri Moore – a self-confident ambassador for good vision 57 Outlook Technology 10 A broad vision of sustainability

20 Anti-Reflex coating and process control

26 Thickness and weight of ophthalmic lenses By

Volpe and Pasquale Fanelli Spotlight 16 “There is no waste at all, only raw materials!” An interview with Alexander Maak 30 One drop and you regain the vision of a 20-year-old?

Spotlight 34 Focusing on natural, healthy and clear vision

Business 38 The IDG framework for people and organizations By

Surveys 42 AR-Coating machinery Page 16 Page 20 Page 26

Gaetano

By Lena Petzold

All about you

News from the international ophthalmic industry

Coburn Technologies named Carla Moncunill as new Group Sales responsible for Europe

Coburn Technologies is pleased to announce the addition of Carla Moncunill Cabré to their global sales team as the new Group Sales Responsible in Europe. In this role, Moncunill will facilitate the extension of Coburn’s sales reach across Southern, Western, and Central Europe. As a leading provider of innovative, end-to-end customer solutions to the world’s lens processing industries and eye care professionals, Coburn is excited to introduce Moncunill and the robust technical and client- centered background she will bring to the table.

Fifth LensWare Convention in Langen (Germany)

concentration on the extension of the “production LMS” by Enterprise Resource Planning (ERP) components (sales, inventory) and supply chain logistics components, as well as the innovated version of LensOrder WEB, licensed by different LensWare partners. Furthermore, different events in the evening cared for team relaxation after the laborious technical sessions. LensWare furtherly will put emphasis on organic growth and a perfect customer support, as well as on achieving maximum stability and implementing features for monitoring of the LMS package, to maximize availability of this utter complex IT solution.

opti 2024 presents itself with faces from the industry

opti 2024 marks the beginning of a new era: the campaign visuals for the optical meeting place from 12 to 14 January 2024 in Munich show the faces of committed individuals in the industry. They all stand for a strong market with strong people and for the new spirit of opti. Together and personal. The cross-media campaign started on 1 September 2023. The new campaign with real people instead of models stands for dynamism in communication.

Ocuco announced growth equity investment

From 3rd to 8th of July the fifth LensWare Convention took place. For this purpose, the office crew and all international consultants met for one week in Langen, to integrally discuss about latest developments in projects, modules and requirements, and to furtherly agree the strategy in the different markets. After an evolutionary growth over the last 15 years, meanwhile about 250 lab partner LMS IT projects are managed by 22 committed “LensWare crew” members in all continents of the world. At this year´s convention decisive topics were discussed. For instance the

Ocuco, a global company for eyecare software solutions, announced a €60 million minority stake investment from Accel-KKR, a global technologyfocused private equity firm. The investment is set to boost Ocuco’s global momentum, enabling the company to meet the eyecare industry’s burgeoning omnichannel demand through Acuitas 3 OmniChannel Edition, Ocuco’s category-defining cloud-based software solution. With Accel-KKR’s backing, Ocuco will also continue to capitalize on strategic Merger & Acquisitions (M&A) opportunities.

You have news for the ophthalmic industry? Submit your press releases to: hanna.diewald@mafo-optics.com or constanze.classen@mafo-optics.com

Carla Moncunill Cabré, Group Sales Responsible Europe

New campaign visuals

The global LensWare team

MAFO 5-23 6 INTERNATIONAL NEWS

Leo Mac Canna, founder and CEO of Ocuco

All about markets

Graphical data

Eye health significantly affects labor markets: workers with vision impairment are 30%

According to Eye Health and the World of Work, 13 million

less likely to be employed, compared to those without. Low- and middle-income regions experiencing about four times more cases than high-income regions.

Source: The International Agency for the Prevention of Blindness

people live with vision impairment linked to their work, with an estimated 3.5 million eye injuries occurring in the workplace every year. This amounts to 1% of all nonfatal occupational injuries.

Source: The International Agency for the Prevention of Blindness

52 trillion US dollars

for climate protection. This sum results when summarizing all climate protection programs, financing commitments, frameworks and demand estimates, in 33 countries studied, up to 2050.

Source: The International Agency for the Prevention of Blindness

Over 90% of vision impairment cases are either preventable or treatable through existing, cost-effective interventions. MAFO 5-23 7

> 90% INTERNATIONAL NEWS

All about products

Innovations and working materials for your lab

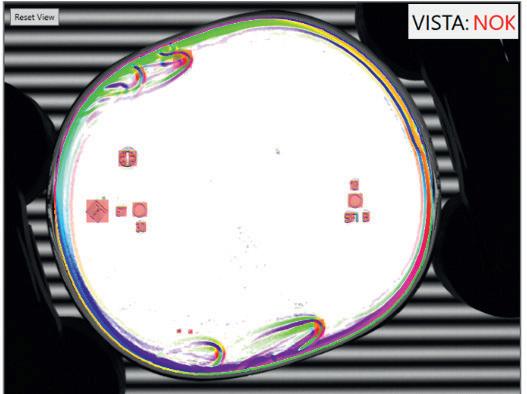

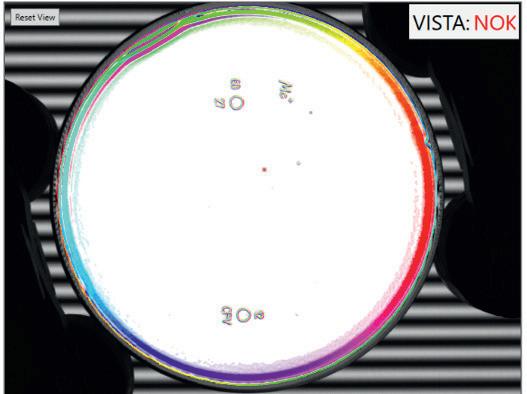

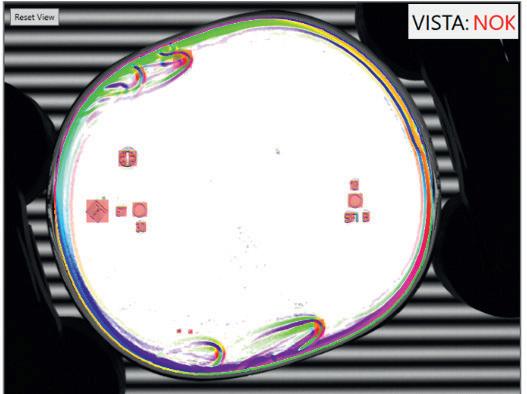

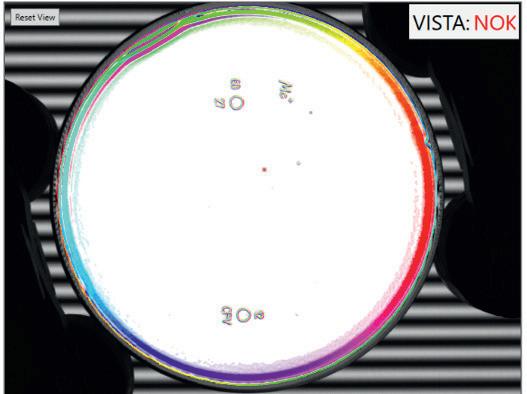

New OptoTech VISTA - Automated Cosmetic Inspection System

The new OptoTech VISTA is especially designed for detecting and localizing defects on ophthalmic lenses. Its integrated optical system screens the lens surface for any irregularities and reliably localizes a comprehensive range of different defect categories that are almost invisible to the human eye (minimal defect size 50μm). It is also optimized to detect coating defects which makes the system suitable for quality control after the coating process. State of the art algorithms result in minimal evaluation time of approx. 12 seconds/lens and thus allow a productivity of up to 300 lenses/h. The intelligent system uses Big Data for targeted decision making. Configurable error zones (different number and error size per zone) are possible to adapt the VISTA to the Lab‘s individual quality standards. The VISTA comes in a new design concept that combines functionality and a compact footprint for easy integration with a modern look. Visit www.optotech.net

MIDO, the leading international eyewear show worldwide, is getting ready to amaze you MIDO is where the world of optics meets in a setting where deals are made and sales closed. Starting the end of September, visitors can register on the MIDO website for the forthcoming edition of the most international eyewear show, set to take place at Fiera Milano Rho February 3rd to 5th 2024. Exhibitors from around the globe have already reserved their area at MIDO, reaffirming the show’s international reach. These days, MIDO is working to build the new edition and to surprise its exhibitors and visitors with novelties, of all kinds: communication tools, Otticlub’s program, influencers, travel packages and so on. Actually, in June, MIDO already surprised: for this new 2024 edition MIDO introduced ‘Spheres’, the new communication campaign created with artificial intelligence, combining human creativity with the innovative power of Artificial Intelligence, the first trade show campaign to be developed with this technology. In addition to its technological and digital soul, MIDO, as a major international event, feels a high responsibility in terms of its impact on the environment, sharing the path toward ISO 20121:2012 certification, which attests to the sustainable management of large events. Visit www.mido.com and the official social channels Instagram (@mido_exhibition), Facebook (@MIDOExhibition), Twitter (@MIDOExhibition) and LinkedIn to stay updated.

Satisloh Introduces Enhanced MES-360 Manufacturing Execution System for Ophthalmic Lens Manufacturing Industry

Satisloh, a global leader in optical manufacturing solutions, is thrilled to announce the launch of an upgraded version of its MES-360 manufacturing execution system. This latest update brings lots of new functionalities that have been developed based on feedback from customers and industry experts. MES-360 has been designed to address the needs of lab managers, production supervisors, machine technicians, and quality teams in mid to large-sized Rx labs. Some of the key features of the new MES-360 software include: Real-time Production Monitoring, Supports Satisloh and 3rd Party Machines, Advanced Data Collection Platform, Coating Batching Tracking, Quality Management Tools and Customizable Workflows with Integrated Smart Conveyor. For more information about MES-360 and Satisloh's comprehensive range of optical manufacturing solutions, visit https://www.satisloh.com/ophthalmic/software/mes-360-software

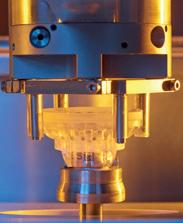

CoreTBA: The Block-less Freeform lens production system from MEI

This new machine represents a game changer in the industry and a revolution in the lens generation process. With its Block-free system, for the first time in history, labs can avoid using tapes, blocks, and wax, or Alloy. This means that it’s not necessary to have taping, de-taping, blocking, and de-blocking machines in the production line anymore. Moreover, with its Dry Cut technology, the CoreTBA doesn’t need a water filtering system and helps you save money and protect the environment. CoreTBA includes seven essential stages of the lens production process in one single unit, with the smallest footprint on the market. All processes, from the digital generation, through the engraving, polishing, and washing, are integrated into one unit. In order to achieve a short machining cycle, all processes occur in parallel, and every section of the unit is fed by a tray conveyor system and digitally controlled loading arms. Visit www.meisystem.com

Advertisement

MAFO 5-23 8 INTERNATIONAL NEWS

SAVE THE DATE

February2,2024

The upcoming conference will take place under the motto:

Next Generation

Planned highlights Machinery processes

3D-printing Coating technology Lens designs

Market data and much more …

Stay tuned and follow us on LinkedIn or subscribe to our newsletter, to get all the news about MAFO – The Conference. The speakers, the final topics and the participants of the panel discussion, matching the motto Next Generation, will be announced in the next weeks. For all questions and suggestions about the conference please write an email to: hanna.diewald@mafo-optics.com / www.linkedin.com/showcase/mafo

THE CONFERENCE

#MAFO

onedaybefore Mido in Milan

CON24

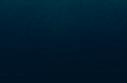

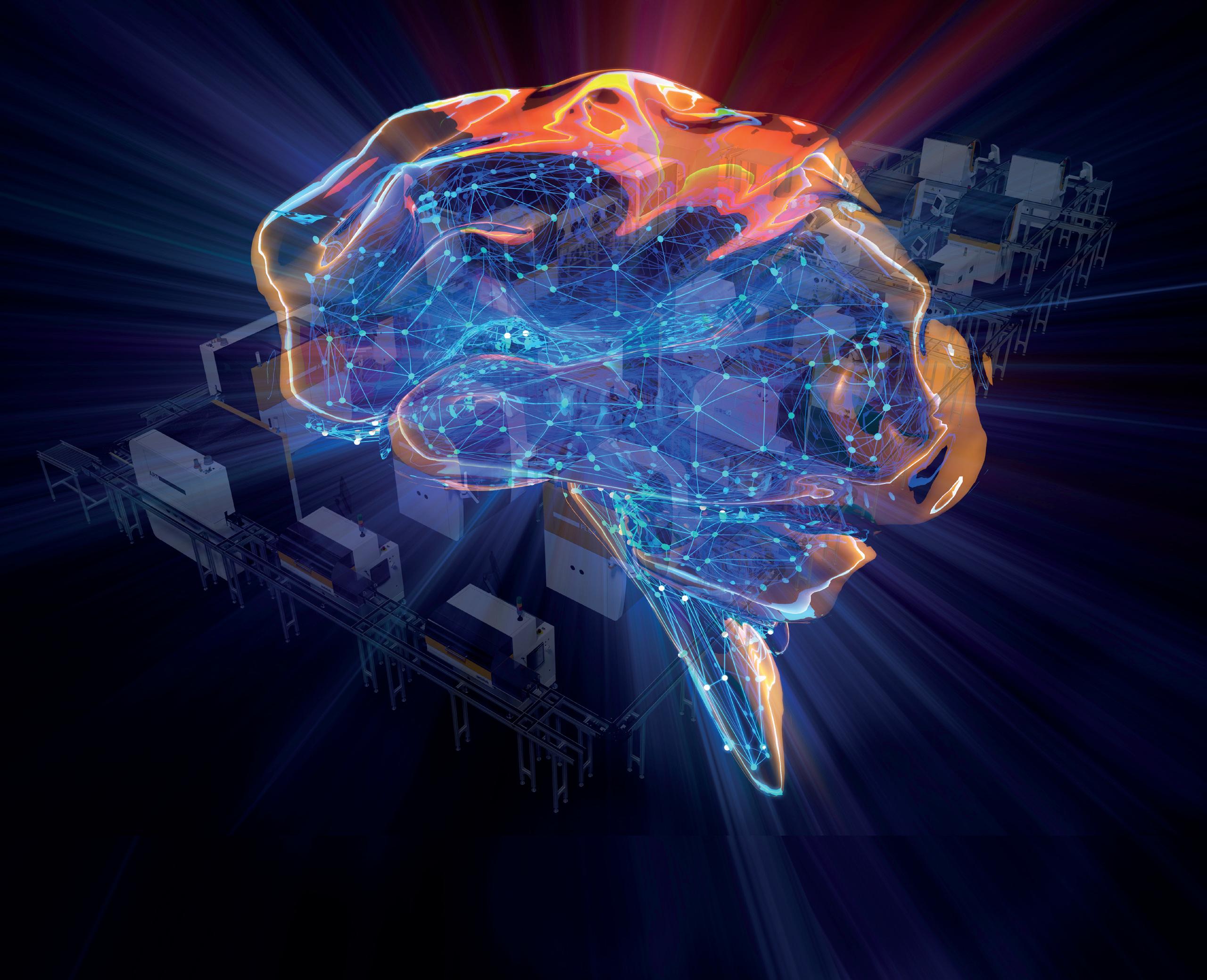

A broad vision of sustainability

Sustainability is a mindset that inspires businesses to think dynamically about both the bottom line and the impact on our planet. By considering filtration, waste management technology and sustainability from other industries, we get a broader vision of what sustainability can be, or should be, for the optical industry.

By Jamal J. El-Hindi

Prior to the “green era”, sustainability had been in practice even when the priority was not the environment. Waste management, filtration, dust colletion and more have been a means to collect or reuse precious resources throughout the manufacturing process. Although environmental conservation has not always been a priority in manufacturing, it has been a means to conserve natural resources and save money.

In the wire industry, companies go through great lengths to collect their waste and strip everything but the raw metals so they can reuse

them. Metal manufacturing mills use huge amounts of water every day, with tanks that hold hundreds of thousands of liters.

Without the environment in mind, these companies had to find ways to reuse this water, especially when expensive coolant and additives were used. The optical industry is like many other industries, requiring ways to reuse water and coolants, disposing of hazardous materials, and trying to reduce waste.

The difference now, of course, is that we are in the “green era”, and we now know the harm our impact has on our planet. The idea of sustainability

Sustainable Processes MAFO 5-23 10 TECHNOLOGY

is not just about reusing resources or making efforts to stop pollution, it has become a mindset. Sustainability is about changing the way you think about business and how your choices not only impact the bottom line, but how they impact the future of our planet and all of us who live on it.

Filtration and technology

Filtration among industries has been a profound part of the manufacturing process for a long time. So much, that large industries turn to specialized filtration companies to provide entire filtration systems. In the optical industry, especially in the United States, we have only recently seen a rise in smaller labs expanding in size. This transformation brings all sorts of new obstacles to overcome, making it more practical to implement filtration practices from other industries. Most smaller labs got along just fine without any special equipment for filtration or waste. As a lab gets bigger, however, it generates more waste, or plastic swarf. Swarf generated from lens grinding takes up a lot of volume, and as labs grow, we see costs such as garbage disposal, hazardous waste removal, coolant, storage, and water increase. Just

the increased volume of swarf alone can cost labs a lot of money, not to mention how much coolant is being thrown away with that swarf. As a lab grows, filtration and waste management become more important. In the optical industry, the main forms of filtration are typically media filtration or centrifuge filtration.

Centrifuges

Centrifuges have been a big player in filtration for a long time, designed to use g-forces to separate particles that vary in density. We use centrifuges for many different applications. They work best when the dirt load is heavy, such as paint sludge, sometimes heavy metal sludge, and a lot with glass manufacturing. In fact, centrifuge technology was the main form of filtration in the optical industry when the lenses were made from glass.

Since then, however, lenses started being manufactured from plastics, which creates a much lighter swarf discharge. This is why media filtration was brought into the industry. Plastic separates much better through some sort of medium, or media (like a coffee filter). There are all sorts of

Sustainable Processes

MAFO 5-23 11 TECHNOLOGY

different media filters, but for manufacturing you need some type of media filter that can handle enough liquid volume for your production. Different filtration technology offers different advantages, such as a gravity filter with a longer discharge ramp provides more time for the swarf to dewater, preventing more coolant from getting thrown away in a landfill. These offer an eco-friendlier filtration process.

Waste management and technology

In recent years, the optical industry started implementing more waste management technology. Swarf compaction, for example, started as a means to reduce the volume of swarf waste, but quickly became a means to retrieve more coolant. We are starting to see labs investing in briquetting technology as a goal to reduce their ecological footprint and help the environment. This has also proven to save manufacturers thousands in coolant costs per month, making it a perfect choice for sustainable manufacturing.

Briquetters

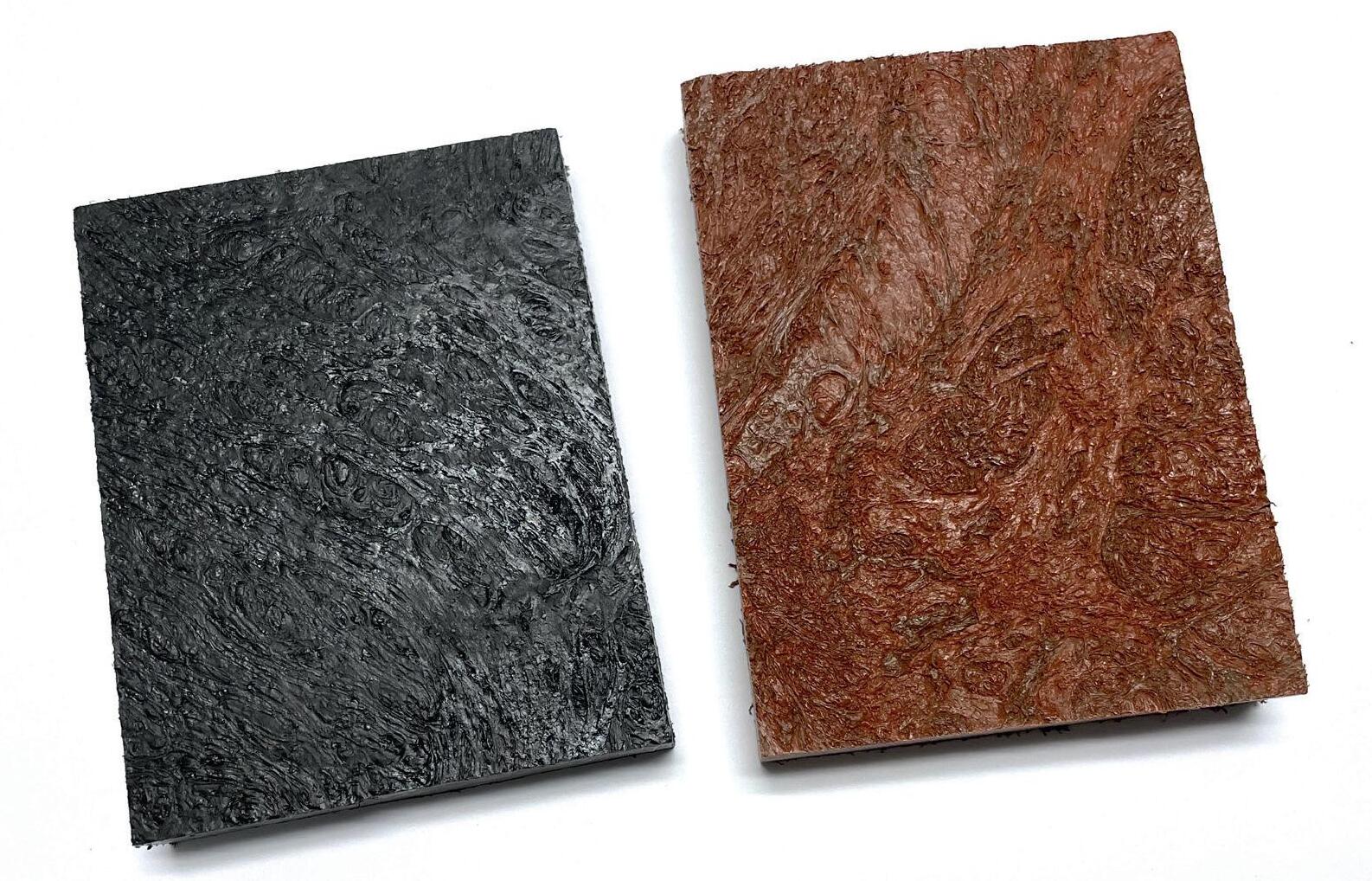

The waste from making lenses takes up a lot of landfill space. Plastics, such as polycarbonate and other thermoplastics used in lens manufacturing do not decompose for hundreds of years. They are also saturated in coolant if not properly dried, which leaches into the ground. Reducing the volume of swarf waste and reclaiming coolant is what brought the briquetting technology to the optical industry.

However, the problem with briquetters is that most are not designed for optical swarf. The first few in the industry were sawdust briquetters, which proved just how difficult lens swarf is to deal with. After several years of development, there are now more options for compacting swarf and retrieving more coolant than ever. With swarf volumes being reduced to a 20:1 reduction, and squeezing nearly all coolant out of the swarf, this may be one of the most environmentally friendly advances in the industry.

Wastewater

The optical industry also has to deal with wastewater and hazardous materials, such as alloy water, spent polish, and other chemicals used in the manufacturing process.

Some labs simply outsource their wastewater treatment by having companies pick up their hazardous materials. This is an expensive solution and the reason why some labs pour those hazardous materials down the drain instead. As environmental regulations increase and government focuses their lens on optical manufacturing, optical labs will be forced to make some difficult decisions.

Optical is certainly not the first industry to encounter these hazards. The same issues have been present in several other industries for many years. Filtration specialists have been creating solutions for these issues, and only in recent history did we see some of that technology spreading to the optical industry.

Wastewater filtration equipment was originally designed for much larger industries that typically have more space and more wastewater

Sustainable Processes

Swarf being filtered in a gravity media filter system.

Different filtration technology offers different advantages.

MAFO 5-23 12 TECHNOLOGY

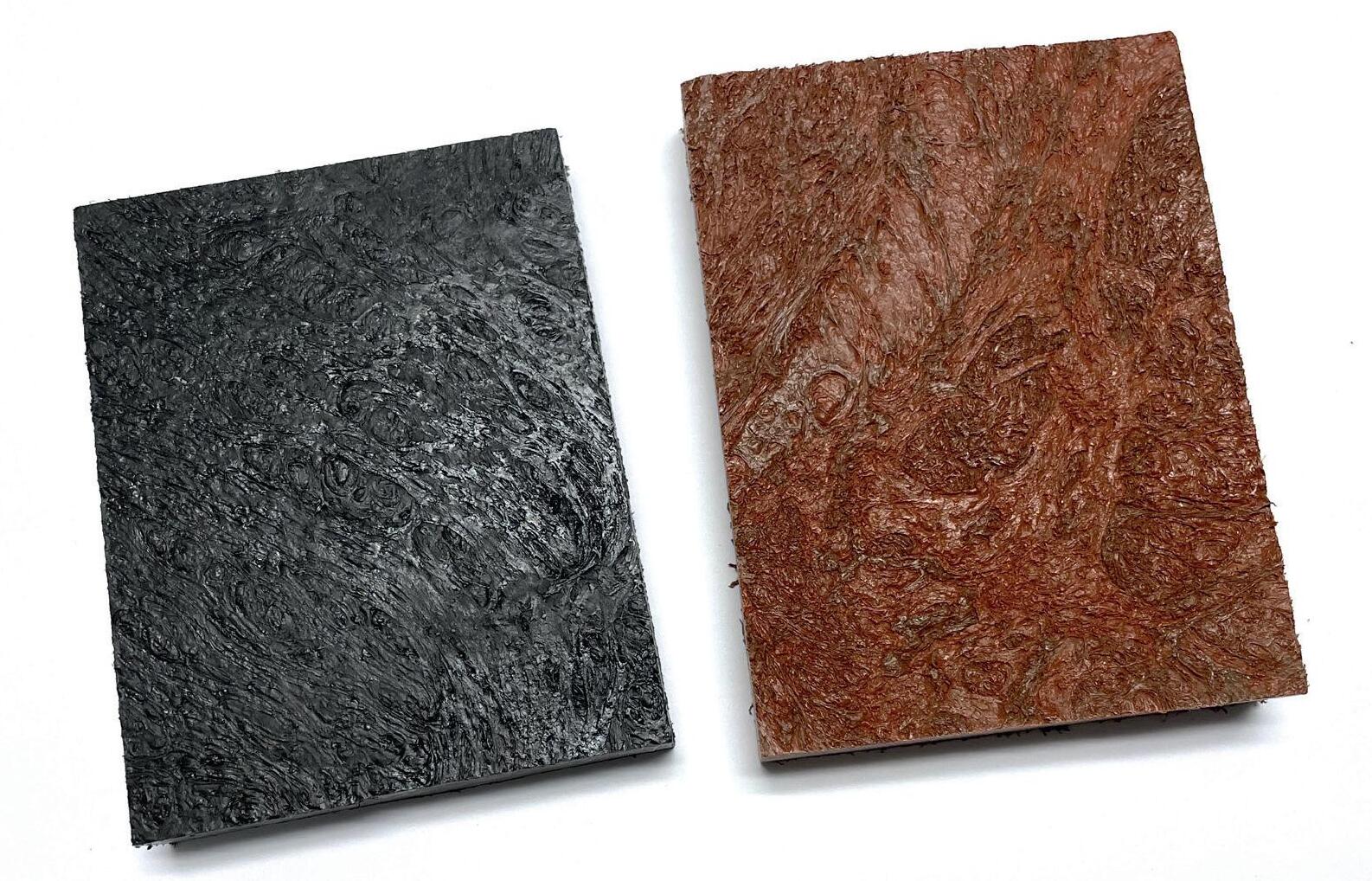

Swarf compacted in to briquettes.

to treat. Technology adapted to the optical industry must be functional and small enough to fit in an already crowded optical lab. Due to this challenge, there are now new technologies available.

Wastewater evaporators and wastewater treatment systems seem to be the leading products available to labs currently. Evaporators – although taking time and a lot of electricity – are great for isolating hazardous materials and removing them from the water, making hazardous waste a lot easier and less expensive to deal with.

Another wastewater treatment system uses a method that large wastewater treatment plants have been using for decades. They use an environmentally safe clay-based chemistry to latch on to the hazardous materials in the water, separating them entirely. The hazardous material can then be extracted by several different filtration methods. One of the prominent methods is using a centrifuge, which separates and condenses the waste material. This allows each lab to safely discharge the wastewater knowing it is free of hazardous materials. This technology is now conveniently provided as a turn-key system for labs to treat their own hazardous process water, with the benefit of a smaller footprint.

Sustainability in other industries

Although the technology available in the optical industry has come a long way, there is still a lot of waste and costs that should be addressed. We can learn much from what other companies have done in other industries to address similar issues.

A vibratory finishing company had an issue with their sustainability plan. They were using a distillation system to treat their hazardous materials; however, their new green initiative took a look at the process and saw how much energy the distilling was using and how much waste they were storing. The distillation system could not treat the hazardous waste fast enough to keep up with what they were producing.

A solution we offered allowed them to treat their hazardous materials with a clay based proprietary chemistry and separated it in a media filter. This procedure used less energy and allowed them to process enough every night that they would no longer need to store their waste. This solution not only made them more sustainable, but actually saved them more money.

In the aluminum industry, there has been a tremendous amount of growth in recent years. Aluminum manufacturing requires fairly clean coolant compared to other metal industries, therefore, filtration has always been a priority. As an equipment supplier to the aluminum industry, this growth is showing new trends in sustainability that we have not seen before.

Not only do these large companies use their buying power to choose equipment that supports sustainability, but we also see them using their influence to change the technology their suppliers provide. Their purchasing power is being used to drive change in the industry by pushing the machine manufacturers to change.

The major players in this industry said they will not move forward with the current media filtration without the promise of a reusable media. Of course, this is not a new technology, instead it has been done many times in the past. However, the problem is that it was never a true sustainable solution due to heavy maintenance and costs to use it. It also did not clean as effectively as disposable media filters. The large aluminum manufacturers forced the filtration companies to re-think their technology and work towards a sustainable solution. Today, this new technology is being installed and will be run in several new aluminum mills. It will no doubt be passed on to the filters supplied to all the other industries these suppliers provide, including the optical industry.

Another company in the wire industry had a similar story. In copper wire manufacturing, the idea of reclaiming your waste has been a priority

Sustainable Processes Advertisement

TECHNOLOGY

for some time. They use large compactors to turn scrap into usable material. They also use large media filters to collect the copper sludge during the manufacturing process. In the past they would purchase media rewinders, which collect the disposable media paper into a roll, so they can burn it to collect more copper from the spent media paper.

One company asked if there was a better way to collect the copper. The burning of the paper was creating hazardous smoke, and the effort to clean the smoke was going to be a hefty cost. Working together, we developed a method that provides better drying, scraping and blowing of the copper fines, so that most of the copper is removed before it rolls up to be thrown away.

This technology is now available to any industry looking to reclaim materials and has also prompted other ways to utilize waste reclamation.

Where do we go from here?

One of the best aspects of working at a filtration company is seeing the need for different solutions among various industries. It always surprises me when veterans of one industry have no concept of a solution that has been in existence in another industry for so long.

Technology in filtration and waste management is improving, and new solutions are becoming available. As we adopt more concepts from other industries, new technologies for smaller labs are available, giving the smaller labs the opportunity to utilize media filtration and compaction technology.

The wastewater treatment systems are becoming more affordable for both larger and smaller labs with some changes to the technology to support smaller labs.

Recycling companies are emerging and starting to offer recycling options for swarf waste. One company in particular, NXTsolve, out of Irving Texas, is taking swarf briquettes and using the material to make several products, presently affecting a highly favorable sustainability impact within the ophthalmic industry.

Their CEO, Anders Hultman, stated “We have identified and created solutions to some of the most notable waste stream recycling challenges

for the industry. Swarf holds a prominent position on our priority list, and we have developed a processing technology to integrate swarf into the production of environmentally sustainable products. We are experiencing substantial collaboration efforts from industry partners as it is clear: our values align well. We maintain a commitment to ongoing innovation as we strive to broaden our contributions of value to the industry.”

Recycling is a large step in making the optical industry more sustainable. With advances in other technologies, recycling swarf waste is the last step to creating a zero ecological footprint. Some labs have already achieved this by partnering with companies like NXTsolve, but now we need more. Recycling companies can only produce as much as they can sell, and therefore run into issues with expansion. If the optical industry can align together and take a note from other industries, it may be possible to influence the technology and push recycling and sustainability forward. ◆

Jamal is a sales and field engineer for Filtertech Inc., with a Masters of Business Administration. As the third generation of this family-owned-and-operated company, he started at an early age building filtration equipment. After finishing his college career, Jamal began working as a field operator, fixing and maintaining filtration equipment across the world. With extensive knowledge of the mechanics and technology behind filtration, he began applying his experience in the field to engineering and design. Today, Jamal works directly with companies across the world, finding filtration solutions to meet the unique needs of multiple industries.

Sustainable Processes

Jamal J. El-Hindi

Alloy and polish before and after treatment samples.

The company NXTsolve is taking swarf briquettes and using the material to make several products.

MAFO 5-23 14 TECHNOLOGY

HIGH-QUALITY TINTING FOR ALL GRADIENTS

CO10

Professional machine for high-quality tinting on all types of lenses. The CO10, equipped with up to 10 stainless steel tinting tanks, not only tints full colored lenses. It even provides 2 -10 digital gradient systems with which you can customize the size and position of gradients. The tinting tank capacity is 5 litres, with easy removable tanks and a flexible drain with a 3-way valve. It also features full temperature control, accurate to +/- 1°C. A user-friendly HMI, complete modularity and an option for modular extraction of tinting vapors mean that the CO10 is the perfect choice for all tinting needs.

Technique. Safety. Expertise. www.scl-intl.com HARD COAT LEADER HARD COAT CLEANING TINTING PERIPHERALS CONSUMABLES EXPERTISE

“There is no waste at all, only raw materials!”

An interview with Alexander Maak about the circular economy

Used frames and spectacle lenses, swarf, packaging or demo lenses – all those things are waste, at least in the eyes of most consumers and companies. Alexander Maak, on the other hand, contradicts this way of thinking and says there are only valuable raw materials. The Managing Director of Interzero is an expert when it comes to the circular economy. This concept offers companies the unique opportunity to secure direct access to raw materials on the one hand, and to have a unique selling point (USP) on the other hand – and all this in the name of sustainability! MAFO talked to Maak about how this works exactly and why circular economy is rewarding for every branch.

By Hanna Diewald

Mr. Maak, you say there is no waste at all, only raw materials. What exactly do you mean by that?

It is quite simple: the world has to learn how to close cycles. We consume an enormous amount of the earth´s raw materials. This year, on August 2nd, we already reached Earth Overshoot Day, the day on which we had already used up all of the earth´s raw materials for this year. Since that day, we have been living off the backs of future generations. And I think, we have to stop doing this!

This means not throwing everything away, but making raw materials out of what many people consider waste, and feeding it back

into production through cycles, to make new products out of it. Thus, we can conserve primary raw materials and conserve the earth´s resources.

That sounds good in terms of sustainability. But what does a company gain from taking part in the circular economy? There are many aspects. I do not think sustainability should cost a lot of money, as ultimately you can combine sustainability with a positive business model. It has to be worthwhile, not only as a marketing slogan but also directly financially.

Sustainable Processes

MAFO 5-23 16 SPOTLIGHT

For example, if you recycle raw materials or waste so well that they become new raw materials for your own production, this has two benefits: you can save money on the purchase of raw materials and it gives you access to raw materials.

Many raw materials are not always easily available due to long supply chains or disruptions. Or you depend on the capacity of suppliers or other factors. By recycling your own waste, which becomes raw materials again, you secure access to raw materials. This does not have to be expensive but can have a positive effect.

Is this a realistic scenario in most industries?

Yes, it is. One way or another it works in every industry. The question is how seriously you address it. For example, if you look at the recycling pyramid (Fig. 1) the first scenario would be to avoid. That is hard to do in the eyewear industry because the consumer needs glasses for instance, therefore it is a product that cannot be avoided

But you could continue to use the frame and only replace the lenses ...

Exactly, but then we would already be at the next scenarios further down: preparing for re-use and recycling. It can also be a USP to refurbish something in such a way as to create new value, and to sell it in the same market or in another market where you want to create a new footprint.

There are many different ways of thinking about this. It all starts with the design: With which kind of material do you start? Are there substitute materials? How easily can the material be recycled? Can it be reprocessed to obtain new properties? How do I get it back from the market? Are there recycling procedures in place? For example, are there collecting boxes at opticians for old spectacles? Where does it go from there? Are there any third markets? Or can one do anything good with them? There are surely people who can not afford spectacles. Looking at the matter in terms of social responsibility too is part of sustainability.

Or one can return old spectacle frames, lenses and demo-lenses to the plastics manufacturer, to turn them into new raw materials, for example in the form of granulates to create new frames out of it.

The industry also creates a lot of swarf. In your opinion, can it be recycled? And if so, what requirements would have to be met for this?

In principle, swarf can be reused. It can be returned to the original manufacturer of the material where it can be recycled. What is needed,

is to get the swarf back to the starting point. That means that some kind of clean collection system is required. This also has to include some kind of detection system, so that different types of plastic are not mixed together.

This can be done, for example, using near-infrared scanners. For example, the approx. 800,000 tonnes of yellow sacks which are recycled each year from Interzero in Germany, are all sorted according to fractions such as polyethylene and polypropylene, Styrofoam, etc. with that technology.

But what if lens manufacturers machine different materials on one machine and the swarf is then all mixed up?

This is actually a more difficult problem. But here, too, there are methods of separation, such as the float/sink method. Whether this is worthwhile, however, needs to be investigated by a chemist in the laboratory in each case.

If separation does not make sense, then in the worst case you have to consider what to do with the waste. However, in my opinion, throwing it away or simply burning it is not an option!

For example, can you use it to make another product, where the mixture is not a disadvantage? That would then be a form of down-cycling – not ideal but still better than burning it.

There are now spectacle lens manufacturers who offer bioplastics for lenses. What do you think of such products?

There are two types of bioplastics: on the one hand, there are compostable bioplastics. That does not make any sense now, because there is no composting plant that can recycle them. If at all, this may become interesting in the future, when a sensible recycling system has been established.

Sustainable Processes

MAFO 5-23 17 SPOTLIGHT

Fig.1: Recycling pyramid.

A bioplastic made from renewable raw materials, on the other hand, such as rapeseed oil or similar may make sense as it has the same properties as current plastics. However, considerations are very specific. You would have to look at the agricultural area concerned and much more. But at least it could have a positive effect on the CO2 balance.

Suppose an ophthalmic lens manufacturer wants to enter the circular economy for the first time, what would be the first step?

The first step would be to sit down with us (editor´s note: meant is an environmental service provider like Interzero) and discuss the technical aspects as well as the suppliers and customers situations: How do you get which material back to where it is needed and what is the goal? Then we would point to different ways to proceed and help to implement them and bring partner together. Compared to other providers, we also lead anyone during the implementation phase and do not leave anyone alone.

One very important general point is that no one can set up a circular economy on their own! It only works in partnership. So, who needs to be involved? In principle, the plastics manufacturer. Then the person who produces the blanks. The person who grinds the lenses out of it, and ultimately the optician, too, if you want the material back. And, of course, the recycling chain needs to be a closed loop, so you need someone to coordinate it all.

That is what we do at Interzero. We coordinate the various logistics flows, processing flows, the retrieval, the legal aspects – waste disposal regulations, for example, are not always easy either. So, we bring all the partners together and control the system.

How can companies be motivated to enter the circular economy?

An extreme approach is regulation by the legislator. For example, if it were stipulated by law that spectacle lenses must contain a specific amount of recycled material. This is currently being discussed for cars, for example. In the case of spectacle lenses – i.e. medical products – this scenario is rather unrealistic.

However, in the EU there are duties or taxes on plastics that are difficult to recycle. This could mean that at some point in the future, if you do not recycle plastic, your product would be more expensive. This could act as a regulation-driven, monetary incentive.

Putting this aside, I find it a much more important and elegant solution when companies create a USP by becoming sustainable and climateneutral. That is something that all consumers can appreciate!

Thirdly, I think it is essential to secure good access to the raw material and to establish a recycling procedure. Today, for example, everyone is talking about electric cars which require cobalt and nickel. These materials come from the Congo, Afghanistan or Russia, which are not reliable sources of supply. So, if you are able to recycle the batteries, this will give you a real strategic advantage.

With spectacles, on the other hand, we are not dealing with simple, straightforward plastics but highly technical ones, which are relatively expensive. The higher the quality of a product, the easier it is to get positive business skills out of it.

Where do you see the greatest potential in the eyewear industry?

There are many different aspects. You can start with the packaging, and I would also include demo lenses as part of this. How does everything get to the optician? In which package sizes? How much of the actual secondary packaging does the optician throw away? Is it possible to make it recyclable? Mister Spex, for example, has introduced reusable boxes. Reusable packaging could also make sense between opticians, lens manufacturers and frame suppliers. However, this would need to be standardized.

Let us come to my last question: What motivates you, personally, to go to work every day?

That is relatively simple. I mentioned the Earth Overshoot Day earlier. As a company, we have managed to push this calculated day back by seven minutes and 16 seconds – globally. That may not sound much at first, but given the size of our company –around 2,000 employees – compared to all the other companies in the world, it is quite an achievement!

So, I am motivated by doing something good. I am trying to leave a better world for my children than I found it and I like to spread this idea. I recently gave a talk to 6- and 7-year-olds at an elementary school and they understood immediately. That was awesome!

We too have understood. Thank you very much for this interview about the circular economy. ◆

Alexander Maak is Managing Director at Interzero - zero waste solutions-, an full-service environmental service provider. Maak has over 20 years of leadership experience and enabled several organizations to achieve a peak performance and exceptional growth and new business. He has also international experince in Continental Europe, UK, USA, Middle East and Asia.

Sustainable Processes

About the interviewee

MAFO 5-23 18 SPOTLIGHT

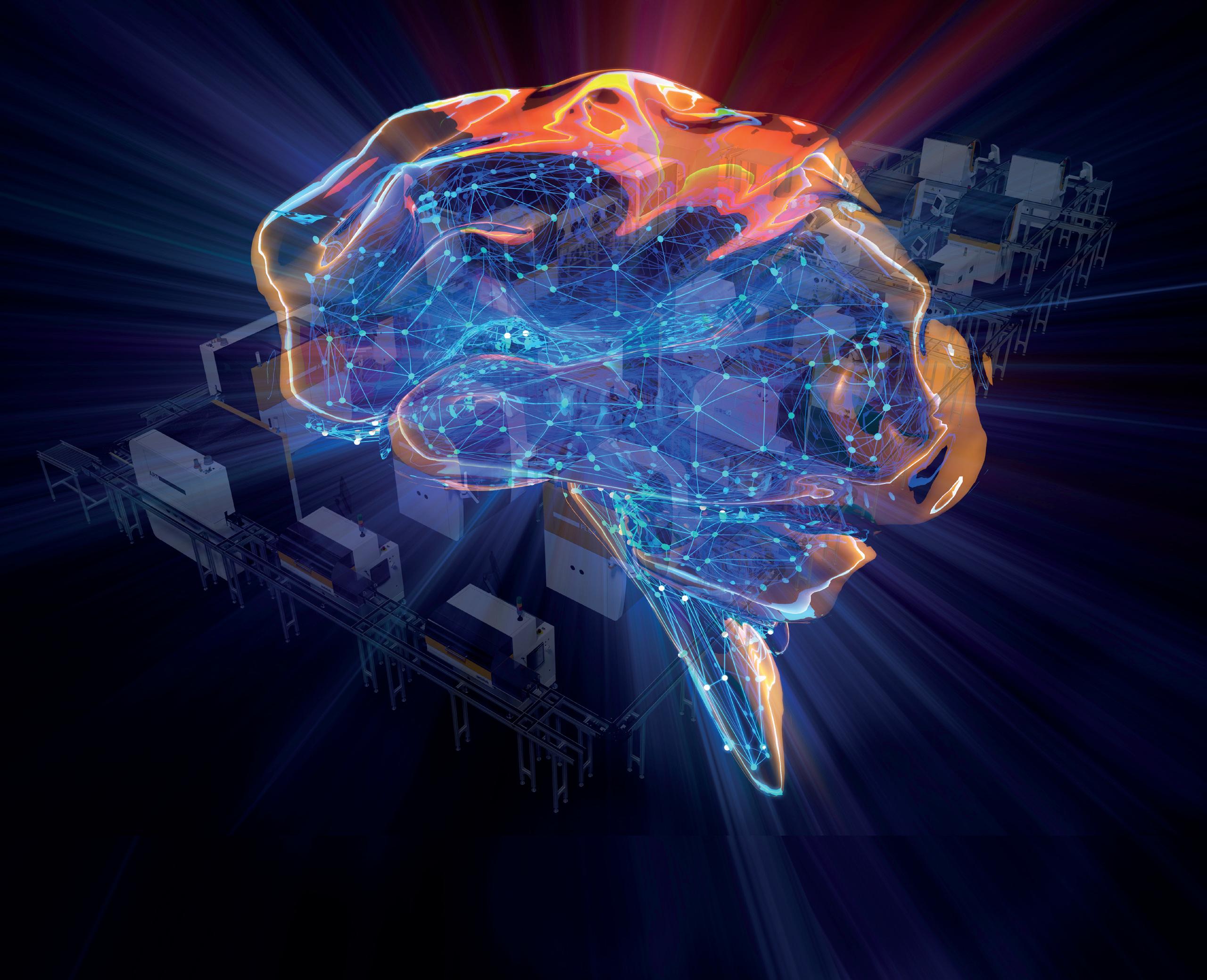

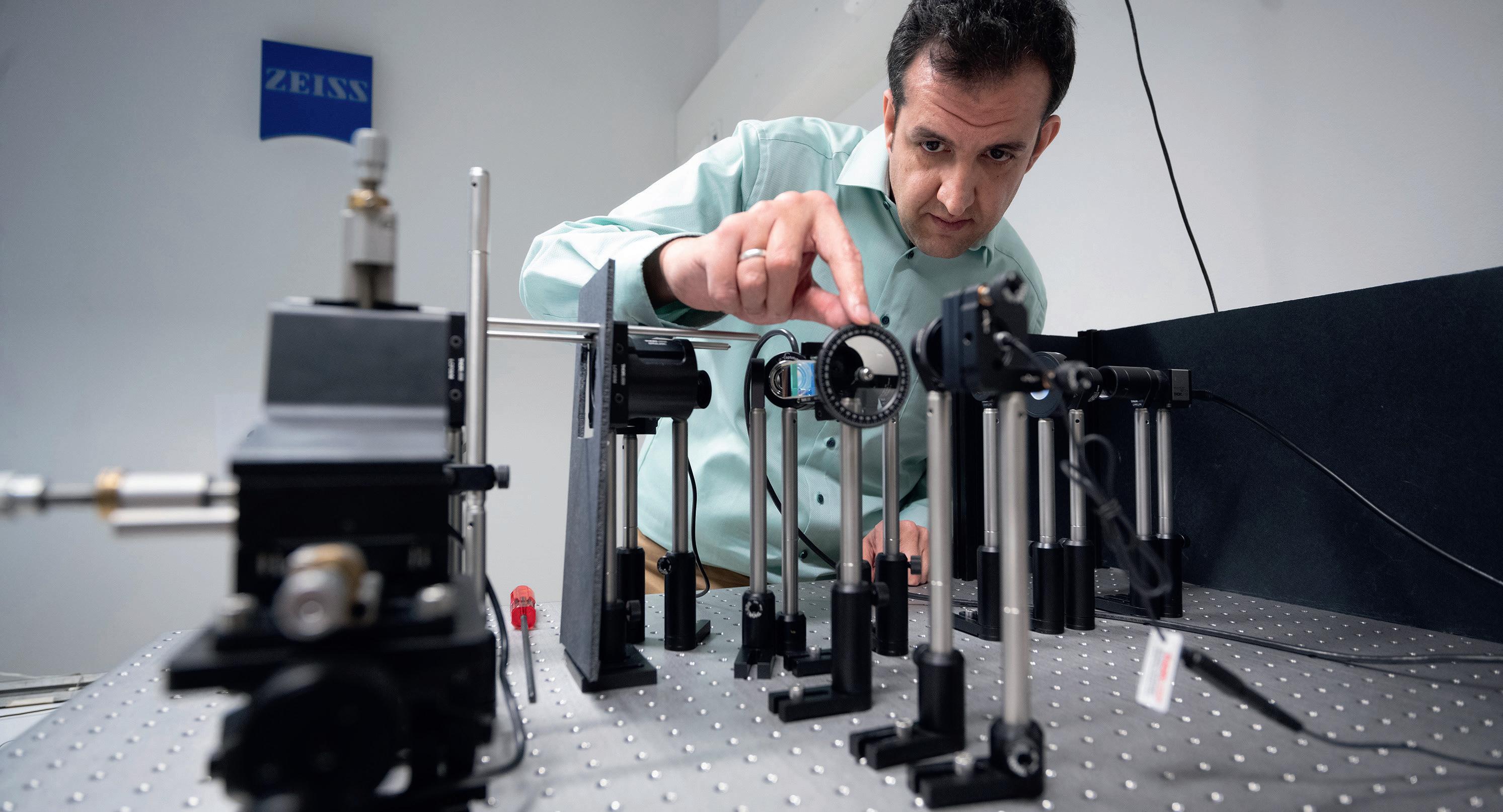

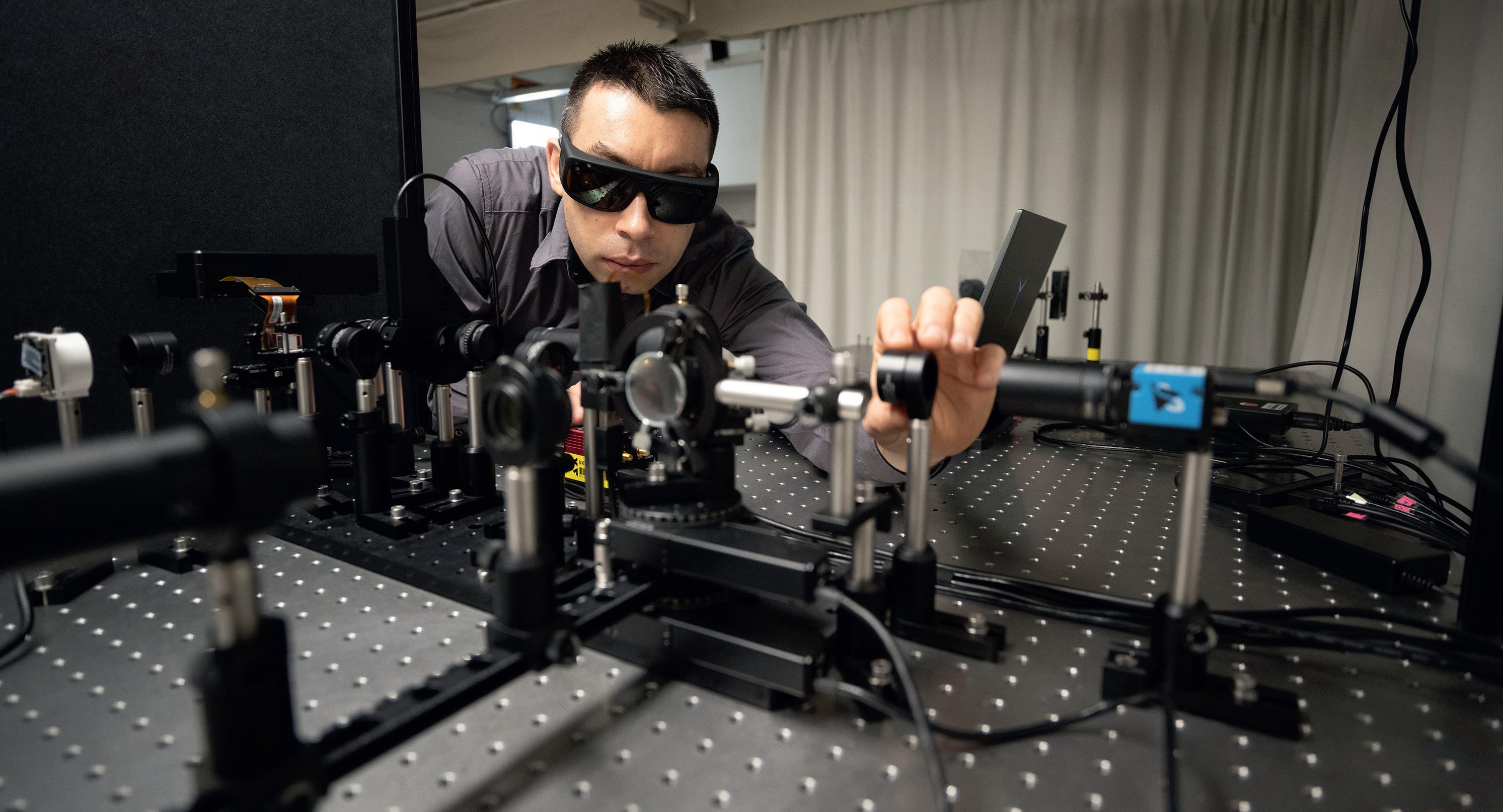

Anti-reflex coating and process control

Gaining control of process parameters by digital means. An approach to reduce scrap and rework.

International competition fuels manufacturing cost reduction, where scrap and rework land an immediate impact. Savings along this line of attack need dedicated process improvement, which in turn requires detailed knowledge of process parameters and their effects on a successful process result. Complex process chains, like anti-reflex (AR) coating, with their extremely large number of influencing parameters pose a considerable challenge for process engineering. By successively introducing tools of digitalization, and by merging them with deep process understanding, engineering will be enabled to take proactive measures before scrap or rework actually happen. A cooperative project of an equipment supplier, a lens manufacturer, and a university research group reached exciting results on the road to digitalization.

To stand their ground in the harsh environment of international competition, manufacturers of ophthalmic lenses need to increase their efficiency continuously. Material procurement costs on the one hand and labor costs on the other are the main drivers to directly reduce production costs. Being successful there leaves a company in the comfortable situation to choose: increase margin, or increase competitiveness (by reducing selling prices).

By Peter Weber

Manufacturing costs reduction

On a first glimpse the approach via procurement of costs reduction seems to be a low hanging fruit: put some pressure onto your suppliers and harvest annual cost reductions. Still, to accomplish this without getting trapped in quality issues, a considerable investment into a straight supply-chain management organization is essential.

Especially for technologically driven companies a promising parallel approach is the deep-dive into one’s own processes. Increasing the

MAFO 5-23 20 TECHNOLOGY

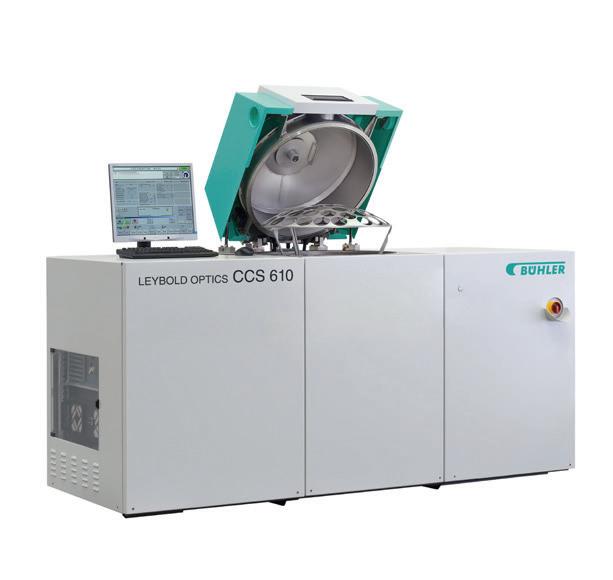

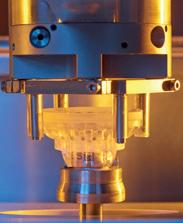

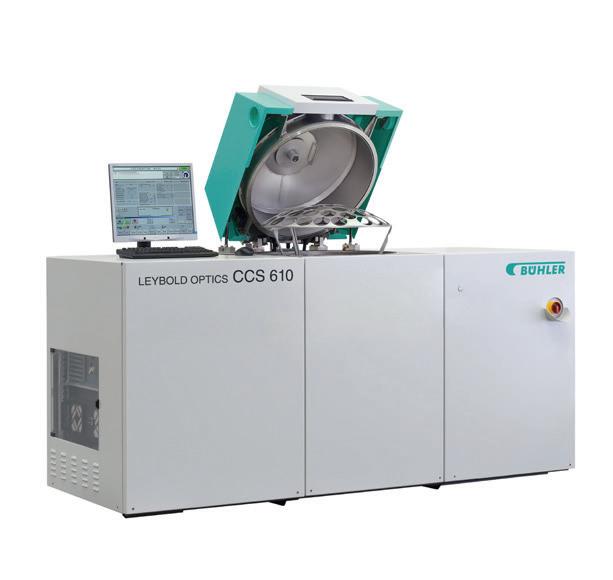

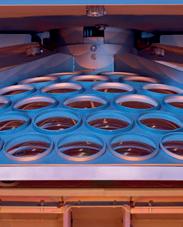

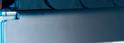

Picture: Bühler Coating

efficiency of manufacturing processes will directly reduce production costs. In industrialized economies the key figure of efficiency is, for good reason, output per laborer. This means that via smart investment in automation, digitalization, and process quality, companies will reduce labor costs and subsequently reduce overall production costs.

Effect of scrap and rework on cost

Talking about process quality inevitably leads to scrap and rework. The good message about scrap and rework is: if reduced, it directly reduces both labor costs as well as procurement costs. And thus, it directly reduces overall production costs, i.e. better margin or competitiveness.

Any part that gets scrapped, already contains raw material to be scrapped. And any such part has gone through a considerable section of the process chain already, having piled up labor and machine costs. The effect of rework often is even more dramatic, as there is not only additional labor and machine time to be wasted. Even more, the unscheduled effort severely disturbs the regular production flow, creating work overload at the workplaces as well as in job preparation and shop-floor scheduling.

Control charts – be proactive

There is one obvious and yet sometimes omitted fact: just by detecting scrap and rework, it is not prevented or reduced. To accomplish that, one needs to identify root causes. Here comes into play what you all know as control charts. The tracking of all those parameters along the process chain, which may influence the final product quality. Tracking these process control parameters makes it possible to correlate fluctuations of certain control parameters to scrap or rework.

Look at the example in figure 1: You see four control charts, each representing one crucial control parameter of a particular process for the last 10 batches. It turns out in final inspection, that part number 7 was not in specification, i.e. scrap. The process engineer could now easily grasp at a glance that the deviation of process parameter 3 might well correlate to the out-of-spec situation of part 7.

Now, the process engineer does not only know that part number 7 needs to be scrapped. He can localize the problem, with a certain probability, on process parameter 3 and take measures. By such experience, as well as by statistical means, warning limits for the control parameters are defined and continuously adjusted.

Practically this means, that a process engineer (or in best case even the operator) is regularly keeping an eye on the control charts and

takes measures, whenever one of the parameters is violating an upper or lower warning limit.

In the example of figure 1 there might also be anticipated an issue with parameter 1, as it seems to have a tendency upwards, maybe violating the upper warning limit in a few batches. With sensibly chosen warning limits, the process engineer can already proactively adjust processes before any scrap or rework actually is produced.

Systematic process control needs effort

Now, in a real industrial environment with complex process chains, one deals with an enormous amount of possibly relevant control parameters. This is the bitter pill to swallow: effort is needed, to make as many of the crucial parameters measurable and accessible to a digital database as possible.

While there is no (or few) process data available (because no data acquisition is in place yet) no digital system can help at that point. An overall process parameter analysis has to be carried out by means of deep process-engineering know-how, to judge which of the parameters actually are relevant, and how to measure and acquire them digitally. The less manual steps there are along a process chain and the higher the degree of automation is, the less effort it takes to acquire the data. Nowadays machines usually come with a set of integrated sensors and interfaces, to digitally get access to process and machine data. For older machines and manual process steps the effort is gradually higher.

1 2 3 4 5 6 7 8 9 10 Parameter 3 1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10 Parameter 4 1 2 3 4 5 6 7 8 9 10

Parameter 1

Parameter 2

MAFO 5-23 21 TECHNOLOGY

Fig. 1: Control charts of four exemplary process control parameters for 10 batches. The black dotted line denotes the average, the red dotted lines mark the warning and control limits respectively of each parameter. In our thought experiment batch 7 is out of specification. The control-chart approach obviously helps to locate root causes. Adjust parameter 3 in the future and prevent this scrap/rework event to reoccur.

Benefits in ophthalmic lens production

The process chain of eyeglass production spreads over the full range from basic manual to fully automated work steps. Subsequently, it is a considerable challenge to cover it completely with digital data acquisition.

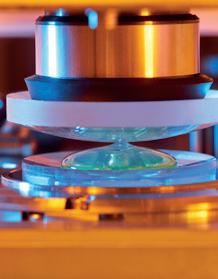

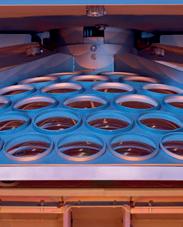

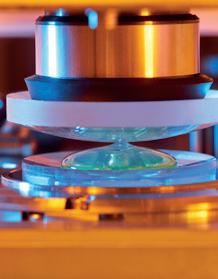

Particularly the anti-reflex coating process features a blend of manual and automated process steps. Within a systematic approach, the first focus is put on the automated part of the process: coating in the vacuumcoating machine. A state-of-the-art vacuum coater measures, collects, and provides a wide range of digital machine and process data, which are, in principle, easily to be accessed for process control.

Dr. Stephan Küper of Bühler Leybold Optics, provider of vacuum coaters for ophthalmic industries, confirms the potential behind the coating process in terms of digital data acquisition. His project team has pushed this topic considerably in the last two years. In cooperation with the research group for Industrial Data Science (INDAS) at Frankfurt University of Applied Sciences, and optoVision, manufacturer of ophthalmic lenses, a big step forward was made in terms of systematic acquisition, presentation, and evaluation of process data.

Although it is well known that the flanking manual processes cause the larger part of scrap and rework, there is big potential in further stabilizing the coating process itself. There are advanced types of coating where process stability still is a challenge. And generally, for the benefit of matching lenses from different batches (with respect to color of residual reflex), better process control is highly desirable.

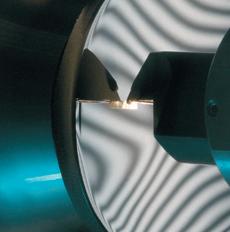

Anti-reflex coating of ophthalmic lenses

Anti-reflex coatings are a major feature of any ophthalmic lens. At an interface between two optical media (air, lens) back-reflection occurs. For an untreated standard glass roughly 4% of the incident light is reflected. Front as well as back side interface suffer from the effect, so you end up with losing a total of 8% of intensity. This holds for a “classical glass” with a refractive index of typically 1.5. To design thinner lenses, material with a refractive index of up to 1.8 is used.

You buy this advantage at the expense of transmission. At each interface of these high-index materials you lose 8% of light intensity. In total only 84% of the incident light would reach the eye. With a good antireflex coating a transmission of up to 99.5% can be accomplished. Thus, for practical as well as cosmetic reasons, an anti-reflex coating is standard for ophthalmic lenses. The wearer of the glasses gets a clearer vision and a better contrast. In communication with other people there are no (or considerably less) disturbing reflexes interfering with eye contact.

An additional emerging feature of anti-reflex coatings is the selective filtering in the blue region of the visible light spectrum. This is a response to increasing exposure of our eyes in daily life to LEDs and TV or computer monitors, which is often perceived as distracting and exhausting.

Composition of anti-reflex coatings

Anti-reflex coatings are so-called dielectric coatings. Such a coating consists of a sequence of several sub-microscopically thin dielectric (non-metallic, i.e. transparent) layers of different refractive indeces (alternating high and low index).

The trick is to tune the thickness and the refractive index of each layer in a way that you get destructive interference between the back-reflected light of the different layer interfaces. Thus, the reflected light is cancelled out and all incident intensity (ideally spoken) is transmitted.

The desired layer thicknesses range in the order of or below 100 nm (which is the 10,000th part of a millimeter). Additional features must be integrated: E.g. a cap layer on top is needed to protect the thin-film system from ambience over life-time and an interface layer at the bottom makes sure that the system permanently adheres to the substrate (i.e. the lens). Altogether this may result in up to 10 or more layers of different materials and different thicknesses, which need to be precisely deposited onto the lens.

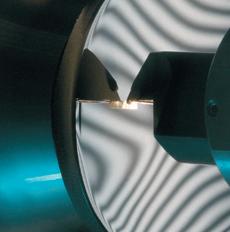

Operation of a vacuum coater

The single layers of an anti-reflex coating consist of different dielectric materials. These silicon-oxide and metal-oxide layers provide an alternating system of high/low refractive index. For deposition on the substrate (the lens), coating material is heated and subsequently evaporated in a crucible at the bottom of a vacuum chamber. The lenses are positioned at the top of the chamber.

In vacuum, the evaporated atoms or molecules propagate (ideally undisturbed) from the bottom to the top and deposit on the lenses, growing a thin film. The heating and evaporation of the material is usually accomplished by an electron beam being targeted at the material.

The thickness of the deposited film on the lenses is mainly controlled by the length of exposure via shutter and by the rate of evaporation via electric power of the beam.

Basically, there are two different approaches. One possibility is to directly evaporate the oxide material onto the substrate. The other is to evaporate the pure silicon or metal, and create an oxygen plasma in the chamber, which reacts with the evaporated material, forming the

MAFO 5-23 22 TECHNOLOGY

One valuable outcome was the finding, that the period between cleaning cycles of the vacuum coaters could be considerably prolonged, significantly increasing the uptime and productivity of the machines.

desired oxide film on the lens. In both cases the stoichiometry, the composition of metal and oxide, significantly controls the refractive index of the respective layer.

Key parameters of the AR coating process

Key output parameters of the AR coating process are: low residual reflex, correct color of residual reflex, no significant surface defects, and, finally, adhesion of the coating over lifetime.

The three first-mentioned are usually judged in a visual inspection, while the latter is checked in an accelerated life-time test and via customer-complaint statistics. Key process parameters for the fulfilment of these output parameters are the thicknesses of each layer and their refractive indices (stoichiometry).

While the thickness is directly accessible from measured data, the refractive index is not. It is controlled indirectly by other process parameters. And even though the thickness is measured directly, it is controlled by several more parameters.

This leads to a complex multiplicity of parameters, which need to be tuned properly for a successful outcome of the process (pressure over time, power of the electron beam over time, partial pressures over time, time of exposure, cleanliness of the vacuum chamber, to name just a few).

Big data needs digitalization

The coating process provides us with a load of relevant process control parameters to deal with. A state-of-the-art vacuum coater comes off-the-shelf with the sensory system and the digital interfaces to straightforwardly get access to these data. “These data” precisely spoken

means: time resolved process and machine data for each coating run (batch). These data can be fed into a database and be evaluated to gain better control of the process. Although relatively comfortably available, it is not yet state-of-the-art, to use these data on a big scale. One reason for that is the lack of proper interfaces into a comfortably usable database. This is now provided by the team of Dr. Küper.

Level I of digitalization

When digital data acquisition is in place for the relevant parameters, the next challenge is to plot them in an expressive way. Technically spoken, process parameters span a vast multidimensional space of variables, which depend on time, on batch number, and in many cases on each other. And there are two classes of variables: first the process control parameters, and second the output parameters, where the former shall be tuned to optimize the latter.

Level I of digitalization is accomplished when process engineering is provided with an interactive cockpit where they can flexibly get access to any representation of the data. It has to be possible to pick just any pair of parameters and plot them against each other in a chart. This helps to find correlations between parameters, particularly between control and output parameters. Furthermore, parameters can be plotted over time or over batches to make visible significant changes and possibly correlate them with certain events (e.g. from the machine log, e.g. cleaning or maintenance).

Plotting parameters over batch finally leads to the classical control chart, where by statistical means, the stability of each process parameter can be tracked. Dr. Küper showed that his team accomplished to provide a full-scale cockpit in this sense (see example in figure 2). Process

MAFO 5-23 23 TECHNOLOGY

Fig. 2: Exemplary control chart from Bühler Leybold Optics database cockpit. The data shown here simulate the cycles of increasing pump-time from batch to batch till next cleaning run simulated data, as no real customer data can be shared here.

engineers can click through the data, choose parameters, choose graphical representations, choose scale, zoom in, zoom out, jump between different graphs, to get the best overview on the interdependencies between the parameters.

The statistical tools for control charts are implemented. Furthermore, warning and control limits could be edited individually for each parameter. This first level of digitalization already provides engineering with an enormous head start. With this set of information, one does not just react on scrap and rework events when output parameters are already off specification. Proactive measures can be taken already when control parameters start to become critical – before scrap and rework actually occur.

Level II of digitalization

As stated before, in complex manufacturing environments, process engineering is confronted with an enormous amount of possibly relevant parameters. It is unrealistic to assume that the resulting control charts can be checked on a sufficiently regular basis visually.

The second level of digitalization provides algorithms, which check all the control charts automatically for violations. Obviously, level I needs to be in place.

From a data science point of view this is just if-then-else queries. The bigger challenge is to have the proper workflows and the qualified personnel in place for action: in case of violations of control limits, the relevant engineers get informed automatically. They would then jump into the situation with their process know-how and decide upon necessary measures of stabilization.

Level III of digitalization

With level I and level II digitalization in place, process engineering is able to react proactively to violation of warning limits of control parameters. This presumes that the influence of each control parameter onto the output parameters is known. In real life, this is not the case.

One is confronted with a large number of control parameters, and for many of them, the correlation towards the output parameters (specifications) is at best vaguely known. Here comes into play the third level of digitalization. It introduces algorithms, which check all parameters for correlations with any other. This may include inter-correlations between the control parameters, but particularly focuses on correlations between each control parameter and the output specifications. The result of this algorithm is a classification of how much each process parameter actually influences one or more output specifications. This information is invaluable for proactively controlling the process. It helps a great deal to focus engineering activities on the right parameters. Also, with respect to cost or cycle time reduction as well as new products´ development, these data can be most useful.

Level IV of digitalization

Finally, machine-learning comes into play. A machine-learning algorithm can be fed with available process data and predicts the outcome of the process, i.e predicts whether the output parameters will be met, or not (scrap or no scrap). The research group Industrial Data Science (INDAS) at Frankfurt University of Applied Sciences tuned their machine-learning algorithms on this challenge. They got the opportunity to feed the algorithm with long-term real process data from optoVision, manufacturer of lenses and partner in the cooperation. After teaching the algorithm with historic process data (process control as well as output parameters, so called labelled data), it was possible to predict whether a particular coating run produced an in-spec or an out-of-spec batch. After each coating run its process data were fed into the algorithm, and the outcome prediction was afterwards counter-checked by standard quality-control procedure.

As Peter Ludewig, Head of Department IT/IS at optoVison, points out, one valuable outcome was the finding that the period between cleaning cycles of the vacuum coaters could be considerably prolonged, significantly increasing the uptime and productivity of the machines.

According to Prof. Schäfer of Frankfurt University’s INDAS group, expectations towards machine-learning still need adjustment.

MAFO 5-23 24 TECHNOLOGY

Process control parameters show important information that can help users to optimize processes.

TECHNOLOGY

Machine-learning is not a silver bullet which answers all questions without further effort. It is definitely a powerful tool but often the black box nature of standard machine-learning algorithms requires further human insight. And particularly, this project showed: although all the data were basically available, there was a considerable effort to be invested by optoVison’s engineering team to classify the data in a technologically meaningful way before finally getting good results from the machinelearning algorithm.

KI – the answer to all questions?

A widespread vision is an “artificial intelligence”, where to enter your problem, and get the proper solution suggested right away. In manufacturing, the challenge of this task is a lot about process understanding, about grasping cause and effect, about metrology and data acquisition. In most cases, there is a lot of “old-school” process analysis to be done before digitalization with its full potential can actually kick in. An algorithm only yields useful answers when asked meaningful questions.

Conclusion

The database and its engineering interface, as presented by Dr. Küper and his team, are a successful realization of level I and level II digitalization. They provide a full-scale cockpit for comfortable and flexible navigation as well as graphical representation of the coating process’ complex parameter space.

The team of Frankfurt University’s INDAS group succeeded in the proof of principle that by teaching a real-life extensive dataset, provided and interpreted by lens manufacturer optoVision, their machine-learning algorithm was able to predict the outcome of single coating runs based on their individual process data. All three partners in unison judge the project as great example of how rewarding a collaboration between

ULTRA PRECISION DIAMOND TOOLS • Diamond tools for any generator • Excellent service • Quick turnaround

equipment manufacturer, producer and researchers can actually be. Bühler Leybold Optics will now make the interface available for customers within the scope of their service packages. The joint project will continue to implement further features of level III and level IV digitalization successively. ◆

Interview partners

1. Dr. Stephan Küper, Director & Head of Business Unit Technology Parts, Bühler Leybold Optics GmbH stephan.kueper@buhlergroup.com

2. Peter Ludewig, Head of Department IT/IS, optoVision GmbH ludewig@optovision.de

3. Prof. Jörg Schäfer, Research Group Industrial Data Science (INDAS), Frankfurt University of Applied Sciences jschaefer@fb2.fra-uas.de

Peter Weber

The author is professor at the University of Applied Sciences in Frankfurt and acts as journalist in the field of science and technology. In the past he managed production and engineering departments in semiconductor and ophthalmic industry. peter.weber@fb2.fra-uas.de

Advertisement

REDEFINING THE EDGE ky diamond.ca

Thickness and weight of ophthalmic lenses

Possibilities to reduce the parameters via software

Ophthalmic lens weight is a rarely considered parameter when purchasing spectacles, both by opticians and end customers, even though too heavy spectacles may feel uncomfortable. On the other hand, much attention is paid to the thickness of the lenses, as thin spectacles are considered high-quality by the public. Let us discover the relationship between thickness and weight of ophthalmic lenses and the possibility of reducing these parameters via software. By

Gaetano Volpe and Pasquale Fanelli

The relationship between weight and thickness in ophthalmic lenses is far from obvious. First, we have to consider all the factors that contribute to determining lens weight and thickness: material of construction, lens diameter (size), shape of the front and rear lens surfaces. Ophthalmic lens material can be divided into two major categories, mineral lenses, made of glass materials, and organic lenses, made of plastics polymers. Nowadays, mineral lenses have almost completely fallen into disuse, so let us consider organic ones.

In ophthalmic optics, materials are often recognized by their refractive index, a dimensionless number that identifies the optical properties of the medium. In fact, the optical power of a lens is determined solely by its shape and its refractive index. Leaving aside the mathematical discussion on the refractive index, we need only to consider that the higher this number is, the more the material is able to deflect light beams (altering the ray vergence) and for this reason a lens made of a high-index material will be thinner (at the same optical power).

Picture: Frank Sonnenberg

MAFO 5-23 26 TECHNOLOGY

Although it is easy to understand the relationship between index and thickness (higher index leads to thinner lenses) the same cannot be said for lens weight: as the refractive index increases, the material density also increases.

Figure 1 shows the average density in grams per cubic centimeter for the main organic materials classified by their refractive index; obviously the denser the material, the greater the weight in a given volume. High-index lenses occupy less volume as they are thinner, but are they heavier because the material is denser? Does the reduction in thickness always compensate for the increase in density, resulting in lighter lenses? We try to respond using optical calculation software.

Refractive index, weight, and thickness

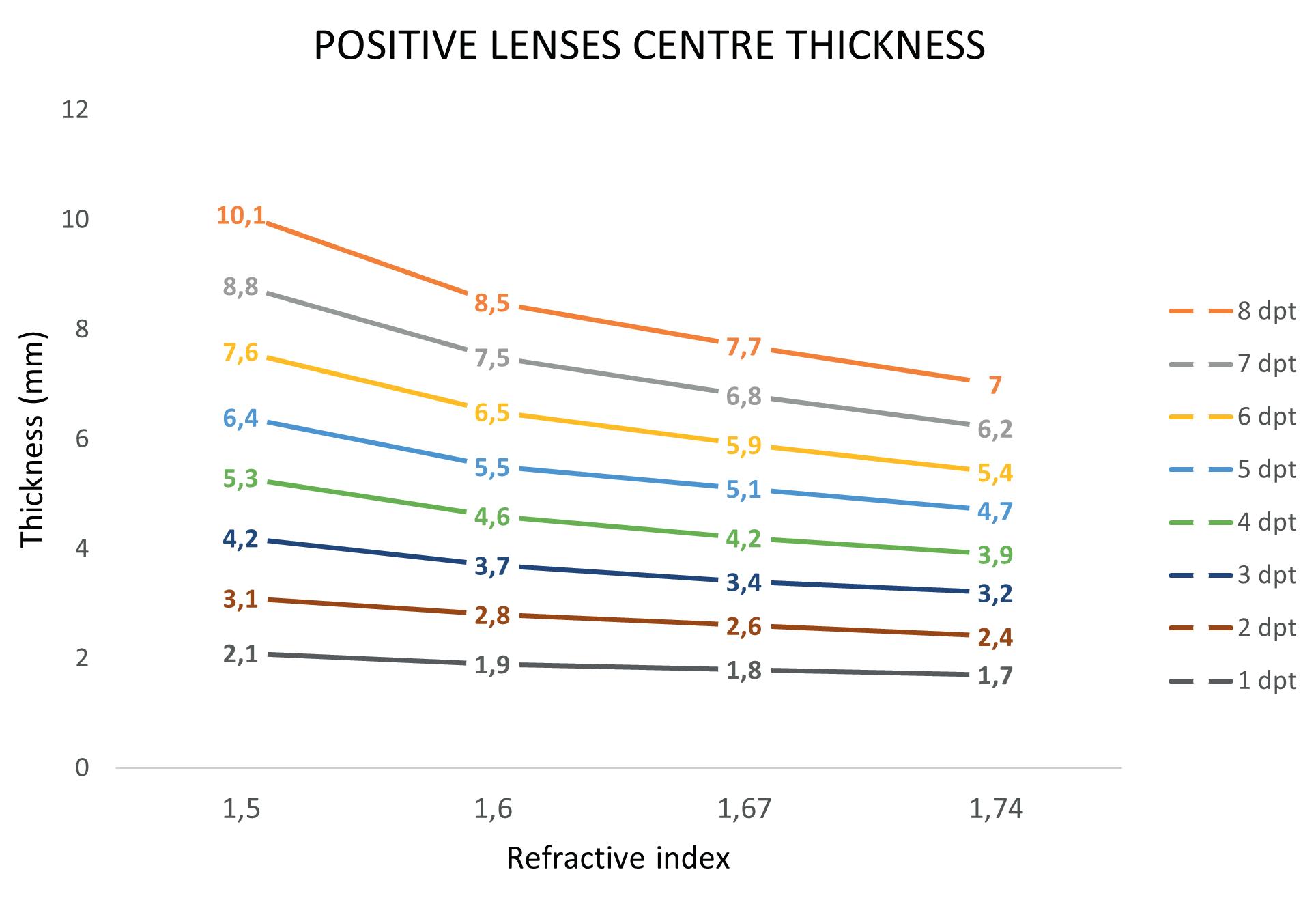

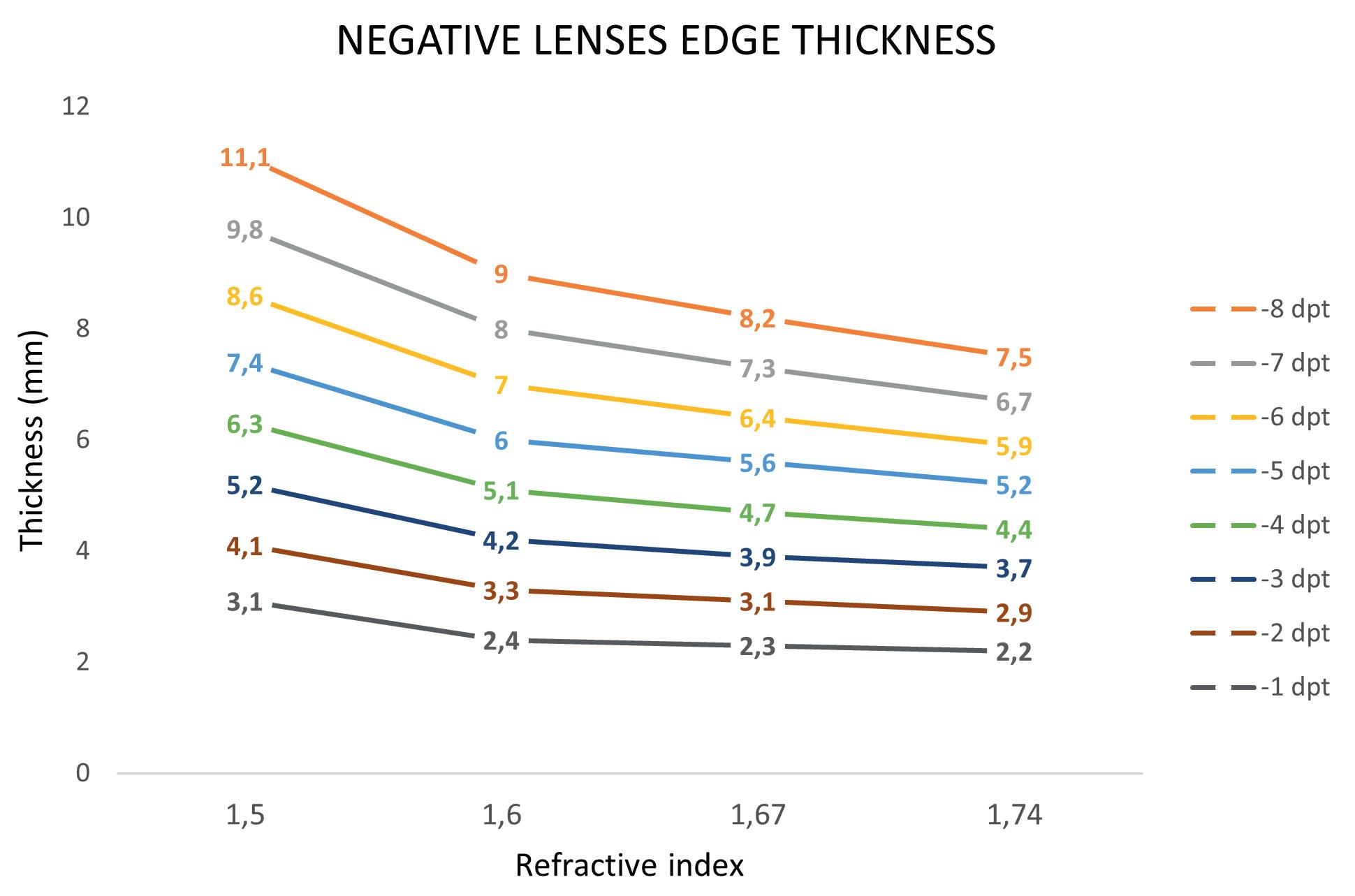

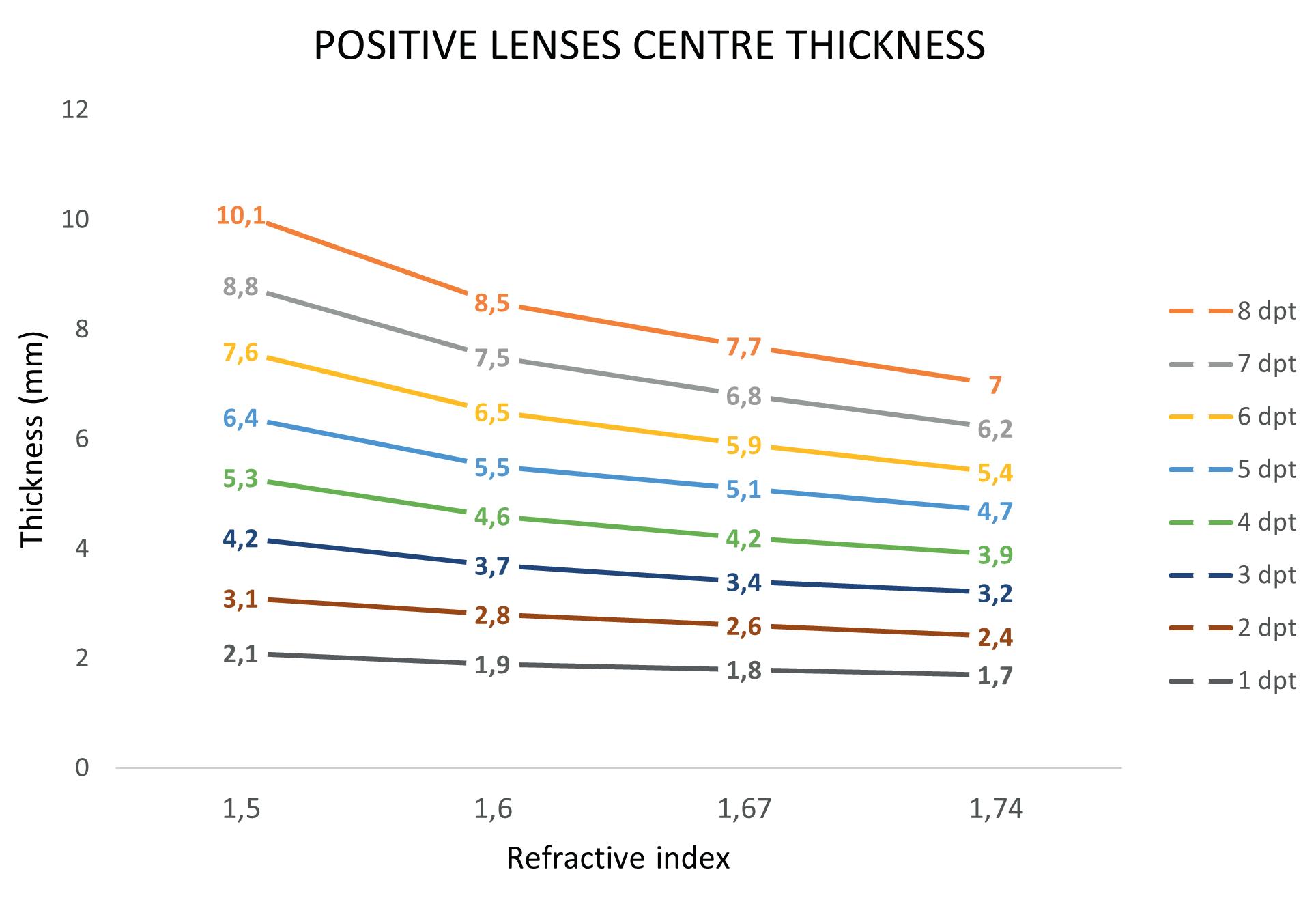

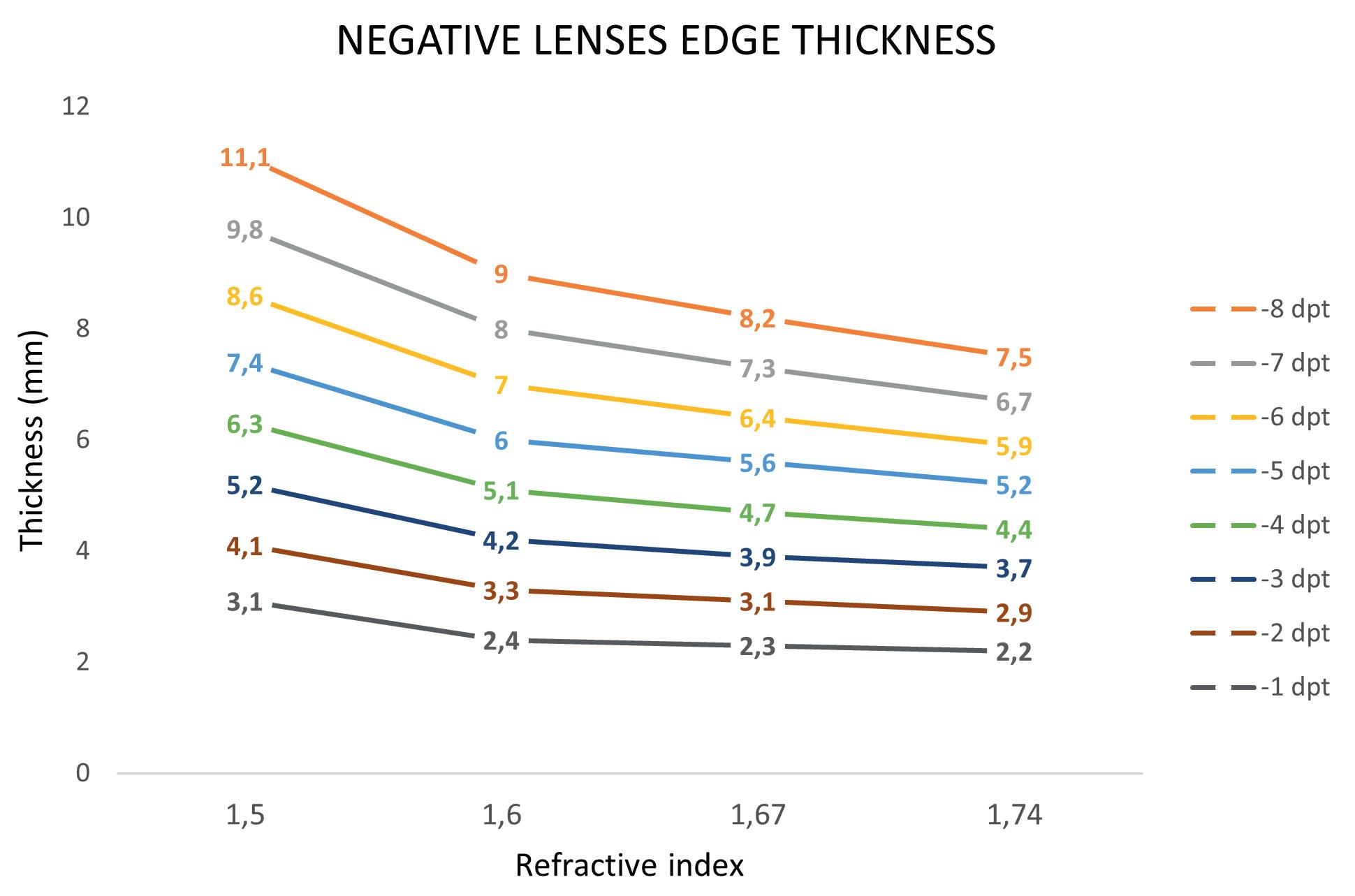

To investigate the relationship between these parameters, we must make comparisons for different optical powers; therefore, we calculate the weight and thickness of ophthalmic lenses with powers ranging from +8 dpt. to -8 dpt., with 1 dpt. steps. To simplify the analysis, we consider circular lenses with a diameter of 65 mm, and we impose that all the lenses have a flat outer surface (outer base has 0 dpt. optical power). In this way we only investigate concave plane or convex plane lenses and thus eliminate the problem of choosing the outer base curvature.

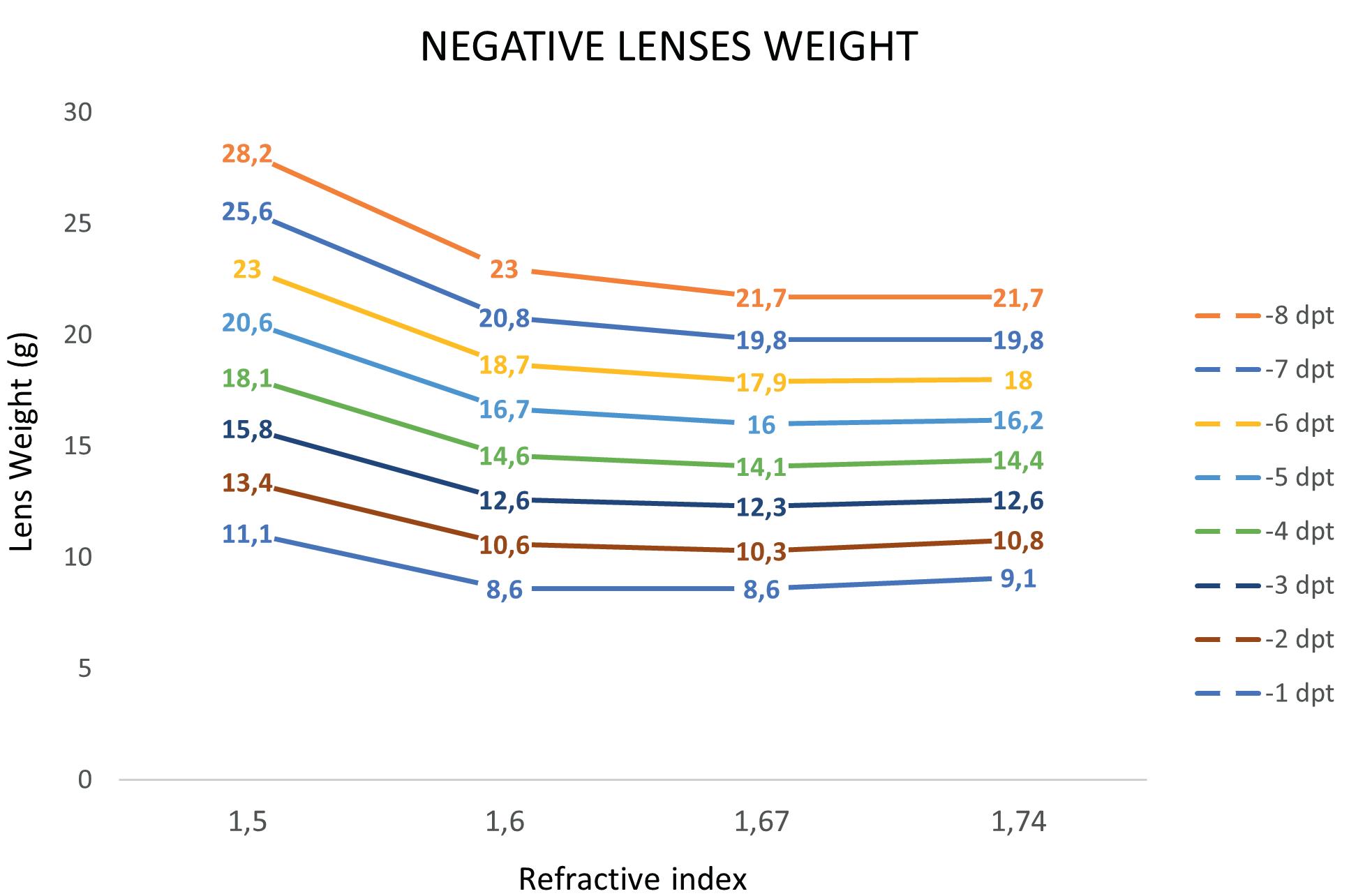

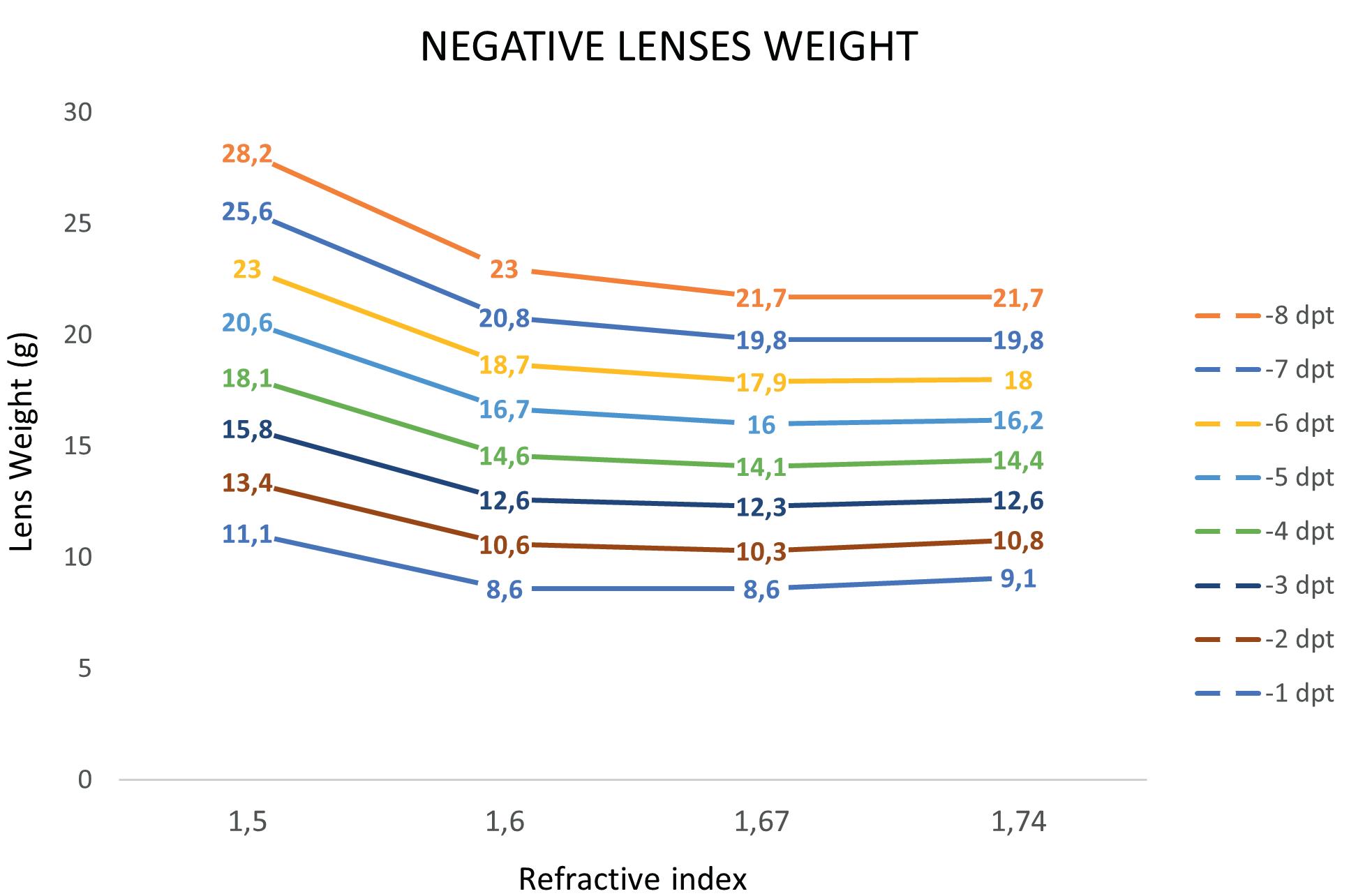

Figure 2 shows the negative lens weight values in grams as the optical power varies for each refractive index. In this graph there is a significant reduction in weight when comparing 1.5 refractive indices with 1.6 refractive indices for each optical power, indicating that in this case the lens thickness reduction can easily compensate for the increase in density. Comparing a refractive index 1.6 with 1.67, on the other hand, the weight reduction becomes more subtle, and you need at least -4 dpt. power to appreciate a 0,5 g weight reduction between these two refractive indices.

Moreover, using refractive index 1.74 does not result in lighter lenses, compared to 1.67 and when the power is lower than -6 dpt., the lenses are even slightly heavier, meaning that the reduction in thickness cannot compensate for the increased density. Nevertheless, lenses produced with 1.74 refractive index material have a significantly lower edge thickness in all cases as shown in figure 3, although the advantage is greater for higher optical powers.

For positive lenses, similar considerations can be drawn from the graphs in figures 4 and 5. However, in this case, the data are less reliable since we have simplified the analysis by considering only lenses with an outer surface of 0 dpt. (plano-convex lenses). In fact, negative lenses are often constructed with flat outer surface (so our data are reasonably reliable), while the choice of outer base curvature can significantly vary the weight and thickness of a positive lens. These considerations are far from obvious, as in the past when mineral lenses were mainly employed, using high-index glass materials meant producing significantly heavier lenses, and people had to accept this drawback in order to have thinner and thus more aesthetically pleasing spectacles.

Software optimization

Besides refractive index considerations, we cannot ignore software algorithms that can improve thickness and weight of ophthalmic lenses by refining the surface calculation process. In the first production phase the software determines the minimum diameter needed to manufacture the required lens, calculates the dioptric surface, and therefore determines the lens thickness (the volume and consequently the weight can be derived accordingly).

This process can sometimes be optimized using an elliptical calculation method, or by exploiting advanced thickness optimization technologies.

Elliptical calculation

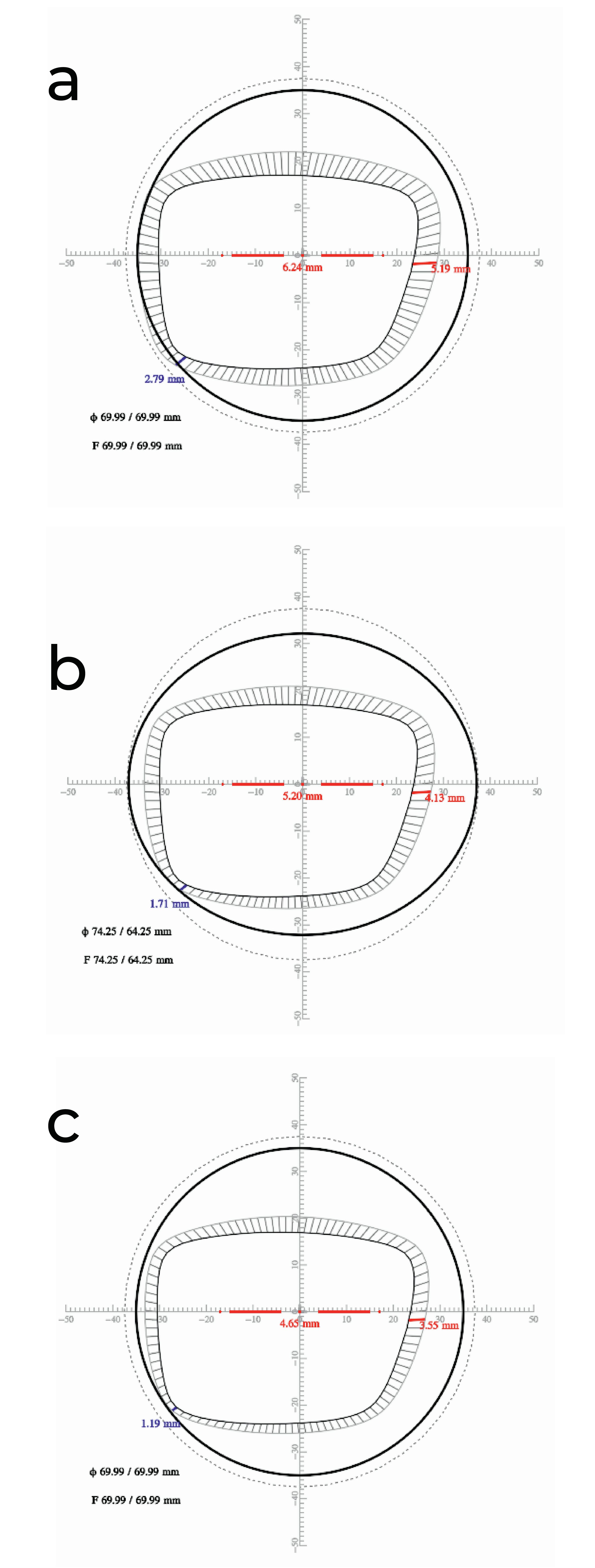

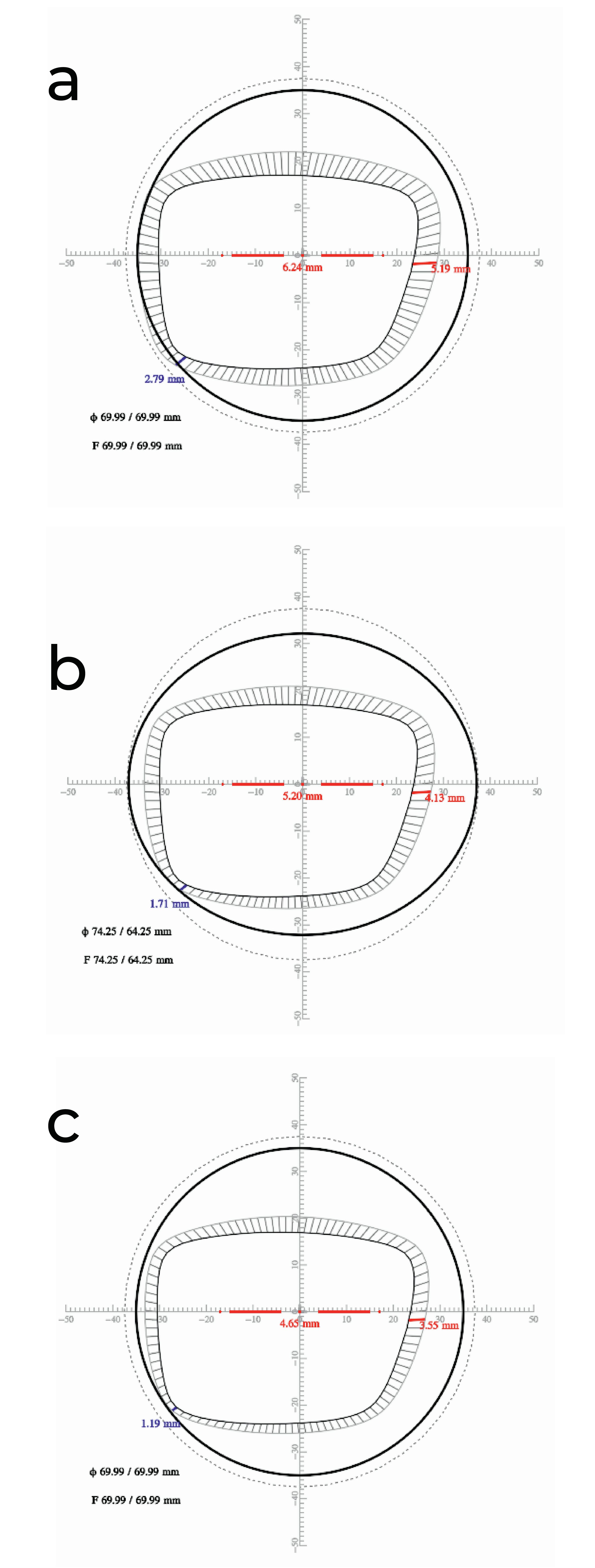

The elliptical calculation, also called pre-calibration, consists of using an ellipse rather than a circumference when determining the minimum diameter required to produce a lens. Let us try to understand step by step how this is achieved.

First of all, the frame shape must be registered to start the calculation, together with the centering data (interpupillary half-distance, mounting height). The software starts by fitting this shape within a circle, that identifies the semi-finished that will be used to produce the lens. In this stage, the semi-finished center is aligned with the lens optical center (determined by the centering parameters).

Next, it is necessary to determine the minimum possible diameter to produce the lens, since the smaller the diameter, the lower the lens weight, the thickness and the production costs will be. To derive the minimum diameter, the software applies an optimal decentration (within a threshold range) by aligning the frame shape geometric center with the semi-finished center. Then it reduces the circle diameter until it touches the lens shape edge. Thus, the minimum (circular) diameter to produce the lens has been determined and the lens can now be produced (Fig. 6-a, thickness graphs in millimeters).

The elliptical calculation can now be made by reducing the vertical diameter of the circle until it reaches the frame shape, thus inscribing it in the optimal ellipse (Fig. 6-b).

Fig. 1: Density of the most common organic materials with their refractive indexes, expressed in grams per cubic centimeter.

MAFO 5-23 27 TECHNOLOGY

Figure 6 shows the difference in lens thickness between the spherical (6-a) and elliptical (6-b) calculations, with the center thickness decreasing from 6.24 mm to 5.20 mm, and the edge thickness also decreasing both at the thickest point (in red) and at the thinnest point (in blue). However, it is important to note that this software optimization is only effective on positive astigmatic lenses that have the highest positive power across the vertical meridian; in fact, the lens shown in figure 6 has the following power: sph. +4,50 dpt. cyl. -2,50 dpt. axis 90°.

Advanced calculation methods

Unlike the elliptical calculation, advanced optimization algorithms aimed at reducing lens thickness are usually effective for both positive and negative lenses. Furthermore, there is no unique method to reduce lens thickness, as it is possible to approach the problem in various ways.

Classically, lenticularization is used to reduce high dioptric power lens thickness. Lenticularization consists of a very rapid curvature change at the lens edge so that the surface is rounded, blunted. However, in that lens area the optical power deviates greatly from

the ocular prescription, putting this zone of the peripheral visual field out of focus.

This technology can be taken to the next level by governing the curvature change through the frame shape, and this is the core of the Crea Size 2.0 algorithm that we developed. Leveraging Crea Size 2.0 technology it is possible to further reduce lens thickness, by implementing a light and thin lenticularization that follows the frame shape in its most peripheral edge, affecting vision as little as possible.

The results of this calculation method can be seen in figure 6-c, where the center and edge thicknesses result even lower than those calculated with the ellipse (Crea Size 2.0 center thickness is 4,65 mm vs 6,24 mm for standard calculation and 5,2 mm for elliptical calculation). Naturally, this also leads to lightening the lens, as you have reduced the lens volume (while maintaining the same material).

Conclusions

Using lens calculation software, we verified that the relationship between lens weight and thickness is not obvious, since high-index materials, which generate thinner lenses, are also the densest. So, increasing the

Fig. 2: Negative lenses weight in relation to power and refractive index, diameter is 65 mm, front power 0 dpt.

Fig. 3: Negative lenses thickness in relation to power and refractive index, diameter is 65 mm, front power 0 dpt.

Fig. 4: Positive lenses weight in relation to power and refractive index, diameter is 65 mm, front power 0 dpt.

Fig. 5: Positive lenses thickness in relation to power and refractive index, diameter is 65 mm, front power 0 dpt.

MAFO 5-23 28 TECHNOLOGY

refractive index does not always reduce lens weight, although a thickness reduction is always present. Using simplified calculation, we presented weight and thickness data for positive and negative lenses with varying power from +8 dpt. to -8 dpt., to draw general considerations.

In addition to the refractive index variation, it is possible to reduce the thickness of ophthalmic lenses by exploiting software optimization algorithms.

The elliptical calculation process, which is very effective in positive toric lenses, was explained in detail to gain awareness of how thickness reduction is achieved in those cases. We also showed how Crea Size 2.0, an advanced algorithm that is an evolution of classical lenticularization, succeeds in obtaining even lower thickness values than the elliptical calculation. These considerations come handy in our daily work, as lighter eyeglasses are often more comfortable and more in harmony with a person's daily life. ◆

Φ 69.99 / 69.99 mm

F 69.99 / 69.99 mm

Gaetano Volpe is a Computer and Automation Engineer. He is a co-founder and Head of Research & Development at ProCrea Tech, freeform lens design company based in Italy. He is pursuing a Ph.D. in Electrical and Information Engineering with the Polytechnic University of Bari. He has a long-time experience in optimization algorithms and lens design.

Φ 74.25 / 64.25 mm

F 74.25 / 64.25 mm

Pasquale Fanelli is an optometrist from University of Salento. He works as product specialist for ProCrea Tech and DAI Optical Industries, Italian ophthalmic lens manufacturer. He also practices as an optometrist in a private clinic and his fields of interest are freeform ophthalmic lenses and advanced contact lenses.

Φ 69.99 / 69.99 mm

F 69.99 / 69.99 mm

Fig. 6: Thickness simulation comparison between standard minimum diameter method (a), elliptical calculation (b), advanced calculation with Crea Size 2.0 (c); refractive index is constant n= 1,6 and optical power is: sph. +4,50 dpt. cyl. -2,50 dpt. axis 90°.

Pasquale Fanelli

Gaetano Volpe

MAFO 5-23 29 TECHNOLOGY

One drop and you regain the vision of

a 20-year-old?

Presbyopia treatment with eye drops

It sounds too good to be true. One drop on the surface of the eye and you can see as well as you did a few years ago. This is the dream of several U.S. pharmaceutical manufacturers. In recent years, they have made some groundbreaking advances in the pharmacological treatment of presbyopia. This article provides an overview of the latest developments and their practical applications. By Lena

Petzold

MAFO 5-23 30 SPOTLIGHT

Brimochol

The first drug expected to improve near vision over a longer period of time is Brimochol. It was developed and produced by the pharmaceutical manufacturer Visus Therapeutics in Irvine, California (USA). Brimochol is a combination of Carbachol and Brimonidin.