OPHTHALMIC LABS & INDUSTRY

We help you to stay in contact

3/2023

▶ Special topic: Ophthalmic Optics in Numbers

The ophthalmic market in a nutshell

Misconceptions about progressive lenses

Consumer sentiment and market data in Europe

▶ Technology

Natural Accommodation Lens

PFAS forever?

▶ Market Survey Generators

BLOCKING PERFORMANCE AT A NEW LEVEL

One auto blocker covering virtually all of a labs’ blocking requirements at highest speed. With CCU Modulo ONE, SCHNEIDER introduces the only auto blocker today with automated block size exchange and achieves unprecedented efficiency in blocking.

Time-consuming manual changes are a thing of the past. CCU Modulo ONE has multiple block sizes – a minimum of three and up to six – readily available. And the best part: The exchanges are carried out automatically and without increasing cycle time.

With the added flexibility, CCU Modulo ONE solves a well-known problem: Inefficient block size distribution and poor machine utilization. For any lab size, a wider range of blocking requirements can be met with a smaller number of machines.

The proprietary lens measuring unit guarantees perfectly oriented lenses. An intelligent fill control provides highly consistent and precise fillings – no under or over fillings. The alloy and block pieces can be refilled during operation. Non-stop uninterrupted blocking for highest throughput, at lowest cost per lens.

ISSN 1614-1598 66527 Volume 19

Eyepress Fachmedien GmbH Saarner Str. 151 45479 Muelheim a. d. Ruhr 66527 Germany

Highest flexibility Little to no downtime Highest throughput www.schneider-om.com CCU m dulo 3+

Hanna Diewald Chief editor

Hanna Diewald Chief editor

Tell us your opinion, ideas and suggestions: hanna.diewald@mafo-optics.com

Where to put the chemicals?

Most people will certainly agree that our environment is worth protecting. But how far should industry be regulated by law?

This is a question that is not always easy to answer, because in some cases very different interests are at stake. In the European Union, for example, regulation of certain chemicals, the PFAS (per- and polyfluoroalkyl substances), is being discussed.

The impact of this decision would be huge, as there are about 10,000 PFAS that can be found in a variety of everyday objects: from pans, to contact lenses, to coatings for spectacle lenses. In the near future, their use may be banned. Environmentalists are already celebrating this as a milestone, but at the same time it also poses a challenge to industry. To learn more about the background to this topic, read the article on page 18.

Another important environmental topic, covered in this issue, which already concerns all labs, is how to handle hazardous waste. In the USA, for example, there are severe penalties for violating the current regulations on preventing contamination of the soil, air and water by harmful substances. In 2018 alone, optical labs were fined $750,000 for repeatedly discharging untreated

wastewater containing cadmium, lead, acid lens cleaner, potassium hydroxide, and muriatic acid. Those that break the law do not always do so deliberately; sometimes it is simply down to ignorance. A good reason to learn more about this topic from the article by Roger Arrowood.

When it comes to the environment and politics, the right way is not always easy to find. It is good that not all topics are so controversial. For example, MAFO was at Vision Expo East on your behalf; an altogether successful event by all accounts.

We interviewed Roland Lorek from the market research institute GfK about current market trends and consumer sentiment.

Furthermore, we will introduce you to a new progressive lens design that does not require fitting height measurement, and you will also find out about the latest thinking on the topic of work organization.

But now please enjoy reading – and in the meantime, I am already thinking about the topics for the next issue.

And what subject areas are you actually most interested in? What should MAFO definitely report on? I am curious to hear your ideas! Just let me know and write an email to hanna.diewald@mafo-optics.com

app.mafo-optics.com

FREE

READ FOR

MAFO 3-23 3 LETTER

Ivette Bruguera

Hartmut Fischer

Ivette Bruguera

Hartmut Fischer

MAFO 3-23 5 MAY / JUNE 2023 MAFO issue May / June 2023 Content Topics in this edition Special Topic Special Topic Special Topic At a glance 6 All about you News from the international ophthalmic industry 7 All about markets Data in graphics 8 All about products Innovations and products for your lab 44 Suppliers Guide 48 Closing Words Dr. Stefan Seifried – a technology enthusiast and nature lover 49 Outlook Technology 14 Natural Accommodation Lens (NAL) By Michael Walach 18 PFAS forever? By Hanna

Spotlight 10 Hazardous waste management By Roger Arrowood 25 The ophthalmic market in a nutshell By Hanna

Spotlight 27 Vision Expo East 2023 30 Discovering the misconceptions about progressive lenses

Business 22 Consumer sentiment and market data in Europe Interview with Roland Lorek 32 Setting priorities By

Surveys 36 Generators Page 10 Page 14 Page 30

Diewald

Diewald

By

All about you News from the international ophthalmic industry

Silmo Singapore´s first edition kept its promises

Silmo Singapore, ASEAN Optical Fair, was held from 12 to 14 April 2023 at Suntec Singapore Exhibition and Convention Centre. Jointly organized by Silmo International and MP Singapore, the show welcomed over 250 international a nd local brands from over 15 countries representing most product families and ranges in the optics and eyewear industry. 2175 professional visitors, optometrists, dispensing opticians and buying groups had the opportunity to browse the latest eyewear, optical products and technologies. With 50% of its attendance from overseas, Silmo Singapore first edition confirms its ambition to become the new business meeting place in Southeast Asia. Top five of the 44 represented countries were Malaysia, China, Australia, Vietnam and Indonesia.

Augmented reality eyeglasses provide comfort for hearing-impaired and multi-language users

Hearing loss compensation and spoken language translation can now be provided using augmented reality (AR) eyeglasses from Beijing LLVision Technology. The glasses display voice translations in text on the lenses in real time. LLVision employs automatic speech recognition technology and artificial intelligence to create, stream and display voice translation in milliseconds. The computer chip integrated in the legs of the glasses translates voice input into text data. The glasses connect wireless to a smartphone app that handles user authentication.

According to the World Health Organization, about 1.5 billion people (nearly 20% of the global population) live with hearing loss – a number that could rise to 2.5 billion by 2050. Another trend is the growing need for international communication. The LEION Hey glasses can enable individuals to cope with both scenarios.

HCP Cureblindness and SightLife join forces

HCP Cureblindness and SightLife International, leading global eye health nonprofits, announced they have joined forces as one organization to make a greater impact in eye care worldwide. Effective immediately, HCP Cureblindness will acquire the SightLife International Program, the global division of the broader SightLife organization, with full integration of systems, programs, and brand to come over the next twelve months. This transition marks the next step of an ever-growing relationship between the two organizations. For 13 years, HCP Cureblindness and SightLife International have collaborated on multiple projects in clinical training, eye bank development, advocacy and prevention in Nepal and Ethiopia.

EssilorLuxottica unveils four-year clinical trial results of its Essilor Stellest lens at ARVO

EssilorLuxottica presented the four-year clinical trial results of its myopia control Essilor Stellest lens for the first time at the 2023 ARVO annual meeting in New Orleans, United States. The findings show that Essilor Stellest lenses continue to exhibit strong efficacy in slowing myopia progression and axial eye elongation in children in the fourth year. The study assessed the four-year increase of myopia and axial eye length of children who wore spectacle lenses with highly aspherical lenslets (HAL). Essilor Stellest lenses are based on the optical design of HAL lenses. The key findings from the study include: HAL lenses saved more than one and a quarter dioptres of myopia on average over four years. Myopia progression and axial eye elongation in children wearing HAL lenses was slower compared to a modelled control single vision lens group. HAL lenses remain effective in slowing myopia progression and axial eye elongation in older children (11-16 y.o.) in the fourth year.

You have news for the ophthalmic industry? Submit your press releases to: hanna.diewald@mafo-optics.com or constanze.classen@mafo-optics.com

Picture: Silmo Singapore

AR eyeglasses. Picture: LLVision

Picture: HCP Cureblindness/SightLife

MAFO 3-23 6 INTERNATIONAL NEWS

Picture: EssilorLuxottica

Source:EuropeanPatentOffice2023

All about markets

Graphical data

New research shows that a significant number of vision corrected U.S. adults are interested in purchasing both contact lenses and glasses, For instance,

18%

Despite a growing number of ways to pay, cash remains the most widespread method of payment in a many countries. The only country where mobile payments had overtaken all other payment types was China, where 67% had used their phones to pay in the past year. India, Indonesia and Nigeria were two more countries with high rates of phone payments.

Source: Statista´s consumer insights

of contact lens-only wearers are very interested in glasses and vice versa also 18% of glasses only-wearers are very interested in contact lenses.

Source: Contact Lens Institute

The leader in the market for cloud infrastructure, Amazon Web Services (AWS), is still ahead of the pack. Amazon’s market share in the worldwide cloud infrastructure market amounted to

32%

in the first quarter of 2023. At the same time, Microsoft gained two points since Q3 2022 and now sits at 23% market share.

Source: Synergy Research Group

MAFO 3-23 7 INTERNATIONAL NEWS

All about products

Innovations and working materials for your lab

New General Manager Asia/Pacific at SCHNEIDER

Since December 2022, Lukas Lechner has joined the SCHNEIDER team to manage and further develop SCHNEIDERs business activities in Asia. With his background in mechanical engineering and an MBA under his belt, Lukas has spent the last nine years in developing a strong sales background in the APAC region. As a representative of SCHNEIDER, Lukas is well-equipped to provide innovative solutions that leverage the latest technology and highest quality available on the market. “Being a member of SCHNEIDER fills me with great enthusiasm, as it is not just the leading organization in its industry, but also a familyowned business with exceptional colleagues”, Lechner says. “Our commitment is to strengthen SCHNEIDERs presence in the APAC region and help our clients to succeed in a challenging global marketplace.” Visit www.schneider-om.com

Agility Autodeblocker from Coburn

Agility Autodeblocker is a completely waterless, automated deblocking system. Developed for large labs seeking speed and efficiency, Agility is the fastest automated deblocking system on the market, capable of deblocking 240 lenses per hour. Agility is ideal for high volume labs that prefer a convenient automated solution. Both lenses are automatically removed from a job tray, placed onto the appropriate deblocking rings, and deblocked simultaneously using a mechanical action. Contrary to deblocking with water jets that displace alloy, cause alloy waste, and produce contaminated water waste, Agility separates the lens from the block in one clean, swift, mechanical action. When combining Agility with the Duality De-Taper & Cleaner and Velocity Lens Coater, customers can fully automate the post-polishing process. Lenses are deblocked, de-taped, cleaned and coated in minutes without operator involvement. Labs can also integrate the Integrity Alloy Recovery System for automated alloy recovery, which is completely waterless as well. Visit www.coburntechnologies.com

Advertisement MAFO 3-23 8 INTERNATIONAL NEWS

Hazardous waste management

Important facts for optical laboratories

A lot of waste is produced in a lab every single day and among them are hazardous substances. Proper handling of sensitive waste is important for the environment, but it is also in the company's own interest.

By Roger Arrowood (this topic

was first published at The Vision Council).

Should optical labs be concerned about managing hazardous waste? This is a fair question and the answer is clearly yes – for a number of reasons. In the United States optical labs are routinely inspected by local, state, and federal environmental regulators. Fire and health department inspectors may report observations to appropriate authorities and violations can become costly. In 2018 optical labs fined $750,000 for repeatedly discharging untreated wastewater containing cadmium, lead, acid lens cleaner, potassium hydroxide, and muriatic acid.

Chemical accidents and the political consequences

The reason for this also lies in history. Prior to 1976, there were very few regulations regarding management of hazardous waste in the United States.

But this lack of regulation paved the way for catastrophic pollution of soil, water, and air. Therefore the Resource Conservation and Recovery Act (RCRA) was passed in 1976, with periodic reviews and updates. It is the primary law governing the disposal of solid and hazardous waste. RCRA was signed into law to address the increasing problems the nation faced from the growing volume of municipal and industrial waste.

The chemical incidents of the past have led to:

▶ Laws

▶ Codification of regulations

▶ Annual book of regulations (CFRs)

▶ Daily federal register

▶ Proposed rules

▶ Final rules

Of particular interest to certain countries MAFO 3-23 10 SPOTLIGHT

Today 10 national EPA regions implement the federal program.

The RCRA allows the EPA to turn over the responsibility of regulating hazardous waste to the states if certain conditions are met. States may adopt hazardous waste regulations, but the program must be at least as stringent as the federal program and a state can have federal and state hazardous waste rules for generators to follow at the same time.

Violations of RCRA

The EPA is authorized to enter, inspect, and obtain samples anytime from any facility where hazardous wastes are generated, stored, treated, transported from, or disposed. Various type of failures to comply with hazardous waste rules can lead to violations. This happens regularly also because the management is typically held to the standard that they “knew or should have known.”

Penalties that a company or an individual may face – for not following the regulations – range from fines to jail and not to underestimate the damage to the public image.

Once the EPA notifies of a violation, and the violation is not corrected within 30 days, the EPA can issue an order requiring compliance by a specified time. If the violation is not corrected within the specified time, civil action in U.S. District Court will commence.

If the violation is not corrected within the specified time, the violator is liable for civil penalties over $50,000 up to $76,764 per day. Any environmental permits they have can be suspended or revoked. Criminal penalties include criminal fines of over $50,000 for each day of violation or imprisonment of one year, or both for anyone who knowingly violates a regulation.

Violations considered knowing (willful) violations are for example:

▶ Transporting hazardous wastes or listed waste to a facility, which does not have a permit to accept waste.

▶ Treating, storing, or disposing of any hazardous waste, characteristic or listed without having a permit.

▶ Making false statements on any legal document used for purposes of compliance with the regulations.

The cradle to grave principle always applies. Therefore, please note: You are always liable for your waste – EVEN if you handled it properly and send it to a proper recycling, treatment, disposal facility! Ensure that the companies you use to manage your waste are properly licensed and comply with all local, state and federal regulations.

What is hazardous waste?

RCRA defines hazardous waste as a solid waste. It can be any garbage, refuse, sludge from a waste treatment plant, or air pollution control facility and other discarded material, including solid, liquid, semisolid, or contained gaseous material resulting from industrial, commercial, mining, and agricultural operations, and from community activities.

Hazardous waste characteristics

1. Ignitability (D001)

▶ An ignitable waste will present a fire hazard during routine management. It is a liquid, other than an aqueous solution, that contains less than 24% alcohol by volume and has a flashpoint less than 140° F (60° C) as determined by a Penske-Martens Closed Cup Tester.

▶ Ex: Alcohols, acetone, and some coating liquids

2. Corrosivity (D002)

▶ A corrosive waste is able to deteriorate containers, damage human tissue and dissolve things. Acids with a pH below 2 or bases with a pH above

▶ Ex: Sulfuric acid, potassium hydroxide, sodium hydroxide, or acetic acid 12.5 are corrosive.

3. Reactivity (D003)

▶ A reactive waste is unstable and has the ability to liberate toxic gases or to react violently or to explode when exposed to air and water.

▶ Ex: Cyanide containing waste, peroxide, or per chlorates

4. Toxicity

▶ This is a list of 20+ chemicals with an identified limit. If you have more than the limit, your material is hazardous.

▶ Ex: Alloy contains lead D008 5 mg/l, and cadmium D006 1.0 mg/l

Types of hazardous waste possibly found in optical labs vary by types of labs: toxics (alloy contaminated wastes), flammables and/or corrosives. It is the responsibility of the facility to determine the waste type and develop a waste management program.

Determining if your waste is hazardous

Use the information on the DOT shipping containers (approved by the U.S. Department of Transportation) that the chemical was shipped in. Look at the label on the chemical container and read the safety data sheet (SDS) for the chemical (look especially at last sections of SDS). Furthermore, you can contact the manufacturer of the chemical or test the material containing the chemical.

Once you know what materials are hazardous at your facility, you must keep a monthly record for twelve months running on how much of each type of hazardous waste you generate. Then record your waste volume each month to determine your level as a hazardous waste generator.

Three categories of hazardous waste generators

1. Very small quantity generator “VSQG”

▶ Produces < 220 lbs /month (less than half a drum or about 25 gallons).

▶ Produces less than 2.2 lbs of acutely hazardous waste/month.

▶ No storage time limit if the total waste stored is under 2200 lbs (about five drums).

▶ Must ensure that hazardous waste is delivered to a person or a facility that is authorized to properly manage its disposal.

MAFO 3-23 11 SPOTLIGHT

▶

VSQGs may, but are not generally required to, notify state department of environmental management to obtain a Resource Conservation and Recovery Act (RCRA) identification (ID) number.

▶ Check with your local regulators to be safe.

▶ A RCRA ID number may be necessary if there is a planned or unplanned episodic event:

An activity that does not normally occur during a generator’s operations and that causes the generator to exceed the threshold for its normal generator category for that month.

Revised in 2016. More information about episodic generation is available on U.S. EPA’s hazardous waste generator site.

2. Small quantity generator

▶ Produces 220 lbs. – 2200 lbs./month (about one half to five drums or 25-250 gallons)

▶ Produces less than 2.2 lbs. of acutely hazardous waste/month

▶ Must obtain an EPA ID number to ship waste

▶ Can store hazardous waste up to 180 days

3. Large quantity generator

▶ Produces more than 2200 lbs/month (more than five drums or 250 gallons)

▶ Produces more than 2.2 lbs of acutely hazardous waste/month

▶ Must obtain an EPA ID number to ship

▶ Storage of hazardous waste is limited to 90 days

Before a hazardous waste can be shipped to a disposal facility, the disposal facility must know what chemical and how much is in the waste. A profile sheet describing the waste must be completed and provided to the disposal facility. A profile provides the necessary information needed to classify the waste for disposal (if the profile is wrong, it can be costly).

Please note: This is where most people make mistakes!

Waste container requirements

Six steps to safe shipping:

▶ Classification: shipping description

▶ Packaging: selection and assembly

▶ Marking of packages

▶ Labeling of packages

▶ Shipping papers & emergency response info

▶ Placarding and marking of vehicles

Storage

A rule of thumb is that the original container that the material arrived in can be used for the waste.

Obviously a container holding hazardous waste must not be handled in a way to cause rupture or a leak and a container holding hazardous waste must be kept closed during storage except when necessary to add or remove waste.

A container storage system must have a base underlying the containers that is free of cracks or gaps and impervious to contain leaks, spills, or precipitation. The container storage system must have sufficient secondary containment capacity to contain 10% of the volume of containers or the volume of the largest container, whichever is greater. Water run-on into the container storage system must be prevented unless the secondary containment capacity is sufficient to hold the required volume and the run on. Spilled or leaked waste and accumulated precipitation must be removed from the collection. Containers holding ignitable or reactive waste must be located at least 50 feet from the facility property line. It should also be noted that a storage container, holding a hazardous waste, must be separated from the other materials or protected from them by means of a dike, berm, wall, or other device.

CFR 262.32 marking

Before transporting hazardous waste or offering hazardous waste for transportation off-site, a generator must mark each container of 110 gallons or less used in such transportation with the following words and information displayed in accordance with the requirements of 49 CFR 172.304:

▶ HAZARDOUS WASTE- Federal Law Prohibits Improper Disposal. If found, contact the nearest police or public safety authority or the U.S. Environmental Protection Agency.

▶ Generator’s name and address

▶ Manifest document number

CFR 262.34 accumulation volume

An appropriate container must be selected for the hazardous waste. Waste containers must be in good condition and compatible with the waste that will be placed into them. Acids and caustics which are corrosive cannot be put into metal containers and a container with a lining must be used for materials that are not compatible with the container.

(c)(1) A generator may accumulate as much as 55 gallons of hazardous waste or one quart of acutely hazardous waste or listed in CFR 261.33(e) in containers at or near any point of generation where wastes initially accumulate which is under the control of the operator of the process generating the waste.

Note: You may also store non-hazardous waste at the same site and it does not count.

MAFO 3-23 12 SPOTLIGHT

Satellite accumulation

For satellite accumulation applies: the waste must be kept at or near the process that generates the waste. It needs to be under the control of the process operator and waste from different types of processes cannot be introduced into this waste drum. The waste should be kept at or near the process until it is full (this drum is not dated). Once this drum is full you have three days to move the drum to storage and put a date on it. Some states now require that as soon as one drop of waste goes into the drum you must date it even at a satellite accumulation site. In general, a hazardous waste label should be on the drum when it is in the work area.

Point accumulation

The same types of waste (hazard classes) from different processes may be placed into a point accumulation drum. As soon as one drop of waste is placed into this drum, an accumulation start date must be placed on the drum.

This drum is usually located in your waste storage area. A hazardous waste label and a hazard label shall be on the drum when it is in the work area.

Shipping

As a general rule hazardous waste is shipped on a hazardous waste manifest (manifest is a tracking tool). This manifest has several copies and the copies are given to: Generator, transporter 1, transporter 2 and the treatment, storage, disposal facility (TSDF). Any alterations must have a line drawn through it, it must be dated, and initialed. The return manifest should be returned to the waste generator within 35 days. If not, call the disposal facility. If the return manifest is not returned within 45 days to the generator, you must notify EPA. The manifest must be kept three years. (CFR 40 Part 262.40 Recordkeeping Requirements).

The EPA requires companies to maintain a supply of placards for the chemicals they ship and to be prepared to make them available to drivers transporting their products.

Universal hazardous waste

Examples for universal hazardous waste are batteries, pesticides, mercury-containing-equipment, bulbs (lamps – fluorescent, high intensity discharge, neon, mercury vapor, high pressure sodium and metal halide).

Those containers should be marked or labeled: “Universal Waste –Lamps” or “Waste Lamps”. The containers must be structurally sound, adequate to prevent breakage, remain closed and show no evidence of leakage. Containers need to be marked with a start date and should not accumulate longer than one year.

Training

And last but not least: do not forget to share your knowledge! The generator must ensure all employees that handle hazardous waste are trained and thoroughly familiar with proper waste handling and emergency procedures, relevant to their responsibilities during normal facility operations and emergencies.

Roger Arrowood has studied graduate level safety and industrial hygiene. He worked for 34 years in environmental health and safety management with major optical manufacturing organizations. Furthermore, he has been working more than 20 years with the laboratory division, created written safety and environmental compliance policies, created employee training modules, developed employee driven safety compliance programs and worked three years as consultant to independent optical laboratories.

◆

Roger Arrowood

MAFO 3-23 13 SPOTLIGHT

The journey from PAL to NAL

Natural Accomodation Lens (NAL)

There is a new multifocal lens. It is a lens that requires a gentle raising or lowering of the chin to facilitate distance, intermediate, and near vision. But unlike progressive addition lenses (PAL), there are no narrow corridors to contend with, and no fitting height measurement is required, the inventors proudly report. This new multifocal lens technology is called NAL, which stands for Natural Accommodation Lens. In the following article the developer reports on his journey and how the new lens design exactly works. By Michael

Walach

Today, all freeform lens design companies are based on the conventional PAL utility, providing distance, intermediate, and near vision with about a ±8 m m progressive corridor. Hundreds of PAL designs and individual optimization nuances offer “unique” or “proprietary” features. Although even the most astute ECPs are not able to study and assess differences, most freeform lens manufacturers tend to offer three types of PAL designs: “good”, “better” or “best”.

The Challenge

The good, the bad and the ugly.

The good : Yes, we are all well familiar with all the wonderful features and benefits of PAL lenses like:

▶ No line.

▶ No image jump.

▶ Three focal distances: far, intermediate and near vision.

MAFO 3-23 14 TECHNOLOGY

The bad: We are all also well aware of some of the less desirable features of the PAL like:

▶ Cumbersome navigation through short and narrow intermediate vision corridors.

▶ Taking accurate and time-consuming fitting height measurements and frequent fitting height redos.

▶ Spatial disorientation, nausea, or dizziness due to peripheral waviness and distortions.

▶ Adaptation period.

The ugly: to be serious, there is nothing aesthetically ugly about a PAL. The good, the bad and the ugly came from a movie that I enjoyed, the 1966 epic spaghetti western film directed by Sergio Leone – remember?

The dream wish list

It is more than 60 years since the introduction of PAL. With new knowledge and technological evolution in computer technology and advancements in software development tools, we have reached the point that our dream wish list can be realized.

First, we must drop our self-imposed limitations, get out of the box, and start our quest armed with new knowledge, unaffected insight, creativity, commitment, and courage. And the dream wish list? Actually, it is not that far-fetched or long, thanks to the numerous PAL advancements we can enjoy today.

▶ No adaption period or non-adapts due to feelings of swim or nausea.

▶ No adaption period or non-adapts due to the learning process of navigation through a short and narrow intermediate vision corridor.

▶ No irritating and costly redos due to inaccurate fitting height measurements.

▶ No fitting height measurements that are often complex and timeconsuming are required.

Gaining insight

Upon extensive deliberations and complex considerations, a multifocal lens that would almost certainly meet the wish list criteria could be developed. After nearly five years of blood, sweat, and tears, a functional, commercially viable, cloud-based freeform digital lens design platform was developed.

That platform is suited to meet all our specialty and vocational lenses, bifocal and multifocal lenses, and our unconventional lens utility objectives. It can be integrated with any lab management system.

To gain new, untainted optical insight, we studied large numbers of fitting height statistical data based on frame measurements, frame shapes, and pantoscopic angles. We have created unconventional eye-lens ergonomic models and studied natural vision dynamics, and natural vision habits, consulted with numerous ECPs, optical business experts, and professionals, and finally the dream lens concept Natural Accommodation Lens (NAL) was born.

NAL has arrived

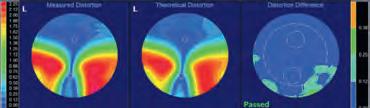

The NAL does not have the short intermediate vision corridor inherent in PALs. NAL has a funnel-shaped visual field comprised of substantially aspheric, lateral power bands that are aligned along a vertical design backbone. The design backbone has mathematically created curvature based on actual natural downward gaze focal length deceleration requirements based on our unique eye/lens interaction ergonomic model, and extensive PAL fitting data.

The focal length deceleration curve addresses natural accommodation requirements for focal lens reduction from six meters (20') all the way to 25 cm (1') along a continuous, smooth focal length deceleration ramp.

Registered as inventor of the lens is Michael Walach, President of Quest Vision Care Specialty Lab and the CEO of QLDS, both located in Largo, Florida. On September 21st, 2021, the USPTO issued US Patent No. US 11,126,012 for Broadview Natural Addition Lens. On March 29, 2022, USPTO granted a second patent, US Patent No. US 11,287,673 B1. NAL® and OMNILUX® are USPTO registered trademarks. The registrant is Quest Vision Care Specialty Lab.

The new NAL should eliminate the peripheral swim effect inherent in PAL due to peripheral defocus. We have been able to achieve that effect by:

▶ The application of substantially lateral aspheric broad power bands aligned vertically along the NAL backbone and interpolated by various bi-quadratic, cubic, and quintic polynomials and splines into one smooth continuous surface.

▶ Complex digital ironing out across visual field peripheral areas.

▶ Significant reduction in focal length deceleration rate along the substantially vertical NAL principal design axis due to a 2 to 4 times longer add power acceleration ramp radically reduces unwanted lateral astigmatism as per Minkwitz theorem.

▶ No adaption period or non-adapts due to the learning process of navigation through a short and narrow intermediate vision corridor. Because the NAL visual field is funnel-shaped, there is no short narrow progressive corridor for the wearer to learn to navigate. As a result, NAL adaptation is virtually instant, and the navigation is intuitive and natural.

MAFO 3-23 15 TECHNOLOGY

NAL focal length backbone deceleration ramp.

▶ No irritating and costly redos due to inaccurate fitting height measurements.

▶ The NAL visual field is shaped like a funnel or martini glass. Therefore, it does not have a short, narrow intermediate vision corridor like a PAL. The NAL has no progressive corridor.

Consequently, no time-consuming fitting height measurement is required, which means that no issues arise from incorrect fitting height. And there are no irritating redos typically caused by PALs ordered with an incorrect fitting height.

To change the focal distance in NAL, the patient gently lowers or raises their chin to fix their gaze on the object viewed and perfectly focus on the distance needed.

The objective of the concept is to provide a youthful, natural single vision viewing experience for active and professional presbyopes. Our numerous wearer studies proved that the actual viewing experience with the NAL is more natural and closer to the visual experience afforded single vision lens wearers.

Remember youthful vision? Remember how natural the transition from the office, golf, bike, tennis, or viewing the computer screen? This is the visual experience that patients desire in their multifocal eyewear.

NAL and its impact on the industry and the patient

Despite the enduring efforts of lens designers worldwide, the bell curve of new PAL concept design innovations is significantly leveling off. There have been over 60 years of PAL design improvements and design modifications. Seiko, Zeiss and Rodenstock pioneered custom back lens optimization over 20 years ago. Since the digital freeform revolution, more than 200 "proprietary" or patented designs have been introduced. New PAL innovation at this time appears to be trying to squeeze water from the stone.

The consequence that comes as no surprise is considerable disorientation among the global ECP community regarding the actual and objective visual performance of the abundance of PAL design offerings.

Most understand that today`s freeform digital technology is more about branding and marketing. Most commonly, it is “good”, “better”

or “best” PAL by major corporate brands and various private labels: the same PAL concept, different day.

It is also important to realize that the prescription eyewear e-commerce business is growing about ten times faster than brick-and-mortar. It seems reasonable to assume that the trend is going to continue.

The ECP brick-and-mortar community should seriously consider this and expand its marketing outreach to include an e-commerce presence.

At this moment, multifocal PAL internet sales are falling far behind brick-and-mortar PAL sales. Still, the NAL with no fitting height requirement creates an opportunity for retailers to expand e-commerce. We assume that the NAL has the potential to shift the numbers in favor of e-commerce significantly.

NAL is available as Omnilux for all daily youthful vision needs. NAL is available in all lens materials and treatments. The Rx power range is +8.00 D to -12.00 D sph, -5.00 D cyl, and prism up to 5.0 D. The ranges can vary, broader or narrower, depending on the type of freeform production line, lens material, Lens Manufacturing System (LMS) and provider being used. ◆

Michael Walach

Michael Walach is the founder of Quest Vision Care Speciality Lab, the industry’s leading specialty lab manufacturing exclusively for wholesale labs, located in Largo, Florida. https://questopticallab.com

MAFO 3-23 16 TECHNOLOGY

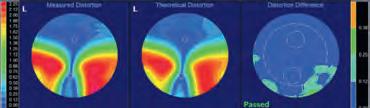

NAL on left and standard PAL design on right.

TECHNOLOGY

History of Progressive Addition Lenses – PAL

The first patent for a progressive lens was British Patent 15,735, granted to Owen Aves with a 1907 priority date. Unlike modern progressive lenses, it consisted of a conical back surface and a cylindrical front with opposing axes to create a power progression. Keeping t hat in mind – although Owen Aves` design was never commercialized – Essilor cannot technically be considered the creator of the first progressive lens. In 1948 Bernard Maitenaz followed in his father`s and grandfather`s footsteps and joined Société des Lunetiers as a research engineer. On March 2, 1951, Bernard Maitenaz deposited an envelope at the National Institute of Industrial Property in France, which included four drawings and mechanical data that would make it possible to manufacture the modern-day progressive lens. On November 25, 1953, Essel submitted the first patent for his invention. The first commercially viable progressive lens in Europe, Essel`s Varilux, was introduced in 1959. In 1965 the Univis Omnifocal was introduced in the United States. The first progressive lenses were made of glass. In 1972 Essel changed its name to Essilor because of the fusion of two companies, Essel and Silor. In 1976 the first organic progressive lens, Essilor`s version of Columbia Resin 39 (CR39) index 1.50, the Varilux Orma, was released. A physicist Werner Koeppen and his team worked on the development of the Varilux Comfort from 1960 into the 1990s, and Varilux became the most successful PAL. Over half a century has passed since the introduction of the PAL, and the world has not been the same.

The PAL evolution and its current state

The advancements in equipment, technology, and software mathematical and development tools have opened the doors to amazing new conceptual and design possibilities − the freeform revolution! First, it was OptoTech`s founder Roland Mandler, who, in 1985, adapted aerospace industry computer numerical control (CNC) technology in the production of ophthalmic lenses. Then, in 1986, Gunter Schneider of Schneider started using CNC technology in precision optics production, which later evolved into ophthalmic lens production. However, the biggest game-changer in PAL evolution came with the development of PAL Freeform Lens Design Software. On October 11, 1977, Japanese scientists Hiroyuki Mukalyama and Kazutoshi Kato filed a patent application for a progressive multifocal lens and manufacturing method. The US 6,019,470 patent was granted on February 1, 2000, and was assigned to Seiko Epson Corporation. On July 18, 2000, the USPTO granted a patent for a spectacle lens with a spherical front side and multifocal back side and process for its production, US6089713A, to Albrecht Hof and Aldabert Hanssen. They then assigned it to Carl Zeiss Vision GmbH. Both patents followed the conventional PAL concept, but instead of utilizing a semifinished lens with the progressive design cast or molded on the front side of the lens, the multifocal surface was created on the back of a rotationally symmetrical front of a semifinished donor lens blank. In addition to the PAL design on the back side of the lens, the final lens back surface was further modified with Individual Optimization. Over the past twenty-plus years, that concept and production technology radically improved multifocal lenses` visual performance and acceptance/adaptability. 704 &

Advertisement

QUAL SAVINGS FROM STOCK IONIZATION, THERMOCOUPLE & INSTRUTECH CONVECTION GAUGES

QUALITY& SAVINGS FROM STOCK INFICON RATE/THICKNESS CONTROLLERS & MONITORS

617-227-1133 • 800-743-17 paula@filtech.com www.filtech.com SCAN FOR OUR FULL CATALOG

705 SILICONE DIFFUSION PUMP FLUIDS

QUAL SAVINGS FROM STOCK

PFAS forever?

Long lasting chemicals – restrictions, chances and challenges

For some, they are “ forever chemicals” that should never be released into the environment; for others, they are necessary substances for the production of everyday consumer products or medical devices, for instance contact lenses. We are talking about per- and polyfluoroalkyl substances – in short PFAS. At first glance, two interests seem incompatible: on the one hand to save the environment and human health and on the other hand to satisfy consumer desires and to not restricting an entire industry. But one authority has now created facts.

By Hanna Diewald

By Hanna Diewald

MAFO 3-23 18 SPOTLIGHT

In early February 2023, the European Chemicals Agency ECHA published a ban proposal on all PFAS. It is a message with huge implications.

A choice for the environment and human health but at the same time, the industry faces huge challenges and stakeholders are lobbying for exemptions – at least for longer transition periods. But why is the topic so hotly debated?

Broadest restriction in history

According to the latest estimates, this group of substances comprises more than 10,000 different substances. It is the broadest restriction proposal in history and many different industries are affected. Among those industries that work with PFAS on a daily basis is also the ophthalmic industry. This is because PFAS are used in spectacle lens coatings as well as in contact lenses.

WATCH VIDEO Advertisement MAFO 3-23

The European Chemicals Agency (ECHA) describes PFAS as follows: “PFAS have a wide range of different physical and chemical properties. They can be gases, liquids, or solid high-molecular weight polymers. Some PFAS are described as long-chain or short-chain, but this does not cover all of the different kinds of structures that are present in the PFAS class, which is very diverse. PFAS can be sorted in many ways based on their structure”.

Individual PFAS had already been banned, but ECHA reports that global manufacturers have started to replace certain PFAS with other PFAS or with fluorine-free substances over the past decades: “This trend has been driven by the fact that scientists and governments around the world first recognised the harmful effects of some PFAS (particularly long-chain PFAS) on human health and the environment. As the focus shifted to other PFAS, these have also been found to have properties of concern” says the agency. This is why such a comprehensive restriction is being discussed.

“Forever chemicals”

Together with 15 European partner media reporters, the so called Forever Pollution Project located more than 17,000 sites across Europe with relevant PFAS pollution, including just over 2,000 hotspots with significant human health risks.

Some PFAS are very effective at resisting heat, stains, grease and water and they are used in high tonnages in a variety of applications. The majority of PFAS are persistent in the environment.

According to ECHA, “Some PFAS are known to persist in the environment longer than any other synthetic substance. As a consequence of

this persistence, as long as PFAS continue to be released to the environment, humans and other species will be exposed to ever greater concentrations. Even if all releases of PFAS would cease tomorrow, they would continue to be present in the environment, and humans, for generations to come”.

PFAS tend to pollute groundwater and drinking water. Certain PFAS are known to accumulate in people, animals and plants and cause toxic effects. Certain PFAS are toxic for reproduction and can harm the development of foetuses. Several PFAS may cause cancer in humans. Some PFAS are also suspected of interfering with the human endocrine (hormonal) system.

According to ECHA the expected mean PFAS tonnage in the European Economic Area (EEA) is 49 million tonnes, leading to emissions of about 4.5 million tonnes during the manufacture and use phase when no action is taken. The overall annual health costs following from exposure to PFAS in Europe has been estimated in a Nordic Council report from 2019 to be between €52 and €84 billion.

Argumentation

The proposal states that: “Different regulatory risk management options have been considered, e.g. CLH and authorisation, but these options follow a substance by substance approach. In contrast, a restriction offers the possibility to define a broad chemical scope, thereby avoiding regrettable substitution of one PFAS by another PFAS (which may not even be engineered yet). […] A restriction can cover a wide range of uses and can address the risks arising from the manufacture and use of the substances as such as well as in other substances, in mixtures and in articles, including imported articles from outside the EU. Hence, a restriction is the most appropriate and effective option to adequately control such a large and complex group of substances which are used in numerous applications.

The chemical scope of the restriction proposal is defined as: any substance that contains at least one fully fluorinated methyl (CF3-) or methylene (-CF2-) carbon atom (without any H/Cl/Br/I attached to it). There are however a few exceptions.”

Current situation

In January 2023, Denmark, Germany, the Netherlands, Norway and Sweden submitted to ECHA a proposal for restriction on the manufacture, placing on the market and use of around 10.000 PFAS.

Two restriction options (ROs) have been assessed. A full ban with no derogations and a transition period of 18 months (RO1), and a full ban with use-specific time-limited derogations (18 month transition period plus either a five or 12 year derogation period).

As specific information on costs of a ban of PFAS for the different actors associated with the addressed uses was scarce and mainly qualitative, the derogations and their duration were mainly based on the availability and applicability of alternatives to PFAS.

RO2 also includes a few time-unlimited, more general derogations, e.g. for PFAS used as active substances in Plant Protection Products (PPP),

MAFO 3-23 20 SPOTLIGHT

Biocidal Products (BP) and human and veterinary Medicinal Products (MP) but there is no general derogation for medical devices. Besides the proposed derogations, the dossier submitters also identified uses for which a derogation could be warranted, but for which the evidence base is weak. These uses are between brackets, which indicates that additional information is needed and should be provided during the third party consultation of the restriction proposal to substantiate a derogation.

Only if substantial evidence is provided, the dossier submitters can assess this and consider whether a derogation is warranted. For the time being, uses between brackets should be read as ‘no derogation’.

Impact on the ophthalmic industry

The potential derogation covers fluoropolymer coatings on ophthalmic lenses and fluorinated monomers used in the polymer matrix of rigid gas permeable contact lenses.

According to Euromcontact: “An internal survey ran by Euromcontact showed that 3 PFAS are used to manufacture RGP contact lenses (HFPM, TFEM, BHI), for which there is currently no alternative. The dossier submitters identified uses for which a derogation could be warranted, but for which the evidence base is still weak. Among them: fluoropolymers and perfluoropolyethers for the use in rigid gas permeable contact lenses. Additional information is needed and should be provided during the consultation of the restriction proposal (March - September 2023) to substantiate a derogation. Only if substantial evidence is provided, the dossier submitters can reconsider whether a derogation is warranted or not.”

Next steps

▶ January 2023: Restriction proposal submitted to ECHA

▶ 22. March 2023: Start of a six month open consultation. The European Chemicals Agency invites interested parties to send in scientific and technical information on the manufacture, placing on the market and use of per- and polyfluoroalkyl substances (PFAS)

▶ 25. September 2023: Open consultation closes.

ECHA’s scientific committees for Risk Assessment (RAC) and for Socio-Economic Analysis (SEAC) will use the consultation input to evaluate the proposed restriction and to form an opinion on it.

▶ Opinions of ECHAs committees sent to the European Commission

Some questions remain unanswered

So there is still a long way to go before all questions can be answered. For example:

▶ Which products will finally end up with exemptions?

▶ Is it legitimate to ban all PFAS without a proper demonstration that each and all of them present an unacceptable risk?

▶ How to ensure that production and associated environmental problems do not simply shift to other countries?

▶ What about the competitive disadvantage for the European industry compared to other continents? ◆

www.eyoto.com sales@eyoto.com Quality assurance, the final inspection. BOOK A DEMO MK002307 Advertisement

SPOTLIGHT

Consumer sentiment and market data in Europe

An interview with Roland Lorek of Growth from Knowledge (GfK)

Things have become unsettled in Europe. Material shortages, the war in Ukraine and the energy crisis have changed Europe but also consumer sentiment. MAFO has talked to Roland Lorek, Market Analyst and Consultant Optics from the market research institute GfK, about how the circumstances are affecting the ophthalmic market in Europe.

By Hanna Diewald

Of particular interest to certain countries

Ophthalmic Optics in Numbers MAFO 3-23 22 BUSINESS

Mr. Lorek, in Europe, the days of long lockdowns and similar restrictions are over for now. How does that affect the European ophthalmic optics market?

The pandemic is now (hopefully finally) over and the markets had already recovered after 2021 and reached or even exceeded their respective pre-corona levels of 2019 again. Now, unfortunately, with the war in Ukraine, related concerns about e.g. gas supply, and especially with the current inflation in Europe, new dark clouds have appeared in the economic environment of the markets.

How does this affect consumer behavior?

What we recognized during the corona pandemic is that consumers in different countries were actually more inclined to shop at the smaller independent optics, rather than the larger chain stores or the chain stores in the city centers, out of fear of the virus. Prices were

not a big problem as the European states gave out financial compensations for Corona losses and customers could save many from other spendings they used to make (e.g. tourism, dining etc).

These two conditions are changing now. The pandemic is over. That means people are no longer afraid of the virus. So now they can go back to the city centers, to the chain stores.

At the same time, consumers have less money in their wallets due to inflation. The mood is gloomier, fewer new things are being purchased.

How does inflation change shopping behavior?

People have less money in their pockets in real terms, they are insecure and try to keep their money together. That will probably mean that within the different types of stores that we have in the markets – independent opticians and chain stores –, we will probably see people become more price sensitive after all and go for lower priced products if necessary.

Ophthalmic Optics in Numbers BUSINESS

Rolan d Lorek

What trends, particularly in the area of spectacle lenses, can be seen from the current figures?

In terms of the type of correction, the European market has shown little change in recent years, although an increase in the proportion of progressive lenses is to be expected here in the medium to long term due to demographic developments. Manufacturers are increasingly offering myopia management solutions for the very young customer groups. Although large quantities are not yet being sold here, the growth rates are considerable.

Almost every major lens manufacturer now offers a lens for myopia control, so we will see to what extent this type of lens develops over the next few years. In terms of refractive indices, the trend toward higher refractive indices in conjunction with thinner lenses is currently continuing.

How have sales developed in terms of ophthalmic lenses?

In terms of spectacle lenses, sales in 2022 in the EU4 countries (DE, ES, IT, FR) grew by about 2% vs 2021, which is nominally about 9% above the pre-crisis level of 2019. Now, taking into account some inflation in the Eurozone, we can say that the markets have recovered well from the corona impact.

Personally, I expect that in 2023, increased production costs and material costs will increasingly be passed on to buyers. To what extent additional sales growth in terms of volume is then possible in the current environment remains to be seen.

How did sales develop in terms of frames?

In terms of spectacle frames, we are nominally pretty much at the level of 2021 in the EU4 group. Especially if you mentally add inflation here, you can see that customers are already starting to reduce their spending, this will also influence the further development of spectacle lenses and frames.

How interested are consumers in buying eyewear online?

Here I have no data basis across Europe to make a general statement. In Germany, we have observed an increasing merging of sales channels across all product groups in recent years, with an increasing share of online sales. This certainly also applies to ophthalmic optics, especially for contact lenses, for example.

But for eyewear in general, the situation is more complicated than in other industries due to the difficulty of online refraction. Overall, we estimate the online share of eyewear sales in the low to mid single-digit percentage range, with a growing trend over the last few years.

In your opinion, are there currently disruptive technologies that could change the market completely? For example, smartglasses?

I am sure that over the next 5-10 years we will still be working with the familiar products, which will, however, continue to evolve in terms of segments. Orthokeratology contact lenses are innovative products, or spectacle lenses for myopia management, but such products do not change the market completely.

Smartglasses have been talked about for many years, and some companies are working on these products, but they have not yet fundamentally changed the market.

What development in the market has surprised you the most?

I found surprising how well the ophthalmic industry in Europe has adapted to the pandemic situation of the last three years. After the first corona quarters, I would not have believed that the markets would be able to return to their previous sales levels as early as 2021.

Thank you very much for the interview ◆

Ophthalmic

in Numbers SPECTACLELENSES Panelmarket RETAIL Jan23-Feb23 SALES EUR fix 4/2023 PRJ 65001 - RG 5906051 - RP 43612679 - ID 619540798 © GfK MONOFOCAL PROGRESSIVE Others Jan 19Dec 19 Jan 20Dec 20 Jan 21Dec 21 Jan 22Dec 22 Jan 19Dec 19 Jan 20Dec 20 Jan 21Dec 21 Jan 22Dec 22 Jan 19Dec 19 Jan 20Dec 20 Jan 21Dec 21 Jan 22Dec 22 Jan 19Dec 19 Jan 20Dec 20 Jan 21Dec 21 Jan 22Dec 22 BUYING GROUP/ INDEP. DE FR ES IT 5.3-3.615.1-0.8 1.0-8.314.66.3 8.6-13.321.1-5.4 9.0-9.220.20.7 +/- % PY 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 SALES EUR fix ( x 1,000,000,000 6% 66% 28% 6% 67% 27% 6% 67% 26% 6% 68% 26% 64% 33% 4% 63% 33% 4% 63% 33% 4% 64% 32% 59% 38% 58% 39% 58% 39% 59% 37% 43% 54% 44% 53% 45% 52% 46% 51%

Optics

MAFO 3-23 24 BUSINESS

Panelmarket retail for spectacle lenses. Sales in Euro fix. Source: GfK

From Brazil to Japan

The ophthalmic market in a nutshell

Spotlight on USA

The overall size of the optical retail market in 2022 is $76.5 billion, including eye exams, frames, spectacle lenses, contact lenses, plano sunglasses, and readers. Spectacle lenses led the market by value, followed by contact lenses and exams. Spectacle lenses made up nearly one-third of the market with a value of $23.6 billion. Overall, there are more than 48,000 brick and mortar optical retail locations in the United States.

Source: The Vision Council

As different as the culture can be in different countries, so is the ophthalmic market. In one country luxury frames are the sales driver, in the next contact lenses. MAFO has taken a closer look at the markets in different countries around the world. Here you will find a brief and concise overview of important key figures.

By Hanna Diewald

By Hanna Diewald

48,000 Ophthalmic Optics in Numbers

Advertisement

Therearemorethan48,000brickand mortaropticalretaillocationsintheUSA. There SPOTLIGHT

There

Spotlight on Brazil

Brazil theoretically has great market potential. Only 34 million people in Brazil use vision aids. The Abióptica association estimates that the eyesight of slightly half of the Brazilian population is impaired. However, so far only one third of those affected use glasses and other vision correction measures. Another third have never seen an ophthalmologist. The market is recovering only slowly from the corona crisis. Ophthalmic exams and treatments deferred in the pandemic still do not reach 2019 numbers, which is stifling the market's recovery. The low purchasing power of lower and middle income groups due to high inflation is doing the rest.

TheeyesightofslightlyhalfoftheBrazilian populationisimpaired,butonlyonethird ofthoseaffecteduseglasses.

Source: Spectaris / GTAI / Abióptica

Spotlight on Italy

Source: Spectaris / GTAI

Spotlight on Japan

marketforluxurysunandprescription frames. There

70%

Italy holds about 70% of the world market for luxury sun and prescription frames and the country also manufactures them under license from most international fashion labels. The main manufacturers are Luxottica, Safilo, De Rigo and Marcolin. Overall, Italy's ophthalmic optics market includes some 850 companies employing 18,000 people, according to ANFAO. In 2021, Italy produced ophthalmic optics products of about 4.2 billion euros, about 35% more than in 2020. More than 90% goes abroad. About 30% of the goods go to the USA.

2.6

In Japan, demand for ophthalmic optics will grow robustly in the coming years. The aging population and the intensive use of electronic devices from an early age provide the basis for this. Statista expects average annual sales growth of 5.5% overall in the period 2022-2025. Although the population is declining here, the average prices per pair of glasses and contact lenses are increasing significantly. Per capita spending on vision care was approximately US$ 56 in 2022 and is expected to increase to approximately US$ 66 by 2025. Contact lenses are the strongest single segment in Japan's ophthalmic optics market in terms of sales. Statista expects sales of around US$ 2.6 billion in 2022. Daily disposable lenses dominate the market with two-thirds. The largest market shares of contact lenses are held by Johnson&Johnson (30%) followed by the Japanese company Menicon and the Swiss company Alcon.

Source: Spectaris / GTAI

Spotlight on Thailand

Local production of eyeglass lenses is on the rise in Thailand. Thai stores sold US$ 457 million worth of ophthalmic optics in 2021. Sunglasses are the largest segment of the industry and tourists are an important customer group. However, Thailand also has the second oldest population in Southeast Asia. Eye diseases and low vision are very likely to increase, and the market is likely to grow.

Source: Spectaris / GTAI

Ophthalmic Optics in Numbers

⅓

Italyholdsabout70%oftheworld

Contactlensesarethestrongestsingle segmentinJapan.Statistaexpects salesofaroundUS$2.6billionin2022.

There 457 MAFO 3-23 26 SPOTLIGHT

ThaistoressoldUS$457million worthofophthalmicopticsin2021.

Largest US professionals gathering in recent years

Vision Expo East 2023

Who wants to know what is happening in the world of ophthalmic optics, travels to New York for Vision Expo East, where the industry meets. This year, the popular eyewear show celebrated a great success, as more visitors came to the show than at any other ophthalmic trade show in the USA in recent years..

MAFO 3-23 27 SPOTLIGHT

Vision Expo East 2023 concluded on Sunday, March 19, following four days of networking events, business meetings, education sessions and not to forget the chance to explore a very wide variety of products from frames, over spectacles, to machines at the booths. The show was held as usual at New York City’s Javits Center, this year from March 16–19. It was the largest gathering of ophthalmic professionals in the United States in recent years and the show was attended by thousands from the international vision care industry. Attendees included optometrists, opticians, contact lens professionals, allied ophthalmic professionals, optical assistants, office managers, frame buyers, lab technicians, students and other leaders in eyecare and eyewear. Vision Expo East featured 425 exhibiting companies this year, encompassing some of the biggest names in eyewear and eyecare. Attendees explored the industry’s top brands in seven unique exhibit neighborhoods. “The business conducted and ideas shared at Vision Expo East shape the future of this incredible industry,” said Mitch Barkley, Vice President of Trade Shows and Events at The Vision Council and co-organizer of Vision Expo. “We’re grateful to all our partners from across the sector who came together and made this show a success.”

Show highlights

In addition to the exhibit hall, industry professionals attended VisionEd – Vision Expo’s continuing education program – which included over 300 hours of sessions ranging from the latest business strategies and fashion trends to patient education tactics and cutting-edge innovations. Additionally, “OptiCon@Vision Expo” returned with an unmatched opticianry education program and exhibit hall experience.

Vision Expo East’s main stage destination “The Bridge” featured a diverse range of inspiring and educational events including a highly anticipated keynote presentation from Jason Romero, a legally blind ultra-runner, and an exclusive conversation with radio personality and author, Delilah.

Vision Expo West 2023

Vision Expo West 2023 will be held in Las Vegas from September 27–30, 2023. The Show’s educational program, together with OptiCon@Vision Expo, will open Wednesday, September 27, and the Exhibit Hall will open Thursday, September 28. Details on registration will be released in the coming months. ◆

MEI

Evochem

BPI

Jiangsu Maat Optical Lens

Ocuco

Filtertech

Entry area

MEI

Evochem

BPI

Jiangsu Maat Optical Lens

Ocuco

Filtertech

Entry area

MAFO 3-23 28 SPOTLIGHT

DAC Technologies

Advertisement

Schneider

Satisloh

Ultra Optics

A&R

ProCrea

General Optics

SPOTLIGHT

Horizons Optical Coburn Technologies

Discovering the misconceptions about progressive lenses

Study insights

Progressive lenses correct presbyopia and so they play a fundamental role in the optical industry. However, do presbyopes really wear progressive lenses? By

Ivette Bruguera

Studies show that 46%[1] of presbyopes in the world still do not use progressive lenses. Specifically, 58 million presbyopes in Europe use alternative solutions to progressive lenses. This statistically significant data confirms that there are different opinions on the part of presbyopes regarding the use of progressive lenses. So, are there misconceptions about progressive lenses?

Recorded opinions confirm that there are clear misconceptions about progressive lenses:

▶ Not wanting to wear PALs[2] yet because it is associated with aging.

▶ Fear of the difficulty of adapting to the new lenses.

▶ Not knowing how PALs work[2]

▶ Thinking it is an expensive product.

Study key findings

Faced with the need to break with all these misconceptions about progressive lenses, Horizons Optical has carried out a study at a European level focusing on five countries, both at user and ECP level, in order to find out first-hand the opinion of presbyopes who still do not wear progressive lenses.

First results confirm that presbyopes have adequate knowledge about age-associated visual conditions and visual solutions such as ophthalmic lenses. However, it is of vital importance for the 40% of presbyopes who do not use PALs[2] to have the appropriate visual solution for their visual needs.

Analyzing in detail the reason for this lack of use[3], these are the relevant statements from the study:

Ophthalmic Optics in Numbers

MAFO 3-23 30 SPOTLIGHT

▶ 11% of users do not use PALs[2] because of the price associated with them.

▶ 23% of users show concern about the difficulty of adapting to progressives.

▶ 33% are not very clear about how they work.

▶ 33% do not use them for other reasons, including wanting to wait to start using progressives.

All of this highlights the need on the part of ECPs to have educational sales tools that help them introduce presbyopes to the world of progressive lenses and thus improve the visual quality and life of these patients.

In this sense, Horizons Optical has presented this February during Mido tradeshow mimesys coach, a virtual simulator that allows the patient to experience the use of progressive lenses and appreciate the advantages of this type of lens, thus becoming a key element in the purchasing decision. ◆

From ECPs perspective, the study confirms that:

▶ They have 1.5 non-adaptations from new PAL users[2] per month.

▶ Progressive lenses are the third cause of non-adaptation. The centering of the lens is critical.

▶ Many patients do not fully understand what a progressive lens consists of and have high expectations.

Experts agree that progressive lenses are the best solution for almost all presbyope patients as the lenses offer better vision at all distances. However, data obtained confirms that there are misconceptions inherent to the progressive lenses that keeps a large group of presbyopes reluctant to start using this type of lens.

Ivette Bruguera is a Product Manager at Horizons Optical. With a degree in Optics and Optometry from the Polytechnic University of Catalonia and a master's degree in project management from the Management School of Madrid. She spent over four years as the lead of EMEA technical support, where she gained valuable experience

Ophthalmic Optics in Numbers

Ivette Bruguera

Reasons why users do not were PALs.

[1] Statista & National Library of Medicine. 2019 Online survey.

[2] PAL: Progressive addition lens

REDEFINING THE EDGE ULTRA PRECISION DIAMOND TOOLS ky diamond.ca • Diamond tools for any generator • Excellent service • Quick turnaround Advertisement SPOTLIGHT

[3] 2022. HO internal survey performed on n=126 users in Europe in 5 countries.

Setting priorities

Targeted and always one after another

You know the problem that the tasks grow over your head and you have the feeling that you are doing lots of things, but there is no land in sight. In order not to sink in the sea of many challenges, there is only one option: you have to set priorities. In doing so, you need to keep your goals in mind and incorporate them into a time management system. But self-discipline is also indispensable.

Do not let emotions rule

There are tasks that no one likes to do and therefore puts them on the back burner. This leads to such tasks ending up at the bottom of the priority list. Prioritization influenced by emotions in this way does not lead to success in the most effective way – in many cases it even leads to a dead end. That's why you should check at every step whether you were guided by facts or by emotions. Because ultimately, the time factor – which cannot usually be influenced – and your own free evaluation determine the prioritization. In addition, there are tasks that are completed as part of the daily routine without questioning their importance. When you tackle the topic of "working more effectively", you should first evaluate all recurring, unexamined tasks according to their importance.

The key factors

The prioritization of tasks is based on two key factors: time and money. This is relatively easy if the tasks can be freely planned and can be dispensed with without jeopardizing business operations (possibly for the time being).

It is difficult when a goal is set that is indispensable for the company. In this case, it must be clarified in advance whether

By Hartmut Fischer

the financial resources are available or whether the company can handle corresponding external financing. If this is not the case, savings potential must be sought elsewhere. Even if the task is of existential importance to your business, you should not put yourself under time pressure. Processes that are completed in a hurry almost always do not lead to the goal, but to unnecessary costs.

Agreeing on binding priorities

To get a project done by a group, you need to set binding priorities in a schedule. It is crucial for success that everyone adheres to this specification. You should therefore create a priority instruction that shows when certain work will start, be completed and who is responsible for it. Particularly in the case of longer processes, it is important that you regularly monitor compliance with the agreed deadlines.

MAFO 3-23 32 BUSINESS

Time and expertise

When you set priorities, it doesn't just mean setting a timeline. You also have to determine which employee has the necessary competence to solve the task delegated to him or her. If the employee is not able to complete the requirements placed on him or her in the desired time, it is not only your priority plan that will fail. It can quickly happen that the employee – who is otherwise so important for the company – is demotivated by the perceived "failure" and thus slackens altogether.

During a process, the basis on which the prioritization was made may change. For longer-term processes, you should therefore check at regular intervals whether the basis on which you set the priorities has changed and whether an adjustment of your prioritization is necessary.

Goal oriented

The priorities of a task are always based on the set goal. It is therefore important that you describe this goal in as much detail as possible. In most cases, the individual tasks that you need to prioritize already follow from this description.

At the top of the list are the tasks that play the biggest role in achieving the goals. If prerequisites are necessary for this that still have to be created, these naturally have priority. Often, one particularly important aspect is not sufficiently illuminated: feasibility. If it only becomes apparent during the ongoing process that the tasks are not feasible or represent too high a risk for operations, a lot of time and effort has been invested without the goal being achieved. This results in unnecessary costs that could have been avoided with a realistic implementation check.

Daily routine organized quickly

The first prioritization is the daily agenda. Here are the various tasks that need to be done independently, that are evaluated and timed. If possible, put all tasks to the test. Especially the daily recurring activities are often done "automatically" without evaluating them according to their importance or necessity.

For the evaluation of the daily routines one often uses the "ABC method". This involves determining what you will do yourself immediately (priority A), what can be done later or delegated (priority B) and what will definitely be delegated (priority C). Proceed according to the following scheme.

MAFO 3-23 33 BUSINESS

What you can delegate depends largely on the staff to whom you can delegate. The level of information of the individual employees plays at least as important a role as their skills. Therefore, consider whether it makes sense to hold regular meetings to exchange information. The better informed your employees are, the more you can delegate to your staff.

Prioritizing projects

Projects are also about the effective achievement of goals. However, an acquisition in itself does not represent a goal. The goal is, for example, to increase sales in a certain segment. In this context, an acquisition would be one way of achieving the goal. An alternative could also be, for example, the streamlining of processes (Lean Management).

Step 1: Goal description

Before you go to the actual prioritization, you should precisely define and determine the goal. Then check whether the financial and human resources are available to achieve the goal. If not, you need to weigh up whether the expected revenues justify additional investments or are justifiable for your business. Only if these prerequisites are given, you determine the details of the target scenario. To do this, note down all the work steps (without prioritizing).

Intermediate step: when several options present themselves

There are often cases where one wants to start projects with results that are "nice to have". That is why the first question in determining financial viability is whether there is an economic necessity. The long-term perspective must also be considered. Whether the boom for individual products or brands will continue in the next few years is an open question in the medium to long term. However, the fact that service will play an increasingly important role in the future – not least as a result of internet trading – is almost certain. Investments in staff training and development are likely to have a more positive impact on sales.

Step 2: Financial feasibility

Once you have decided on a project, you need to check whether it can be financed. In particular, when you need to borrow outside capital,

the question arises as to whether the planned course of action is sensible and, above all, purposeful (see intermediate step). If alternatives are available, compare them. In doing so, you should also bear in mind that it may make sense to cut back on the defined target if this means that the liquidity of your business can be protected.

Step 3: Chronological order

After you have clarified necessity and funding, you put the individual steps in chronological order. You start with the goal and then proceed backwards. Since you cannot yet foresee how long it will take to work through the entire process, mark the goal with 0 and calculate backwards in days: goal = 0, measure 10 = 0-3, measure 9 = measure 10-2, measure 8= measure 9-1, etc. would be an example.

The various steps of a project are linked to each other. One task can only be completed when another has already been completed. To create a structure, you therefore need to break down the individual tasks as much as possible to create the flow. However, you do not have to go into the last detail if the task is delegated as a block. For example, if a room is to be expanded and an adjoining room has to be painted for this purpose, you specify by when a decision must be made as to which painter will do it and by when he must have completed the work.

To complete the timeline prioritization, ask yourself the following questions about each task:

▶ Is the task absolutely necessary to achieve the goal? If not, mark this task so that you can perhaps postpone it in favor of a more important task or do without it.

▶ Where does the task need to be placed in the timeline?

▶ If this section is occupied in the timeline, check whether the tasks can be processed in parallel in the time period. If this is not possible, the measure that contributes most to achieving the goal has priority.

In this way, you work through measure by measure until you have developed the optimum sequence. Since the sequence is often changed, you should preferably create the list in a spreadsheet program (e.g. Excel). ◆

TASK IMPORTANT TASK URGENT TASK URGENT? PRIORITY A: IMMEDIATELY, DO IT YOURSELF PRIORITY B: TAKE CARE OF LATER, DELEGATE PRIORITY C: DELEGATE YES YES NO NO NO A-B-C-METHOD

Hartmut Fischer

MAFO 3-23 34 BUSINESS

Hartmut Fischer has been a freelance journalist for the past 13 years, specializing in SMEs and retail issues. As a coach, he also advises companies on communication issues.

HARD COATING AT BEST PURE TECHNOLOGY

CDS 1000

The fully automated CDS 1000 is the most reliable hard coating machine. Producing up to 160 lenses/h, it is a perfect fit for medium and large size labs. It features six cleaning tanks and offers continuous and fast processing without any batching. Varnishing takes place by thermal polymerization. An automatic refill system provides consistent and stable process control - keeping detergent and varnish tanks at the same level and condition. A unique water cascading and filtrating system enables city water savings up to 75%, making the CDS 1000 an environmentally-friendly coater.

Technique. Safety. Expertise. www.scl-intl.com HARD COAT LEADER HARD COAT CLEAning TinTing PERiPHERALs ExPERTisE