7 minute read

PROMOFS

Materials for smarter sensing technologies

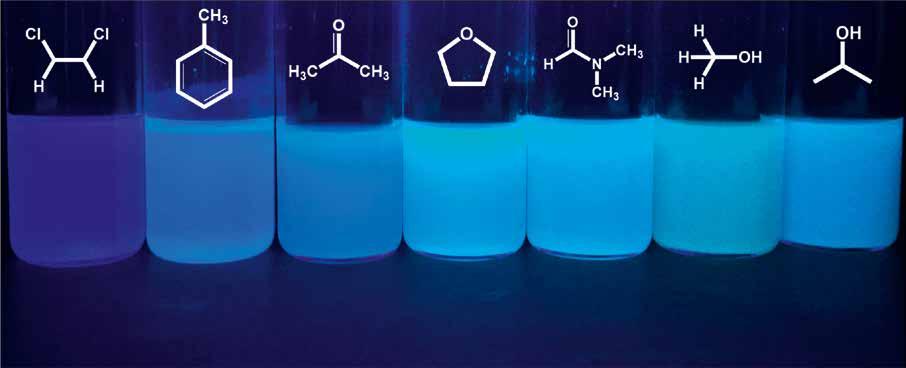

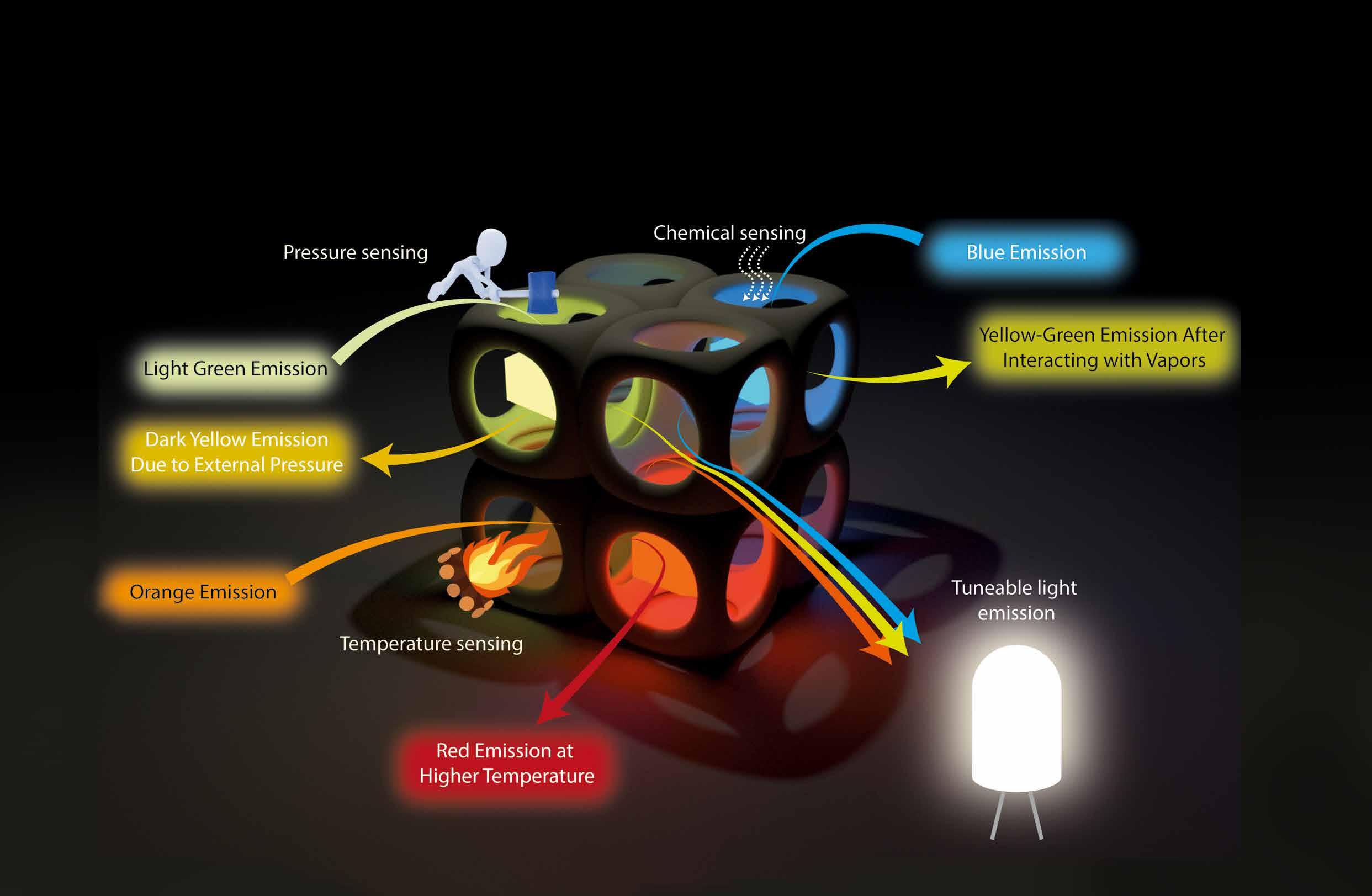

Multifunctional photonic sensing capabilities of the luminescent Guest@MOF material engineered for detection of different physical and chemical stimuli. (Graphics by Dr Abhijeet Chaudhari)

Metal-organic framework (MOF) materials hold rich potential with respect to the development of smart sensing technologies, as they can be tuned and adapted to detect different stimuli. We spoke to Professor Jin-Chong Tan about the work of the PROMOFS project in discovering and characterising new MOFs, research which holds wider relevance to several areas of industry.

The materials currently used to develop photonic sensors have some significant limitations, because they cannot offer high selectivity, low detection limit, fast response time, and low-cost fabrication all at once. Based at the University of Oxford in the UK, Professor Jin-Chong Tan is the Principal Investigator of the PROMOFS project, an ERC-funded initiative which aims to overcome these shortcomings. “We are developing noninvasive sensors based on luminescence, so they can be used to detect physical and chemical perturbations,” he outlines. This could be small changes in temperature or pressure for example, with researchers looking at materials capable of detecting very low concentration of chemicals especially volatile organic compounds (VOCs). “This is at the level of parts per million (ppm), or even parts per billion (ppb). There are highend techniques which can do that, but they are expensive and they are not portable,” continues Professor Tan.

Metal-organic frameworks

This forms the wider backdrop to the PROMOFS project’s research, with Professor Tan and his team working with metal-organic frameworks (MOFs), inspired to a degree by a class of naturally-occurring materials called zeolites. While these materials have a similar crystallinity and porosity structure as MOFs, they are not as tunable, so researchers in the project are designing new MOFs. “We are designing new materials. We have a novel family of ‘OX’-type MOF materials here at Oxford that we are developing, and we are targeting certain sensing applications,” says Professor Tan. These materials are engineered to overcome the limitations associated with traditional sensing materials. “The materials we are developing have high sensitivity combined with improved selectivity. Unlike the conventional resistive sensors, our sensing materials exhibit a significantly faster response time under ambient conditions,” explains Professor Tan.

Researchers are working to develop composites of these MOFs, with a view to using their porosity to confine a functional guest molecule, which is encapsulated within the cavity of the MOF. “This typically is a luminescent complex, a molecule that emits light. So, if you shine UV light at it, it can convert that particular wavelength into visible light, a colour. We can then use the variation in emission colour or intensity as a means of detecting physical or chemical stimuli,” explains Professor Tan. “We are building prototype sensors out of these MOF composites, in the form of low cost thin-film devices for example.”

The MOF effectively acts as a host, housing the luminescent guest, with Professor Tan and his team investigating different combinations and the unique photophysical properties that host-guest interactions lead to. There are two main components to MOFs; the metal nodes, which act like joints, and the organic linkers which act as bridges, and together they form the periodic framework. “We can design different combinations of the host and guest in a composite

assembly to enable different types of sensing. Furthermore we are developing new ways for shaping these sensing materials to create different morphologies, such as 1D fibres, 2D coatings, and 3D printed objects, so that they can be deployed in different ways,” outlines Professor Tan.

This opens up a wide range of possible applications, including many in chemical sensing, yet a deeper characterisation of these materials is essential before they can be widely applied. This is an issue that Professor Tan is addressing in the project. “A range of techniques are available to characterise crystalline materials, to verify that they have the right kind of crystal structure and functional properties. We use X-ray diffraction, infrared spectroscopy, nanoindentation, and fluorescence spectroscopy for example,” he explains. Sophisticated techniques are also applied to look at the vibrational behaviour of these systems using high-resolution synchrotron and neutron sources. “So we can study how the host framework – the MOF – interacts with the luminescent guest, that is encapsulated in the cavity,” says Professor Tan. “That helps us to understand how these systems behave when they are empty, and when they are subject to different analytes.”

Applications

The wider aim of the project is to apply these MOFs, with researchers seeking to harness their advantages over traditional materials in the development of photonics sensors for practical applications. A number of applications have been identified, including in the biomedical sector, for example to diagnose and monitor patients with diabetes. “A major challenge here is to detect small quantities of acetone in the human breath, which is a non-invasive biomarker for diabetes. We are really looking at parts per million concentration, or even less than that, making it hard to detect,” outlines Professor Tan. Another application is in force sensing, for enabling the detection of a mechanical response. “Strain or deformation of the MOF framework can cause changes in the light emission behaviour of the material. So we can calibrate this response to give a read-out of the stress distribution experienced by the sensor,” says Professor Tan.

A wide variety of other possibilities have been identified beyond these specific examples, and Professor Tan is keen to explore the potential of this technology in terms of real-world applications. This could be a type of portable, low-cost sensor, capable of detecting toxic VOCs or for monitoring changes in temperature,

If you shine UV light at a luminescent MOF with sensing capabilities, it can convert that particular wavelength into visible light, a colour. We can then use the variation in emission colour or intensity as a means of detecting physical or chemical stimuli.

pressure or pH for example, which could play an important role in many different areas. “There is huge scope out there. There are potential applications in the medical healthcare sector, environmental monitoring, food safety, civil security, just to give a few examples,” says Professor Tan. Together with his team at the University, Professor Tan has developed a series of new materials and composite systems targeting these sensing applications, and several patents have been filed. “We are looking at how to exploit these materials,” he continues.

This will run alongside continued investigations into new MOFs, with researchers seeking to discover further examples with intriguing new properties. While the first stage in the project involves looking at MOFs for single functions, Professor Tan says the next step is to build multi-functional sensors. “It may be that a particular MOF may be good at detecting acetone, while another might be good for detecting humidity. Thus it will be exciting to combine different MOFs in tandem, to achieve multi-functional devices,” he outlines.

PROMOFS Nanoengineering and Processing of Metal-Organic Framework Composites for Photonic Sensors

Project Objectives

The PROMOFS project lies in the field of nanoporous materials engineering, focusing on the discovery, characterisation and application of metal-organic frameworks (MOFs) as an innovative platform for disruptive photonics sensing technology. The nanoscale pores of MOFs enable confinement of light-emitting molecules, to accomplish unconventional Guest@MOF photoluminescent composite systems.

Project Funding

ERC Consolidator Grant (Project ID: 771575) EU contribution: € 2 431 911 (2018-2023)

Contact Details

Professor Jin-Chong Tan Multifunctional Materials & Composites (MMC) Laboratory, Department of Engineering Science, University of Oxford, Parks Road, Oxford OX1 3PJ, United Kingdom. T: +44 1865 273925 E: jin-chong.tan@eng.ox.ac.uk W: www2.eng.ox.ac.uk/tan

A.K. Chaudhari and J.C. Tan, “Dual-Guest Functionalised ZIF-8 Framework for 3D Printing White Light-Emitting Composites”, Advanced Optical Materials, 8, 1901912 (2020) -https://doi.org/10.1002/adom.201901912 M. Gutiérrez, C. Martín, M. Van der Auweraer, J. Hofkens, and J.C. Tan, “Optoelectronic Materials Based on Gaq3@ ZIF-8 Metal-Organic Framework Composites for SolidState Lighting”, Advanced Optical Materials, 2000670 (2020). https://doi.org/10.1002/adom.202000670 A.K. Chaudhari, B.E. Souza, and J.C. Tan, “Electrochromic Thin Films of Zn-based MOF-74 Nanocrystals Facilely Grown on Flexible Conducting Substrates at Room Temperature”, APL Materials, 7, 081101 (2019). https://doi.org/10.1063/1.5108948

Professor Jin-Chong Tan

Professor Jin-Chong Tan heads the Multifunctional Materials & Composites Laboratory (MMC Lab) in the Department of Engineering Science at the University of Oxford. His research group focuses on porous framework materials, polymer composites, and hybrid thin films for advanced functional and structural applications.