Cementitious and specialist boards

British Gypsum®

26

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26

BMDW4832 PAGE 26 BMDW5.5-50-3 PAGE 38 BMDW4832 PAGE 26

BMDW4832 PAGE 26 BMDW5.5-50-3 PAGE 38 BMDW4832 PAGE 26

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 Renderflex®

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26

BMDW4832 PAGE 26 BMWD4.8-38-3

*Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation.

14 FIXING FINDER 15 *

8.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 10.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 16.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 18.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 20.0 WHX32 PAGE 25 TSTF5.5-50-3 PAGE 37 WHX42 PAGE 25 24.0 WHX32 PAGE 25 TSTF5.5-50-3 PAGE 37 WHX42 PAGE 25 6.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 6.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE WHX42 PAGE 25 15.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 6.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 6.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 15.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16

Benx® and RCM®

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE

BMDW4832 PAGE

BMWD4.8-38-3

Cemboard® Multipurpose®

Siltech®

26

26

PAGE 38 BMDW4832 PAGE

Y-Wall®

PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMDW5.5-62-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMDW5.5-62-3 PAGE 38 BMDW4832 PAGE 26 12.5 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 15.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16

H®

Rigidur

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 4.5 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 10.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 16.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 18.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 20.0 WHX32 PAGE 25 TSTF5.5-50-3 PAGE 37 WHX60 PAGE 25 24.0 WHX32 PAGE 25 TSTF5.5-50-3 PAGE 37 WHX60 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 3.2 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 6.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 8.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 10.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 WS Extreme® WS Basic® Cembrit® Cempanel® BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMDW5.5-62-3 PAGE 38 BMDW4870 PAGE 26 BMDW4832 PAGE 26 BMDW5.5-62-3 PAGE 38 BMDW4870 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 PB® HD® Multi Force® N/A Internal Purpose Board CEMENTITIOUS AND SPECIALIST BOARDS *

Fermacell® and James Hardie® Specialist interior boards

Fermacell® and James Hardie® Cementitious and specialist boards

16 FIXING FINDER 17 * 12.5 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 CWAS45 PAGE 34 15.0 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 CWAS45 PAGE 34 10.0 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 CWAS45 PAGE 34 12.0 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 CWAS45 PAGE 34 15.0 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 CWAS45 PAGE 34 12.0 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 CWAS45 PAGE 34 10.0 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.5 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 6.0 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.5 DWSDE32 PAGE 27 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 LaDura® Duripanel®

Securtex® BMDW4842 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4842 PAGE 26 BMDW4842 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4842 PAGE 26 BMDW4842 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4842 PAGE 26 BMDW4842 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4842 PAGE 26 Hydropanel® Bluclad® W. Defence® DURASTEEL® 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 8.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 10.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 16.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 18.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 20.0 WHX32 PAGE 25 TSTF5.5-50-3 PAGE 37 WHX60 PAGE 25 22.0 WHX32 PAGE 25 TSTF5.5-50-3 PAGE 37 WHX60 PAGE 25 24.0 WHX32 PAGE 25 TSTF5.5-50-3 PAGE 37 WHX60 PAGE 25 28.0 WHX32 PAGE 25 TSTF5.5-62-3 PAGE 37 WHX60 PAGE2 5 36.0 WHX32 PAGE 25 TSTF5.5-62-3 PAGE 37 WHX80 PAGE 25 ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16

Versapanel®

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD5.5-62-3 PAGE 26 BMDW4850 PAGE 26 BMDW4832 PAGE 26 BMWD5.5-62-3 PAGE 26 BMDW4850 PAGE 26 BMDW4832 PAGE 26 BMWD5.5-62-3 PAGE 26 BMDW4850 PAGE 26 BMDW4832 PAGE 26 BMWD5.5-62-3 PAGE 26 BMDW4870 PAGE 26 BMDW4832 PAGE 26 BMWD5.5-62-3 PAGE 26 BMDW4870 PAGE 26 10.0 F35 PAGE 28 DWSDZ25 PAGE 22 DWSC32 PAGE 24 12.5 F35 PAGE 28 DWSDZ25 PAGE 22 DWSC38 PAGE 24 15.0 F35 PAGE 28 DWSDZ38 PAGE 22 DWSC42 PAGE 24 18.0 F45 PAGE 28 DWSDZ45 PAGE 22 DWSC50 PAGE 24 6.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 ≥ 0.5 ≤ 1.0 ≥ 1.0 ≤ 2.5 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 1.0 ≥ 1.0 ≤ 2.5 ≥ C16 Fermacell® HardieBacker®

ETEX®, Promat® and Siniat®

Versaroc®

Euroform®

12.5 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 8.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 8.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 PowerPanel® HardiePlank®

HardiePanel® Windbreaker® BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.5 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE25 ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Cem-Rock® eXtreme® Greenspan® BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 N/A Internal Purpose Board N/A Internal Purpose Board CEMENTITIOUS AND SPECIALIST BOARDS * *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation.

Not For Encasement

TSTF5.573-7 PAGE 36

TSTF5.573-7 PAGE 36

TSTF5.573-7 PAGE 36

TSTF5.573-7 PAGE 36

TSTF5.573-7 PAGE 36

N/A

25

Resistant Building Products® Specialist interior boards ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLI CATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16

WHX42 PAGE 25

WHX42 PAGE 25

WHX42 PAGE 25

WHX42 PAGE 25

WHX42 PAGE 25

WHX60 PAGE 25

WHX60 PAGE 25

WHX42 PAGE 25

WHX42 PAGE 25

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE38 BMDW4832 PAGE 26 N/A Internal Purpose Board WHX42 PAGE 25 WHX42 PAGE 25 WHX42 PAGE 25 WHX42 PAGE

BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 Base Board® 20-20® 6.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16

Multi-proXS® Multi-Rend®

Not For Encasement CEMENTITIOUS AND SPECIALIST BOARDS *

18 FIXING FINDER 19 * 6.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 8.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 9.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 10.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 12.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 15.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 18.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 6.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 9.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 12.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 9.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 12.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 15.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 18.0 WHX32 PAGE 25 TSTF4.838-3 PAGE 37 20.0 WHX32 PAGE 25 TSTF5.550-3 PAGE 37 25.0 WHX32 PAGE 25 TSTF5.550-3 PAGE 37

DWSDE32 PAGE 27 TSTF4.838-3 PAGE 37 9.0 DWSDE32 PAGE 27 TSTF4.838-3 PAGE 37 ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ 4.0 ≤ 18.0 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 2.5 ≥ 1.2 ≤ 4.0 ≥ C16 WeatherKem® MultiKem®

Fire® FireKem® BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMDW5.5-50-3 PAGE 26 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMDW5.5-50-3 PAGE 26 BMDW4832 PAGE 26 Impact® BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-38-3 PAGE 38 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMWD4.8-50-3 PAGE 38 BMDW4850 PAGE 26 BMDW4832 PAGE 26 BMDW5.5-50-3 PAGE 26 BMDW4850 PAGE 26 BMDW4832 PAGE 26 BMDW5.5-38-3 PAGE 26 BMDW4832 PAGE 26 BMDW4832 PAGE 26 BMDW5.5-38-3 PAGE 26 BMDW4832 PAGE 26 6.0 EVUCD35 PAGE 29 DWSDZ25 PAGE 22 EVUCD35 PAGE 29 9.0 CWAS45 PAGE 34 CWASD45 PAGE 34 CWAS45 PAGE 34 12.0 CWAS45 PAGE 34 CWASD45 PAGE 34 CWAS45 PAGE 34 ≥ 0.5 ≤ 1.0 ≥ 1.0 ≤ 2.5 ≥ C16 Steel (mm) Timber INTERNAL APPLICATION EXTERNAL APPLICATION BRAND THICKNESS (mm) Steel (mm) Timber ≥ 0.5 ≤ 1.0 ≥ 1.0 ≤ 2.5 ≥ C16

6.0

Kemwell

Multi-pro® BMDW4842 PAGE 26 BMDW4842 PAGE BMDW4842 PAGE 26 BMDW4842 PAGE BMDW4842 PAGE 26 BMDW4842 PAGE 26 BMDW4842 PAGE BMDW4842 PAGE 26 BMDW4842 PAGE 26 6.5 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 10.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 9.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25 12.0 WHX32 PAGE 25 TSTF4.8-38-3 PAGE 37 WHX42 PAGE 25

WHX42 PAGE

WHX42

WHX42 PAGE

Resistant Building Products® Cementitious and specialist boards

Construction® STS®

25

PAGE 25

25 WHX42 PAGE

25

WHX42 PAGE 25

TSTF5.593-7 PAGE 36

N/A

*Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation.

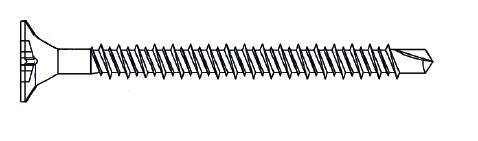

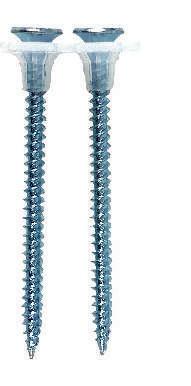

Fine Thread Drywall Screws(Zinc)

Designed For: Fixing plasterboard to metal stud up to 1.0mm Bugle

Head Style: Bugle Drive: Phillips 2 Drill Point: Sharp point

AISI C1022 Coating: Electro plated zinc

Material: Carbon steel Thread Form: Twin thread, fine

Product Range

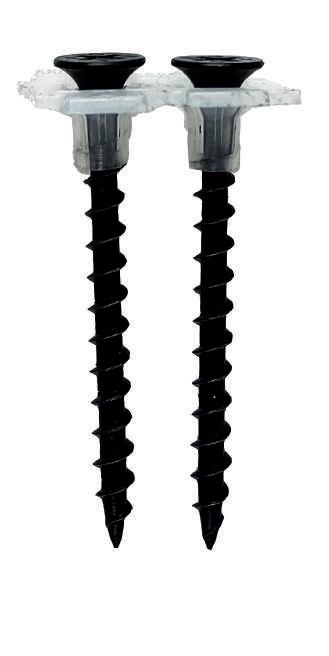

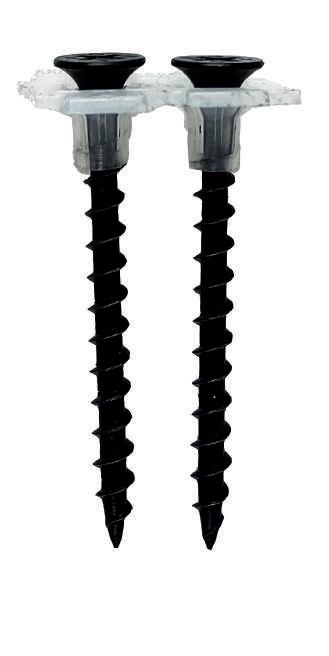

Fine Thread Drywall Screw (Black Phosphate)

Product Range

Designed For: Fixing plasterboard to metal stud up to 1.0mm

Head Style: Bugle

Drive: Phillips 2

Drill Point: Sharp point

Material Grade: AISI C1018

Coating: Black phosphate

Shank Material: Carbon steel

Thread Form: Twin thread, fine

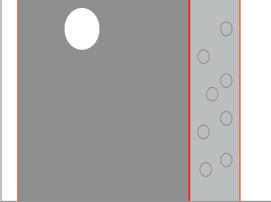

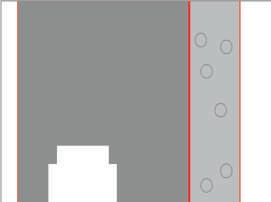

Metal

Steel Thickness

Metal Track Plasterboard

Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100 sales@evolutionfasteners.co.uk www.evolutionfasteners.co.uk 20 21 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation.

*

DRYWALL DRYWALL

CODE SIZE MAX BOARD THICKNESS BOX DWSZ25 3.5 x 25.0 mm 15 mm 1,000 DWSZ32 3.5 x 32.0 mm 22 mm 1,000 DWSZ38 3.5 x 38.0 mm 28 mm 1,000 DWSZ42 3.5 x 42.0 mm 32 mm 1,000 DWSZ50 3.5 x 50.0 mm 40 mm 1,000 DWSZ65 4.2 x 65.0 mm 55 mm 500 DWSZ75 4.2 x 75.0 mm 65 mm 500 DWSZ90 4.2 x 90.0 mm 80 mm 500 DWSZ100 4.2 x 100.0 mm 90 mm 500 DWSZ125 4.8 x 125.0 mm 115 mm 250 DWSZ150 4.8 x 150.0 mm 140 mm 200 Diameter Surface Hardness Core Hardness 3.5mm 710.0HV 480.0HV 4.2mm 630.0HV 460.0HV 4.8mm 670.0HV 470.0HV Hardness Rating (Vickers scale) Diameter Tensile Strength Shear Strength 3.5mm 6.1kN 4.5kN 4.2mm 7.3kN 4.9kN 4.8mm 11.0kN 7.3kN Ultimate mechanical performance

Point 3.5mm Super sharp point 4.2mm Super sharp point 4.8mm Super sharp point Ultimate pull out values 0.6mm 1.0mm 1.2mm 0.8kN 1.9kN 2.1kN 0.9kN 1.8kN 2.2kN 0.9kN 2.2kN 2.6kN Steel Thickness

Material Grade:

Shank

Diameter

Track Plasterboard Technical Data

Data Diameter Surface Hardness Core Hardness 3.5mm 540.0HV 480.0HV 4.2mm 620.0HV 450.0HV 4.8mm 590.0HV 460.0HV

Rating (Vickers scale) Diameter Tensile Strength Shear Strength 3.5mm 6.5kN 4.4kN 4.2mm 8.1kN 5.1kN 4.8mm 12.3kN 7.0kN

Diameter Point 3.5mm Super sharp point 4.2mm Super sharp point 4.8mm Super sharp point Ultimate pull out values 0.6mm 1.0mm 1.2mm 0.8kN 1.6kN 2.0kN 0.9kN 2.1kN 2.4kN 1.0kN 2.1kN 2.6kN

Technical

Hardness

Ultimate mechanical performance

CODE SIZE BOX DWSP25 3.5 x 25.0 mm 1,000 DWSP32 3.5 x 32.0 mm 1,000 DWSP35 3.5 x 35.0 mm 1,000 DWSP38 3.5 x 38.0 mm 1,000 DWSP42 3.5 x 42.0 mm 1,000 DWSP45 3.5 x 45.0 mm 1,000 DWSP50 3.5 x 50.0 mm 1,000 DWSP55 3.5 x 55.0 mm 1,000 DWSP65 4.2 x 65.0 mm 500 DWSP75 4.2 x 75.0 mm 500 DWSP100 4.2 x 100.0 mm 500 DWSP3935 3.9 x 35.0 mm 1,000 DWSP3945 3.9 x 45.0 mm 1,000 DWSP3955 3.9 x 55.0 mm 1,000

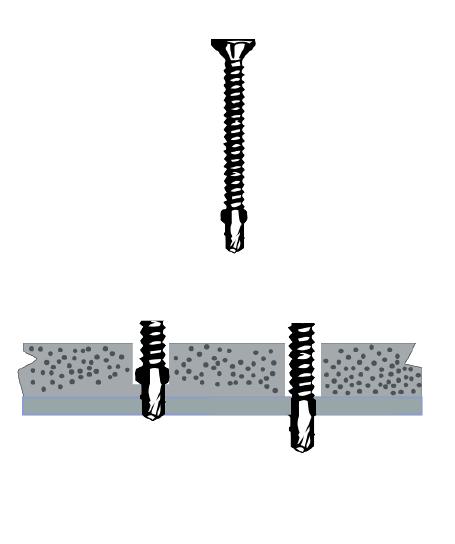

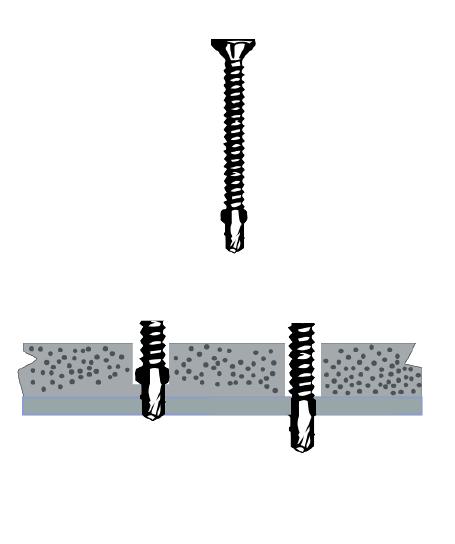

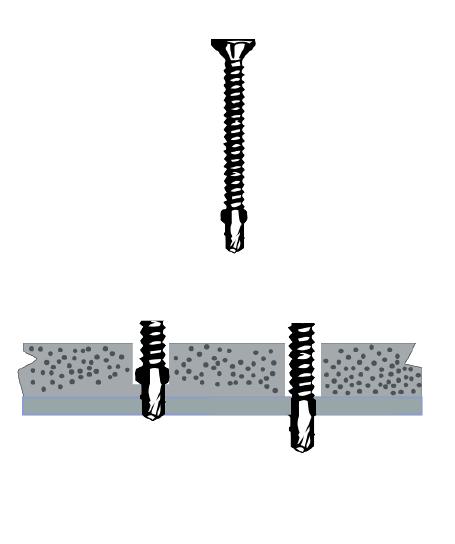

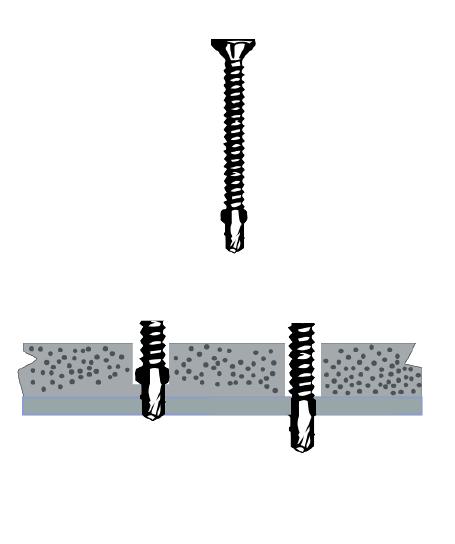

Bugle Head Self-Drill Drywall Screws

Zinc Coating

Designed For: Fixing plasterboard to heavier gauge metal section (up to 2.5mm)

Head Style: Bugle

Drive: Phillips 2

Drill Point: Self drill point

Material Grade: AISI C1022

Coating: Electro plated zinc or Black Phosphate

Shank Material: Carbon steel

Thread Form: Twin

Product Range

Wafer & Pan Head Self-Drill Drywall Screws

Product Range

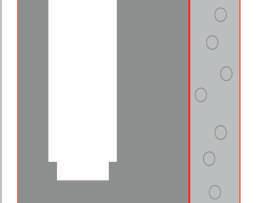

The assembly of drywall track and ceiling track systems

Ultimate pull out values (metallic substrate)

Metal Track Plasterboard

Technical Data

Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100

22 23 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

sales@evolutionfasteners.co.uk www.evolutionfasteners.co.uk

DRYWALL DRYWALL

Black Phosphate

Technical Data Diameter Surface Hardness Core Hardness 3.5mm 620.0HV 470.0HV 4.2mm 630.0HV 460.0HV 4.8mm 610.0HV 480.0HV

Rating (Vickers scale) Diameter Tensile Strength Shear Strength 3.5mm 7.3kN 5.0kN 4.2mm 11.0kN 7.5kN 4.8mm 14.2kN 9.8kN Ultimate mechanical performance Diameter Point 3.5mm Self drill point 4.2mm Self drill point 4.8mm Self drill point 1.2mm 1.6mm 1.5kN 2.0kN 4.0kN 1.7kN 2.2kN 4.5kN 1.8kN 2.2kN 4.8kN Steel Thickness Diameter Point 3.5mm Self drill point 4.2mm Self drill point 4.8mm Self drill point Ultimate pull out values (timber substrate) 15.0mm 27.0mm 0.9kN 1.6kN 1.1kN 1.8kN 1.5kN 3.0kN Embedment Depth

Hardness

CODE SIZE MAX BOARD THICKNESS BOX COAT DWSDZ25 3.5 x 25.0 mm 12 mm 1,000 Zinc DWSDZ32 3.5 x 32.0 mm 15 mm 1,000 Zinc DWSDZ38 3.5 x 38.0 mm 20 mm 1,000 Zinc DWSDZ42 3.5 x 42.0 mm 25 mm 1,000 Zinc DWSDZ50 3.5 x 50.0 mm 35 mm 1,000 Zinc DWSDZ65 4.2 x 65.0 mm 50 mm 500 Zinc DWSDZ75 4.2 x 75.0 mm 60 mm 500 Zinc DWSDZ90 4.2 x 90.0 mm 75 mm 500 Zinc DWSDZ100 4.2 x 100.0 mm 85 mm 500 Zinc DWSDZ125 4.8 x 125.0 mm 110 mm 250 Zinc DWSDP3525 3.5 x 25.0 mm 12 mm 1,000 PHOS DWSDP3535 3.5 x 35.0 mm 15 mm 1,000 PHOS DWSDP3545 3.5 x 45.0 mm 25 mm 1,000 PHOS DWSDP3555 3.5 x 55.0 mm 35 mm 1,000 PHOS

Pan Head Wafer Head Designed For:

Drive: Phillips 2

Grade:

C1022

Shank Material: Carbon steel Thread Form: Single Diameter Surface Hardness Core Hardness 4.2mm 600.0HV 450.0HV Hardness Rating (Vickers scale) Wafer Head

Material

AISI

Coating: Electroplated zinc

CODE SIZE WAFER HEAD PAN HEAD BOX WHDZ13* 4.2 x 13.0mm 1,000 WHSDZ12 4.2 x 12.0mm 1,000 WHSDZ19 4.2 x 19.0mm 1,000 WHSDZ25 4.2 x 25.0mm 1,000 WHSDZ50 4.2 x 50.0mm 500 WHDP13 4.2 x 13.0mm 1,000 WHSDP12 4.2 x 12.0mm 1,000 PHDZ12* 3.9 x 12mm 1,000 PHSDZ12 3.9 x 12mm 1,000 * Sharp Point Metal Track Metal Stud Diameter Tensile Strength Shear Strength 4.2mm 9.5kN 6.1kN Ultimate mechanical performance Diameter Drill Point 4.2mm Tek 2 Ultimate pull out values 1.2mm 1.8mm 2.5mm 1.6kN 2.2kN 4.2kN Steel Thickness Pan Head Diameter Surface Hardness Core Hardness 3.9mm 609.0HV 480.0HV Hardness Rating (Vickers scale) Diameter Shear Strength 3.9mm 8.57kN Ultimate mechanical performance

Coarse Thread Drywall Screw (Black Phosphate)

Product Range

Designed For: Fixing plasterboard to timber

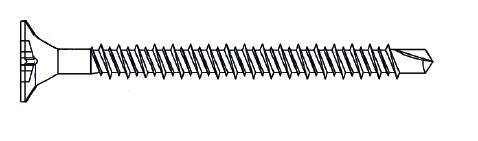

Cementitious Board Screws

Product Range

Designed For: Fixing cementitious and other dense boards to timber and metal substrates

Head Style: Double countersunk with nibs

Recess type: Phillips No. 2

Patent (pending)

Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100 sales@evolutionfasteners.co.uk www.evolutionfasteners.co.uk 24 25 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

DRYWALL DRYWALL

Head Style: Bugle Phillips

Drill Point: Sharp point Material Grade: AISI C1022 Coating: Black Phosphate Shank Material: Carbon steel Thread Form: Single DWSC25 3.5 x 25.0mm 0 - 9mm 1,000 DWSC32 3.5 x 32.0mm 0 - 12.5mm 1,000 DWSC35 3.5 x 35.0mm 0 - 15mm 1,000 DWSC38 3.5 x 38.0mm 0 - 15mm 1,000 DWSC42 3.5 x 42.0mm 0 - 18mm 1,000 DWSC50 3.5 x 50.0mm 0 - 25mm 1,000 DWSC65 4.2 x 65.0mm 0 - 40mm 500 DWSC75 4.2 x 75.0mm 0 - 50mm 500 DWSC90 4.8 x 90.0mm 40 - 65mm 500 DWSC100 4.8 x 100.0mm 50 - 75mm 500 DWSC110 4.8 x 110.0mm 65 - 85mm 200 DWSC120 4.8 x 120.0 mm 75 - 95mm 200 DWSC130 4.8 x 130.0 mm 85 – 105mm 200 DWSC150 4.8 x 150.0 mm 95 - 125mm 200 DWSC170 4.8 x 170.0 mm 115 – 145mm 200 DWSC3925 3.9 x 25 mm 0 - 9mm 1,000 DWSC3935 3.9 x 35 mm 0 - 15mm 1,000 DWSC3945 3.9 x 45 mm 0 - 20mm 1,000 CODE SIZE MAX BOARD THICKNESS BOX DWSC3955 3.9 x 55 mm 0 - 30mm 1,000 Parameter Value Material Yield Strength 606.30 N/mm2 Ultimate Tensile Strength 8.4 kN Ultimate Shear Strength 7.2 kN Surface Hardness 625.0 HV 1.0 Core Hardness 450.0 HV 1.0 Mechanical Properties 15mm 25mm 1.2 kN 2.8 kN Pull Out Resistance (C16 Timber) Embedment Depth Drive: Technical Data

2

Evolution

Thread

Material Grade:

Coating:

EvoShield® Technical Data Diameter Surface Hardness Core Hardness 4.2mm 553.6HV 414.0HV Hardness Rating (Vickers scale) Diameter Tensile Strength Shear Strength 4.2mm 6.9kN 5.0kN Unfactored Mechanical Performance Diameter Drill Point 4.2mm Tek 2

1.2mm 1.8mm 2.5mm 1.6kN 1.9kN 3.8kN Steel Thickness Diameter 4.2mm Ultimate Pull Out Loads (kN) in C16 Timber 15mm 30mm 50mm 1.9 kN 2.7 kN 3.2 kN Embedment Depth

Thread Type:

Universal

Carbon steel

C1022

1,000Hr

Unfactored pull out values (metallic substrate)

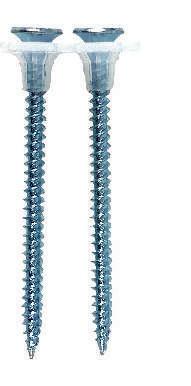

WHX32 4.2 x 32 mm 200 WHX42 4.2 x 42 mm 200 WHX60 4.2 x 60 mm 200 WHX80 4.2 x 80 mm 200 WHX100 4.2 x 100 mm 200 CODE SIZE EVOSHIELD COATING BOX WHL08114 4.2 x 32 mm 200 WHL08158 4.2 x 42 mm 200 Bi-metal tip for attaching board to wood stud or metal stud High and low thread for stable driving Large wafer head with ribs allows good countersink and clamps the board firmly

Ceramic Coated Cementitious Board Screw

Self-drilling Cementitious Board Screw

Designed For: Fixing cementitious and other dense boards to timber and metal substrates Head

Double countersunk with nibs

Patent (pending) Evolution

Product Range

Designed For: Fixing cementitious and other dense boards to timber and metal substrates

Head Style: Double countersunk with nibs

Recess type: Phillips No. 2 Thread Type: Patent (pending) Evolution

Product Range

1,000Hr EvoShield®

Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100

26 27 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

sales@evolutionfasteners.co.uk www.evolutionfasteners.co.uk

DRYWALL DRYWALL

Style:

Recess

Thread Type:

Universal Thread Carbon steel Material Grade: A2 /

Bi-metal BMDW4832 4.8 x 32 mm 200 BMDW4842 4.8 x 42 mm 200 BMDW4850 4.8 x 50 mm 200 BMDW4870 4.8 x 70 mm 200 CODE SIZE BOX BI-METAL Major Diameter 4.8 mm Ultimate Pull Out Loadings (kN) 0.70 1.00 1.20 1.50 2.00 2.50 1.10 kN 1.20 kN 1.60 kN 1.80 kN 2.20 kN 3.60 kN Steel Thickness (mm) Steel Substrates (S275 JR Mild Steel) Timber Substrates Major Diameter 4.8 mm Timber Grade Embedment Depth (mm) Load (kN) C16 (soft wood) 27.0 35.0 2.60 3.00 Masonry Substrates Major Diameter 4.8 mm Masonry Grade Embedment Depth (mm) Load (kN) 7N Aerated Concrete (Breeze Block) 35.0 0.8

type: Phillips No. 2

Carbon Steel/

Technical Data

Universal Thread Carbon steel Material Grade:

Coating:

DWSDE32 4.2 x 32 mm 1,000 10,000 DWSDE42 4.2 x 42 mm 500 5,000 CODE SIZE BOX CARTON EVOSHIELD

C1022

Technical Data Diameter Surface Hardness Core Hardness 4.2mm 553.6HV 414.0HV Hardness Rating (Vickers scale) Diameter Tensile Strength Shear Strength 4.2mm 6.9kN 5.0kN Unfactored Mechanical Performance Diameter Drill Point 4.2mm Tek 2 Unfactored pull out values (metallic substrate) 1.2mm 1.8mm 2.5mm 1.6kN 1.9kN 3.8kN Steel Thickness Diameter 4.2mm Ultimate Pull Out Loads (kN) in C16 Timber 15mm 30mm 50mm 1.9 kN 2.7 kN 3.2 kN Embedment Depth Bi-metal tip for attaching board to wood stud or metal stud High and low thread for stable driving Large wafer head with ribs allows good countersink and clamps the board firmly

Tough Board Screws

Designed For: Fixing dense and hard surfaced boards to both drywall track/ timber base materials

Head Style: Countersunk with 4 nibs

Drive Bit: Phillips No. 2

Drill Point: Sharp point

Material Grade: SAE C1022 Carbon Steel

Coating: Black phosphate

Shank material: Carbon steel

Effective thread

Product Range

Under Cutting Drywall

Designed For: Fixing plasterboards with thick paper fascia to metal studs (0.5mm to 1.0mm) or timber

Head Style: Undercutting ring

Drive Bit: Phillips No. 2

Drill Point: Sharp point

Material Grade: SAE C1022 carbon steel (hardened min. 55HRC)

Coating: 5µm manganese phosphate

Shank material: Carbon steel

Thread form: Fine (twin starting)

Product Range

Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100

28 29 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

sales@evolutionfasteners.co.uk www.evolutionfasteners.co.uk

DRYWALL DRYWALL

DWSFCP3919 3.9 x 19.0 mm 1,000 F35 3.9 x 35.0 mm 1,000 F45 3.9 x 45.0 mm 1,000 F55 3.9 x 55.0 mm 1,000 CODE SIZE BOX Diameter Surface Hardness Core Hardness 3.9mm 600.0HV 460.0HV Hardness Rating (Vickers scale) Diameter 3.9mm Ultimate pull out values (steel section) 0.6mm 1.0mm 1.2mm 0.8kN 1.9kN 2.2kN Steel Thickness Diameter 3.9mm Ultimate Pull Out Values (Timber) 15mm 0.8 kN Embedment Depth Technical Data

legth: Fully threaded

Technical Data Notional Diameter 3.9mm Withdrawal Resistance: Ultimate Loads in Steel Substrates (kN) 0.5mm 0.7mm 1.0mm 1.2mm 0.80 1.10 1.60 1.80 Steel Thickness Notional Diameter 3.9mm Withdrawal Resistance: Safe Working Loads in Steel Substrates (kN) 0.5mm 0.7mm 1.0mm 1.2mm 0.33 0.46 0.53 0.60 Steel Thickness Notional Diameter Embedment Depth (mm) Timber Grade Ultimate Load (kN) Safe Working Load (kN) 3.9mm 15.0 (min) C16 2.2 0.73 Withdrawal Resistance: Timber Substrates (kN) Ultimate Tensile Strength Ultimate Shear Strength Surface Hardness Core Hardness 6.50 kN 2.20 kN 535.5 HV 0.3 449.4 HV 0.3 Mechanical Properties No. Samples Coating Type Coating Type Observation(s) 5 Manganese Phosphate 72 No white or red rusting Corrosion Resistance

EVUCD35 3.9 x 35.0 mm 1,000 EVUCD45 3.9 x 45.0 mm 500 CODE SIZE BOX

Fine Thread Collated Drywall Screws (Zinc)

Designed For: Fixing plasterboard to metal studs of 0.5mm - 1.0mm

Bugle Phillips 2 Sharp

Product Range

Fine Thread Collated Drywall Screws (Black Phosphate)

Designed For: Fixing plasterboard to metal studs of 0.5mm - 1.0mm

Style: Bugle

Bit: Phillips 2

Point: Sharp

Grade: AISI C1022

Black Phosphate

Shank material: Carbon Steel

Thread form: Twin

Effective thread length: Fully threaded

OUR 2020 BI-METAL AND STAINLESS STEEL SCREW FASTENER GUIDE ALSO AVAILABLE NOW

Technical Data

Email: sales@evolutionfasteners.co.uk

Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100

30 31 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

sales@evolutionfasteners.co.uk www.evolutionfasteners.co.uk

DRYWALL DRYWALL

Material Grade:

C1022 Electroplates Zinc Shank material: Carbon Steel Thread form: Twin Effective

Fully threaded CDWFZ25 3.5 x 25 mm 15 mm 1,000 CDWFZ32 3.5 x 32 mm 22 mm 1,000 CDWFZ35 3.5 x 35 mm 25 mm 1,000 CDWFZ38 3.5 x 38 mm 28 mm 1,000 CDWFZ42 3.5 x 42 mm 32 mm 1,000 CODE SIZE MAX BOARD THICKNESS BOX CDWFZ45 3.5 x 45 mm 35 mm 1,000 CDWFZ50 3.5 x 50 mm 40 mm 1,000 CDWFZ55 3.5 x 55 mm 45 mm 1,000 CDWFZ75 4.2 x 75 mm 65 mm 500 Head Style: Drive Bit: Coating: Diameter Tensile Strength Shear Strength Torque 3.5mm 1.4kN 0.8kN 2.7Nm 4.2mm 1.6kN 0.9kN 2.9Nm Ultimate mechanical performance Diameter Surface Hardness 3.5mm 550HV 4.2mm 550HV Hardness Rating (Vickers scale)

AISI

thread length:

Drive

Drill

Material

Head

Coating:

Technical Data Diameter Tensile Strength Shear Strength Torque 3.5mm 1.4kN 0.8kN 2.7Nm 4.2mm 1.6kN 0.9kN 2.9Nm Ultimate mechanical performance Diameter Surface Hardness 3.5mm 550HV 4.2mm 550HV Hardness Rating (Vickers scale)

Range CDWFP25 3.5 x 25 mm 1,000 CDWFP32 3.5 x 32 mm 1,000 CDWFP35 3.5 x 35 mm 1,000 CDWFP42 3.5 x 42 mm 1,000 CDWFP45 3.5 x 45 mm 1,000 CODE SIZE BOX CDWFP50 3.5 x 50 mm 1,000 CDWFP55 3.5 x 55 mm 1,000 CDWFP3955 3.9 x 55 mm 1,000

Product

Sales and Customer Service Tel: +44 (0) 141 647 7100 Fax: +44 (0) 141 647 5100

* Coarse Thread Collated Drywall Screws (Black Phosphate)

Product Range

Designed For: Fixing plasterboard to timber

Style: Bugle Drive Bit: Phillips 2 Drill Point: Sharp point

Grade: AISI C1022

Black Phosphate

material: Carbon Steel

form: Single

Self-Drill Collated Drywall Screws

Designed For: Fixing plasterboard to heavier gauge drywall track (up to 2.5mm)

Head Style: Bugle

Drive Bit: Phillips 2

Drill Point: Tek 2

Material Grade: AISI C1022

Coating: Electroplated zinc / Black Phospate

Shank material: Carbon Steel

Fire Tested: Yes, to EN1364-1

Effective thread length: Fully threaded

Product Range

Technical Data

Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100

32 33 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation.

sales@evolutionfasteners.co.uk www.evolutionfasteners.co.uk

DRYWALL DRYWALL

Material

Shank

Thread

CODE SIZE BOX CDWCP25 3.5 x 25 mm 1,000 CDWCP32 3.5 x 32 mm 1,000 CDWCP35 3.5 x 35 mm 1,000 CDWCP38 3.5 x 38 mm 1,000 CDWCP42 3.5 x 42 mm 1,000 CDWCP45 3.5 x 45 mm 1,000 CDWCP50 3.5 x 50 mm 1,000 CDWCP55 3.5 x 55 mm 1,000 CDWCP65 4.2 x 65 mm 500 CDWCP75 4.2 x 75 mm 500 CDWCP3935 3.9 x 35 mm 1,000 Head Style: Diameter Tensile Strength Shear Strength Torque 3.5mm 1.4kN 0.8kN 2.7Nm 4.2mm 1.6kN 0.9kN 2.9Nm Ultimate mechanical performance Diameter Surface Hardness 3.5mm 550HV 4.2mm 550HV Hardness Rating (Vickers scale) Technical Data

Head

Coating:

0.6mm 1.2mm 1.8mm 2.0mm 0.5kN 1.4kN 1.9kN 2.7kN Ultimate pull out values Substrate thickness Diameter 3.5mm Diameter Tensile Strength Shear Strength 3.5mm 8.0kN 5.0kN Ultimate Mechanical Performance Surface hardness Core hardness 640.0HV 445.0HV Hardness Values

CODE SIZE BOX COATING CDWFDZ25 3.5 x 25.0mm 1,000 Zinc CDWFDZ35 3.5 x 35.0mm 1,000 Zinc CDWFDZ45 3.5 x 45.0mm 1,000 Zinc CDWFDZ50 3.5 x 50.0mm 1,000 Zinc CDWSDP3525 3.5 x 25.0mm 1,000 PHOS CDWSDP3535 3.5 x 35.0mm 1,000 PHOS CDWSDP3545 3.5 x 45.0mm 1,000 PHOS

Collated Exterior Board Screws

Designed For: Collated exterior drywall screws designed for exterior use

Head Style: Bugle Point Style: Sharp

Form: Fine Thread

Grade: SAE C1022 low carbon steel hardened min. 55 HRC)

1,000 hour Evolshield

Product Range

3.9 x 45.0mm Sharp 1,000

3.9 x 45.0mm Self-drilling 1,000

Collated Tough Board Screws

Designed For: Fixing dense and hard boards to track or timber substrates Head Style: Reduced cross section countersunk head with undercut nibs

Style: Phillips No. 2

Form: Twin hi-lo thread

Hardened carbon steel (AISI C1022)

Coating: Black phosphate (approx 48 hours NSST)

Product

FOR FURTHER ADVICE OR INFORMATION ON ANY OF OUR PRODUCTS OR TESTING, CONTACT OUR TECHNICAL DEPARTMENT ON

Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100

34 35 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

sales@evolutionfasteners.co.uk www.evolutionfasteners.co.uk

DRYWALL DRYWALL

Material

CWAS45

CWASD45

CODE SIZE POINT BOX Nominal

(mm) 3.9mm Withdrawal Resistance: Ultimate Loads in Steel Substrates (kN) 0.5mm 0.7mm 1.0mm 1.2mm 0.68kN 0.79kN 1.05kN 1.26kN Steel Thickness Pull through resistance: Ultimate loads in plasterboard substrate (kN) Nominal diameter (mm) Substrate Load (kN) 3.9 12.5mm standard plasterboard 0.6 Nominal diameter (mm) Surface (HV0.3) Core (HV0.3) 3.9mm 574.3 468.4 Hardness Rating (Vickers scale) Nominal diameter (mm) Shear strength (kN) Tensile strength (kN) 3.9mm 4.3 8.50 Ultimate mechanical performance Technical Data

Thread

Coating:

Diameter

Point

Thread

FastenerMaterial:

Technical Data Parameter Value Material Yield Strength 619.46 N/mm2 Ultimate Tensile Strength 7.4 kN Ultimate Shear Strength 12.0 kN Surface Hardness 600.0 HV 1.0 Core Hardness 460.0 HV 1.0 Mechanical Properties 0.5mm 0.7mm 1.0mm 0.68kN 0.79kN 1.05kN Steel Thickness Pull Out Resistance Timber Embedment 15.0mm 0.8 kN

CODE SIZE BOX CDWFCP3919 3.9 x 19.0 mm 1,000 CDWFCP3930 3.9 x 30.0 mm 1,000 CDWFCP3945 3.9 x 45.0 mm 1,000

Range

+44 (0)141 647 7100

* SuperTek® 7 Wing Drill

Timber Tek

Product Range

Designed For: When timber is being fastened to thicker steel section or where extremely hard steels defeat normal tek screws

Head Style: Double Countersunk

Drive: Torx® 30

Thread Form: 24 threads per inch fine thread, ‘V’ fluted

Drill Point: Tek 7 spiral point

Shank Material: Carbon steel

Material Grade: SAE C1022

Coating: 1000Hr EvoShield®

Recommended Drill Speed: 1,500 - 2,500 RPM

Product Range

Designed For: Fixing timber or composites to steel

Head Style: Countersunk ot countersunk with nibs Drive: Phillips® No. 2 or No. 3 Thread Form: Coarse thread (Tek 3)

Shank Material: Carbon steel

Material Grade: SAE C1022

Coating: 500Hr EvoShield®

Technical Data

Tek 3 range – Unfactored pull out values

Wing drill Tek 3 range - for light steel

Tek 7 range – Unfactored pull out values

5.5x180mm 155mm Wing drill Tek 4 rangefor medium gauge steel

drill Tek 5 range - for heavy steel

Unfactored pull out values

5.5x65mm 28mm

TSTF5.5-85-5 5.5x85mm 50mm

TSTF5.5-100-5 5.5x100mm 65mm TSTF5.5-110-5 5.5 x 110mm 75mm

TSTF5.5-135-5 5.5x135mm 100mm TSTF5.5-150-5 5.5x150mm 115mm TSTF5.5-180-5 5.5x180mm 145mm

36 37 WINGDRILL WINGDRILL Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100

www.evolutionfasteners.co.uk *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation.

sales@evolutionfasteners.co.uk

CODE SIZE BOX TSTF5.5-73-7 5.5 x 73mm 100 TSTF5.5-93-7 5.5 x 93mm 100 TSTF5.5-118-7 5.5 x 118mm 100 TSTF5.5-143-7 5.5 x 143mm 100 Diameter Surface Hardness Core Hardness 5.5mm 543.4 HV0.3 408.4 HV0.3 Hardness Rating (Vickers scale) Diameter Tensile Strength Shear Strength 5.5mm 10.3kN 6.9kN Ultimate Mechanical Performance

Diameter Drill point 5.5mm Tek 7 4.0mm 6.0mm 8.0mm 10.0mm 15.0mm 13.9kN 13.7kN 12.9kN 14.1kN 14.3kN Steel Thickness Head Threads Wings Point Winged Reamer

Data

Technical

Diameter Drill point 4.2mm Tek 3 4.8mm Tek 3 5.5mm Tek 3 1.2mm 1.6mm 2.0mm 2.5mm 3.0mm 4.0mm 1.0kN 1.2kN 1.9kN 3.5kN 3.9kN 4.8kN 1.1kN 1.5kN 2.5kN 3.6kN 3.9kN 4.4kN 1.2kN 2.3kN 3.0kN 4.0kN 4.6kN 5.7kN Steel Thickness

4 range – Unfactored pull out values Diameter Drill point 6.3mm Tek 4 2.5mm 3.0mm 4.0mm 5.0mm 6.0mm 4.1kN 4.7kN 5.9kN 6.4kN 7.2kN Steel Thickness

5 range

Diameter Drill point 5.5mm Tek 5 4.0mm 5.0mm 6.0mm 8.0mm 10.0mm 12.5mm 4.2kN 9.8kN 10.4kN 11.7kN 12.5kN 13.8kN

Tek

Tek

–

Steel Thickness

CODE SIZE EFFECTIVE THREAD LENGTH TSTF4.2-38-3 4.2x38mm 22mm TSTF4.8-38-3 4/8x38mm 22mm TSTF4.8-45-3 4.8x45mm 27mm TSTF5.5-50-3 5.5x50mm 30mm TSTF5.5-62-3 5.5x62mm 40mm TSTF5.5-80-3 5.5x80mm 60mm TSTF5.5-100-3 5.5x100mm 80mm TSTF5.5-120-3 5.5x120mm 100mm TSTF5.5-150-3 5.5x150mm

TSTF5.5-180-3

CODE

THREAD LENGTH TSTF6.3-60-4 6.3x60.0mm FULL TSTF6.3-85-4 6.3x85.0mm FULL Wing

CODE

THREAD LENGTH TSTF5.5-42-5 5.5x42mm 13mm TSTF5.5-65-5

130mm

SIZE EFFECTIVE

SIZE EFFECTIVE

Diameter Surface Hardness Core Hardness 4.2mm 582.6HV 477.8HV 4.8mm 570.0HV 474.1HV 5.5mm 592.1Hv 478.8HV 6.3mm 587.4 HV0.3 468.9 HV0.3 Hardness Rating (Vickers scale) Diameter Tensile Strength Shear Strength 4.2mm 10.4kN 5.2kN 4.8mm 12.4kN 6.4kN 5.5mm 20.1kN 10.3kN 6.3mm 22.7kN 15.2kN Ultimate Mechanical Performance Wings ream hole larger than threads so threads will not engage board. Wings break off when they hit steel, then threads engage to elevate board jacking

Bi-Metal Wing-Drill Tek Screw

Designed For: Fastening when stainless steel product is required, e.g. in aluminium sheeting and panels

Countersunk

Phillips® No. 2 or No. 3 or Torx® 25

Coarse thread (Tek 3)

Product Range

Bi-metal wing drill tek screw range – for light steel

AISI 304/ EN 1.4301 (A2) or AISI 316/ EN 1.4401 (A4)

Bi-metal wing drill tek screw range– for heavy steel

38 WINGDRILL Tel: +44 (0)141 647 7100 Fax: +44 (0)141 647 5100 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. * Head Threads Wings Point Winged Reamer

CODE SIZE EFFECTIVE THREAD LENGTH BMWD4.8-38-3 4.8x38mm 24.0mm BMWD5.5-50-3 5.5x50mm FULL BMWD5.5-62-3 5.5x62mm 40.0mm BMWD5.5-80-3 5.5x80mm 60.0mm BMWD5.5-100-3 5.5x100mm 60.0mm BMWD5.5-120-3 5.5x120mm 60.0mm

CODE SIZE EFFECTIVE THREAD LENGTH BMWD5.5-65-5 5.5x65mm FULL BMWD5.5-85-5 5.5x85mm 50.0mm BMWD5.5-110-5 5.5x110mm 50.0mm BMWD5.5-135-5 5.5x135mm 50.0mm

Diameter Surface Hardness Core Hardness 4.8mm 390.0HV 270.0HV 5.5mm 390.0HV 270.0HV Hardness Rating (Vickers scale) Diameter Tensile Strength Shear Strength 4.8mm 9.8kN 8.2kN 5.5mm 11.6kN 9.8kN Ultimate Mechanical Performance Diameter Substrate50mm timber 4.8mm 1.6kN 5.5mm 3.0kN Pullover Performance Tek 3 range – Unfactored pull out values Diameter Drill point 4.8mm Tek 3 5.5mm Tek 3 1.2mm 1.6mm 2.0mm 2.5mm 3.0mm 4.0mm 1.9kN 2.7kN 3.5kN 4.5kN 5.0kN 6.3kN 2.0kN 2.4kN 3.6kN 4.3kN 5.1kN 6.7kN Steel Thickness Tek 5 range – Unfactored pull out values Diameter Drill point 5.5mm Tek 5 4.0mm 5.0mm 6.0mm 8.0mm 10.0mm 12.5mm 4.5kN 5.9kN 7.3kN 8.9kN 10.7kN 11.9kN Steel Thickness

Head

Thread

Shank

Material Grade:

Recommended Drill Speed:

Technical Data

Style:

Drive:

Form:

Material: Stainless steel

1,500 - 2,500 RPM

Visit our website www.evolutionfasteners.co.uk for latest product information offers and Evolution news Sales and Customer Service sales@evolutionfasteners.co.uk Tel: +44 (0) 141 647 7100 Fax: +44 (0) 141 647 5100 Wings ream hole larger than threads so threads will not engage board. Wings break off when they hit steel, then threads engage to elevate board jacking

British Gypsum® is a subsidiary of Saint-Gobain S.A. and specialises in the manufacture of various products used in interior partitioning systems, inter alia.

Gyproc® is a brand name of British Gypsum®.

The British Gypsum® White Book® and Site Book® are good learning tools for anyone using British Gypsum® products.

More information on British Gypsum® products is available from their website, www.british-gyspum.com.

They can also be contacted by telephone call to +44 (0) 115 945 1000.

STANDARD PLASTERBOARDS

Gyproc® HandiBoard®

Gyproc® Plank®

Gyproc® WallBoard®

Gyproc® WallBoard 4TE®

Gyproc® WallBoard Duplex®

Gyproc® WallBoard Ten®

A range of standard plasterboards in smaller board sizes for easier handling over full-size boards. The intent is to allow easier fixing to 16” (approx. 406mm) and 24” (approx. 610mm) joist centres

A range of thick standard plasterboards intended to give an increased acoustic performance over that of normal thickness standard plasterboards.

A range of standard plasterboards intended to be a cost-effective solution for most interior drylining applications.

A range of standard plasterboards with four tapered edges intended for use in public spaces where surfaces are subject to strong, direct lighting.

A range of standard plasterboards with integral vapour control membrane for use where vapour control and a plasterboard lining are both necessary.

A range of standard plasterboards designed to meet the guidance stated in the Building Regulations Approved Document E (specifically that plasterboards have a minimum mass of 10kg/m2).

PERFORMANCE PLASTERBOARDS

Gyproc® Glasroc X® is a sheathing board designed to provide temporary weather protection for structural steel frame (SFS) constructions where the façade/ cladding system is connected back to the SFS.

Gyproc® Habito® is a high strength plasterboard for fixing heavy items to, such as radiators, shelves, TVs, etc.

Glasroc® F® including all derivatives of this board family (FireCase and MultiBoard), this is a class A1 non-combustible glass fibre reinforced gypsum board for fire case scenarios.

Glasroc® H® is a TileBacker® board designed for frequent exposure to moisture and as a base for the adhesion of tiling.

Gyproc® DuraLine® including all derivatives of this board family (standard and MR) is a moisture resistant core board for enhanced sound insulation and impact resistance.

Gyproc® FireLine® including all derivatives of this board family (standard, Duplex, MR and CoreBoard) is a fire-resistant glass fibre reinforced gypsum board for general use in partitions and ceilings.

Gyproc® SoundBloc® including all derivatives of this board family (standard, F, MR, Rapid and Rapid MR) is a high-density sound resistant gypsum plasterboard.

Knauf Gips KG® is a family-owned business based in Germany and specialises in the manufacture of various products used in interior partitioning systems, inter alia.

More information on Knauf® products is available from their website, www.knauf. co.uk.

They can also be contacted by telephone call to +44 (0) 800 030 4135.

Knauf® offers a selection of standard plasterboards, which includes (but is not limited to):

STANDARD PLASTERBOARDS

Wallboard® A range of standard plasterboards with an ivory paper face for use in the majority of internal partitions and dry lining applications.

Baseboard® A range of standard plasterboards with an ivory paper face that comes in smaller sizes than full-size boards for use on ceilings where a plaster finish is required.

Plank® A range of standard plasterboards with an ivory paper face that is a key component in many partition and floor systems where it acts as an acoustic mass layer.

Vapour Panel® A range of standard plasterboards that feature a metallised polyester foil laminate on the grey paper face to create an effective vapour barrier.

PERFORMANCE PLASTERBOARDS

Fire Panel® is a fire-resistant plasterboard for use as a cladding component in drylining partitions.

Sound Panel® is a high-density plasterboard for better acoustic performance over standard plasterboards.

Moisture Panel® is a moisture-resistant plasterboard for use in partially humid areas such as kitchens and bathrooms.

Impact Panel® is a heavy-duty plasterboard for use in applications where greater resistance to impacts is required.

STANDARD PLASTERBOARDS

GTEC® Standard Board® A range of standard plasterboards for most internal partition, lining and ceiling applications.

GTEC® Base Board® A range of lightweight standard plasterboards intended to be used as a base for skim finishes.

Siniat® is a subsidiary of ETEX Group S.A. and specialises in the manufacture of various products used in interior partitioning systems, inter alia. GTEC® is a brand name of Siniat®.

More information on Siniat® products is available from their website, www.siniat.co.uk.

They can also be contacted by telephone call to +44 (0) 127 537 7773

Siniat® offers a selection of standard plasterboards under their GTEC® brand, which includes (but is not limited to):

GTEC® Vapour Board® A range of standard plasterboards with an additional laminated vapour control layer.

GTEC® Contour Board® A range of standard plasterboards designed to be flexible and used in the construction of curved partitions.

GTEC® Plank® A range of standard plasterboards intended to act as an acoustic mass.

PERFORMANCE PLASTERBOARDS

GTEC® MultiPurpose® A range of performance plasterboards (calcium silicate based) intended for versatility in multiple usage scenarios.

GTEC® Universal® A range of performance plasterboards intended to combine impact resistance and acoustic performance.

GTEC® Moisture Board® A range of performance plasterboards intended for use in humid conditions such as in kitchens.

GTEC® Aqua Board® A range of performance plasterboards intended for use where water resistance is required such as kitchens and bathrooms.

GTEC® dB Board® A range of performance plasterboards intended to provide superior acoustic performance.

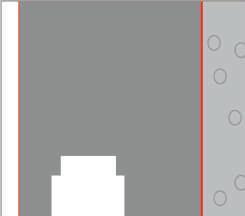

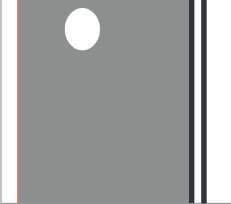

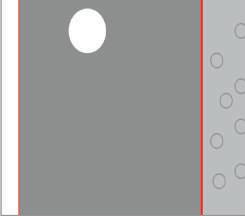

CEMENTITIOUS AND SPECIALIST BOARDS

PAGE 15

Gyproc® Rigidur H® including all derivatives of this board family (standard and Activ’Air®) is a gypsum-based fibre cement board for use in the GypWall Extreme® system. It offers superior mechanical strength and is intended for use in high traffic applications.

GTEC® Fire Board® including all derivatives of this board family (standard, Fire MR and Fire V) is a fire-resistant performance plasterboard.

GTEC® Megadeco® A range of pre-sealed performance plasterboards intended to offer combined fire, impact and acoustic performance.

TECHNICAL TECHNICAL 40 41 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

6

PAGE 6 PAGE 9

PAGE

PAGE 8

PAGE 7 PAGE 10

Georgia-Pacific® LLC is a subsidiary of Koch Industries Inc. and specialises in the manufacture of various products used in interior partitioning systems, inter alia.

More information on Georgia-Pacific® products is available from their website, www.gp.com.

They can also be contacted by telephone call to +00 (1) 800 225 6119.

Georgia-Pacific® offers a selection of performance plasterboards, which includes (but is not limited to):

PERFORMANCE PLASTERBOARDS

ToughRock® including all derivatives of this board family (standard, FireGuard 45®, FireGuard X® and FireGuard C®) is a fire-resistant plasterboard for use as a cladding component in drylining partitions offering 45 minutes of protection in fire scenarios.

DensShield® is a tough plasterboard designed for use as a tile backing board.

DensArmor® including all derivatives of this board family (standard, FireGuard and Plus) is a moisture-resistant and toughened plasterboard for demanding internal drylining applications.

CALCIUM SILICATE, MAGNESIUM OXIDE AND VERMICULITE BOARDS

DensDeck® including all derivatives of this board family (standard and Prime®) is a fire-resistant board with fiberglass reinforcement for roofing applications.

DensGlass® is a fire and moisture resistant sheathing board with fiberglass reinforcement.

RCM Ltd® is a subsidiary of Benx Ltd and specialises in the manufacture of various render carrier and sheathing board products used in interior partitioning systems, inter alia.

More information on RCM® products is available from their website, www.buildingboards.co.uk.

They can also be contacted by telephone call to +44 (0) 800 612 4662.

RCM® offers a selection of specialist boards under their various brands, which includes (but is not limited to):

CEMENTITIOUS AND SPECIALIST BOARDS

CEMBOARD® is a sheathing board designed to provide temporary weather protection for structural steel frame (SFS) constructions where the façade/ cladding system is connected back to the SFS.

Multipurpose® is a versatile cellulose fibre cement board offering excellent strength, weathering and acoustic properties.

Siltech® is a non-combustible, flexible calcium silicate board with offers superior workability.

Renderflex® is a high-performance cellulose fibre cement board, offering excellent strength, weathering and stability properties when used with polymer renders.

Y-Wall® is a flexible calcium silicate-based cement board for use as a fire rated sheathing board.

DensGlass® For fixing details of this board, refer to page 63.

CALCIUM

Promat® is a subsidiary of ETEX N.V. and specialises in the manufacture of various products used in interior and exterior systems, inter alia.

Masterboard® is a multi-purpose board suitable for a variety of applications and offers up to 30 mins fire resistance. It is intended for use in areas of high humidity such as swimming pools.

Supalux® is a fire protection board offering up to 240 minutes of fire protection while maintaining improved moisture resistance. It is intended for use in areas with high temperatures.

CALCIUM SILICATE, MAGNESIUM OXIDE AND VERMICULITE BOARDS

Euroform® is a subsidiary of SIG plc and specialises in the manufacture of various products used in interior and exterior systems, inter alia.

More information on Euroform® products is available from their website, www.euroform. co.uk.

They can also be contacted by telephone call to +44 (0) 192 586 0999.

Euroform® offers a selection of boards under their various brands, which includes (but is not limited to):

PAGE 11

Rendaboard® is a render carrier board designed for high-impact resistance, acoustic performance and score-and-snap workabi lity. This board is rated A1 non-combustible.

Versabacker® is a water resistant, mesh reinforced tile backer board.

Versafire® is a fire and moisture resistance board that also offers excellent impact resistance and acoustic performance.

Versaliner® including all derivatives of this board family (standard and SF) is a sheathing board intended to offer fire-resistance, impact resistance and racking resistance while maintaining snap-and-score workability.

PAGE 16

Versaroc® is an Ordinary Portland Cement (OPC) and inorganic fibre reinforced cementitious board for exterior sheathing of Structural Framing Systems (SFS) due to its high durability and non-combustibility.

Versapanel® including all derivatives of this board family (standard and A2) is a cement bonded particle board for use in dry, humid and exterior conditions. It is designed for resistance against rot, moisture and impact.

More information on Promat® products is available from their website, www.promat.co.uk. They can also be contacted by telephone call to +44 (0) 800 588 4444.

Promat® offers a selection of specialist boards, which includes (but is not limited to):

Vermiculux® is a fire protection board offering up to 240 minutes of fire protection designed specifically for encasement and fire protection of structural steel sections.

Promatect® including all derivatives of this board family (250®, L-500® and HD®) is a fire-resistant board for the protection of steelwork and mezzanines.

Promafour® is a fire protection board designed to resist temperatures up to 1,000°C for use specifically in chimneys and around fireplaces.

SQBoard® is a brand name of ScrewQuick Ltd. and specialises in the manufacture of chloride free magnesium oxide boards, inter alia.

More information on ScrewQuick® products is available from their website, www. sqboard.net.

They can also be contacted by telephone call to +44 (0) 330 053 9322

Promat® offers a selection of specialist boards, which includes (but is not limited to):

SQBoard® is a multi-purpose board suitable for a variety of internal and external applications. The boards are specified as non-combustible with good water and impact resistance.

TECHNICAL TECHNICAL 42 43 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

SILICATE, MAGNESIUM OXIDE AND VERMICULITE BOARDS

CALCIUM SILICATE, MAGNESIUM OXIDE AND VERMICULITE BOARDS

CEMENTITIOUS AND SPECIALIST BOARDS

PAGE 9 PAGE 11

PAGE 14

PAGE 12

PAGE 13

Cembrit® is a multinational company based in Denmark (with local offices around the globe) and specialises in the manufacture of roofing, cladding and building board products, inter alia.

More information on Cembrit® products is available from their website, www.cembrit.co.uk.

They can also be contacted by telephone call to +44 (0) 203 372 2300.

Cembrit® offers a selection of specialist boards, which includes (but is not limited to):

CEMENTITIOUS AND SPECIALIST BOARDS

Windstopper® Extreme® is a fibre cement board for use in external applications. It is designed to absorb and release moisture without negatively affecting the durability, strength or performance of the board.

Windstopper® Basic® is a fibre cement board for use in external applications. It is designed to have a low vapour transmission resistance which enables moisture to pass through from inside the building.

Cempanel® including all derivatives of this board family (standard & A2) is a fibre cement board for use in sheathing and general-purpose applications. It is noted to have good racking resistance and can be used for lining inside shipping containers.

PB® is a lightweight board designed to be easily cut and lifted. It is designed for external decorative rendering or used as an element within internal fire rated partition walls and ceilings.

HD® is an uncoated, untreated high-density building board/ cladding sheet for use in demanding climates. It is noted as durable, dimensionally stable and impact resistant.

Multi Force® is a cement board designed for use in internal partitions and dry lining applications due to its good impact resistance and acoustic insulation properties.

Fermacell® is a subsidiary of James Hardie® Europe GmbH and specialises in the manufacture of various products used in interior and exterior systems, inter alia.

More information on Fermacell® and James Hardie® products is available from their website, www.jameshardie.co.uk.

They can also be contacted by telephone call to +44 (0) 121 311 3480.

James Hardie® offers a selection of boards under their various brands, which includes (but is not limited to):

CEMENTITIOUS AND SPECIALIST BOARDS

Fermacell® is a multi-purpose building board for internal dry lining purposes.

HardieBacker® is a cement board that has no loose aggregates or fillers and is intended for use as a tile backerboard and is intended to be used in moisture sensitive areas like kitchens and bathrooms.

PowerPanel H2O® is an advanced water-resistant cement bonded board ideal for walls, floors and ceilings. It is also an ideal render carrier board and is designed for use in damp conditions.

HardiePlank® is a low maintenance weatherboard and is used for fibre cement cladding and texturing on residential buildings.

HardiePanel® is a cementitious board comprised of ordinary Portland cement, sand and cellulose fibres. It is intended for use in exterior cladding and façade applications.

HardieWindbreaker® is a cementitious board comprised of ordinary Portland cement, sand and cellulose fibres. It is intended for use in exterior sheathing applications as a weather defence board with high fire-resistance, water-tightness and structural racking strength.

Greenspan® is a company based in the Republic of Ireland and specialises in the manufacture of various products used in interior and exterior systems, inter alia.

More information on Greenspan® and products is available from their website, www.greenspan.ie.

CEMENTITIOUS AND SPECIALIST BOARDS

Cem-Rock® is a cement board that is intended for use in both interior and exterior applications.

Cem-Rock® eXtreme® is a cement board for use in applications where high racking, pull through and pull out strength is required. It can be used for interior or exterior applications.

ETEX® N.V. is a multinational company based in the Netherlands (with local offices around the globe) and specialises in the manufacture of roofing, cladding and building board products, inter alia.

ETEX® owns many well-known brands including Cedral®, Durlock®, Equitone®, Eternit®, Gyplac®, Kalsi®, Pladur®, Promat®, Siniat® and Superboard®.

For the purposes of this document, only specialist boards sold under the Promat® and Siniat® brands are considered.

More information on ETEX® products is available from their website, www.etexgroup.com. They can also be contacted by telephone call to +32 2778 1211.

ETEX® offers a selection of specialist boards, which includes (but is not limited to):

CEMENTITIOUS AND SPECIALIST BOARDS

LaDura® is a gypsum-based, wood-fibre reinforced fibreboard intended to have superior fire, moisture and impact resistance. It was designed for use in high-traffic area such as schools, hospitals and hotel corridors.

Duripanel® is a highly durable cement particle board for use in load bearing applications and as an alternative to chipboard or plywood and is intended for use in a variety of general-purpose applications.

Securtex® is a reinforced plasterboard for secure partition systems.

Hydropanel® is a cement fibre board for internal use in wall, ceiling and floor applications. It offers high levels of moisture, impact and acoustic resistance.

Bluclad® is a cement fibre board suitable for external sheathing, direct render and other textured finishes.

Weather Defence® is an external sheathing board, faced with water repellent material for superior weather protection.

DURASTEEL® is a steel faced blast resistant panel for high impact, fire and blast resisting applications.

They can also be contacted by telephone call to +353 (0) 698 2222.

Greenspan® offers a selection of boards under their various brands, which includes (but is not limited to):

CEMENTITIOUS AND SPECIALIST BOARDS

Kemwell Fire® International Ltd specialises in the manufacture of various fire-rated products used in interior and exterior systems, inter alia.

More information on Kemwell Fire® and products is available from their website, www.kemwell-fire. com.

They can also be contacted by telephone call to +44 (0) 121 285 3156.

Kemwell Fire® offers a selection of boards under their various brands, which includes (but is not limited to):

WeatherKem® is a specialist calcium silicate-based fibre cement board combining weather, moisture and fire resistance properties with high impact strength and sound insulation. It is primarily used as an external sheathing board on metal and timber framing systems.

MultiKem® MP-1000® is an easy to install, non-combustible calcium silicate building board combining fire, moisture and impact resistance with thermal insulation properties. It provides up to 120 minutes fire resistance.

FireKem® FP-900® is an easy to install, clean and lightweight, non-combustible calcium silicate fire protection building board. It has multi-purpose applications and is commonly used for commercial and industrial building projects.

Kemwell® Impact® is a non-combustible fire, blast and impact protection board and barrier system used for critical internal and external applications in the commercial, industrial, transport and energy sectors.

TECHNICAL TECHNICAL 44 45 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

PAGE

PAGE 17

15 PAGE 16

PAGE 17 PAGE 18

CEMENTITIOUS AND SPECIALIST BOARDS

Resistant Building Products® Ltd specialises in the manufacture of various fire-rated and moisture resistant products used in interior and exterior systems, inter alia.

More information on Resistant Building Products® and products is available from their website, www.resistant.co.uk. They can also be contacted by telephone call to +44 (0) 289 074 9400.

Resistant Building Products® offers a selection of boards under their various brands, which includes (but is not limited to):

PAGE 19

Multi-pro® is a versatile passive fire protection board.

Multi-proXS® is an extra strong magnesium oxide (MgO) board with extra embedded layers of reinforcing mesh to offer improved racking strength and offers good fire resistance properties.

Multi-Rend® is an external render carrier board with a heavily keyed surface to receive a wide range of finishes.

Base Board® is a building board intended for use as a s heathing or render carrier board. It is designed as an alternative to OSB or plywood boards in such applications.

20-20® is a fibre cement building board designed to be tough and durable with exceptional pull-out strength and A1 non-combustible fire rating.

CEMENTITIOUS AND SPECIALIST BOARDS

STS® Ltd specialises in the manufacture of various building board products used in interior and exterior systems, inter alia.

More information on STS® and products is available from their website, www.sts-uk. com.

They can also be contacted by telephone call to +44 (0) 113 202 2010.

STS® offers a selection of boards under their various brands, which includes (but is not limited to):

PAGE 19

Construction® is a heavy-duty fibre cement board with good fire protection properties for both internal and external applications. It is intended to be versatile and cover the following purposes: Fire protection board Render carrier board Tile backer board Ceiling board Cladding receiver board.

The board offers good performance in fire protection, water resistance and sound reduction.

TECHNICAL TECHNICAL 46 47 *Use of the National Accreditation Logo refers solely and only to tests performed and included on our Schedule of Accreditation. *

W WHILST WE HAVE TRIED TO INCLUDE AS MANY BOARD TYPES AS WE CAN, NOT ALL WILL BE FEATURED. IF YOU HAVE ANY QUESTIONS, PLEASE CONTACT OUR SALES AND TECHNICAL TEAM FOR FURTHER INFORMATION Tel: +44 (0) 141 647 7100 Fax: +44 (0) 141 647 5100 Email: sales@evolutionfasteners.co.uk

To support our various commercial and technical partners, as well as support specifiers and end users of our products, the Company provides testing services in our captive UKAS (United Kingdom Accreditation Service) accredited laboratory on system components or entire system mock-ups for the purposes of supporting the use of our products in conjunction with such a component or system by empirical

S SPECIFICATIONS AND LABORATORY SERVICES

Where applicable, we will always perform such empirical testing pursuant to tests included on our schedule of accreditation.

Where empirical tests fall out with the scope of our schedule of accreditation, we will always apply the provisions of our accredited ISO/ IEC 17025 quality management system to ensure that the results of such testing are validated. Our schedule of accreditation can be viewed on the UKAS website, www.ukas.com.

This service is generally provided on a pro gratis basis, contingent ultimately on the specification and use of the Companies’ products for the application.

The Company has significantly invested in creating a centre of excellence not only by purchasing research grade analytical equipment, but also in the creation of an exceptionally highly skilled multi-disciplinary team of civil, chemical, mechanical and structural engineers. The Company urges readers of this document to make use of our technical resources as they are generally provided on a pro gratis basis.

- Mechanical properties of fasteners and systems including tensile strength, compressive strength, material yield strength, shear strength, bending capacity, torque capacity, surface/ core hardness, depth of case hardening, etc

Mechanical interaction properties of fastener assemblies including withdrawal resistance, pry-out resistance, pull-through resistance, torque behaviour, delamination strength, lap-shearing/ block-tearing resistance, etc,

- Corrosion resistance properties of fasteners and fastener assemblies including neutral salt spray resistance, cyclic corrosion resistance, wetting and humidity resistance, coating thickness measurement, etc,

- Failure analysis techniques utilising light metallurgical microscopy or SEM (Scanning Electron Microscope) microscopy, high speed videography, metrology, etc,

Chemical composition and PMI (Positive Material Identification)utilising our extensive spectrometrysuite of XRF (X-Ray Fluorescence), FTIR (Fourier Transform Infrared), UV-Vis (Ultraviolet-visible) and OES (Optical Emission Spectrometry) spectrometry techniques.

If you want to discuss how we can support you using our extensive laboratory and technical capabilities, contact the Evolution Technical Team for further assistance by e-mail to technical@evolutionfasteners.co.uk or by telephone call to +44 (0) 141 647 7100.

48 49

The testing and analytical services we offer include, but are not limited to:

SPECIFICATIONS AND LABORATORY SERVICES SPECIFICATIONS AND LABORATORY SERVICES *Use of the National Accreditation

refers

and only to tests

and included on our Schedule of Accreditation. *

Logo

solely

performed

Fasteners

British Gypsum® STANDARD PLASTERBOARDS PERFORMANCE PLASTERBOARDS CEMENTITIOUS AND SPECIALIST BOARDS Knauf Gips KG® STANDARD PLASTERBOARDS PERFORMANCE PLASTERBOARDS Siniat® STANDARD PLASTERBOARDS PERFORMANCE PLASTERBOARDS Georgia-Pacific® PERFORMANCE PLASTERBOARDS CALCIUM SILICATE, MAGNESIUM OXIDE AND VERMICULITE BOARDS Euroform® CALCIUM SILICATE, MAGNESIUM OXIDE AND VERMICULITE BOARDS CEMENTITIOUS AND SPECIALIST BOARDS RCM Ltd® CEMENTITIOUS AND SPECIALIST BOARDS Promat® CALCIUM SILICATE, MAGNESIUM OXIDE AND VERMICULITE BOARDS SQBoard® CALCIUM SILICATE, MAGNESIUM OXIDE AND VERMICULITE BOARDS Cembrit® CEMENTITIOUS AND SPECIALIST BOARDS PAGE

40 40 40 40 41 41 41 41 41 41 42 42 42 42 42 42 43 43 43 43 43 43 44 44 ETEX® CEMENTITIOUS AND SPECIALIST BOARDS Fermacell® CEMENTITIOUS AND SPECIALIST BOARDS Greenspan® CEMENTITIOUS AND SPECIALIST BOARDS Kemwell Fire® CEMENTITIOUS AND SPECIALIST BOARDS Resistant Building Products® CEMENTITIOUS AND SPECIALIST BOARDS STS® CEMENTITIOUS AND SPECIALIST BOARDS 44 44 45 45 45 45 45 45 46 46 46 46 PAGE

INDEX Technical

BOARDS

BOARDS

DWSZ DWSP DWSDZ DWSDP WHDZ WHSDZ WHDP WHSDP PHDZ PHSDZ DWSC WHX WHL BMDW DWSDE DWSFCP 20 21 22 22 23 23 23 23 23 23 24 25 25 26 27 28 F EVUCD CDWFZ CDWFP CDWCP CDWFDZ CDWSDP CWAS CWASD CDWFCP TSTF (WING DRILL) TSTF (TIMBER TEK) BMWD 28 29 30 31 32 33 33 34 34 35 36 37 38 CODE CODE PAGE PAGE TECHNICAL FIXING FINDER 6 8 15 6 9 7 10 9 11 11 16 14 12 13 15 16 17 17 18 19 19 TECHNICAL FIXING FINDER 50 51

This document is wholly authored and published by Evolution Fasteners UK Ltd (herein referred to as “the company” or “Evolution®”.

This document is intended to be a training tool and educational in nature only. The contents of this document do not constitute any form of warranty or guarantee. The Company provides an industry leading warranty which is detailed in a separate document.

The use of this document does not alleviate, mitigate or otherwise change the legal obligations, or, statutory and regulatory burdens or undertakings of the reader apropos any law, statute, act, regulation, directive, standard, inter alia. This includes, but is not limited to the requirements under the Building Regulations and/ or the Construction (Design and Management) Regulations, amongst others.

The Company recommends that on every occasion, the reader of this document undertakes their own research and determination as to whether a product or products are suitable for their specific application. Readers of this document are implored to seek the advice of the third parties mentioned in this document on their components and inter-compatibility with other parties’ components.

Where references or citations are made, it is in the ‘Harvard Style’ pursuant to the guidance laid out by Imperial College London (Imperial College London, 2017).

ACKNOWLEDGEMENTS, LICENSES, TRADEMARKS AND COPYRIGHT

Unless otherwise noted or referenced: all information, text, illustrations and content herein remain the intellectual property of the Company.

Throughout this document, various third-party logos, brand names and trademarks are used under the fair dealings’ provisions of the Copyright, Designs and Patents Act 1988, herein referred to as “the 1988 Act”, specifically pursuant to Sections 29, 29A and 30 of the 1988 Act.

The use of such logos, brand names or trademarks is not intended to convey any commercial relationship, or otherwise, between the Company and the third party concerned.

The use of such logos, brand names or trademarks is solely intended to benefit and aid the reader in the initial visual recognition of such third party.

This document is strictly published and provided without prejudice, without recourse, non-assumptist, errors and omissions excepted, no assured value, no liability and all rights reserved.

The use of the UKAS logo and ILAC logo relates only to accredited tests pursuant to our schedule

of accreditation, tests out with our schedule are marked “NC”. For the most current version of our schedule please visit www.ukas.com.

TERMS AND CONDITIONS OF SALE

21.1 Without limiting its other rights or remedies, the Company may terminate this Contract with immediate effect by giving written notice to the Buyer if: (a) the Buyer commits a material breach of any term of the Contract and (if such a breach is remediable) fails to remedy that breach within days of that party being notified in writing to do so; (b) the Buyer takes any step or action in connection with its entering administration, provisional liquidation or any composition or arrangement with its creditors (other than in relation to a solvent restructuring), being wound up (whether voluntarily or by order of the court, unless for the purpose of a solvent restructuring), having receiver appointed to any of its assets or ceasing to carry on business or if the step or action is taken in another jurisdiction, in connection with any analogous procedure in the relevant jurisdiction; (c) the Buyer suspends, threatens to suspend, ceases or threatens to cease to carry on all or a substantial part of its business; or (d) the Buyer's financial position deteriorates to such an extent that in the Company's opinion the Buyer's capability to adequately fulfi its obligations under the Contract has been placed in jeopardy.

21.2 Without limiting its other rights or remedies, the Company may suspend provision of the Goods under the Contract or any other contract between the Buyer and the Company the Buyer becomes subject to any of the events listed in clause

21.1(a) to clause 21.1(d), or the Company reasonably believes that the Buyer is about to become subject to any of them, or the Buyer fails to pay any amount due under this Contract on the due date for payment.

21.3 Without limiting its other rights or remedies, the Company may terminate the Contract with immediate effect by giving written notice to the Buyer if the Buyer fails to pay any amount due under the Contract on the due date for payment.

21.4 On termination of the Contract for any reason the Buyer shall immediately pay to the Company all of the Company's outstanding unpaid invoices and interest.

21.5 Termination of the Contract shall not affect any of the parties' rights and remedies that have accrued as at termination, including the right to claim damages in respect of any breach of this Contract that existed at or before the date of termination.

21.6 Any provision

GENERAL 1. (a) All orders placed with Evolution Fasteners UK Limited (”the Company”) by the Company’s customer (“the Buyer”) for the sale and the purchase of goods (“the Goods”)are subject to the terms and conditions set out below which shall constitute the contract between the Company and the Buyer (“the Contract”). No modifications or variations to these terms and conditions and no other terms and conditions shall be valid or effective unless expressly accepted in writing by a director of the Company. (b) Any subsequent orders placed with the Company shall be deemed to be placed subject to these terms and conditions unless expressly agreed otherwise in writing by a Director of the Company.