Unleashing ultra-efficient and easy-to-use machine learning (ML) on the edge with Nordic’s groundbreaking nRF54L Series and Neuton.AI’s automated TinyML platform

Nordic Semiconductor, the global leader in ultra-low-power wireless connectivity solutions, today announced its acquisition of the intellectual property and core technology assets of Neuton.AI, a pioneer in fully automated TinyML solutions for edge devices. This ignites a new era of ML on the edge by combining Nordic’s industry-leading nRF54 Series ultra-low power wireless SoCs with Neuton’s revolutionary neural network framework – bringing scalable, high-performance AI to even the most resource-constrained devices.

Nordic Semiconductor, the global leader in ultra-low-power wireless connectivity solutions, today announced its acquisition of the intellectual property and core technology assets of Neuton.AI, a pioneer in fully automated TinyML solutions for edge devices. This ignites a new era of ML on the edge by combining Nordic’s industry-leading nRF54 Series ultra-low power wireless SoCs with Neuton’s revolutionary neural network framework – bringing scalable, high-performance AI to even the most resource-constrained devices.

“This is a generational leap in embedded compute power and efficiency,” said Vegard Wollan, CEO and President at Nordic Semiconductor. “By uniting Nordic’s lowpower wireless leadership with Neuton.AI’s cutting-edge TinyML platform, we empower developers to build a new class of always-on,

AI-powered devices—faster, smaller, and more power-efficient than ever.”

A leap in scalable, accessible intelligence Neuton.AI’s patented technology breakthrough lies in its fully automated platform, which creates ML models typically under 5 KB in size – up to 10x smaller and faster than other approaches. With exceptional ease of use, these models require no manual tuning or data science expertise, enabling rapid deployment across 8-, 16-, and 32-bit MCUs. Through its innovative neural network framework, which builds ultra-small models automatically without predefined architectures, Neuton.AI offers accurate, energy-efficient, and fast AI for edge applications in the consumer, healthcare, and industrial markets – all while preserving precious device and system resources such as power and code memory.

Low power meets compute intelligence “We are proud to enable the powerful combination of Neuton’s advanced ML technology with the performance of Nordic’s ultra-low power nRF54 Series, redefining what’s possible in ultra-efficient machine learning applications,” said Oyvind Strom, EVP ShortRange at Nordic Semiconductor. “Together, we’re enabling developers to build smarter, ultra-low-power devices that deliver true machine learning at the edge, not only for the nRF54 Series, but across the wide portfolio of all Nordic’s wireless connectivity SoCs.

Embedded AI will now become more accessible and scalable than ever. Neuton’s advanced ML technology enables effortless integration and trusted intelligence for next-generation edge AI devices.”

Enabling the future of edge AI

This acquisition comes as demand for edge node intelligence accelerates. With TinyML chipset shipments expected to reach $5.9 billion by 2030*, Nordic is prepared to capitalize on the opportunity by offering developers a robust, ready-toscale AI/ML toolkit for applications such as predictive maintenance, smart health monitoring, process automation, gesture recognition, next-gen consumer wearables, and IoT devices.

Integration and outlook

The acquisition includes all intellectual property and selected assets of Neuton.AI, along with its performance-driven team of 13 highly skilled engineers and data scientists. The Neuton.AI brand and platform will continue to operate during the initial integration phase, ensuring uninterrupted service for current users and partners. Financial terms remain undisclosed. Completion of the transaction is subject to customary regulatory approvals.

*Source: ABI Research

■ Nordic Semiconductor www.nordicsemi.com

3 | Nordic Semiconductor accelerates edge AI leadership with acquisition of Neuton.AI

6 | CIS launches USB 3.2 cameras powered by Infineon’s EZ-USB™ controllers for enhanced data transfer and performance

6 | Deadline Nearing to Enter 2025 Create the Future Design Contest

7 | MIPS and Cyient Semiconductors collaborate to bring Custom RISC-V-based intelligent power solutions to AI Power Delivery, Industrial Robotics, and Automotive

8 | What’s in your water? Check with TDS Click from MIKROE

8 | Tria’s new family of compute modules powered by Qualcomm Dragonwing processors now support Windows, Android and Linux

9 | New at Mouser: Arduino Portenta Proto Kit VE for Industrial Automation, Environmental, and Machine Vision Applications

10 | Sensirion launches new digital humidity and temperature sensors with protective cover

10 | Renesas Brings USB-C Rev. 2.4 Support to New Ultra-LowPower RA2L2 Microcontroller Group

11 | Infineon OptiMOS™ 80V and 100V, and MOTIX™ enable high-performing motor control solutions for Reflex Drive's UAVs

12 | Würth Elektronik presents its Skoll-I Bluetooth® module

12 | Siemens’ PAVE360™ to support new Arm Zena Compute Subsystems

13 | Infineon collaborates with Typhoon HIL to accelerate development of xEV power electronic systems using real-time hardware-in-the-loop platform

Management

Managing Director - I onela G anea

Editorial Director - Gabriel N eagu

Accounting - I oana P araschiv

Advertisement - Irina G anea

Web design - Eugen Vărzaru

Contributing editors Cornel Pazara

PhD. Paul S vasta

PhD. N orocel C odreanu

PhD. Marian Blejan

PhD. B ogdan G rămescu

14 | Meet the Challenge of Accurate Voltage Sensing in Electric Vehicles with Isolation Amplifiers

18 | Mouser Equips Engineers to Navigate the Expanding World of Robotics with In-Depth Online Resources

19 | OpenGMSL™ Association Announces Formation to Revolutionize the Future of In-Vehicle Connectivity

20 | ROHM Develops Breakthrough AI-Equipped MCUs

22 | Secure external memory and protect your software IP

26 | Crossing the chasm with success – WBG

30 | Advanced Energy launches medical CF-Rated AC-DC power supplies that simplify isolation and speed Time-to-Market

31 | HPT5K0 series: 5kW power supplies with 400VDC and 800VDC model additions

32 | New Interactive eBook from Mouser and TDK Explores Challenges in Precision, Speed, and Efficiency for Industrial Automation

33 | Murata Unveils New Whitepaper on Pioneering Wellness Technology

34 | New OMRON E8Y-L pressure sensors are easy, compact, and flexible

36 | The drive to SiC in electrification

40 | Charging station with that certain extra

44 | Designing Edge Sensors with Artificial Intelligence –Part 1

48 | DigiKey’s Thought Leadership on Sustainable Futures

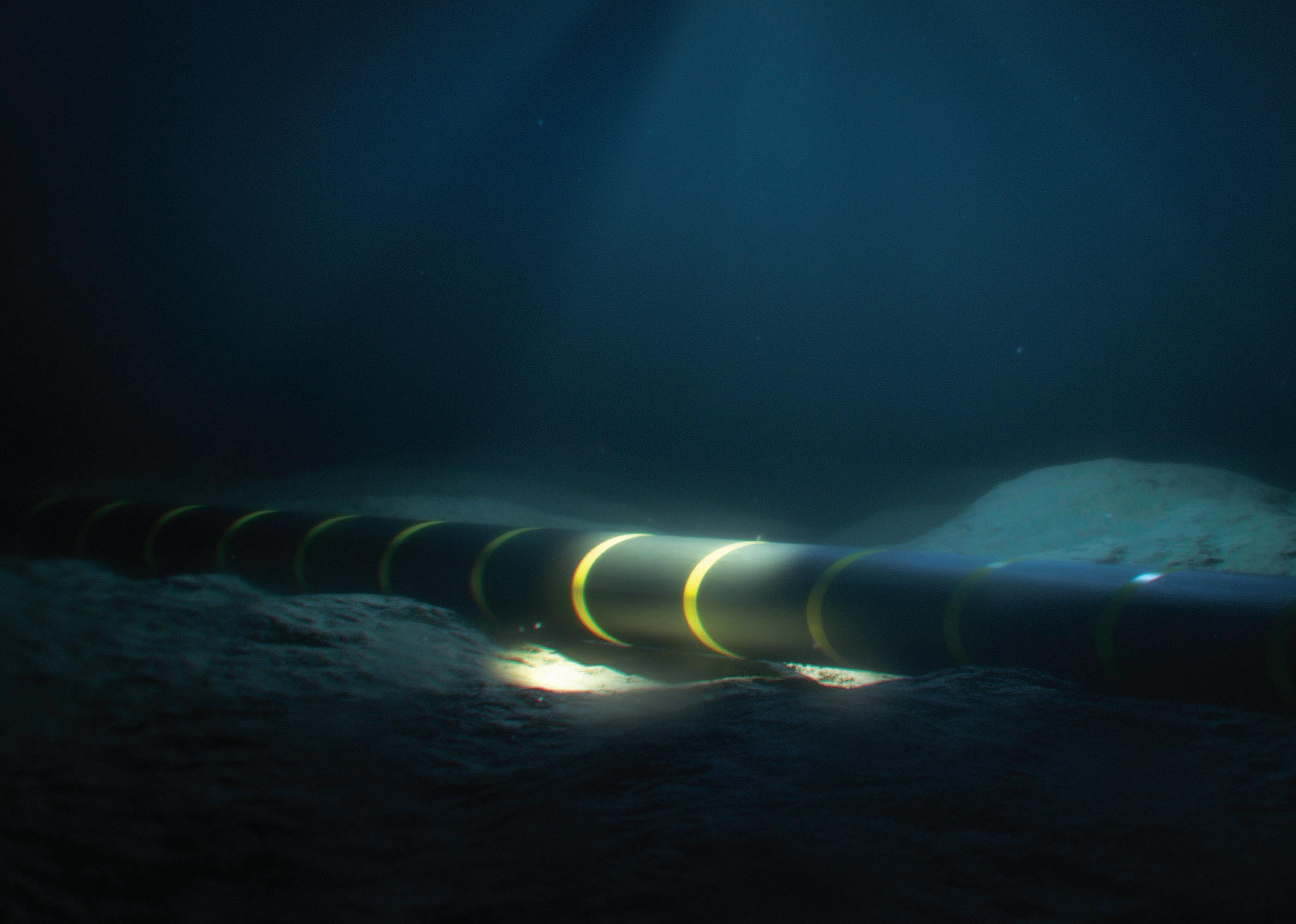

52 | Coherent OTDR testing of ultralong-distance submarine optical networks to safeguard global internet traffic

Azi” is

CIS launches USB 3.2 cameras powered by Infineon’s EZ-USB™ controllers for enhanced data transfer and performance

Infineon Technologies AG provides its EZ-USB™ FX10 and FX5 controllers to CIS Corporation for its new USB 5 Gbit/s and 10 Gbit/s camera. These next-generation devices build on the EZ-USB FX3, a widely adopted USB peripheral controller, by adding support for high-speed USB 10 Gbit/s and LVDS interfaces. This advancement increases total data bandwidth by up to 275 percent compared to the previous generation, enabling significantly faster data transfer and improved system performance.

The EZ-USB FX10 features dual Arm® Cortex®-M4 and M0+ cores, 512 KB of flash memory, 128 KB of SRAM, 128 KB of ROM, and seven serial communication blocks (SCBs). It includes a cryptography accelerator and a high-bandwidth data subsystem that enables direct memory access (DMA) transfers between LVDS/LVCMOS interfaces and USB ports at speeds of up to 10 Gbit/s. An additional 1 MB of SRAM supports USB data buffering. The controller also offers USB-C connection detection and flip-mux functionality, removing the need for external logic components. This combination of processing power, interface flexibility, and integrated features supports a wide range of high-speed USB applications.

With the introduction of its new USB 3.2 cameras, CIS aims to expand beyond the industrial image processing market into sectors such as logistics, robotics, medical technology, and life sciences – areas where connectivity, speed, image quality, and compact design are critical. Product samples are already finalized, and mass production is scheduled to begin in July. In addition, CIS is expanding its portfolio with new camera models across multiple resolutions.

The upcoming 4K version of the camera integrates CIS’s proprietary Clairivu™ image signal processor (ISP). Despite this added complexity, the low power dissipation of EZ-USB FX5 and FX10 allows the device to fit into a compact 29 mm cubic housing – reducing the volume by approximately 50 percent compared to CIS’s previous 4K model. Combined with plugand-play USB connectivity, this compact design greatly enhances the camera’s versatility and ease of integration. The EZ-USB FX10 is available now. Further information is available at www.infineon.com/ez-usb-fx10

■ Infineon Technologies | www.infineon.com

Time is running out to enter the 2025 Create the Future Design Contest, an exciting challenge — sponsored by Mouser Electronics – to engineers and students worldwide to create the next great thing. Mouser, which has sponsored the contest for over a decade, has joined again with valued manufacturers Intel® and Analog Devices, Inc. (ADI) as co-sponsors. The competition is produced by SAE Media Group, an SAE International Company, and Tech Briefs magazine. COMSOL is also a principal sponsor of the contest.

The contest opened for entries on March 3 and closes on July 1, 2025. The grand prize winner receives worldwide recognition and a cash prize of $25,000 for an innovative product that benefits society and the economy. Previous contests have produced more than 15,000 design ideas from engineers, entrepreneurs and students in more than 100 countries.

“At Mouser, advancing innovation has been rooted in our foundation since the company’s earliest days,” said Kevin Hess, Mouser Electronics’ Senior Vice President of Marketing. “We proudly support programs like the Create the Future Design Contest that bring out the best in engineers, innovators, and students.”

The Create the Future Design Contest promotes product designs that enhance humanity, improve healthcare quality, or help provide sustainable solutions. Previous grand prizewinning entries include self-destroying plastics, a self-contained organ and limb transport device, and an economical, rapid screening device to prevent food-borne illness.

The contest was created in 2002 by the publishers of Tech Briefs magazine to help stimulate and reward engineering innovation. The grand prize winner will be chosen from the winners in seven entry categories: Aerospace and Defense, Automotive/Transportation, Electronics, Manufacturing and Materials, Medical, Robotics and Automation, and Energy, Power and Propulsion.

• For more information, visit www.mouser.com/createthefuture

• For more Mouser news and our latest new product introductions, visit www.mouser.com/newsroom

MIPS and Cyient Semiconductors collaborate to bring Custom RISC-V-based

intelligent power solutions to AI Power Delivery, Industrial Robotics, and Automotive

Cyient Semiconductors Private Limited, a fast-growing custom silicon company based in Hyderabad, and MIPS, a global leader in RISC-V processor IP, today announced a strategic collaboration to develop domain-optimized ASIC (application-specific integrated circuit) and ASSP (application-specific standard product) solutions that leverage the MIPS Atlas portfolio of advanced, efficient processor IP.

The partnership will focus on enabling real-time, safety-critical applications, power delivery, and compute efficiency in demanding platforms for automotive, industrial, and data center markets. Motor Control & Data Center Power Delivery are focal platforms to leverage Cyient’s Analog Mixed Signal capabilities and MIPS Atlas CPU IP.

“As compute systems scale from cloud to the edge, intelligent power delivery is emerging as a key enabler of performance and efficiency,” said Suman Narayan, CEO of Cyient Semiconductors. “Our collaboration with MIPS allows us to bring together embedded intelligence and advanced power architectures in custom silicon platforms built on a scalable, open foundation. Together, we are designing tomorrow’s semiconductors - purpose-built for a more connected and power-efficient world.”

“The problem of power efficiency and motor control are both real-time compute workloads for which MIPS M8500 microcontrollers are the optimal choice,” said Sameer Wasson, CEO of MIPS. “Building around our best-in-class real-time and controlloop performance and efficiency, Cyient can bring their unique capability in intelligent power delivery into custom ASIC and ASSP designs to build differentiated solutions that meet our customers unique needs in their target markets.”

Demand for software defined vehicles, data center infrastructure, and industrial automation is driving growth for custom silicon. Customers can build advanced, differentiated solutions that are easy to program using MIPS advanced processor IP, based on the open RISC-V instruction set architecture, combined with Cyient intelligent power and mixedsignal design expertise.

■ Cyient Semiconductor | https://cyientsemi.com

■ MIPS | https://mips.com

■ Mouser Electronics | www.mouser.com https://international.electronica-azi.ro

Easily add alarms, voice prompts, automated announcements

A compact add-on board from MIKROE, the embedded solutions company that dramatically cuts development time by providing innovative hardware and software products based on proven standards, enables the Total Dissolved Solids (TDS) in water to be measured, providing an accurate indicator of water quality. A new addition to the 1800-strong mikroBUS™-enabled Click board™ family, TDS Click features the CD4060B oscillator from Texas Instruments, supported by the LMV324 op-amp, MCP3221 ADC from Microchip, and dual-voltage regulation using LP2985AIM5-3.0 and ADM8829.

TDS Click features a multi-stage signal conditioning circuit that amplifies, rectifies, and filters the signal from the connected TDS probe, delivering a clean DC voltage proportional to the TDS level.

The output can be accessed either as an analogue voltage or a digital I2C signal, selectable via the onboard ADC SEL jumper. Operating with both 3.3V and 5V logic levels, it ensures broad MCU compatibility.

TDS Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. This latest Click board also features the ClickID function which simplifies use by enabling the host system to seamlessly and automatically detect and identify this add-on board.

■ MIKROE | www.mikroe.com

Tria’s new family of compute modules powered by Qualcomm Dragonwing processors now support Windows, Android and Linux

The new family of embedded compute modules from Tria™, an Avnet company specializing in manufacturing embedded compute boards, not only have Qualcomm Dragonwing™ processors on board—they now support different operating systems. These options include Android, Windows 11 IoT Enterprise, and Yocto Linux. The variety of operating systems supported enable the modules to be used for embedded designs in the industrial, medical, agriculture and construction sectors, as well as any embedded application that can benefit from edge computing, machine learning and AI.

At the heart of these modules are high-performance, lowpower Qualcomm Dragonwing™ processors, providing advanced technology in customised solutions. With advanced edge AI and seamless networking capabilities, Qualcomm Dragonwing™ targets embedded systems for various industries. These processors have been designed for speed, scalability and reliability, enabling customers to achieve smarter decision making, better efficiencies and to reach the market faster.

This means that Tria’s new lineup offers a powerful CPU and AI combination at lowest power consumption, enabling embedded designs to benefit from higher performance and increased capabilities.

Microsoft Windows with ARM now available Tria also now provides Microsoft Windows with ARM, allowing a transition from the x86 architecture to ARM with the same OS. This transition was previously not possible, since Windows on ARM was not available.

“Our collaboration with Qualcomm Technologies has enabled us to deliver high performance and low power technology with highest quality they are used to receiving from Tria in our new compute modules,” said Christian Bauer, Product Marketing Manager, Tria Technologies. “This family of modules is the only one available to offer compatibility with multiple operating systems at a competitive price.”

“With multi-OS support across Tria’s new modules powered by Qualcomm Dragonwing™ and Snapdragon platforms, customers gain the flexibility of Windows, Android and Linux across our different platforms”, said Douglas Benitez, Senior Director, Business Development, Qualcomm Europe, Inc. “Our collaboration with Tria is accelerating industrial innovation—delivering high performance, low power compute and accelerated AI at the edge.”

Several options to support different embedded computing needs

The four new Tria offerings are on SMart Mobility Architecture COM (SMARC) standard modules and Open Standard Modules (OSM), designed primarily for industrial automation and robotic applications. They are:

• Qualcomm Dragonwing™ IQ-615 processor powered modules supporting Linux

• Qualcomm Dragonwing™ QCS5430 and QCS6490 processors, with a combination of Linux, Android and Windows 11 IOT Enterprise OS

• Qualcomm Dragonwing™ IQ9 Series processors, supporting Linux

• Snapdragon® X Elite processor, supports Windows 11 IOT Enterprise OS

■ Tria | www.tria-technologies.com

Mouser Electronics, Inc., the authorized global distributor with the newest electronic components and industrial automation products, is now shipping the Portenta Proto Kit VE (Vision Environment) from Arduino. The Portenta Proto Kit VE accelerates the prototyping phase quickly, efficiently, and without conventional limitations, equipping users with advanced tools to tackle any challenge in predictive maintenance, environmental sensing, machine vision, logistics tracking and EV charging applications.

The Arduino Portenta Proto Kit VE available from Mouser, includes a full set of innovative Modulino nodes for reliable sensing and actuation capabilities with seamless Cloud connectivity through the Arduino Global Pro 4G Module, and an Arduino Cloud for Business Voucher all working together to process visual and environmental data for a wide range of applications, such as object recognition, people counting, air quality monitoring, and industrial automation. At the heart of the kit is the powerful Portenta H7, paired with the versatile Portenta Mid Carrier, supporting advanced processing and edge machine learning, ensuring prototypes are future-ready and functional.

With tools for environmental sensing, machine vision, and motion detection, as well as cloud-enabled remote monitoring, this flexible and comprehensive kit leverages the Arduino IDE on the software side to develop quick, scalable, IoT-enabled prototypes that bring your ideas to life and quickly transition from functional prototypes to final products. This kit (with the included Proto Shield) has everything from power supplies to cables, providing everything needed for rapid prototype development.

• To learn more, visit: www.mouser.com/new/arduino/arduino-portenta-proto-kit-ve

■ Mouser Electronics | www.mouser.com

Sensirion has launched the SHT40-AD1P-R2 and SHT41AD1P-R2 digital humidity and temperature sensors, now available through their global distribution network. Designed for demanding environments, these sensors deliver high accuracy and reliability and are equipped with a removable protective cover to ensure durability during handling and deployment.

The SHT40-AD1P-R2 and SHT41-AD1P-R2 are the latest additions to Sensirion’s renowned family of digital humidity and temperature sensors. They are engineered to provide accurate measurements, with the SHT40-AD1P-R2 offering ±1.8% RH (max. ±3.5%) and ±0.2°C, and the SHT41-AD1P-R2 delivering ±1.8% RH (max. ±2.5%) and ±0.2°C accuracy. Built with a compact DFN housing, the sensors are ideal for space-constrained applications and can easily be integrated into a wide range of devices and systems thanks to their standard I2C interface and fixed 0x45 I2C address.

The removable protective cover is a key feature, offering additional protection during both handling and deployment, ensuring they perform reliably even in high-volume production environments. Whether used in industrial systems, HVAC equipment, or consumer products, these sensors combine durability, ease of integration, and high-precision measurement for a variety of applications.

■ Sensirion | www.sensirion.com

Renesas Electronics Corporation, a premier supplier of advanced semiconductor solutions, today introduced the RA2L2 microcontroller (MCU) group with ultra-low power consumption and the industry’s first support for the new UCB-C Revision 2.4 standard. Based on a 48-MHz Arm Cortex M23 processor, the new MCUs offer a rich feature set that makes them ideal for portable devices and PC peripherals such as gaming mice and keyboards.

The new USB Type-C Cable and Connector Specification Release 2.4 has reduced voltage detection thresholds (0.613V for 1.5A source, and 1.165V for 3.0A source). The RA2L2 MCUs are the industry’s first MCUs to support these new levels.

The RA2L2 MCUs employ proprietary low-power technology that delivers 87.5 μA/MHz active mode and software standby current of just 250nA. They also offer an independent operating clock for the low-power UART, which can be used to wake up the system when receiving data from WiFi and/or Bluetooth® LE modules. Along with the USB-C support, this combination of features makes the RA2L2 the premier solution available for portable devices such as USB data loggers, charge cases, barcode readers and other products.

In addition to USB-C with CC detection up to 15W (5V/3A) and USB FS support, the new MCUs offer LP UART, I3C, and CAN interfaces, giving designers the ability to reduce component count, saving cost, board-space and power consumption.

The RA2L2 MCUs are supported by Renesas’ Flexible Software Package (FSP). The FSP enables faster application development by providing all the infrastructure software

needed, including multiple RTOS, BSP, peripheral drivers, middleware, connectivity, and networking as well as reference software to build complex AI, motor control and cloud solutions. It allows customers to integrate their own legacy code and choice of RTOS with FSP, thus providing full flexibility in application development. The FSP eases migration of existing IP to and from other RA devices.

“The RA2L2 Group MCUs are our first to realize full-speed USB along with USB-Type C connector support. They also ensure system costs remain low by reducing external components, and they offer the same low-power characteristics as our popular RA2L1 devices,” said Daryl Khoo, Vice President of Embedded Processing Marketing Division at Renesas. “These new devices demonstrate our commitment and ability to quickly deliver the solutions our customers require.”

Key Features of the RA2L2 MCUs

• Core: 48 MHz Arm Cortex-M23

• Memory: 128-64 KB Flash, 16 KB SRAM, 4 KB Dataflash

• Peripherals: USB-C, USB-FS, CAN, Low Power UART, SCI, SPI, I3C, I2S, 12-bit ADC (17-channel), Low Power Timer, Real-Time Clock, High-Speed On-chip Oscillator (HOCO), Temp Sensor

• Packages: 32-, 48- and 64-pin LQFP; 32- and 48-pin QFN

• Security: Unique ID, TRNG

• Wide Ambient Temperature Range: Ta = -40°C to 125°C

• Operating Voltage: 1.6V – 5.5V; USB Operating Voltage: 3.0V to 3.6V

Availability

The RA2L2 MCUs are available now, along with the FSP software. Renesas is also shipping an RA2L2 Evaluation Kit. More information is available at renesas.com/RA2L2. Samples and kits can be ordered either on the Renesas website or through distributors.

■ Renesas Electronics Corporation | www.renesas.com

Infineon OptiMOS™ 80 V and 100 V, and MOTIX™ enable high-performing motor control solutions for Reflex Drive's UAVs

Reflex Drive, a deep tech startup from India has selected power devices from Infineon Technologies AG for its nextgeneration motor control solutions for unmanned aerial vehicles (UAVs). By integrating Infineon’s OptiMOS™ 80 V and 100 V, Reflex Drive’s electric speed controllers (ESCs) achieve improved thermal management and higher efficiency, enabling high power density in a compact footprint. Additionally, the use of Infineon’s MOTIX™ IMD701 controller solution – which combines the XMC1404 microcontroller with the MOTIX 6EDL7141 3-phase gate driver IC – delivers compact, precise, and reliable motor control. This enables improved performance, greater reliability, and longer flight times for UAVs.

Reflex Drives’s ESCs with field-oriented control (FOC) offer improved motor efficiency and precise control, while its high-performance BLDC motors are designed for optimized flight control and enable predictive maintenance of drive systems. Weighing only 180 g and with a compact volume of 120 cm³, the ESCs can deliver continuous power output of 3.8 kW (12S/48 V, 80 A continuous). Due to their lightweight design, robust power output, and consistent FOC control –even under demanding weather conditions – make them ideal for motors in the thrust range from 15 to 20 kg. Therefore, they are particularly suitable for drone applications in the fields of agricultural spraying technology, seed dispersal, small-scale logistics, and goods transport.

“Our partnership with Reflex Drive is an important contribution to our market launch strategy and presence in India,” says Nenad Belancic, Global Application Manager Robotics and Drones at Infineon. “Our partner has proven its expertise with numerous customers who have obtained aviation certifications. In addition, the company has presented its innovative technologies enabled by Infineon systems at important international industry events.”

“Our collaboration with Infineon has led to significant advances in UAV electronics,” says Amrit Singh, Founder of Reflex Drive “We believe drones have the potential to transform industries, from agriculture to logistics, and with Infineon’s devices, we can help drive this transformation at the forefront.”

• More information is available at: www.infineon.com/cms/en/partners/design-partners/sunmint-electronics/?intc=intc24050001_202505_glob_en_pss.p. pam_pam_reflexdrive&type=documentreferral

■ Infineon Technologies | www.infineon.com

Compact and versatile: The Skoll-I wireless module combines Bluetooth® Classic und Bluetooth® LE in a compact module.

Image source: Würth Elektronik

Manufacturer of electronic and electromechanical components, introduces Skoll-I, a compact wireless module that combines both Bluetooth® Classic and Bluetooth® LE (Low Energy) version 5.4 in a single solution. Measuring just 16.6 × 12 × 1.7 mm, the module is already certified for conformity in all major target markets, accelerating the launch of new applications.

Würth Elektronik’s new Bluetooth® Classic / Bluetooth® LE module with integrated antenna is suitable for use in medical devices, industrial automation and control systems, in security technology and IoT clients such as cost-efficient predictive maintenance. These applications typically require energy-efficient operation.

Small and versatile

Combining Bluetooth® Classic and Bluetooth® LE in a compact module offers a unique opportunity for developing devices that need to connect to both legacy and modern devices. Skoll-I also offers an easy way to replace the Puck-I Bluetooth® module, which can no longer be qualified for new developments due to the withdrawal of the Bluetooth 2.0 specification. Skoll-I complies with Bluetooth® Core Specification Version 5.4 and supports BR, EDR 2/3 Mbps, Bluetooth® LE, and LE 1/2 Mbps. The module is certified to CE, FCC, IC, TELEC, and ETA-WPC standards.

Compelling all-in-one package

The WE Bluetooth® LE Terminal App provides a quick and easy way of testing as well as the basis for developing new, custom apps. Additional services include the Wireless Connectivity software development kit (SDK), the WE UART terminal, and an evaluation board that can be easily connected to a PC to provide access to all module pins for testing.

■ Würth Elektronik eiSos | www.we-online.com

Siemens’

Siemens Digital Industries Software announced that it is expanding its longstanding relationship with Arm and adding support for the newly launched Arm® Zena™ Compute Subsystems (CSS) in its PAVE360™ software, designed for software–defined vehicles (SDV).

Zena CSS, Arm’s first-generation CSS for automotive, is a pre-integrated and validated compute subsystem optimized for performance, power and area and designed to accelerate development for the AI-defined vehicle.

As the automotive industry enters a new phase of SDVs where intelligent, AI-defined functionality provides an opportunity for greater vehicle differentiation, a new development methodology and mindset is required.

“The era of AI-defined vehicles is an opportunity to bring new in-vehicle experiences to life, but it will require a much faster speed of development and deployment,” said Suraj Gajendra, vice president of automotive products and software solutions, Automotive Line of Business, Arm. “With the help of virtual platform solutions like PAVE360 from Siemens, Arm is enabling our partners to begin software development on Zena CSS before physical silicon is available, significantly reducing development time for new software solutions.”

“Our work with Arm demonstrates that it’s no longer enough that vehicle development is software defined – the process now needs to be systems-aware with the full vehicle system developed in parallel to help ensure that the entire system meets requirements and will require continuous verification,” said David Fritz, vice president, Hybrid and Virtual Systems,

Siemens Digital Industries Software. “Siemens is in a unique position to support this new approach as we enable customers to develop multi-domain (across electronics, hardware and application development) digital twin for validation and integration that encompasses the whole System-on-a-Chip (SoC), electronics/ electrical (E/E) system and vehicle development flow.”

Customers can now use Siemens’ PAVE360 to develop software for Zena CSS before silicon availability, and within the SOAFEE community, the virtual prototyping environment will become a key technology to enable SOAFEE Blueprints. . They can then functionally validate software in-system and accurately model SoC algorithms and hardware/ software interaction, helping to mitigate the inevitable challenges posed by software-defined and systems-aware vehicle development.

PAVE360™, as part of Siemens’ SDV framework, brings together the Innexis™ software environment, Veloce™ hardwareassisted verification and validation system, Teamcenter® software for Product Lifecycle, Polarion™ for Application Lifecycle Management (ALM), and Simcenter™ Prescan and Simcenter™ Amesim™ software for simulation to provide a more integrated approach to software-defined development.

The initial support for Zena CSS, based on Innexis Architecture Native Acceleration (ANA), is now available from Siemens as part of PAVE360. Automotive customers can start developing software today and, once silicon is available, continue through the PAVE360 digital twin flow seamlessly transitioning to accurate performance and power analysis using Innexis Developer Pro. In parallel, PAVE360 enables requirements and verification to be linked together providing a digital twin that is systems-aware, mitigating the inevitable system integration storm experienced by vehicle developers today.

• To learn more about how Siemens is supporting Zena CSS and enabling the automotive industry to move towards a software-defined, system-aware working methodology, visit: www.siemens.com/PAVE360blogZenaCSS

■ Siemens | www.siemens.com

Infineon collaborates with Typhoon HIL to accelerate development of xEV power electronic systems using real-time hardware-in-theloop platform

Infineon Technologies AG announced a collaboration with Typhoon HIL, a leading provider of Hardware-in-the-Loop (HIL) simulation solutions, to provide automotive engineering teams with a fully-integrated, real-time development and test environment for key elements of xEV powertrain systems. Customers working with Infineon’s AURIX™ TC3x/TC4x automotive microcontrollers (MCUs) can now use a complete HIL simulation and test solution using Typhoon’s HIL simulator for ultra-high fidelity motor drive, on-board charger, BMS, and power electronics emulation, which provides a plug-and-play interface via the Infineon TriBoard Interface Card.

The solution offered by Infineon and Typhoon HIL includes any of several Typhoon HIL Simulators for real-time digital testing, a suite of testbed hardware and software tools, and the Infineon TriBoard Interface Card, which supports Infineon AURIX TC3xx and TC4xx evaluation boards and plugs directly into a single row of DIN41612 connectors on the front panel of the HIL Simulator. The solution streamlines validation workflows, expedites design and testing processes, and reduces development costs and complexity for customers. Typhoon HIL also offers an “Automotive Communication Extender” product for its HIL Simulator solution based on an AURIX TC3xx processor, which will provide an enhanced communication interface that allows customers to connect to a larger number of heterogenous ECUs under test via CAN, CAN FD, LIN, and SPI protocols.

• The TriBoard Interface Card is available today at: www.infineon.com/cms/en/partners/design-partners/ typhoon-hil

• For more information on using Typhoon HIL’s platform with Infineon AURIX microcontrollers, visit: www.typhoon-hil.com/products/hil-interfaces/hil-infineoninterface-cards

■ Infineon Technologies | www.infineon.com

This article examines the operating principles of isolation amplifiers. It then introduces a transformerbased example that uses iCoupler technology from Analog Devices, reviews its potential applications in EV/HEV development, and presents an evaluation board to help begin the design process.

Author: Rolf Horn, Applications Engineer

Designers of electric vehicles (EVs) and hybrid electric vehicles (HEVs) need to meet the demand for higher performance, faster charging, and greater efficiency. One of the many electronic functions that can help satisfy these demands is accurate voltage sensing for optimal power control.

However, automotive applications are particularly challenging. Power electronics must function reliably for decades despite temperature extremes and the presence of high voltages that demand suitable isolation. Voltage-sensing circuits for these applica-

tions must offer high bandwidth, low error and drift, and high common-mode transient immunity (CMTI) while meeting automotive standards like AEC-Q100. These requirements are especially relevant for critical components in EVs and HEVs, including inverters, DC/DC converters, and onboard chargers.

Transformer-based isolation amplifiers are well suited to these applications. These devices use advanced technology to achieve excellent performance over decades of exposure to harsh conditions.

Operating principles of transformerbased isolation amplifiers

Isolation amplifiers are specialized differential amplifiers that provide electrical isolation between input and output circuits. This isolation can be achieved through several means, but transformerbased isolation amplifiers like the ADuM3195 (Figure 1) offer unique advantages for EV/HEV applications..

In transformer-based designs, isolation is achieved through transformer coupling. The basic principle of operation involves the following steps:

1. The input signal is converted into a high-frequency carrier signal.

2 This carrier signal is then transmitted across the isolation barrier via a transformer.

3. On the secondary side of the transformer, the original signal is reconstructed from the carrier.

The transformer serves two crucial functions. It provides galvanic isolation between input and output circuits, allowing safe measurement of high voltages and protecting sensitive circuitry. It also enables signal transfer without a direct electrical connection across the isolation barrier. Transformer-based isolation offers significant advantages for voltage-sensing applications. These amplifiers effectively reject common-mode voltages, crucial in noisy electrical environments. In addition, modern designs achieve wide bandwidths suitable for many power electronic applications.

Performance advantages of planar micro-transformers for isolation amplifiers

i Coupler, technology, developed by Analog Devices, represents an advancement in isolation amplifier design. iCoupler devices feature planar micro-transformers with a typical diameter of approximately 0.5 millimeters (mm), enabling remarkably compact solutions. The small size also provides inherent resistance to external magnetic fields, enhancing reliability.

Central to iCoupler performance is a polyimide insulation layer (Figure 2). This insulation provides high thermal and mechanical stability, making the device exceptionally durable. It can withstand surge voltages exceeding 10 kilovolts (kV) and offers long-term reliability when operating continuously at 400V root mean square (VRMS).

An essential feature of iCoupler technology is its ability to operate at high frequencies, supporting data transfers up to 150 Mbits/s (megabits per second). This is achieved in part through a highly efficient signal encoding methodology. Data is encoded into 1 nanosecond (ns) pulses that enable fast data transfer and low power consumption, typically less than 1 milliampere (mA) per channel (Figure 3).

This AEC-Q100-compliant version of the ADuM3195 is specifically designed for automotive environments. It has an isolation voltage of 3,000 VRMS, an output offset voltage of ±6 millivolts (mV) (max) at 25°C, a gain error of ±0.5% (max), a bandwidth of 210 kilohertz (kHz), a gain drift of ±27 parts per million per °C (ppm/°C) (max), and an offset drift of -22 microvolts per °C (μV/°C) (typical).

2

ADuM3195 isolation amplifier uses transformerbased isolation.

to iCoupler performance is a polyimide insulation layer that provides high thermal and mechanical stability.

Figure 3 A highly efficient encoding method allows iCoupler devices to transfer data at 150 Mbits/s and draw typically less than 1 mA per channel. ©

Additionally, iCoupler devices incorporate input glitch filters to reduce noise and ensure clean signal transmission, enhancing performance in electromagnetically noisy automotive environments.

Key features of automotive-qualified isolation amplifiers i Coupler technology has been implemented in several devices, including the ADuM3195WBRQZ isolation amplifier.

The device has a CMTI of 150 kV per microsecond (kV/μs) (typical), an operating temperature range of -40°C to 125°C, configurable gain settings, and comes in a 16-lead QSOP.

These features make the ADuM3195 WBRQZ suitable for accurate, isolated voltage measurements in challenging automotive applications, including:

• Voltage monitoring in battery management systems (BMSs)

• Feedback loops in power supplies

• Inverter and motor drive systems

The high accuracy, wide bandwidth, low power consumption, and robust isolation capabilities make the ADuM3195WBRQZ a particularly effective solution for voltage sensing in EV/HEV systems.

Isolation amplifier requirements for inverters, DC/DC converters, and onboard chargers

The ADuM3195WBRQZ isolation amplifier addresses critical challenges in EV/HEV power systems, including inverters, DC/DC converters, and onboard chargers.

Its 210 kHz bandwidth enables sub-5 μs response times, crucial for efficient charging, precise inverter control, and minimized voltage ripple in DC/DC converters. This high bandwidth also allows for smaller passive components and supports wide-bandgap device integration, enhancing overall system efficiency and power density.

The high-impedance input of the ADu M3195WBRQZ minimizes measurementrelated power loss and stabilizes converter and inverter operations. Reducing current draw also decreases stress on auxiliary circuits, improving system reliability.

The ADuM3195WBRQZ’s high temperature tolerance allows it to be placed near heat-generating components like electric motors, onboard chargers, and regenerative braking systems to help prevent thermal runaway, manage thermal cycling, and avoid hotspots in power electronics.

For DC/DC converters handling various output voltages, the ADuM3195WBRQZ’s low offset error and offset drift ensure accurate voltage feedback across temperature variations. This accuracy contributes to precise control, reduced ripple, and improved drivetrain performance.

The 3,000 VRMS isolation voltage of the ADuM3195WBRQZ protects low-voltage electronics and occupants from highvoltage systems (up to 400 V). It provides effective noise rejection between power stages and control circuits in EV battery systems while interfacing with low-voltage systems (12/48 V).

By meeting these critical requirements, the ADuM3195WBRQZ enhances the performance, efficiency, and safety of EV/HEV power systems.

It is worth noting that the ADuM4195 is available for higher voltage system requirements, providing an isolation voltage up to 5,000 VRMS and low-voltage electronics protection up to 800 V.

Jumpstart ADuM3195 development EVAL-ADuM3195EBZ (Figure 4) is a compact evaluation board designed for test

• AC measurement capability: With minor modifications, the board can measure AC voltages, which can be helpful for motor drive inverter output monitoring, AC charging system measurements, and electromagnetic interference (EMI)/noise analysis on high-voltage lines.

• Low-power option: For lower power consumption, the power disable (PDIS) input can disable the internal power supply when energy needs to be used judiciously.

Figure 4

The EVAL-ADuM3195EBZ evaluation board is designed for setup and testing of the ADuM3195.

especially relevant for EV/HEV battery systems. This allows developers to monitor battery pack voltages, measure individual cell voltages in a BMS, and interface with high-voltage DC bus lines.

• Configurable input range: The input voltage divider can be adjusted to accommodate different voltage ranges common in EV/HEV systems. For example, a 400VDC bus is typical in many EVs, 800V systems in newer EV architectures, and lower voltage ranges for 48V mild hybrid systems.

www.digikey.com

Mouser Electronics, Inc., the authorised global distributor with the newest electronic components and industrial automation products, equips engineers with the latest innovative solutions in its extensive online robotics resource centre. Combining engineering and computer science, robotics continues to drive innovation across industries, reshaping automation, manufacturing, healthcare, and more. From precisiondriven industrial systems to AIenhanced automation, robotics is redefining efficiency, safety, and performance in complex applications. Advancements in robotics span multiple domains. Soft robotics, designed to mimic organic movement, have revolutionised prosthetic development, enabling lifelike artificial limbs with enhanced dexterity. Meanwhile, sweeping robotics integrate advanced components like Time-of-Flight (ToF) sensors and antennas to optimise autonomous

cleaning. In industrial settings, robots automate repetitive and hazardous tasks, boosting productivity, while collaborative robots (cobots) optimise workflows and free human workers for strategic roles. As artificial intelligence (AI) and machine learning (ML) advance, robots are becoming smarter and more adaptable, paving the way for seamless human-robot collaboration.

Mouser’s robotics content hub provides comprehensive resources, including articles, blogs, eBooks, and products, designed to guide users through the complexities of robotics. Selecting the right robotic system is crucial to optimising performance in specific environments. Mouser’s expert technical team and trusted manufacturing partners curate technical articles and resources to help engineers identify key differences, such as automated guided vehicles (AGVs) versus autonomous mobile robots (AMRs), helping engineers navigate critical

design decisions and implement the most effective robotic solutions.

Mouser stocks the industry’s widest selection of semiconductors and electronic components, including the following products and solutions for robotics applications:

• The AD-GMSL522-SL Gigabit Multimedia Serial Link (GMSL™) robotics rapid development platform from Analog Devices, Inc.(ADI) is a GMSL-enabled NVIDIA Jetson Xavier™ NX-based carrier board and software solution that allows for simple camera-to-display conversion. This solution creates a scalable, user-friendly GMSL platform for receiving and transmitting data. The platform enables demonstrations and ecosystem development by serving as a hardware platform for software development.

• The VL53L7CH ToF sensor by ST Microelectronics is an 8×8 (64 zones) multizone sensor with an ultrawide 90° diagonal Field of View. This sensor offers a Compact and Normalised Histogram innovative output for AI applications that require multizone raw ToF sensor data. The sensor is used in cup rim detection for coffee machines and beverage dispensers, people-counting for smart buildings, and other applications like floor sensing for robotics and vacuum cleaners.

• The AEAT-901B incremental magnetic encoders by Broadcom provide an integrated solution for angular detection within a complete 360° rotation. These encoders use magnetic technology for motion control and sensing activities, which helps eliminate mechanical contact and free the device from mechanical wear and tear. The magnetic encoders feature 256 to 10,000 CPR resolution, a -40°C to 125°C operating wide temperature range, and a 5V single supply.

• The RA8E2 480MHz microcontrollers by Renesas Electronics achieve 6.39CM/MHz (CoreMarks per MHz), enabling demanding and compute-intensive applications like endpoint AI and robotics. Using the Arm® Cortex® M85 core with a 7-stage superscalar pipeline (vs. 6-stage on the CM7 core) brings an unprecedented 30% higher scalar performance, improving efficiency versus the predecessor.

To learn more, visit: https://resources.mouser.com/robotics

■ Mouser Electronics www.mouser.com

A leading automotive original equipment manufacturer (OEM), Tier 1 suppliers, semiconductor manufacturers and ecosystem partners today announced the formation of the OpenGMSL Association, an initiative bringing together industry leaders to transform SerDes transmission of video and/or high-speed data as an open, worldwide standard across the automotive ecosystem.

The demands of modern automotive systems - from ADAS (Advanced Driver Assistance Systems) to infotainment and autonomous driving - are growing rapidly.

ADAS vision systems heavily rely on high-quality video data to make critical, real-time decisions that improve driver safety and reduce accidents. Meanwhile, touchscreen infotainment systems demand high-speed, low-latency connectivity to deliver seamless, immersive user experiences.

These factors are driving up development costs for new vehicles, complicating integration, stifling innovation, and ultimately slowing advancements in safety.

With the launch of OpenGMSL Association, participation in a worldwide standard allows for innovation in autonomous driving, ADAS, and infotainment, among other applications. OEMs and suppliers can thereby accelerate time to market using solutions that operate efficiently together, thus lowering operational costs.

OpenGMSL’s standard is based on ADI’s industry-leading, road-proven Gigabit Multimedia Serial Link (GMSL) technology.

Paul Fernando, President of OpenGMSL Association, shared, “With over 1 billion GMSL ICs shipped and adoption by more than 25 global OEMs and 50 Tier-1 suppliers, GMSL is one of the most mature and roadproven high-speed video link technologies

in the automotive industry. OpenGMSL builds on this strong foundation to accelerate innovation across autonomous driving, ADAS, and next-gen infotainment - growing an already thriving ecosystem into an open, collaborative future.”

OpenGMSL Association is a non-profit entity with its own independent board of directors and encourages global participation. Products developed using the standard will require mandatory compliance testing to ensure seamless, multivendor interoperability.

For more information, please visit www.opengmsl.org. Automotive OEMs, suppliers, semiconductor manufacturers and ecosystem partners interested in joining the OpenGMSL Association can inquire at info@openGMSL.org

■ Analog Devices www.analog.com

ROHM has developed AI-equipped MCUs (AI MCUs) – ML63Q253x-NNNxx / ML63Q255x-NNNxx – that enable fault prediction and degradation forecasting using sensing data in a wide range of devices, including industrial equipment such as motors. These MCUs are the industry’s first* to independently execute both learning and inference without relying on a network connection.

As the need for efficient operation of equipment and machinery continues to grow, early failure detection and enhanced maintenance efficiency have become key challenges. Equipment manufacturers are seeking solutions that allow real-time monitoring of operational status while avoiding the drawbacks of network latency and security risks. Standard AI processing models, however, typically depend on network connectivity and high-performance CPUs, which can be costly and difficult to install.

In response, ROHM has developed groundbreaking AI MCUs that enable standalone AI learning and inference directly on the device. These network-independent solutions support early anomaly detection before equipment failure – contributing to a more stable, efficient system operation by reducing maintenance costs and the risk of line stoppages.

The new products adopt a simple 3-layer neural network algorithm to implement ROHM’s proprietary on-device AI solution “Solist-AI™.” This enables the MCUs to perform learning and inference independently, without the need for cloud or network connectivity.

AI processing models are generally classified into three types: cloud-based, edge, and endpoint AI. Cloud-based AI performs both training and inference in the cloud, while edge AI utilizes a combination of cloud and on-site systems - such as factory equipment and PLCs - connected via a network.

Typical endpoint AI conducts training in the cloud and performs inference on local devices, so network connection is still required. Furthermore, these models typically perform inference via software, necessitating the use of GPUs or high-performance CPUs.

In contrast, ROHM’s AI MCUs, although categorized as endpoint AI, can independently carry out both learning and inference through on-device learning, allowing for flexible adaptation to different installation environments and unit-to-unit variations, even within the same equipment model.

The data generated by this tool can also serve as training data for the actual AI MCU, supporting pre-implementation validation and improving inference accuracy. To facilitate adoption, ROHM has built an ecosystem in collaboration with partner companies, offering comprehensive sup-

Equipped with ROHM’s proprietary AI accelerator “AxlCORE-ODL,” these MCUs deliver approximately 1,000 times faster AI processing compared to ROHM’s conventional software-based MCUs (theoretical value at 12MHz operation), enabling realtime detection and numerical output of anomalies that “deviate from the norm”. In addition, high-speed learning (on-site) at the point of installation is possible, making them ideal for retrofitting into existing equipment.

These AI MCUs feature a 32-bit Arm® Cortex®-M0+ core, CAN FD controller, 3phase motor control PWM, and dual A/D converters, achieving a low power consumption of approximately 40mW. As such, they are ideally suited for fault prediction and anomaly detection in industrial equipment, residential facilities, and home appliances.

The lineup will consist of 16 products in different memory sizes, package types, pin counts, and packaging specifications. Mass production of 8 models in the TQFP package began sequentially in February 2025. Among these, two models with 256KB of Code Flash memory and taping packaging are available for purchase, along with an MCU evaluation board, through online distributors.

ROHM has released an AI simulation tool (Solist-AI™ Sim) on its website that allows users to evaluate the effectiveness of learning and inference prior to deploying the AI MCU.

These AI MCUs integrate a 32-bit Arm® Cortex®M0+ core (Maximum operating frequency: 48MHz) and ROHM’s proprietary AI accelerator AxlCORE-ODL that performs learning and inference using a 3-layer neural network. On top, leveraging versatile timer functions such as 3-phase motor control PWM along with a wide range of serial interfaces like CAN FD and 12-bit A/D converter enables flexible support for control and data processing in industrial equipment, residential facilities, and home appliances.

ROHM AI MCUs utilize a standard Arm® core, ensuring compatibility with commercially available tools as well as ROHM’s proprietary integrated development environment. To evaluate learning and inference, an AI operation verification simulator is provided, along with a real-time viewer for assessing AI effectiveness.

port for model development and integration. Going forward, ROHM will continue to expand this ecosystem, providing more user-friendly environments by assisting with training data creation and proposing optimal implementation methods.

Solist-AI™ is ROHM’s on-device AI solution designed for edge computing applications. Drawing inspiration from the musical term “Solist (Soloist)”, which signifies solo performance, this innovative solution enables real-time learning and inference directly on standalone edge devices without relying on cloud servers.

Powered by ROHM’s proprietary ondevice learning AI technology, Solist-AI™ is characterized by its compact design and low power consumption, contributing to the expansion of sustainable AI innovation. Solist-AI™ is a trademark or registered trademark of ROHM Co., Ltd.

Further details on the AI MCU development support system and an overview of each product can be found on ROHM’s dedicated AI MCU development system support page (below). www.rohm.com/lapis-tech/product/micon/ solistai-software

ROHM Website Resources

• Solist-AI™ Sim: PC-executable simulator for verifying AI operation

• Solist-AI™ Scope: Real-time viewer for assessing AI effectiveness (included with reference software)

• Reference Software: Sample software for AI MCUs

• Integrated Development Environment: LEXIDE-Ω (developed by ROHM)

* ROHM June 4, 2025 study on MCU products

■ ROHM Semiconductor www.rohm.com

Nowadays, embedded systems are constantly growing their memory requirements because of increasing connectivity functionality and application-level complexity. Many microcontrollers on the market provide storage density in the range of few Megabytes, which only a decade ago would have been regarded as more than sufficient and future-proof for the average application. On the other hand, integrating even more non-volatile memory requires quite a large silicon area, impacting the cost of the product significantly. A suitable alternative solution is using external memory, which can be purchased in volumes at comparably lower prices and with several densities’ options, typically starting from few to tens of Megabytes.

Author: Giancarlo Parodi, Principal Product Marketing Engineer Renesas Electronics

The external memory solution is suitable not only to hold application data but also application code, therefore removing any concern about the supplier roadmap to be able to fulfill future needs. On the other hand, some additional aspects must be taken into consideration like the performance of the code executing from the external memory, and how to protect the application code from cloning or modification. For the first problem, the solution is to use a memory with a wide interface which increases the physical throughput for the serial lines. Memories with an octal inter-

face provide one of the best choices in terms of tradeoff between the number of IO connections and the achievable 2x throughput improvement compared to the legacy quad-spi interface. Normally such modern memories also support slightly higher operating frequencies so that the performance improvement is even more significant.

Protecting the content of the memory requires usage of cryptography techniques to encrypt the code, since otherwise it would be easy for an attacker to connect to

the memory and read out the stored information with small effort. To avoid latencies for the decryption process it is necessary to use design solutions which are fast and performed in line with the instruction fetching process, in other words transparent from the CPU perspective.

The latest Renesas MCUs like the RA8x1 series implement a so-called ‘decryption on the fly’ (DOTF) architecture which serves exactly this purpose. A conceptual representation of the solution can be seen in Figure 1.

The principle is quite simple and based on the AES encryption/decryption standard, using counter mode (CTR) as specified in NIST SP800-38A. The principle of CTR mode operation is shown in Figure 2. In CTR mode, a set of counters are used as input to a block cypher function, to generate a secret output which is then exclusive-

ORed with the plaintext (or cyphertext) to encrypt (or decrypt) the message data. The sequence of counters must be chosen so that every input block in the set is different and unique.

This requirement is valid for all ‘messages’ (i.e. data items) which are encrypted using the same key.

One nice property of CTR mode is that the cypher functions associated with the counter can be performed upfront independently from each other, and do not need to wait for the data block to be available. This helps to reduce latency while reading out the encrypted data from the octa memory, since the generation of the output block can be done in parallel. Also, a certain plaintext block can be recovered independently from any other block, which is convenient for fetching program data, since depending on the program flow the processor might request to read code at non-sequential address locations.

The parameters used to define the counters need to be chosen carefully to ensure their uniqueness. An AES block is 16 bytes (128 bits) in size; therefore, the counter must be also 128 bits wide. Every encrypted block in memory is aligned to 16 bytes too, and to create a unique counter a concatenation of an initial value and the memory address can be used.

The initial value is essentially a nonce (unique, random number used once) and the address of the encrypted block being read has the 4 LSBs masked, to create the counter value according to the following scheme:

counter [127:0] = InitialValue [127:28] || (MemoryAddress [31:4] >> 4).

There are a couple of further interesting features in the implementation which are very useful to make it a flexible and userfriendly solution. First, the application can define an address boundary for which the decryption on the fly will be used, or otherwise bypassed, as shown in Figure 3.

This makes it very convenient if the application wants to partition the flash contents between code and other data, where the code gets decrypted on the fly and the data gets simply read without decrypting. The latter allows also the application to use another key or encryption mode for the data and avoids sharing the application code encryption/decryption key for multiple purposes.

As for the alignment of the DOTF area, even though the AES encryption standard implies a minimum alignment of 16 bytes, given the typical organization of a

flash memory, the boundary shall rather be placed on a sector or block size (the minimum flash unit size which can be erased while programming). In the implementation, the DOTF boundary is configurable to 4KB address alignment; in fact the application shall anyway avoid having a memory block storing both DOTF and non-DOTF data, which would make in-field-updates and factory programming unnecessarily complicated.

The flash memory device is mapped linearly into the addressable space of the MCU, and the Octa IP takes care of issuing the appropriate read commands, this is typically called XiP (execute-in-place) operation mode. For the encrypted area any access to the requested 16-byte blocks can be done efficiently by issuing one time the required address, and then reading the data continuously, thereby reducing the OctaSPI protocol overhead to a minimum.

so these can be stored safely in memory without confidentiality and integrity concerns.

The DOTF engine supports 128-, 192- and 256-bit size keys for maximum flexibility and future-proof choices, and there is no limit on the number of different keys which can be used to decrypt a specific image. The latter implies that any firmware update can use a different key if desired, and there is no need to share the same key between different MCUs.

Preparing the new image can be conveniently done offline on a secure host, before sending the image update to a device in the field or sending the encrypted image to a contract manufacturer for programming. The initial decryption key, or a “key update key” (for updating the decryption key in the field) can be injected securely in the MCU during production. Injected keys, whether in the field or at production stage, are always bound to the specific MCU, so that cloning is prevented.

Furthermore, the IP provides countermeasures to protect against side channel attacks.

All runtime operation is performed transparently by the hardware, and the provided software drivers take care to initialize and load the parameters for the DOTF operation (initial value, boundaries) and the key, before operation can start.

All MCUs which require memory expandability and complex application requirements will benefit from such kind of solution, which ensures the MCU developer will enjoy a solid application roadmap, and at the same time protect the software investment. For more information on the RA MCU family, please visit: www.renesas.com/ra.

Another important aspect is how the decryption key is handled and loaded. In devices supporting DOTF, there is a dedicated AES engine implemented within the IP but the key for the decryption process gets loaded over a private bus connection to the Renesas secure IP; this avoids leaking the key value over the internal MCU bus interconnect.

Additionally, the keys handled by the Renesas secure IP are themselves encrypted,

■ Renesas Electronics www.renesas.com

For the power designer any new technology that makes it possible to improve performance whilst simultaneously making products smaller and more energy efficient is a very exciting conceptwe’re talking holy grail territory. Over the last century the world of power electronics has witnessed many inventions and innovations and without going right back to the Thyratron, the latest major innovation was the move from analog to digital control. However, we are now witnessing a new, huge stride forwards in technology, the implementation of Wide Band Gap (WBG) semiconductors.

Author: Patrick Le Fèvre Chief Marketing and Communication PowerBox

Gallium Nitride and Silicon Carbide have been used in radio power amplifiers and high voltage diodes for years, but it was only a few years ago that they become part of the power switching chain in the form of transistors. Adopting a new technology is full of challenges that somewhat surprisingly are not always technical. Learning is an important part of the road to success but market adoption and

building a new ecosystem are far more complicated than it may seem at first. Let’s take a snapshot of where WBG currently stands and what are the remaining challenges.

The Early Adopters boosted GaN adoption!

Inevitably, for new technologies Time-toMarket is a long process, and from original

research, patenting, technology introduction and market adoption, this could be more than 10 years. We are all aware of the camel-back curve (Figure 1) and for those of us who belong to the Technology Enthusiasts category, the success of a new technology will come from the pragmatists and conservatives.

Introduced in 2005, digital control in power supplies has been broadly adopted but after 20 years it is still considered by skeptics to be a curiosity. In normal circumstances it would have been the same for the adoption of WBG, but market demand for smaller, lower power consumption, industry modernization, emerging technologies and the famous Artificial Intelligence have contributed to the speed of the learning and implementation processes.

As the Applied Power Electronics Conference (APEC) is celebrating its 40th anniversary, it is good to remind that for many technology analysts, the cornerstone of WBG took place at APEC-2018 when ‘challengers’ demonstrated the commercial potential of WBG technology.

It is not possible to name all of them but among the leaders promoting GaN I would say that the Efficient Power Conversion’s (EPC) idea to implement GaN in LiDAR was really interesting, especially with that technology becoming preponderant in the new generation of vehicles (Figure 2).

Their capacity to manage high-currents with minimal losses is paramount for enhancing accuracy and extending range in LiDAR systems. GaN's efficiency and power density advantages enable the development of smaller, lighter LiDAR systems, making it a suitable solution for

LiDAR, an acronym for “Light Detection And Ranging” is a technology that uses laser pulses to map out an environment. When the pulse contacts an object or obstacle, it reflects or bounces back to the LiDAR unit. The system then receives the pulse and calculates the distance between it and the object based on the elapsed time between emitting the pulse and receiving the return beam.

LiDAR systems are capable of processing a high volume of pulses with some systems emitting millions of pulses per second. As the returning beams are processed, the system generates a comprehensive view of the surrounding environment, enabling the use of sophisticated computer algorithms to discern shapes and identify objects such as cars and people.

Due to their high-frequency operation, which enables faster laser pulse modulation, LiDAR applications were part of the early adopter of the GaN technology.

various applications, including automotive, security, robotics, drones, and aerospace. Behind the scenes, the development of LiDAR applications has contributed to the adoption of GaN and is representing a significant volume.

2018 was also the year in which USB adapter manufacturers started to consider implementing WBG technology to offer more power in smaller packaging and to gain a competitive advantage. I mentioned EPC but Navitas Semiconductors is another example of an innovative company that in the early days pushed GaN integration to a higher level by packaging drivers and switches on the same substrate.

Making Complex Simple –

The Key to success!

When first presented, WBG power semiconductor utilization was limited by the number of drivers available, making it

difficult for power designers to consider the technology. Also, new technologies are always questioned regarding reliability and sustainability. Market adoption depends on how simple it is for power designers used to conventional MOSFETs to use WBG, and semiconductor manufacturers’ speed in developing ‘ready-touse’ solutions that include driver, protection, monitoring and many other functionalities into a single chip.

This not only simplifies implementation but also reduces the overall size of the power stage, and combined with higher switching frequencies make it possible to reduce the size of magnetics, thus increasing power density whilst reducing the overall volume and mass of the power supply.

As mentioned, among the many products that could benefit from the implementation of WBG technology, we could pinpoint portable equipment chargers. As end-users we all expect USB chargers to deliver more power, to charge faster and to be smaller and lighter.

In 2020, this wish became a reality and one example of the benefit of using WBG GaN to achieve that is a 110W Mini fast charger that is over 12 times smaller than the 96W charger supplied with the Apple MacBook Pro 16 launched by OPPO (Figure 3). This has been made possible by combining the Navitas GaNFast power ICs with a planar transformer, an optimized topology and a higher switching frequency.

At the same time, EPC released a GaN IC integrating everything to make it simple for power designers to implement into their new designs (Figure 4). Those examples illustrate how WBG GaN manufacturers rapidly moved from ‘complex’ to ‘simple’ to implement the technology, contributing to generate volume and market adoption.

High power GaN setting-up a foundation for future!

As we have seen, driven by the consumer segment, power designers soon realized the benefits offered by GaN to offer more power in smaller packaging. Power designers had to face several challenges to develop high switching frequency using GaN technology in very compact packaging but that was a really exciting time for many of us.

Presented examples addressed low and mid power applications but as well, WBG received high interest for high power applications such as Electric Vehicles (EV), renewable energy and many others.

Electric Vehicles (EV) have seen a significant uptake of WBG technology and as of today it is the dominant technology in battery chargers, power trains and as already mentioned, equipment such as LiDAR.

EV is often presented as the showcase for the adoption of WBG though less wellknown is the role of Information and Communication Technology (ICT) in supporting research on GaN and SiC.

This research aimed to develop the next generation of power supplies to support hyper-processors applications and data centers for Artificial Intelligence (AI). The rapid adoption of AI is accompanied by a

significant growth in data volume and increased computing requirements. By 2025, the data volume is projected to reach 180 zettabytes, up from 15 zettabytes in 2015. According to OpenAI researchers Dario Amodei and Danny Hernandez, the amount of computing power used for deep learning to train state-of-the-art AI models has been doubling every 3.4 months since 2012. This continuous increase in computational power directly impacts electricity consumption, with AI data centers expected to account for up to 7% of global electricity demand by 2030.

Optimizing energy utilization has always been a concern for the ICT manufacturers, requiring all suppliers, from infrastructure to components to reduce energy consumption. From the early days of research to improve the power supplies, AC/DC or DC/DC energy efficiency, power electronics designers explored new technologies and partnerships with semiconductors manufacturers.

Several papers have been presented at APEC and other conferences. It’s worth mentioning Navitas Semiconductors, who at APEC 2022 presented “Electrify Our World” introducing the benefits of WBG in ICT and, in 2024, the materialization of the utilization of that technology in power supplies for datacenters, where they predicted that power demand per unit will ultimately reach 10kW (Figure 5 insert).

Exploring the optimum benefits of combining GaN and SiC, the company released a 8.5kW, 98% efficiency reference design, complying with the with Open Compute Project (OCP), Open Rack v3 (ORv3) specifications and ready for stringent energy efficiency standards (Figure 5). This is a good representation of what has been achieved when combining WBG and other advanced technologies to power today and tomorrow ICT applications and more to be expected.

LiDAR, USB charger and ICT are representing a significant part of the market but other segments such as industrial, railway, medical are also investigating the benefits of that technology though have some concerns about the reliability and availability of new technologies.

As presented by the market analysts, despite GaN having been on the market for several years the market remains fragmented with each GaN manufacturer offering different combinations of products and services addressing specific segments.

To get the best out of GaN, power designers must work in close cooperation with semiconductor manufacturers and embrace one-stop solutions (GaN transistor, driver, protection, etc.) tightened to a single source, albeit raising concerns about the risks of using products from a

new supplier with limited history and financial background.

That, without mentioning some applications e.g., railway apps requiring 25 years lifetime and products availability for maintenance, requiring a solid and sustainable supply chain are part of complex equation when considering a new technology.

Due to that, the adoption in industrial, railway and medical applications may be slower than in EV, ICT and consumers but the obvious benefit of WBG motivated designers to explore that way.

One example is the outcome from COSEL research to combine digital control, GaN and planar magnetics that makes it possible to offer very compact power solutions that are easy to integrate into small space environments (Figure 6).

That will make it possible to house the power supply and a battery backup in the same volume as the conventional version of a similar power supply. As we are moving forwards to new applications requiring higher performances, WBG will gain market shares and follow the same path followed by the early adopters.

Many of the challenges faced by power designers when WBG technology was presented eight years ago at APEC have been overcome and there is no doubt that GaN and SiC successfully crossed the chasm. The number of applications adopting WBG will continue to grow although at the same time new disruptive technologies are reaching the market offering power designers exciting opportunities for research and development.

Starting my career within the power industry more than 40 years ago when moving from linear to switching power conversion, I crossed the chasm several times with passion and I would like to encourage young engineers to do the same, cross the chasm to approach the mythical 99.99% efficiency.

References:

Powerbox (PRBX): https://www.prbx.com

COSEL: https://en.cosel.co.jp

Navitas Semiconductor: https://navitassemi.com

Efficient Power Conversion (EPC): https://epc-co.com/epc

Applied Power Electronics Conference: https://apec-conf.org

GaN Technology – Material, Manufacturing, Devices and Design

(Edited by Maurizio Di Paolo Emilio): https://link.springer.com/book/10.1007/97 8-3-031-63238-9

■ Powerbox (PRBX) www.prbx.com

Standard off-the-shelf line of 425 W supplies are certified to IEC 60601-1 and streamline critical medical device product development

Advanced Energy Industries, Inc., a global leader in highly engineered, precision power conversion, measurement and control solutions, announced the new NCF425 series of CF-rated medical open frame AC-DC power supplies.

The system-level cardiac floating (CF) rating is the most stringent medical device electrical safety classification, with certification needed for equipment that has direct contact with the heart or bloodstream.

Advanced Energy is one of the few innovators providing standard off-the-shelf CF-rated power products. Today’s launch further expands its CF-rated portfolio, which was initially released in September 2024 with the groundbreaking release of the NCF150 series followed by the NCF250 and NCF600 series. Advanced Energy’s NCF series achieves a sub-10 μA leakage current and integrates the high levels of isolation required in critical medical devices.

“The NCF425 is the fourth in our NCF family of off-the-shelf CF-rated AC-DC power products for medical devices,” said Emdrem Tan, Advanced Energy’s Executive Vice President, System Power. “Advanced Energy offers the broadest portfolio of standard CF-rated products in the industry, with this new release offering additional options for designing critical medical systems. It helps reduce the number of isolation components needed, and minimizes system size, cost, and time to market.”

NCF425 seriesThe NCF family is designed to simplify thermal and EMI management, reduce system size and weight, and reduce the bill of materials (BOM). It also includes functionality normally provided at the system level, reducing time and complexity in the development process.

The NCF425, certified to the medical safety standard IEC 60601-1, delivers a maximum output power of 425 W in a 3.5 x 6 x 1.5-inch form factor. It also features 5 kV defibrillator pulse protection and meets the highest possible (2 x MOPP) means of patient protection rating, which requires isolation to 4 kVac and a creepage of at least 8 mm.